Embryo grain separating device for rice machining

A rice processing and separation device technology, which is applied in the direction of solid separation, separating solids from solids with airflow, and filtering and sieving, can solve the problems of weak connection, simple structure of the separation device, and poor separation effect, so as to achieve the convenience of wind Select the effect of separation, improve the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

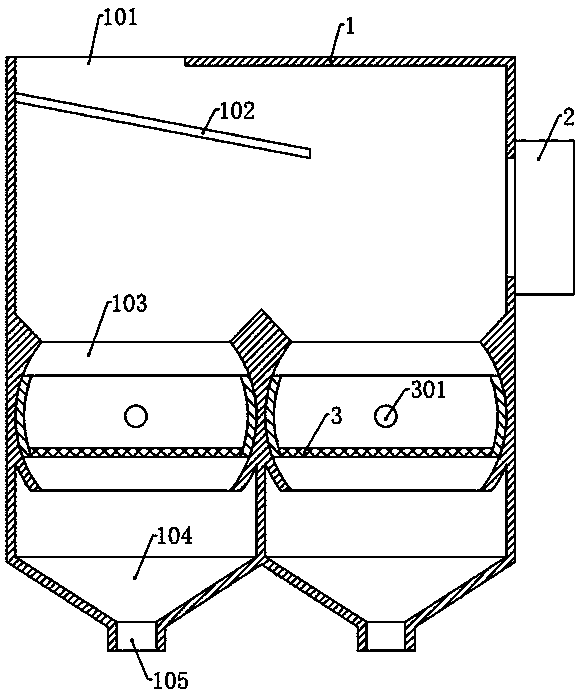

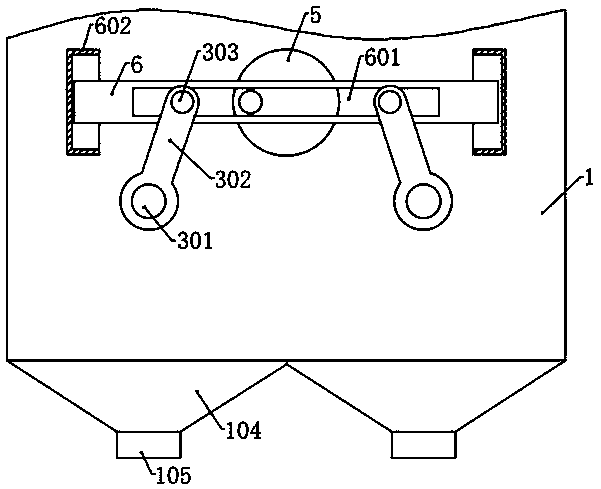

[0028] Please refer to accompanying drawing, the present invention provides a kind of technical scheme: a kind of germ grain separation device for rice processing, comprises separation case 1, and the top left side of separation case 1 is provided with feed inlet 101, and the bottom of feed inlet 101 is fixed There is an inclined material guide plate 102, and the right side wall of the separation box 1 is provided with an air inlet corresponding to the bottom end of the material guide plate 102, and a fan 2 is arranged at the air inlet, and the lower part of the inner cavity of the separation box 1 is symmetrically provided with Two screening chambers 103, the screening chamber 103 is provided with a screening mechanism, the bottom of the screening chamber 103 is provided with a collection hopper 104, and the bottom of the collection hopper 104 is fixed with a discharge pipe 105; the screening mechanism includes a screen 3, a screen 3 The left and right ends of the left and rig...

Embodiment 2

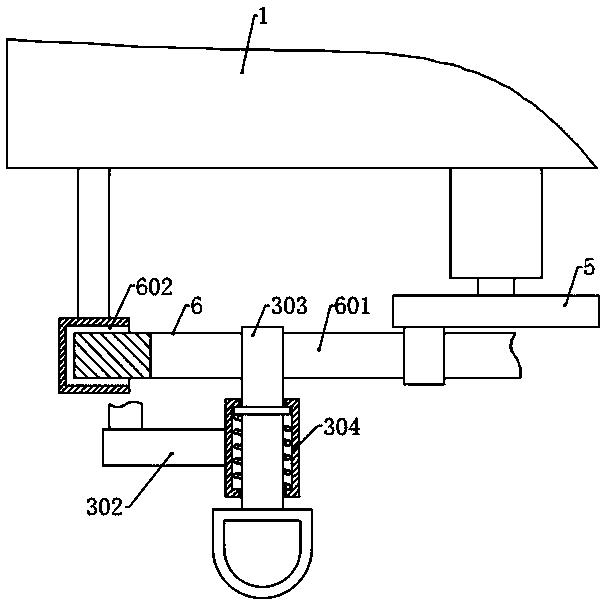

[0033] On the basis of Embodiment 1, a fixed cylinder 304 is fixed on the top of the rotating rod 302, and a spring plate is slidably connected to the fixed cylinder 304. A spring is arranged between the outer ends of the spring plate fixed cylinder 304, and the connecting shaft 303 is slidably connected to the The barrel 304 is fixed coaxially with the spring plate, the two ends protrude from the fixed barrel 304, and the inner end is correspondingly connected with the connecting groove 601, and the outer end is fixed with a handle.

[0034] After the bran husks and germ kernels in the two screening chambers 103 are sieved by the sieve 3, the particles passing the sieve 3 are discharged through the discharge pipe 105 for collection; The shaft 303 moves outwards to disengage from the connecting groove 601, and then the rotating rod 302 is rotated manually, so that the screen 3 is rotated downward, so that the material on the screen 3 can be discharged through the collecting hop...

Embodiment 3

[0036] On the basis of Embodiment 1, the right side of the material guide plate 102 is provided with an inclined adjustment plate 4, and the angle of inclination of the adjustment plate 4 and the material guide plate 102 is the same, and the direction is opposite. plate, the top of the vertical plate is fixed with a horizontal plate, and the horizontal plate is slidingly connected to the top surface of the separation box 1, and the right side of the vertical plate is rotatably connected with a screw rod 401, and the screw rod 401 is threadedly connected with the right side wall of the separation box 1, And one end stretches out the separation box 1 and is fixed with a turning handle.

[0037] When it is necessary to adjust the whereabouts of the rice on the material guide plate 102, the screw 401 is rotated through the handle, and due to the restriction between the horizontal plate and the top surface of the separation box 1, the screw 401 drives the vertical plate and the adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com