Distributed efficient flotation machine

A flotation machine, distributed technology, applied in flotation, solid separation and other directions, can solve the problems of difficult to achieve the best state of flotation, inflexible flotation method, difficult closed-circuit flotation, etc., to achieve stable flotation effect, The effect of shortened flotation time and high flotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

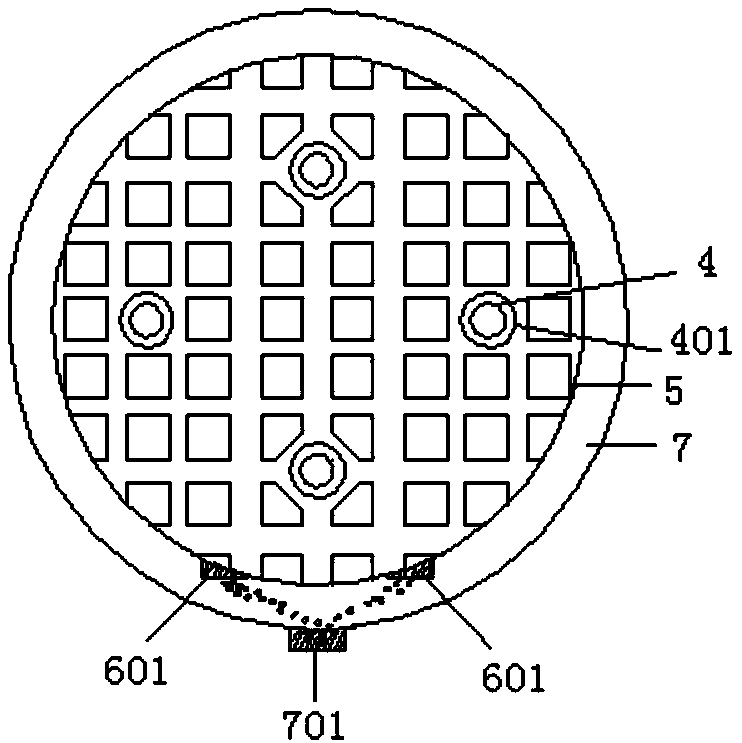

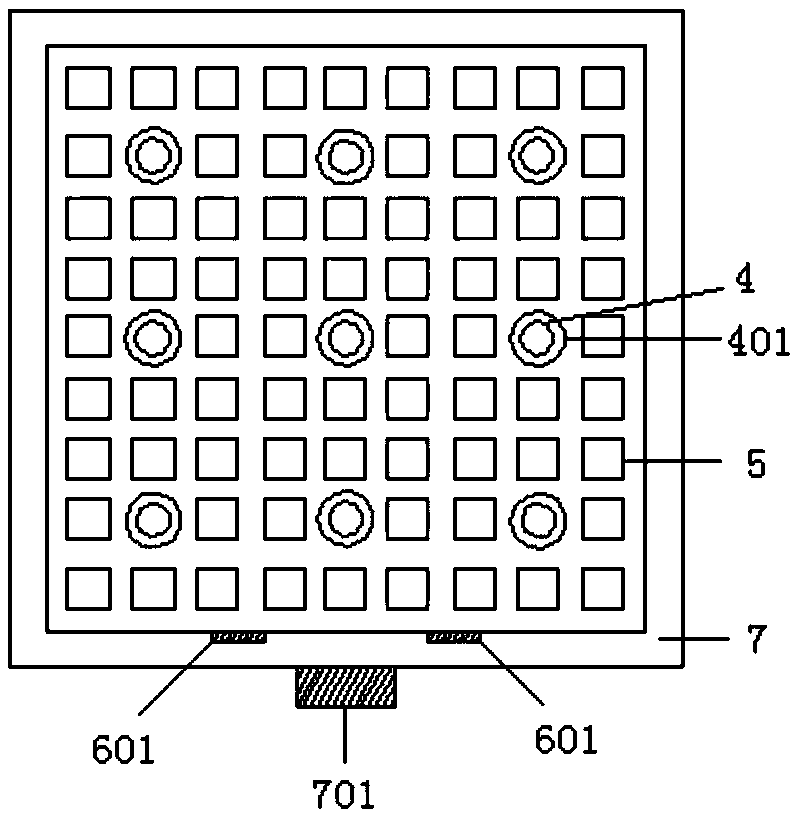

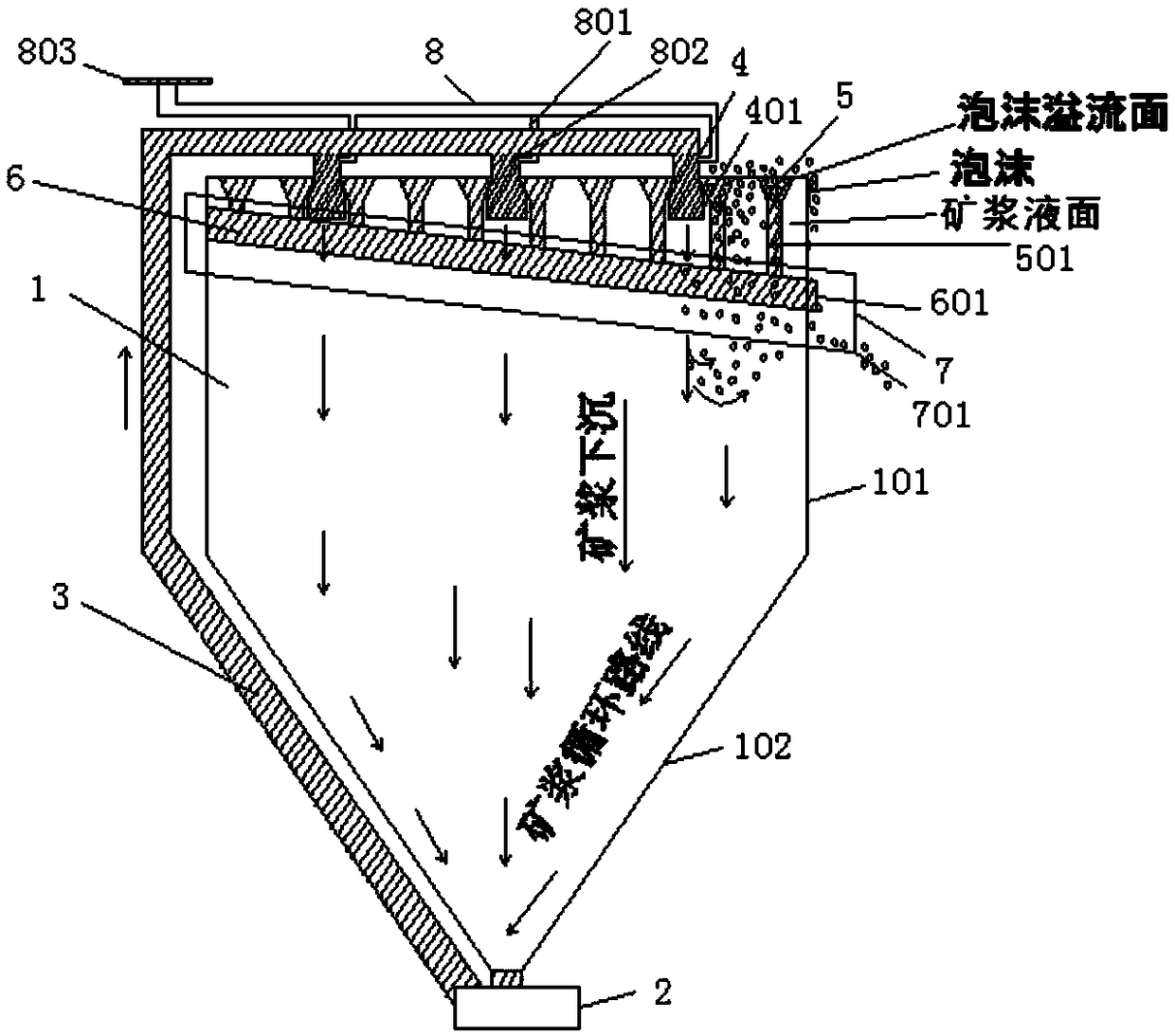

[0018] A distributed high-efficiency flotation machine, including a vertical cone barrel 1, a centrifugal wear-resistant slurry pump 2, a slurry PE conduit 3, a slurry nozzle 4, a foam collection cone trough 5, a foam collection main pipe in the barrel 6, and a Foam ring collection tank 7, gas main air pipe 8, described vertical vertebral barrel 1 is divided into upper barrel 101 and lower barrel 102, and described upper barrel 101 is an open cylinder (embodiment one, as figure 1 Shown) or square cylinder (embodiment two, such as figure 2 As shown), the lower bucket 102 is a corresponding conical cylinder or a square pyramid cylinder, and all the ore pulp runs from top to bottom without dead angle, and there is no area for the ore particles to se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com