Coke oven gas methanation feeding method

A feeding method and technology of coke oven gas, which is applied in the field of LNG production, can solve the problems of high cost and long feeding time, and achieve the effect of saving feeding time and reducing cost consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for feeding coke oven gas methanation of the present invention comprises the following steps:

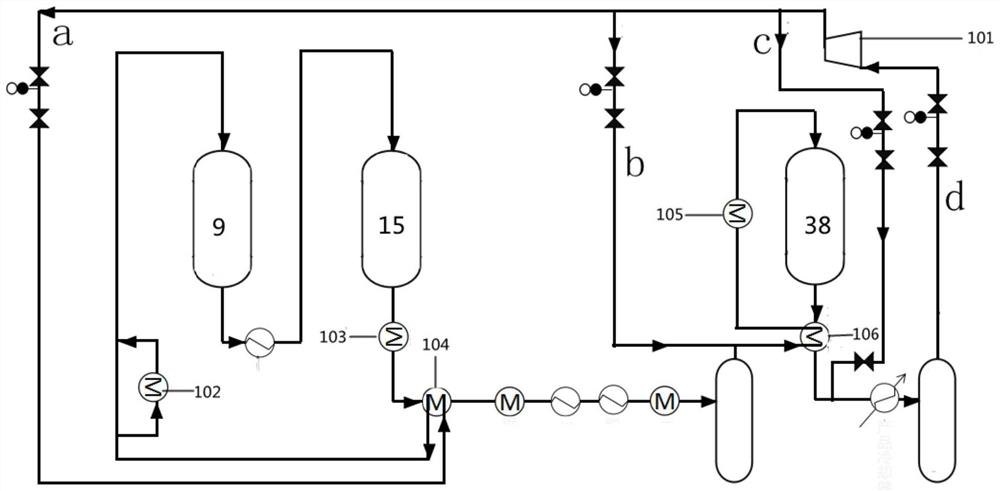

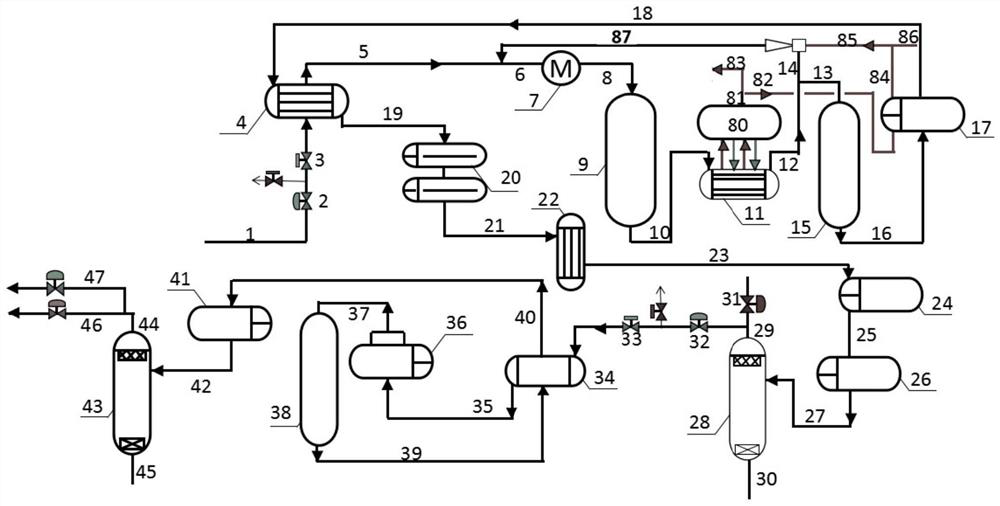

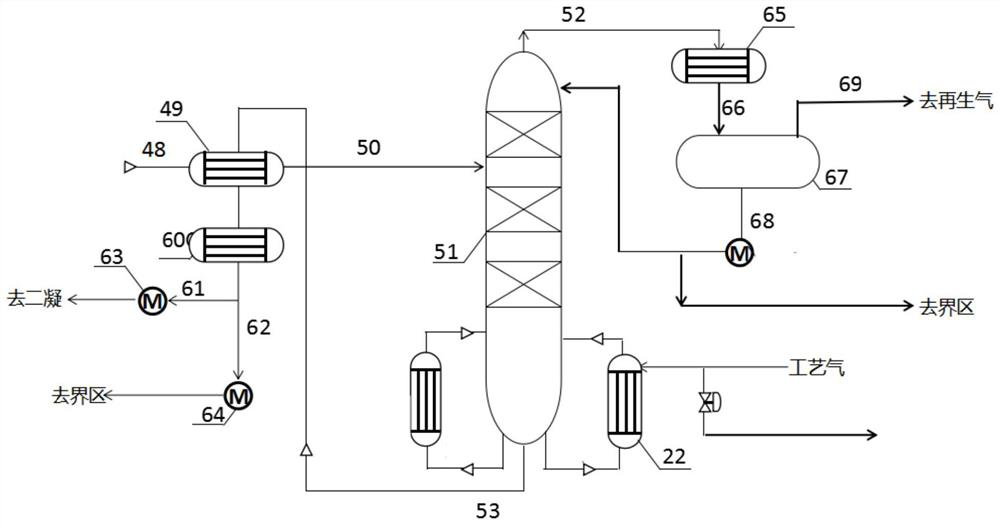

[0030] (1) If figure 1 , start the fan 101, and cycle the temperature of the primary methanation reactor 9, the secondary methanation reactor 15, and the tertiary methanation reactor 38. The primary methanation reactor 9, the secondary methanation reactor 15, the third The stage methanation reactor 38 is arranged on the circulating pipeline, the circulating pipeline includes pipeline a, pipeline b and pipeline d, the circulating pipeline is provided with a heating device and a start-up fan 101, and the heating device includes an electric furnace 102, a steam superheater A103, a first material inlet and outlet The material heat exchanger 104, the supplementary heater 105, the second material inlet and outlet material heat exchanger 106, the inlet temperature of the second stage methanation reactor 9 after heating is 350°C, and the outlet temperature is 330°C; the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com