Purification method of manganese sulfate solution

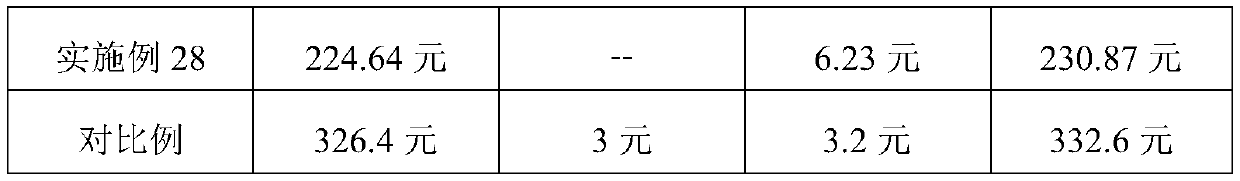

A technology of manganese sulfate solution and purification method, which is applied in the direction of manganese sulfate, and can solve the problems of high cost of purification process and low purification rate of manganese sulfate solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of saponified organic phase: Take 1L of manganese sulfate solution, which contains: 30g / L of Mn 2+ , 0.3g / L of Ca 2+ and 15g / L of Mg 2+ . Adjust the pH value of manganese sulfate solution to 3, control the volume ratio of P204 extractant and sulfonated kerosene to be 1:5, prepare 1L of organic extractant, and use ammonia water with a concentration of 8mol / L to saponify the organic extractant to form ammonia The organic phase was saponified, wherein the saponification rate was 70%.

[0038] The first extraction: use the ammonia saponified organic phase to carry out 5-stage countercurrent extraction with the manganese sulfate solution to be purified to obtain a manganese-rich organic phase. Among them, the volume ratio of saponified organic phase to manganese sulfate solution at each stage is 2:1, the extraction temperature at each stage is 25°C, and the extraction time at each stage is 5 minutes.

[0039] The first stripping: using sulfuric acid with a co...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is that the manganese sulfate solution in embodiment 2 comprises: the Mn of 10g / L 2+ , 0.1g / L of Ca 2+ and 5g / L of Mg 2+ . It can be known by calculation that the removal rate of calcium ions in the manganese sulfate solution is 99.1%, and the removal rate of magnesium ions is 97.2%.

Embodiment 3

[0046] The difference between embodiment 3 and embodiment 1 is that the manganese sulfate solution in embodiment 3 comprises: the Mn of 50g / L 2+ , 0.45g / L of Ca 2+ and 20g / L of Mg 2+ . It can be known by calculation that the removal rate of calcium ions in the manganese sulfate solution is 99.1%, and the removal rate of magnesium ions is 95.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com