Method and device for flotation by adopting spiral rotor and application

A flotation device and spiral technology, applied in flotation, solid separation, etc., can solve the problems of reduced target particle concentration of incoming ore pulp, misleading flotation equipment manufacturing industry, and low gas-liquid mixing efficiency, so as to achieve smooth flow into the tank Performance improvement, volume reduction, and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

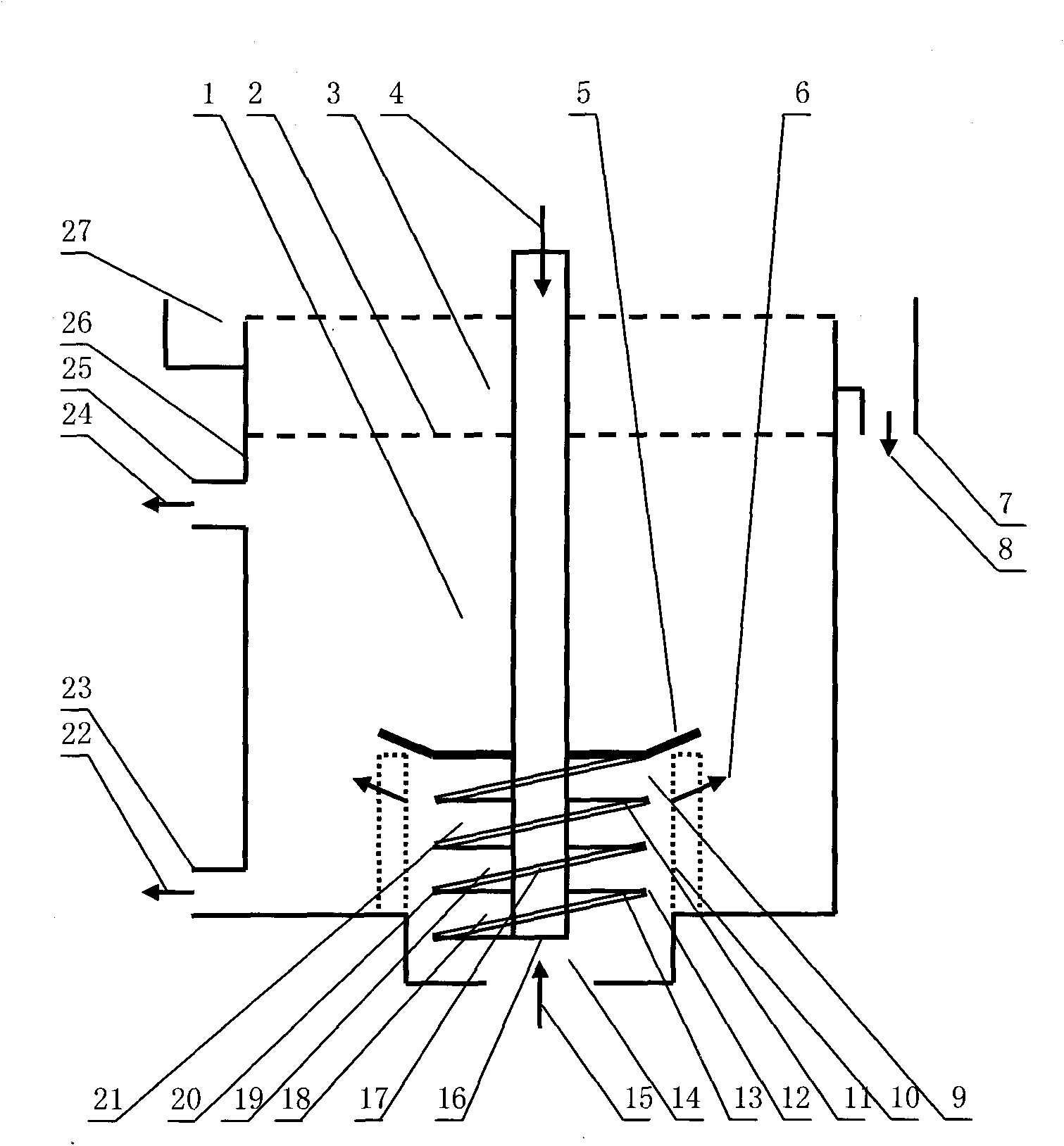

[0042] Embodiment 1: A helical rotor floating device

[0043] figure 1 The flotation cell shown uses a helical rotor floatation device. The floating device 9 is arranged in the lower central area of the flotation cell body 26 and includes a helical rotor 11 and a stator 10 . The stator 10 is a conventional stator. The screw rotor 11 consists of screw blades 12 and a hollow rotor shaft 16 . Wherein, the number (or the number of heads) of the spiral blade 12 is 1; the diameter is 300mm; the pitch is 50mm; the thickness of the hollow interlayer is 2mm; the air holes 13 on the top surface of the blade are 1mm in diameter, and are arranged in N rows×M radial arrangement in each row; The top is provided with a dish-shaped rotor top cover 5 with an outer diameter of 400mm; the air holes 13 of the end blades are built-in air holes formed by tubular passages in the hollow interlayer. The hollow rotor shaft 16 is a shaft section wrapped by the helical blades 12, and the hollow sha...

Embodiment 2

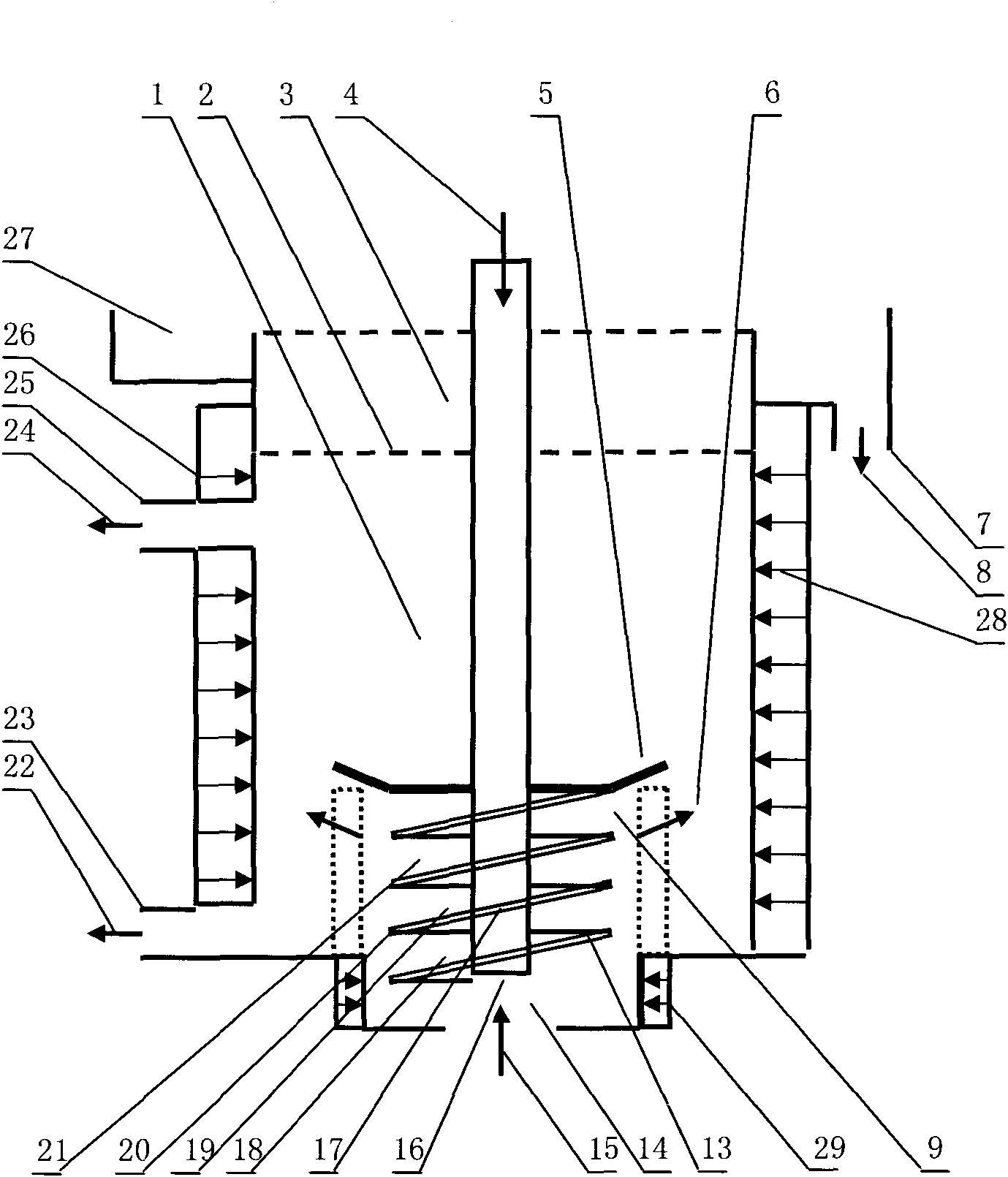

[0046] Embodiment 2: Another helical rotor floating device

[0047] figure 2 The flotation cell shown is an improved structure of the first embodiment, the basic structure is the same as that of the first embodiment, and a helical rotor floating device is used. The floating device 9 is arranged in the lower central area of the flotation cell body 26 and includes a helical rotor 11 and a stator 10 . It is characterized in that: an ultrasonic device 29 is provided at the entrance of the floating device, the ultrasonic device 29 and the flotation tank body 26 are of an integrated structure, and the ultrasonic frequency is 20kHz-1×10 6 kHz, sound intensity 0.5-200w / cm 2 . The inflowing pulp 15 enters the floating device 9 after applying ultrasonic energy by the ultrasonic device 29 .

[0048] The working principle of the present invention is: when the inflowing pulp 15 enters the ultrasonic device 29 through the inflowing pulp inlet 14, due to the effect of the set ultrason...

Embodiment 3

[0050] Embodiment 3: Another helical rotor floating device

[0051] from figure 2 It can be seen that the ultrasonic device 29 can also be arranged in a split type. When the ultrasonic treatment of the inflowing pulp 15 takes a long time, such as 1-2 minutes, it is more advantageous to install the ultrasonic device 29 in a separate manner.

[0052] The inventor has found in the course of research that some minerals (such as quartz-type gold ore, differentiated type silicate gold ore) can obtain a very high target particle recovery rate by adopting the helical rotor floating device; some minerals (such as Ultra-fine particle type gold ore, high mud type low-grade zinc oxide ore) adopts conventional flotation method, the target particle recovery rate is very low, and in the case of using the screw rotor floating device, the set ultrasonic energy treatment is applied to the inflow ore pulp 1-30 seconds, can significantly increase the recovery rate of target particles, and grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com