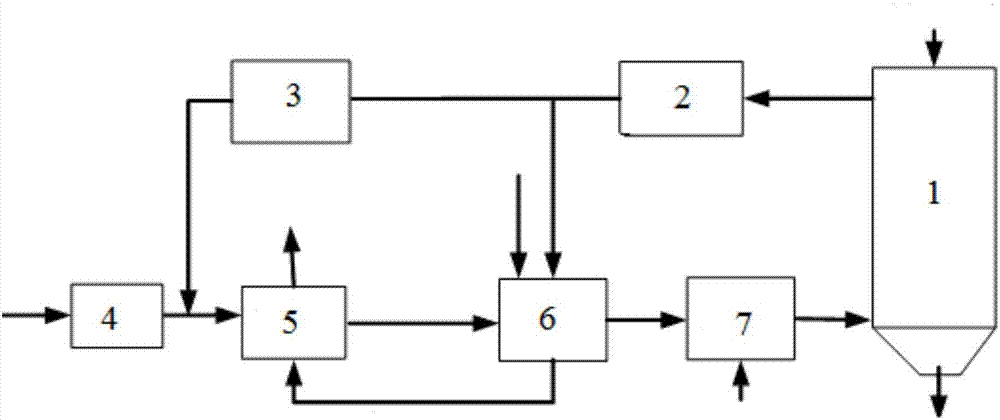

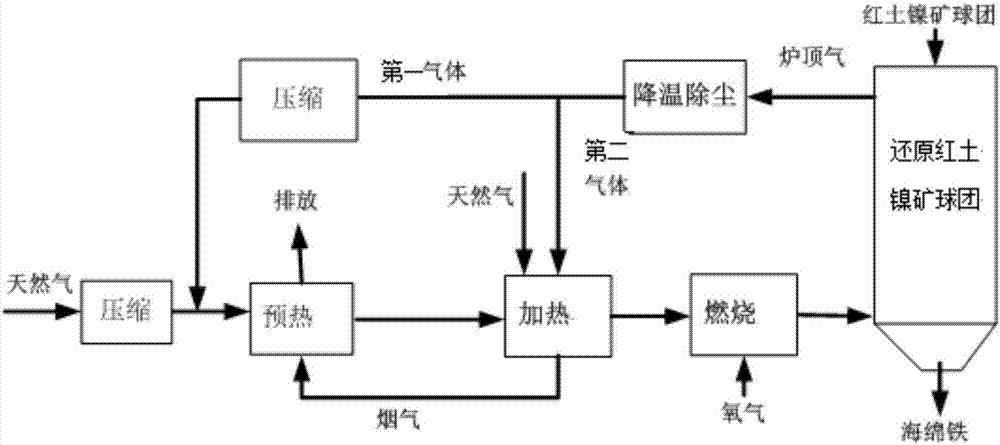

Natural gas tri-reforming red earth nickel ore pellet reducing system and method

A laterite nickel ore and natural gas technology, applied in the direction of reducing gas emissions, furnace types, furnaces, etc., can solve the problems of complex wet process, high requirements for equipment in process conditions, and long process, so as to reduce energy consumption and methane Content, the effect of realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The natural gas is mixed with the first gas, and the resulting mixture contains CO and H 2 The volume ratio is 18%, CH 4 The volume ratio is 23%. The mixed gas is sent to the preheater, the temperature is raised from 40°C to 210°C, and then sent to the heater to rise to 780°C. The obtained temperature-rising mixed gas is sent to the burner to undergo partial oxidation reaction with oxygen to obtain reducing gas, the temperature is 960℃, where CO and H 2 The volume ratio is 33%, CH 4 The volume of the gas is 16%, and the reducing gas is sent to the shaft furnace. The sponge iron produced by the reduction of laterite nickel ore pellets contains metallic iron and metallic nickel. Metallic iron and metallic nickel can be used as catalysts for the reforming reaction of methane, carbon dioxide and methane in the reducing gas to generate CO and H 2 . CO and H 2 During the upward movement, it fully contacts with laterite nickel ore pellets moving from top to bottom, and further...

Embodiment 2

[0060] The natural gas is mixed with the first gas, and the resulting mixture contains CO and H 2 The volume ratio is 16%, CH 4 The volume ratio is 22%. The mixed gas is sent to the preheater, the temperature is raised from 50°C to 300°C, and then sent to the heater to rise to 800°C. The obtained temperature-rising mixed gas is sent to the combustor to undergo partial oxidation reaction with oxygen to obtain reducing gas with a temperature of 1050℃, in which CO and H 2 The volume ratio is 30%, CH 4 The proportion of the volume is 13%, and the reducing gas is sent into the shaft furnace. The sponge iron produced by the reduction of laterite nickel ore pellets contains metallic iron and metallic nickel. Metallic iron and metallic nickel can be used as catalysts for the reforming reaction of methane, carbon dioxide and methane in the reducing gas to generate CO and H 2 . CO and H 2 During the upward movement, it fully contacts with laterite nickel ore pellets moving from top to b...

Embodiment 3

[0063] The natural gas is mixed with the first gas, and the resulting mixture contains CO and H 2 The volume ratio is 17%, CH 4 The volume ratio is 21%. The mixed gas is sent to the preheater, the temperature is raised from 40°C to 200°C, and then sent to the heater to rise to 700°C. The obtained temperature-rising mixed gas is sent to the combustor to undergo partial oxidation reaction with oxygen to obtain reducing gas, the temperature is 950℃, in which CO and H 2 The volume ratio is 40%, CH 4 The proportion of the volume is 15%, and the reducing gas is sent into the shaft furnace. The sponge iron produced by the reduction of laterite nickel ore pellets contains metallic iron and metallic nickel. Metallic iron and metallic nickel can be used as catalysts for the reforming reaction of methane, carbon dioxide and methane in the reducing gas to generate CO and H 2 . CO and H 2 During the upward movement, it fully contacts with laterite nickel ore pellets moving from top to bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com