Method for extracting valuable metal elements from coal gangue

A technology for metal elements and coal gangue, which is applied in the field of extracting valuable substances from coal gangue minerals, can solve the problems of secondary pollution, high requirements on corrosion resistance, a large amount of residues and waste water, etc., and achieves the effect of improving activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

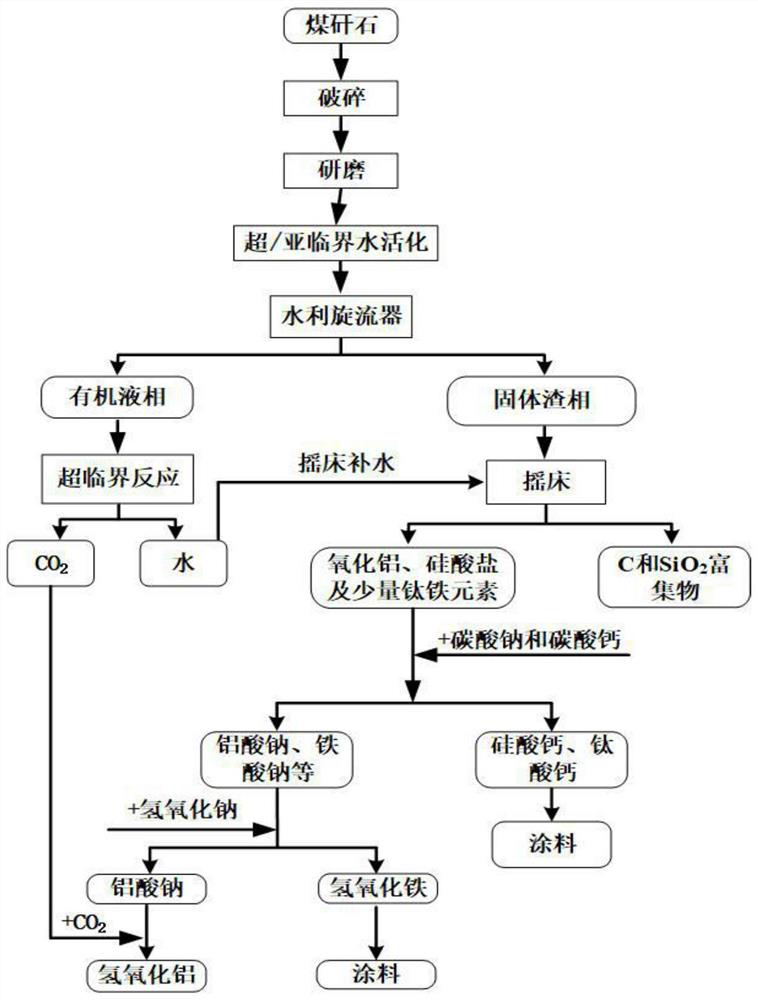

[0033] Table 1 shows the phase composition of coal gangue minerals. Such as figure 1 As shown, coal gangue minerals were crushed and ground to 74 microns, and activated at 320°C and 8 MPa subcritically for 30 minutes to obtain activated coal gangue ore. After activation, most of the minerals were dissociated, and then classified into organic Liquid phase and slag phase, the separated organic liquid phase is changed into carbon dioxide and water through supercritical reaction. The supercritical reaction temperature is 373°C and the pressure is 22.5MPa. And alumina, silicate and ore containing a small amount of ilmenite element, the enriched ore of carbon and silicon dioxide is electro-selected to obtain high-grade carbon and silicon dioxide, the grade of carbon is 90%, and the grade of silicon dioxide is 95%. Alumina, silicate and minerals containing a small amount of ilmenite are added with sodium carbonate and calcium carbonate for roasting. The roasting temperature is 850°...

Embodiment 2

[0035] Table 1 shows the phase composition of coal gangue minerals. Such as figure 1 As shown, the coal gangue ore is crushed and ground to 36 microns, and activated at 250 °C and 20 MPa subcritically for 30 minutes to obtain the activated coal gangue ore. After activation, most of the minerals are dissociated, and then classified into organic Liquid phase and slag phase, the separated organic liquid phase is changed into carbon dioxide and water through supercritical reaction. The supercritical reaction temperature is 373°C and the pressure is 22.5MPa. And alumina, silicate and ore containing a small amount of ilmenite element, the enriched ore of carbon and silicon dioxide is electro-selected to obtain high-grade carbon and silicon dioxide, the grade of carbon is 80%, and the grade of silicon dioxide is 90%. Alumina, silicate and minerals containing a small amount of ilmenite are added with sodium carbonate and calcium carbonate for roasting. The roasting temperature is 75...

Embodiment 3

[0037] Table 1 shows the phase composition of coal gangue minerals. Such as figure 1 As shown, the coal gangue ore is crushed and ground to 0.15 mm, and activated at 400 °C and 15 MPa subcritically for 30 minutes to obtain activated coal gangue ore. After activation, most of the minerals are dissociated, and then classified into organic Liquid phase and slag phase, the separated organic liquid phase is changed into carbon dioxide and water through supercritical reaction. The supercritical reaction temperature is 373°C and the pressure is 22.5MPa. And alumina, silicate and ore containing a small amount of ilmenite element, the enriched ore of carbon and silicon dioxide is electro-selected to obtain high-grade carbon and silicon dioxide, the grade of carbon is 75%, and the grade of silicon dioxide is 76%. Add sodium carbonate and calcium carbonate to alumina, silicate and minerals containing a small amount of ilmenite for roasting, the roasting temperature is 950°C, dissolve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com