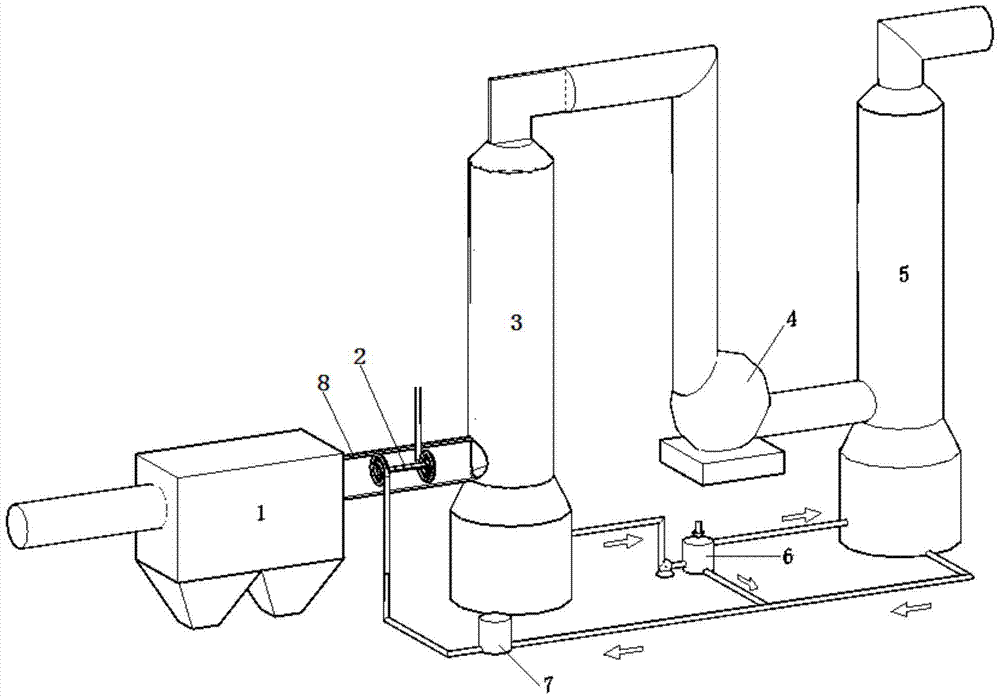

A device and method for double-circuit flue gas purification

A flue gas purification, double-loop technology, applied in the field of flue gas purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

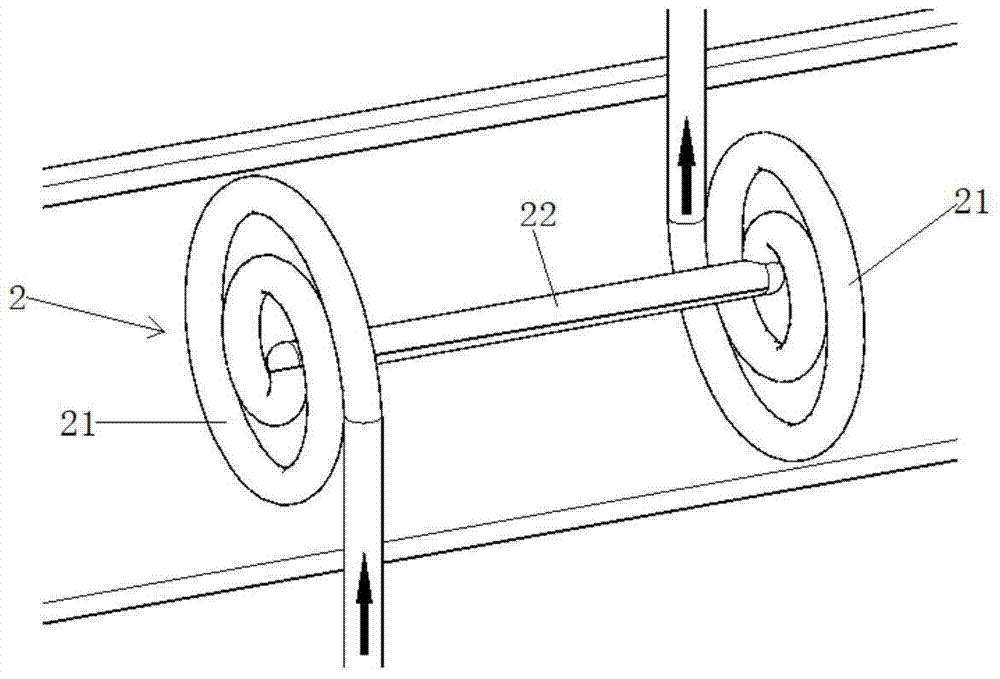

Method used

Image

Examples

Embodiment 1

[0063] The first-stage absorption liquid: the mass concentration of potassium humate is 8wt%, and the pH is 10.

[0064] The second-stage absorption liquid: the mass concentration ratio of potassium humate and sodium chlorite is 8:0.1, and the pH is 9.

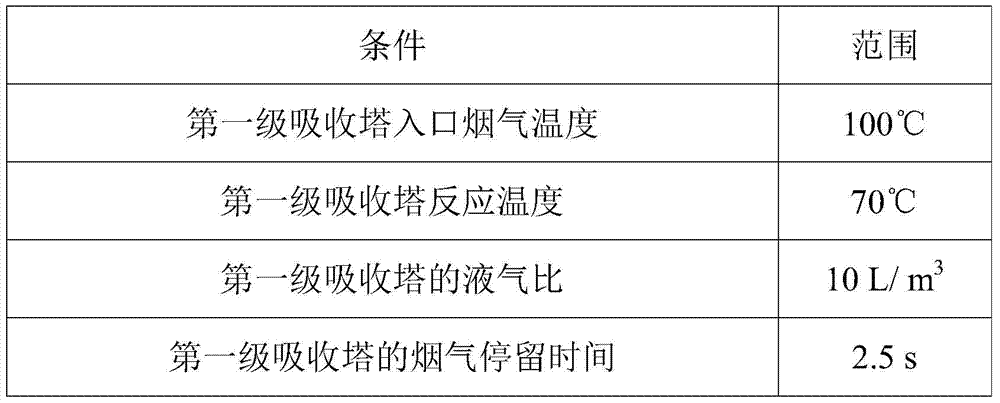

[0065] The reaction conditions of the double-loop flue gas purification system are shown in Table 2.

[0066] Table 2

[0067] condition

[0068] The flue gas is purified according to the above conditions, and it is detected that the desulfurization efficiency reaches 97%, the denitrification efficiency reaches 81%, the mercury removal efficiency reaches 86%, and the CO 2 , HCl and HBr removal efficiencies were 48%, 90% and 80%.

Embodiment 2

[0070] The first-stage absorption liquid: the mass concentration of potassium humate is 10wt%, and the pH is 11.

[0071] The second-stage absorption liquid: the mass concentration ratio of potassium humate and sodium chlorite is 6:0.5, and the pH is 8.5.

[0072] The reaction conditions of the optimized double-loop flue gas purification system are shown in Table 3.

[0073] table 3

[0074] condition

[0075] The flue gas is purified according to the above conditions, and it is detected that the desulfurization efficiency reaches 98%, the denitrification efficiency reaches 83%, the mercury removal efficiency reaches 90%, and the CO 2 , HCl and HBr removal efficiencies were 46%, 91% and 83%.

Embodiment 3

[0077] The first-stage absorption liquid: the mass concentration of potassium humate is 12wt%, and the pH is 12.

[0078] The second-stage absorption liquid: the mass concentration ratio of potassium humate and sodium chlorite is 6:0.3, and the pH is 8.

[0079] The reaction conditions of the optimized double-loop flue gas purification system are shown in Table 4.

[0080] Table 4

[0081]

[0082]

[0083] The flue gas is purified according to the above conditions, and it is detected that the desulfurization efficiency reaches 99%, the denitrification efficiency reaches 84%, the mercury removal efficiency reaches 88%, and the CO 2 , HCl and HBr removal efficiencies were 48%, 87% and 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com