Patents

Literature

183results about How to "Achieve primary separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

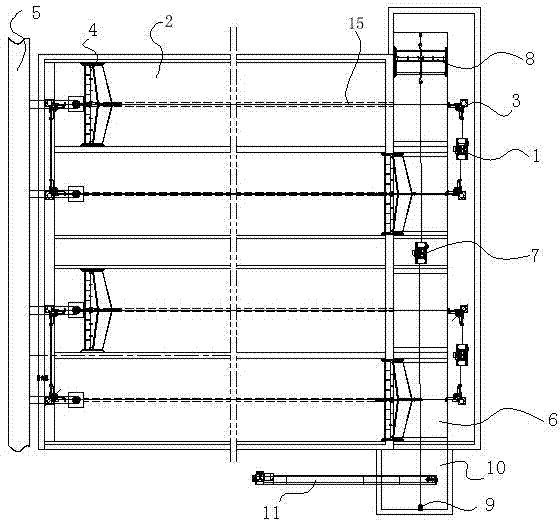

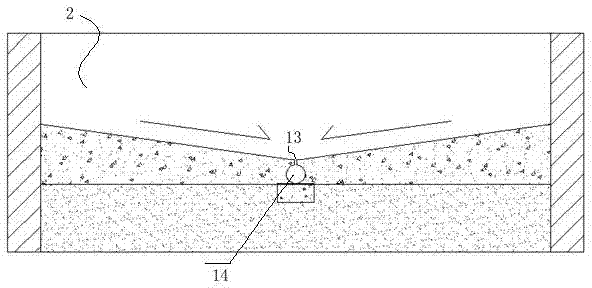

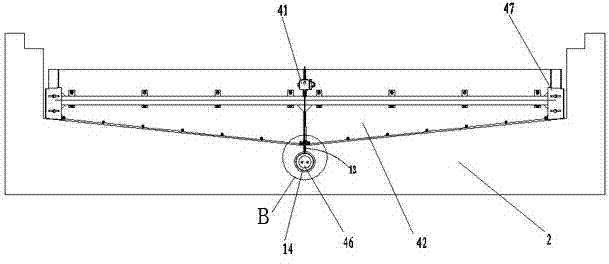

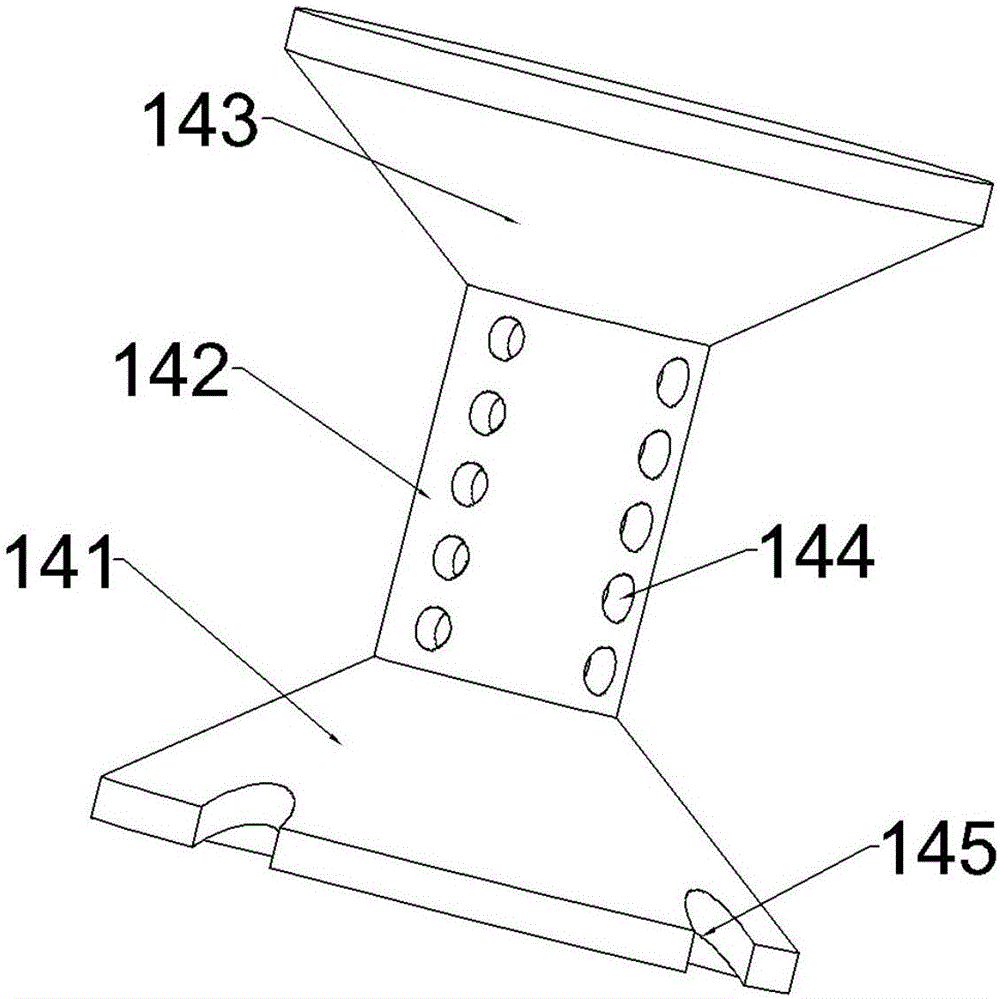

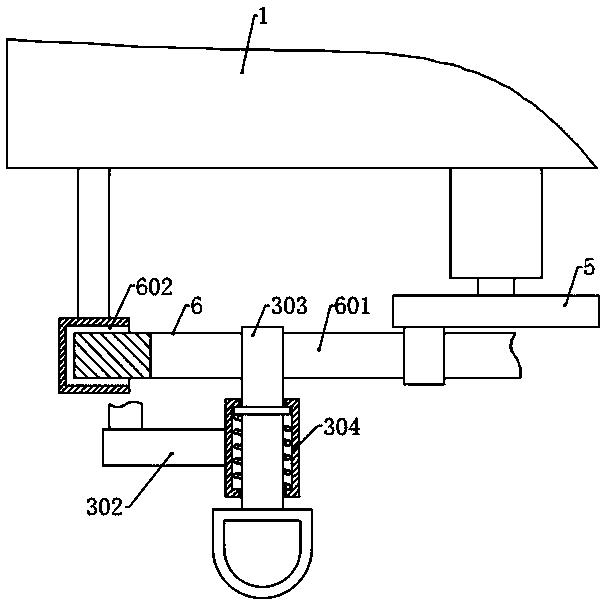

Feces and urine separated type scraper blade feces cleaning system

The invention discloses a feces and urine separated type scraper blade feces cleaning system which comprises a longitudinal feces cleaning ditch and a feces scraping mechanism arranged in the feces cleaning ditch. The longitudinal feces cleaning ditch is obliquely arranged, a feces collecting ditch is arranged at the outlet of the high end of the longitudinal feces cleaning ditch, and a urine collecting ditch is arranged at the low end of the longitudinal feces cleaning ditch. When the feces scraping mechanism is used for cleaning feces, urine flows downwards into the urine collecting ditch under the gravity, feces enters the feces collecting ditch under the action of the feces scraping mechanism, the urine and the feces are automatically separated, and subsequent processing is facilitated.

Owner:GUANGDONG NANMU MACHINERY & EQUIP

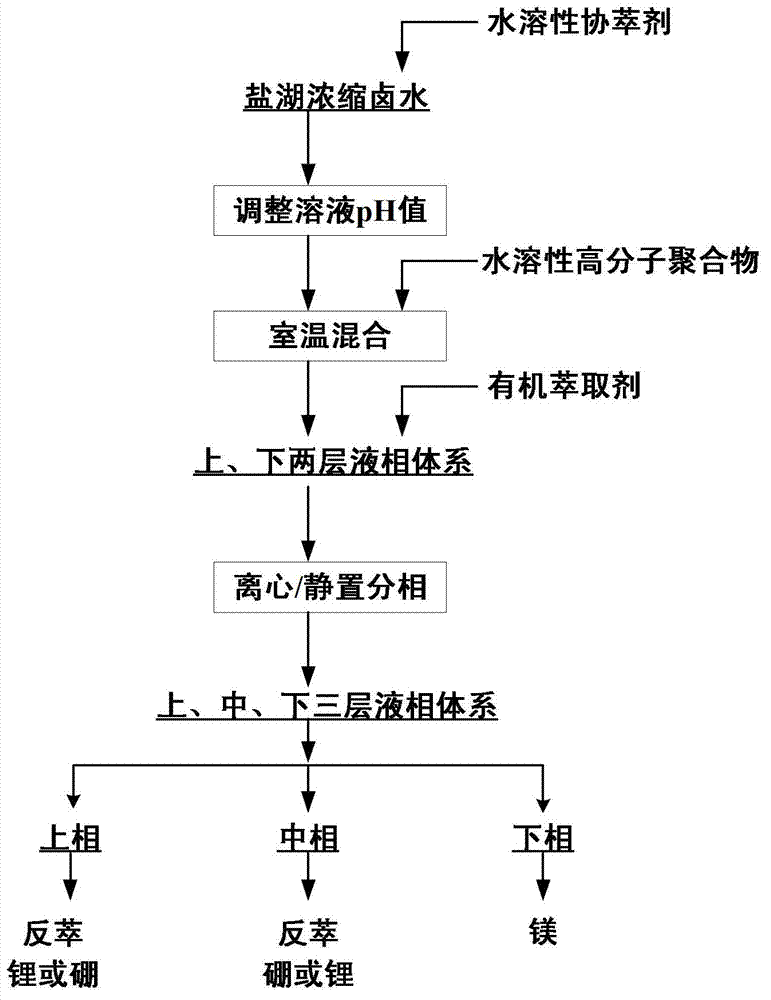

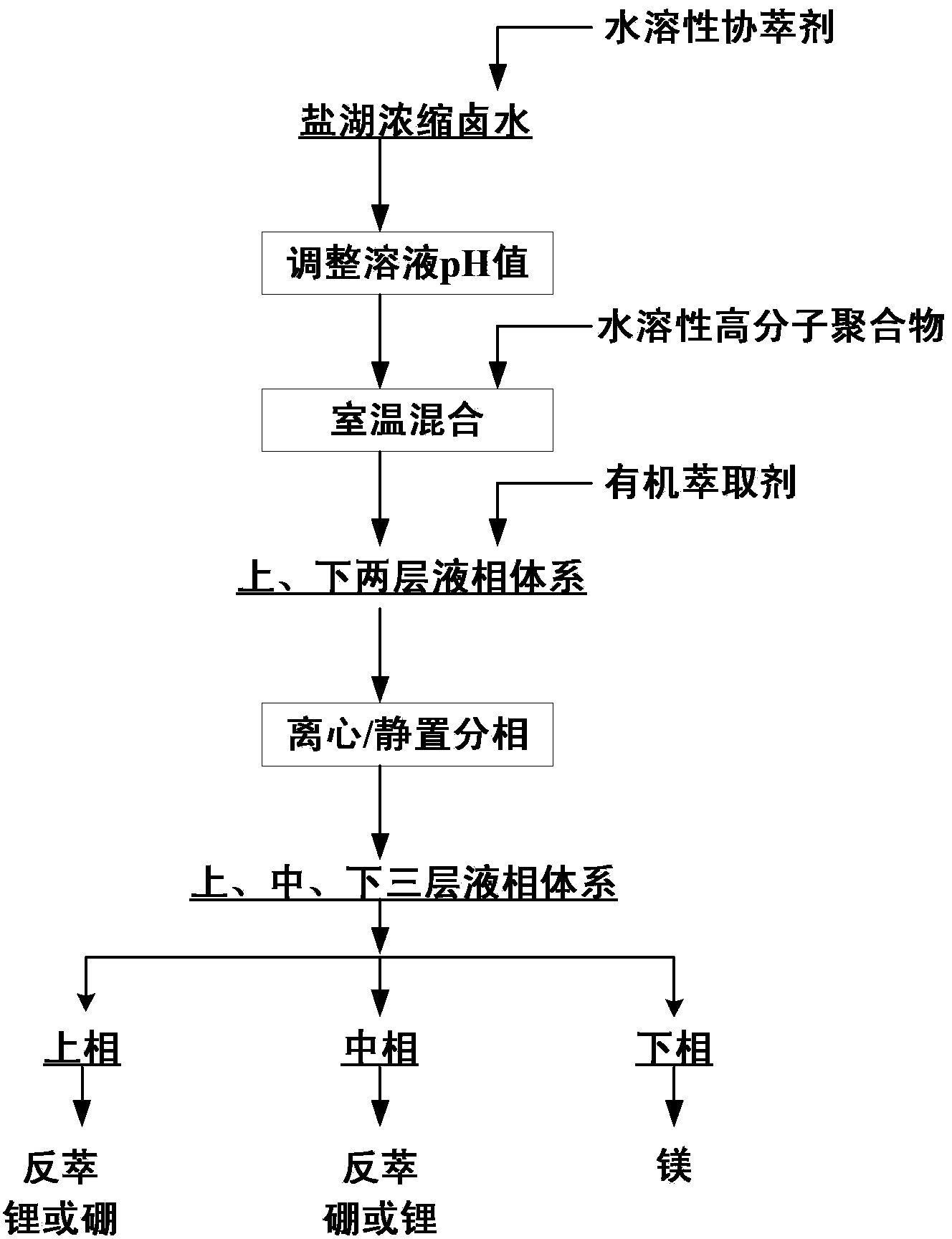

Method for preenriching and separating lithium and boron from salt lake brine by liquid-liquid-liquid three-phase extraction

InactiveCN103031448AAchieve primary separationWide range of pH adaptationLithium compoundsBoron compoundsImpurityPolymer

The invention relates to a method for preenriching and separating lithium and boron from salt lake brine by liquid-liquid-liquid three-phase extraction, which comprises the following steps: adding water-soluble auxiliary extractant into a salt lake concentrated brine solution, regulating the pH value of the brine, adding water-soluble high molecular polymer, and thoroughly mixing at room temperature to obtain an upper / lower two-layer liquid-phase system; adding organic extractant, and mixing to obtain an upper / middle / lower three-layer liquid-phase system; and taking the upper and middle phases from the three-liquid-phase system, and respectively recovering lithium and boron in the upper and middle phases by back washing. The invention can simultaneously enrich and extract lithium and boron by one-step extraction from high-magnesium / lithium-ratio salt lake brine, and can separate the lithium and boron from abundant coexistent ions of magnesium, calcium and other impurity metals in the brine. The lithium and boron are respectively selectively enriched from the upper and middle phases in the three-liquid-phase system to implement primary separation, thereby facilitating the subsequent purification and refinement. The three-liquid-phase extraction can be carried out under neutral or weakly-acidic conditions, and has strong adaptability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

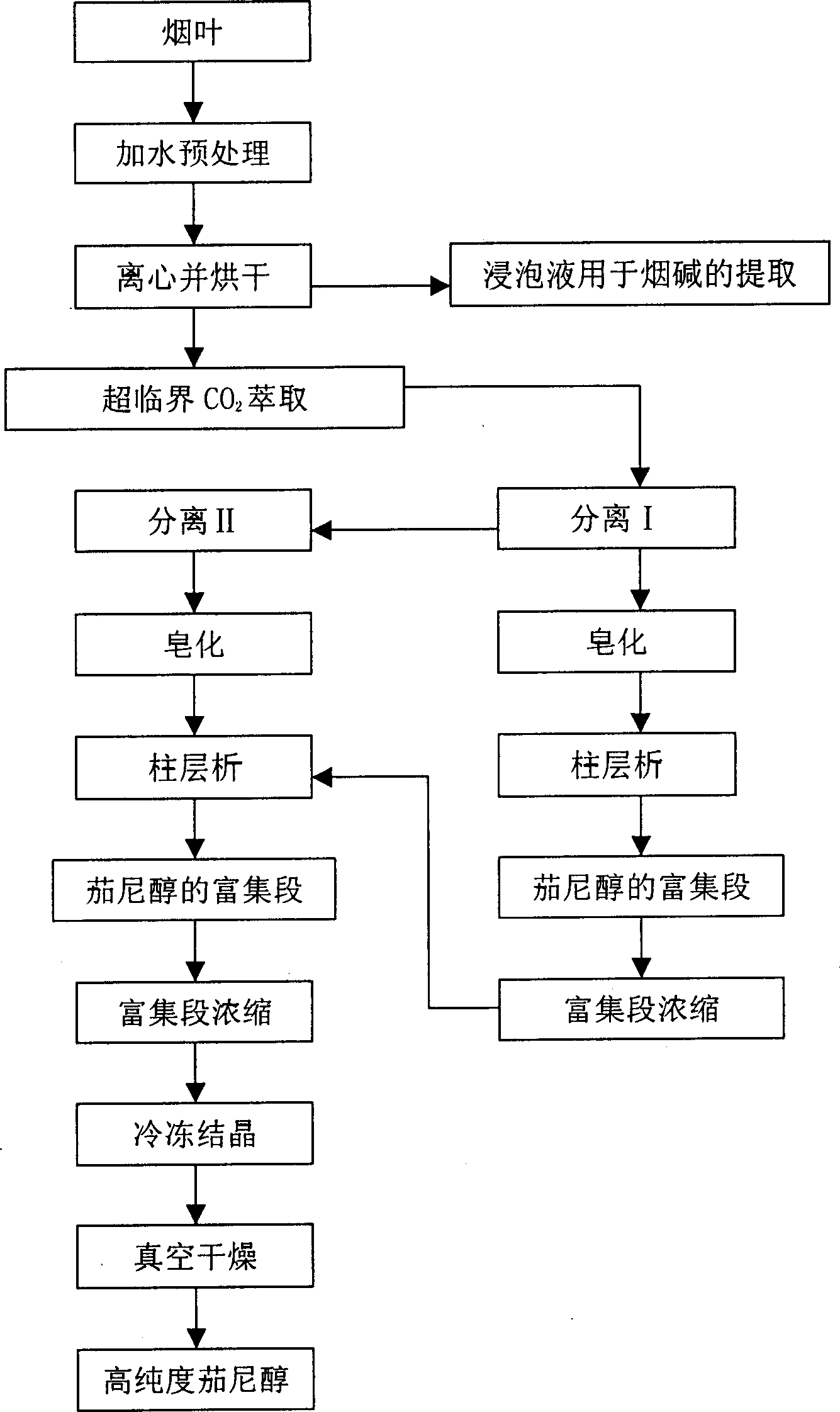

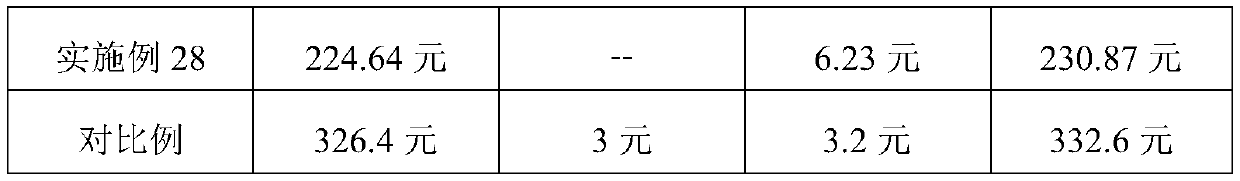

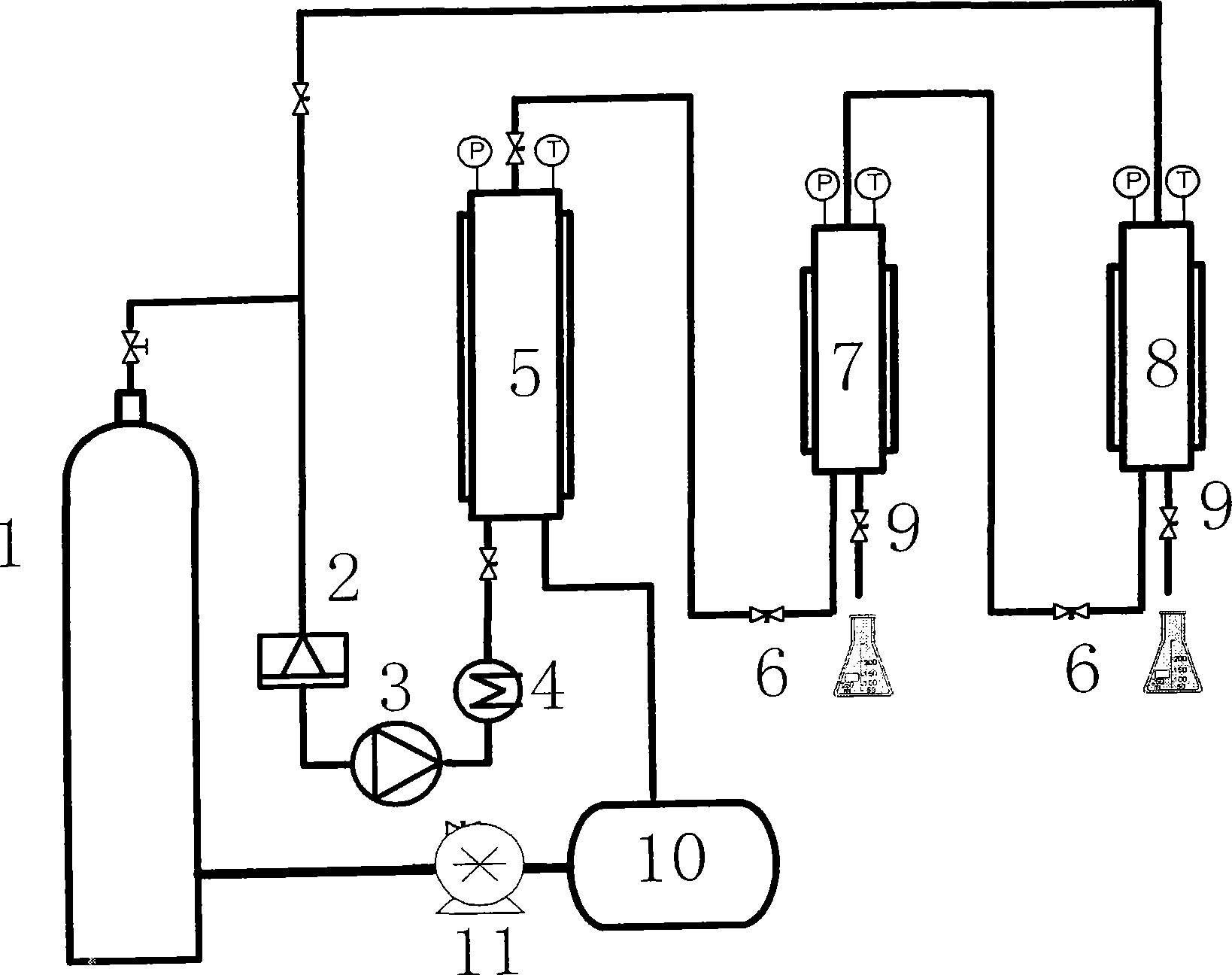

Method for extracting high-purity solanesol

InactiveCN1817834AHigh extraction rateImprove extraction efficiencyHydroxy compound separation/purificationAlcoholPre treatment

Extraction of high-purity solanesol is carried out by taking waste tobacco leaf as raw materials, adding into water to have pre-treatment, centrifugal drying, supercritical CO2 extracting by two-stage separating, saponification treating the solanesol coarse cream in NaOH alcohol solution, column chromatographing, decompressing and concentrating the eluent, freeze crystallizing and vacuum dry treating to obtain final product with purity above 95%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

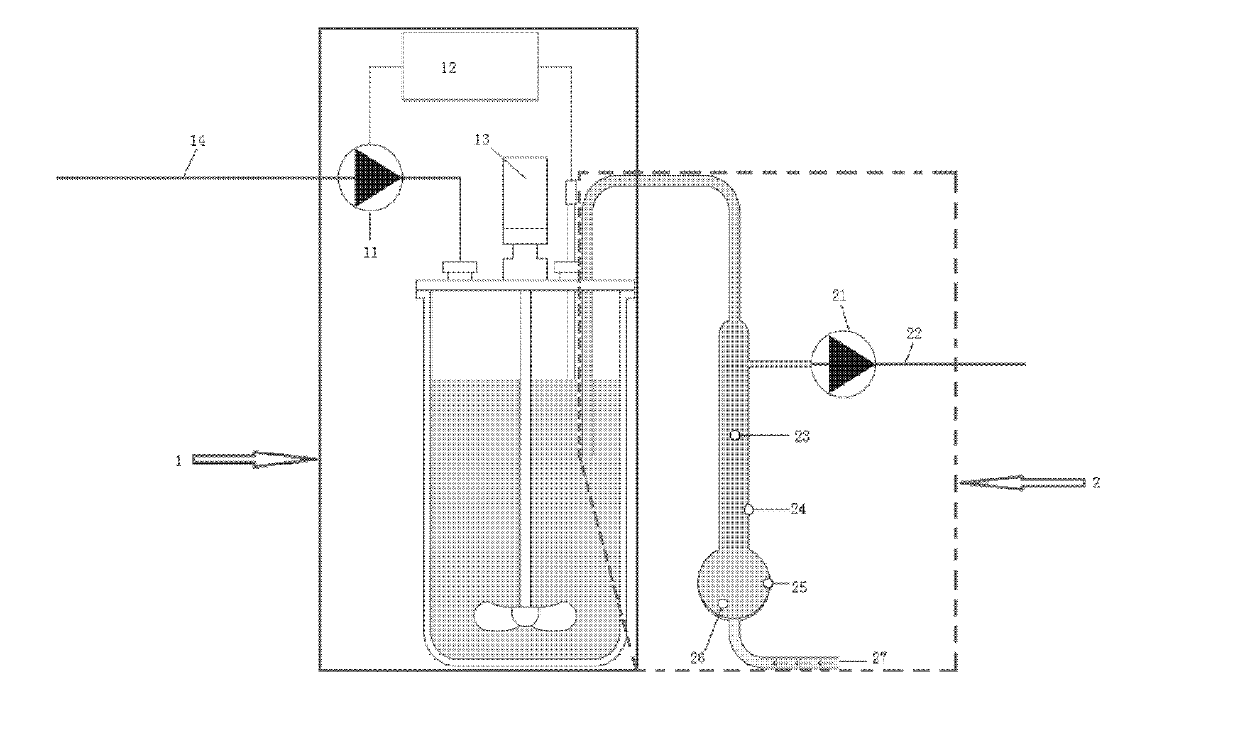

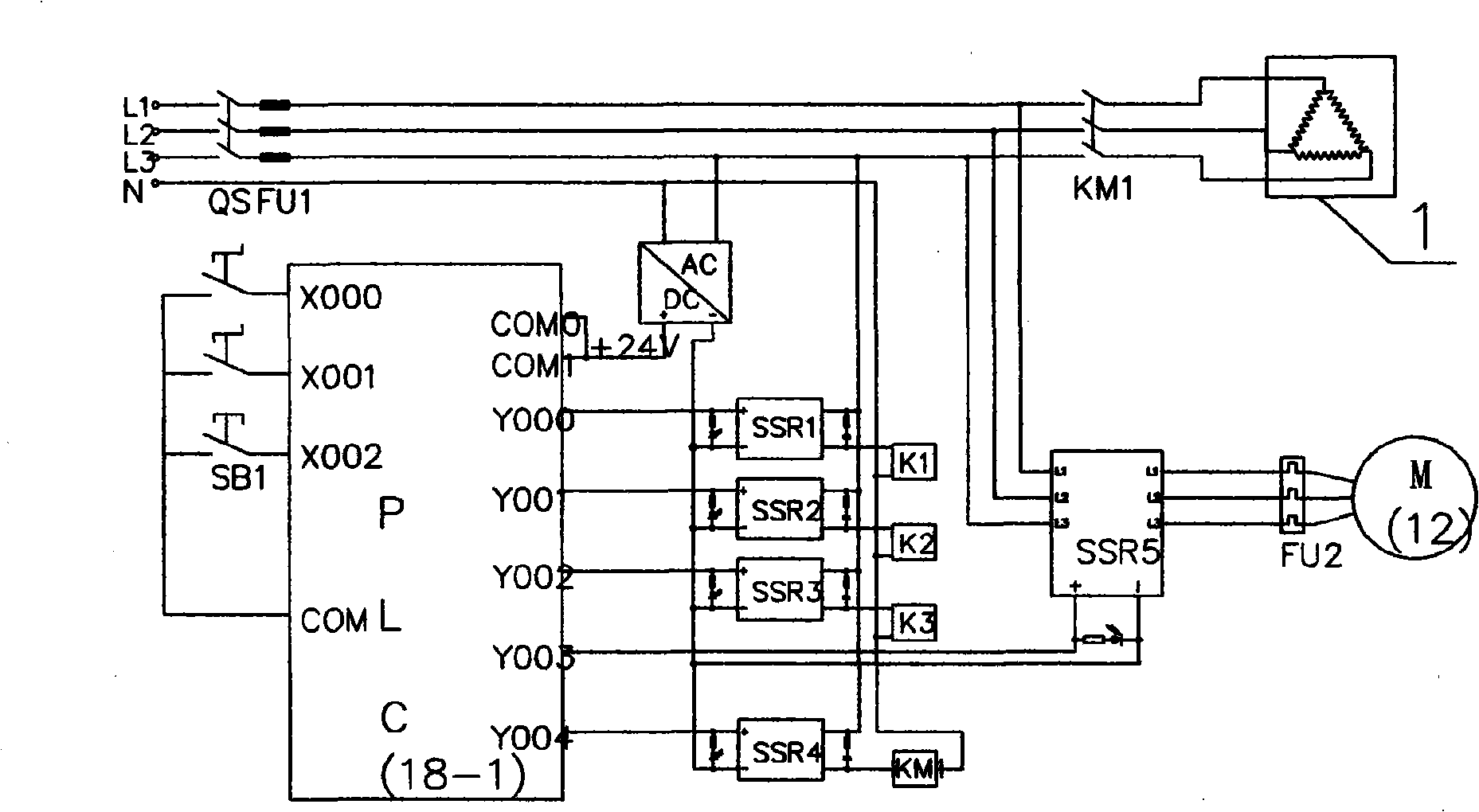

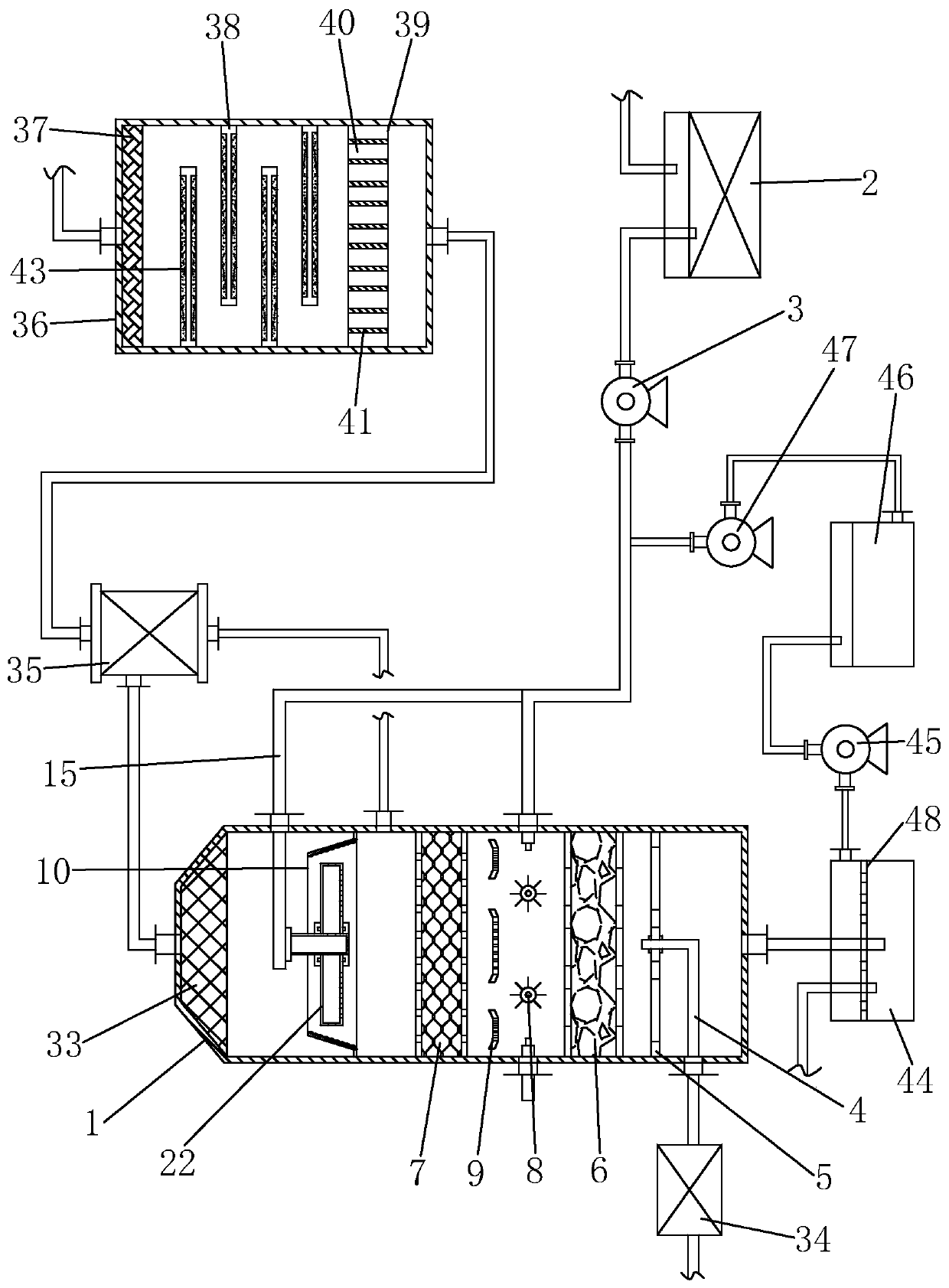

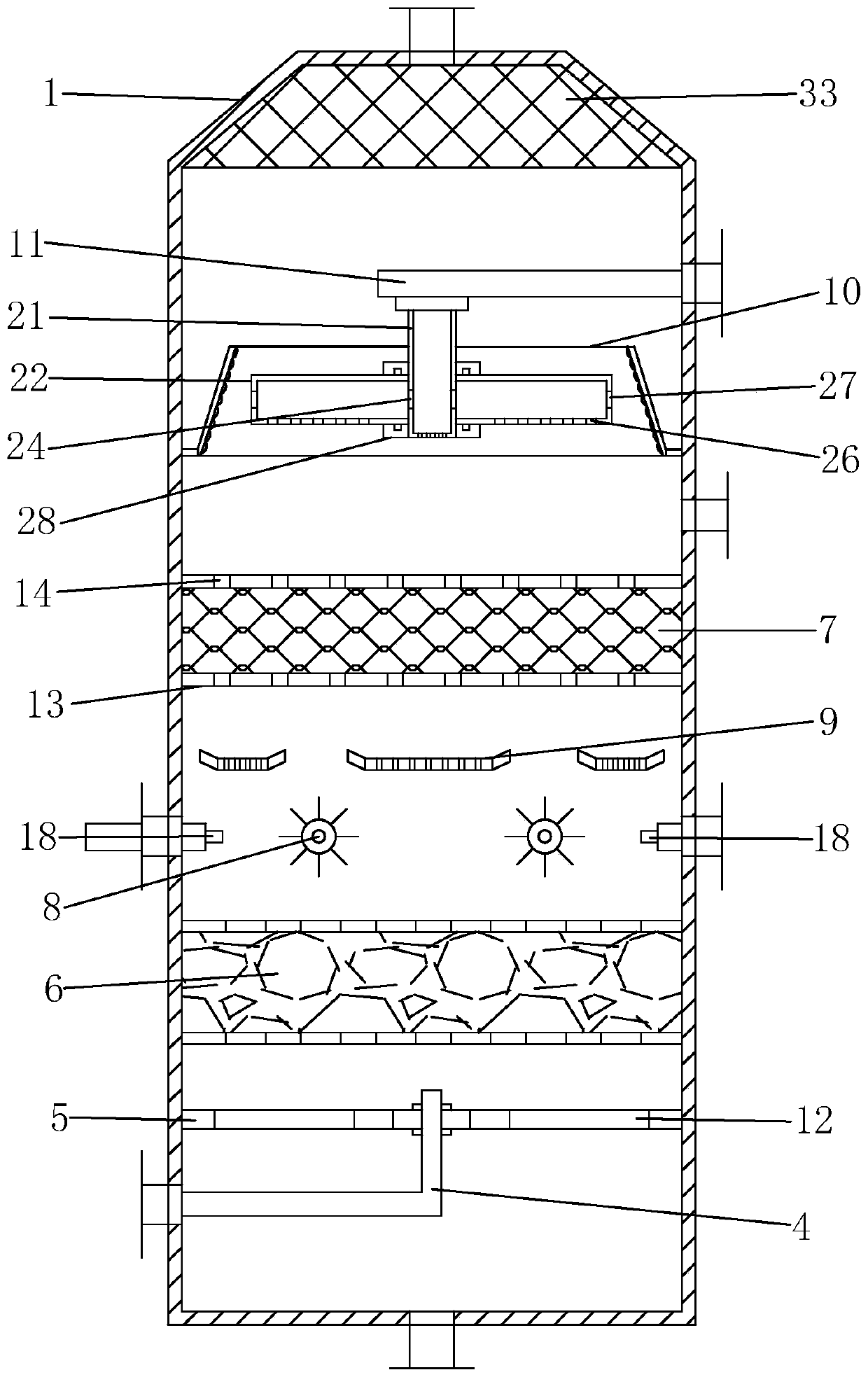

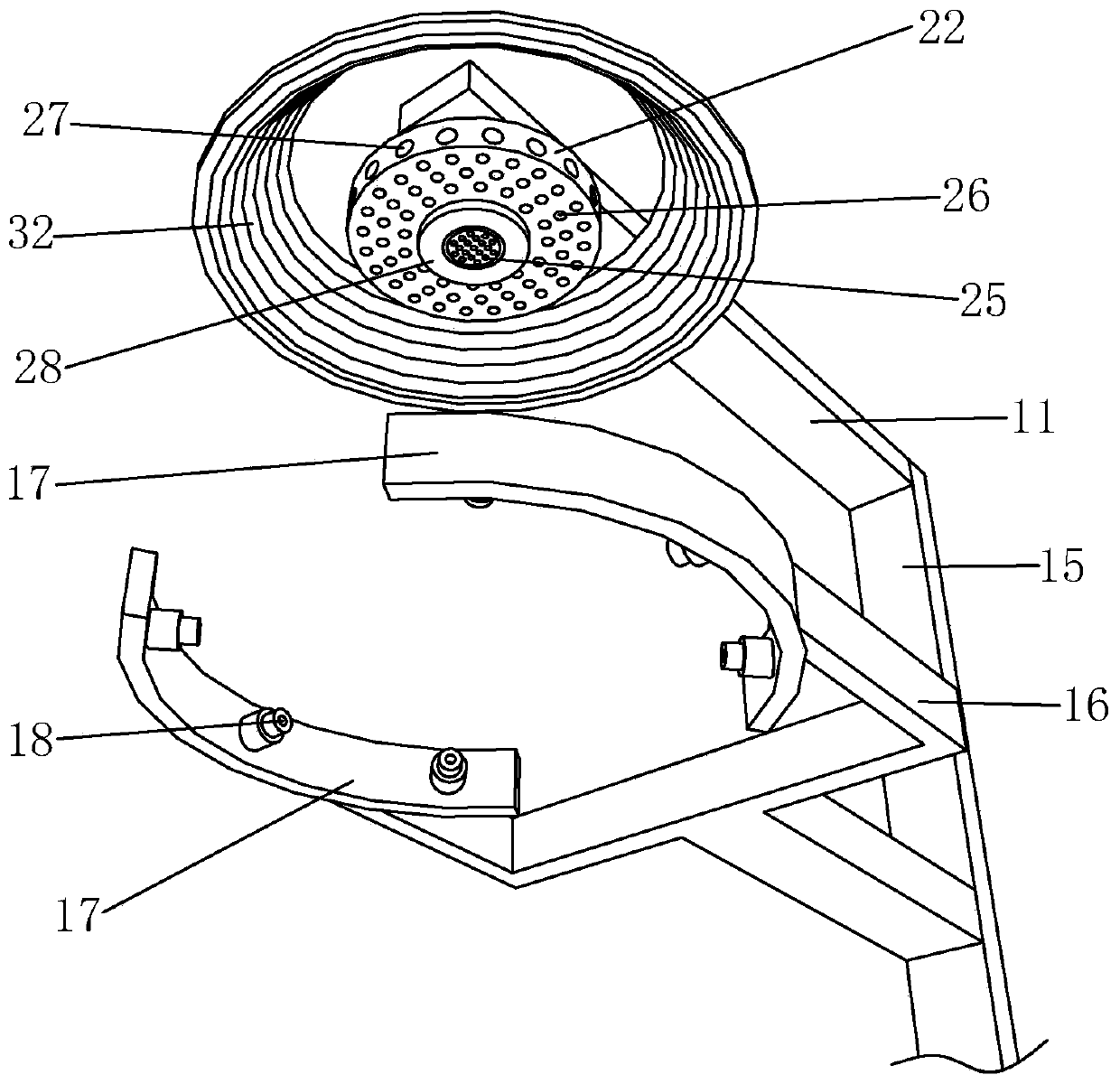

High-yield reactor for protein production, and production method and application thereof

InactiveCN103305417AReduce abnormal structural changesHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion CultureFiber

The invention discloses a high-yield reactor, and a production method and an application thereof. The high-yield reactor comprises a bioreactor and an ATF perfusion apparatus connected with the bioreactor. The protein production method using the high-yield reactor comprises the following steps: 1, connecting the ATF perfusion apparatus with the bioreactor, and completing an offline disinfection or online disinfection program; 2, inoculating seed cells to the bioreactor to a work volume according to the density, and sampling and detecting the number and biochemical indexes of the cells each 24h; 3, starting the ATF apparatus program for perfusion culture when the density of living cells increases to a certain density; and 4, collecting a culture solution in the bioreactor or filtered through hollow fibers in the ATF perfusion apparatus, and purifying to obtain required protein products. The high-yield reactor has the advantages of great shortening of the technological exploitation time of monoclonal antibody or fusion protein expression, production cost reduction, benefiting for the project registering and reporting and the project period shortening, and acceleration of the accomplishment application speeds of the biopharmacy industry.

Owner:WUXI BIOLOGICS CO LTD

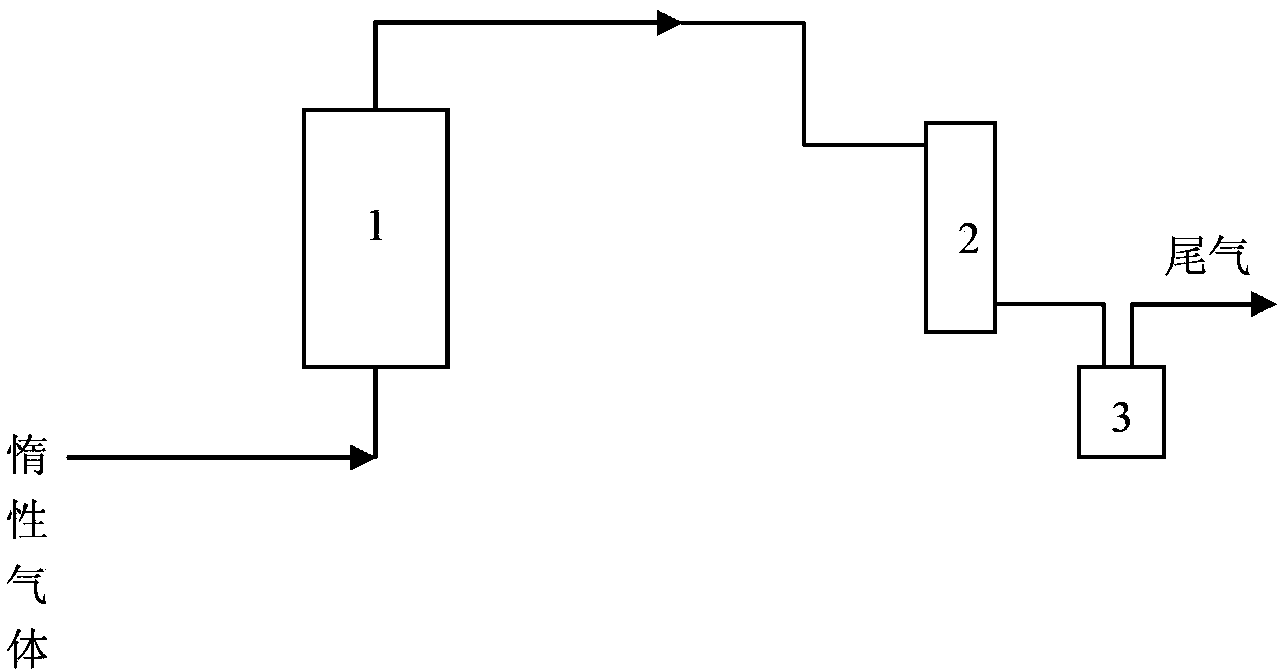

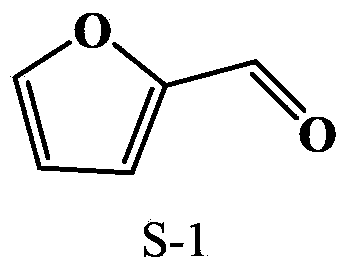

Method for preparation of furfural by biomass microwave mild pyrolysis

The invention discloses a method for preparation of furfural by biomass microwave mild pyrolysis. The method includes: 1) pretreating a biomass raw material by an inorganic acid catalyst or an inorganic salt catalyst; 2) taking microwave as a heat source, conducting mild pyrolysis on the biomass raw material pretreated in step 1), and subjecting the pyrolytic gas to condensation, thus obtaining furfural. The method provided in the invention has the advantages of simple process, high processing efficiency, short procedure and easy operation, short production cycle, and low cost.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

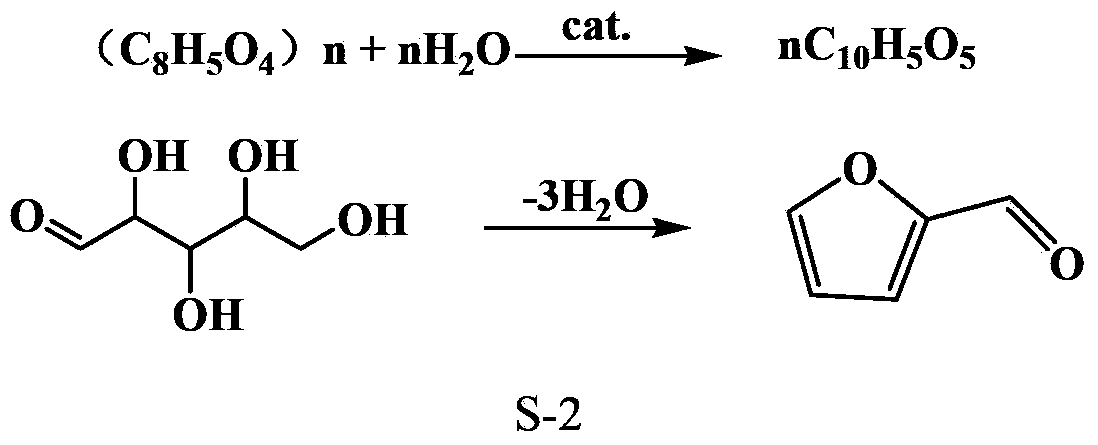

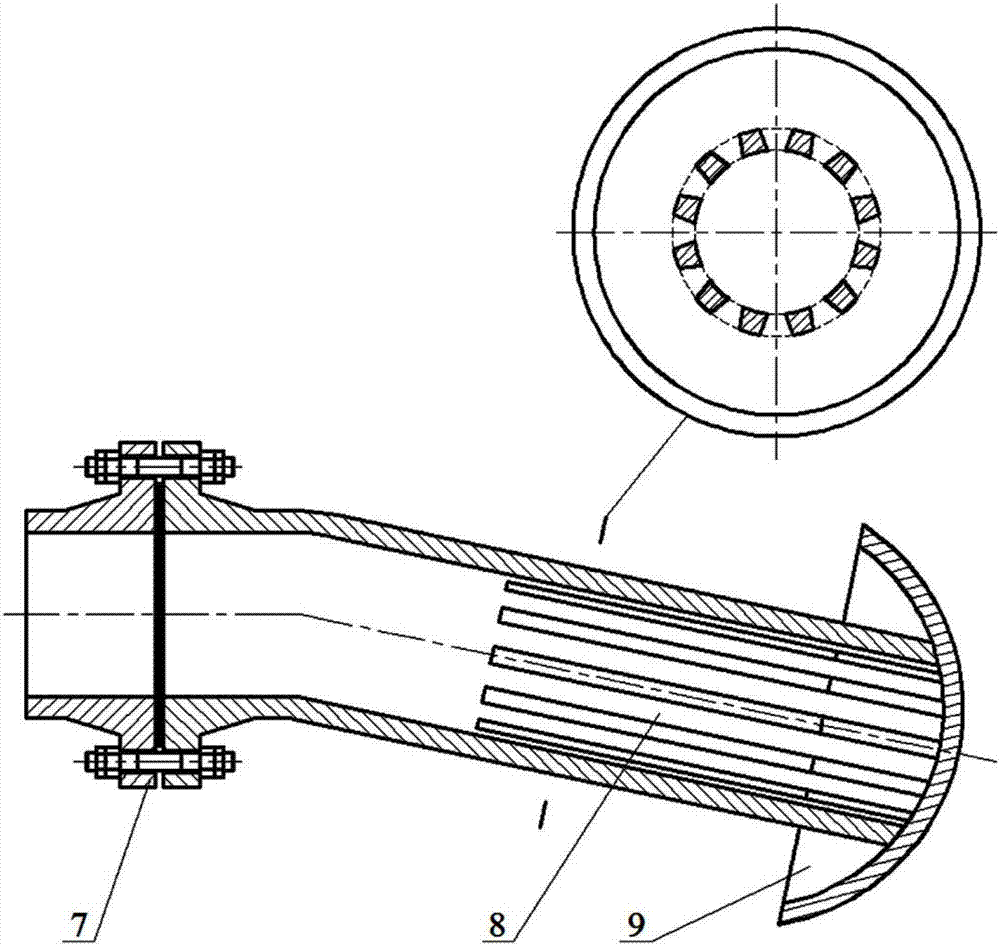

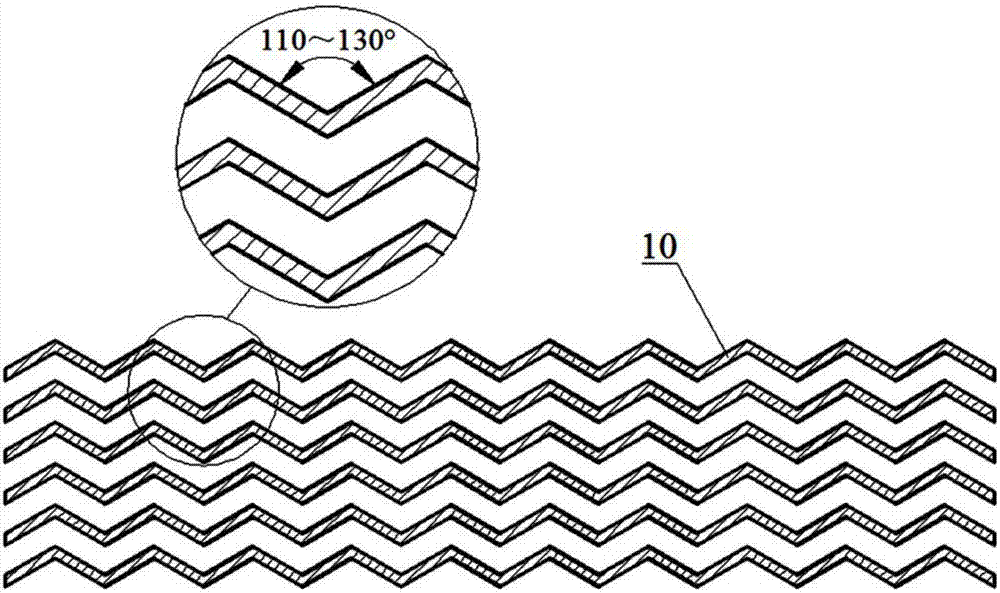

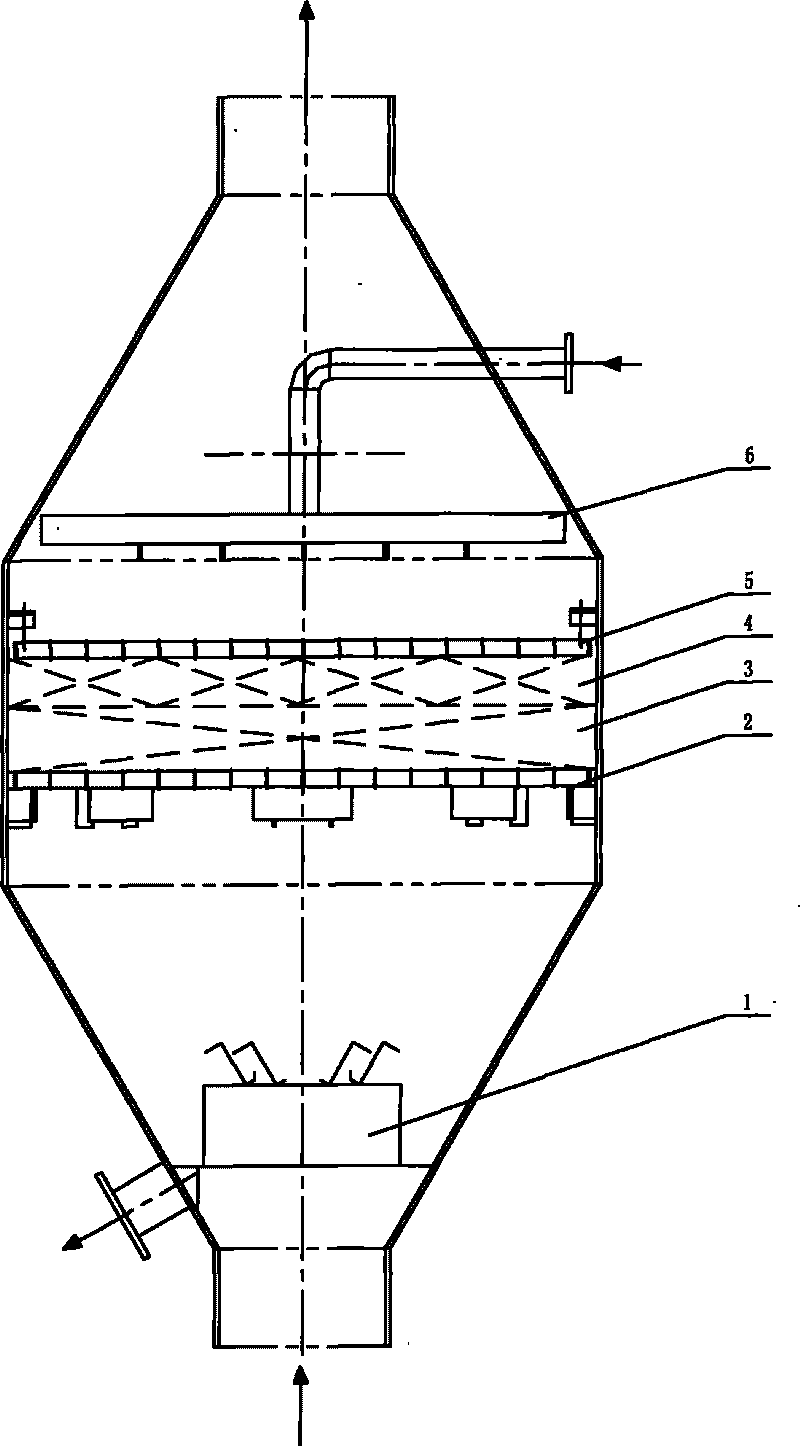

Inclination pipe type underwater pre-dewatering degassing separation apparatus

ActiveCN106938152ALarge interface coverageLarge coverage areaLiquid degasificationLiquid separationWater dischargeUnderwater

The present invention provides an inclination pipe type underwater pre-dewatering degassing separation apparatus, which is used for direct underwater pre-dewatering degassing of gas-containing well flow. According to the inclination pipe type underwater pre-dewatering degassing separation apparatus, the crude oil vertical online separation technology and the crude oil horizontal online separation technology are organically combined to achieve the efficient pre-separation and the rapid pre-dewatering degassing of oil, gas and water according to the inclination type arrangement and the tube structure; the diversion pipe adopts the narrow seam type round pipe and the collision type hemispherical plate to complete the initial gas-liquid separation, the corrugated plate group uses a group of corrugated plates stacked at equal intervals in a vertical direction to complete the secondary gas-liquid separation, and the associated gas in the oil well production liquid is completely separated out; the gas-liquid separation pipe performs the corrugated plate inclination pipe type oil-water pre-separation treatment to remove the most of the water phase in the oil well production liquid; the small liquid droplets in the associated gas are completely removed by the gas discharging balancing device according to the two-stage filtration gas of the capture liquid and the filtration liquid under the gas scrubbing action of the balance pipe; the water discharging pipe timely discharges the low oil content production water; and the sand rinsing pipe is used for periodically rinsing sand particles and other debris deposited on the bottom portion of the gas-liquid separation pipe.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for recycling tungsten, vanadium and titanium from SCR waste catalysts

InactiveCN106011503ASequential extractionAchieve mutual separationProcess efficiency improvementTungstateRaffinate

The invention discloses a method for recycling tungsten, vanadium and titanium from SCR waste catalysts. The method comprises the following steps: after the SCR waste catalysts are cleaned, the SCR waste catalysts are smashed and screened, sodium carbonate is doped into the SCR waste catalysts to be evenly stirred, mixed powder is sintered at a high temperature to obtain a sintered material, water is added for leaching out, and a sodium salt mixed solution containing tungsten and vanadium is obtained; under the condition that the pH value of the solution is large than 12, tungsten is selectively extracted, and an ammonium salt solution is used for reverse extraction to obtain an ammonium tungstate solution; under the condition that the pH value of raffinate obtained after tungsten extraction ranges from 10 to 11.5, vanadium is extracted, and a sodium hydroxide solution is used for reverse extraction to obtain a sodium vanadate solution containing a small amount of tungsten; and titanium is left in leaching residues to obtain a rich-titanium material. According to the method, separation of tungsten and vanadium from impurities such as phosphorus, arsenic and silicon is achieved, and primary separation and efficient enrichment of tungsten, vanadium and titanium are achieved.

Owner:无锡市华东电力设备有限公司

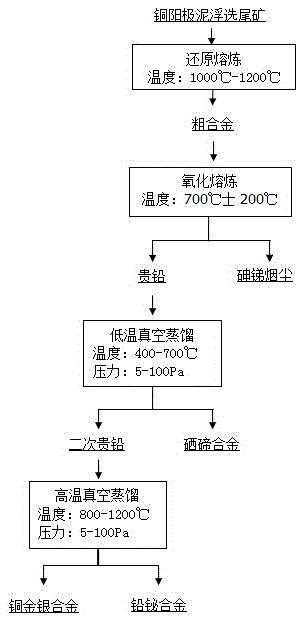

Method for recovering valuable metals from copper anode mud flotation tailings

InactiveCN105483384ASettle the lossHigh removal rateSelenium/tellurium compundsProcess efficiency improvementSootAntimony

The invention relates to a method for recovering valuable metals from copper anode mud flotation tailings and belongs to the technical field of thermometallurgy. The method comprises: firstly, performing retailoring on the copper anode mud flotation tailings to obtain a reduction product, and then performing oxidative blowing on the reduction product to obtain rich lead and arsenic and antimony containing soot; first-stage low-temperature vacuum distillation: performing primary low-temperature vacuum distillation on the obtained rich lead under the conditions of a temperature of 400-700 DEG C and a pressure of 1-100Pa for 1-3h, thereby obtaining secondary rich lead and a selenium-tellurium alloy; and second-stage high-temperature vacuum distillation: performing primary high-temperature vacuum distillation on the obtained secondary rich lead under the conditions of a temperature of 800-1200 DEG C and a pressure of 1-100Pa for 1-3h, thereby obtaining a lead-bismuth and a copper-gold-silver alloy. The method for recovering valuable metals from copper anode mud flotation tailings is safe and controllable in whole process flow, simple and convenient to operate, simple in equipment needed, free from three-waste emissions, and environment-friendly.

Owner:KUNMING UNIV OF SCI & TECH

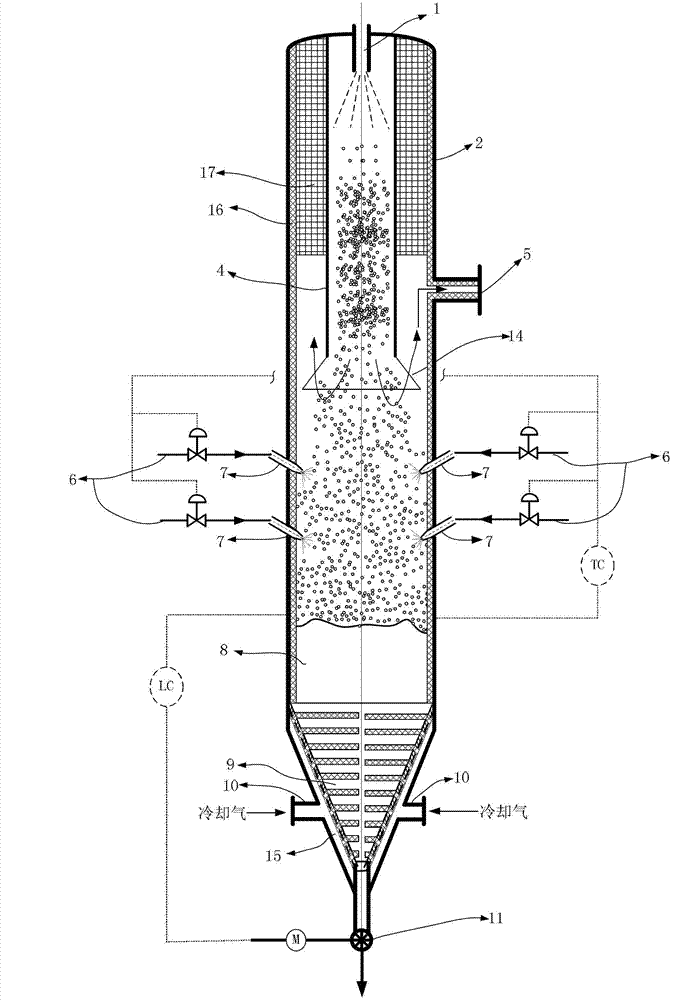

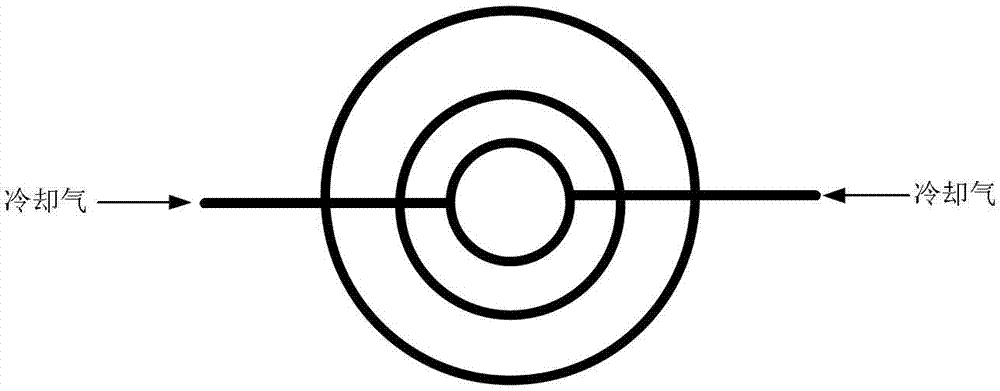

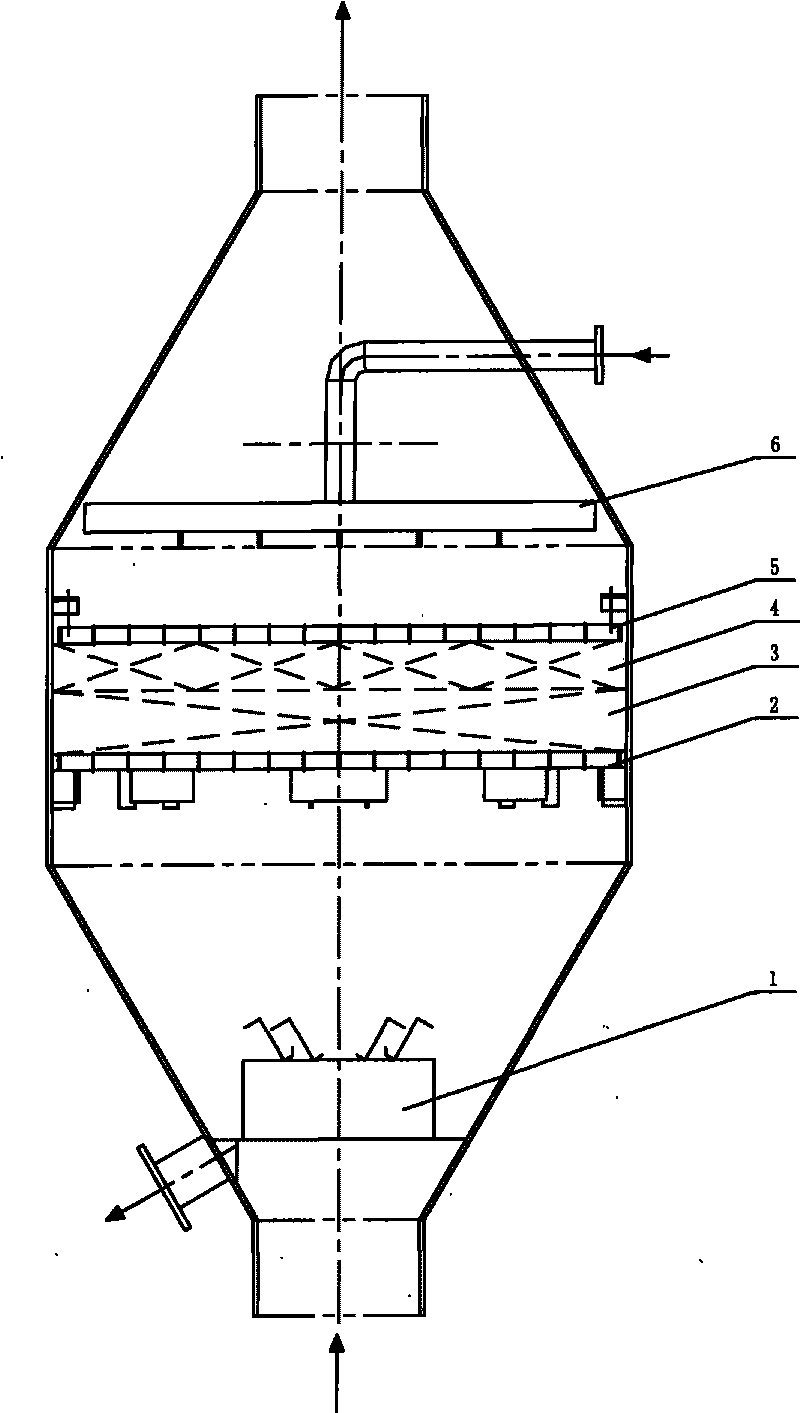

Dry-process slag discharge device and method for entrained flow bed

ActiveCN103031156AAchieving Clean TransformationMeet cooling requirements to different temperaturesGranular/pulverulent flues gasificationWater dischargeSlag

The invention relates to a dry-process slag discharge device and method for an entrained flow bed. The device is sequentially divided into a reaction section, a cooling section and a slag discharge section from top to bottom, wherein the reaction section comprises an inner barrel; the inner barrel is fixed on the top wall of the reaction section, and is opened downwards; the top wall of the reaction section is provided with a feed nozzle in a penetrating mode, which is opened to the internal space of the inner barrel; and the side wall of the reaction section is provided with a product gas outlet. According to the invention, gas flow deflection is utilized to implement primary separation of the gas product and solid product, and the solid coke slag and gas product are respectively cooled to satisfy the requirements of cooling the solid product and gas product to different temperatures; and the entrained flow bed operation and moving bed operation are combined to substitute the slag tank on the lower part of the entrained flow bed to further cool the coke slag, thereby effectively reducing the black water discharge amount and implementing clean conversion of coal resources.

Owner:ENN SCI & TECH DEV

Zinc and cobalt separation method

ActiveCN106119560AHigh recovery rateAchieve primary separationProcess efficiency improvementSlagNinetieth percentile

The invention provides a zinc and cobalt separation method. The zinc and cobalt separation method specifically includes the steps that 1, most metal in slag with high content of zinc and cobalt enters leaching solutions in a leaching mode, the leaching rate reaches 95% of above, and the metal recovery rate is high; 2, iron, copper and cadmium are removed in a combined mode, the purification process is simplified, the content of the iron, the copper and the cadmium in the solutions can be lowered to 5 mg / L or below, and the purification efficiency is high; 3, preliminary separation of the zinc and the cobalt is realized, the technology is simple, and the operation is easy; and 4, residual zinc is further removed, and complete separation of the zinc and the cobalt is realized. According to the method, the technology is simple, separation of the zinc and the cobalt is complete, the consumption is small, the production cost is low, and the recovery rate of the zinc and the cobalt in materials containing the zinc and the cobalt can reach 90% or above.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

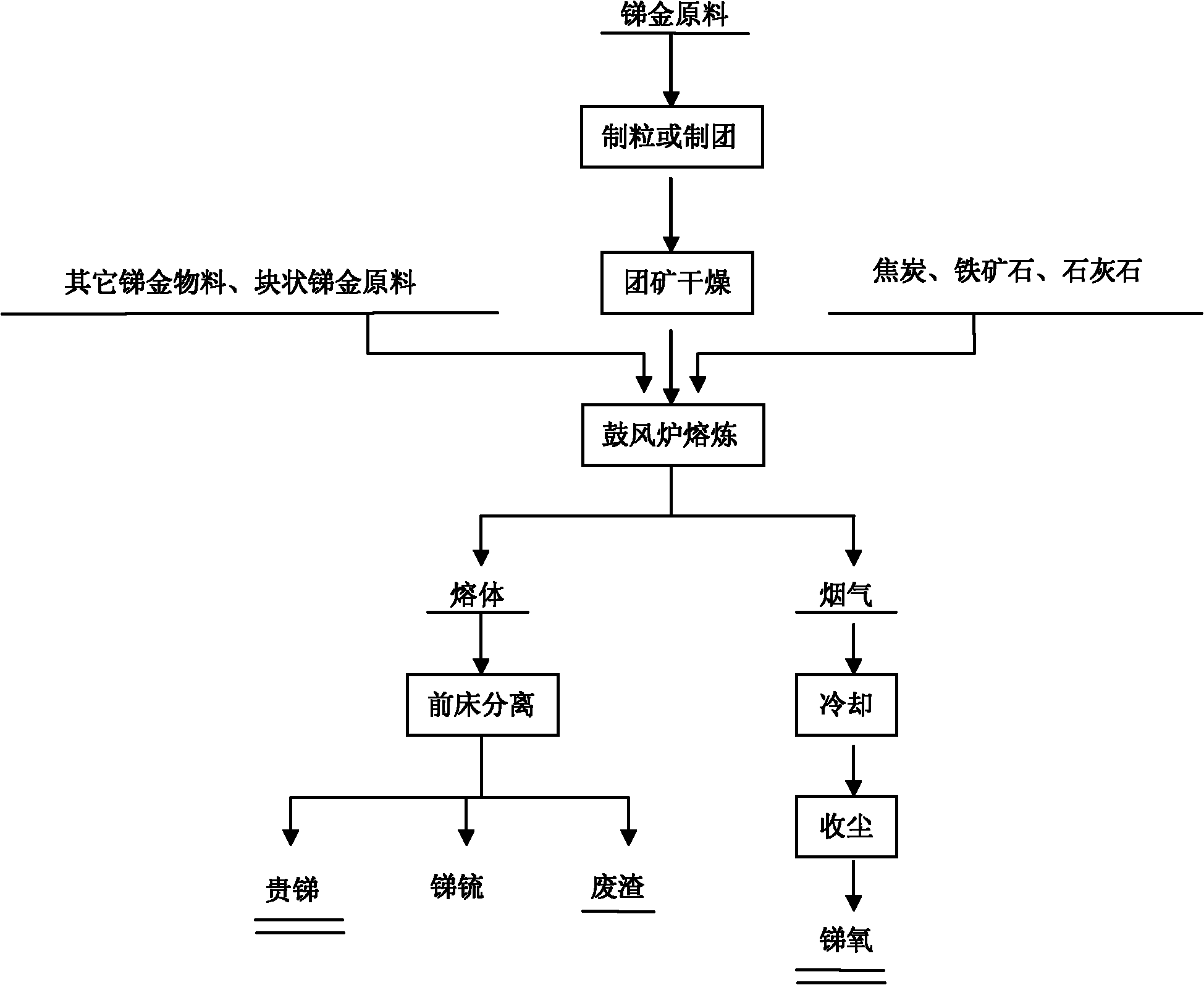

Process for preliminarily separating antimony from gold in antimony-gold material

The invention discloses a process for preliminarily separating antimony from gold in an antimony-gold material, comprising the steps of: adding a percentage of lime in the antimony-gold material with diameter of less than 5mm and pressing the antimony-gold material to be spherical; drying the antimony-gold material and inputting blocky antimony-gold material in a blast furnace; adding iron ore, lime stone and coke into the blocky antimony-gold material, and volatilizing and smelting the blocky antimony-gold material with the blast furnace, wherein most of the antimony is oxidized into antimony oxide including 75-78% of antimony to be volatilized and a small part of the antimony enters an external crucible through throat port with other sulfides and gold to be separated so that waste slag,antimony matte and expensive antimony including 800-1000g / t of gold grade are obtained and the preliminary separation of the antimony and the gold is realized. By means of the process, the problem that the antimony and the gold in the antimony-gold material cannot be separated perfectly is solved; and production proves that both the direct yields of the antimony and the gold are above 90%.

Owner:HUNAN CHENZHOU MINING CO LTD

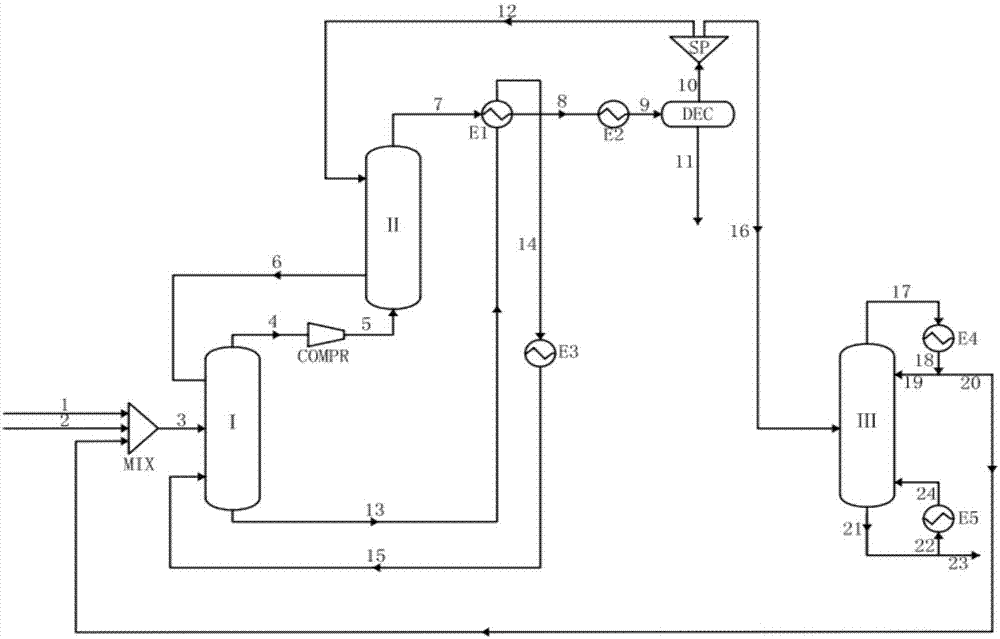

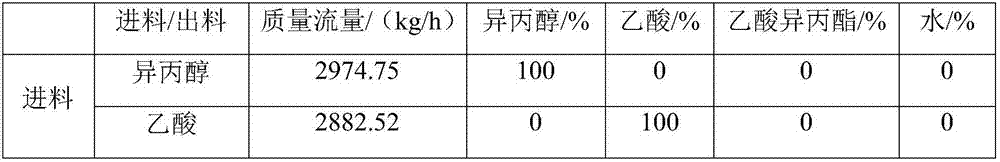

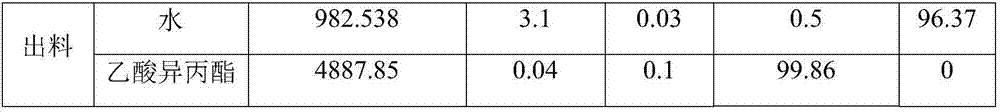

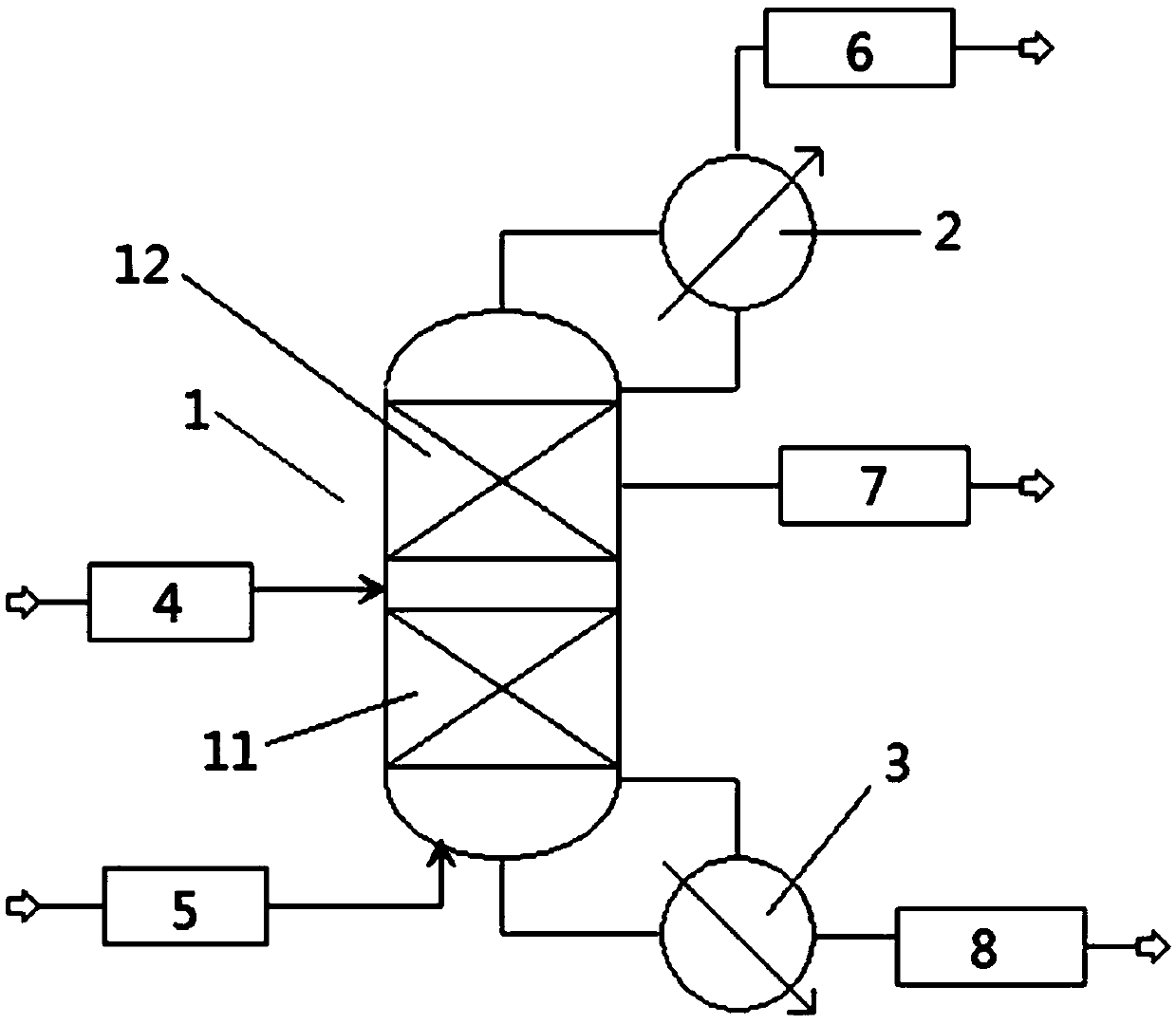

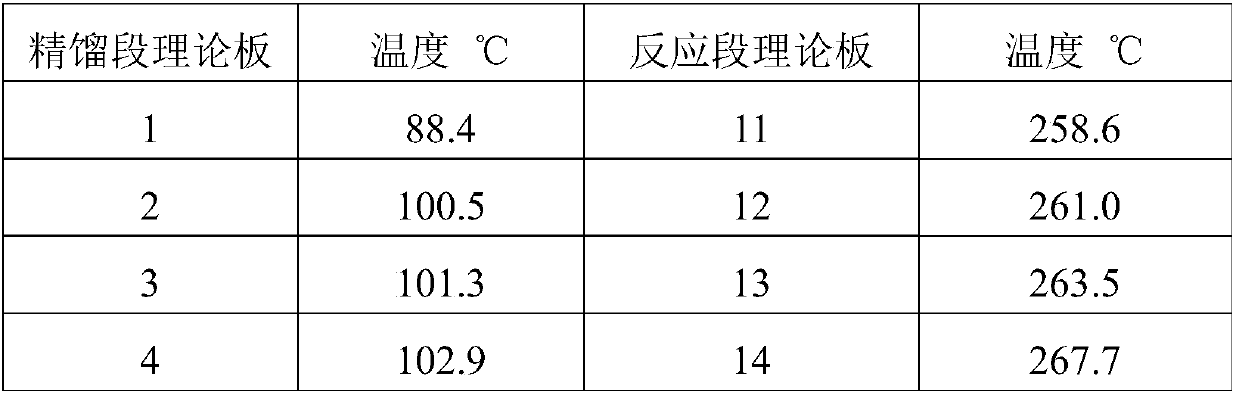

Method and apparatus for synthesizing isopropyl acetate by differential thermal coupling reactive distillation

PendingCN107954866AAchieve integrationImprove conversion rateOrganic compound preparationCarboxylic acid esters preparationReboilerPhase splitter

The invention relates to a method and apparatus for synthesizing isopropyl acetate by differential thermal coupling reactive distillation. The apparatus comprises: a feeding mixer, a low-pressure reaction column, a high-pressure distillation column, a product refining column, a phase splitter, a separator, a compressor, a thermal coupling heat exchanger, a condenser and an auxiliary reboiler. Theapparatus for synthesizing isopropyl acetate by differential thermal coupling reactive distillation allows synthesis of high-purity isopropyl acetate during distillation process; a traditional reactive distillation column is split into the high-pressure distillation column and the low-pressure reaction column, high-temperature steam at the top of the high-pressure distillation column is used to heat the reboiler of the low-pressure reaction column, the two columns share one heat exchanger, heat of the top steam of the high-pressure distillation column is made full use, and heat efficiency of the process is improved. By synthesizing isopropyl acetate via the differential thermal coupling reactive distillation process, esterification, distillation separation and thermal coupling are integrated; material that is not fully reacted flows back for reuse, so that total conversion rate of a reactant is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Reaction device and method for adiponitrile production

ActiveCN109678756AImprove conversion ratePreliminary separationChemical industryPreparation by ammonia-carboxylic acid reactionLateral lineLiquid phase

The invention relates to a reaction device and a method for adiponitrile production. The reaction device comprises a reactive distillation tower, a fractional condenser at the tower top and a reboilerat the tower bottom, wherein the reactive distillation tower comprises a reaction section and a distillation section located above the reaction section and is provided with two feeding ports and three discharging ports, a first feeding port is located between the reaction section and the distillation section, a second feeding port is located in the tower bottom, a first discharging port of the reactive distillation tower is located in the fractional condenser at the tower top, a second discharging port is a lateral line liquid phase discharging port and located in the middle of the distillation section, a third discharging port is a tower bottom liquid phase discharging port, and adiponitrile is produced from adipic acid as a raw material by the reaction device through liquid phase catalytic ammoniation. With the adoption of a reactive distillation mode, countercurrent sufficient contact of ammonia and adipic acid at the reaction section is realized, meanwhile, water as a reaction product can leave the reaction area in a vapor state, and accordingly, conversion rate of adipic acid and selectivity of adiponitrile are increased.

Owner:SHANGHAI JIAO TONG UNIV

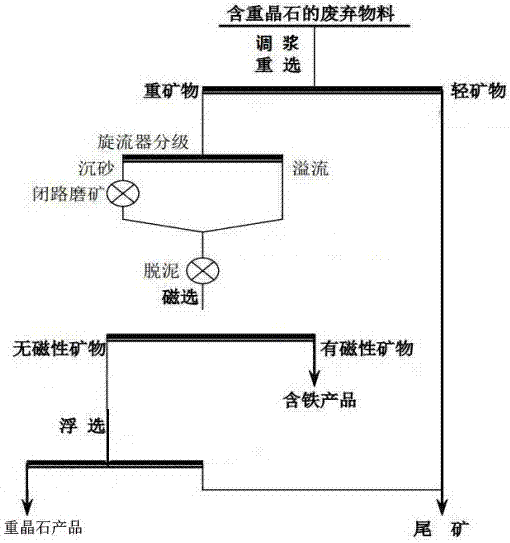

Combined ore dressing method for waste materials containing low-grade barite

InactiveCN106944249AEfficient separationFull recoveryMechanical material recoveryWet separationMagnetic separatorLower grade

The invention discloses a combined ore dressing method for waste materials containing low-grade barite. The method comprises the following steps that 1, powdery materials are prepared into ore pulp by adding water; 2, the ore pulp obtained in the step 1 is fed into gravity dressing equipment for dressing; 3, pulp mixing is conducted on heavy ore obtained in the step 2, obtained heavy ore pulp is fed into a hydrocyclone for classifying to obtain a sand setting product and an overflow product, and the sand setting product enters ore grinding equipment for ore grinding; 4, mixing and desliming are conducted on the ore grinding product and the overflow product which are obtained in the step 3, and pulp mixing is conducted after desliming; 5, ore pulp obtained in the step 4 is fed into a magnetic separator for separation; 6, pulp mixing is conducted on a non-magnetic product obtained in the step 5, and obtained ore pulp is fed into a flotation machine for 4-6-segment grading flotation; 7, filtering, reagent removing and whitening are conducted on a barite powder product obtained in the step 6, and a barite product is obtained. According to the method, the qualified barite powder product can be obtained from the waste materials, the method is applied to the industries of chemical engineering, petroleum drilling, medicine and the like, and the economical efficiency of secondary resource utilization is improved.

Owner:JIUQUAN IRON & STEEL GRP

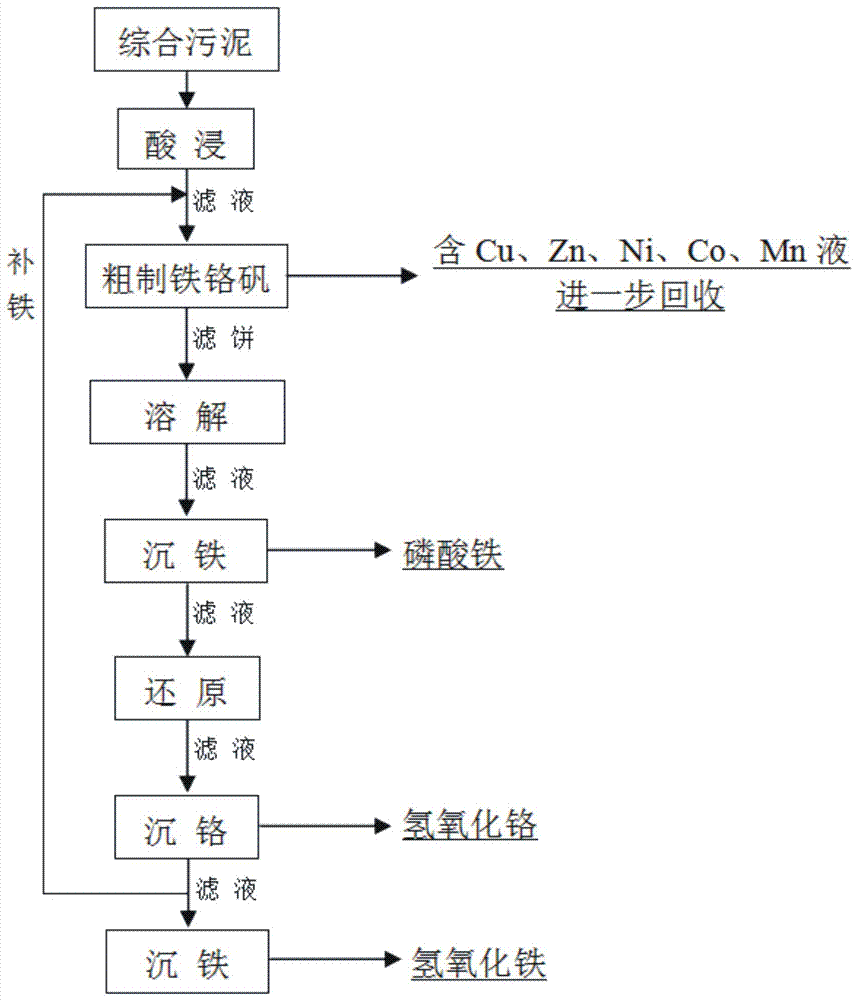

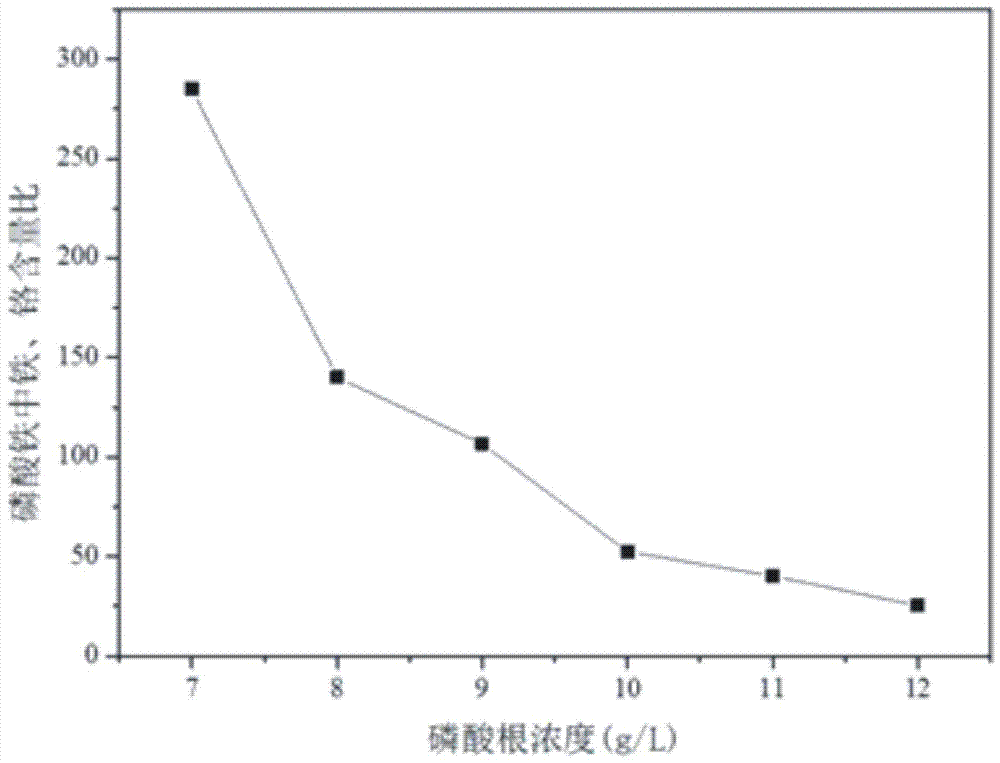

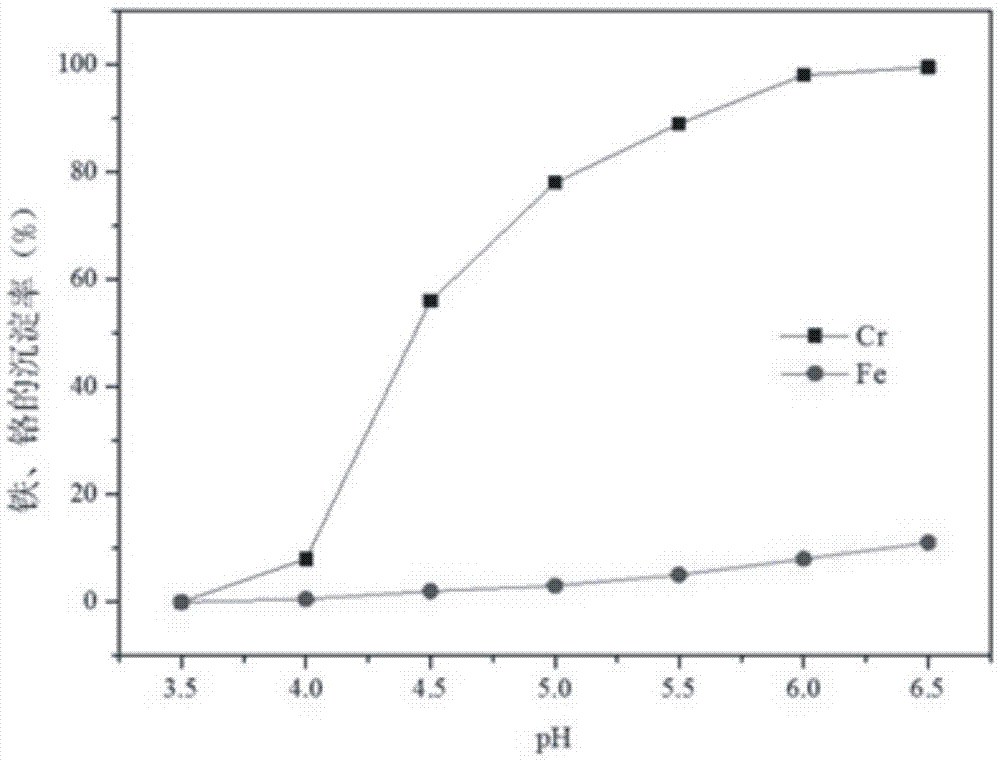

Method for separating and refining iron and chromium from polymetallic hazardous waste

ActiveCN107324303AReduce processing timeReduce processing costsIron oxides/hydroxidesCalcium/strontium/barium sulfatesChromium(III) hydroxideSludge

The invention discloses a method for separating and refining iron and chromium from polymetallic hazardous waste. The phosphate radicals carried by sludge are utilized to precipitate Fe<3+> selectively for preparing iron phosphate and isolating Fe<3+> from Cr<3+>, and since Cr<3+> can be precipitated by the phosphate radicals, a method of excessive Fe<3+> is adopted to prevent the formation of chromium phosphate precipitation in the process; the residual Fe<3+> can be reduced to Fe<2+> by scrap iron, then an alkaline solution is added to adjust the pH to a certain value so as to selectively precipitate Cr<3+> for preparing chromium hydroxide, and further separation of iron and chromium can be achieved. According to the method for separating and refining iron and chromium from the polymetallic hazardous waste, no heating is needed during the whole process, ferric ions and the phosphate radicals in the hazardous waste are comprehensively utilized, and thus the cost is low; meanwhile, no waste water and waste residues are produced, and thus the method is environment-friendly; iron phosphate and chromium hydroxide can be obtained from respective extraction, wherein iron phosphate has high economic values and can be used in battery materials, ceramics and other raw materials, and chromium hydroxide can be used in pigments, chemicals and other industry raw materials.

Owner:青川县天运金属开发有限公司

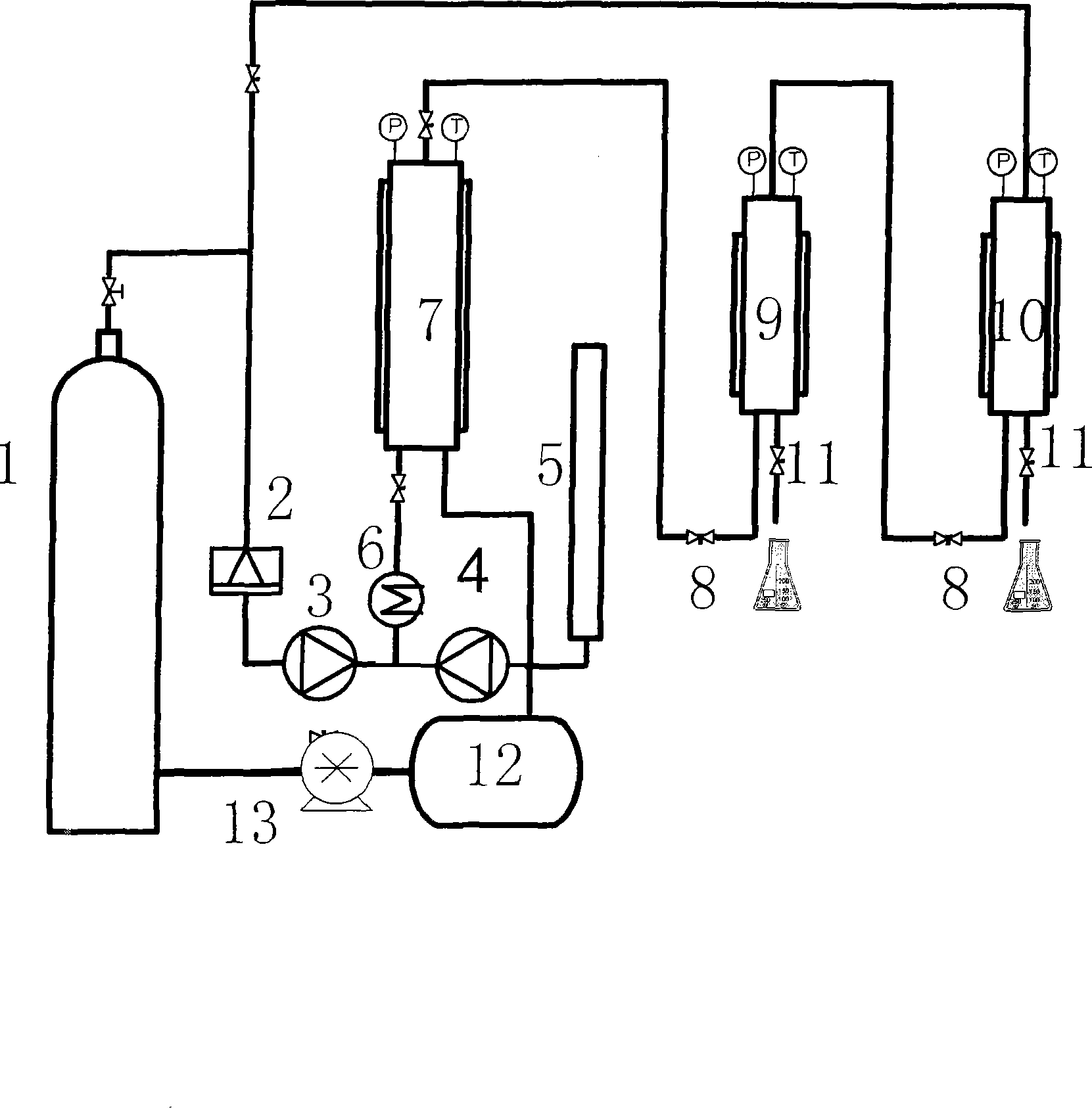

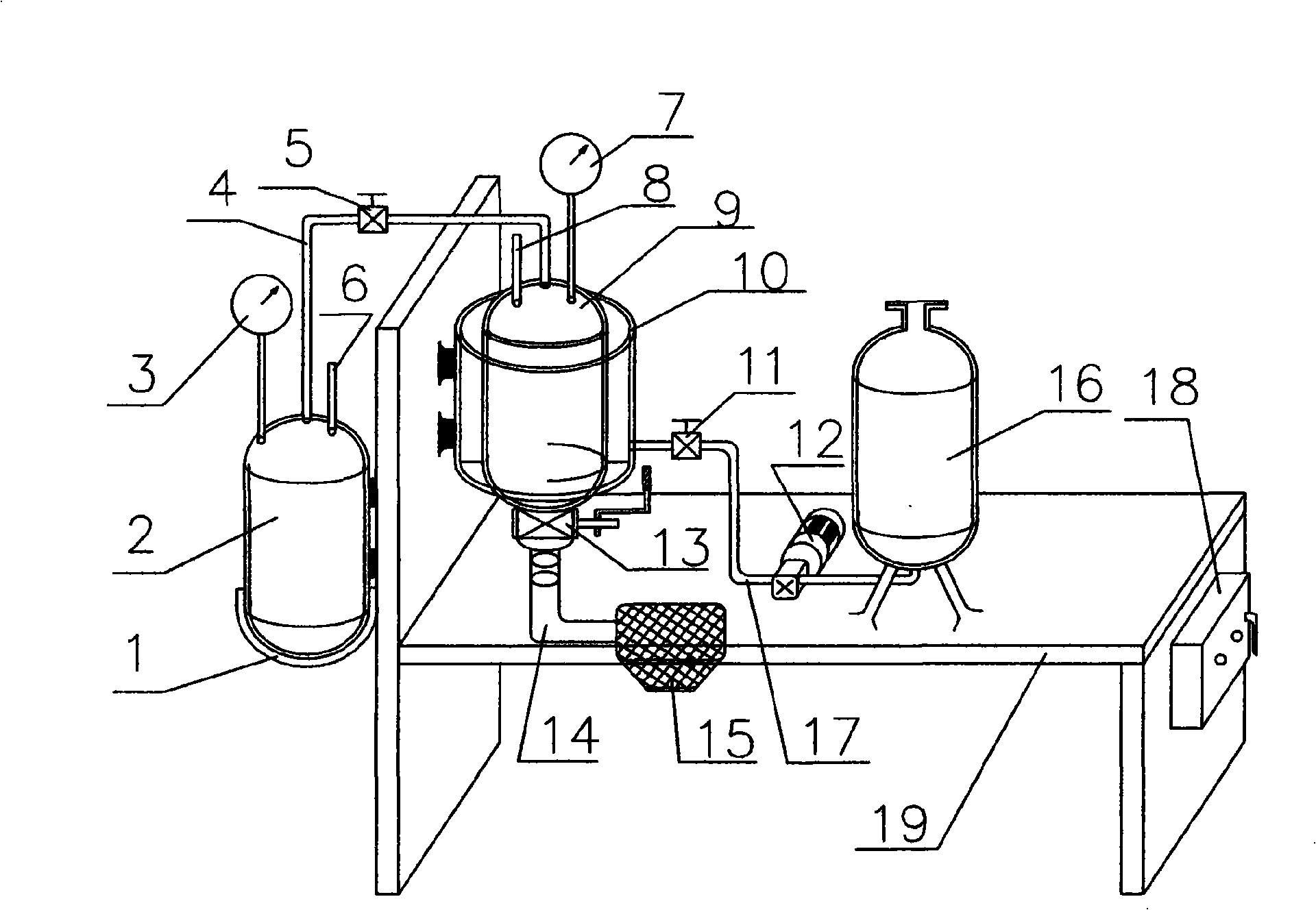

Supercritical safflower extracting process

ActiveCN101019909AHigh yieldRealize extraction and separationAntibacterial agentsMetabolism disorderHigh concentrationWax

The supercritical safflower extracting process includes the following steps: the first extraction of the safflower material with supercritical CO2 as extractant, two-stage of decompression separation to obtain vegetable wax and volatile safflower oil, the second extraction of the safflower residue to obtain macromolecular non-polar matter, the third extraction of the safflower residue in the presence of entrainer and CO2 and decompression separation to obtain polar matter and entrainer. The present invention has high volatile safflower oil yield, realizes the extraction and separation of volatile oil and wax in one step and utilizes the non-polar matter in safflower effectively. The present invention has the advantages of high product concentration and capacity of producing high concentration medicine preparation easily.

Owner:山西华卫药业有限公司

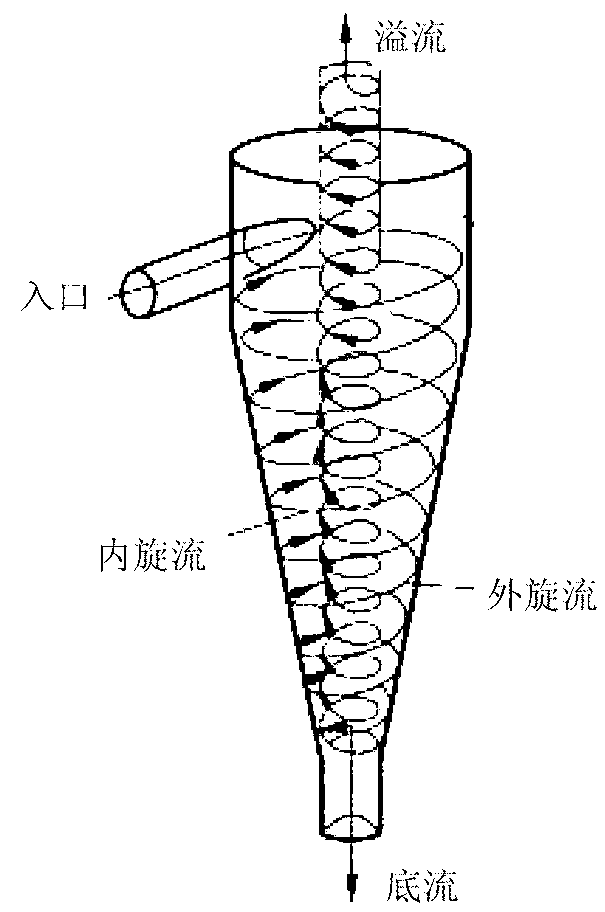

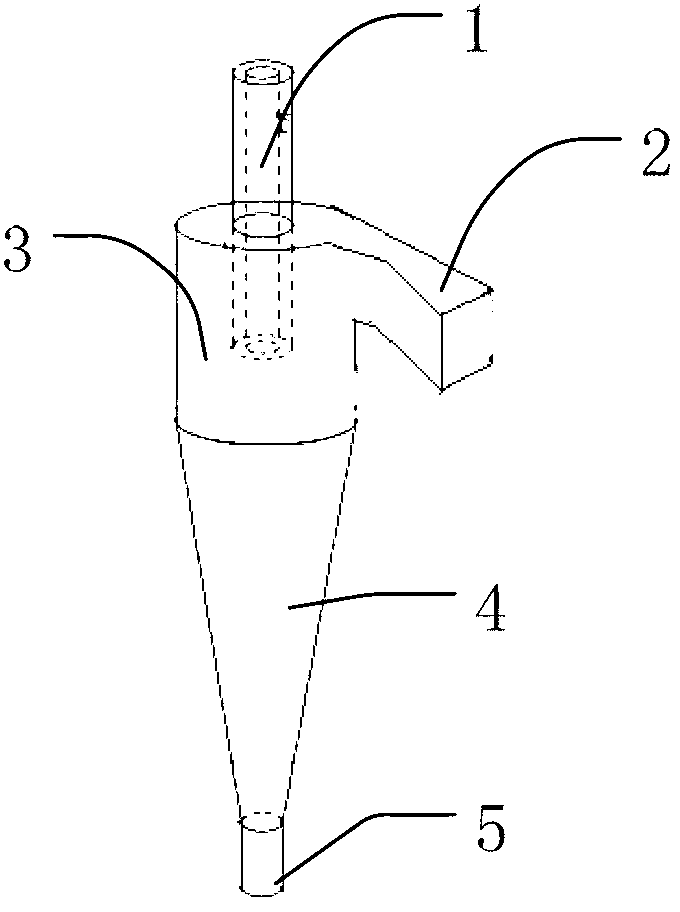

Hydrocyclone with variable pipeline section area at inlet section

InactiveCN103008123AImprove separation efficiencySimple structureReversed direction vortexEngineeringMechanical engineering

The invention belongs to the technical field of a hydrocyclone, and particularly relates to a hydrocyclone with the variable pipeline section area at an inlet section. The inlet section of the hydrocyclone is tangent with a column section, and the upper surface of the inlet section is flush with the upper surface of the column section; in the movement direction of medium, a front half section of an inner side surface of the inlet section of the hydrocyclone inclines toward the direction of an outer side surface, so as to allow the sectional area of a pipeline in the front half part of the inlet section to taper; and the oblique direction of the rear half section of the inner side surface of the inlet section of the hydrocyclone is opposite to the front half section of the inner side surface of the inlet section of the hydrocyclone. The hydrocyclone can allow the speed of working medium to increase in the front half part of the inlet section of the hydrocyclone; prefractionation of the coarse particles and fine particles is realized by inertia; separation efficiency of the hydrocyclone is improved; the required equipment of the hydrocyclone is simple; the investment is few; the cost is low; and volume production is easy to realize.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

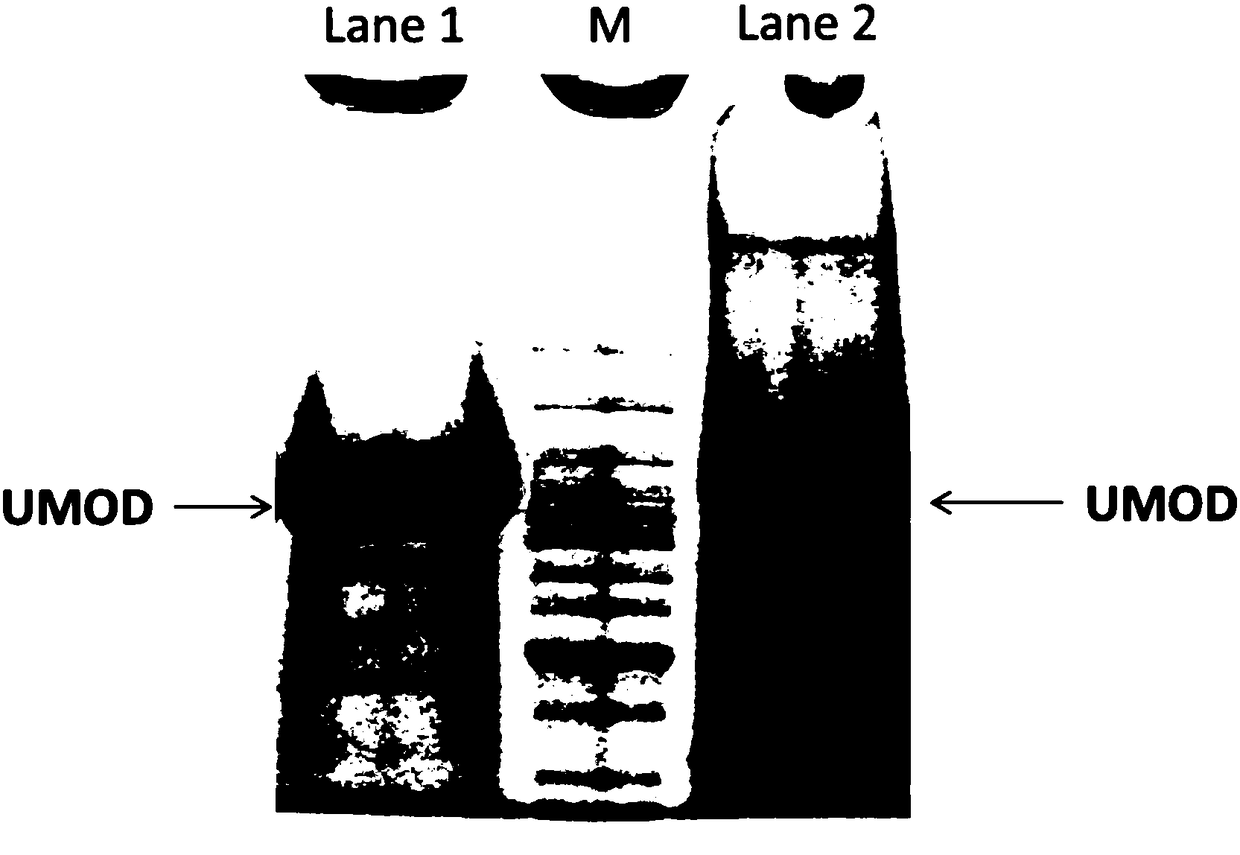

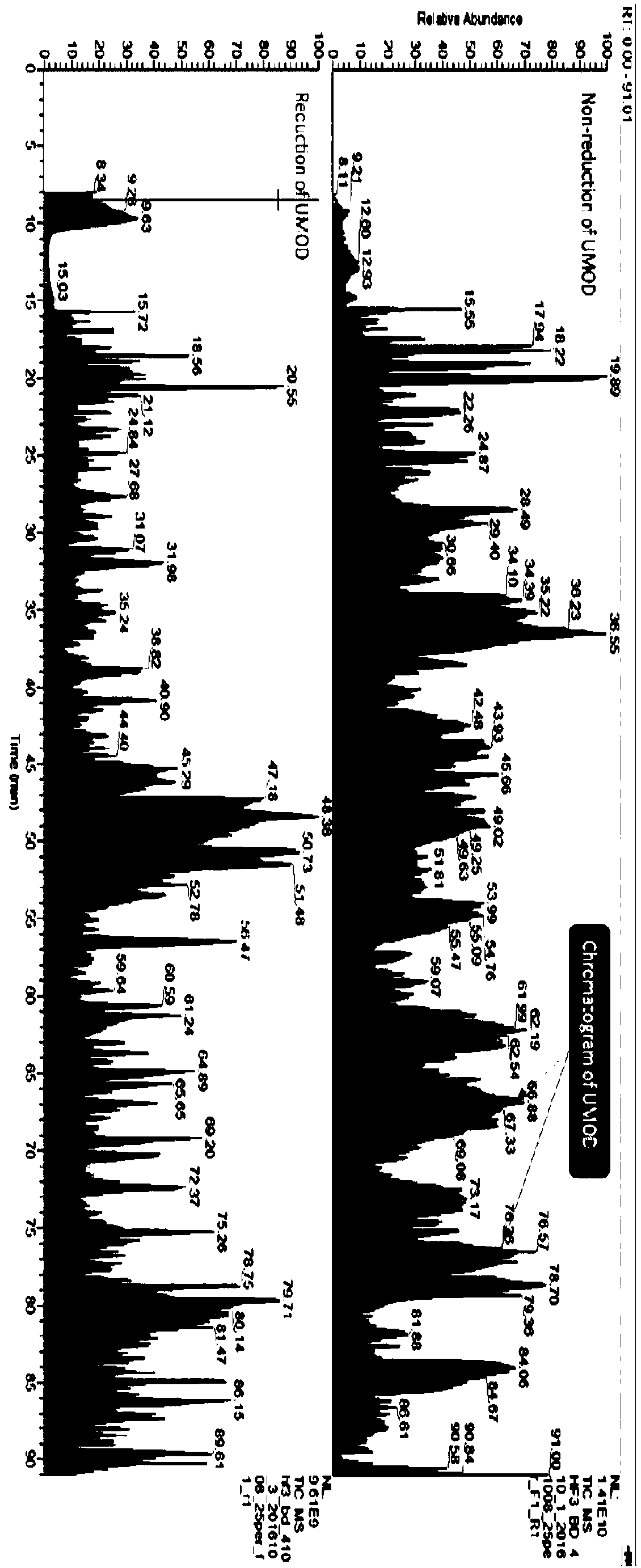

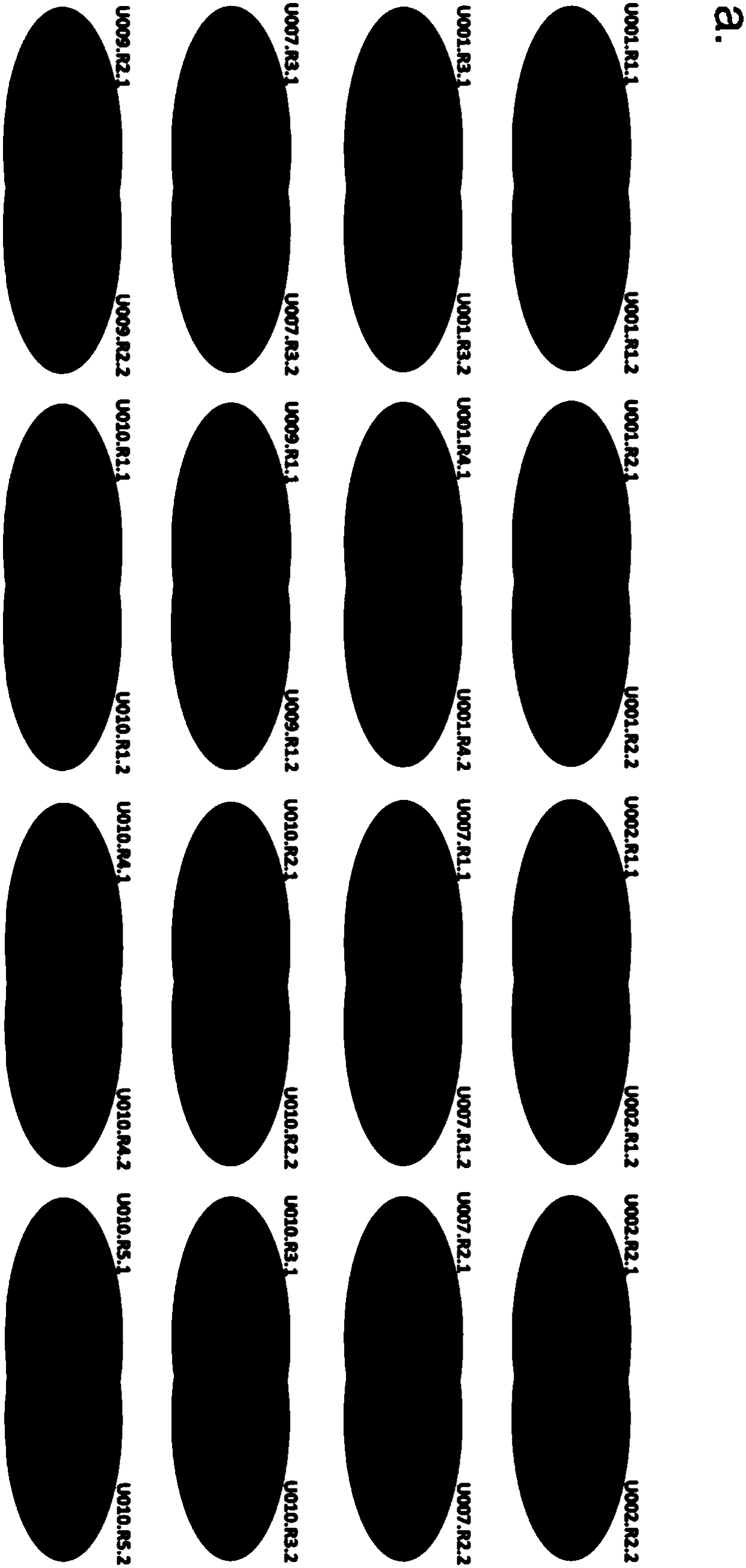

Preparation method of urinary protein and detection method for urinary proteome

PendingCN108333263AEasy to prepareImprove accuracy and repeatabilityComponent separationPreparing sample for investigationChemistryMass spectrum analysis

The invention discloses a detection method for urinary proteome, which includes the steps of preparation of urinary protein, separation at protein or peptide level, and mass spectrum identification. The method of preparation of urinary protein includes steps of: 1) performing ultracentrifugation to a urine sample at normal temperature for a certain time and rejecting the supernatant and maintaining a precipitate; 2) adding a proper amount of resuspending buffer liquid to the precipitate in the step 1) to re-suspend the precipitate; 3) adding a reducing agent, which can break a disulfide bond,to the resuspension liquid and heating the resuspension liquid for 10-60 min at 37-80 DEG C; 4) adding a cleaning buffer solution to the solution in the step 3) and performing high-speed centrifugation for a certain time, and rejecting the supernatant and maintaining a precipitate; 5) re-dissolving the precipitate in the step 4) with a digestive buffer solution, and performing in-solution enzymolysis to proteins or performing protein separation through one-dimensional electrophoresis (SDS-PAGE). The method simplifies preparation process of urinary protein and improves accuracy and repeatability of detection. The method can be used for high-throughput quantitative deep detection of the urinary proteome.

Owner:北京松果天目健康管理有限公司

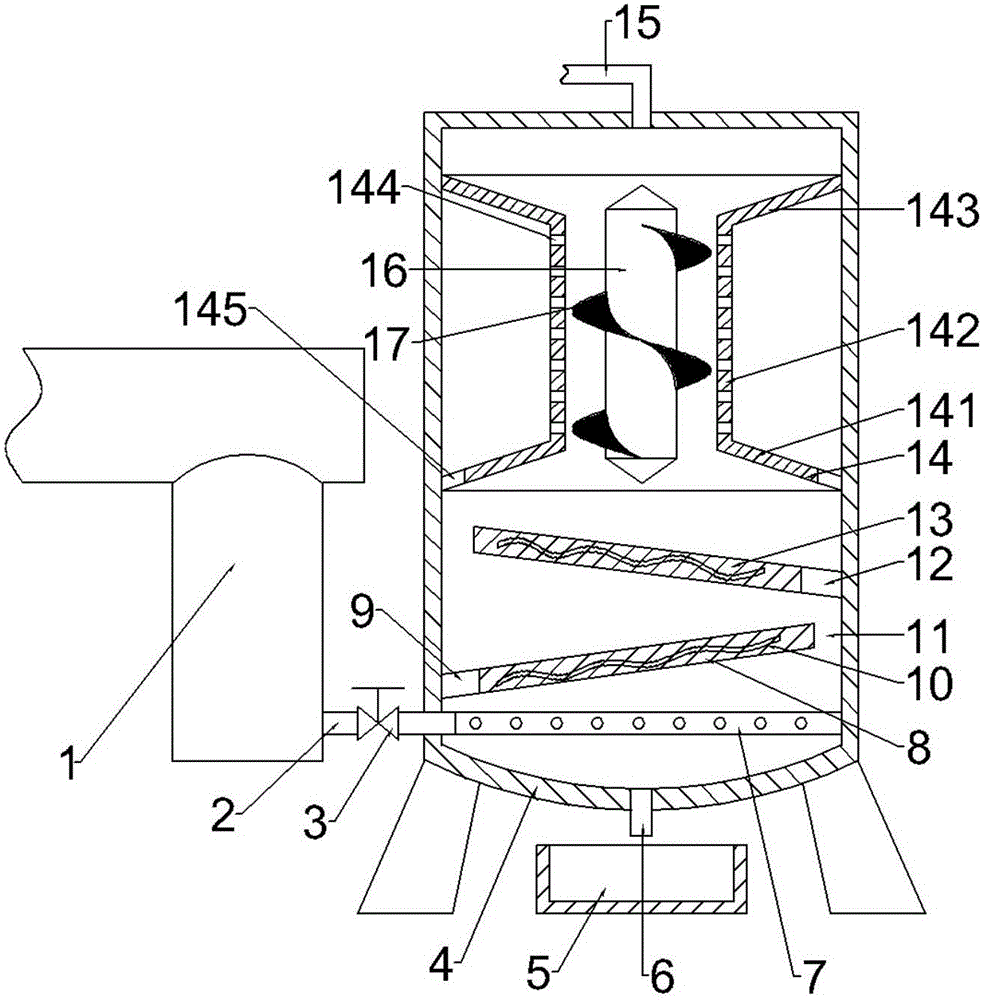

Flash-explosion hemp degelatinizing technology with cryogenic processing and device

InactiveCN101255609AAvoid damageAchieve primary separationMechanical treatmentFibre treatment to obtain bast fibreEngineeringHigh pressure

The invention relates to a hemp degumming technology using a steam explosion with a low-temperature treatment and a device. The invention relatest to the hemp degumming technology, in particular to the steam explosion hemp degumming technology, comprising: firstly ramie is marinated for 15 hours in the temperature of 25 deg C; then the ramie which is already marinated by water is put into a groove which contains a solution of NaOH with a concentration of 18 percent to be processed alkali treatment; then the ramie is kept in high pressure; after being kept in high pressure the hemp fiber is processed a decompression steam explosion treatment with the low-temperature treatment. The hemp degumming technology of the invention has the advantages of that a low rate of incomplete glue, light fibre damage, no pollution, reducing cost of degumming, saving degumming time.

Owner:LANYAN GROUP

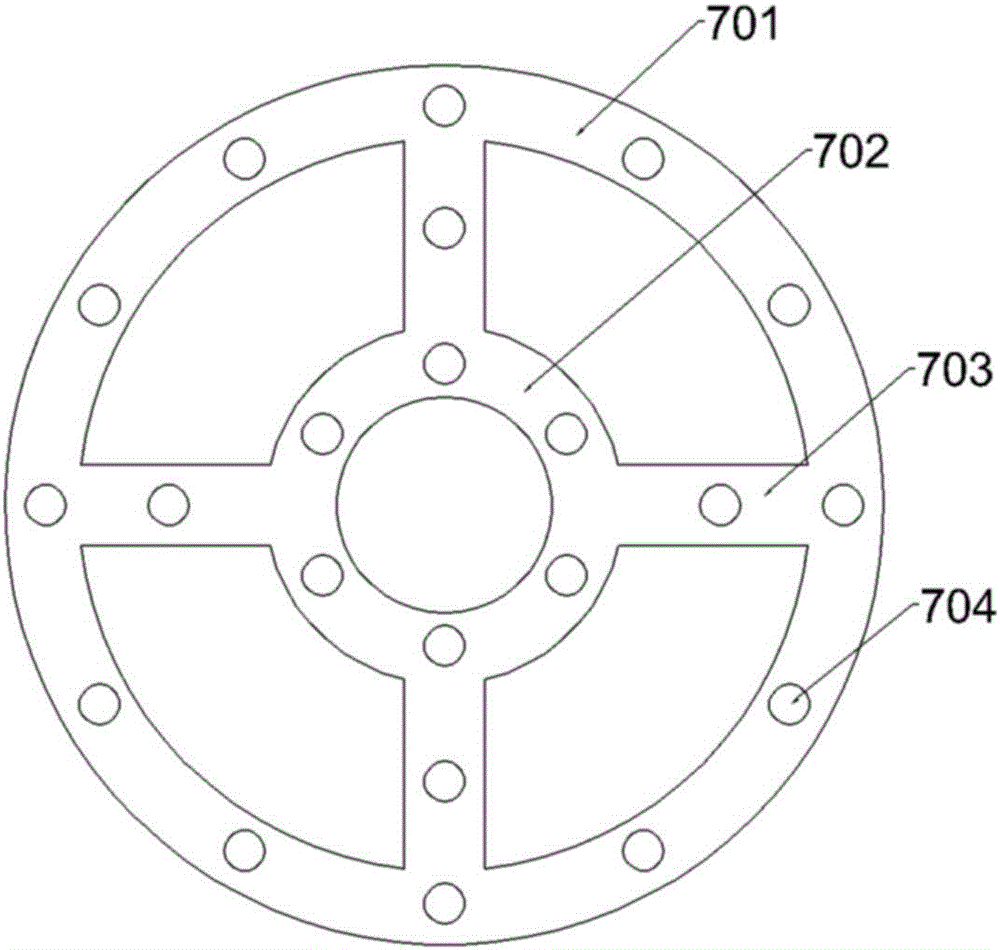

Pulp gas-water separation device for papermaking field on basis of centrifugal force principle

InactiveCN106422542AIncrease profitAchieve primary separationDispersed particle separationHeat resistanceWater vapor

A pulp gas-water separation device for the papermaking field on the basis of a centrifugal force principle comprises a shell, a conveying pipeline and a conveying branch pipe, and the conveying pipeline is connected with a vacuum coated roller and connected with the conveying branch pipe. The conveying branch pipe is communicated with the bottom of the shell. The conveying branch pipe is communicated with an air distribution device at the bottom in the shell. A first baffle is fixedly arranged on the upper portion of the air distribution device, the first baffle is obliquely arranged toward the right upper portion, the left end of the first baffle is fixedly connected with the left side wall of the shell, and a gap is reserved between the right end of the first baffle and the shell. The device has the advantages that heating resistance wires are specially buried in the first baffle and a second baffle to make gas and water smoothly separated and steam containing slurry continues keeping the vapor state; surface tension of the slurry is large, so the slurry in the steam can be left on the surface of the first baffle and the surface of the second baffle and left along baffle surfaces with certain inclination angles, and primary separation of the steam and the slurry is achieved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

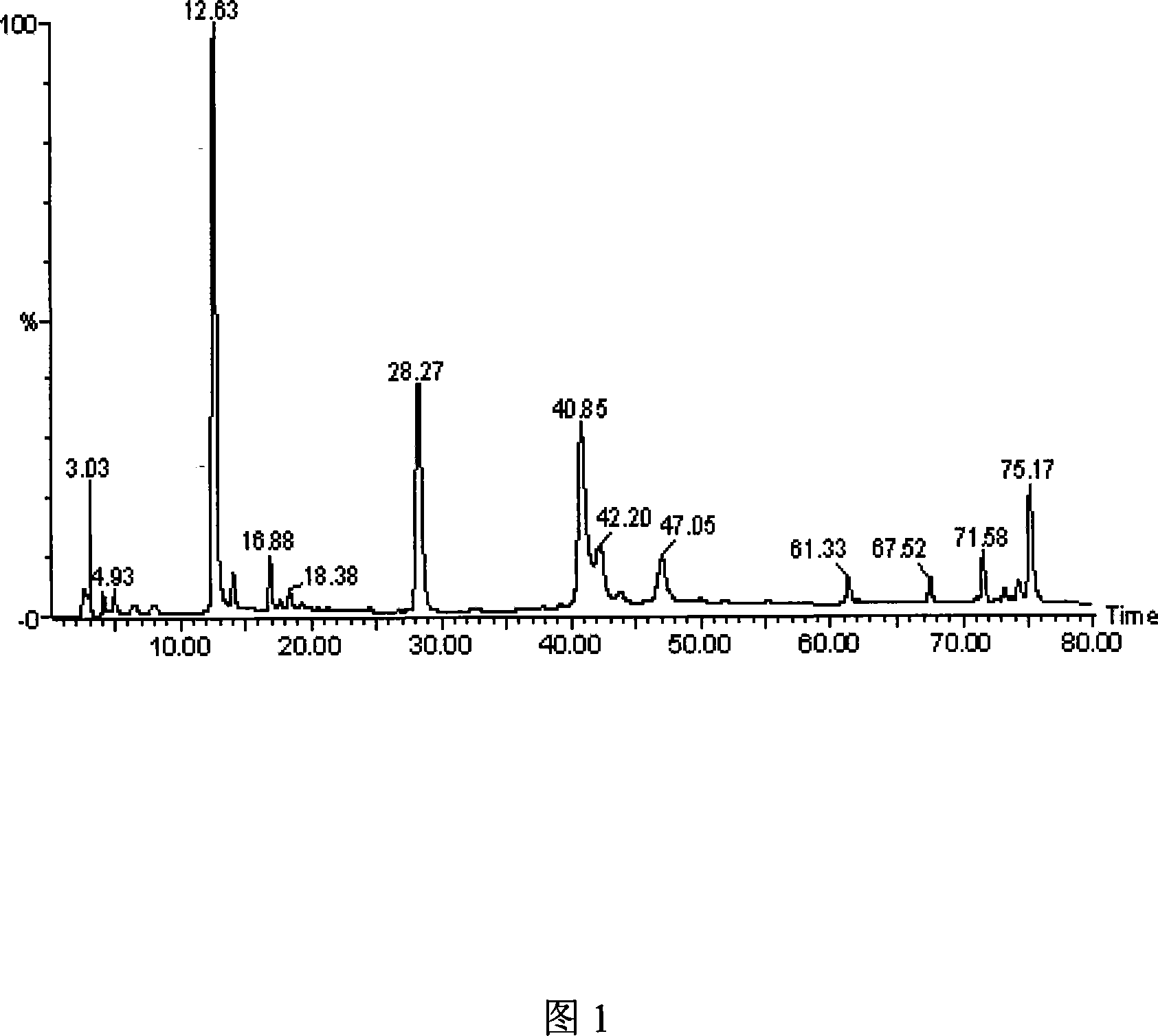

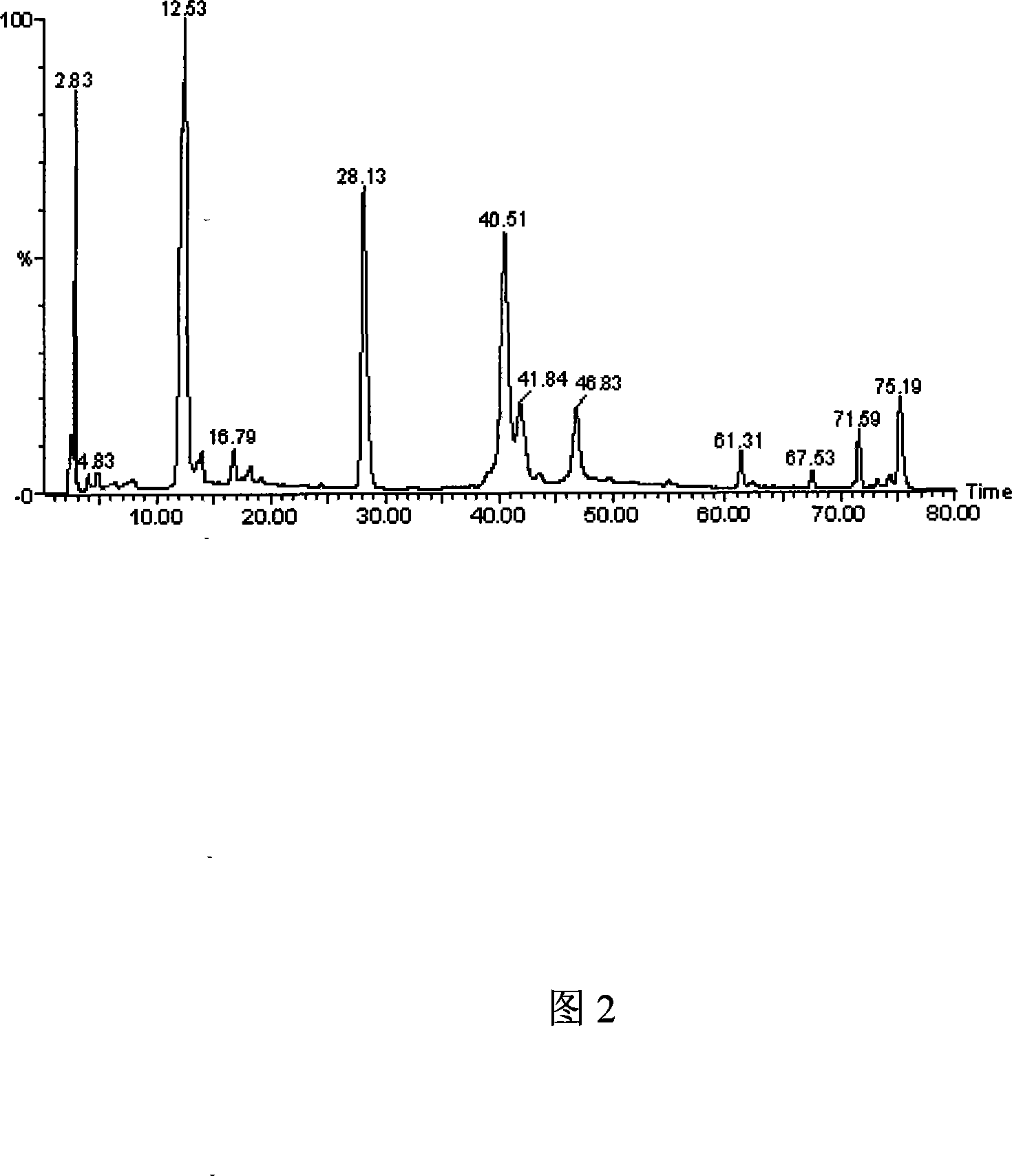

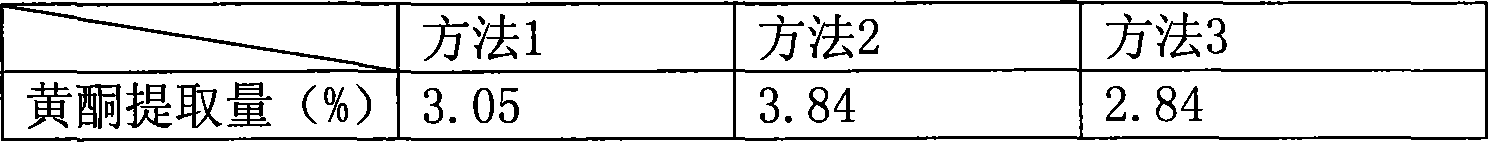

Method for extracting and enriching saussurea involucrate total flavone

InactiveCN101041653AHigh extraction rateNo lossSugar derivativesBulk chemical productionSolventChemistry

The invention discloses an extracting and enriching method of total flavone of saussurea involucrate, which is characterized by the following: proceeding supercritical CO2 extraction for saussurea involucrate; breaking cell wall in the decompressing course after supercritical extraction; reducing the resistance during mass transfer course; stripping low-polarity evaporating component to penetrate alcohol and plant component mutually; improving the extracting quantity by 37-120%.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Novel electrophoresis waste gas treatment process and multi-stage efficient degreasing spraying tower thereof

PendingCN110465157AIncrease contact areaEasy to recycleCombination devicesChemical industrySpray tower

The invention discloses a novel electrophoresis waste gas treatment process and a multi-stage efficient degreasing spraying tower thereof. The waste gas treatment process comprises: (a) preliminary impurity removal; and (b) spraying absorption. The spraying tower comprises a tower body and a liquid storage box, wherein an L-shaped gas conduction pipe, a fixed plate, an active carbon filler layer,a chemical industry filler layer, a hairbrush roller, a flow baffle, a liquid collecting hood, a distribution pipe and a liquid distributor are respectively arranged in the tower body. According to the present invention, the waste gas treatment process has characteristics of reliable operation, high treatment efficiency and good treatment effect, and can effectively remove harmful substances fromwaste gas and reduce the harmfulness of waste gas, such that the waste gas can achieve the industrial emission standards; and the spraying tower has characteristics of novel structure, large sprayingrange and complete spraying, and can increase the contact area between the absorption liquid and the waste gas and improve the absorption effect of the absorption liquid.

Owner:上海萧川机械设备有限公司嵊州分公司

Mist catching separation device

InactiveCN101721859AStrong anti-blockingGood separation effectDispersed particle separationCorrosionEngineering

The invention discloses a mist catching separation device, which comprises a pressing grid and a support frame. The pressing grid and the support frame are sequentially fixed in a tower body or a container from top to bottom; a mist catching wire mesh is arranged between the pressing grid and the support frame; the mist catching wire mesh and a plate coalescent pack are laminated between the pressing grid and the support frame; and the plate coalescent pack is positioned under the mist catching wire mesh. The mist catching separation device adopts a structure that the mist catching wire mesh is combined with the plate coalescent pack to form a liquid-mist separation component, the plate coalescent pack has strong anti-blocking so as to realize initial mist separation, and the mist subjected to the initial separation is subjected to secondary separation of the mist catching wire mesh to achieve better separation effect; therefore, the use range of the mist catching separation device is broadened, equipment corrosion is excellently reduced, service life is prolonged, treatment capacity is improved, valuable materials are recycled, environment is protected, atmospheric pollution is lightened and the like.

Owner:天津天大凯泰化工科技有限公司

Method for preparing persimmon fruit pigments

InactiveCN104693834AUniform particle size distributionEasy to operateNatural dyesSolubilityFiltration

The invention discloses a method for preparing persimmon fruit pigments. The method comprises the steps of raw material processing, high pressure microfluidics superfine grinding processing, fermentation processing, extraction, macroporous resin column chromatography, polyamide column chromatography, absorption and purification of pigments solution by sephadex gel filtration chromatography and separation and purification of persimmon fruit pigments by preparative liquid chromatography, by means of the method, the water solubility impurities in the pigments solution can be effectively removed, the primary separation of pigment monomers is achieved, the separation of monomers of the persimmon fruit pigments is effectively achieved, and the purity of a product is guaranteed.

Owner:桂林得坤生物科技股份有限公司

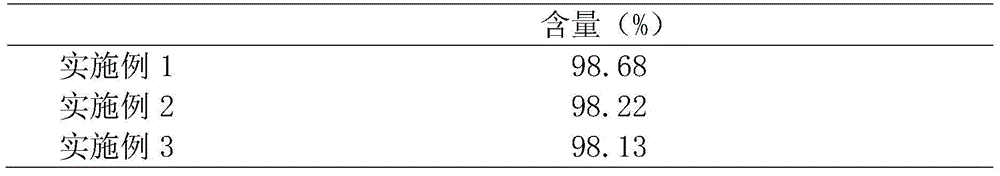

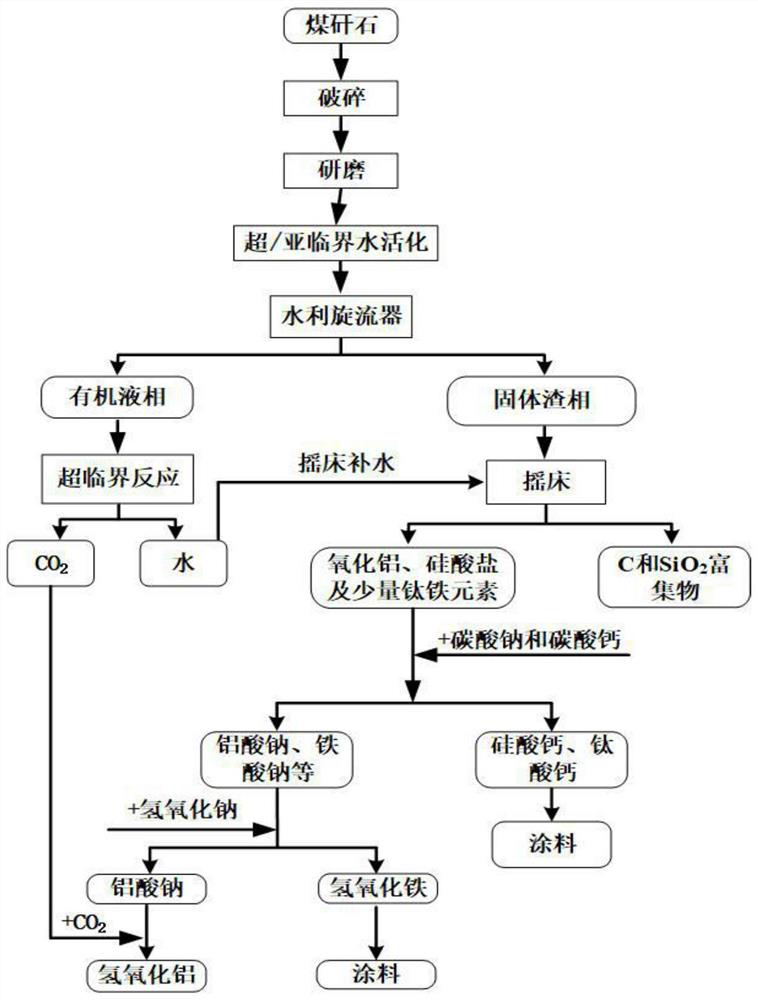

Method for extracting valuable metal elements from coal gangue

PendingCN113061728AHigh activityLow chemical stabilitySilicaIron oxides/hydroxidesSodium acid carbonateCoal gangue

The invention provides a method for extracting valuable metal elements from coal gangue. The method comprises the following steps of: crushing and grinding coal gangue ore, performing supercritical / subcritical water activation, classifying the coal gangue ore into an organic liquid phase and a slag phase by a hydrocyclone, and synthesizing carbon dioxide and water from the organic liquid phase through a supercritical reaction, wherein the carbon dioxide is used for a subsequent sodium aluminate reaction to obtain aluminum hydroxide, the water is used for supplementing water to a shaking table, and the slag phase passes through the shaking table to obtain enriched ore of carbon and silicon dioxide, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements. Carbon and silicon dioxide are separated and collected through electric separation, aluminum oxide, silicate and ore containing a small amount of titanium and iron elements are added into sodium carbonate and calcium carbonate to be roasted and dissolved after roasting, slag of calcium silicate and calcium titanate is obtained and can be used as a coating, a dissolving solution contains sodium aluminate, sodium ferrite and other substances, sodium hydroxide is added into the dissolving solution to generate ferric hydroxide and sodium aluminate, the ferric hydroxide can be used as a coating, and carbon dioxide is introduced into the sodium aluminate to generate aluminum hydroxide which is used as an inorganic flame-retardant additive.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Purification method of manganese sulfate solution

ActiveCN111187907AImprove purification efficiencyEasy to separateManganese sulfatesManganese sulphateSulfate

The invention provides a purification method of a manganese sulfate solution. The purification method comprises the following steps: S1, an extracted organic phase is prepared, and the extracted organic phase is saponified to obtain a saponified organic phase; S2, the manganese sulfate solution is extracted for the first time through the saponified organic phase to obtain a manganese-rich organicphase; S3, the manganese-rich organic phase is reversely extracted with sulfuric acid for the first time to obtain a primary purified manganese sulfate solution and a first regenerated organic phase;and S4, the pH value of the primary purified manganese sulfate solution is adjusted, and the primary purified manganese sulfate solution is purified for the second time through the saponified organicphase to obtain a high-purity manganese sulfate solution and a calcium-magnesium-rich organic phase. According to the purification method, no expensive reagent is used for purifying the manganese sulfate solution, the extraction rates of manganese, calcium and magnesium ions are controlled only by controlling the pH value of the solution, the manganese ions are separated from the calcium and magnesium ions accordingly, the purification cost is low, and the purification rate of the manganese sulfate solution is increased through the repeated extraction and reverse extraction process.

Owner:CHINA ENFI ENGINEERING CORPORATION

Supercritical extraction process of water extracted and alcohol deposited safflower residue

The supercritical extraction process of water extracted and alcohol deposited safflower residue includes low temperature drying the safflower residue at 60 deg.c; the first supercritical CO2 extracting at 8-12 MPa and 35-60 deg.c, the first separation at 8-10 MPa and 0-12 deg.c to obtain vegetable wax and the second separation at 1-6 MPa and 20-45 deg.c to obtain volatile safflower oil; the second extracting at 22-32 MPa and 35-60 deg.c, and separation at 2-6 MPa and 20-40 deg.c to obtain macromolecular non-polar matter. The present invention utilizes the non-polar matter in safflower effectively, realizes the initial separation of different kinds of matter and raises the comprehensive economic value of safflower processing.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

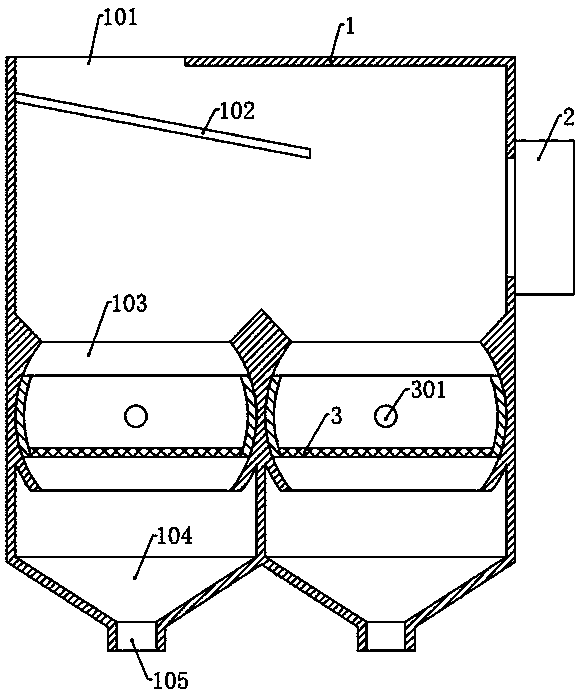

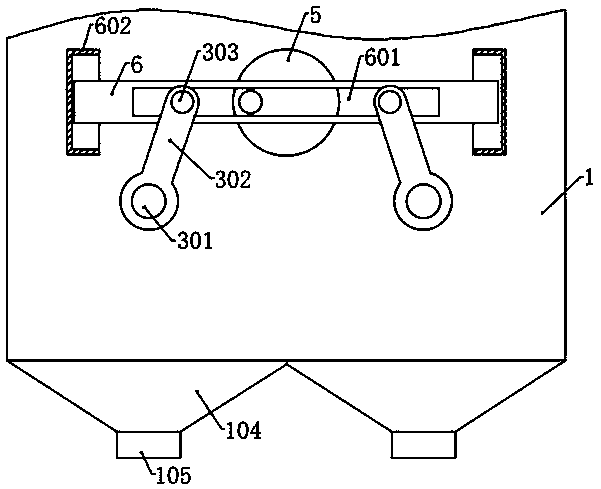

Embryo grain separating device for rice machining

InactiveCN111299157AAchieve primary separationEasy to separateSievingGas current separationAgricultural scienceAgricultural engineering

The invention discloses an embryo grain separating device for rice machining and belongs to the technical field of rice machining. The embryo grain separating device for rice machining comprises a separation box. A feeding opening, a guiding plate, an air inlet and a fan are arranged on the upper part of the separation box. The lower part of the separation box is symmetrically provided with two screening cavities. Screening mechanisms are arranged in the screening cavities. Each screening mechanism comprises a screening net. The screening nets are connected with a shaking assembly. Rice is fedinto the separation box, the rice falls along the guiding plate, the fan conducts winnowing on the falling rice, and then initial separation action is achieved; by means of rotation of a rotating motor and a rotating disk, under the action of a short shaft and a connection groove, the moving rod is made to move up and down in a reciprocating manner, so that by means of the connection groove and aconnection shaft, two rotating rods are made to simultaneously swing in a reciprocating manner, and then the screening nets in the screening cavities are driven to swing in a reciprocating manner; and in this way, screening and separation are conducted on bran and embryo grain in the two screening cavities, and then the separation effect is further improved.

Owner:何海

Method for preenriching and separating lithium and boron from salt lake brine by liquid-liquid-liquid three-phase extraction

InactiveCN103031448BAchieve primary separationWide range of pH adaptationLithium compoundsBoron compoundsImpurityPolymer

The invention relates to a method for preenriching and separating lithium and boron from salt lake brine by liquid-liquid-liquid three-phase extraction, which comprises the following steps: adding water-soluble auxiliary extractant into a salt lake concentrated brine solution, regulating the pH value of the brine, adding water-soluble high molecular polymer, and thoroughly mixing at room temperature to obtain an upper / lower two-layer liquid-phase system; adding organic extractant, and mixing to obtain an upper / middle / lower three-layer liquid-phase system; and taking the upper and middle phases from the three-liquid-phase system, and respectively recovering lithium and boron in the upper and middle phases by back washing. The invention can simultaneously enrich and extract lithium and boron by one-step extraction from high-magnesium / lithium-ratio salt lake brine, and can separate the lithium and boron from abundant coexistent ions of magnesium, calcium and other impurity metals in the brine. The lithium and boron are respectively selectively enriched from the upper and middle phases in the three-liquid-phase system to implement primary separation, thereby facilitating the subsequent purification and refinement. The three-liquid-phase extraction can be carried out under neutral or weakly-acidic conditions, and has strong adaptability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Dispersion and control-selective desliming method in bauxite

A controlled dispersing-selective desliming method in the reverse floatation of bauxite features that according to the difference of various components in said bauxite in crushibility and surface characteristics, the sodium carbonate as disperser is added during the grinding step. Its advantages are high grinding efficiency, low consumption of floatating agent, and high Al-Si ratio in ore sludge.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com