Patents

Literature

34results about How to "Shorten flotation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collophanite flotation collector and method for preparing same

ActiveCN101797536AStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

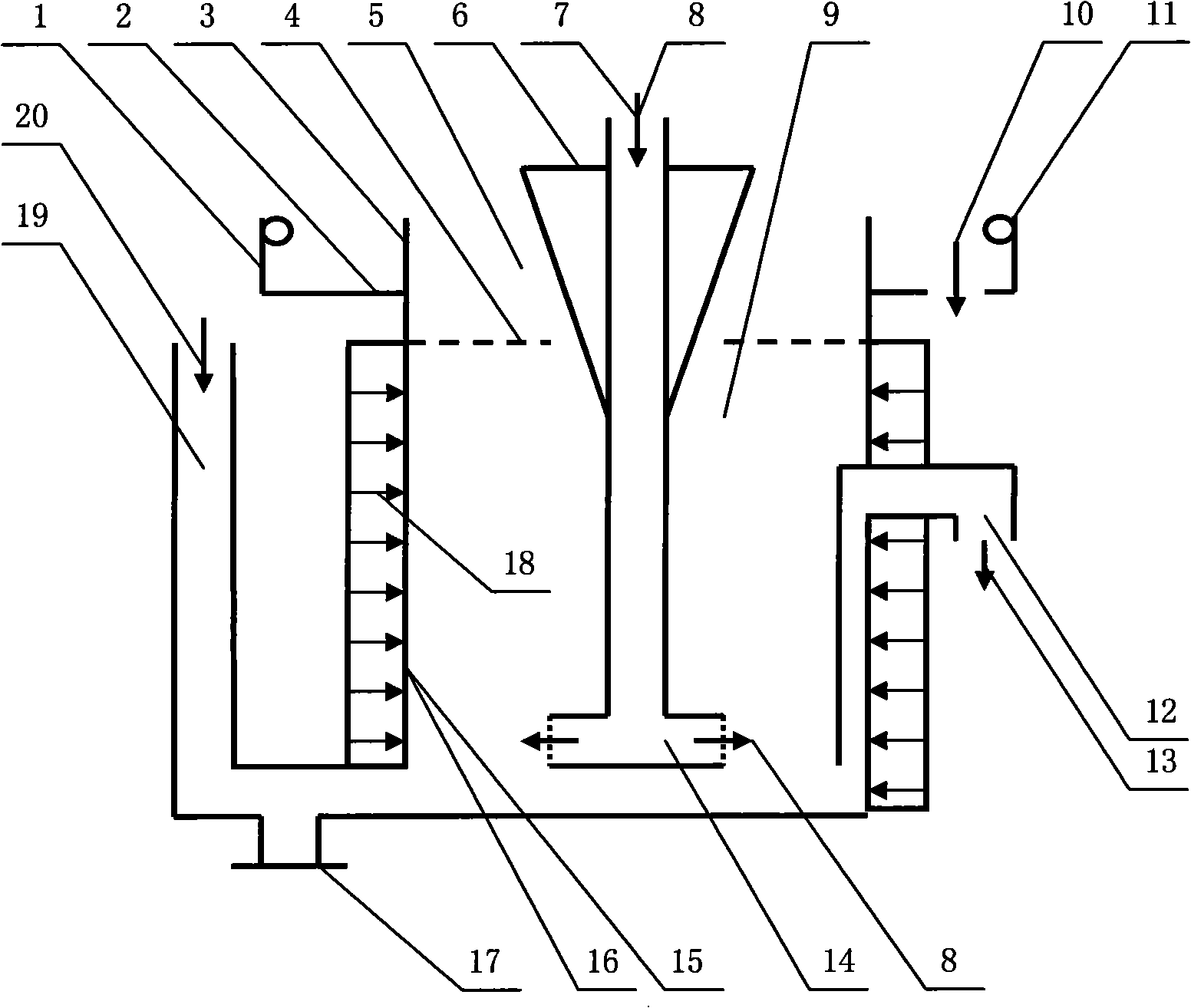

Ultrasonic flotation method and device and application thereof

The invention relates to an ultrasonic flotation method and a device and application thereof, which comprise the following steps: arranging an ultrasonic device in or outside a floatation tank body, starting the ultrasonic device when the floatation device carries out the mineral floatation, using ultrasonic waves to irradiate floatation pulp, providing a high-energy elastic mechanical wave to the pulp, initiating an ultrasonic cavitation effect, generating a large number of cavitation bubble particle flows which flow at high speed, and effectively washing the surfaces of the ore particles in the pulp to enable target ore particles to expose the fresh surfaces; at the same time, using ultrasonic energy to improve the activity of medicament in the pulp, quickening adsorption process of the medicament and the surfaces of the target ore particles to further improve the effects of breaking, restructuring and floating of mineralized bubbles in a pulp system, and thus realizing the optimization of flotation process.

Owner:佛山市兴民科技有限公司

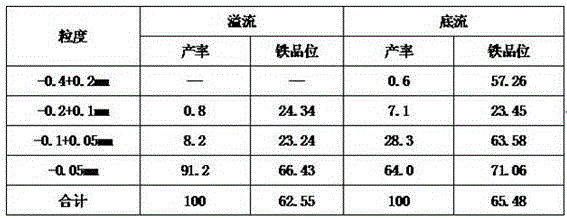

Comprehensive recovery process of intense-weathering poor vanadium titano-magnetite

InactiveCN103157551AImproved flotation indicatorsHigh yieldFlotationWet separationMagnetiteProduct base

The invention provides a comprehensive recovery process of intense-weathering poor vanadium titano-magnetite. The comprehensive recovery process of the intense-weathering poor vanadium titano-magnetite comprises the steps of prescreening, crushing, dry separation, primary grinding, primary magnetic separation, secondary grinding, secondary magnetic separation, strong magnetic separation, floating separation and syrup mixing, and titanium floating separation. The process of titanium floating separation comprises the steps of rough separation, scavenging for two times, and fine separation for four times. According to the comprehensive recovery process of the intense-weathering poor vanadium titano-magnetite, the problems that a throwing tail is high in grade and recovery rate of titanium concentrate is low when an existing process and an existing device are used for processing the intense-weathering poor vanadium titano-magnetite are solved. The index of finished products based on the comprehensive recovery process is that the grade of iron ore concentrate is 64% and yield of the iron ore concentrate is 37%, the grade of the titanium concentrate is 42% and the yield of the titanium concentrate is 41%, and the grade of fine-grain gangue iron is lower than 7% and the grade of titanium is lower than 1%.

Owner:SHANDONG QIANSHUN MINING & METALLURGY SCI

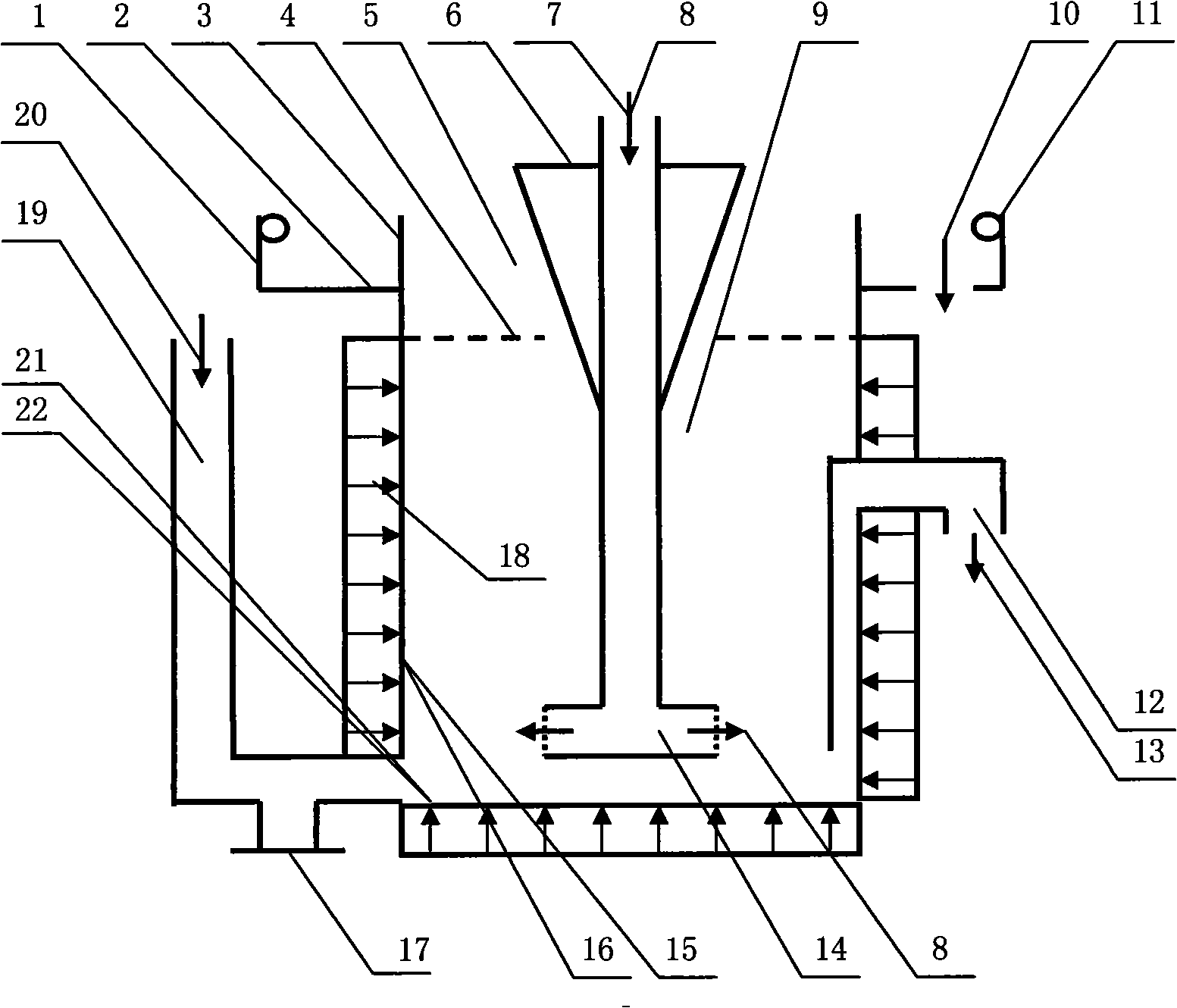

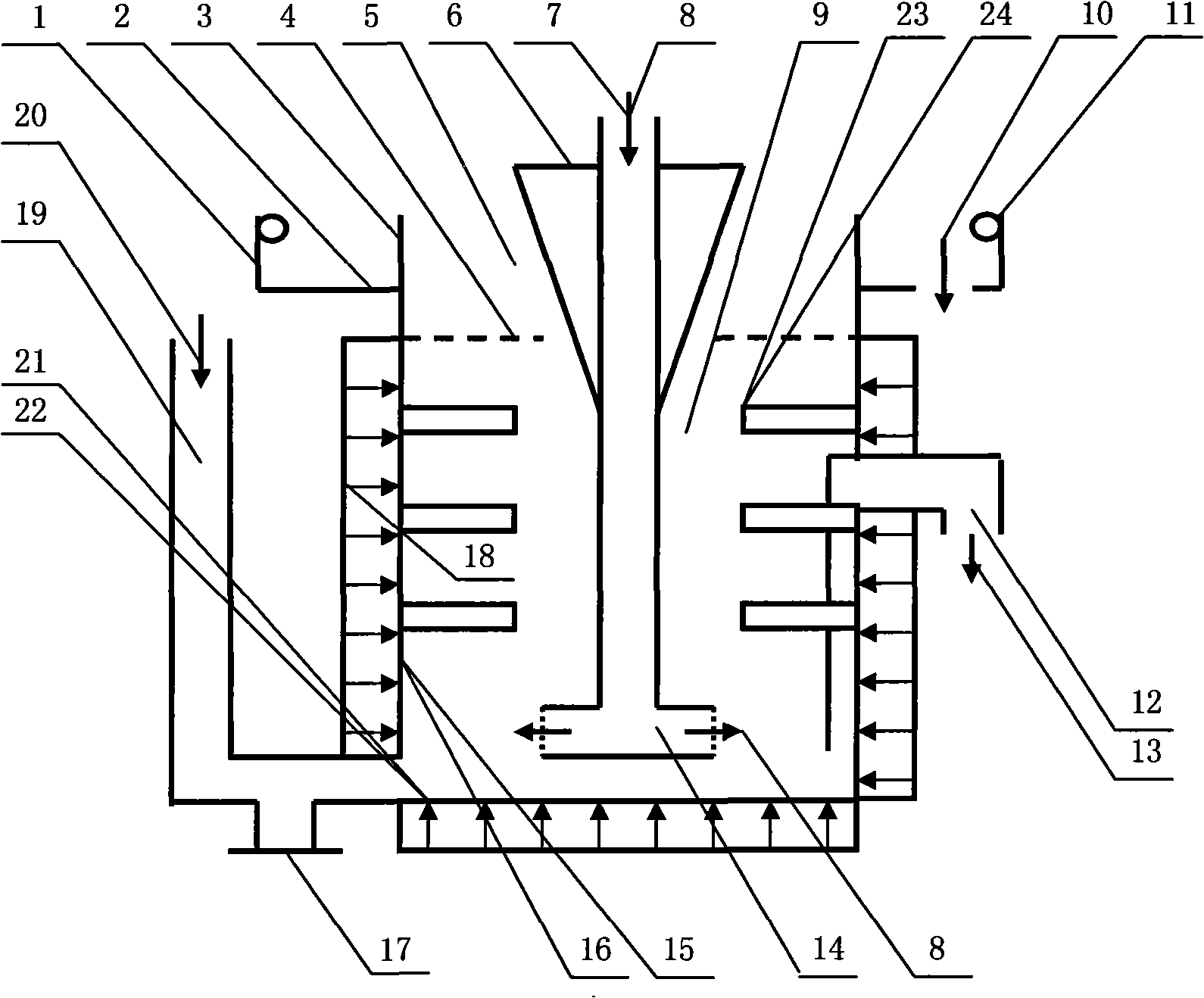

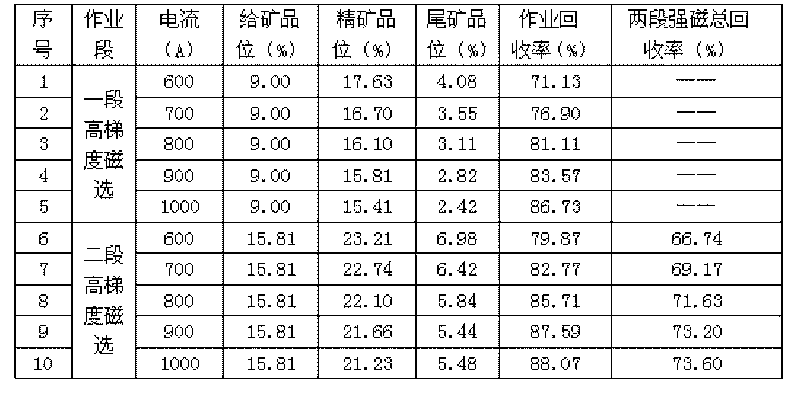

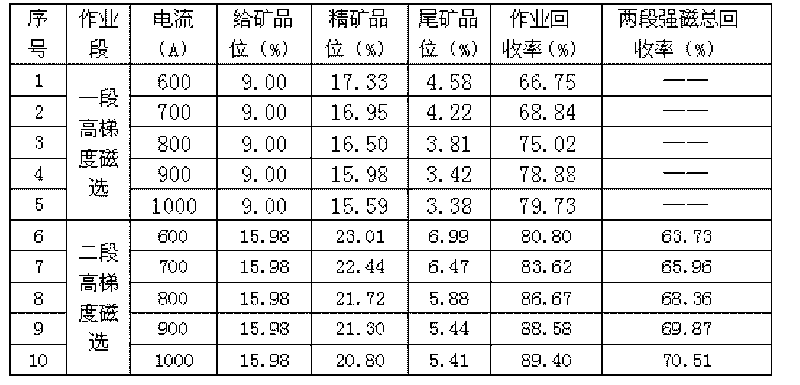

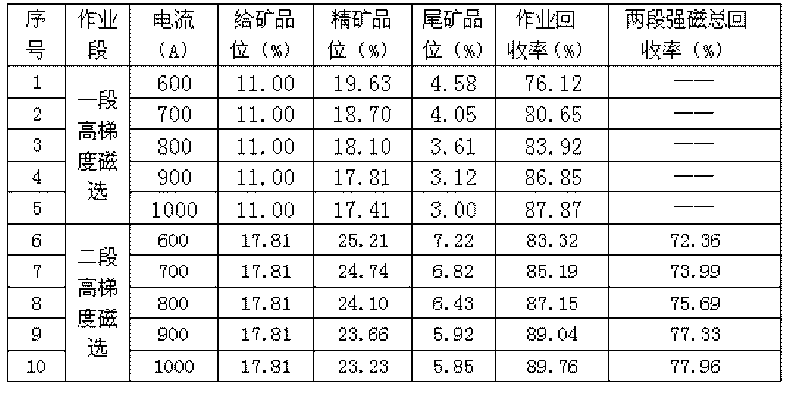

Process for recycling ilmenite through two stages of magnetic separation

ActiveCN101722103AImprove qualityHigh recovery rateHigh gradient magnetic separatorsIlmeniteTitanium

The invention relates to the field of ilmenite separation, in particular to a process for recycling ilmenite from a raw ore through magnetic separation. The technical problem to be solved is to provide an ilmenite recycling process with high recovery rate. The technical scheme for solving the technical problem is to provide the process for recycling the ilmenite through two stages of high-gradient magnetic separation. The process comprises the following steps: performing primary high-gradient magnetic separation on the raw ores after a preparation operation to obtain a primary high-gradient magnetic concentrate; and performing secondary high-gradient magnetic separation on the primary high-gradient magnetic concentrate after the preparation operation to obtain a secondary high-gradient magnetic concentrate. The process can be applied in the field of the ilmenite separation, improves the recovery rate of titanium and reduces production cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

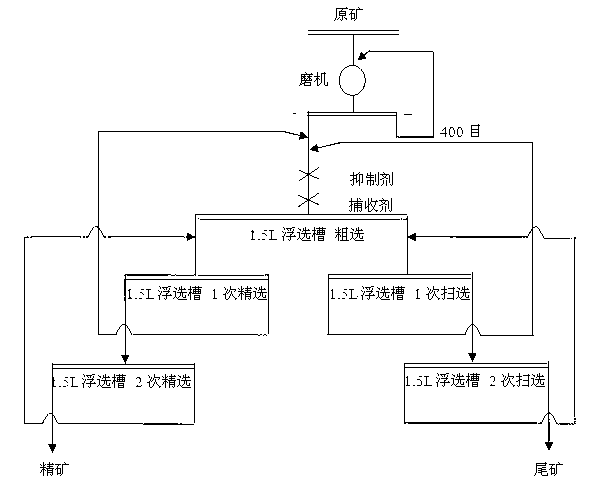

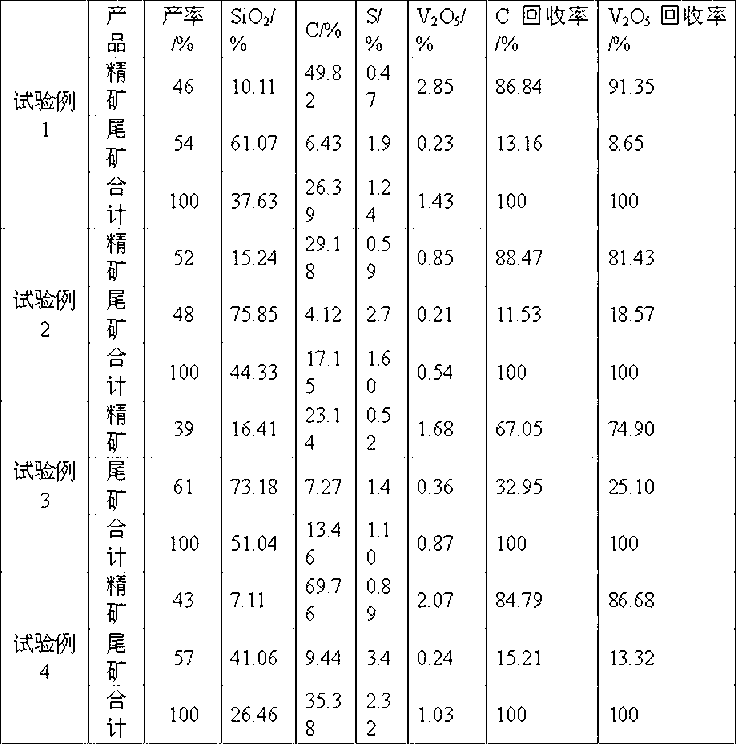

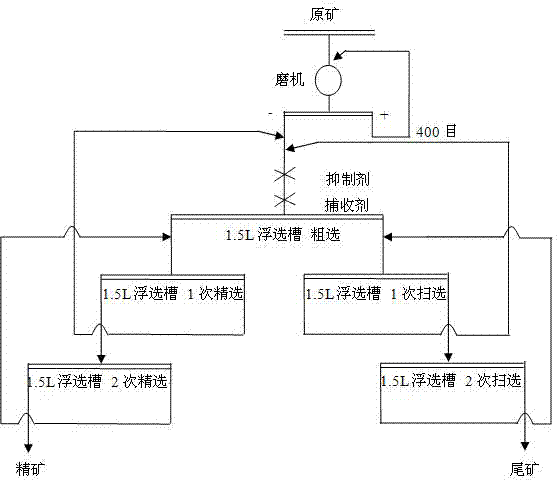

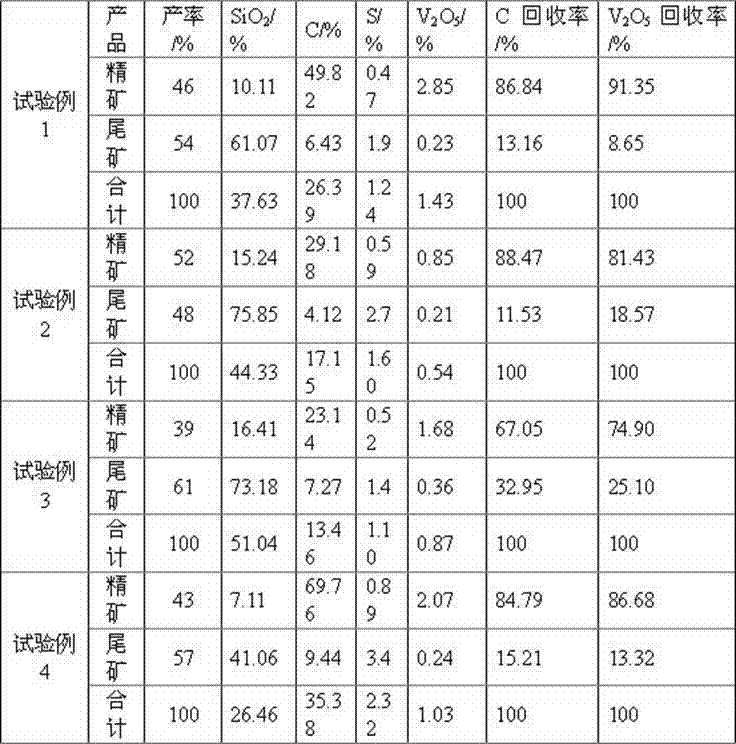

Composite beneficiation reagent for extracting vanadium from stone coal

The invention relates to a composite beneficiation reagent for extracting vanadium from stone coal. The composite beneficiation reagent for extracting the vanadium from the stone coal is characterized in that the composite beneficiation reagent is composed of a component A, a component B, a component C, a component D and water, the component A is kerosene and / or diesel oil, the component B is quaternary ammonium salt class matter and / or aliphatic amine hydrochloride class matter, the component C is any one or more of alcohol ranging from C4 to C8, 4-methyl-cyclohexyl-methanol, MIBC, terpenic oil, methyl triisopropoxy silane, and the component D is any one or more of alkyl-sulfonate ranging from C8 to C12, OP-10 and Tween-60. The composite beneficiation reagent for extracting the vanadium from the stone coal is prepared by a plurality of components according to a certain proportion and a rule, combination of the components of the reagent can be adjusted according to different mineral properties so that a series of flotation reagents can be prepared, and thebest use effect is achieved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

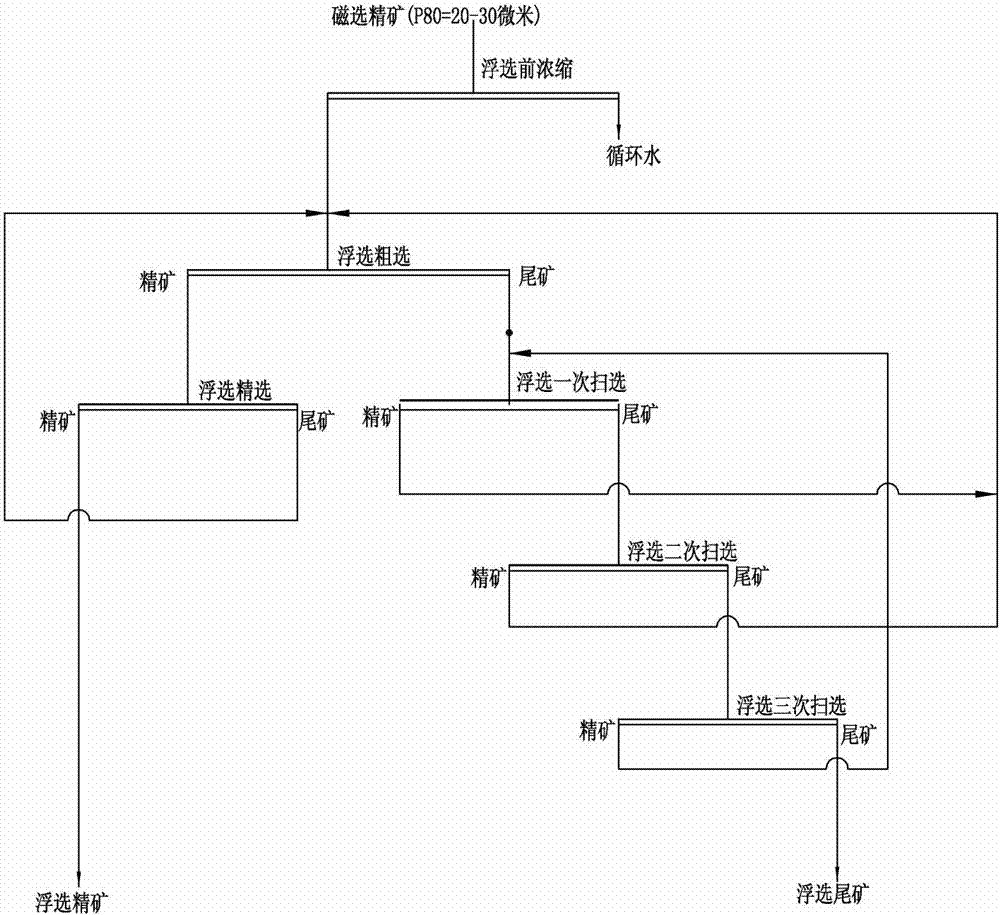

Micro-fine particle hematite greater circulation mine returning negative ion reverse flotation technology

The invention relates to a micro-fine fine particle hematite greater circulation mine returning negative ion reverse flotation technology. The technology is characterized in that magnetic concentrate with the Fe-grade being 40-41% and the granularity being P80=20-30 micrometers is fed into a thickener to be subjected to concentration after magnetic separation, then is fed to a negative ion reverse flotation operating system in an underflow mode and then is fed into circulating water in an overflow mode. Firstly, the magnetic concentrate is fed into flotation rough concentration operation, underflow concentrate of the flotation rough concentration operation is fed into flotation fine concentration operation, foam tailings of the flotation rough concentration operation is fed into scavenging operation, and the scavenging operation is divided into three times of scavenging operation; foam tailings of the first time scavenging is fed into the second time scavenging, foam tailings of the second time scavenging is fed into the third time scavenging, underflows of the first time scavenging and the second time scavenging both return to the flotation rough concentration operation, and the underflow concentrate of the third time scavenging operation returns to the first time scavenging. The foam tailings scavenged by the third time scavenging operation are the final flotation tailings, the underflow concentrate of the flotation fine concentration operation is the final concentrate, the grade of the final concentrate is 65.9%, and the iron recovery rate is 88.5%.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

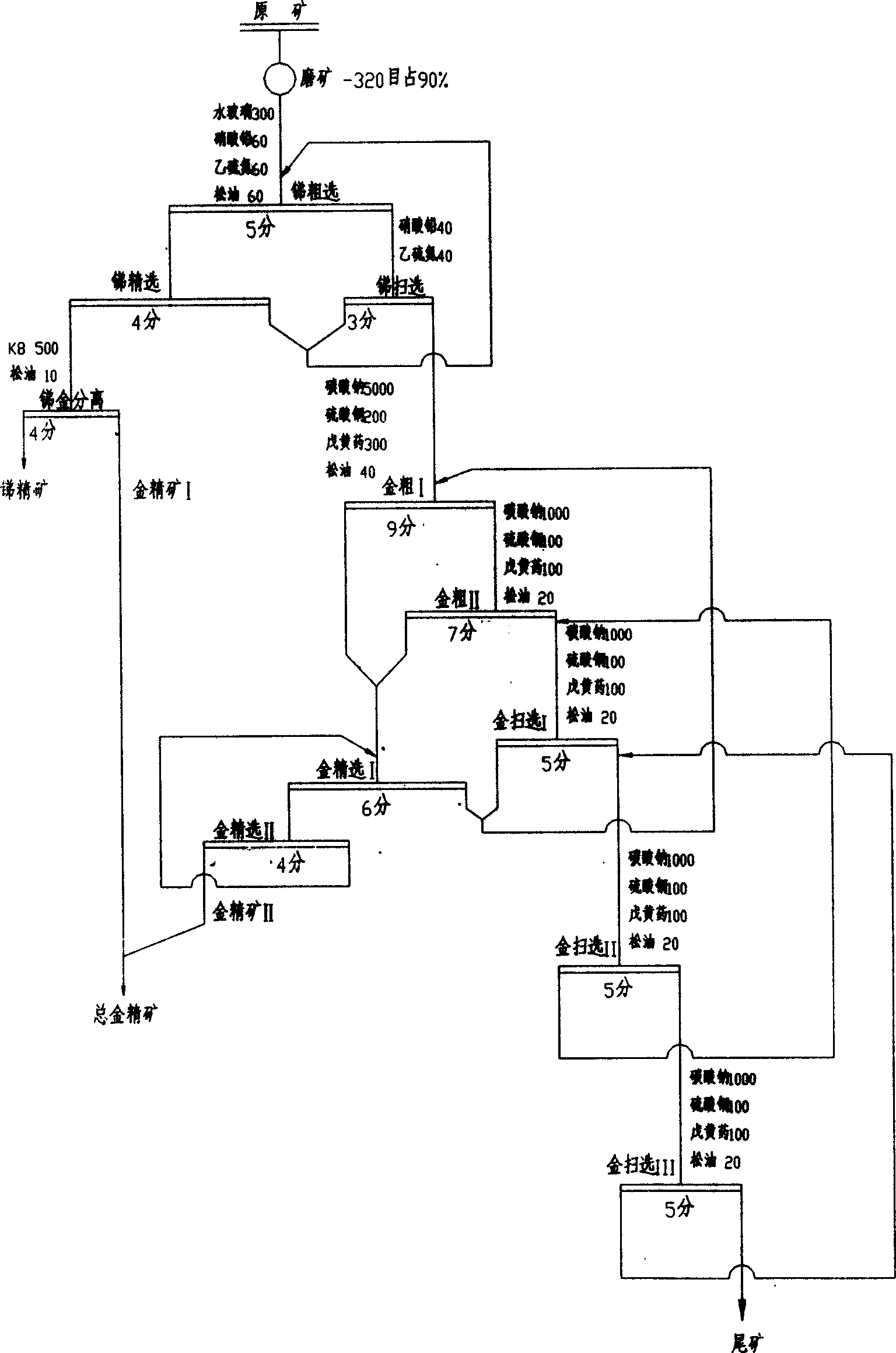

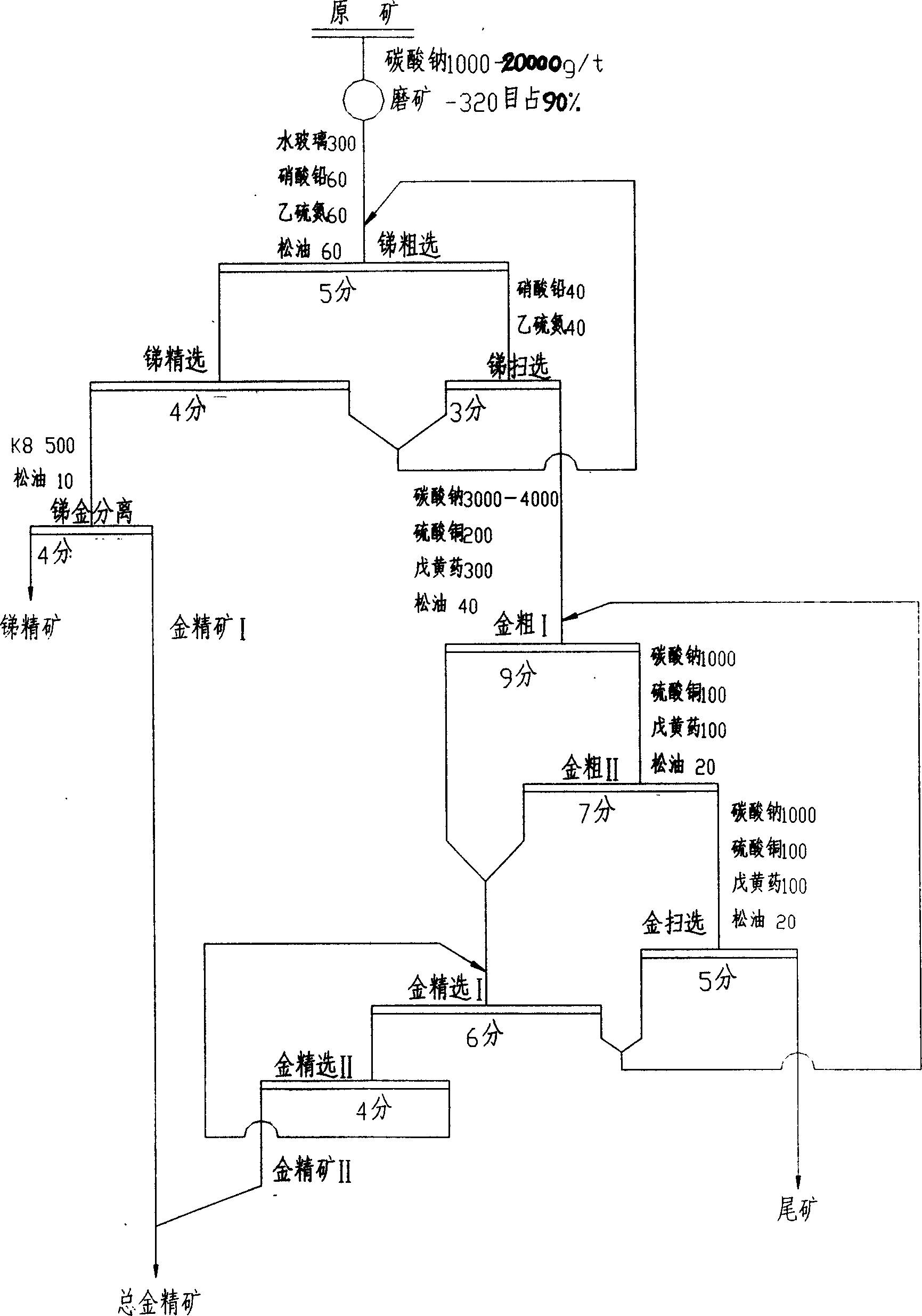

New technology for flashing speed activation flotation of Carin type gold mine

InactiveCN1544155AFloating speed is fastPromote differentiationFlotationGrain treatmentsPyriteEconomic benefits

The invention is a new technique of flash activation select flotation of Carlin-type gold ore, during the grinding course of Carlin-type gold ore at a 320-eye grinding fineness accounting for 85-90%, preadding sodium carbonate at 1000-2000g / t. as regulating agent, to make golden arsenical pyrite and pyrite able to firstly absorb activating agent sodium carbonate at the first time of dissociating a fresh surface, accelerating floatation of the gold ore and promoting differentiation of medium ore to make total recovery of gold selection reach 81% and the recovery show a net increase of 7-11 percents; at the same time, omitting complex technique of eliminating mud, reducing the loss caused by fine mud containing gold, reducing number of times of finely selection and scan-selection, simplifying technical flow and largely heightening economic benefits.

Owner:KUNMING METALLURGY INST

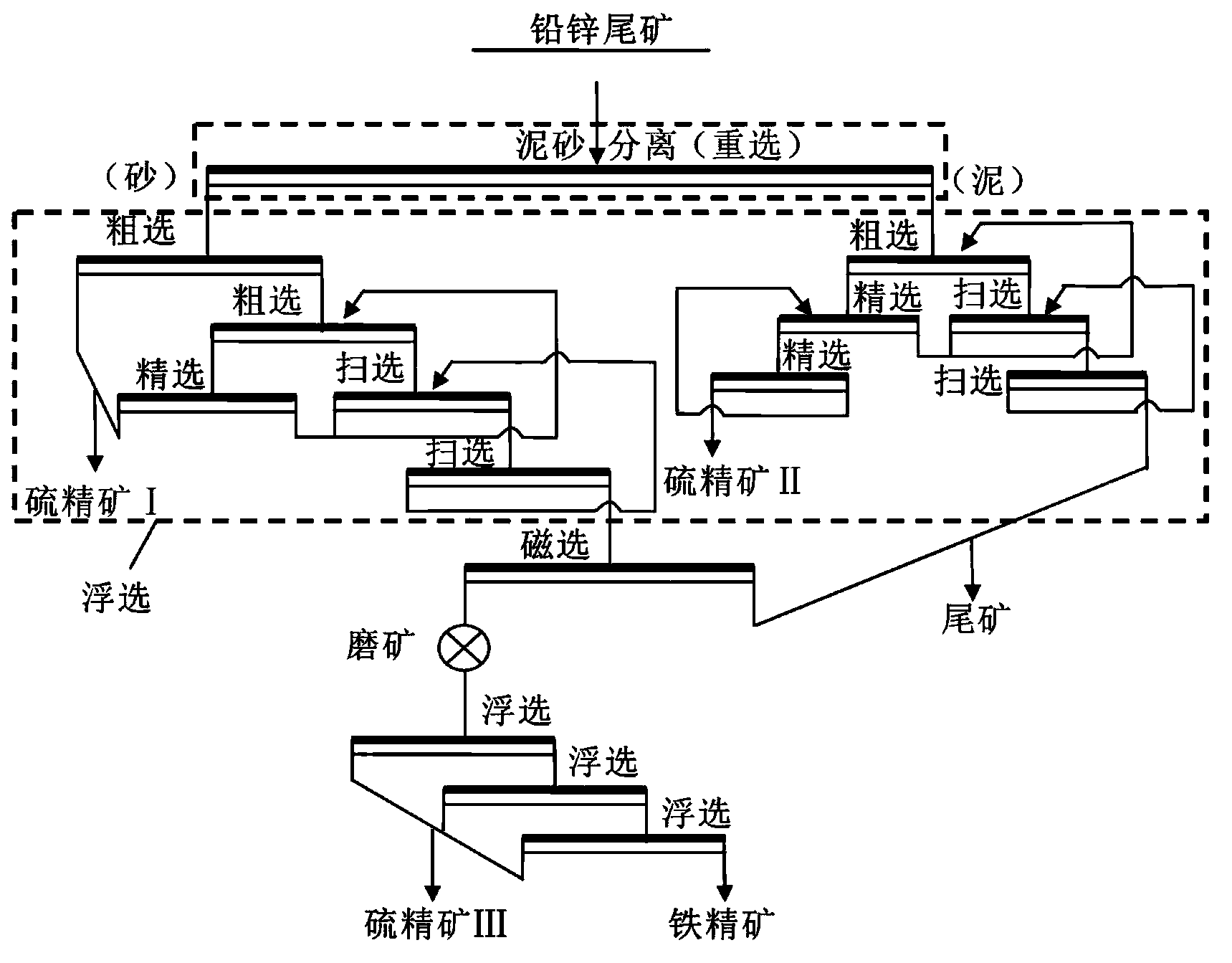

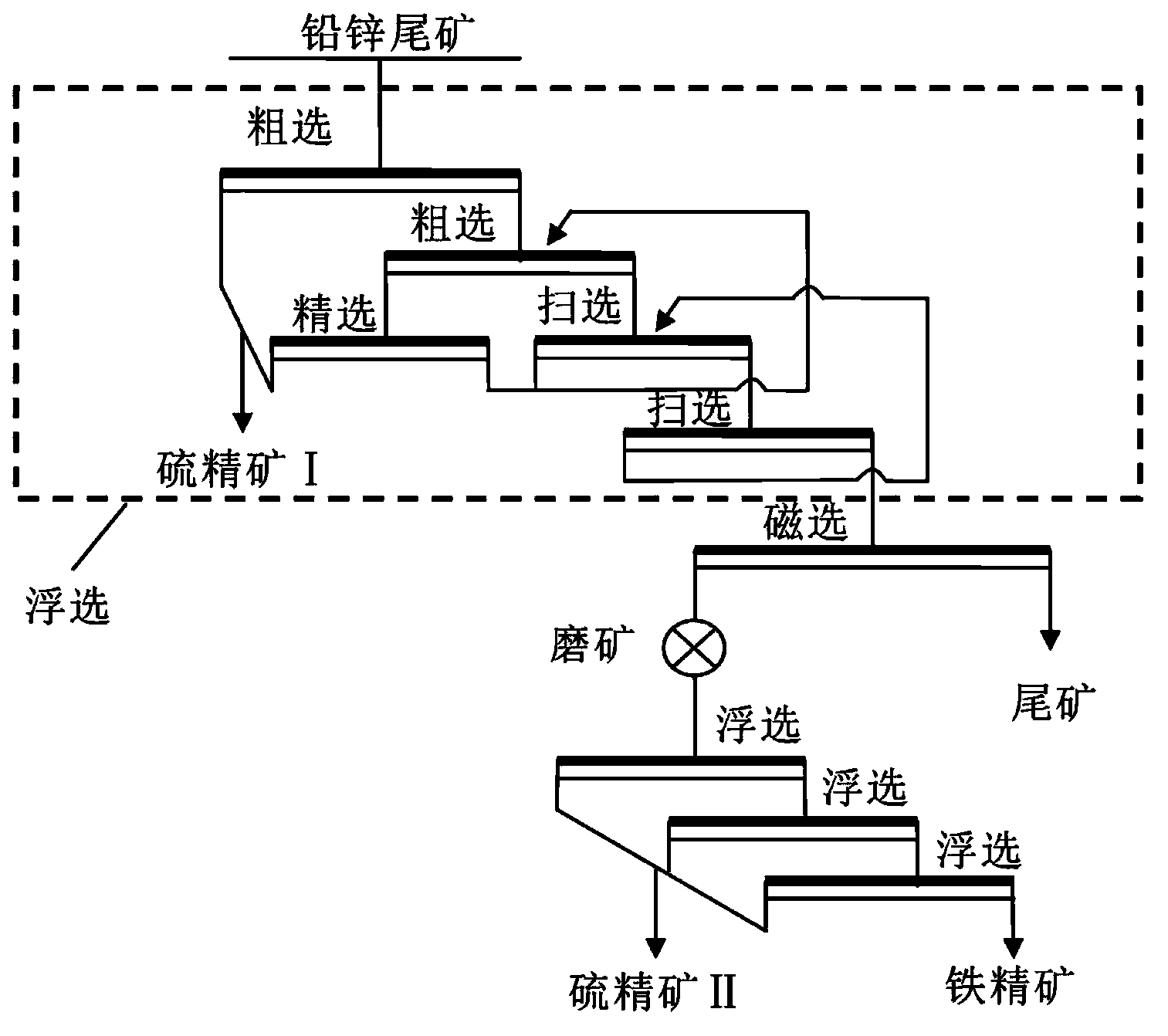

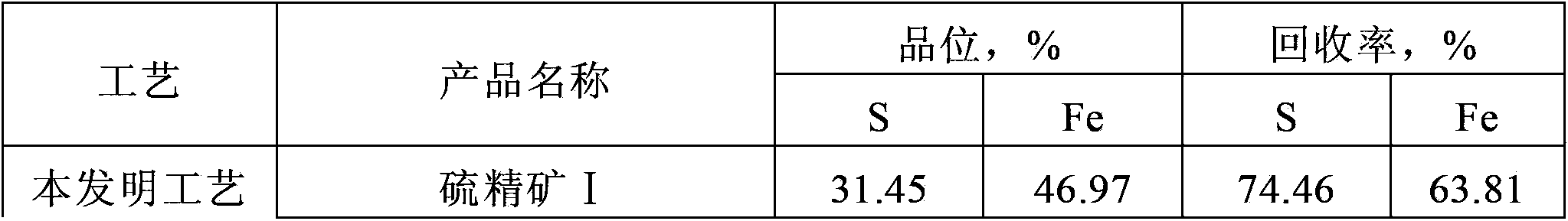

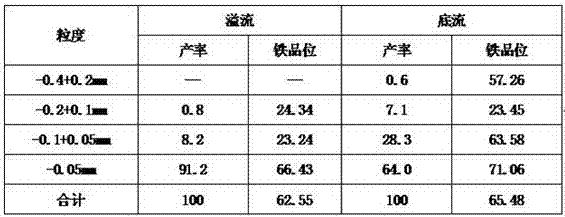

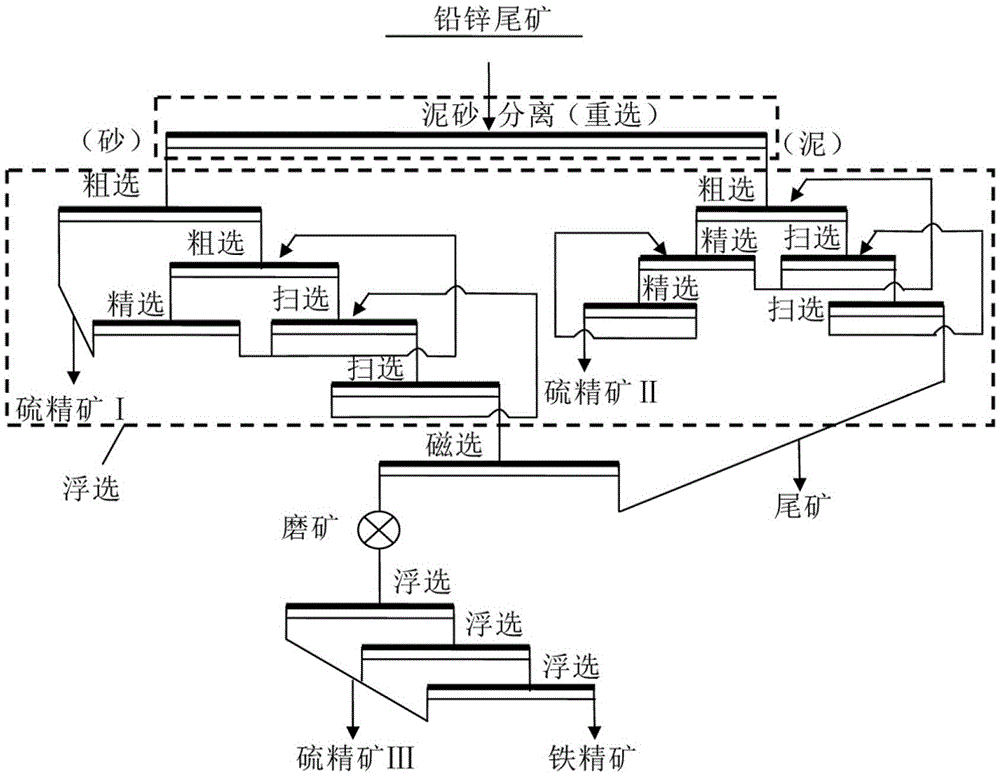

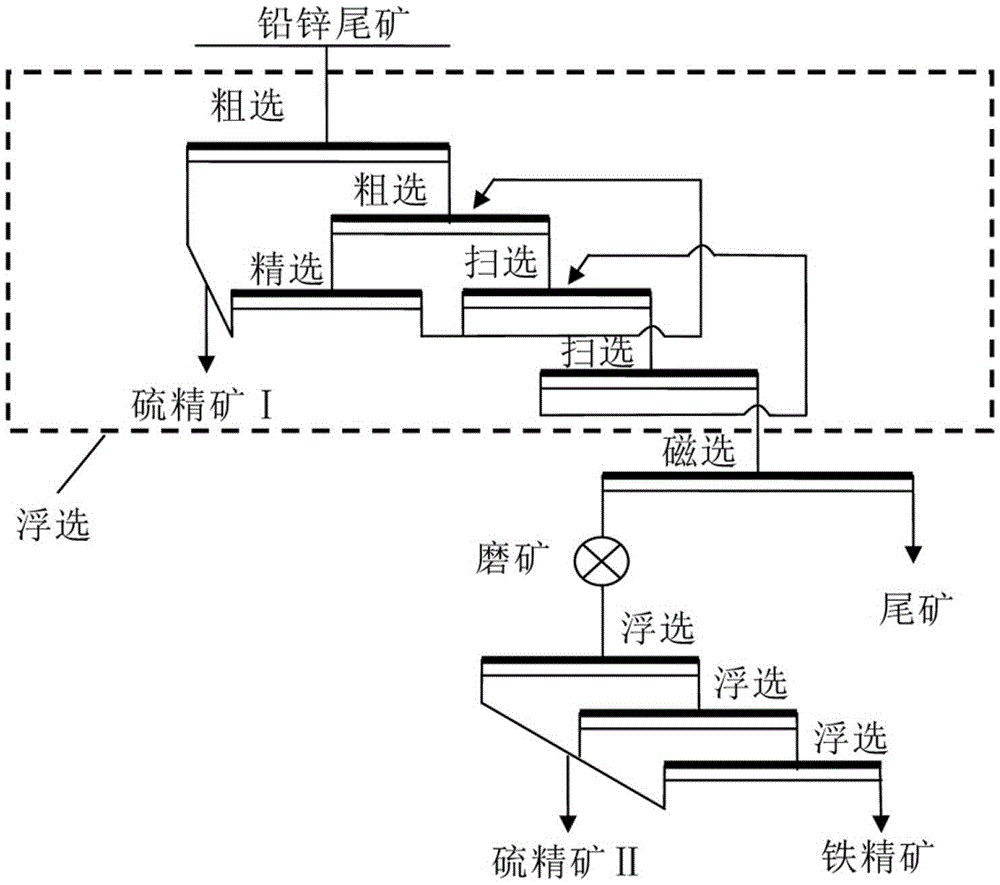

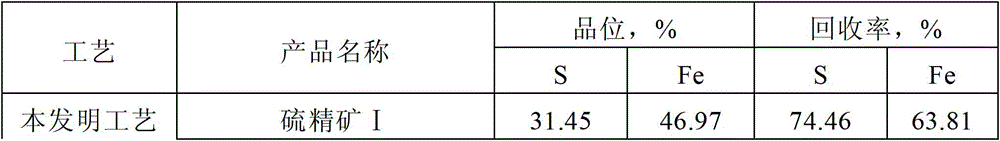

Mineral separation combination process for recycling pyrite from lead-zinc tailings

The invention relates to a mineral separation combination process for recycling pyrite from lead-zinc tailings. The mineral separation combination process comprises step 1, performing mud and sand separation on the lead-zinc tailings through a spiral chute; step 2, performing sulfur flotation on mud and sand which are separated out through the spiral chute; step 3, performing magnetic separation iron extraction on the sand which is separated out through the spiral chute through the tailings after the sulfur flotation, performing flotation desulfurization on rough concentrate obtained through magnetic separation and achieving the recycling of the pyrite in the lead-zinc tailings. The sulfur grade in obtained mixed sulfur concentrate is larger than 31%; the iron grade in iron concentrate is larger than 64% and the sulfur content is smaller than 0.5%; the sulfur recovery rate in the lead-zinc tailings is as high as 95% and the iron recovery rate in the lead-zinc tailings is as high as 88%. According to the mineral separation combination process for recycling the pyrite from the lead-zinc tailings, the operation is stable, the mineral separation index is high, the comprehensive utilization of resources can be achieved, the pollution to the environment can be reduced, and the good economic benefit can be brought to enterprises.

Owner:有研资源环境技术研究院(北京)有限公司

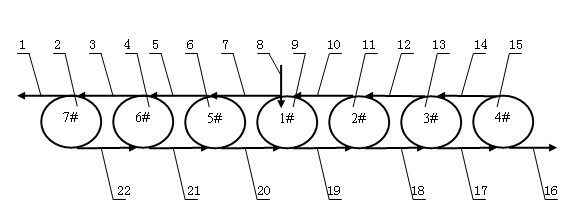

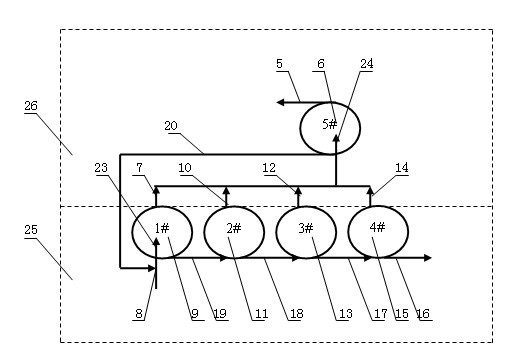

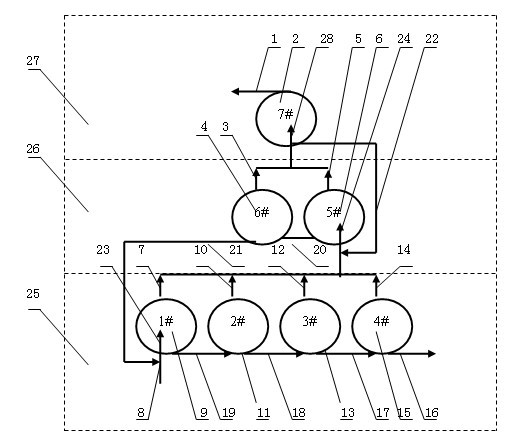

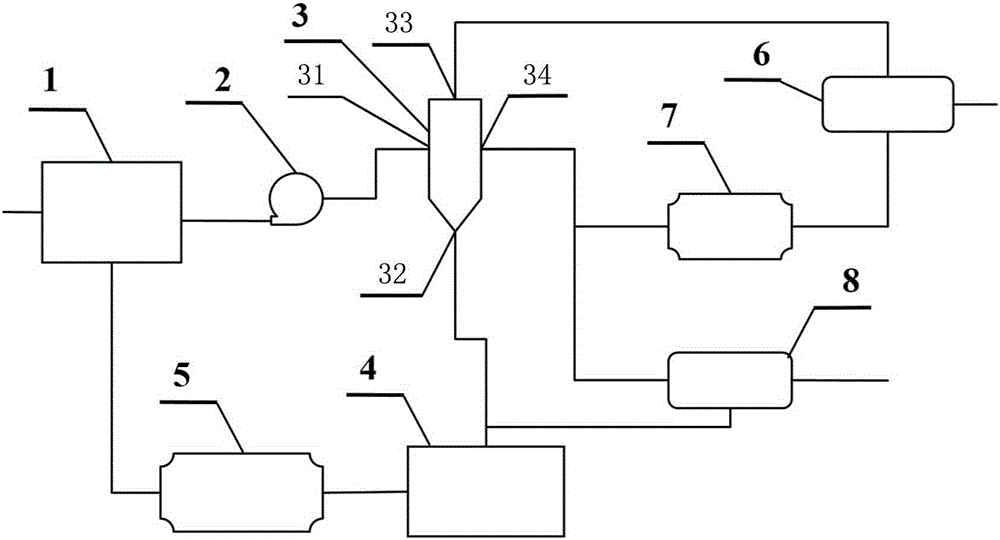

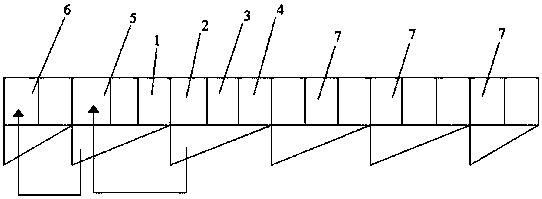

Flotation method and flotation system of whole-course open circuit floatation for concentrate slurry

InactiveCN101920225ATarget particle content reductionFlotation recovery is easy to control stablyFlotationProcess engineeringChemistry

The invention relates to a flotation method and a flotation system of whole-course open circuit floatation for concentrate slurry. The whole-course open circuit floatation means that the concentrate slurry produced in any flotation tank no longer flows into a flotation system where the flotation tank in which the concentrate slurry is produced is arranged, the concentrate slurry flows into a postpositional flotation system in an irreversible flow manner (i.e. a complete single-way forward flow manner), and a choiceness process is finished in at least one postpositional flotation system. The flotation tank at least comprises a flotation tank provided with spiral rotors and / or an ultrasonic device. The concentrate slurry is slurry flowing out above the liquid level in the flotation tank in a mineralized bubble form. In the flotation process of the flotation method, the tail slurry produced in any flotation tank flows out of the flotation tank in which the tail slurry is produced in the irreversible flow manner and flows into the postpositional flotation system of the flotation system for sequentially scavenging until the tail slurry of the system is produced. The invention can overcome the defect of futile cycle flotation for target particles, the flotation time is greatly shortened, and medicine and energy consumption are significantly reduced.

Owner:XINGMIN TECH ZHUZHOU

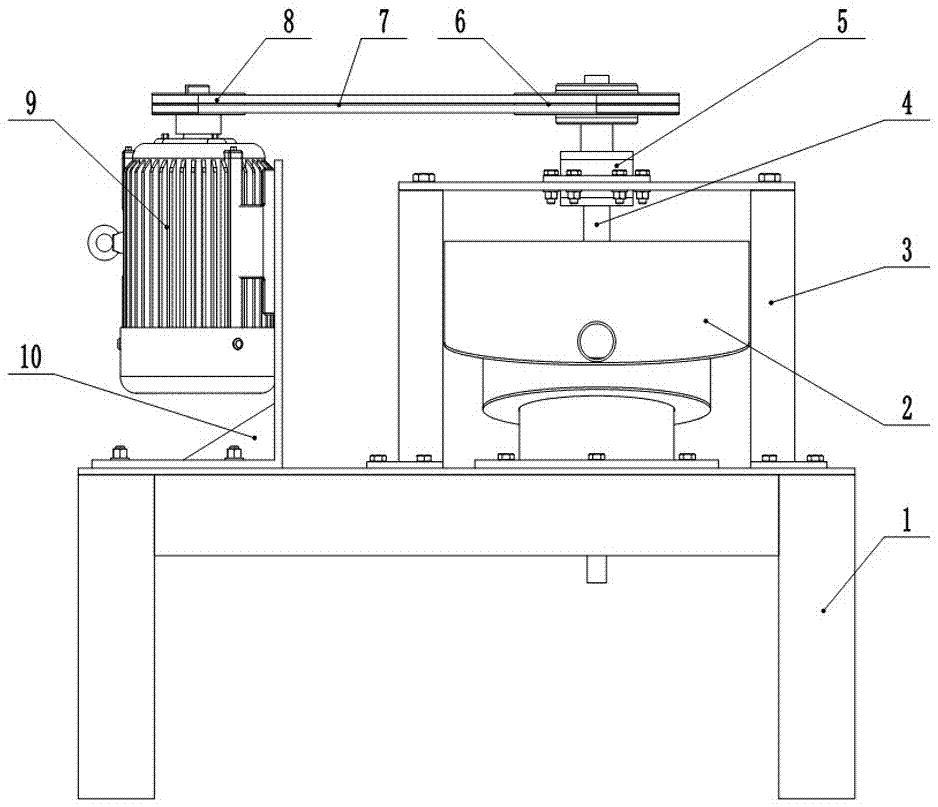

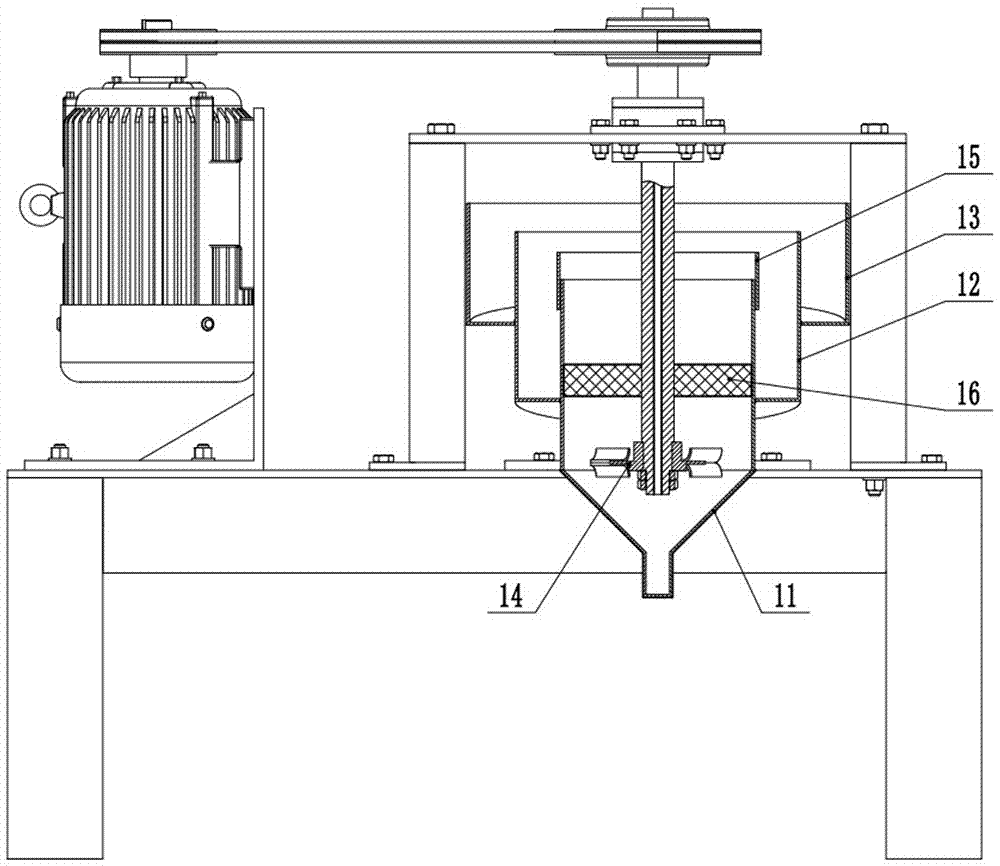

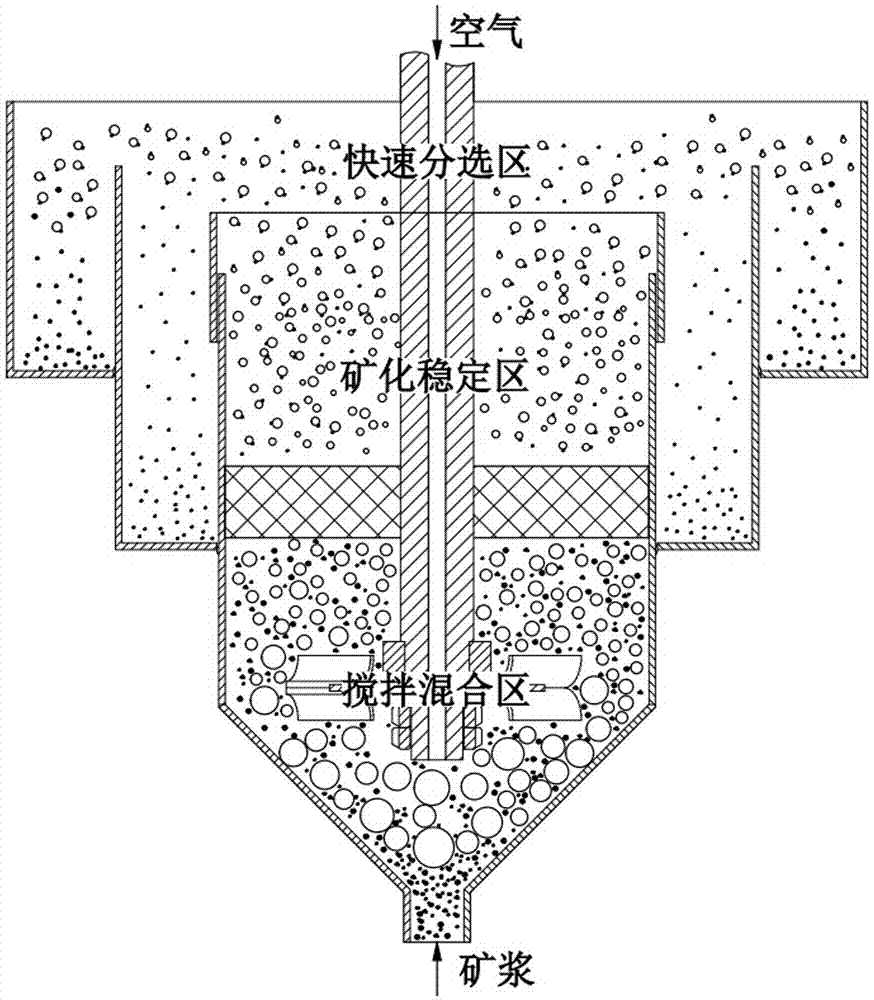

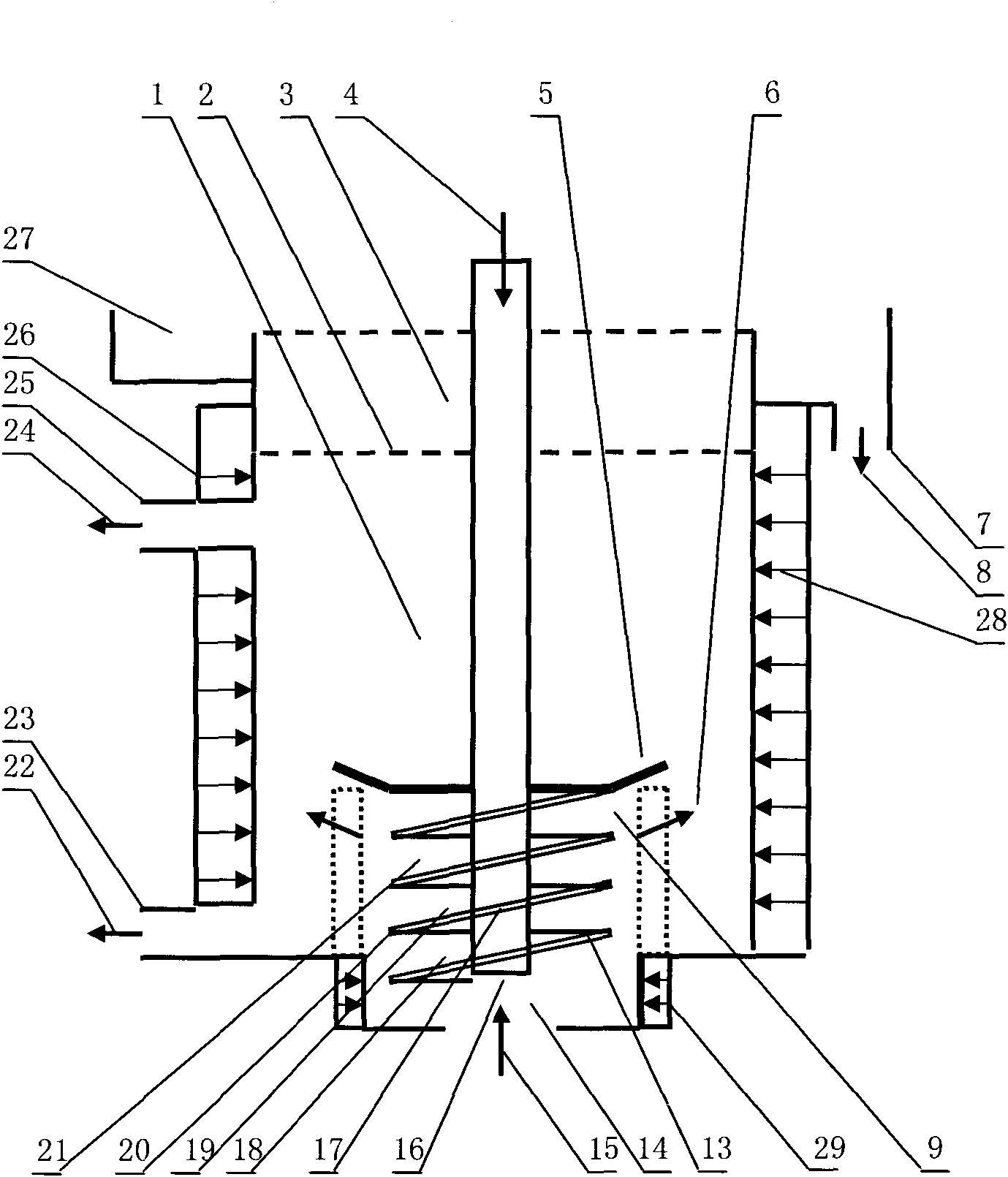

Coarse grain flotation machine

The invention discloses a coarse grain flotation machine which comprises a rack. A sorting barrel, a bearing pedestal support and a motor seat are arranged on the rack. A large belt wheel is arranged at the top end of a stirring shaft. The bottom end of the stirring shaft stretches into the sorting barrel and is provided with a stirrer. The sorting barrel is composed of an inner barrel, a middle barrel and an outer barrel. The middle barrel is fixed to the outer wall of the inner barrel. The outer barrel is fixed to the outer wall of the middle barrel. The upper edge of the outer barrel is higher than the upper edge of the middle barrel. The upper edge of the middle barrel is higher than the upper edge of the inner barrel. An ore feed opening is formed in the bottom of the inner barrel. A filling medium is arranged on the upper middle portion of the inner barrel. A tailing outlet is formed in the bottom of the middle barrel. A concentrate outlet is formed in the bottom of the outer barrel. The coarse grain flotation machine is suitable for separation and purification of minerals which are coarse in flotation target mineral grain size and meanwhile are influenced by fine silt in the flotation process; and the coarse grain flotation machine is mainly applied to aluminosilicate non-metal ore sorting and flotation and separation of oxidized ore and other minerals, such as flotation of multiple minerals of andalusite, kyanite, phosphorite, rare earth ore, oxidized ore, other aluminosilicate and the like.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Dispersion and control-selective desliming method in bauxite

A controlled dispersing-selective desliming method in the reverse floatation of bauxite features that according to the difference of various components in said bauxite in crushibility and surface characteristics, the sodium carbonate as disperser is added during the grinding step. Its advantages are high grinding efficiency, low consumption of floatating agent, and high Al-Si ratio in ore sludge.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

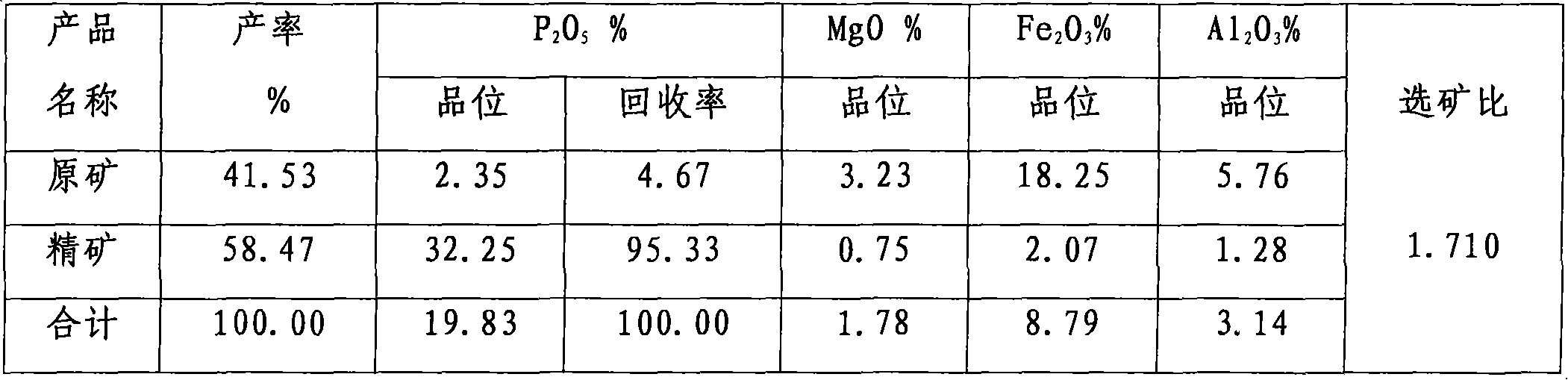

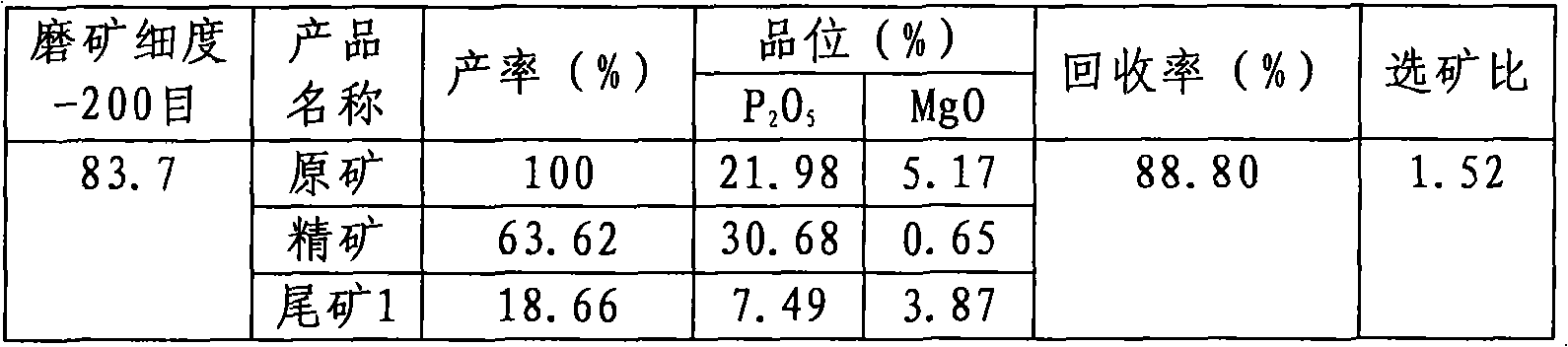

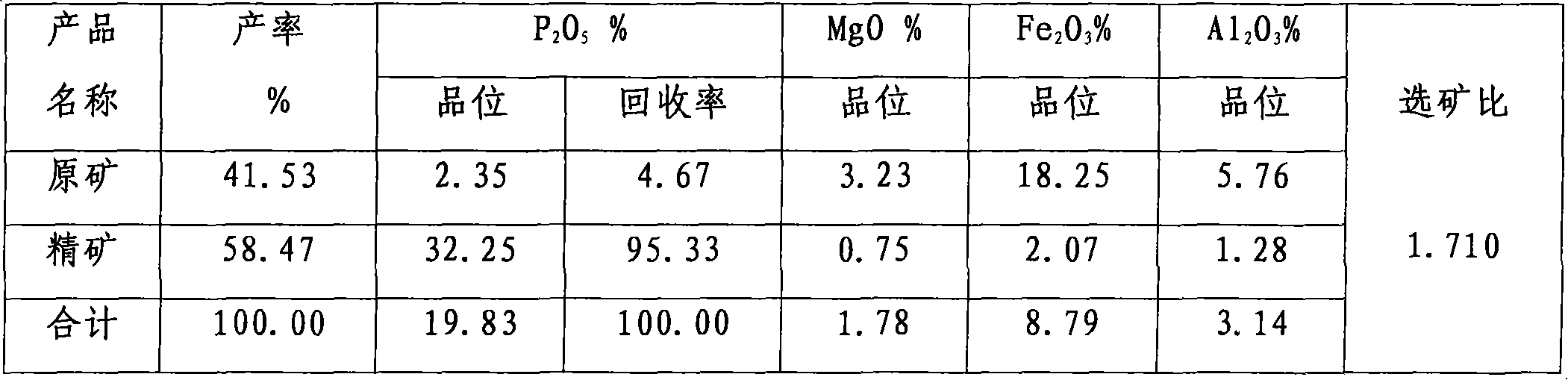

Collecting agent capable of efficiently removing carbonate minerals in collophane

ActiveCN103721855AShorten flotation timeIncreased flotation speed and collector dispersibilityFlotationEthyl esterEnvironmental chemistry

The invention relates to a collecting agent capable of efficiently removing carbonate minerals in collophane. The technology of the collecting agent includes the steps that (1) a saponification reaction is carried out on fatty acid with the content of oleic acid with an 18 carbon chain and linoleic acid with an 18 carbon chain larger than 65%, (2) diethyl 1,2-phenylenediacetic acid with the mass percent ranging from 5% to 25% is added into the saponification product at the temperature ranging from 40 DEG C to 50 DEG C to carry out emulsification, and obtaining the collecting agent capable of efficiently removing the carbonate minerals in the cellophane, and (3) the collecting agent is used for collecting the carbonate minerals in the cellophane in a reverse-flotation mode. Under the condition that the same number of collecting agents are added, and the MgO contents in obtained concentrates are similar, compared with 7-minute-flotation-time fatty acid saponification flotation without adding the diethyl 1,2-phenylenediacetic acid, the floatation time is shortened by more than 36%, and the carbonate-mineral flotation speed is quickened by more than 20%.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

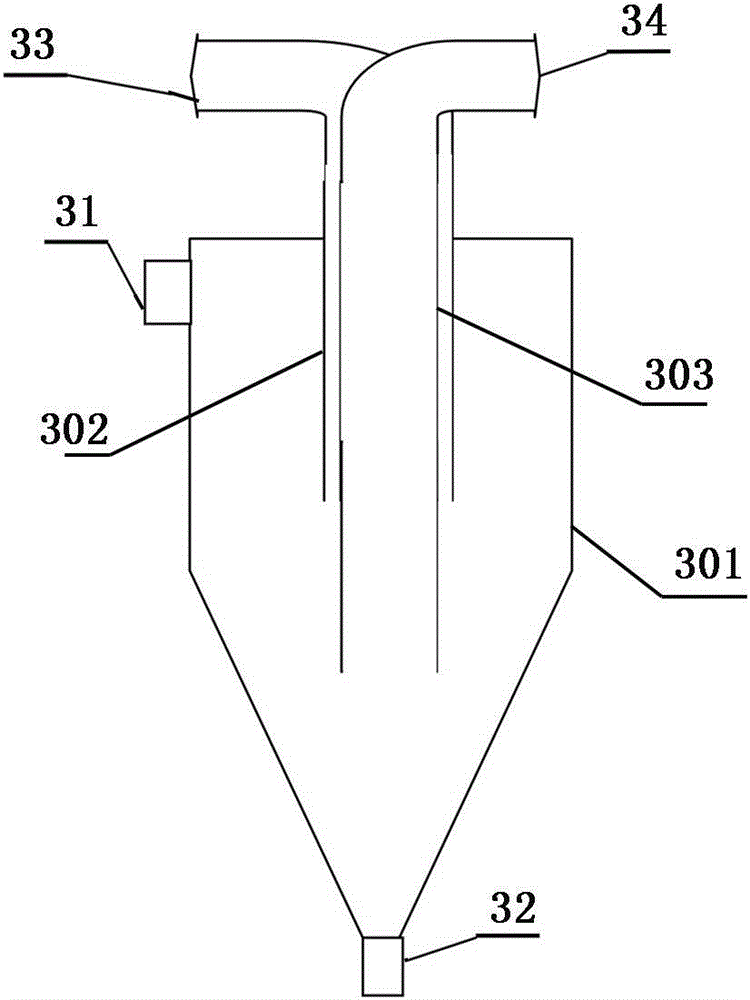

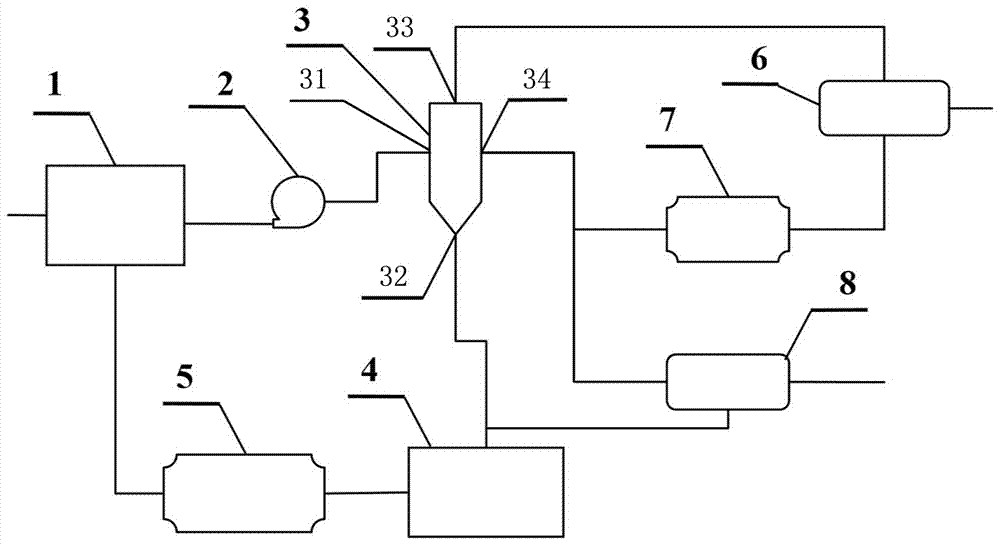

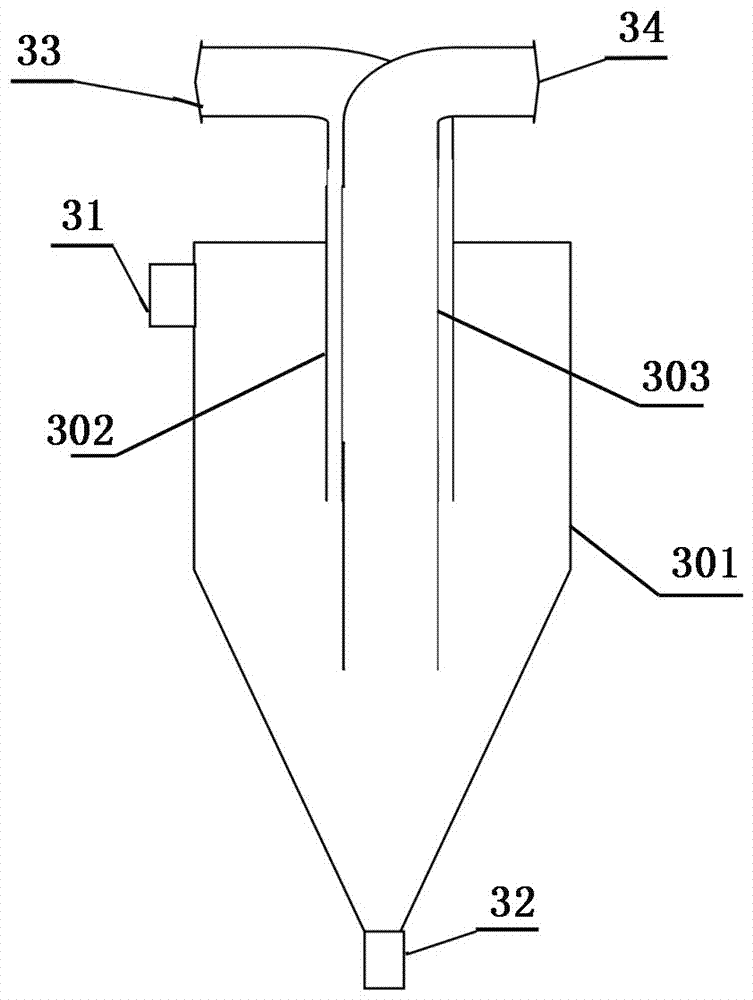

Ore grinding grading system and method capable of controlling derichment of iron minerals

The invention discloses an ore grinding grading system and method capable of controlling derichment of iron minerals. The ore grinding grading system comprises a feeding pulp tank, a feeding pump, a double-overflow-pipe swirler, a sand setting pulp tank, a mill, first separation equipment and an open-circuit grinding machine. The double-overflow-pipe swirler is provided with a swirler inlet, a setting sand outlet, an outer overflow outlet and an inner overflow outlet. An outlet of the feeding pulp tank is connected with an inlet of the feeding pump. An outlet of the feeding pump is connected with the swirler inlet. The setting sand outlet is connected with an inlet of the mill. An outlet of the mill is connected with the feeding pulp tank. The outer overflow outlet is connected with the first separation equipment. The inner overflow outlet is connected with an inlet of the open-circuit grinding machine. An outlet of the open-circuit grinding machine is connected with the first separation equipment. The ore grinding grading method includes the steps that ore pulp is fed into the double-overflow-pipe swirler to be graded, and the graded setting sand products, outer overflow products and inner overflow products are processed separately. By means of the ore grinding grading system and method capable of controlling derichment of the iron minerals, derichment of the iron minerals in setting sand can be reduced, the handling capacity of the mill is improved, the energy consumption for ore grinding is reduced, and the quality of ore concentrate products is improved.

Owner:湖南金磨科技有限责任公司

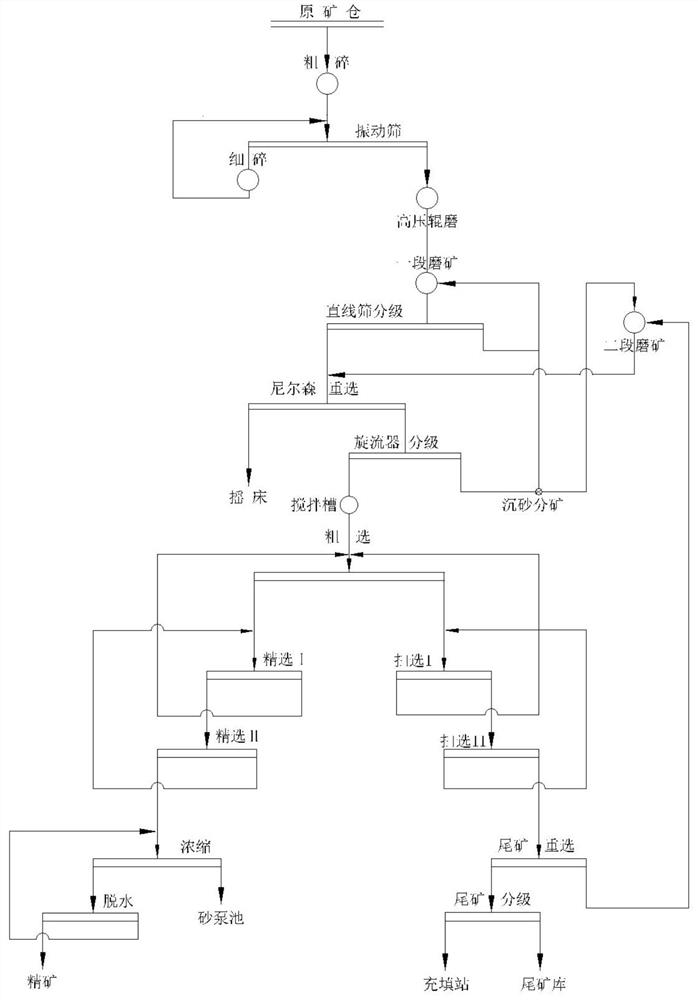

Low-grade mineral separation process

PendingCN113731625AReduce the particle sizeImprove crushing efficiencyGrain treatmentsWet separationOre concentrateMining engineering

The invention discloses a low-grade mineral separation process, and relates to the technical field of mineral separation. The process comprises the following steps that coarse crushing operation is conducted on ores in a raw ore bin to obtain coarse crushed products, the coarse crushed products are fed into a vibrating screen for screening, undersize products return to a cone crusher for fine crushing operation, then the undersize products are fed into the vibrating screen, oversize products fall into a fine ore bin, materials in the fine ore bin are fed into a high-pressure roller mill, and the materials are fed into a ball mill A through a feeding chute; ball-milling discharged ore is conveyed to a linear screen, the undersize products sequentially enter two nelson concentrators for reselection, and the oversize products return to the ball mill A for regrinding; and the reselected concentrate enters a Nelson table concentrator for concentration and then is subjected to flotation operation, the flotation concentrate is sold to a smeltery, the tailings enter a reselection workshop for reselection through the table concentrator, the table concentrator concentrate is a final product of the tailings reselection workshop section and returns to a ball mill B for regrinding through a hose pump, and the chute tailings and the table concentrator tailings are classified through a cyclone, subjected to sand setting and discharged to the underground for filling operation; According to the process, the ore grinding effect is good, and the ore grinding process handling ability and the ore grinding index are improved.

Owner:HENAN JINYUAN GOLD MINING CO LTD

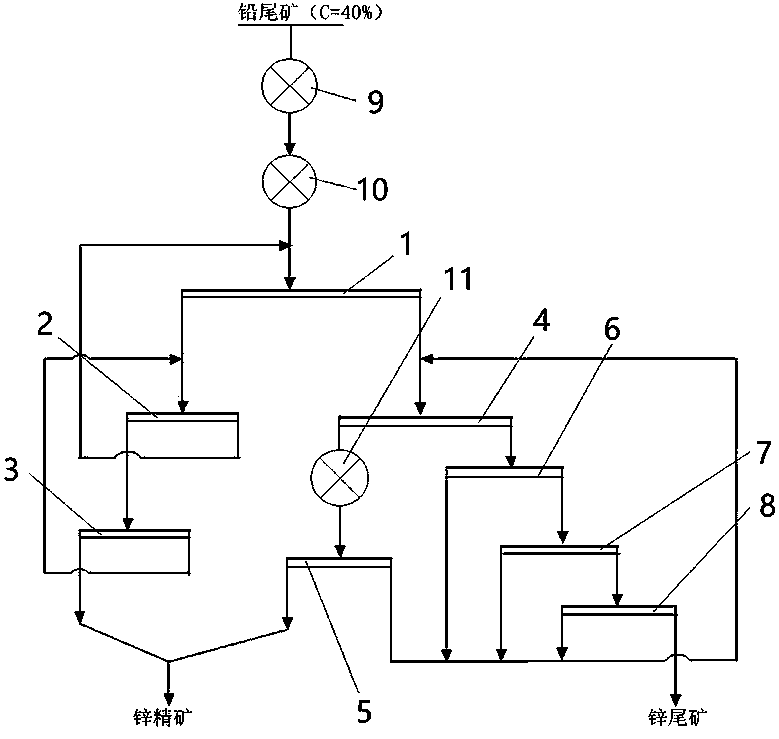

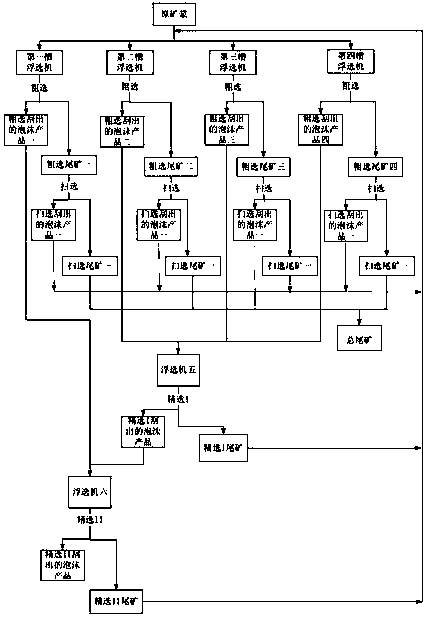

Machine-column-machine rapid and efficient zinc flotation method and system

The invention discloses a machine-column-machine rapid and efficient zinc flotation method. The method adopts the flotation procedure of one time of roughing and two times of concentration of a flotation machine, one time of roughing and one time of concentration of a flotation column and three times of sweeping of the flotation machine. Firstly, coarse particle zinc which is easy to float is rapidly produced through the flotation machine, then zinc which is floated in medium difficulty is produced in concentration of the flotation column through the flotation column, zinc which is very difficult to float is produced under synergy of the flotation column through the long-time excitation and capturing functions in the flotation machine, the floating time and procedure of the zinc minerals which are easy to float are shortened, the cyclic loss of the medium minerals is reduced, and the zinc minerals difficult to float have longer time and much chance to float. The method not only well solves the problem that the same kind of minerals have different floatability, but also solves the problem that zinc minerals of different size fractions have different floatability, achieves refine selection, remarkably improves the zinc recovery rate, achieves efficient zinc flotation, and has great importance significance for improving the zinc recovery rate and concentrate quality, saving energy, reducing consumption and achieving clean production.

Owner:南京银茂铅锌矿业有限公司

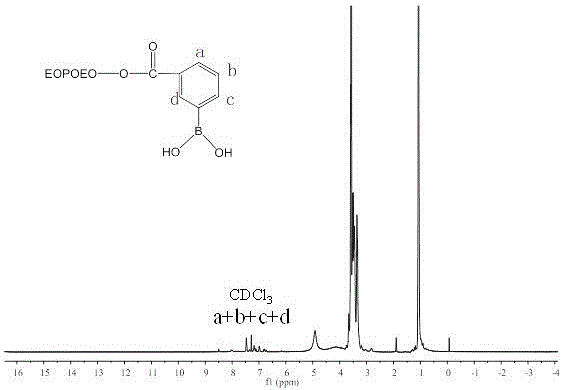

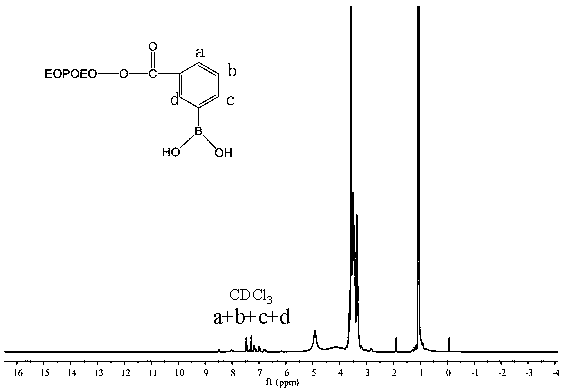

Method for separating and purifying o-hydroxyl compound

ActiveCN106278852AHigh enrichment factorHigh purityIon-exchange process apparatusIon-exchanger regenerationPhenylboronic acidNatural product

The invention relates to a method for separating and purifying an o-hydroxyl compound, and belongs to the field of natural product separation and purification. The method comprises the steps that firstly, alizarin red and K2HPO4 are added into a colorimetric tube, then phenylboronic acid functionalized PEO20PPO60PEO20 is added, the solution is diluted with distilled water, full shaking is carried out, and the mixture is mixed to be uniform; the mixture is poured into a flotation column after still standing, then normal propyl alcohol is added, gas flowing speed is regulated, and flotation is started; after the system is divided into two phases, the volume of the upper phase is recorded, and the alizarin red concentration in the upper phase is measured. The double aqueous phase flotation system is set up for flotation separation of o-hydroxyl compound alizarin red; synthesized phenylboronic acid functionalized PEO20PPO60PEO20 is added to serve as a complementing agent and can be effectively combined with alizarin red, meanwhile, functionalized PEO20PPO60PEO20 can be effectively adsorbed on a hydrophobic bubble interface, and flotation separation of water-soluble alizarin red is achieved; obtained alizarin red is large in the enrichment factor and high in purity, and the yield of the product can be increased.

Owner:JIANGSU UNIV

Biological enzyme deinking method for waste paper

InactiveCN1240900CIncrease the reaction concentrationHigh catalytic efficiencyFats/resins/pitch/waxes removal in pulpPaper recyclingFiltrationSewage

Provided is a biological enzyme deinking method for waste paper, in which flotation applies polyoxyethylene alkyl ether as flotation auxiliary, deinking process applies compound enzyme as deinking agent. The method improves the white content of the regenerated pulp by chemistry method, which is enhanced to 5-8% higher, and the COD value of the discharged sewage reduced more than 60%. The paper pulp filtration performance is further increased and the strength is similar, thus it can meet requirement of making different papers.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

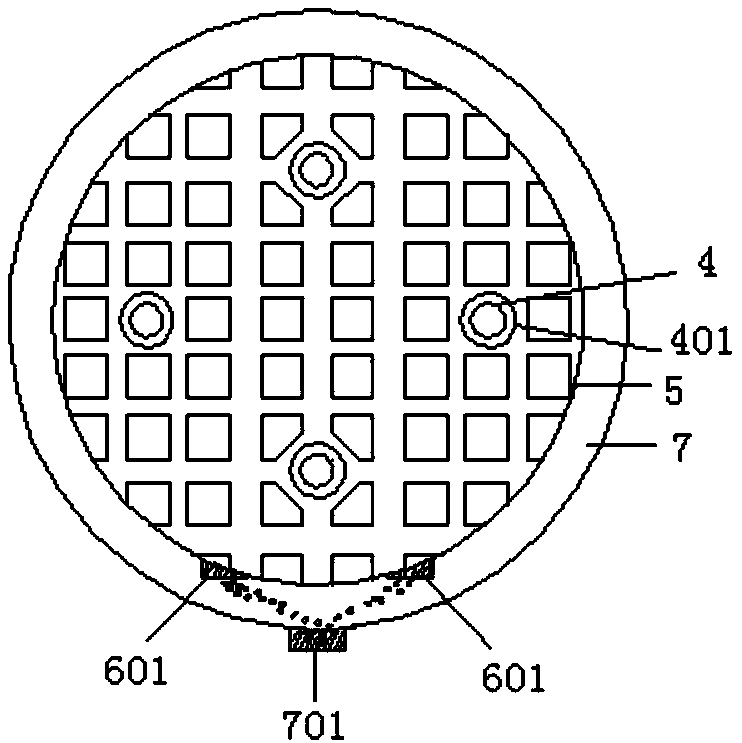

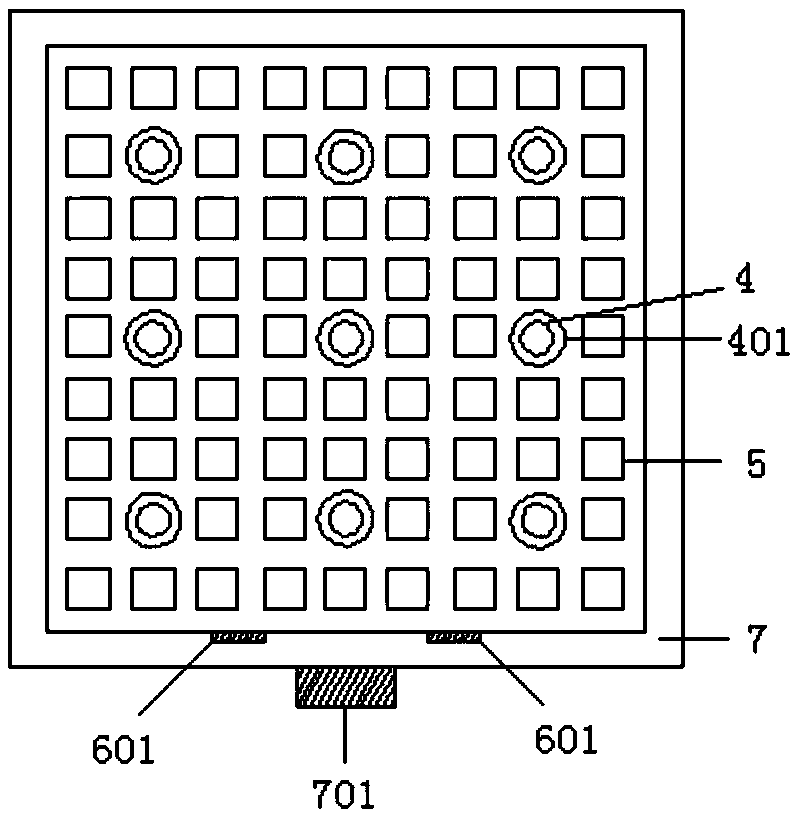

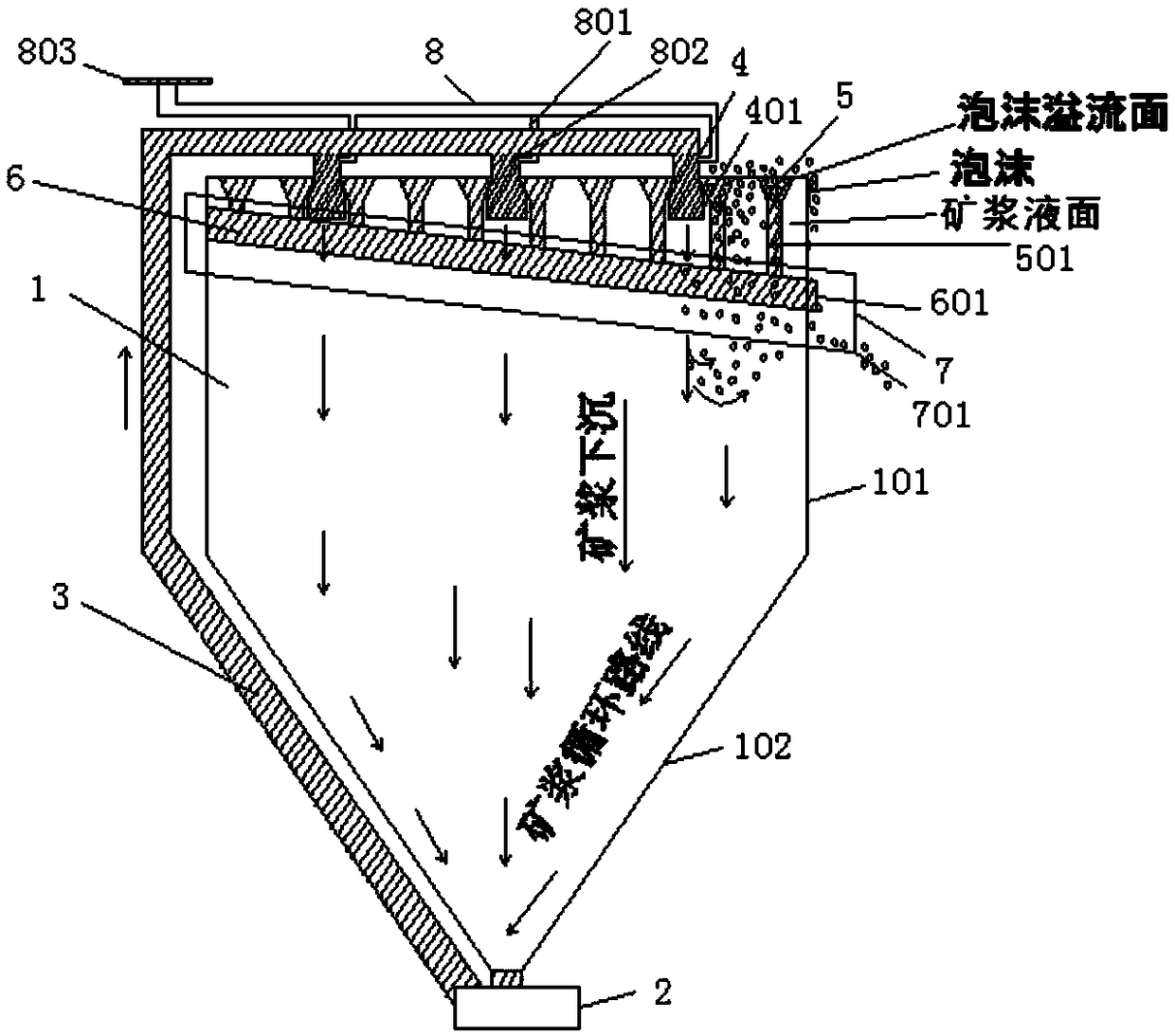

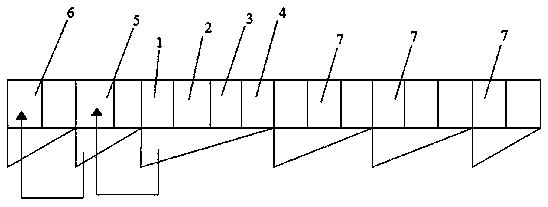

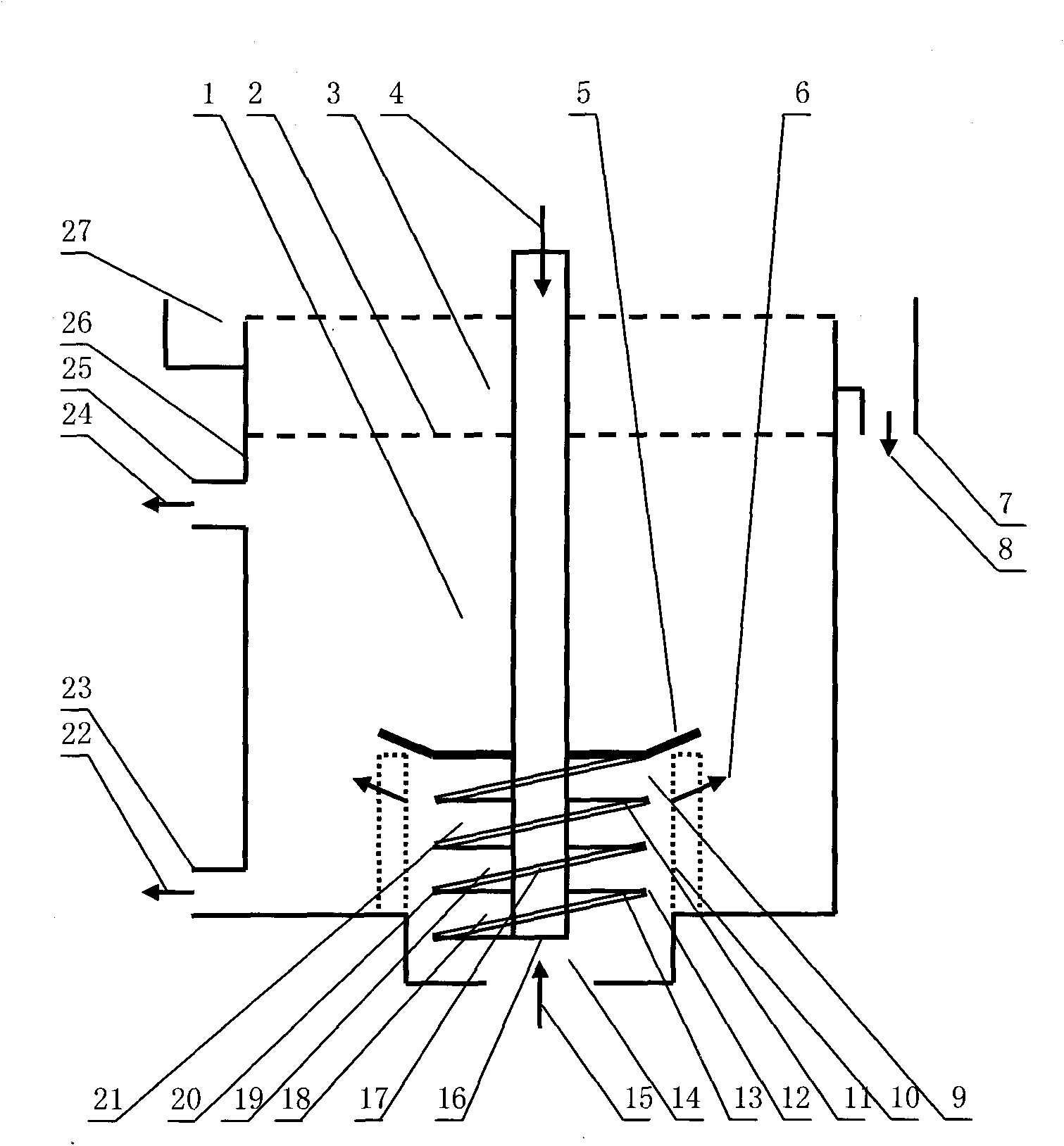

Distributed efficient flotation machine

The invention discloses a distributed efficient flotation machine. The distributed efficient flotation machine comprises a vertical tapered barrel (1), a centrifugal abrasion-resistant slag slurry pump (2), an ore pulp PE pipe (3), a plurality of ore pulp spray heads (4), a tapered foam collection tank (5), an intra-barrel foam collection main pipe (6), an annular extra-barrel foam collection tank(7) and an inflation main pipe (8). The vertical tapered barrel (1) is divided into an upper barrel body (101) and a lower barrel body (102), wherein the upper barrel body (101) is an open cylinder or a quadrangular square cylinder, and the lower barrel body (102) is a conical cylinder or a rectangular cylinder; and the bottom of the lower barrel body (102) is connected with the centrifugal abrasion-resistant slag slurry pump (2) and the ore pulp PE pipe (3), the ore pulp PE pipe (3) extends to a position above the top of the vertical tapered barrel (1) from bottom to top and is provided withthe ore pulp spray heads (4) which communicate with one another and face downwards, and the ore pulp spray heads (4) extend to the ore pulp level in the vertical tapered barrel (1).

Owner:王益庆

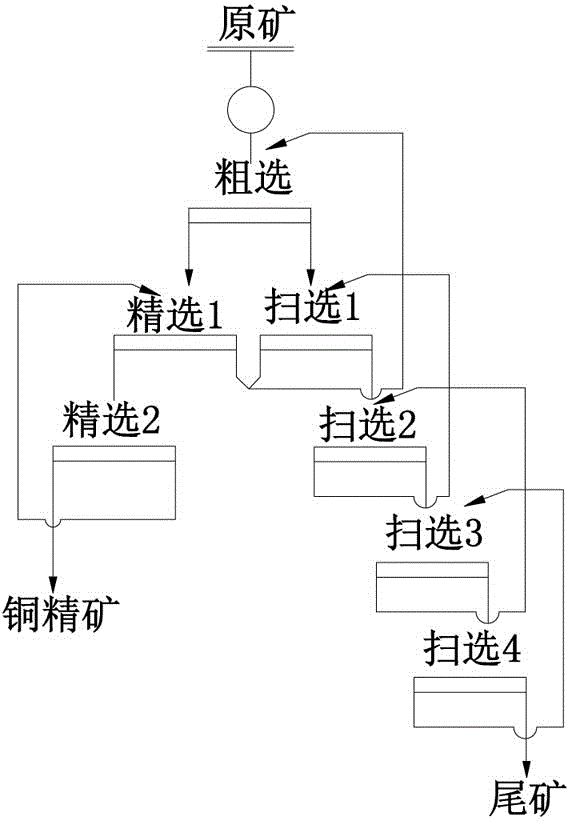

Sorting process for improving beneficiation recovery rate of nonferrous metals

The invention discloses a sorting process for improving the beneficiation recovery rate of nonferrous metals. According to the sorting process, under the conditions that original flotation equipment conditions and the plant layout are not changed and the types of the beneficiation reagents and the usage amount are unchanged, the internal structure of the original process flow of the beneficiationplant is optimized, a float product obtained through a first tank flotation machine in roughing operation of flotation target minerals is directly used as the foam product of the concentration operation I to enter the concentration operation II to undergoes sorting so that a part of easy-to-float target minerals can enter the next operation preferentially, the circulation amount of the previous concentration operation can be reduced , the flotation time can be shortened, the sorting out of the target minerals which are easy to float can be realized, and finally the recovery rate of the concentrate products can be improved.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

Beneficiation process for copper sulphide ore

The invention relates to the improved technology for metallurgy beneficiation, in particular to a beneficiation process for copper sulphide ore. After raw ore is ground through a ball mill, pulp is obtained. 1,200 g-1,500 g of lime, 100 g-150 g of lotus leaf and taro leaf juice, 100 g-120 g of lotus leaf and taro leaf residues and 50 g-70 g of pine oil are added in each ton of raw ore, the pH of the pulp is adjusted to be equal to 8, and copper concentrates with the copper content higher than 20% and tailings with the copper content lower than 0.039% are obtained after the pulp is subjected to rough selecting, two-stage fine selecting and four-stage scavenging. The beneficiation production cost is low, a collecting agent is free of toxicity and harm, environment friendliness is achieved, no corrosiveness exists for equipment, the recycling rate is high, and the beneficiation process is mainly used for beneficiation of sulphide ore and oxidized ore.

Owner:刘合琼

A grinding and grading system and method capable of controlling anti-enrichment of iron minerals

A grinding and grading system and method capable of controlling the reverse enrichment of iron minerals, the system includes an ore feeding slurry tank, an ore feeding pump, a double overflow pipe cyclone, a sand settling ore slurry tank, a mill, and a first sorting equipment. And open-circuit grinding mill, double overflow tube cyclone is equipped with cyclone inlet, sand settling outlet, outer overflow outlet and inner overflow outlet, the outlet of the feeding slurry tank is connected with the inlet of the feeding pump, feeding The outlet of the pump is connected to the inlet of the cyclone, the outlet of the sand settling is connected to the inlet of the mill, the outlet of the mill is connected to the ore feeding slurry tank, the overflow outlet is connected to the first sorting equipment, and the inner overflow outlet is connected to the open-circuit grinding mill. The inlet is connected, and the outlet of the open-circuit grinding mill is connected with the first sorting equipment; the method is to send the pulp into the double overflow tube cyclone for classification, and separate the graded sand settling products, external overflow products and internal overflow products. to be processed. The invention can reduce the anti-concentration of iron minerals in the sand, improve the processing capacity of the mill, reduce the energy consumption of grinding and improve the quality of concentrate products.

Owner:湖南金磨科技有限责任公司

A combination process for recovering pyrite from lead-zinc tailings

The invention relates to a mineral separation combination process for recycling pyrite from lead-zinc tailings. The mineral separation combination process comprises step 1, performing mud and sand separation on the lead-zinc tailings through a spiral chute; step 2, performing sulfur flotation on mud and sand which are separated out through the spiral chute; step 3, performing magnetic separation iron extraction on the sand which is separated out through the spiral chute through the tailings after the sulfur flotation, performing flotation desulfurization on rough concentrate obtained through magnetic separation and achieving the recycling of the pyrite in the lead-zinc tailings. The sulfur grade in obtained mixed sulfur concentrate is larger than 31%; the iron grade in iron concentrate is larger than 64% and the sulfur content is smaller than 0.5%; the sulfur recovery rate in the lead-zinc tailings is as high as 95% and the iron recovery rate in the lead-zinc tailings is as high as 88%. According to the mineral separation combination process for recycling the pyrite from the lead-zinc tailings, the operation is stable, the mineral separation index is high, the comprehensive utilization of resources can be achieved, the pollution to the environment can be reduced, and the good economic benefit can be brought to enterprises.

Owner:有研资源环境技术研究院(北京)有限公司

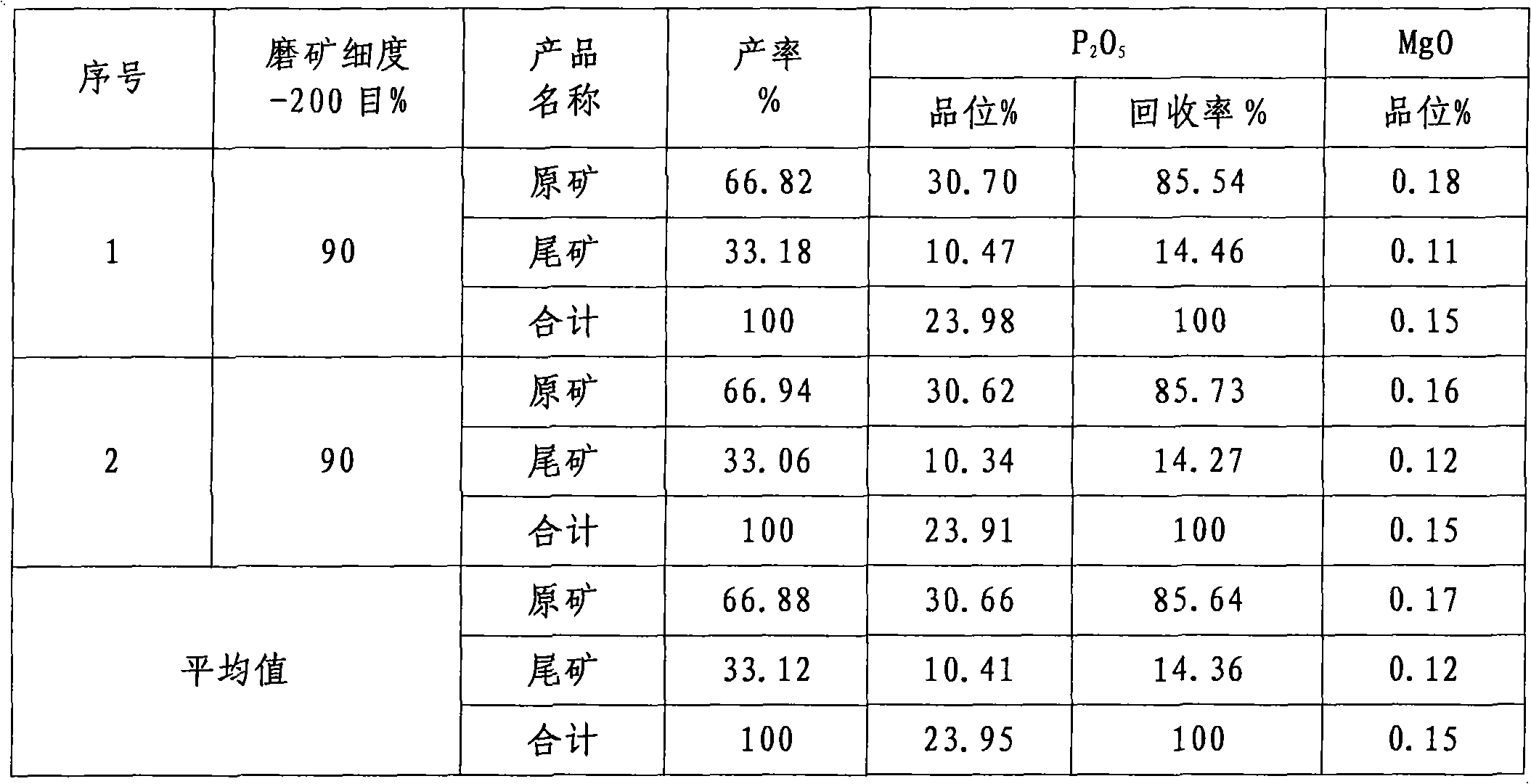

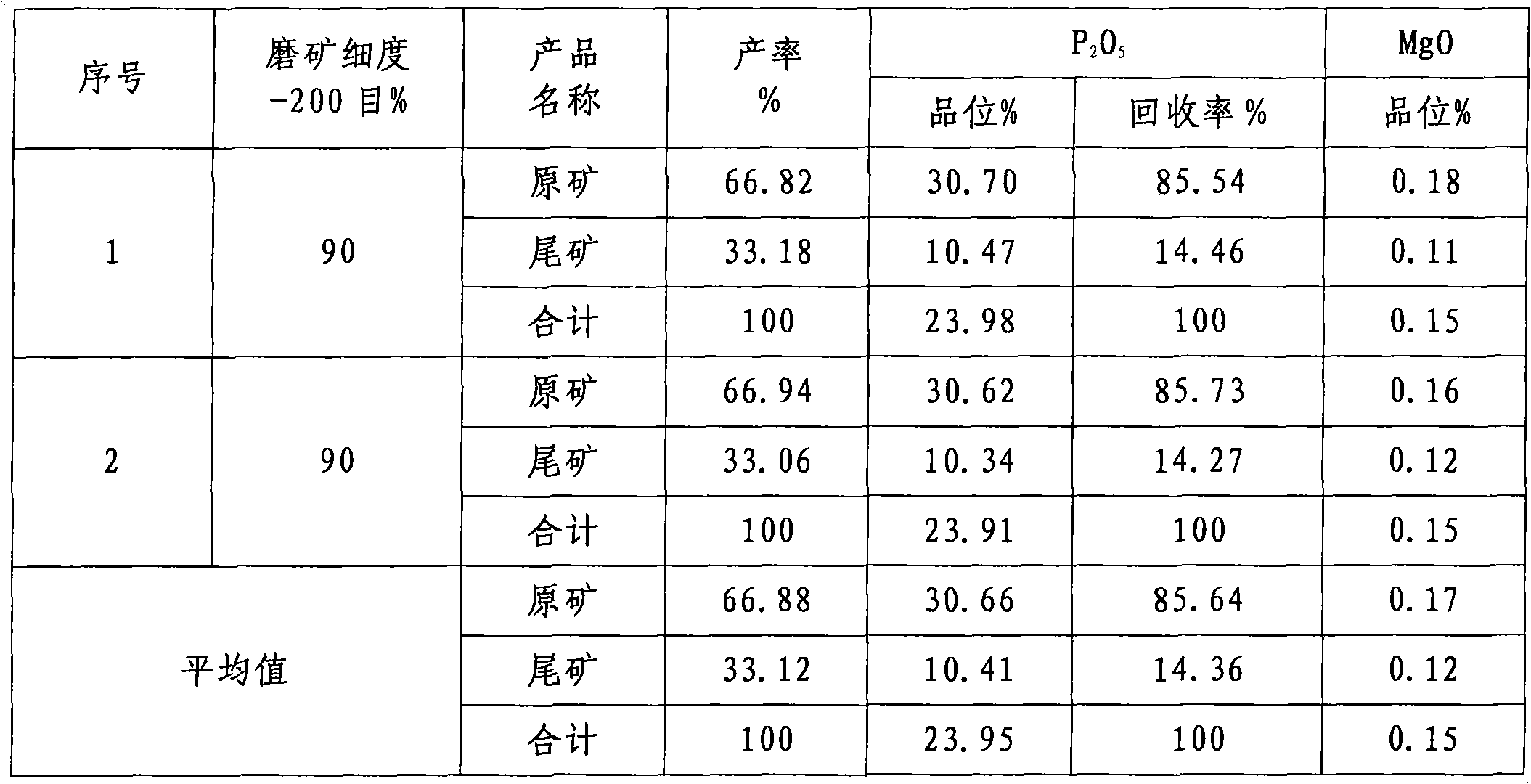

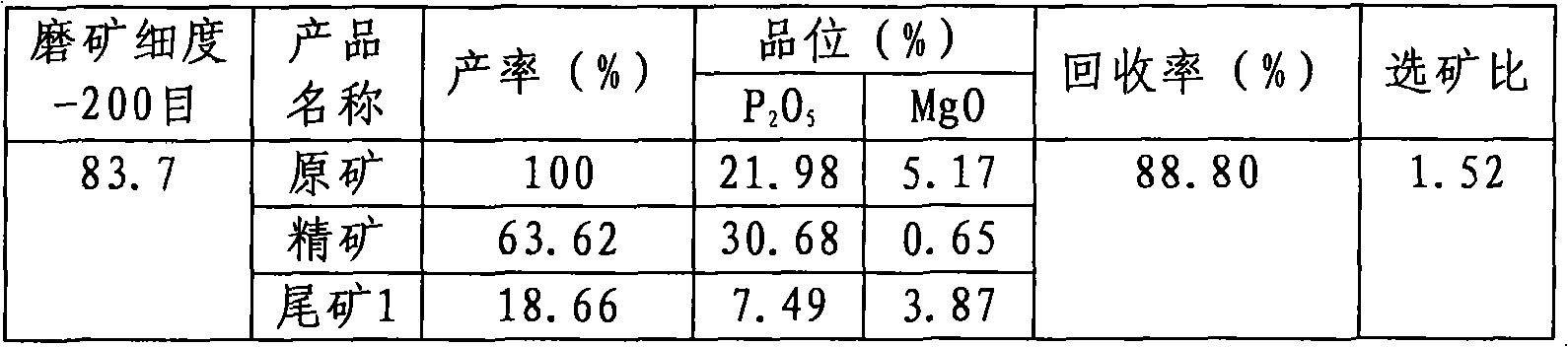

A kind of siliceous colloidal phosphate positive flotation collector and preparation method thereof

The invention discloses a positive flotation collector for siliceous collophosphate rock and a preparation method thereof, and relates to the technical field of collophosphate rock flotation. 6-9 parts of sodium triethanolamine oleate, 1-2 parts of anionic surfactant, and 1-3 parts of fatty alcohol are mixed at normal temperature, and the mixture is uniformly stirred and mixed at normal temperature to prepare a collector for positive flotation of silicocolloid phosphate rock. The mixed fatty alcohol is prepared by isooctanol and n-octanol in a ratio of 1:1. The anionic surfactant is one or more of sodium lauryl sulfate, sodium laureth sulfate, and sodium cetyl sulfonate. The collector has good water solubility and dispersibility under normal temperature conditions, can effectively flotation rate, shorten the flotation space, is economical and environmentally friendly, and is suitable for popularization and use. The collector is applied to the positive flotation of low-grade and high-silica phosphate rock. After dilution, 0.5-0.7kg / t collector is added at room temperature (15-25°C), and through a positive flotation roughing operation, it can be mixed with oil. Compared with acid collectors, the flotation yield and recovery rate were increased by about 6% and 9%, respectively, within 3 minutes of flotation time.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

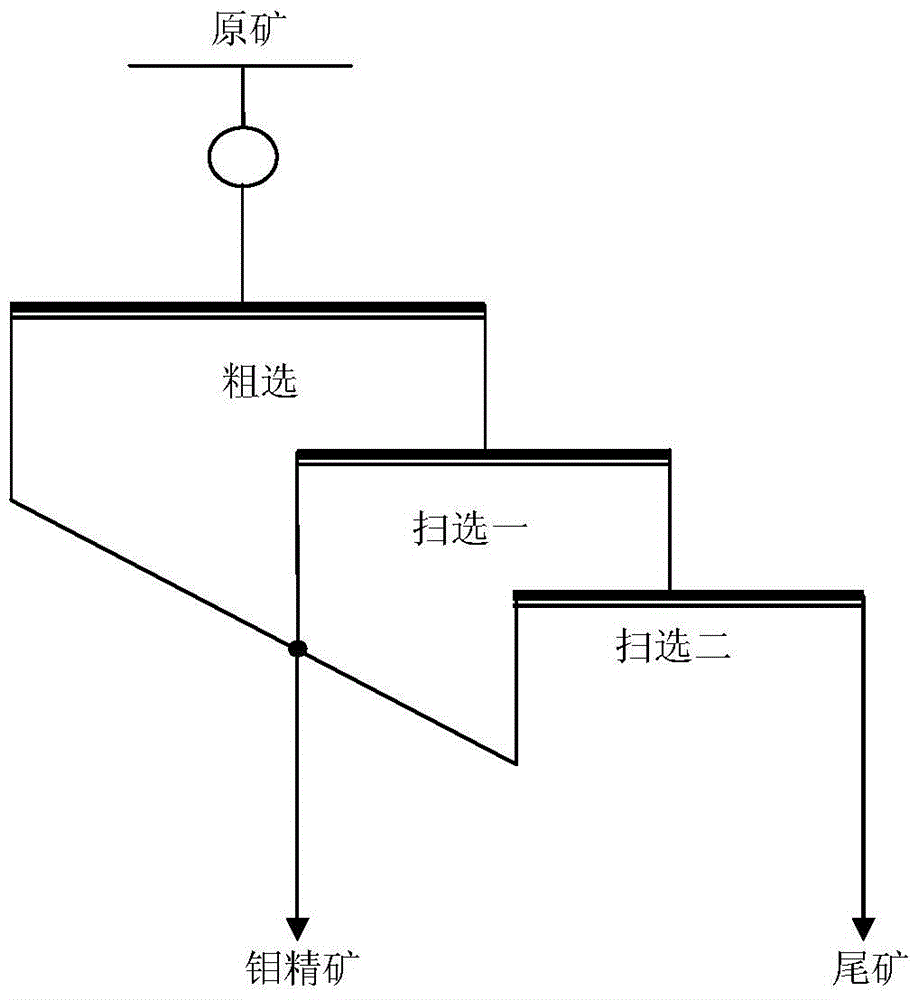

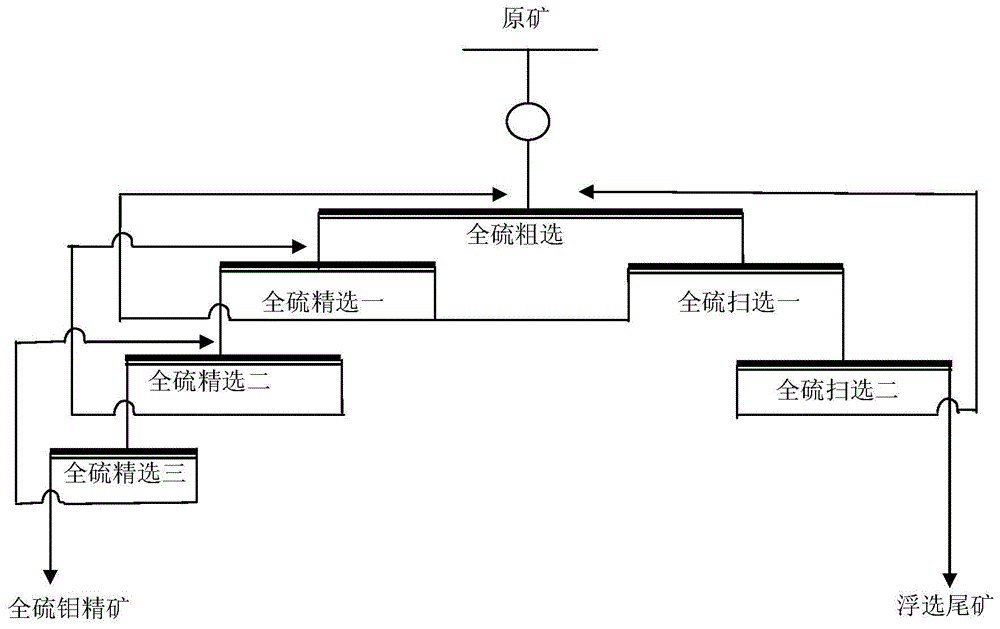

Application of a composite collector for beneficiation of fine-grained porphyry molybdenum ore

ActiveCN103769308BStrong harvesting abilityGood choiceFlotationResource utilizationComposite application

Owner:GUANGDONG INST OF MINERAL APPL

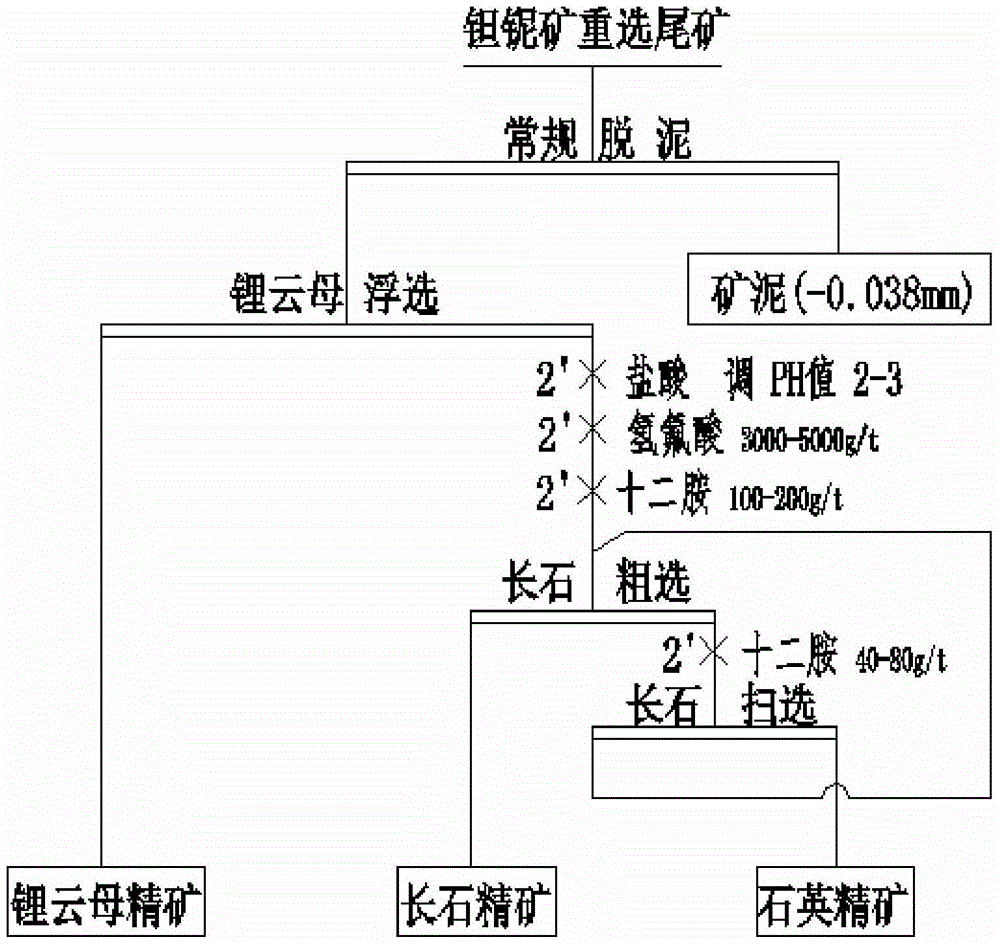

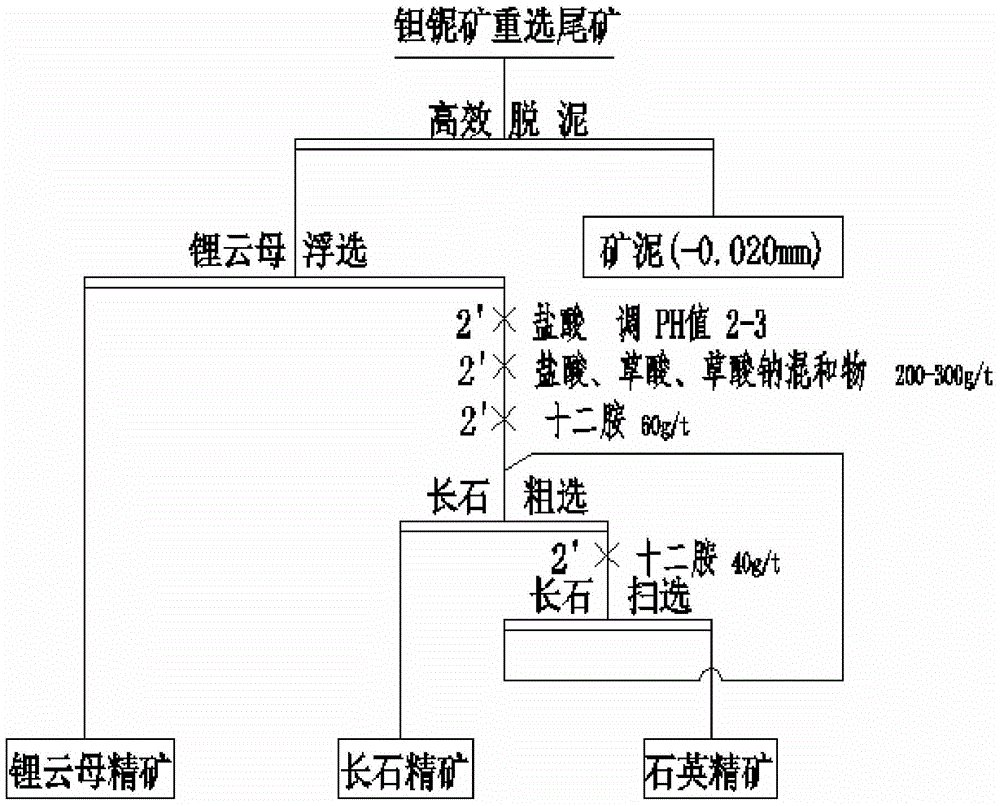

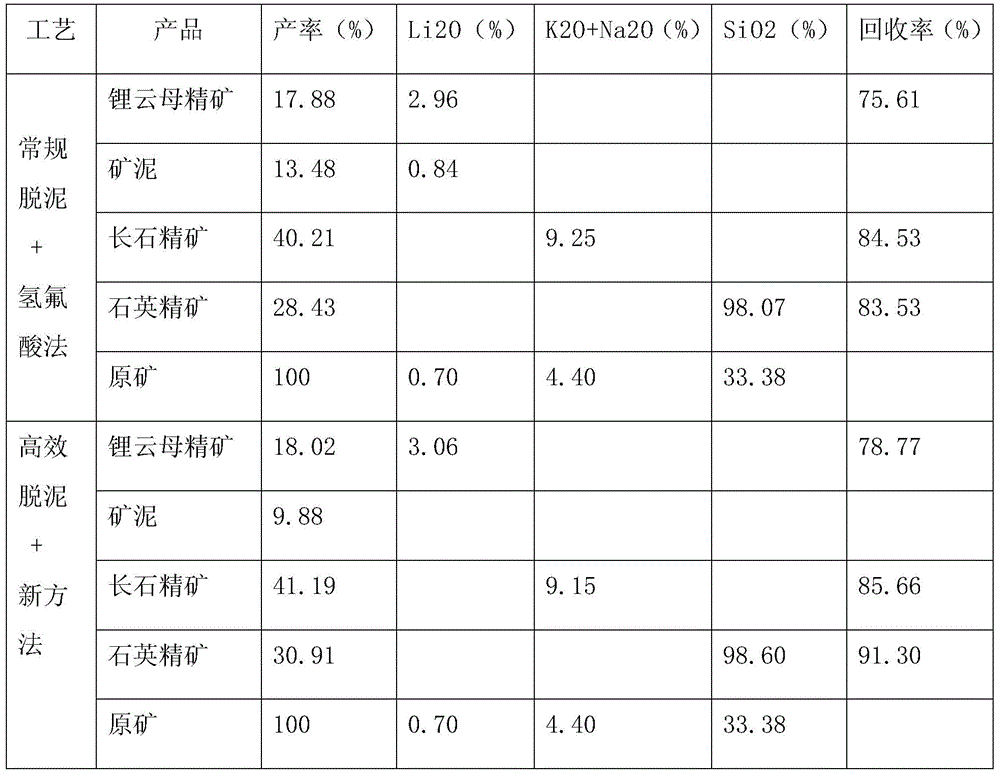

A method for optimizing feldspar and quartz from tantalum-niobium ore

Owner:JIANGXI XULI MINING IND CO LTD

Method for floating bauxite

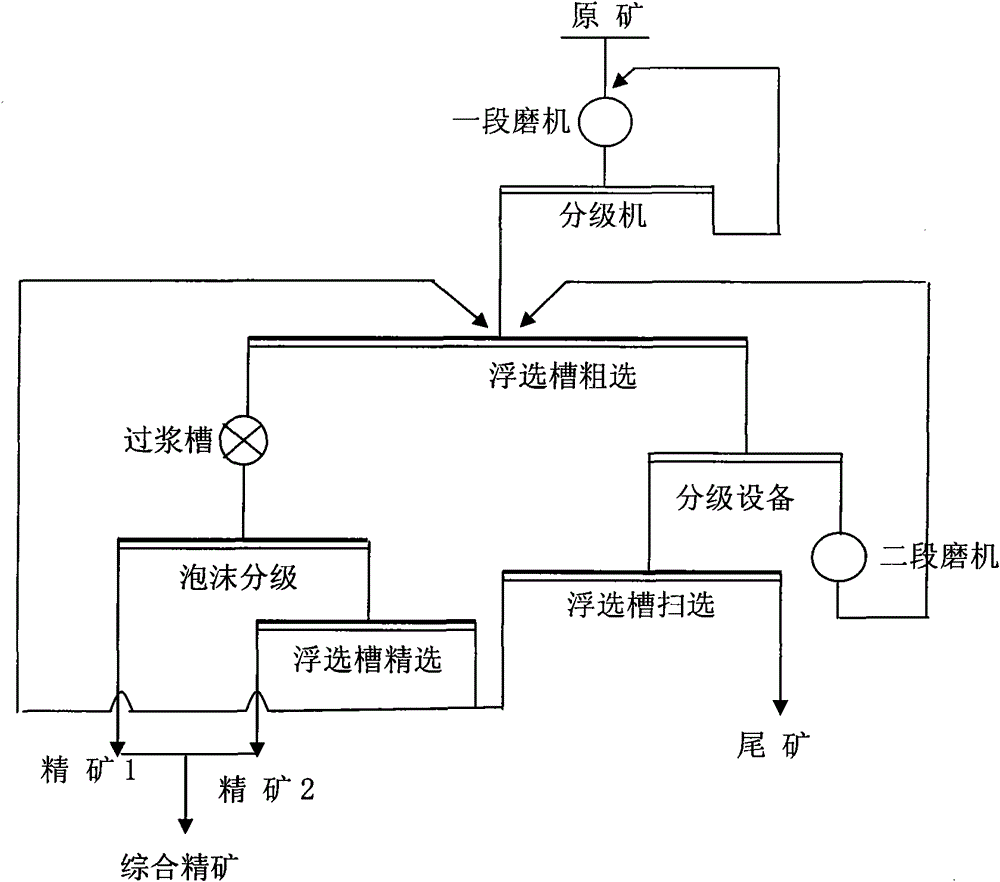

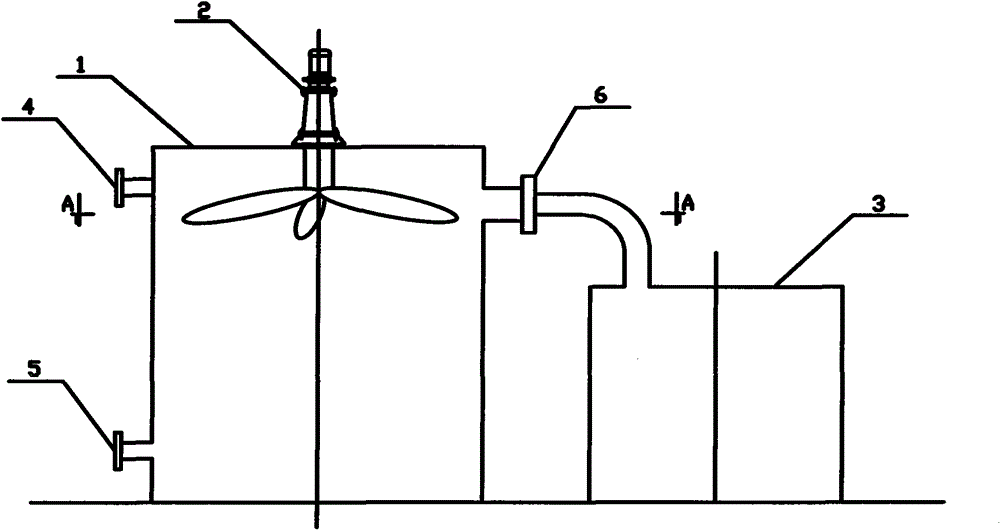

The invention relates to a method for floating bauxite, which is characterized in that: a froth product of grinding and rough concentration enters a pulp filtering tank and the enriched mineralized froth floats on the surface of ore pulp and overflows from the overflow opening of the pulp filtering tank to give a concentrate I; the defrothed impure ore pulp flows downwards, bottom-flow ore pulp enters a concentrating and floating tank under the action of a slag pulp pump, and a froth product of the concentration is used as a concentrate II; the bottom flow of the concentration returns to rough concentration operation, the bottom flow of the rough concentration is scavenged, the froth of the scavenged returns to the rough concentration operation, and the bottom flow of the scavenging is used as tailings; and the concentrate I and the concentrate II are combined to form the final concentrate. The method of the invention effectively solves the froth transport problem, stabilizes the ore pressure of the ore pulp feed and the floatation process, reduces the water consumption of the floatation system, improves floatation concentration, reduces the floatation time of qualified concentrate, improves equipment capacity, improves ore dressing indexes, reduces production cost and provides qualified bauxite concentrate material for the Bayer-process production of alumina.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

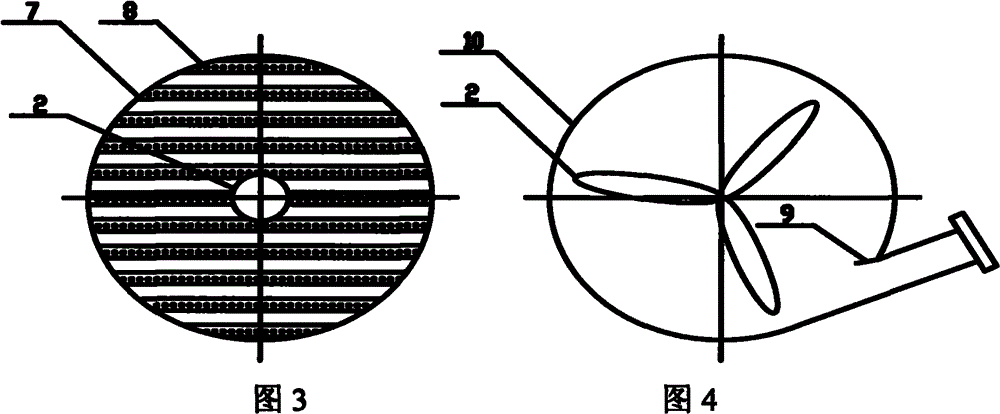

Method and device for flotation by adopting spiral rotor and application

The invention discloses a method for flotation by adopting a spiral rotor, which is characterized in that a floating device is provided with the spiral rotor which rotates to generate a spiral gas field; inflow ore pulp undergoes gas-liquid mixing with the spiral gas field over one time in the process of flowing through a spiral channel; and outflow ore pulp flows out of the floating device in anirreversible flow way. The spiral rotor is provided with a hollow rotor shaft in a vertical central region; at least one spiral blade is arranged on the outer surface of a lower shaft of the hollow rotor shaft; a rotor top cover is arranged on the top of the spiral blade; a hollow shaft cavity of the hollow rotor shaft is filled with compressed air; and the compressed air in the hollow rotor shaft enters into the abdominal cavity of the spiral blade through a rotor shaft air hole, is outwards ejected through a blade air hole and forms the spiral gas field inside and outside the spiral channel. The method and the device for flotation are applied to the flotation process of all solid materials which at least comprise non-ferrous ore, ferrous metal ore and nonmetallic ore, and particularly lean ore and complex and difficultly selected ore.

Owner:XINGMIN TECH ZHUZHOU

Collophanite flotation collector and method for preparing same

ActiveCN101797536BStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

A method for separating and purifying o-hydroxyl compounds

ActiveCN106278852BHigh enrichment factorHigh purityIon-exchange process apparatusIon-exchanger regenerationPhenylboronic acidAlcohol

The invention relates to a method for separating and purifying an o-hydroxyl compound, and belongs to the field of natural product separation and purification. The method comprises the steps that firstly, alizarin red and K2HPO4 are added into a colorimetric tube, then phenylboronic acid functionalized PEO20PPO60PEO20 is added, the solution is diluted with distilled water, full shaking is carried out, and the mixture is mixed to be uniform; the mixture is poured into a flotation column after still standing, then normal propyl alcohol is added, gas flowing speed is regulated, and flotation is started; after the system is divided into two phases, the volume of the upper phase is recorded, and the alizarin red concentration in the upper phase is measured. The double aqueous phase flotation system is set up for flotation separation of o-hydroxyl compound alizarin red; synthesized phenylboronic acid functionalized PEO20PPO60PEO20 is added to serve as a complementing agent and can be effectively combined with alizarin red, meanwhile, functionalized PEO20PPO60PEO20 can be effectively adsorbed on a hydrophobic bubble interface, and flotation separation of water-soluble alizarin red is achieved; obtained alizarin red is large in the enrichment factor and high in purity, and the yield of the product can be increased.

Owner:JIANGSU UNIV

Composite beneficiation reagent for extracting vanadium from stone coal

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com