Feces and urine separated type scraper blade feces cleaning system

A technology for separation of feces and urine and cleaning of feces, which is applied in animal houses, applications, animal husbandry, etc., can solve the problems of difficult cleaning, high motor power, and difficulty, and achieve easy transportation and handling, and reduced solid content , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

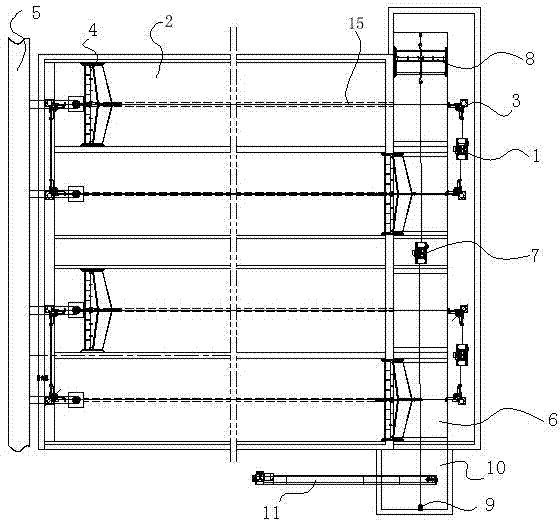

[0027] refer to figure 1 As shown, the excrement and urine separation type scraper cleaning system of the present invention includes two longitudinal dung cleaning ditch 2 and a dung scraping mechanism arranged in the vertical dung cleaning ditch 2, and the vertical dung cleaning ditch 2 is obliquely arranged, and its high One end outlet is provided with feces collection ditch 6, and the lower end is provided with urine collection ditch 5, which is convenient for urine to flow into urine collection ditch 5 under the action of gravity.

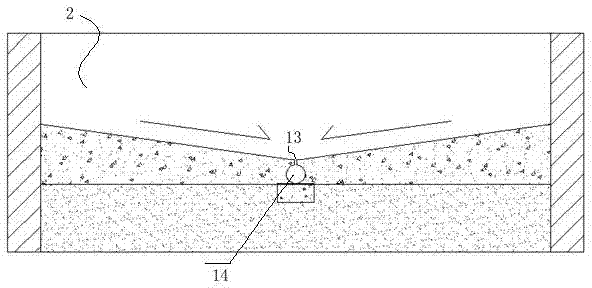

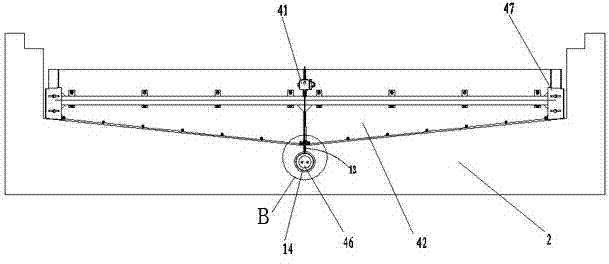

[0028] Such as figure 2 , image 3 As shown, in a preferred embodiment of the present invention, the cross section of the vertical dung cleaning ditch 2 is "V" shaped, and the bottom edge of the manure scraping mechanism matches the cross section of the vertical dung cleaning ditch 2 .

[0029] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com