Treatment system and treatment method for reducing content of impurities in soluble manganese sulfate solution

A treatment system and technology of impurity content, applied in the field of electrode material preparation, can solve problems such as low impurity removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

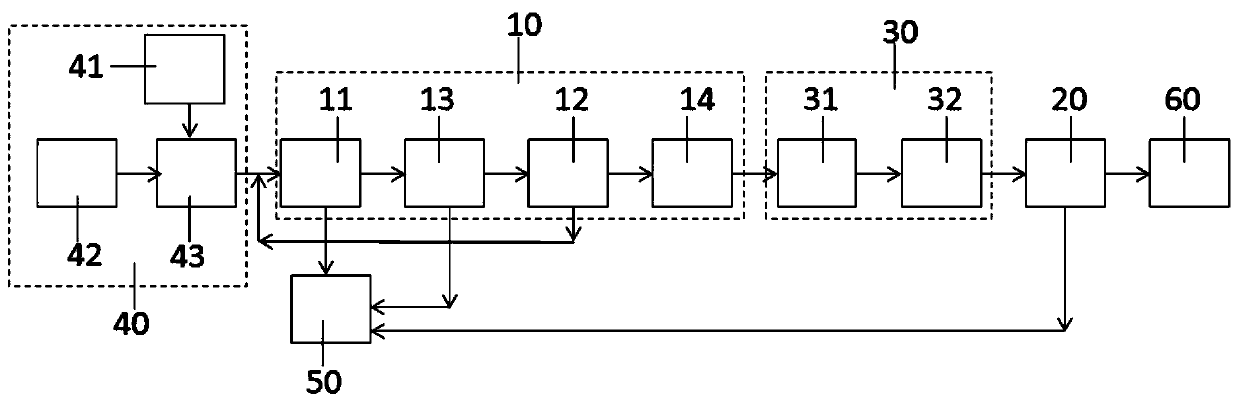

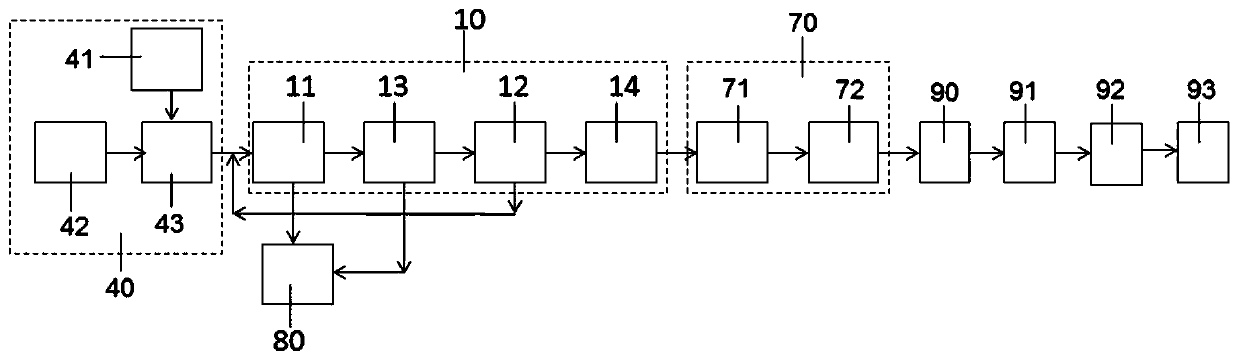

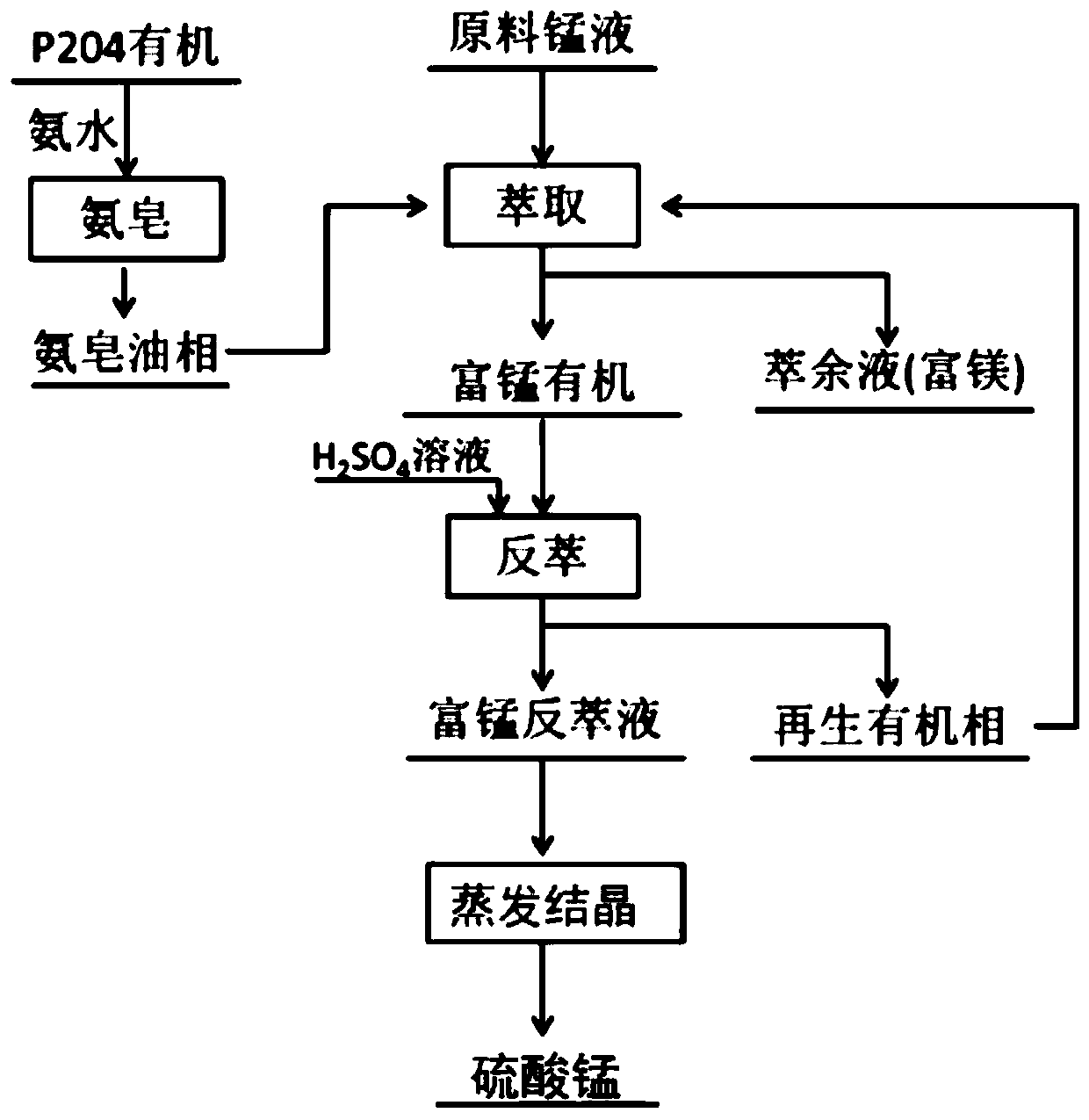

Method used

Image

Examples

Embodiment 1

[0079] Manganese sulfate solution with Mn content of 50g / L, Mg content of 40g / L and Ca content of 0.5g / L was prepared, and the actual content of each ion in the manganese sulfate solution was determined by atomic absorption.

[0080] The organic phosphorus extractant is composed of P204 and sulfonated kerosene, wherein the volume content of P204 is 20%. Ammonia water and the above-mentioned organophosphorus extractant are used for saponification, and the saponification rate is 70%.

[0081] The pH of the manganese sulfate solution is adjusted to 3, and the volume ratio of the manganese sulfate solution and the organic phosphorus extractant is 1:1, and a multi-stage extraction process is carried out to obtain a manganese-rich organic phase, wherein the temperature of the extraction process is 25 ° C, and the extraction The time is 4min, and the phase separation time is 7min.

[0082] The volume ratio of the stripping agent (1mol / L sulfuric acid) to the manganese-rich organic p...

Embodiment 2

[0085] The difference with embodiment 1 is:

[0086] The pH of the soluble manganese salt solution was adjusted to 2 before carrying out the extraction process.

Embodiment 3

[0088] The difference from Example 1 is: before carrying out the extraction process, the pH of the soluble manganese salt solution was adjusted to 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com