Corn harvester with straw collecting function

A harvester and straw technology, which is applied in the field of farming and animal husbandry, can solve the problems of straw calorific value loss, easy moldy straw, and high collection cost, and achieves the reduction of calorific value loss, the coherent structure of the ear picking mechanism and the peeling mechanism, and the high reuse rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

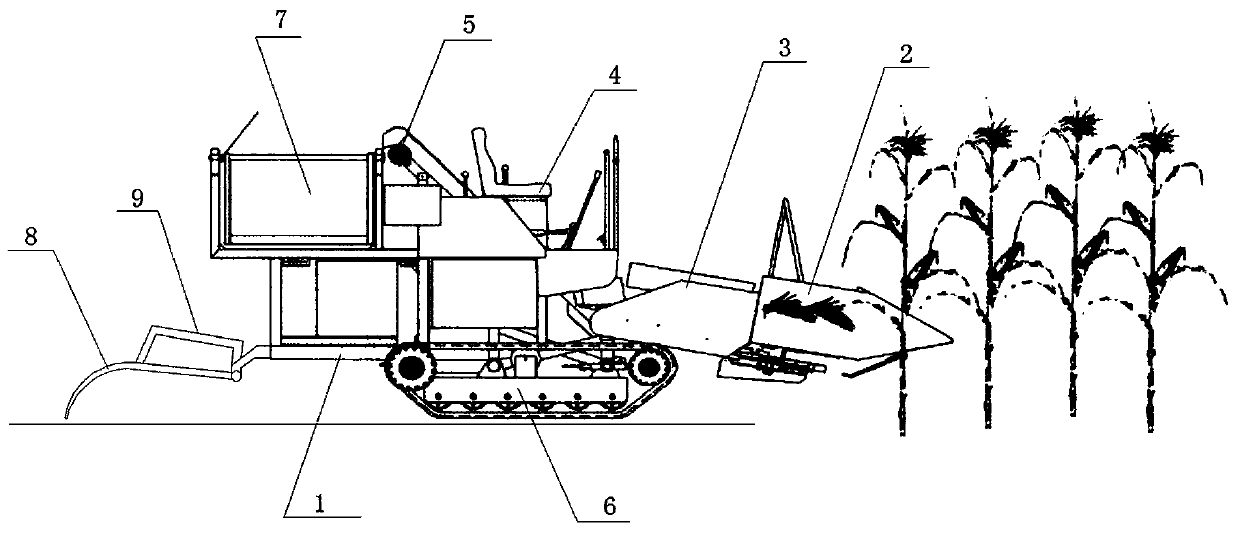

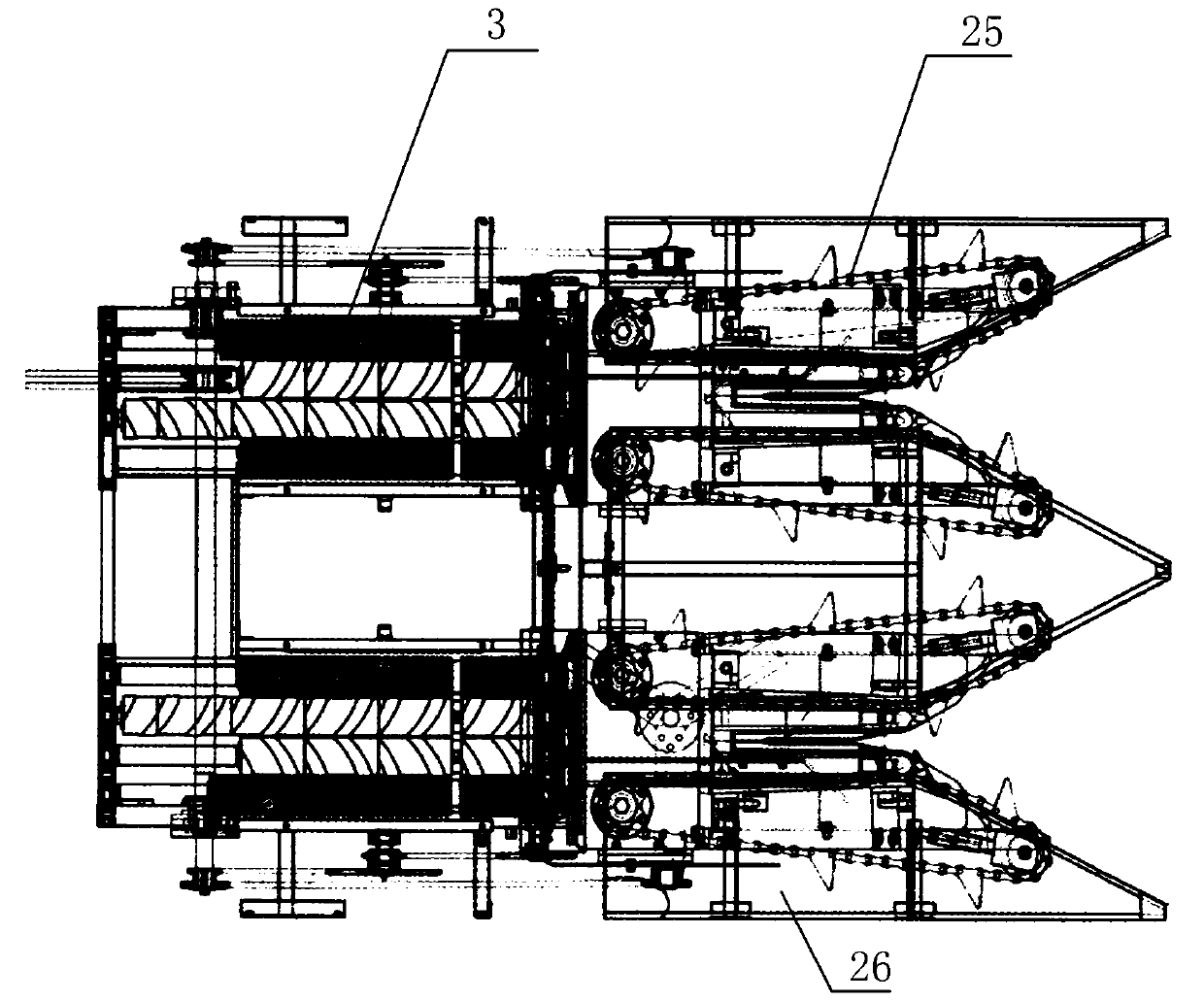

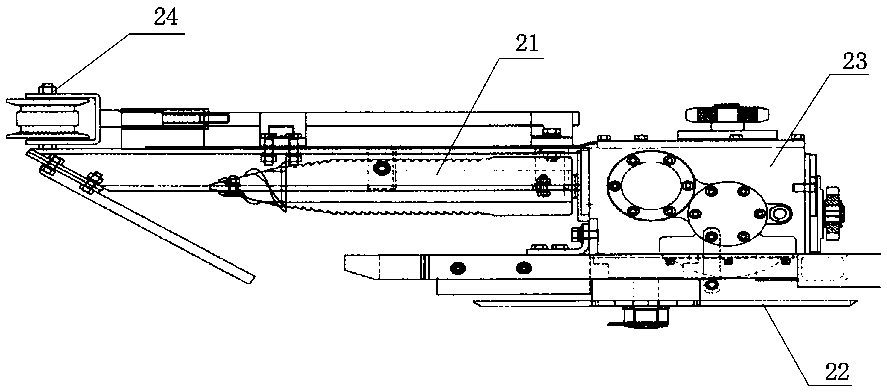

[0035] Such as Figure 1~Figure 11 As shown, the corn harvester with stalk collection function of the present invention includes a frame 1, an ear picking mechanism 2, a peeling mechanism 3, a driving platform 4 and an elevator 5, and the ear picking mechanism 2, the peeling mechanism 3, and the driving platform 4 and the elevator 5 are all located on the frame 1, the bottom of the frame 1 is provided with a walking chassis 6, the engine is provided in the frame 1, and the fringe picking mechanism 2 is located at the front of the driving platform 4, The fringe picking mechanism 2 cuts the stalks in the upright state and separates the ears from the stalks. The outlet of the fringe picking mechanism 2 is connected to the inlet of the peeling mechanism 3. At the front part of the platform 4, the ears enter the peeling mechanism 3 through the diversion of the ear picking mechanism 2, and the ear bracts are peeled off by the peeling mechanism 3. The outlet of the peeling mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com