Supercritical extraction process of water extracted and alcohol deposited safflower residue

A water extraction, alcohol precipitation, and supercritical technology, which is used in pharmaceutical formulations, medical preparations containing active ingredients, and plant raw materials to achieve the effect of increasing comprehensive economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

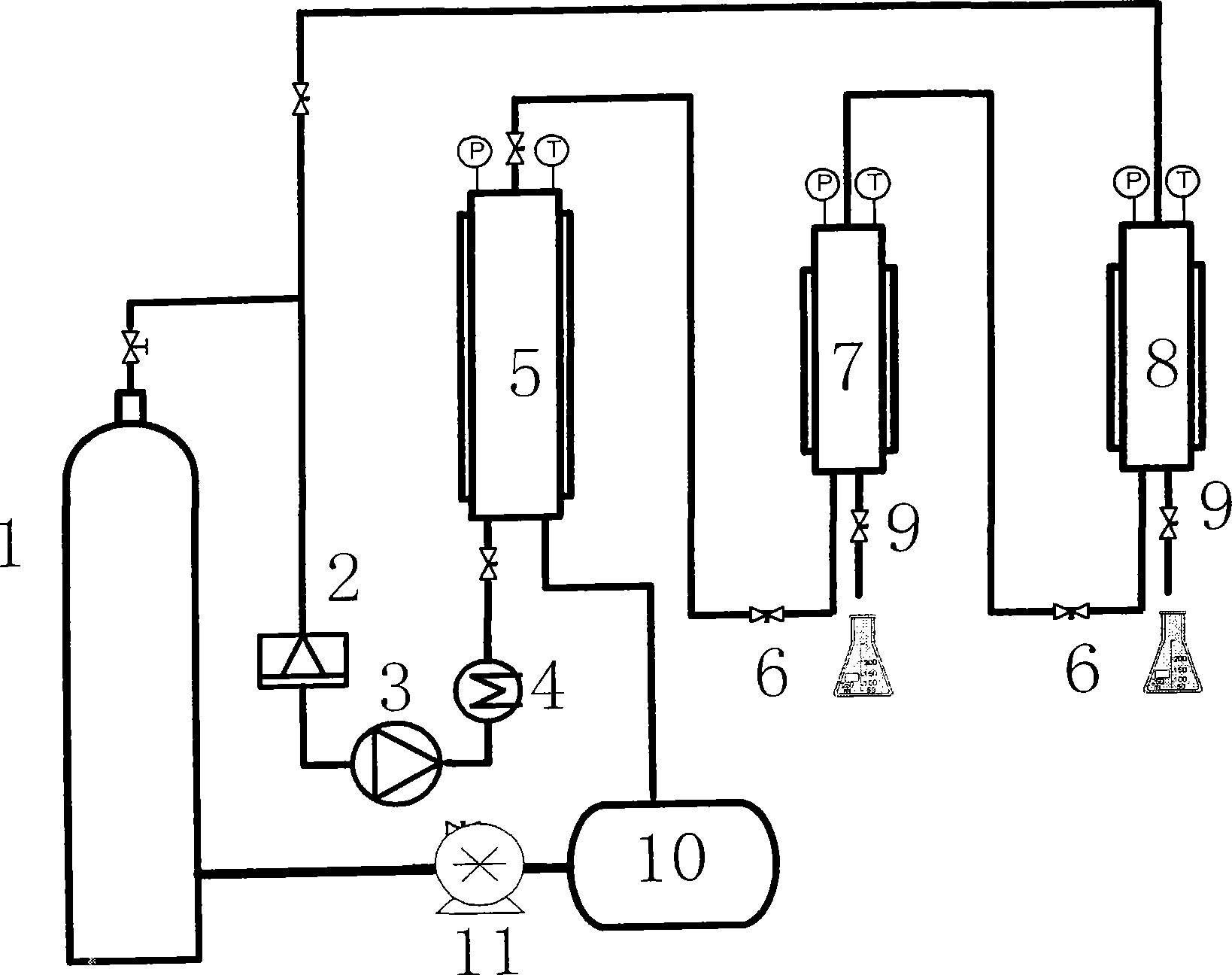

[0017] Example 1: Take 100 grams of safflower residue extracted by water and alcohol, grind to 0.15mm-1mm, dry at a low temperature below 60°C, place it in the extraction tank 5 and seal it. Open the gas tank 1, the carbon dioxide reaches the extraction tank 5 through the condensation tank 2 and the high-pressure pump 3, and conducts the first extraction at 8MPa and 60°C. The extract enters the primary separation tank 7, and performs primary separation at 8MPa and 12°C to obtain safflower wax. Carbon dioxide continues to enter the secondary separation tank 8, 6MPa, 45 ℃ secondary separation of safflower volatile oil. After separation, the clean carbon dioxide fluid is condensed by the condenser and recycled in the device. After 2 hours of dynamic operation, 1.7 grams of safflower volatile oil and 0.06 g of vegetable wax were obtained from the separation tank. Increase the pressure to 25mpa, and carry out the second extraction of the raffinate of the safflower water-extracted...

Embodiment 2

[0018] Example 2: Take 100 grams of safflower water extraction and alcohol precipitation residue, grind to 0.15mm-1mm, dry at a low temperature below 60°C, put it in the extraction tank 5 and seal it. Open the gas tank 1, the carbon dioxide reaches the extraction tank 5 through the condensation tank 2 and the high-pressure pump 3, and conducts the first extraction at 10MPa and 45°C. The extract enters the primary separation tank 7, and performs primary separation at 9MPa and 8°C to obtain safflower wax. The carbon dioxide continues to enter the secondary separation tank 8, and the safflower volatile oil is separated in the secondary separation at 1MPa and 20°C. After separation, the clean carbon dioxide fluid is condensed by the condenser and recycled in the device. After 6 hours of dynamic operation, 2.4 grams of safflower volatile oil and 0.08 g of vegetable wax were obtained from the separation tank. Increase the pressure to 28mpa, and carry out the second extraction on t...

Embodiment 3

[0019] Example 3: Take 100 grams of safflower residue extracted by water and alcohol, crush to 0.15mm-1mm, dry at a low temperature below 60°C, put it in the extraction tank 5 and seal it. Open the gas tank 1, the carbon dioxide reaches the extraction tank 5 through the condensation tank 2 and the high-pressure pump 3, and conducts the first extraction at 12MPa and 35°C. The extract enters the primary separation tank 7, and performs primary separation at 10MPa and 12°C to obtain safflower wax. Carbon dioxide continues to enter the secondary separation tank 8, 4MPa, 30 ℃ secondary separation of safflower volatile oil. After separation, the clean carbon dioxide fluid is condensed by the condenser and recycled in the device. After 6 hours of dynamic operation, 3.5 grams of safflower volatile oil and 0.08 g of vegetable wax were obtained from the separation tank. Increase the pressure to 32mpa, and carry out the second extraction on the safflower water-extracted alcohol-precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com