Patents

Literature

124results about How to "Increase work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

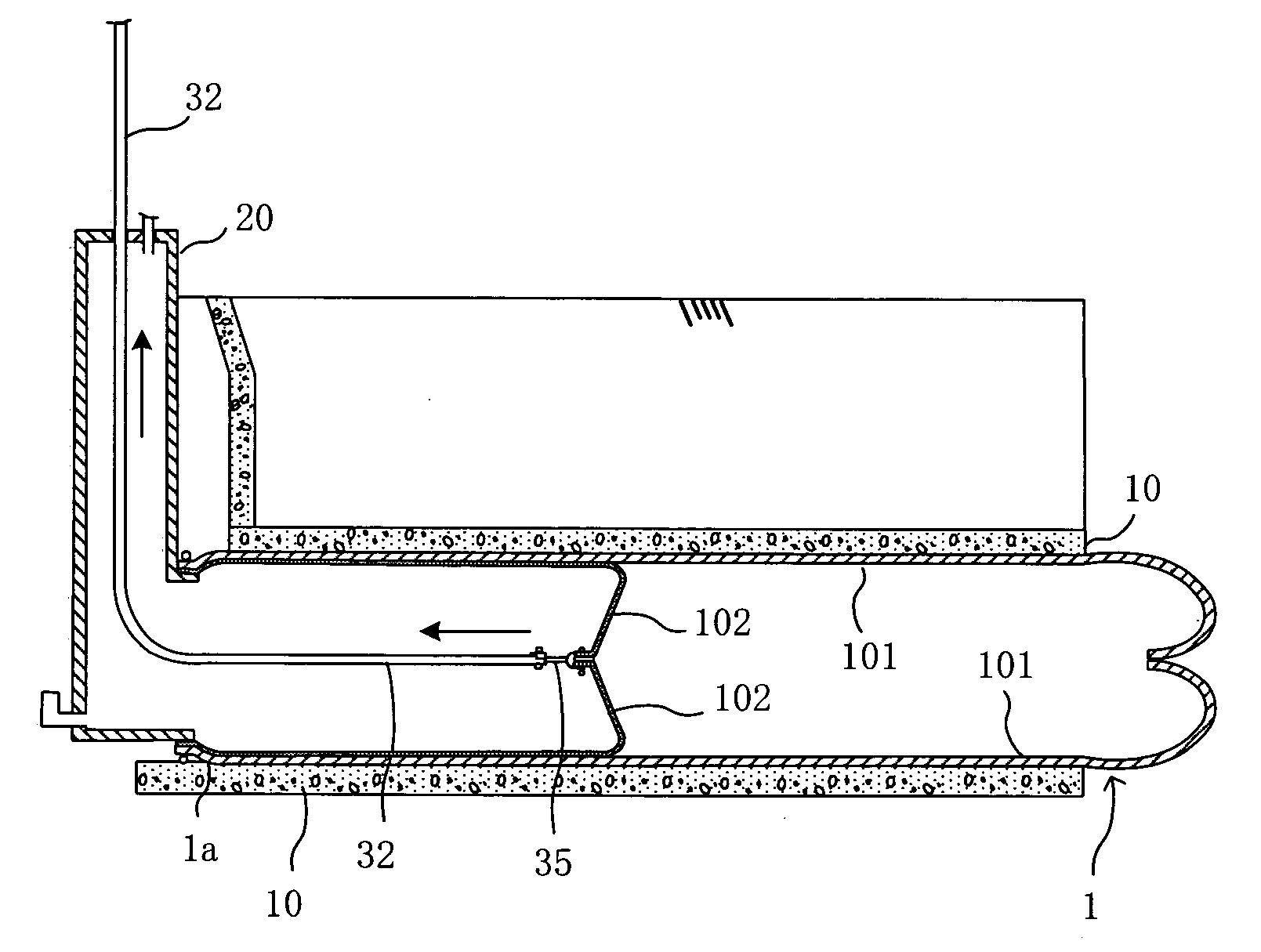

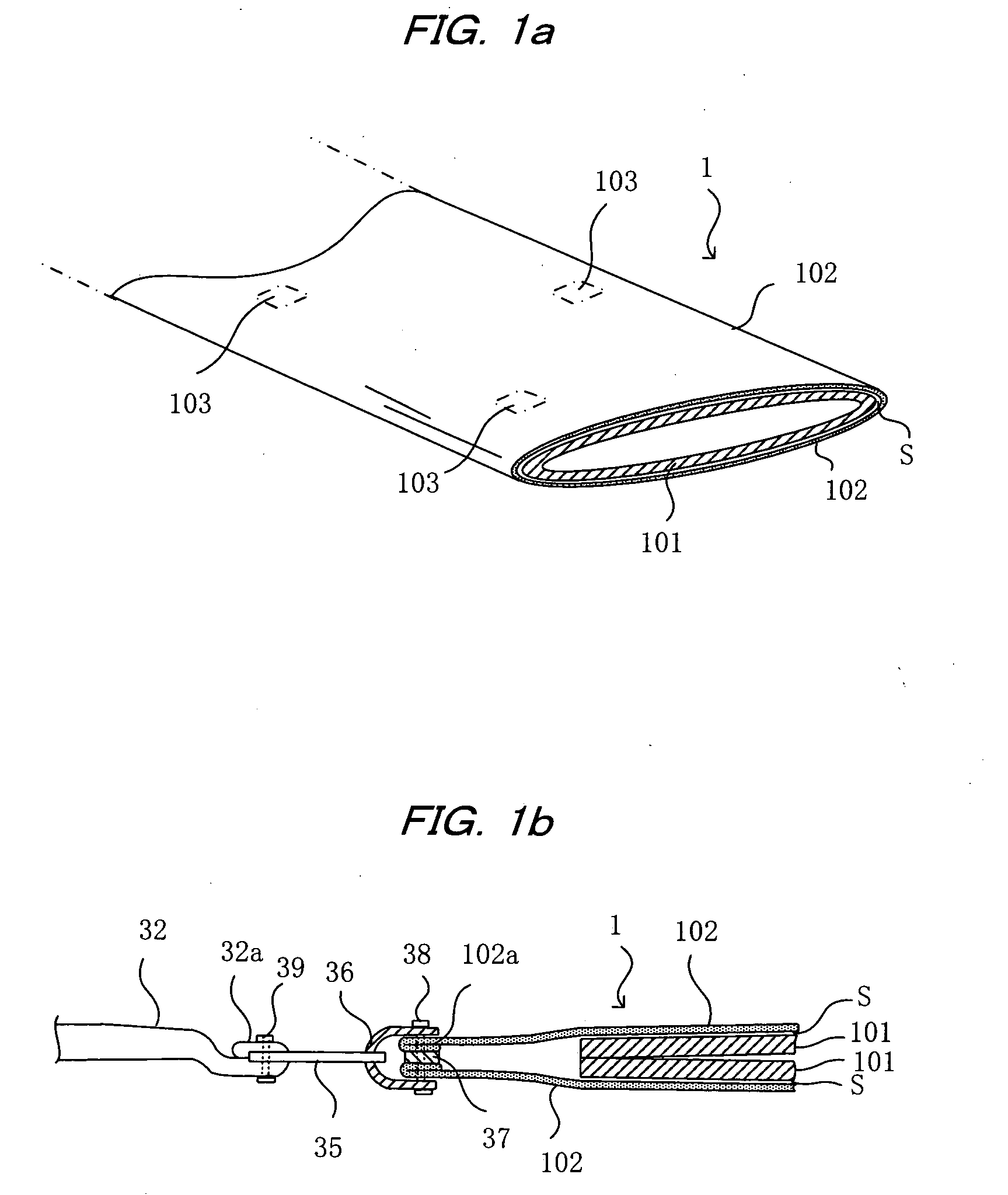

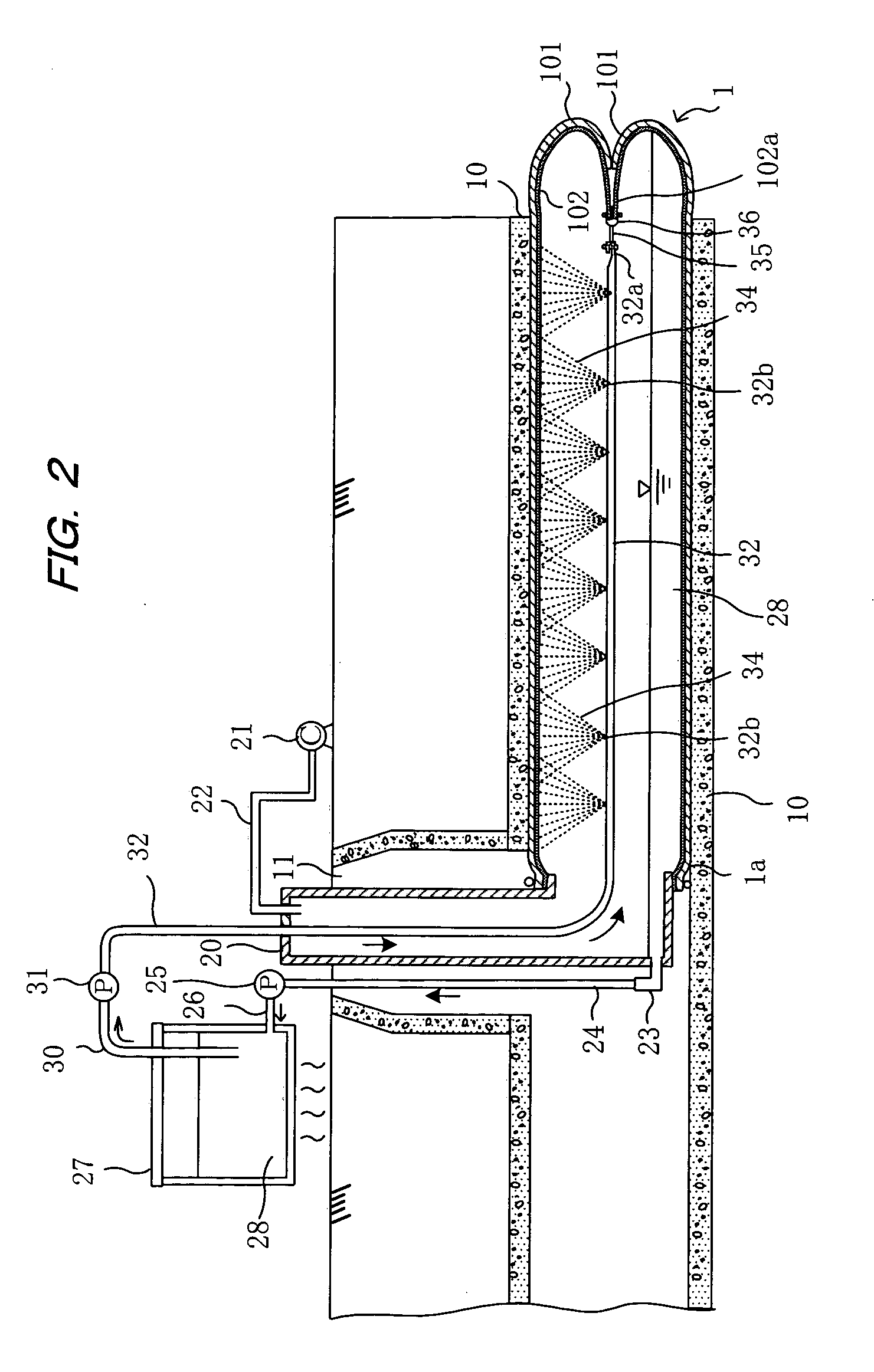

Pipe-lining material and pipe-lining method

InactiveUS20100154187A1Reduction factorIncrease the number ofPipe elementsAbsorbent materialChemistry

The pipe-lining material includes a pipe-shaped resin absorbent material impregnated with a liquid curable resin, and a tube that covers the pipe-shaped resin absorbent material and that can be removed from the pipe-shaped resin absorbent material. The curable resin impregnated in the pipe-shaped resin absorbent material is cured in a state in which the pipe-lining material is pressed against the internal peripheral surface of the existing pipe, the tube covering the pipe-shaped resin absorbent material of the pipe-lining material is removed from the pipe-shaped resin absorbent material after the curable resin impregnated in the pipe-shaped resin absorbent material has been cured, and the surface of the pipe-shaped resin absorbent material having the cured resin is used as the internal peripheral surface of the rehabilitated existing pipe. The internal peripheral surface can be prevented from becoming rough and the coefficient of roughness of the internal peripheral surface of the rehabilitated existing pipe can be reduced because the internal peripheral surface of the existing pipe is a cured, firm resin surface.

Owner:SHONAN GOSEI JUSHI SEISAKUSHO KK

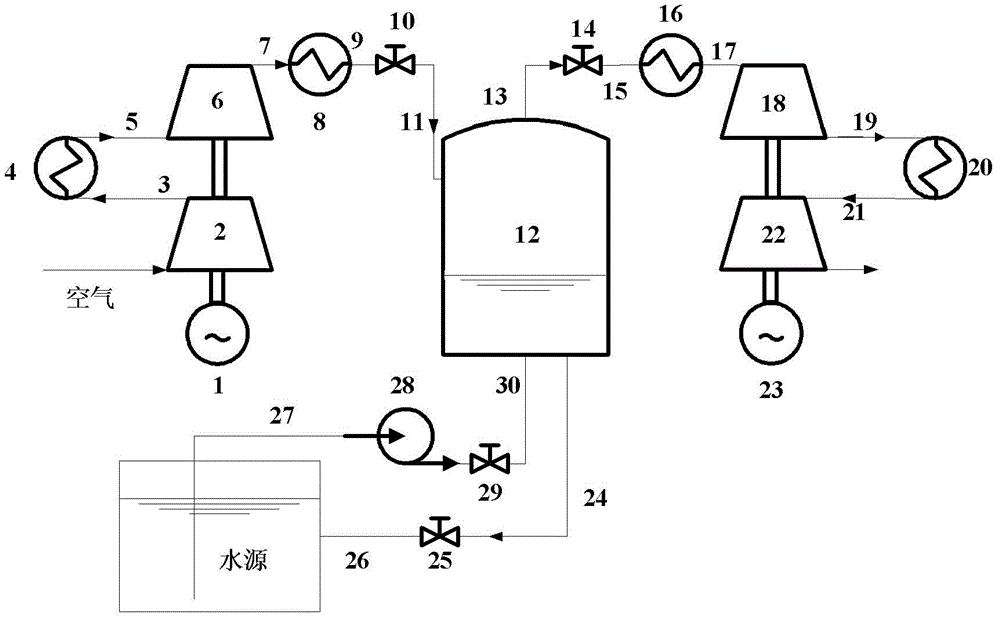

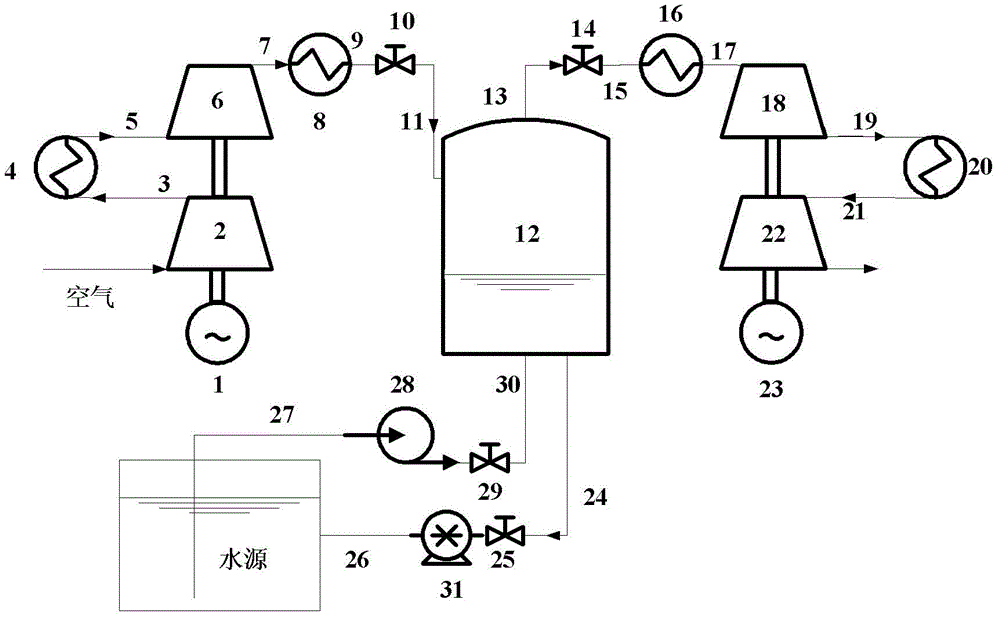

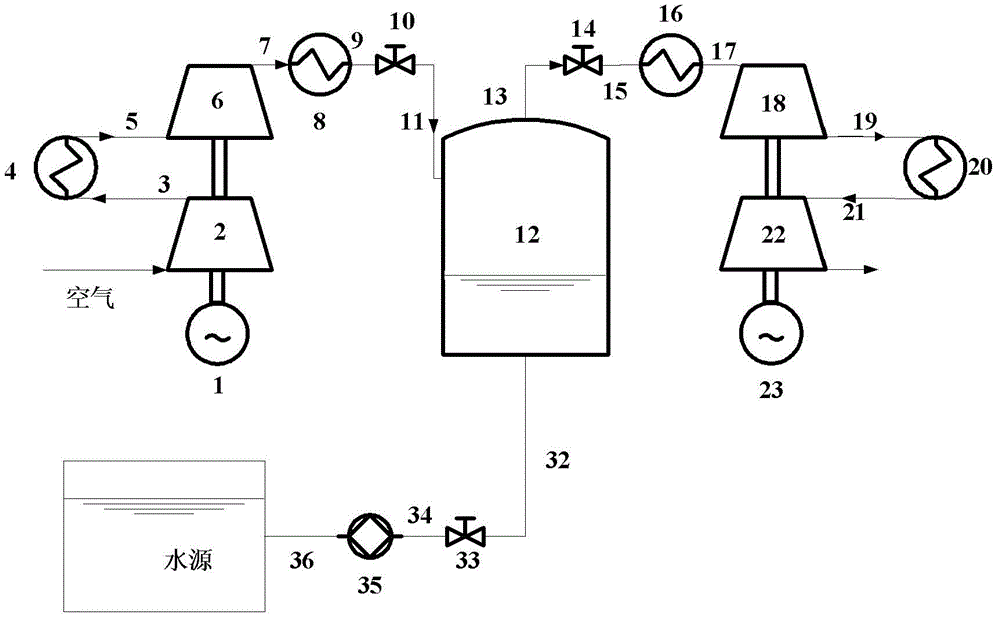

Compressed air energy storage system

ActiveCN104005802AAddressing Changes in PressureImprove efficiencySteam engine plantsThermal energy storageWater source

The invention provides a compressed air energy storage system. The compressed air energy storage system comprises an energy storage assembly, an air storage device, a water pump and an energy releasing assembly; the air storage device is a closed container for prestoring water; the water pump is arranged on a pipeline of the gas storage device; the energy storage assembly comprises an electromotor and a compressed unit which is provided with at least one compressor; a rotary shaft of the compressed unit is connected with a rotary shaft of the electromotor; an air outlet of the compressed unit is connected with an air inlet of the air storage device through a valve; the energy releasing assembly comprises an electric generator and an expansion unit which is provided with at least one expansion machine; a rotary shaft of the expansion unit is connected with a rotary shaft of the electric generator; an air inlet of the expansion unit is connected with an air outlet of the gas storage device through a valve. According to the compressed air energy storage system, the expansion unit and the compressed unit work under constant pressure and the energy storage system is high in efficiency and good in safety.

Owner:中储国能(北京)技术有限公司

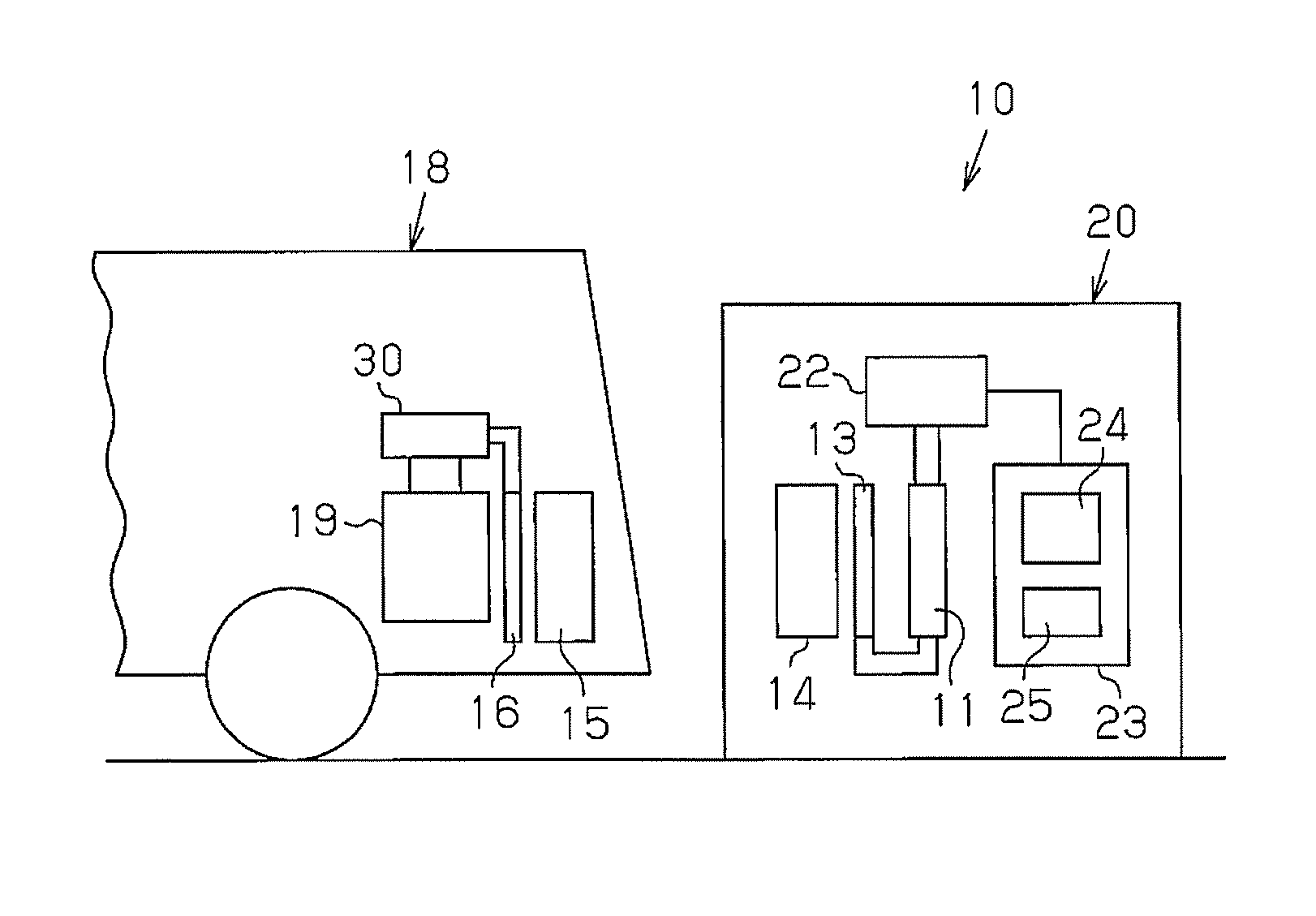

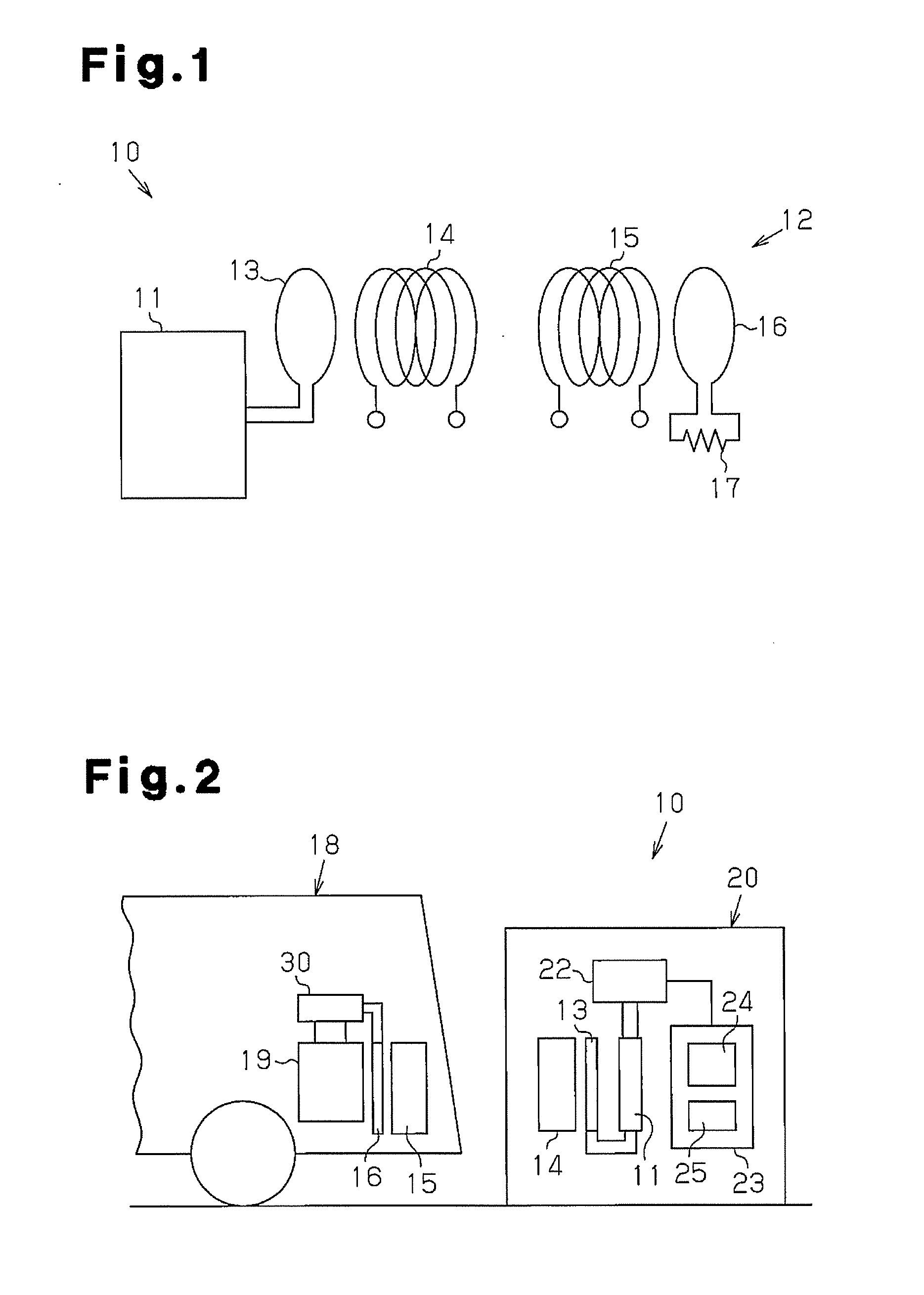

Non-contact power transmission device

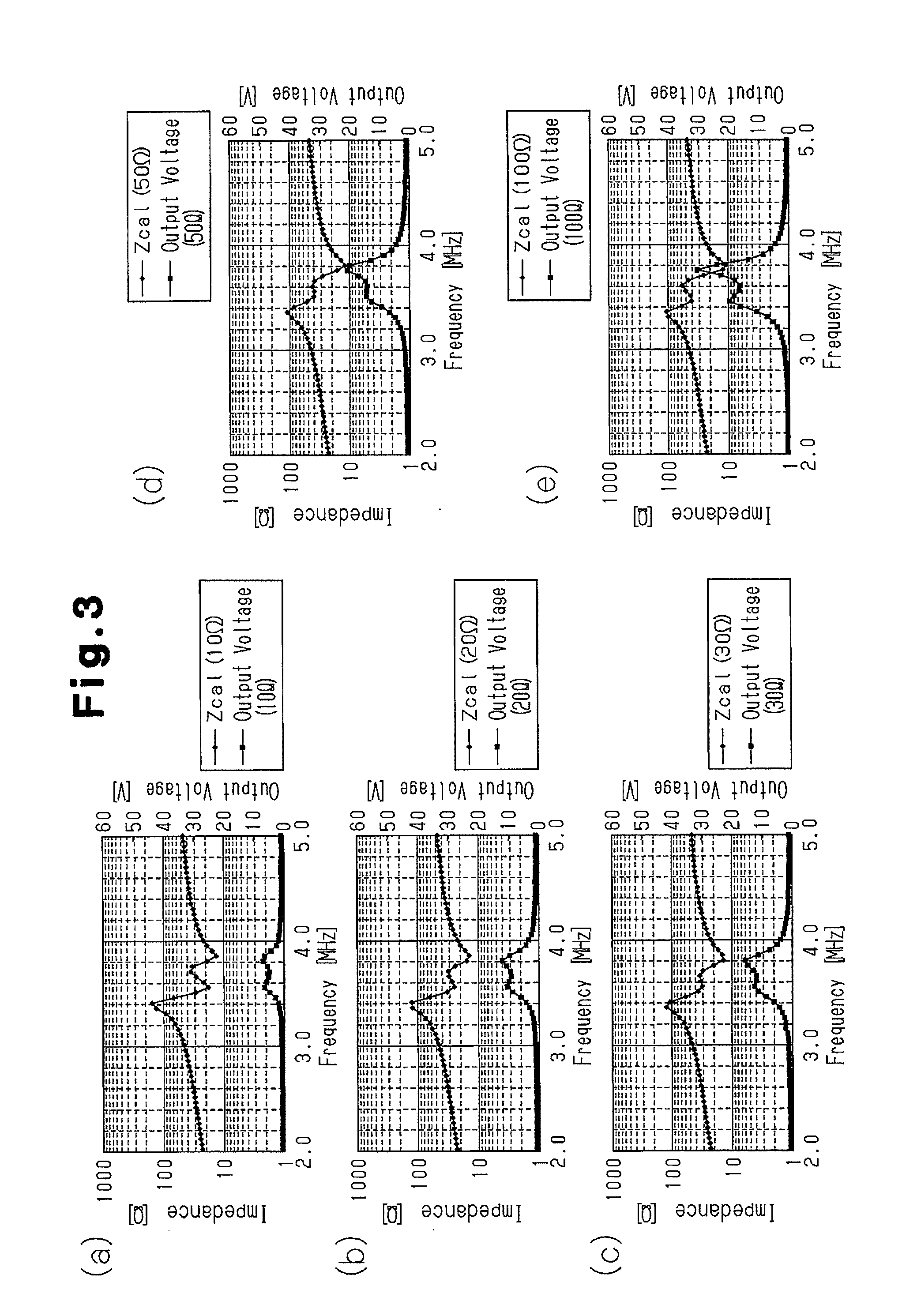

InactiveUS20120104998A1Efficiently performIncrease workRail devicesCharging stationsPhysicsPower transmission

A non-contact power transmission device includes an alternating current power supply, a resonant system, a load, an impedance measuring section and an analyzing section. The resonant system has a primary coil connected to the alternating current power supply, a primary-side resonant coil, a secondary-side resonant coil and a secondary coil. The load is connected to the secondary coil. The impedance measuring section can measure the input impedance of the resonant system. The analyzing section analyzes the measurement results obtained from the impedance measuring section.

Owner:TOYOTA IND CORP +1

Compound red sage root freezing-dried powder injection containing salvianolic acid B and its preparation method

InactiveCN101085000AIncrease workIncrease cardiac outputPowder deliveryHydroxy compound active ingredientsSalvianolic acid BFreeze-drying

The invention provides a compound red sage root freeze dried powder injection containing salvianolic acid B and its preparing process, wherein the injection comprises root of red rooted saliva, notoginseng and borneol, and is prepared through extracting root of red rooted saliva and notoginseng to obtain red sage root extract, pseudo-ginseng extract, dissolving baras camphor with right amount of ethanol, coating with beta-cyclodextrin, charging injection for water into red sage root extract, notoginseng or red sage root and notoginseng extracts for dissolving, boiling, cooling down, filtering, mixing filtrate with baras camphor beta-CD inclusion solution, charging mannitol, adding right amount of water for injection, adjusting pH, and freeze-drying. In the obtained freeze dried injection, calculated by salvianolic acid B (C36H30O16), the content of red sage root 6.25-100.00mg / g freeze-dried powder solid.

Owner:TIANJIN TASLY ZHIJIAO PHARMA

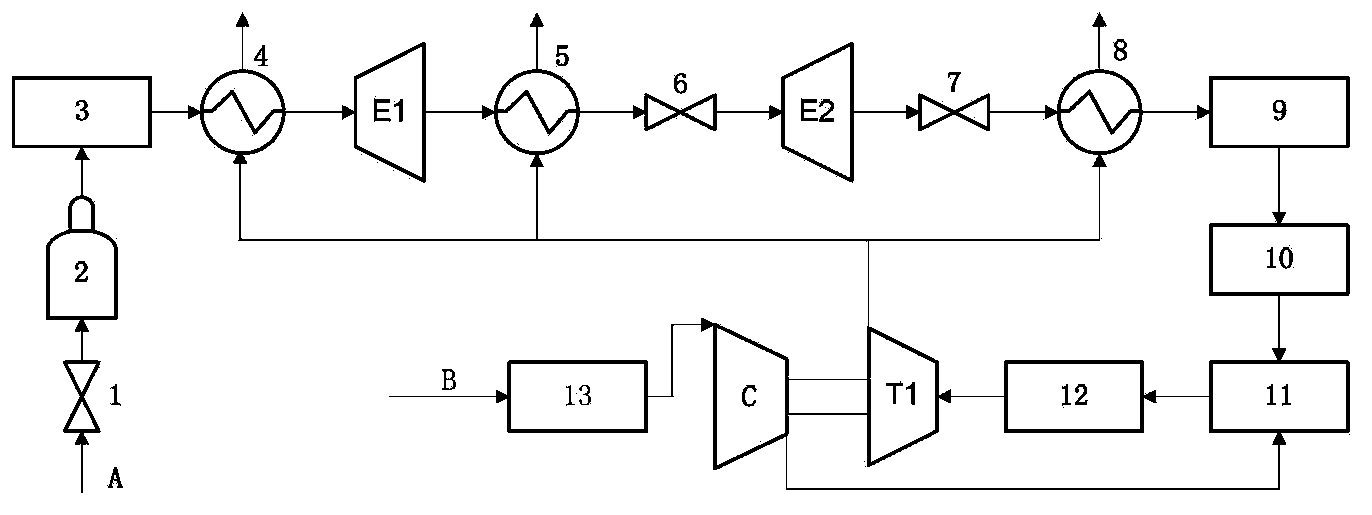

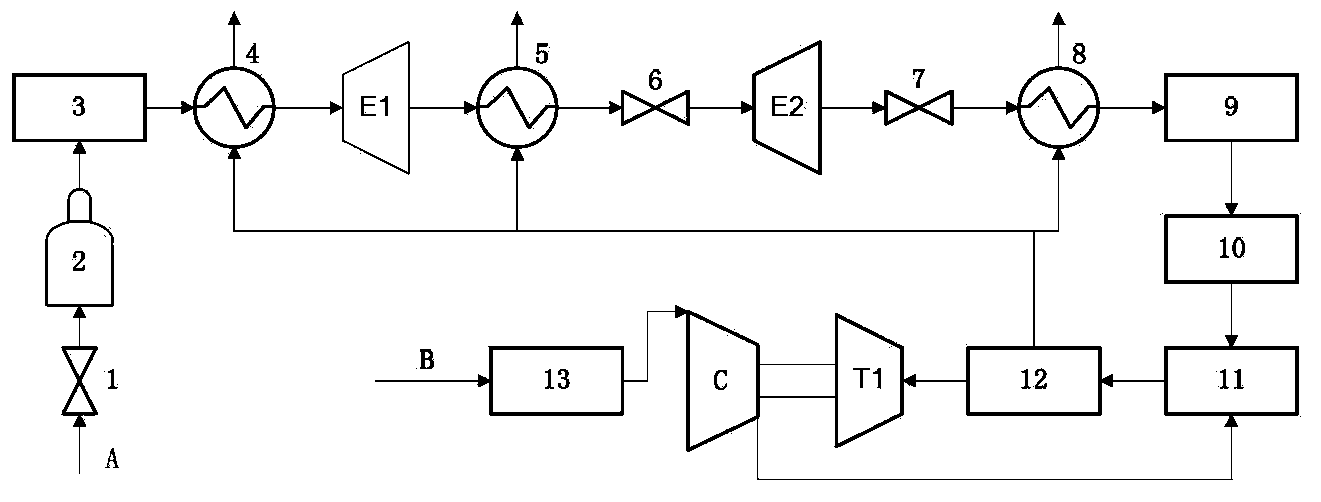

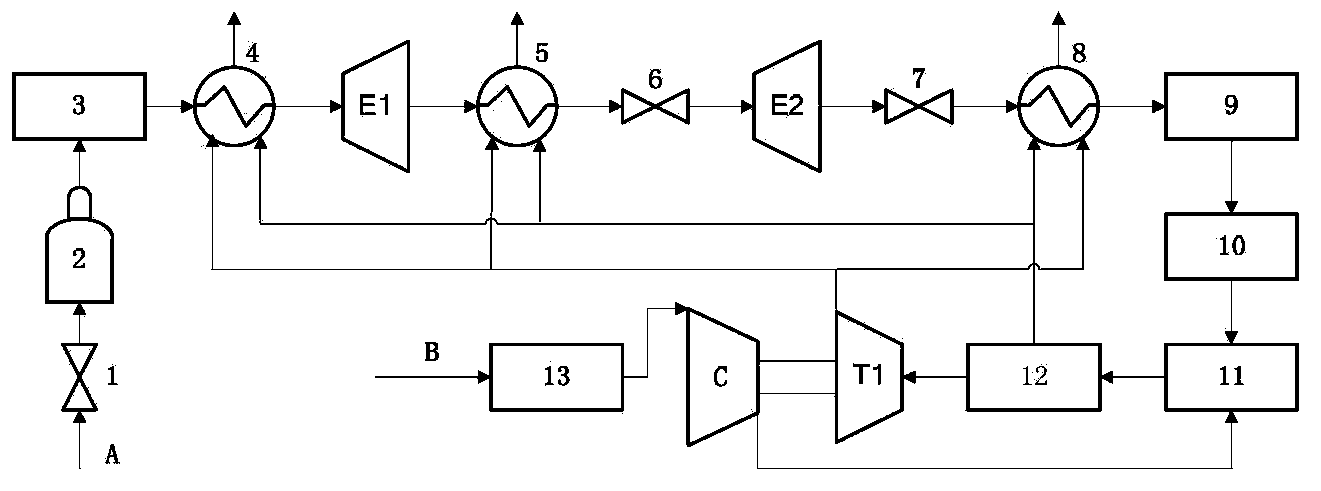

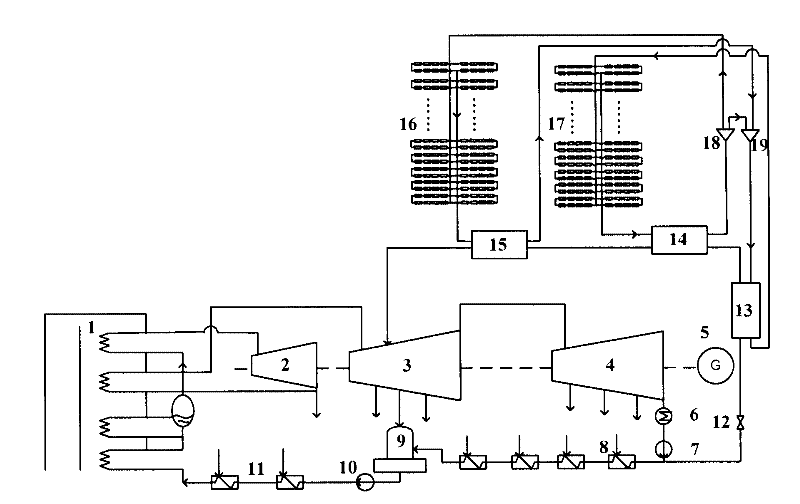

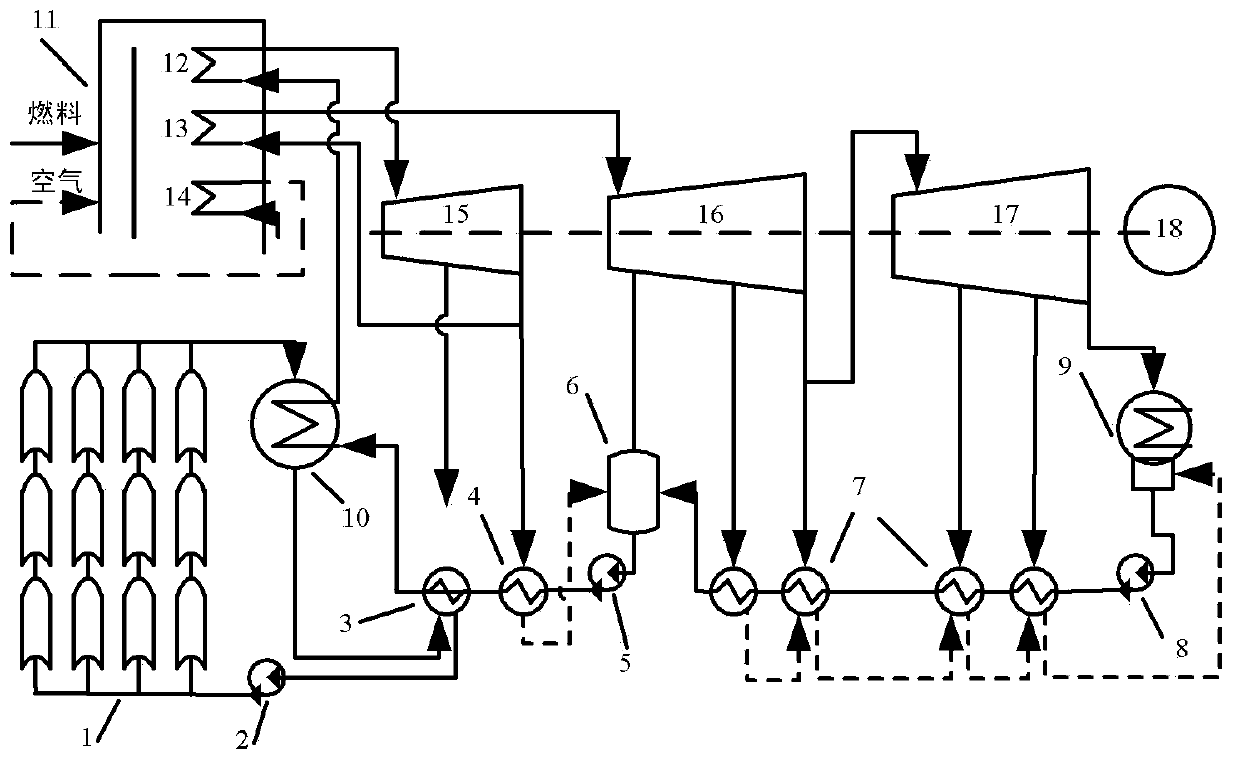

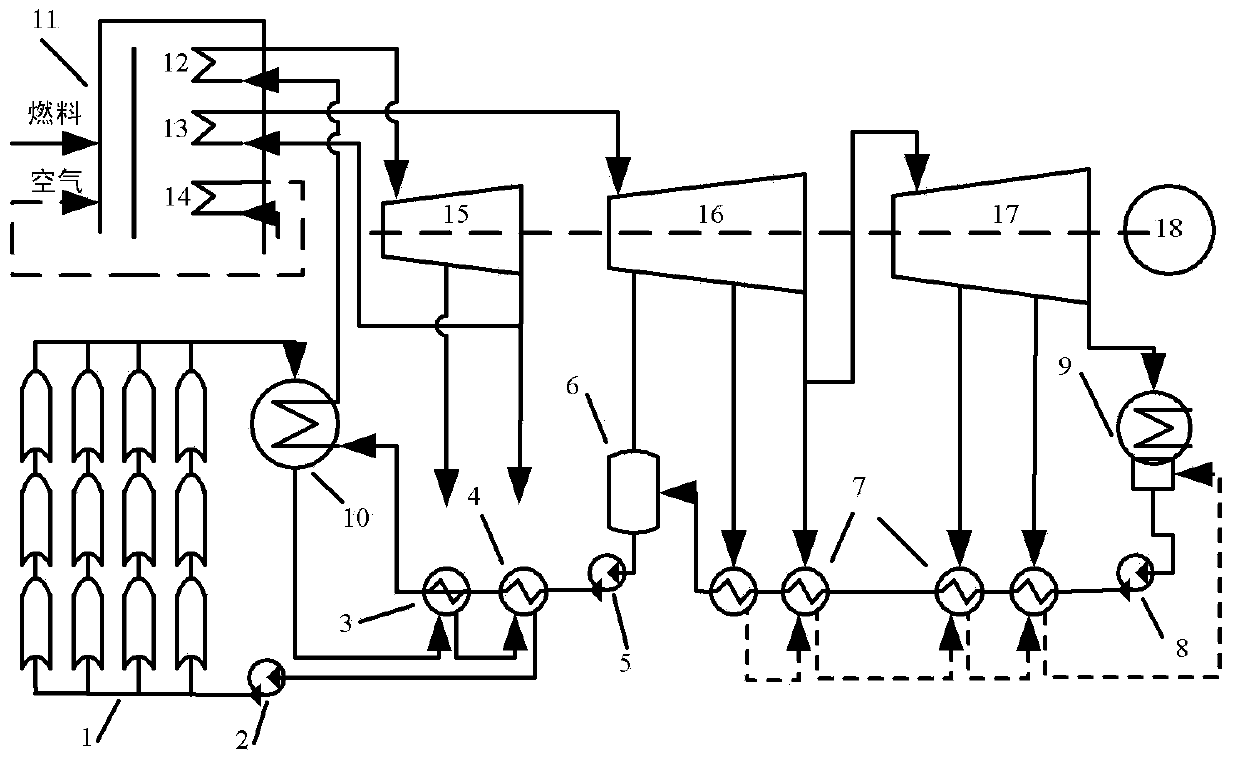

System and method for comprehensively utilizing residual heat of compressed natural gas engine (CNGE)

ActiveCN103437870APrevent "freezing" phenomenonAvoid icingInternal combustion piston enginesFuel supply apparatusNatural gas consumptionCompressed natural gas

The invention discloses a system and a method for comprehensively utilizing residual heat of a compressed natural gas engine (CNGE), which relates to a novel energy-saving technology of an engine. In the method, high-pressure fuel gas output by a high-pressure gas cylinder is heated with tail gas and / or the residual heat of water in a cylinder sleeve by using a residual heat exchanger, and the high-pressure fuel gas is depressurized and treated by using two stages of expansion machine devices (a variable-expansion-ratio expansion machine serving as one stage and a fixed-expansion-ratio expansion machine serving as the other stage), so that the fuel gas pressure needed by engine combustion is reached; meanwhile, pressure energy and residual heat are utilized comprehensively by using the expansion machines, so that the output shaft power of the engine is increased, the system efficiency of the engine is increased, the driving mileage is increased, and natural gas consumption is reduced. The device disclosed by the invention is compact in structure, and is reliable in performance; 80 percent of energy consumed in a natural gas compressing process is recovered, so that the advantage of natural gas serving as engine fuel gas is improved remarkably.

Owner:中科九朗(北京)能源科技有限公司

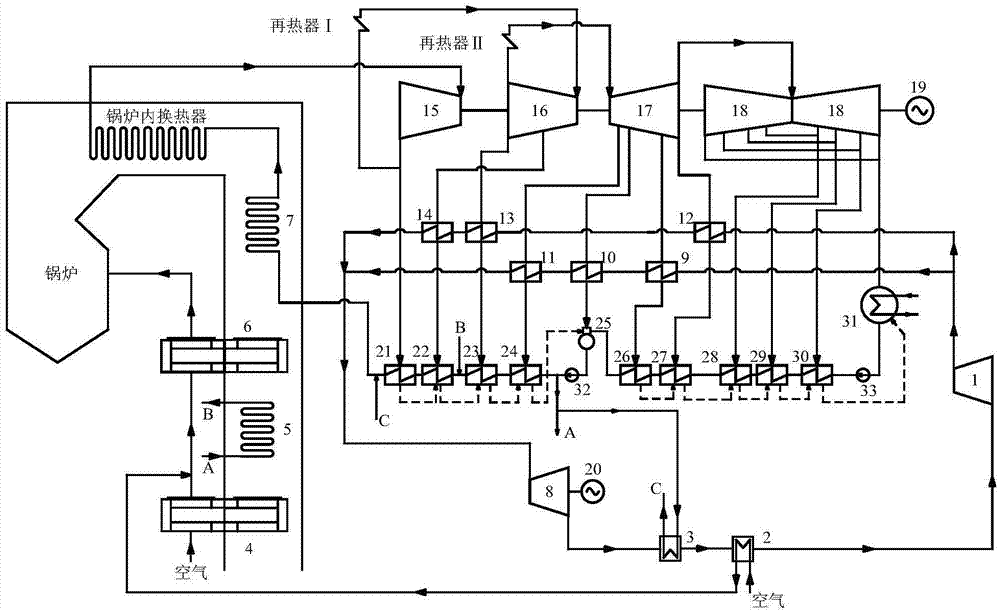

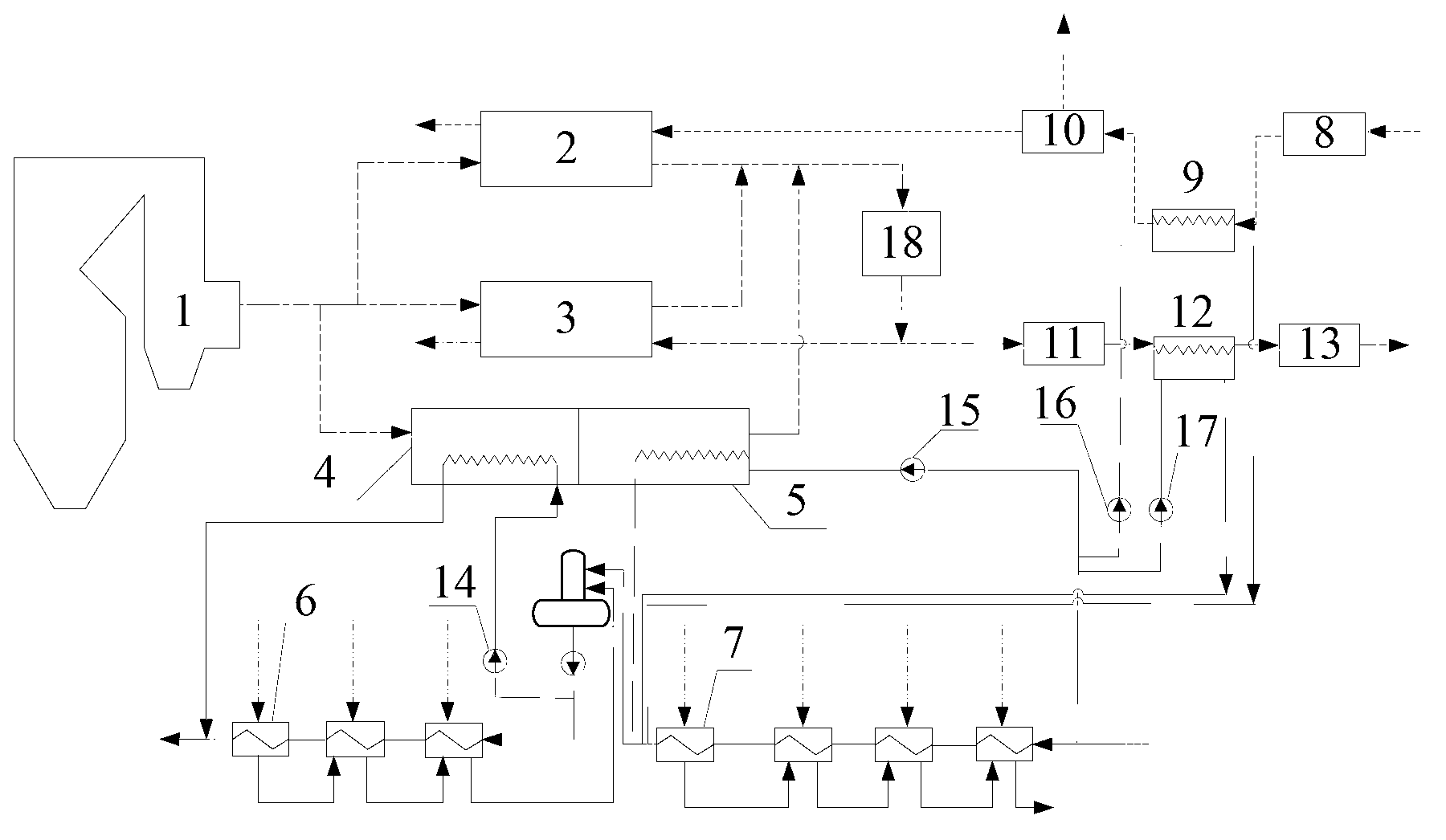

Coal-fired secondary reheating steam turbine generator unit integrated with supercritical CO2 circulation

ActiveCN107989667ALower extraction temperatureReduce superheatSteam useIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention belongs to the technical field of secondary reheating steam turbine generating and energy saving and discloses a coal-fired secondary reheating steam turbine generator unit integrated with supercritical CO2 circulation. The unit comprises a coal-fired boiler, a secondary reheating steam turbine generator unit and a supercritical CO2 circulating generation system. Six-stage extractionsteam connected with a high pressure cylinder and an intermediate pressure cylinder is connected with steam-CO2 heat exchangers and enters corresponding feed water regenerative heaters after heatingCO2; in the CO2 circulating generation system, CO2 at an outlet of a compressor is divided into two streams, the two streams are heated by three stages of steam-CO2 heat exchangers respectively and are converged to enter a CO2 turbine for working, and CO2 exhaust enters the compressor after passing through a CO2-feed water heater and a CO2-air preheater sequentially; in a flue at the tail of the boiler, air is divided into two streams, and the two streams are preheated by the CO2-air preheater and a low-temperature air preheater respectively and are converged to enter a main air preheater. Bythe aid of the integrated system, the superheat degree of regenerative extraction steam of the secondary reheating unit and the exergy loss of air preheating are substantially reduced, the work of a steam turbine is increased, and the efficiency is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

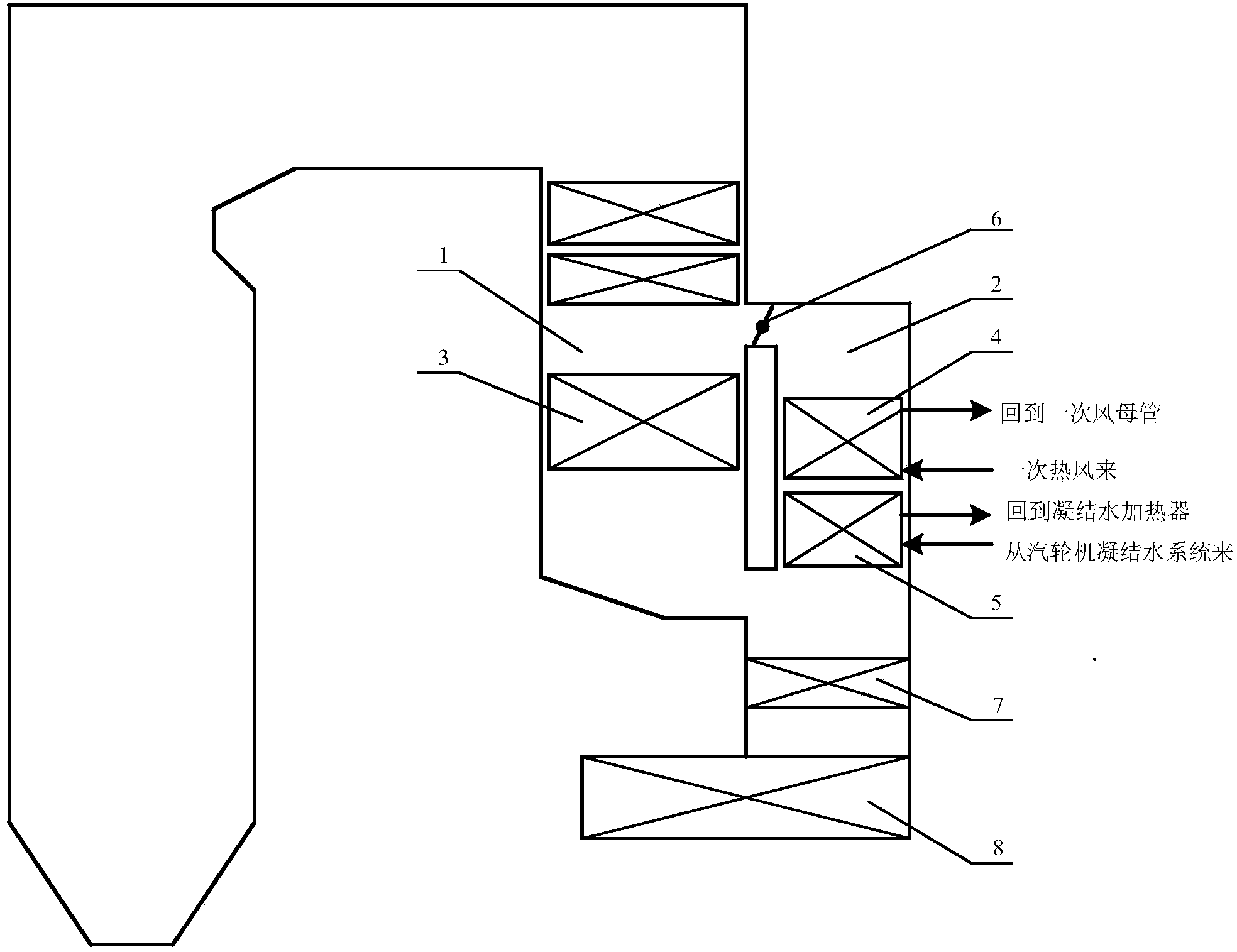

Waste heat utilization system capable of guaranteeing lignite boiler dry output and SCR safe flue gas temperature

InactiveCN103486566AReduce coal consumptionIncrease workLiquid degasificationFeed-water heatersFlueProcess engineering

The invention discloses a bootstrap system capable of guaranteeing lignite boiler dry output and SCR safe flue gas temperature. The bootstrap system comprises a boiler tail flue and a flue gas denitrification SCR which is arranged at the tail end of the boil tail flue. A bypass flue communicated with the boil tail flue is further parallelly connected between a flue gas inlet of an economizer and a flue gas inlet of the flue gas denitrification SCR. The bypass flue is internally and sequentially provided with a primary-air tubular heater and a low-pressure economizer which are used for lowering temperature of flue gas entering the flue gas denitrification SCR. Due to the arrangement that the bypass flue is additionally arranged on the tail portion of a boiler, and the primary-air heater is arranged on the upper portion of the bypass flue, primary-air temperature is ensured to meet requirements of a coal pulverizing system. The amount of flue gas passing through the economizer can be regulated by the bypass flue, so that flue gas temperature at the exit of the economizer can be regulated. The primary air is heated to the temperature as required by the high-temperature flue gas at the inlet of the economizer, and meanwhile, the flue gas temperature in the bypass flue is lowered through the low-pressure economizer, so that the flue gas temperature at the inlet of the SCR can meet the requirements of catalyst.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

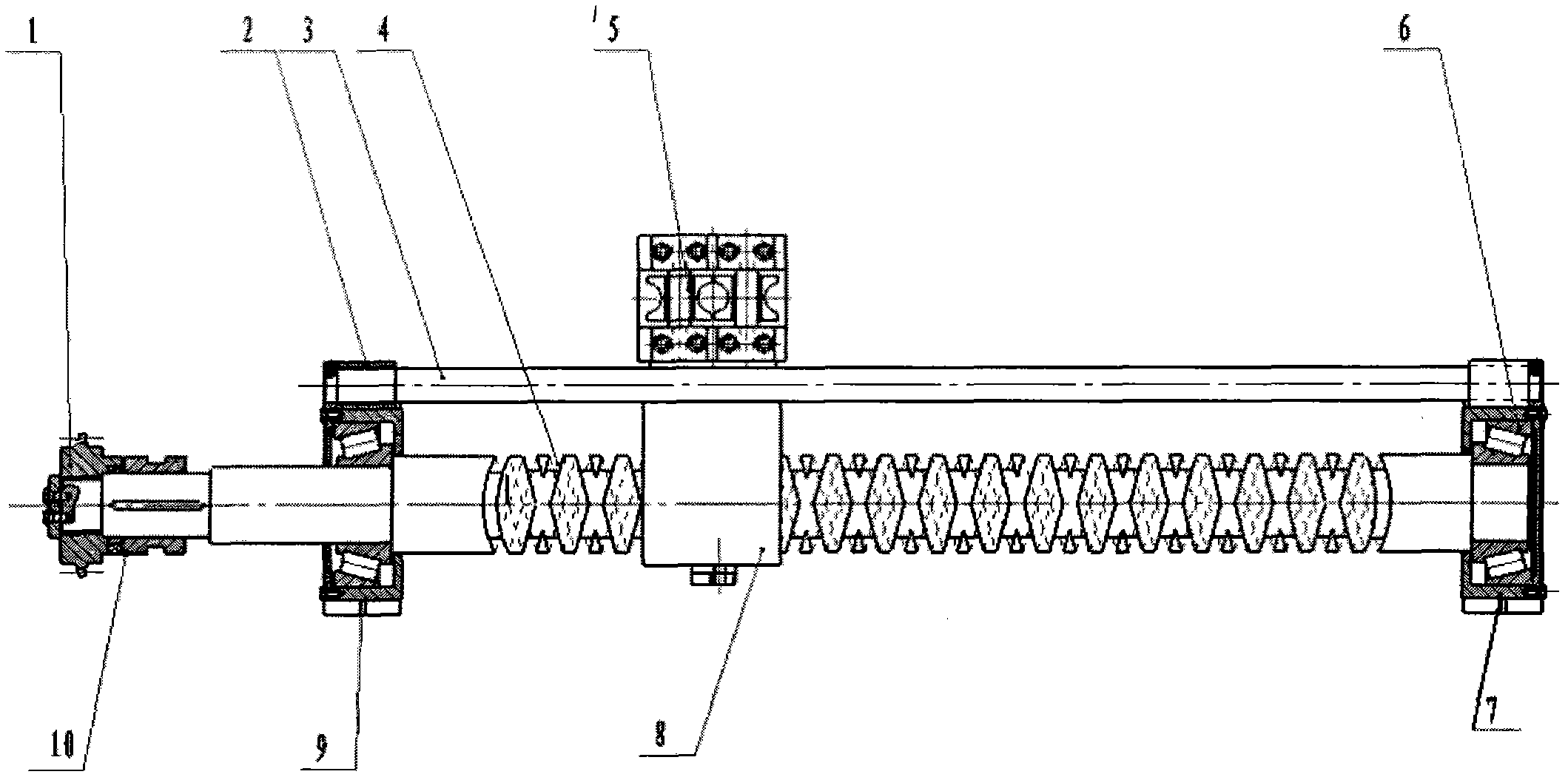

Winch rolling spiral rope arranging method

The invention discloses a winch rolling spiral rope arranging method which includes: (a) first, a chain wheel (1) is driven by a chain to drive a bi-directional threaded rod (4) to rotate; (b) then, the bi-directional threaded rod (4) drives a sliding block nut (8) matched with the bi-directional threaded rod (4) through threads to move; (c) the sliding block nut (8) drives a rope arranging support (5) on the sliding block nut (8) to move to generate linear movement for arranging ropes; (d) after the sliding block nut (8) moves to a limit position, the direction of motion of the sliding block nut (8) is changed; and (e) the sliding block nut (8) moves toward the reverse direction to drive the rope arranging support (5) connected with the sliding block nut (8), so that a reciprocating rope arranging process is completed. Even arrangement of steel wire ropes can be achieved, and the winch rolling spiral rope arranging method has the advantages of uniform-acceleration reversing and uniform working, prevents the steel wire ropes from being messy in order arrangement and pressing each other, and avoids rope disorder and the phenomena of severe deformation, torsion, bending and knotting of the steel wire ropes.

Owner:肖湘

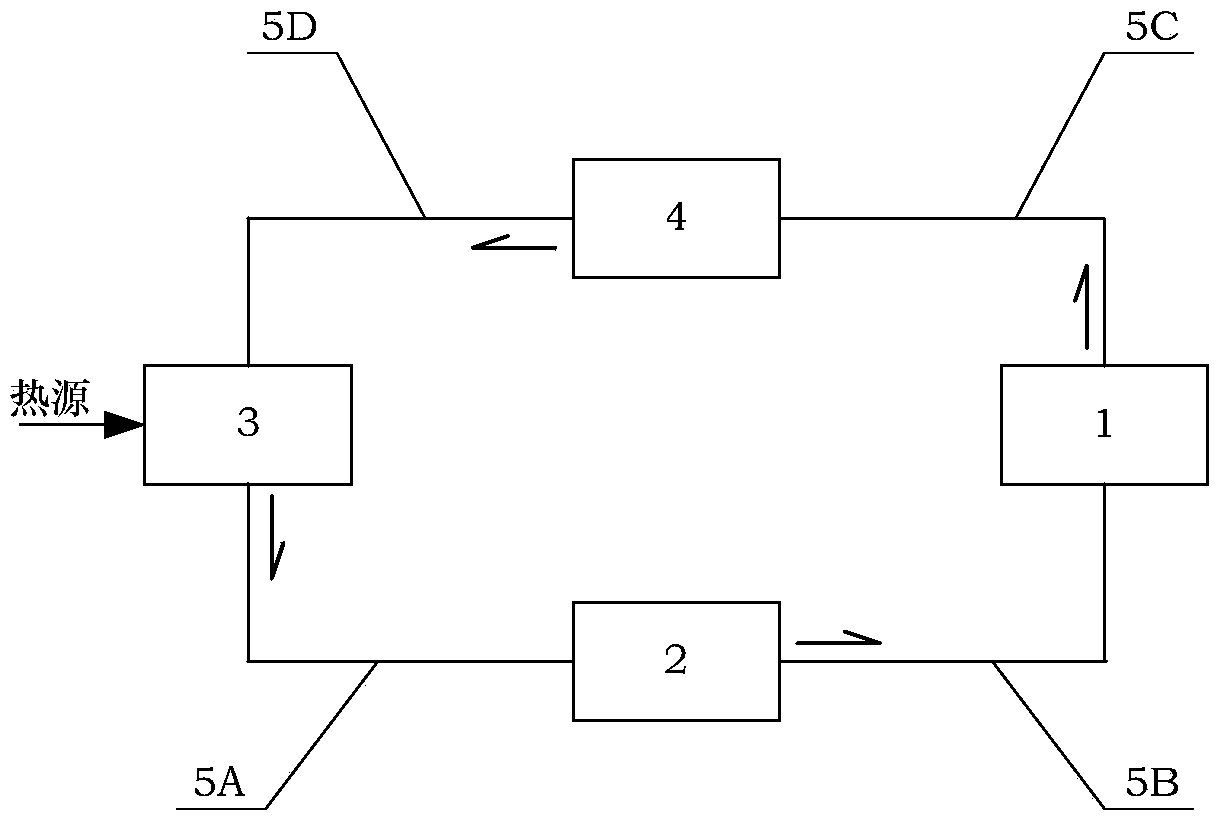

Steam-injection-type solar and thermal power station complementary generating system

InactiveCN102454563AIncrease workIncrease power generationSteam generation heating methodsFrom solar energySolar technologySuperheater

The invention discloses a steam-injection-type solar and thermal power station complementary generating system. The generating system comprises a first parabolic-trough-type solar collector, a solar steam generator, a diverter, a second parabolic-trough-type solar collector, a solar superheater, a mixer, a solar preheater, a coal burning boiler as well as a high pressure cylinder, an intermediate pressure cylinder and a low pressure steam cylinder of a steam turbine, wherein feedwater passes through the solar preheater, the solar steam generator and the solar superheater, and indirectly absorbs solar energy through conduction oil or enters the solar collectors to absorb the solar energy so as to be converted into superheated steam, and the superheated steam is injected the high pressure cylinder or the intermediate pressure cylinder of the steam turbine; and the superheated steam is mixed with the superheated seam generated by the coal burning boiler in the high pressure cylinder or the intermediate pressure cylinder of the steam turbine, and the mixture expands to do work in the high pressure cylinder or the intermediate pressure cylinder of the steam turbine to output power to a generator so as to carry out electricity generation. The generating system provided by the invention can be used for realizing the dilatation and consumption reduction of a thermal power station and solving the problem of unstable and discontinuous solar energy, thereby being beneficial to the large-sale popularization and application of a solar energy technology.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

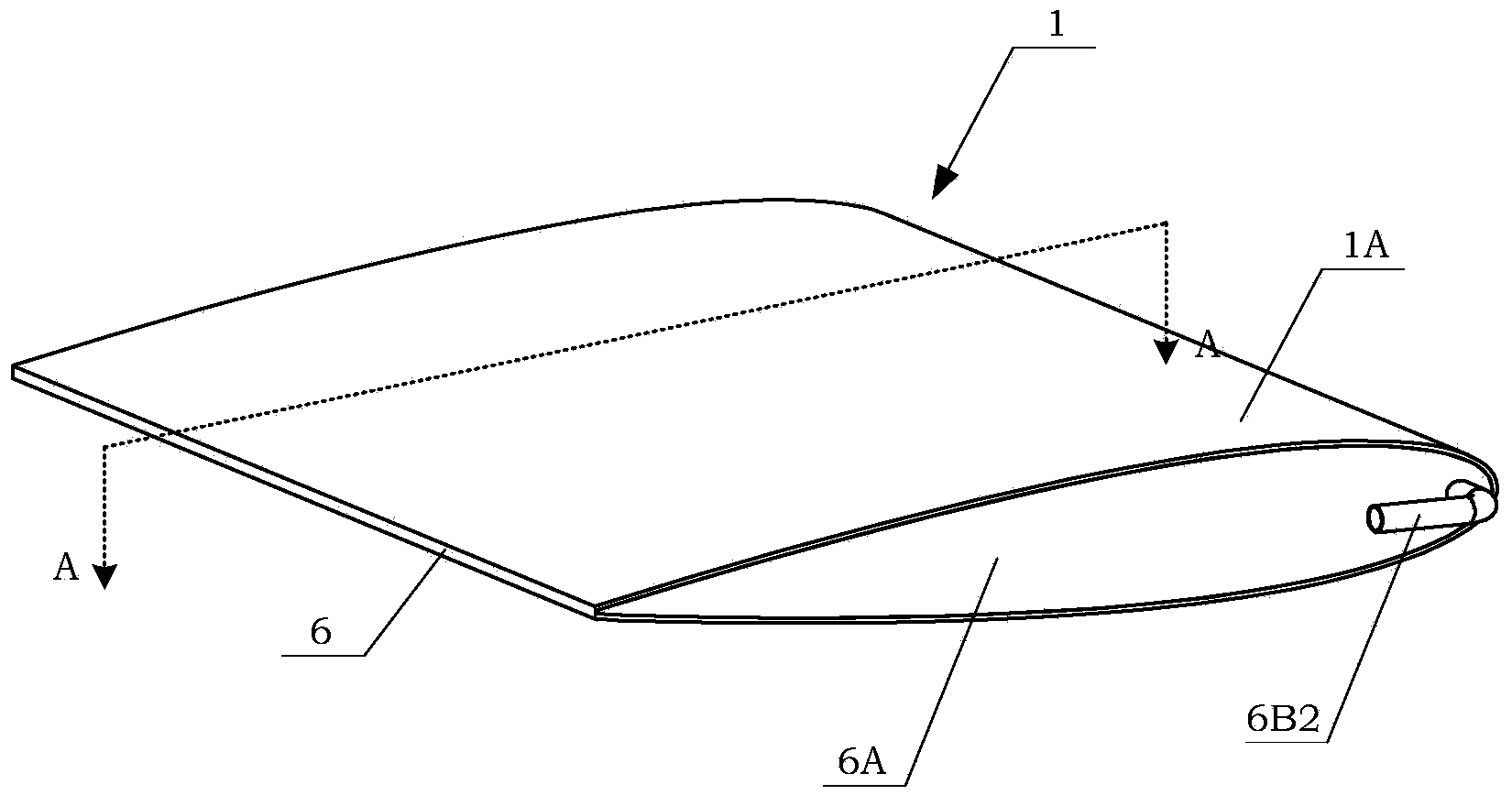

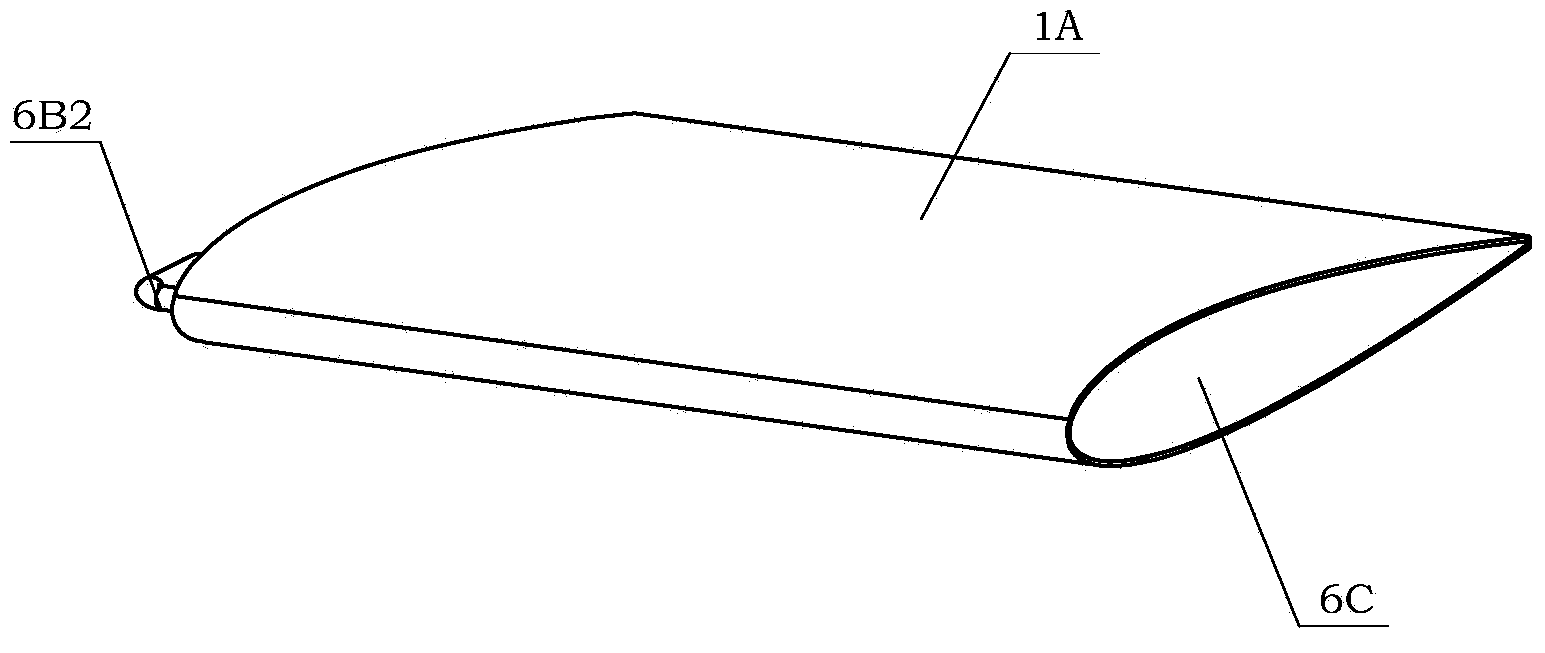

Novel wing icing prevention system using airborne waste heat

The invention discloses a novel wing icing prevention system using airborne waste heat. According to the system, the connection among a skin heat exchanger, a rotary compressor, an evaporator and an electronic expansion valve is realized through a pipeline; a liquid storage device is additionally arranged in an anti-icing cavity of each wing, and a double-skin structure is changed. According to the system disclosed by the invention, an evaporative-cycle anti-icing manner is adopted to an unmanned aerial vehicle, heat source heat of airborne electronic equipment is sufficiently absorbed by using the evaporator and the heat exchanger, is transferred to skin in a flute-shaped tube impact jet flow manner and is subjected to heat exchange with outside supercooling wet air, and the temperature of the skin is increased to the minimum anti-icing temperature, so as to reach the anti-icing effect.

Owner:BEIHANG UNIV

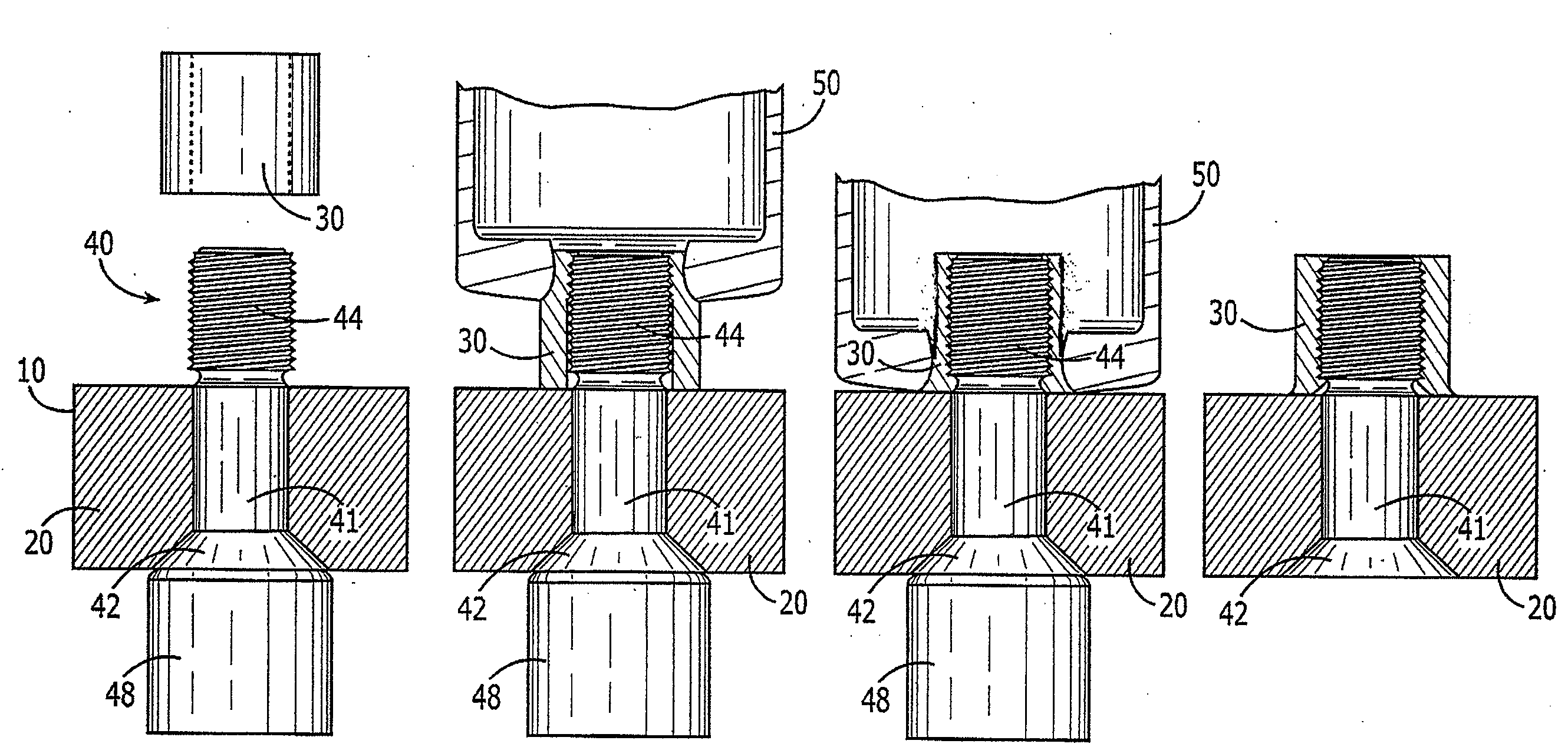

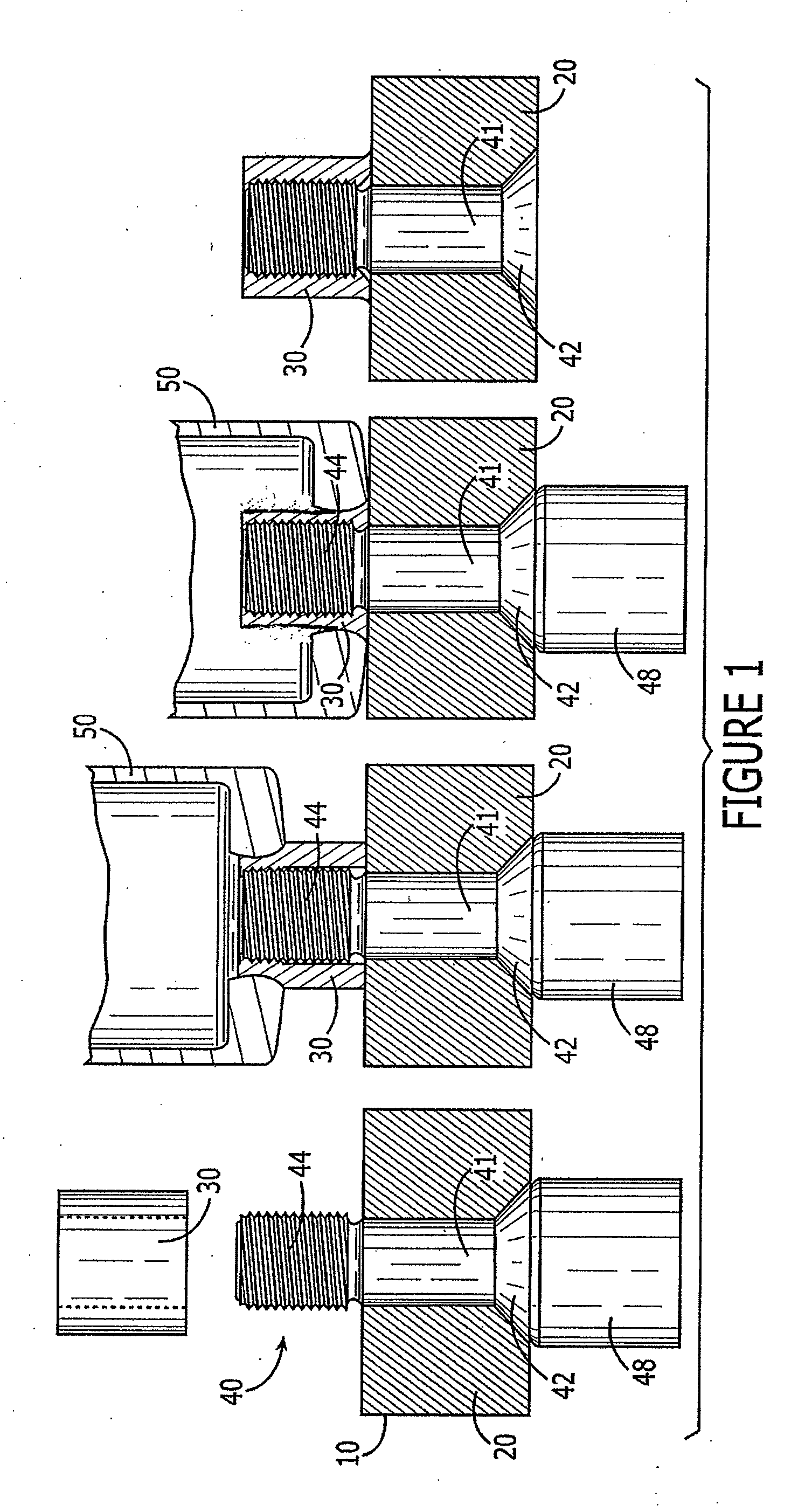

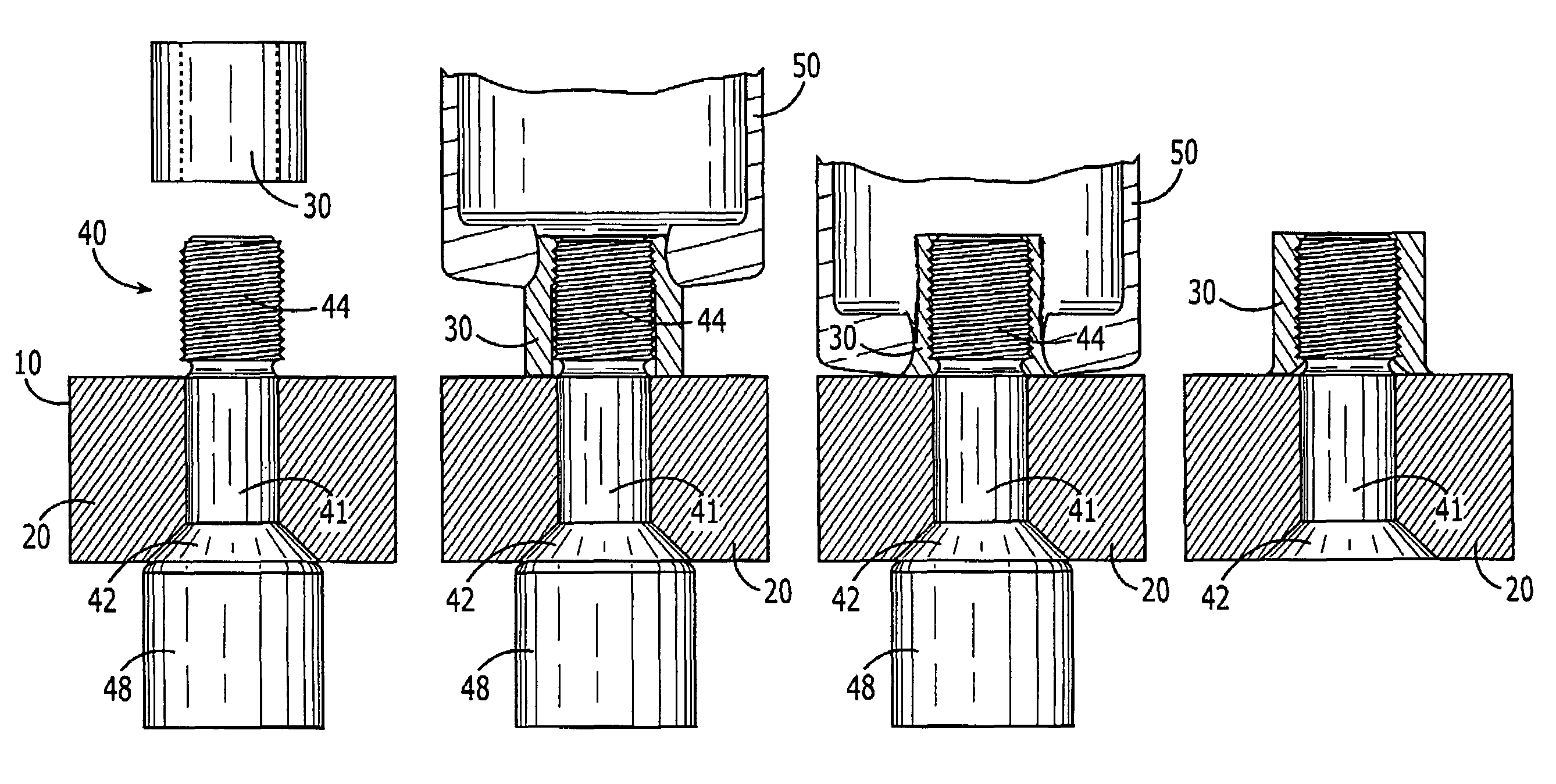

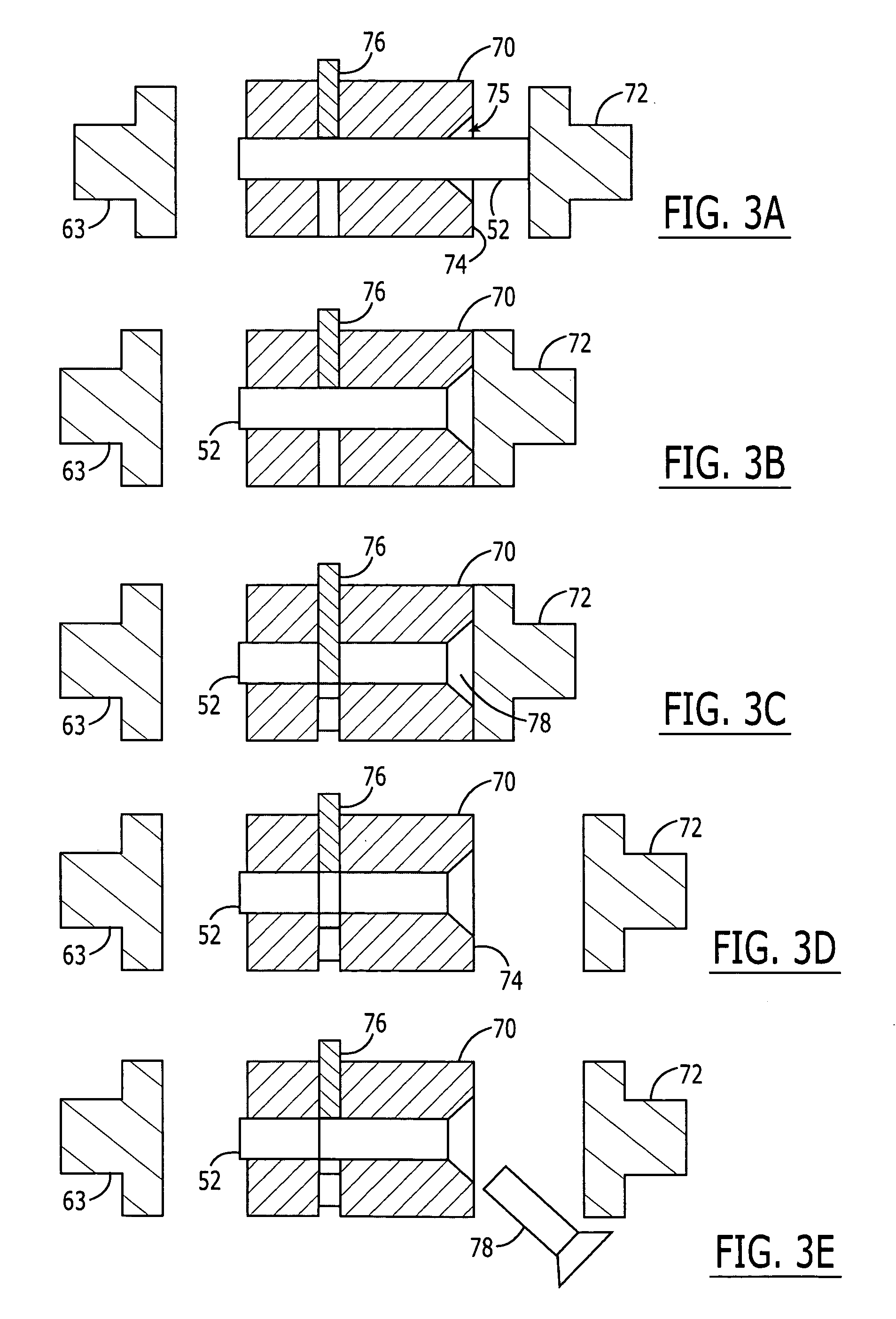

Hybrid Fastening System

A hybrid fastening system comprising a female fastener component, i.e., swage collar, fabricated from a titanium or titanium-alloy material, preferably Ti-3Al-2.5V, and a mating titanium or titanium-alloy material male fastener component, i.e., threaded pin, each preferably pre-coated with an organic coating material comprising an organic, phenolic resin. The threaded pin component is installed through two or more structural components to be joined. The swage collar component is then deformed or swaged onto the threads of the pre-coated threaded pin component to achieve the same, if not improved, fastener / joint performance characteristics of existing lockbolt systems using aluminum-alloy material swage collar components.

Owner:THE BOEING CO

Hybrid fastening system and associated method of fastening

A hybrid fastening system comprising a female fastener component, i.e., swage collar, fabricated from a titanium or titanium-alloy material, preferably Ti-3A1-2.5V, and a mating titanium or titanium-alloy material male fastener component, i.e., threaded pin, each preferably pre-coated with an organic coating material comprising an organic, phenolic resin. The threaded pin component is installed through two or more structural components to be joined. The swage collar component is then deformed or swaged onto the threads of the pre-coated threaded pin component to achieve the same, if not improved, fastener / joint performance characteristics of existing lockbolt systems using aluminum-alloy material swage collar components.

Owner:THE BOEING CO

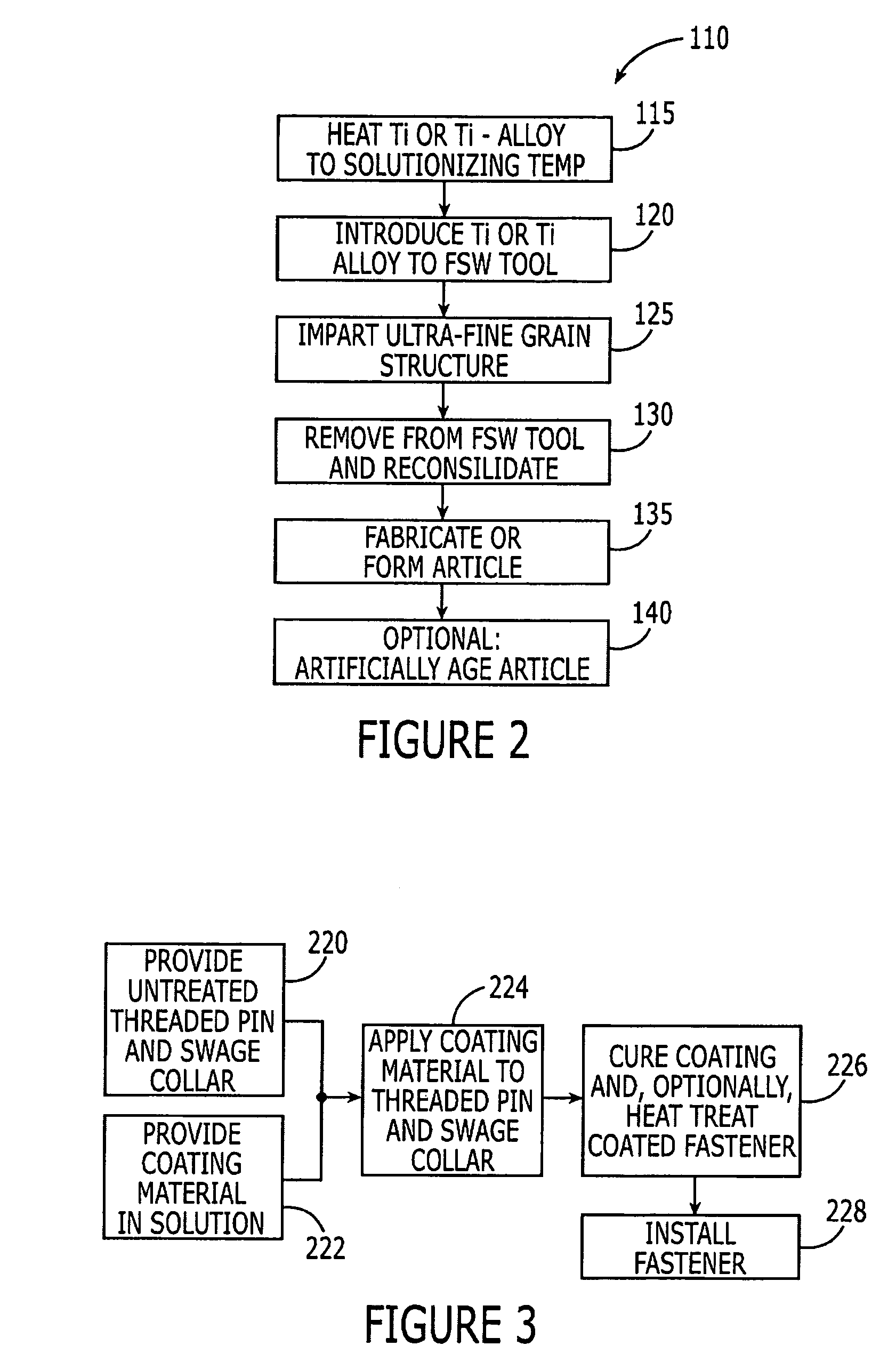

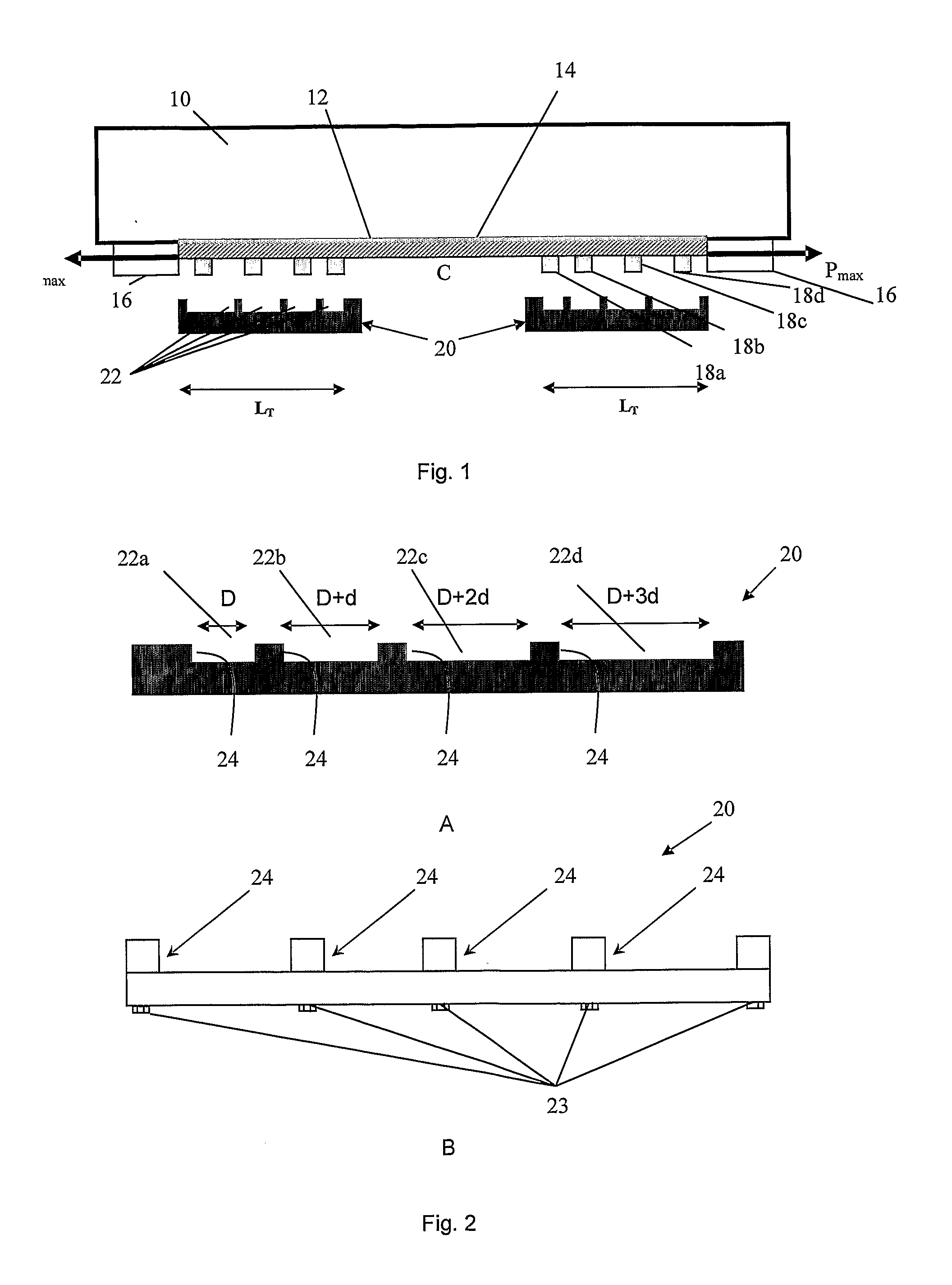

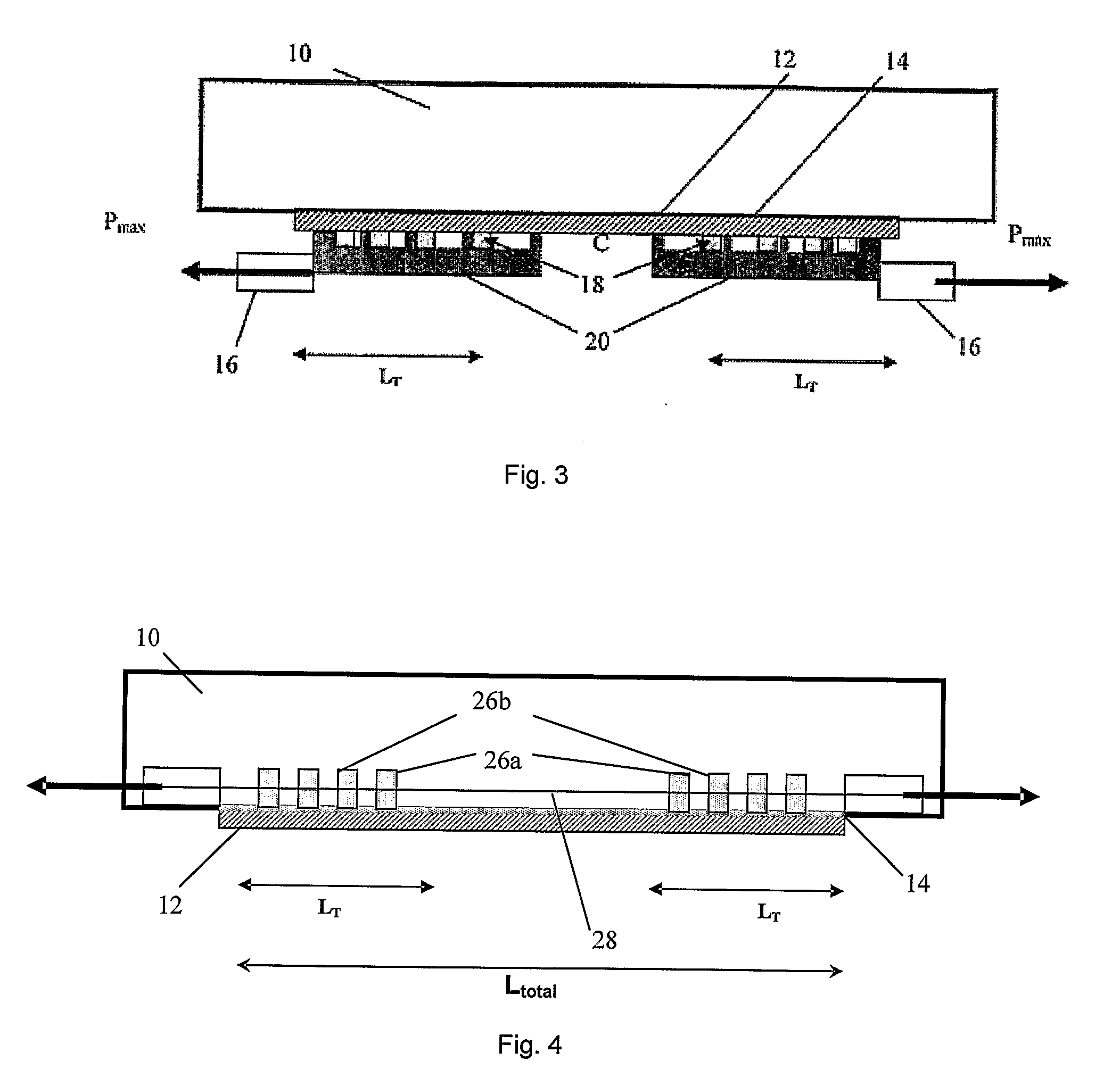

Method

InactiveUS20110000606A1Increase workSupport function be reduceCovering/liningsWallsPre stressingGrout

Method for applying a reinforced composite material, such as a fibre reinforced polymer (FRP) laminate or a steel reinforced polymer (SRP) laminate or a steel reinforced grout (SRG) composite, to a structural member. The method comprises the steps of: applying a curable adhesive to a surface of the structural member and / or a surface of the reinforced composite material, and bringing said surfaces into contact. A pre-stressing force, Pmax, is directly or indirectly applied to the reinforced composite material. The pre-stressing force, Pmax, to which a treatment length, LT, of the reinforced composite material is subjected is then decreased so that the reinforced composite material along the treatment length, LT, will be less pre-stressed than the reinforced composite material adjacent to the treatment length, LT, when the adhesive has cured.

Owner:AL EMRANI MOHAMMAD +2

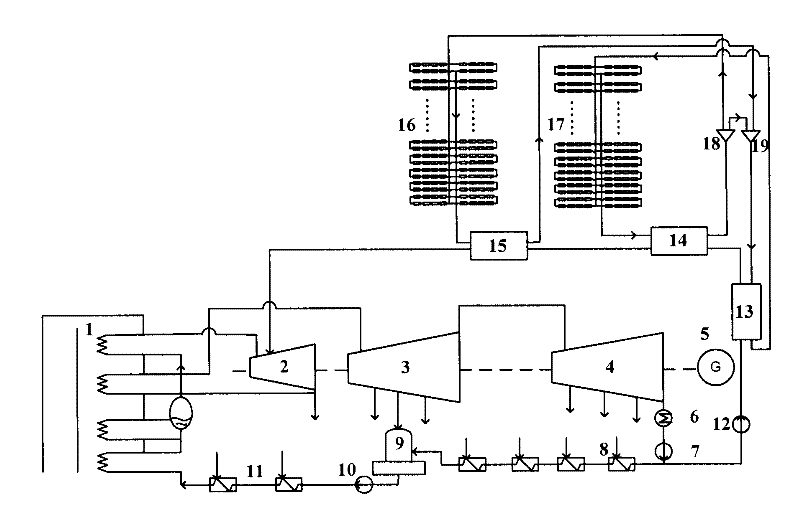

Power generation system capable of realizing complementation between solar energy and biomass energy

InactiveCN104179647AEfficient use ofReduce lossesFrom solar energyMachines/enginesAir preheaterThermal energy

The invention discloses a power generation system capable of realizing complementation between solar energy and biomass energy. The power generation system comprises a slot type solar heat collection sub-system, a biomass after-burning sub-system and a power generation sub-system, wherein the slot type solar heat collection sub-system comprises a solar heat collection field, an oil-water heat exchanger and a heat conduction oil pump, and is used for receiving and gathering solar radiation energy; supplied water is heated up to a certain temperature or is heated until becoming steam by the oil-water heat exchanger; waste heat of heat conduction oil is used for replacing part or all high-pressure cylinder extract air of a steam turbine for heating the low-temperature supplied water; the biomass after-burning sub-system comprises a biomass boiler, a superheater, a reheater and an air pre-heater, and is used for generating high-temperature flue gas and heating products at an outlet of the oil-water heat exchanger and steam at an outlet of a high-pressure cylinder into high-temperature and high-pressure steam; the power generation sub-system comprises the steam turbine and a generator set, and is used for converting received thermal energy into electric energy and outputting the electric energy. After the power generation system capable of realizing complementation between solar energy and biomass energy is adopted, the problem that a slot type solar single thermal power generation system is low in main steam parameter can be solved, the dosage of biomass is reduced, and the biomass resource collection, transportation and storage costs can be lowered.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

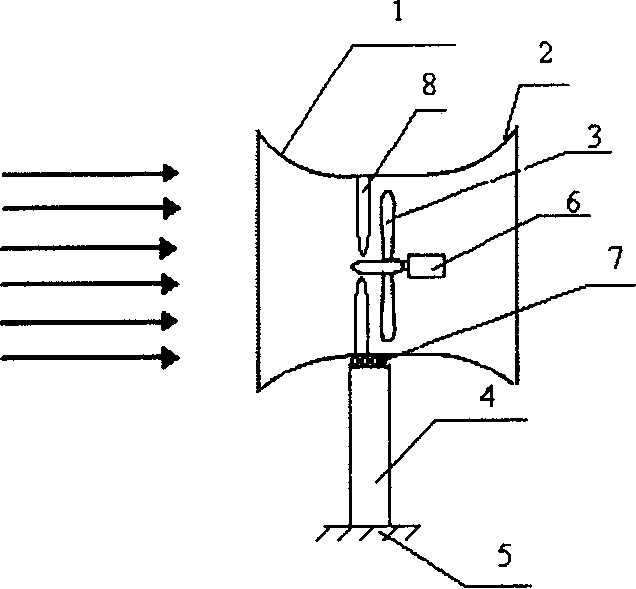

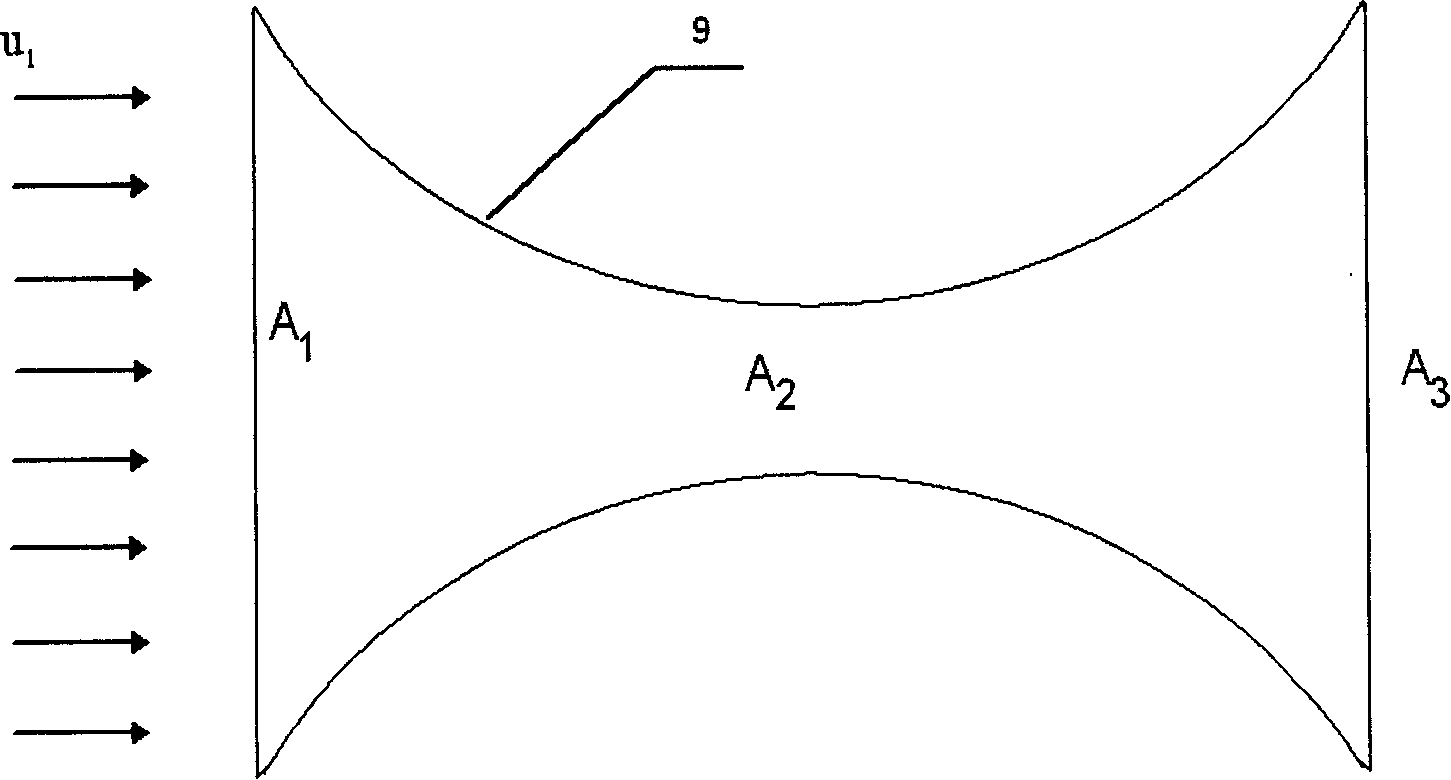

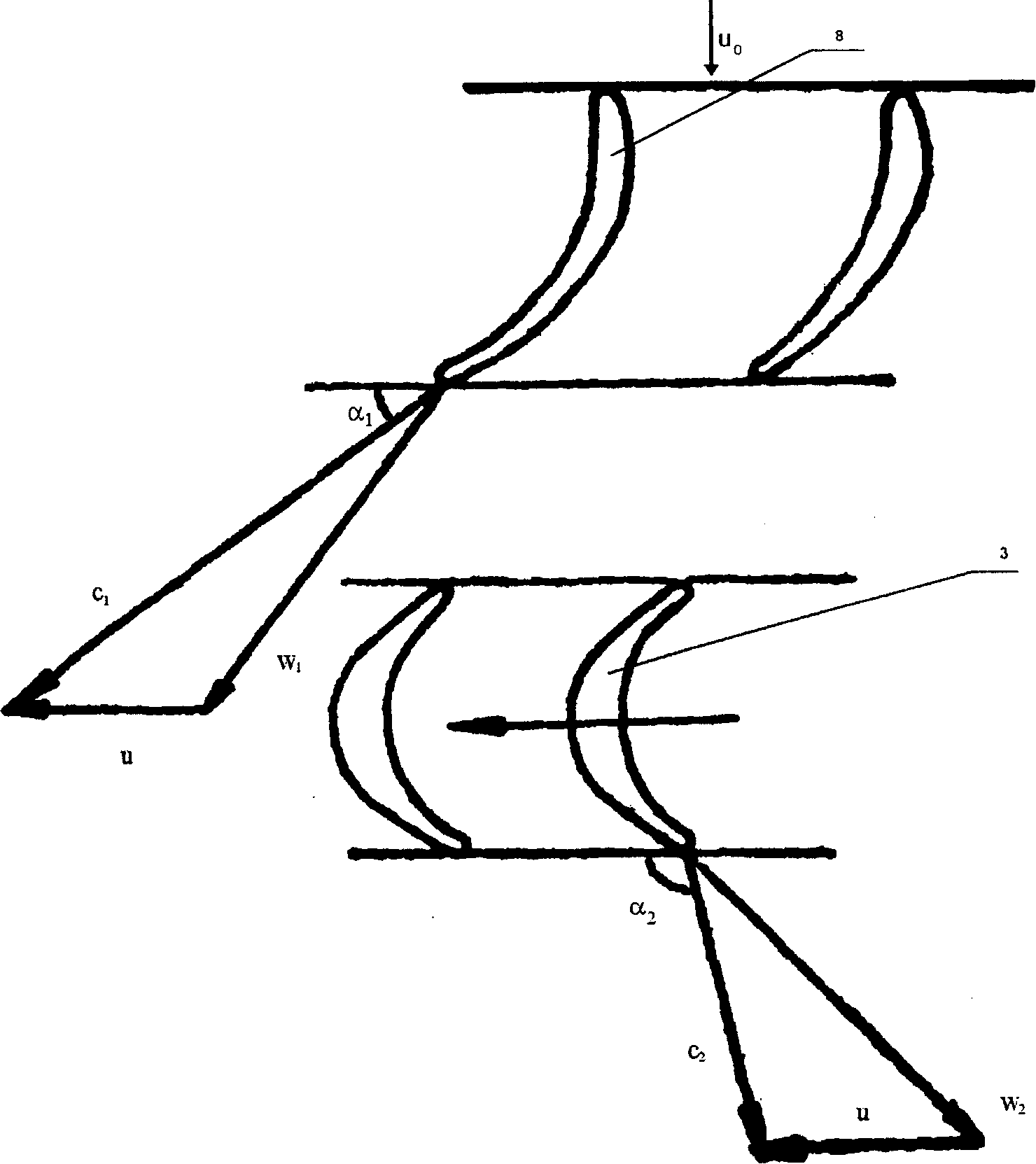

Free-running blade mean-pole wind-power generator of contraction and enlargement nozzle

InactiveCN1746487AReduce power generation costsIncrease workMachines/enginesWind motor combinationsTowerTurbine

A dynamic and static blades turbine with dwindled then widened spout comprises tower base, blower fixed on the top of the base and a dynamo drove by the blower. The dynamic blades are coaxially fixed to the laryngeal part of the spout. The inlet and outlet of the spout are in bugle shape. In front of the dynamic blade, install static turbine guide blade. More wind is collected by the enlarged spout inlet then accelerated by the dwindled laryngeal. The additional blade not only changes wind direction but accelerate wind speed. The dynamic blade is an impulse type which generates work in excess of the limits of Betz theory, so maximizing the utility of wind and lowing down the cost.

Owner:SHANGHAI UNIV

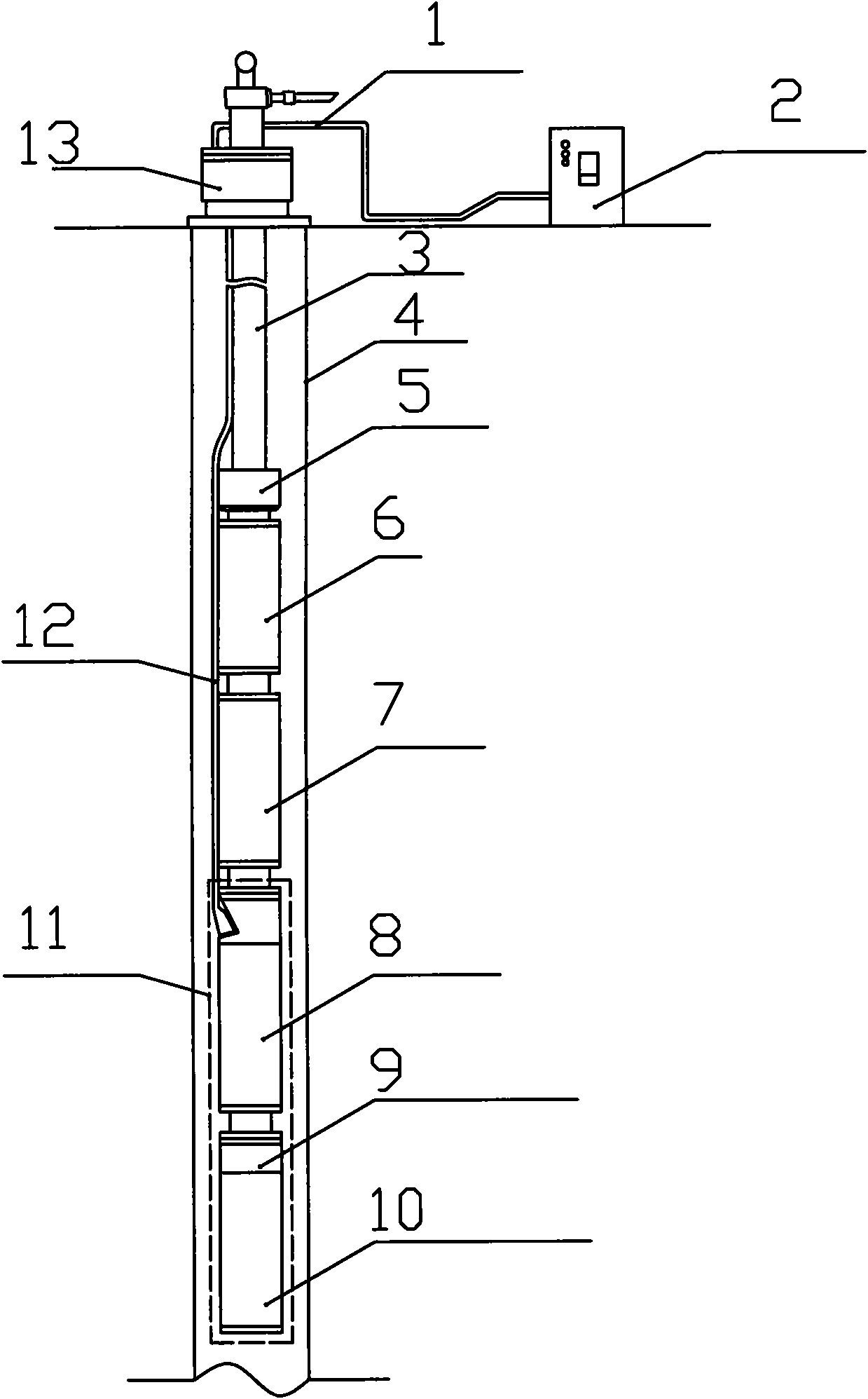

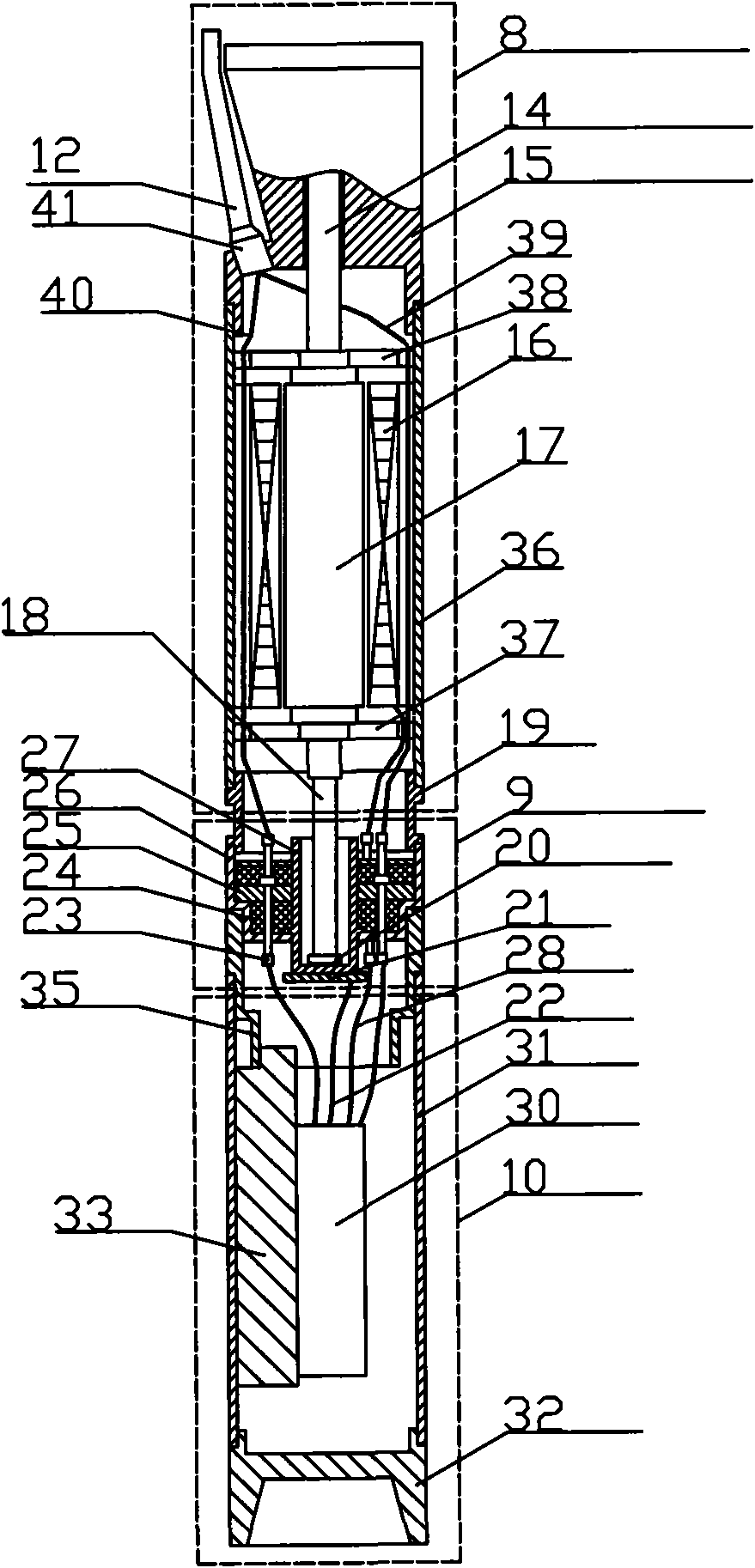

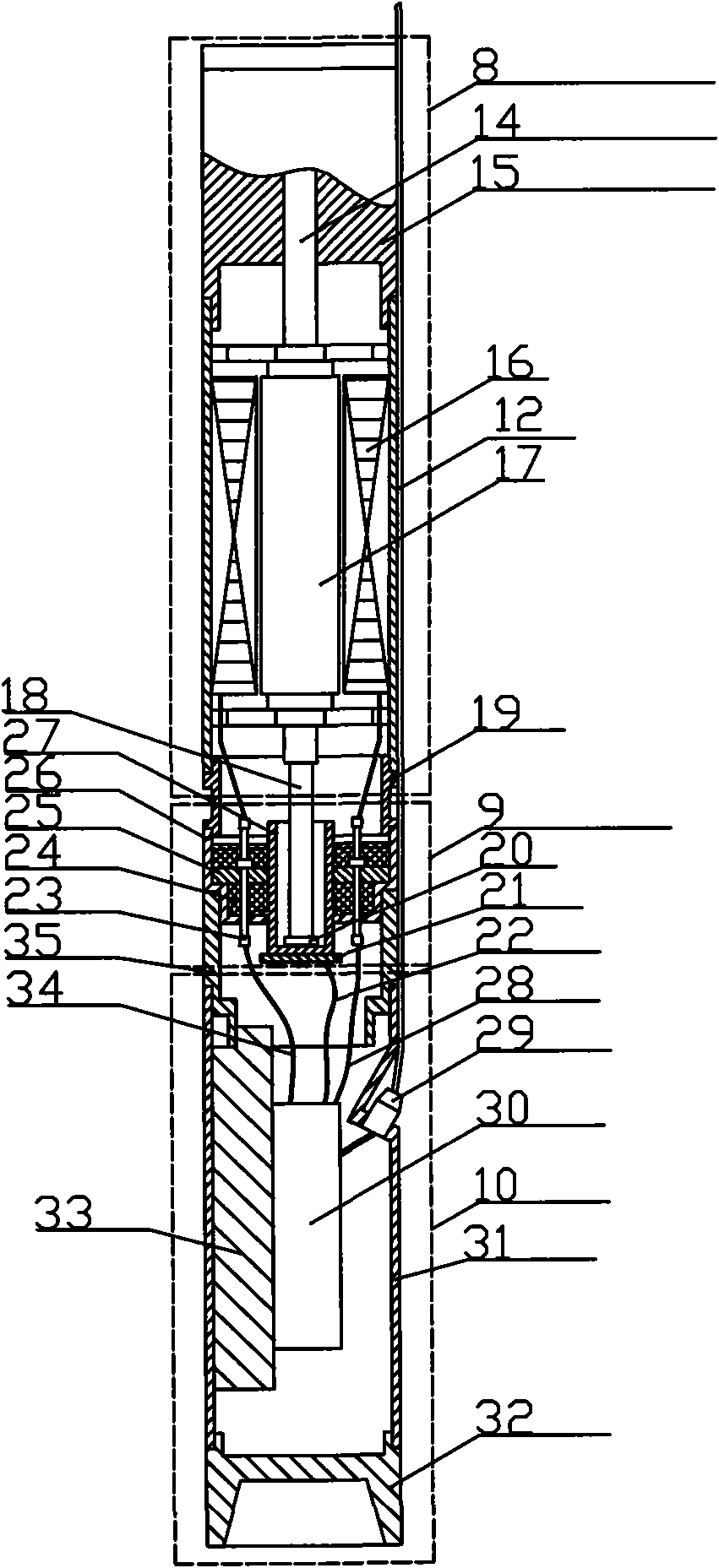

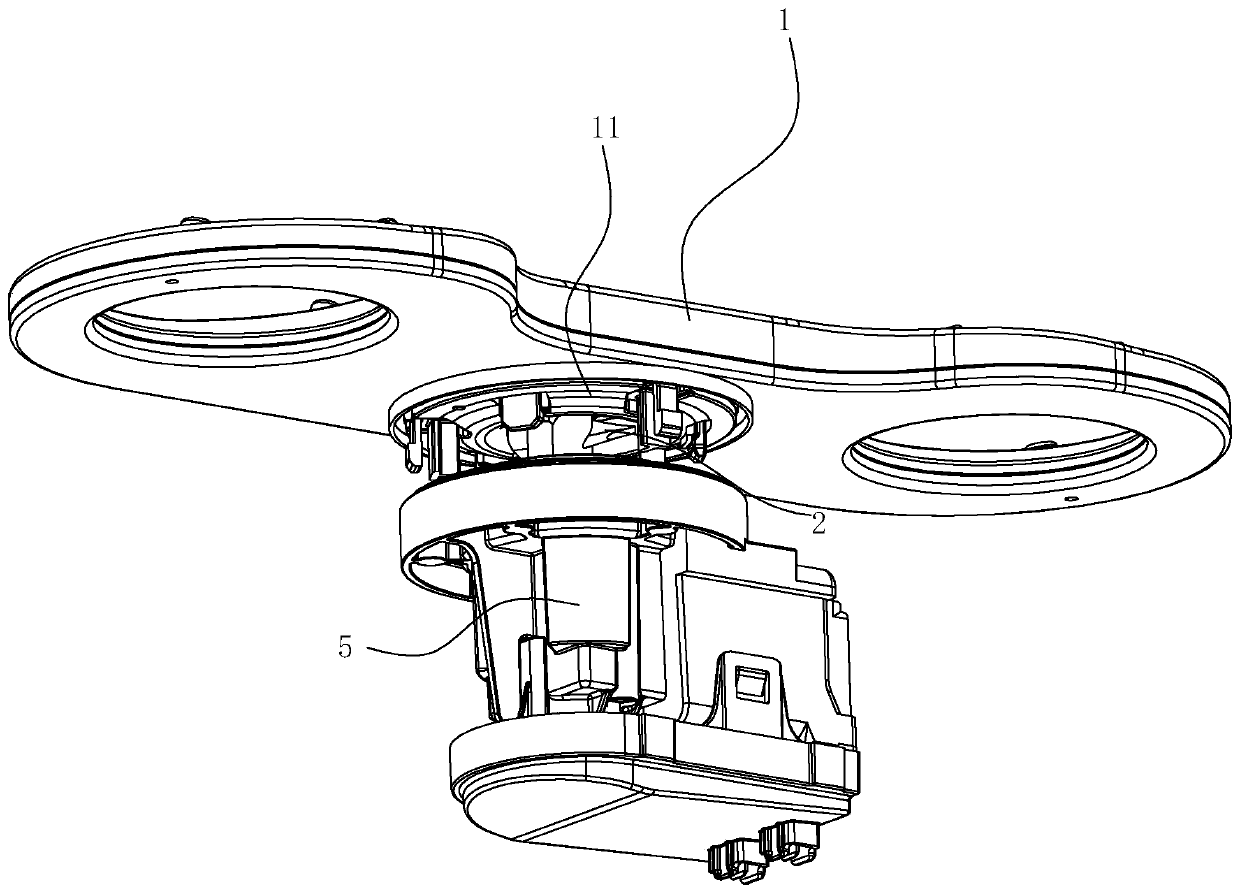

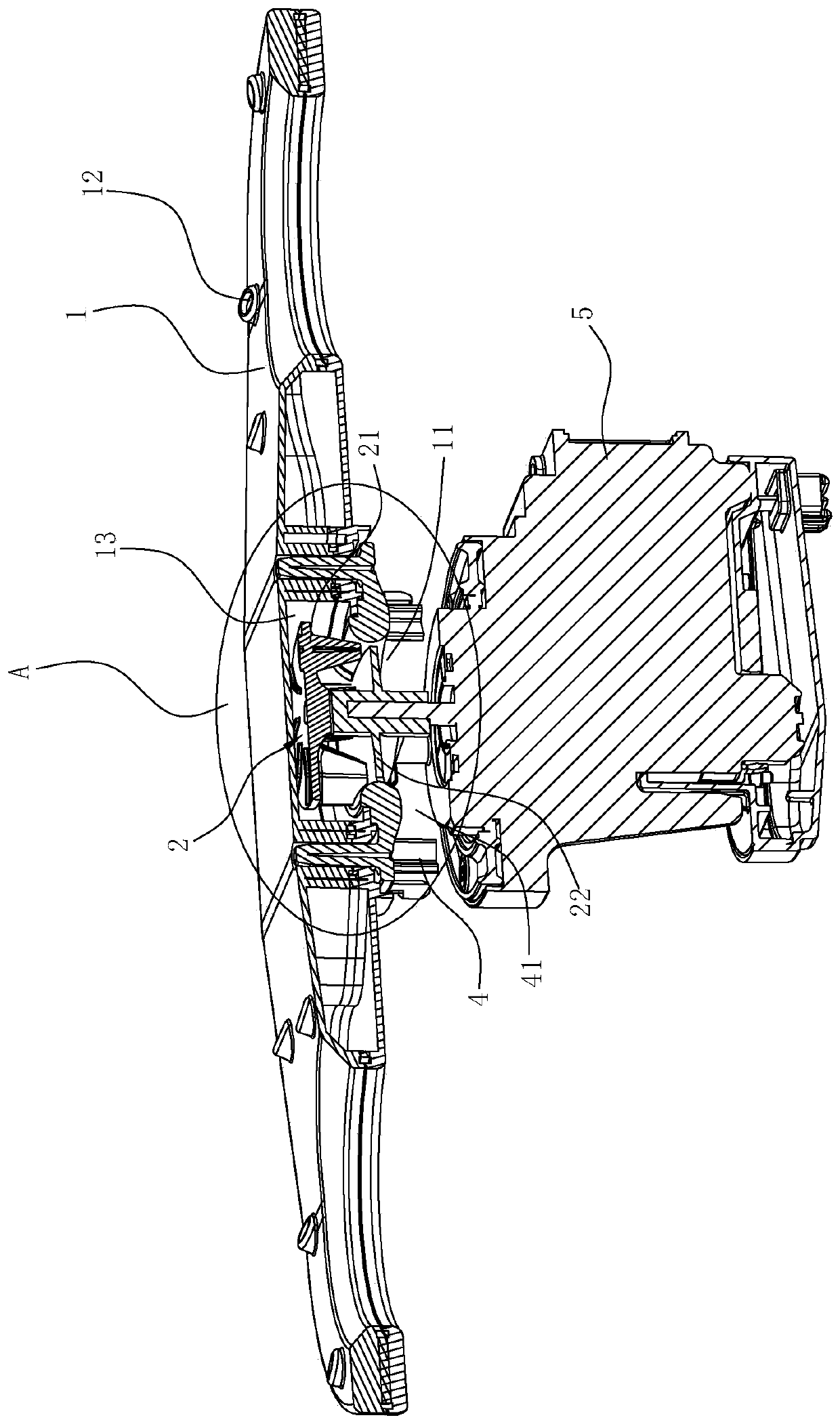

Submersible servodrive system

InactiveCN101877564AImprove efficiencyImprove power densityElectronic commutation motor controlMeasurement apparatus housingsPower factorElectric machine

A submersible servodrive system comprises a pump. The system is characterized in that the pump is connected with a servo motor system by a protector; a ground control device is connected with ground power supply by a cable; the cable is connected with the servo motor system; the ground power supply is controlled by the ground control device to supply power to a servo motor and the pump; the servo motor system comprises the servo motor and a servo controller; a motor shaft of the servo motor is provided with a position detection device which outputs the position signal detected by the position detection device to the servo controller; the servo controller controls the servo motor to run; and the position detection device is fixed on the servo controller by a sealing device. The system has high power factor, high energy saving rate and high flexibility, further saves power, can realize flexible production and reduces the operation cost. When being started, a pumping unit can provide large torque, combine with soft start and reduce the power of a matching motor of the pumping unit.

Owner:杭州坤泽采油设备有限公司

Semi-open type water pump and washing machine to which water pump is applied

ActiveCN110469538AReduce energy lossIncrease the water flow rateTableware washing/rinsing machine detailsPump componentsImpellerEnergy loss

The invention relates to a semi-open type water pump. The semi-open type water pump comprises a shell and an impeller. A water inlet is formed in the first side wall of the shell, a water outlet is formed in the second side wall of the shell, and a containing cavity for containing the upper portion of the impeller is formed in the position, corresponding to the water inlet, in the shell. The upperportion of the impeller at least comprises a first shaft located in the center, an end cover covering the upper end of the first shaft, and first blades distributed on the lower wall face of the endcover at intervals and arranged around the periphery of the first shaft. The upper wall face of the end cover is arranged close to the inner top wall of the containing cavity, and a gap is formed between the upper wall face of the end cover and the inner top wall of the containing cavity. According to the semi-open type water pump structure, the lower portion of the impeller is of an open type structure exposed out of the shell, the upper portion of the impeller is arranged in the shell, and the upper end of the impeller is sealed; and through the arrangement of the end cover, vortexes formedbetween the upper end of the impeller and the inner top wall of the containing cavity can be avoided, energy losses are reduced, work applied to fluid is improved, thus, the flow speed of effluent ofa spraying arm is increased, and then the washing effect is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

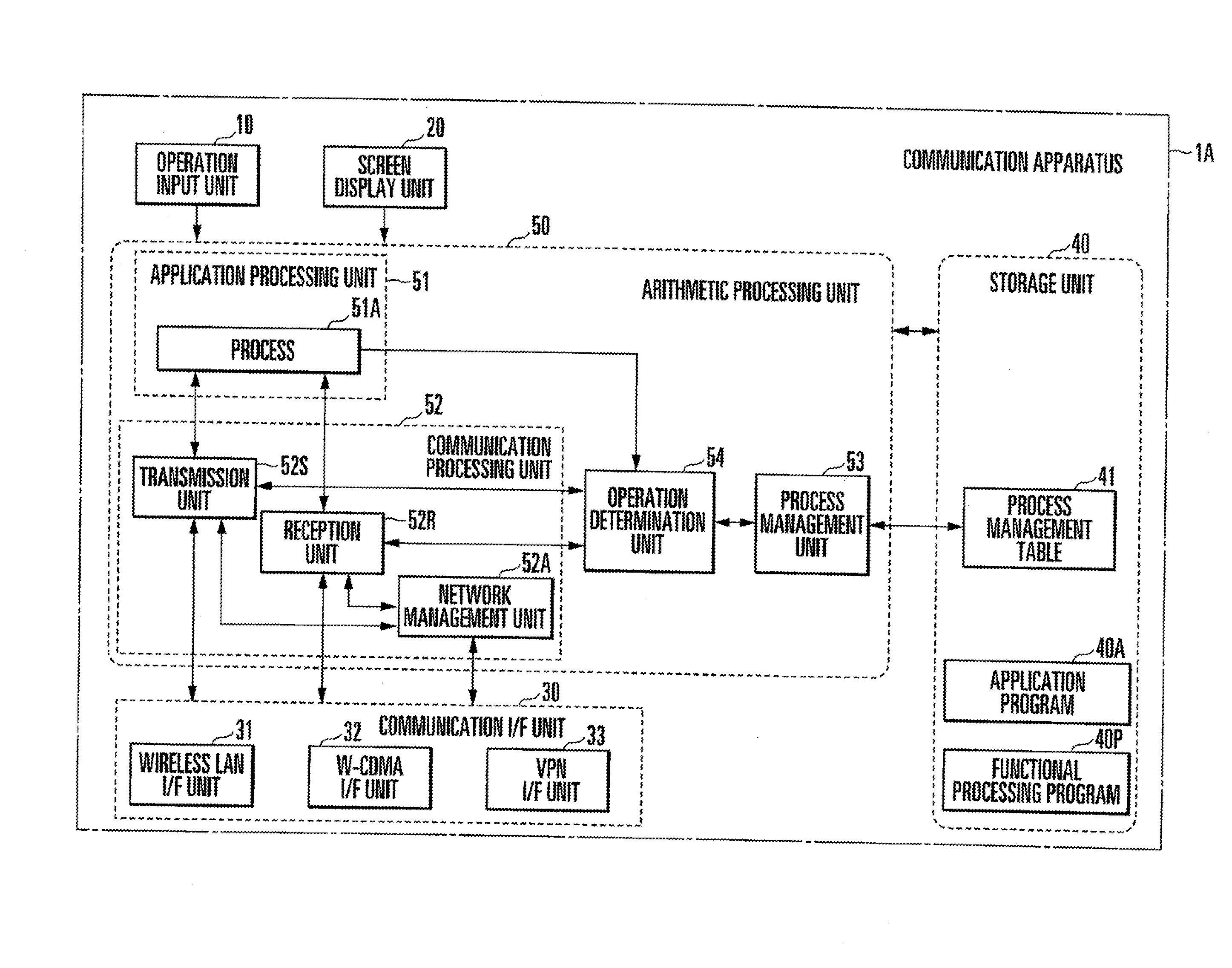

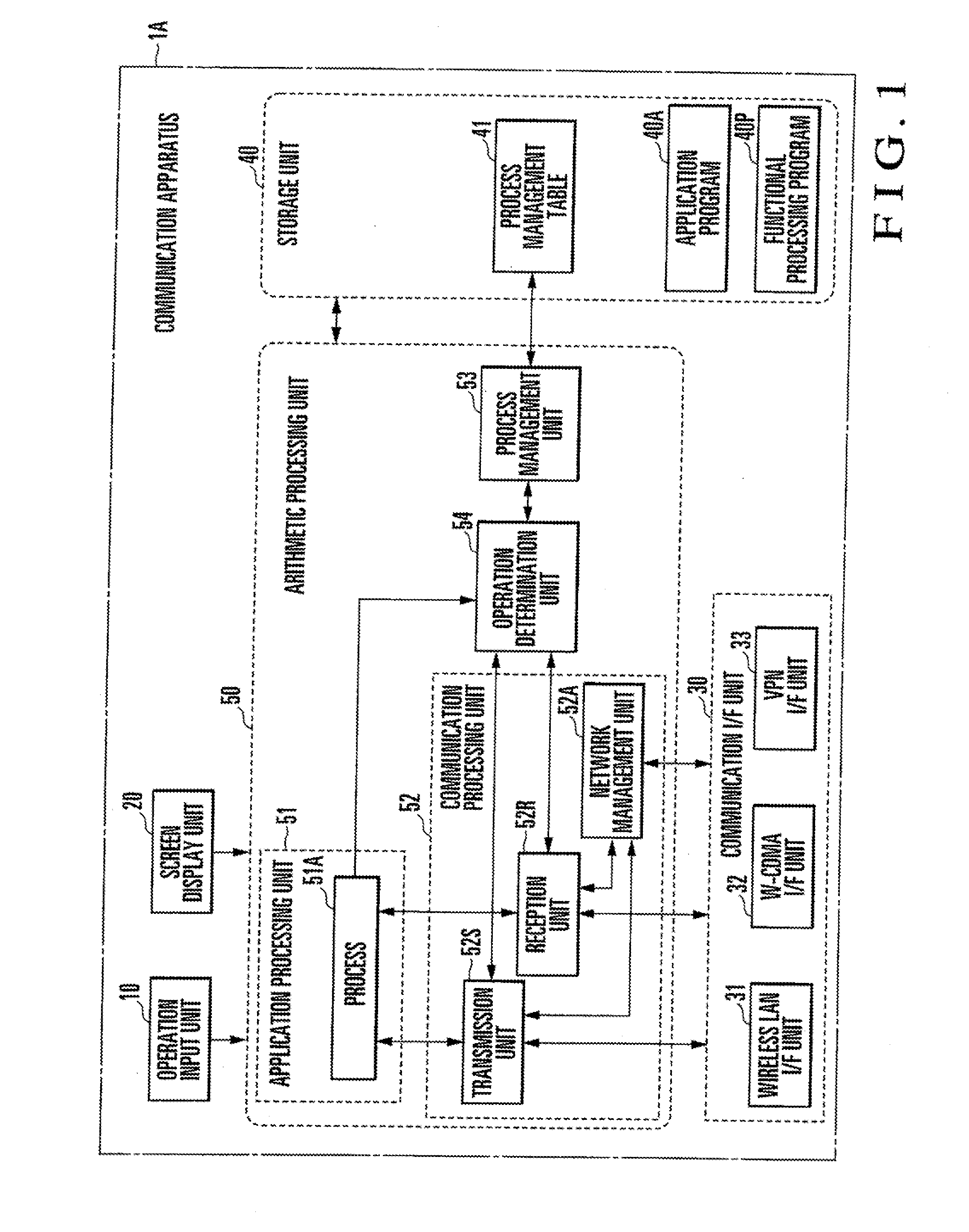

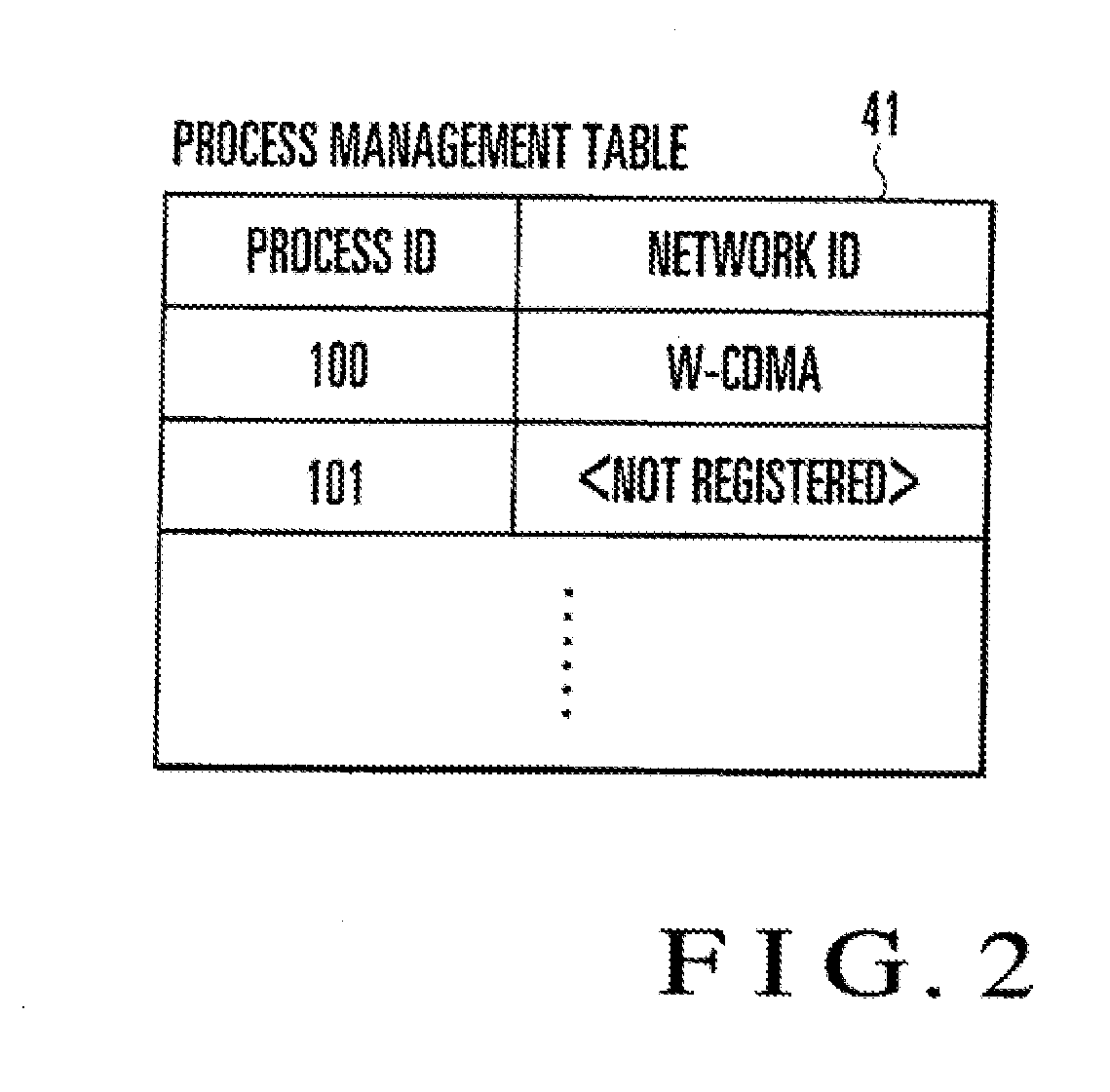

Communication apparatus, communication control method, and program

InactiveUS20100186068A1Prevent transferIncrease workDigital data processing detailsConnection managementReal-time computingCommunication control

When a process (51A) is to execute new data reception, an operation determination unit (54) determines whether to permit data reception by the process by comparing a communication corresponding network ID representing a communication network to be used for data communication by the process with a process corresponding network ID acquired by a process management unit (53).

Owner:NEC CORP

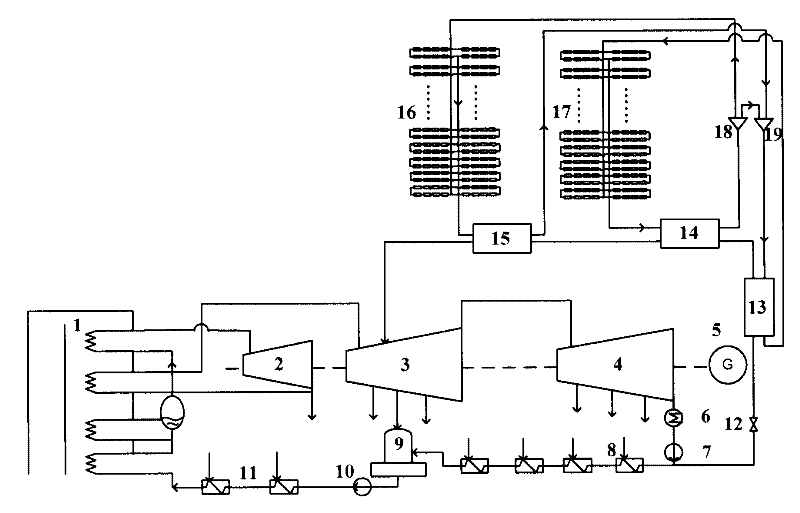

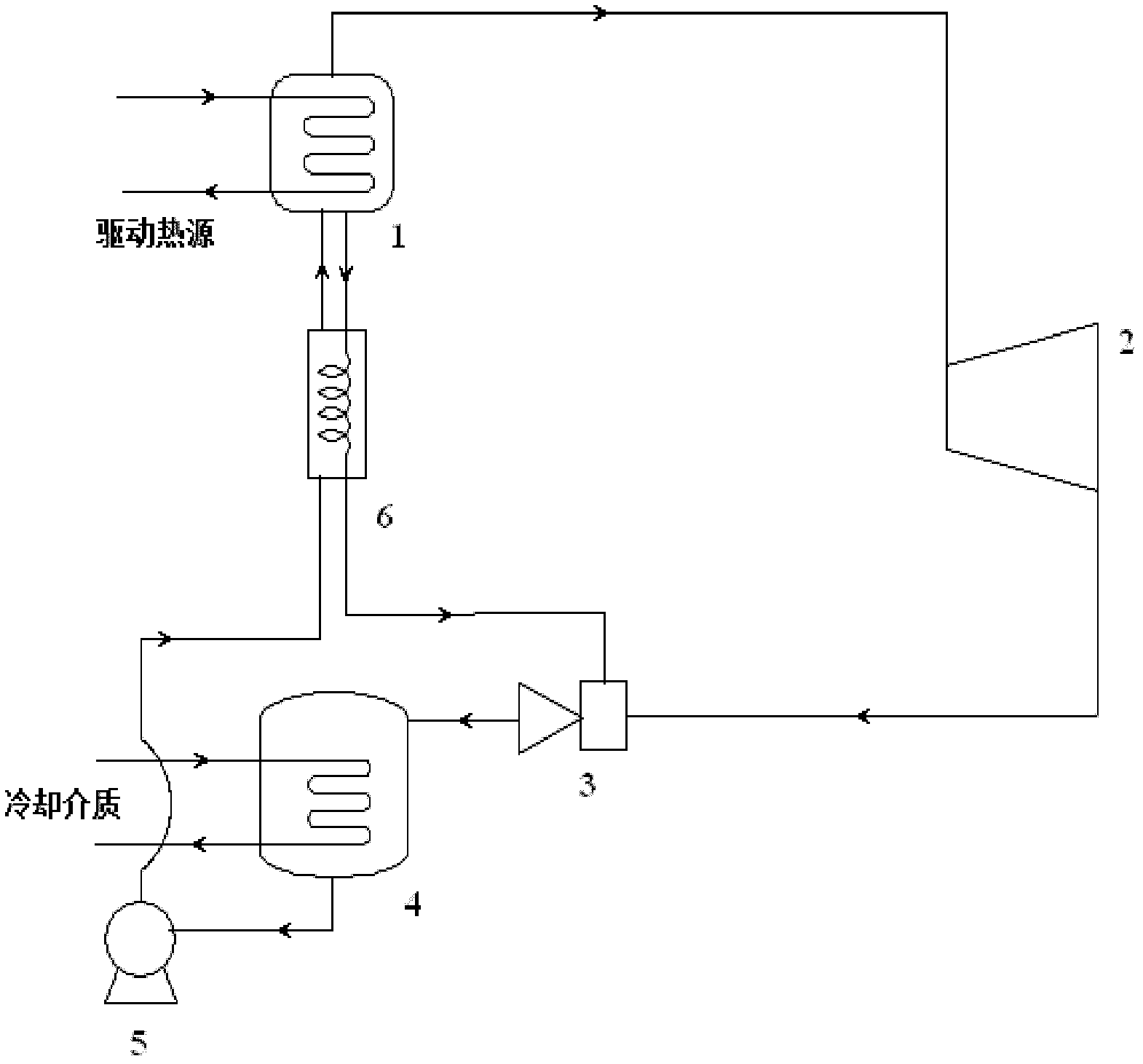

Low-grade thermally-driven Rankine power generation device with ejector

InactiveCN102635416AIncrease workHigh heat conversion efficiencySteam engine plantsInjectorWorking fluid

The invention discloses a low-grade thermally-driven Rankine power generation device with an ejector, which comprises a generator, an expansion machine, a power generator, an ejector, an absorber, a circulating pump and a solution heat exchanger. The circulating pump transports the working fluid required to complete an absorption process in the absorber to the generator through the low-temperature side of the solution heat exchanger; an absorbent solution on the high-temperature side of the solution heat exchanger is cooled and then fed into the ejector; the working fluid in the generator is heated by an input heating source so as to generate high-pressure working steam; the high-pressure working steam is fed into the expansion machine for doing work through expanding; the working steam subjected to expansion is fed into the ejector, and is injected by the working fluid in the ejector; and finally, the working steam is fed into the absorber to complete the absorption process. According to the invention, the expansion machine can do more mechanical work in the process of expansion, so that the heat conversion efficiency is higher; and the mechanical work consumed in the process of transporting the solution subjected to absorption to the generator by the circulating pump is obviously reduced, therefore, the net power generation efficiency of the whole device is greatly improved.

Owner:ZHEJIANG UNIV

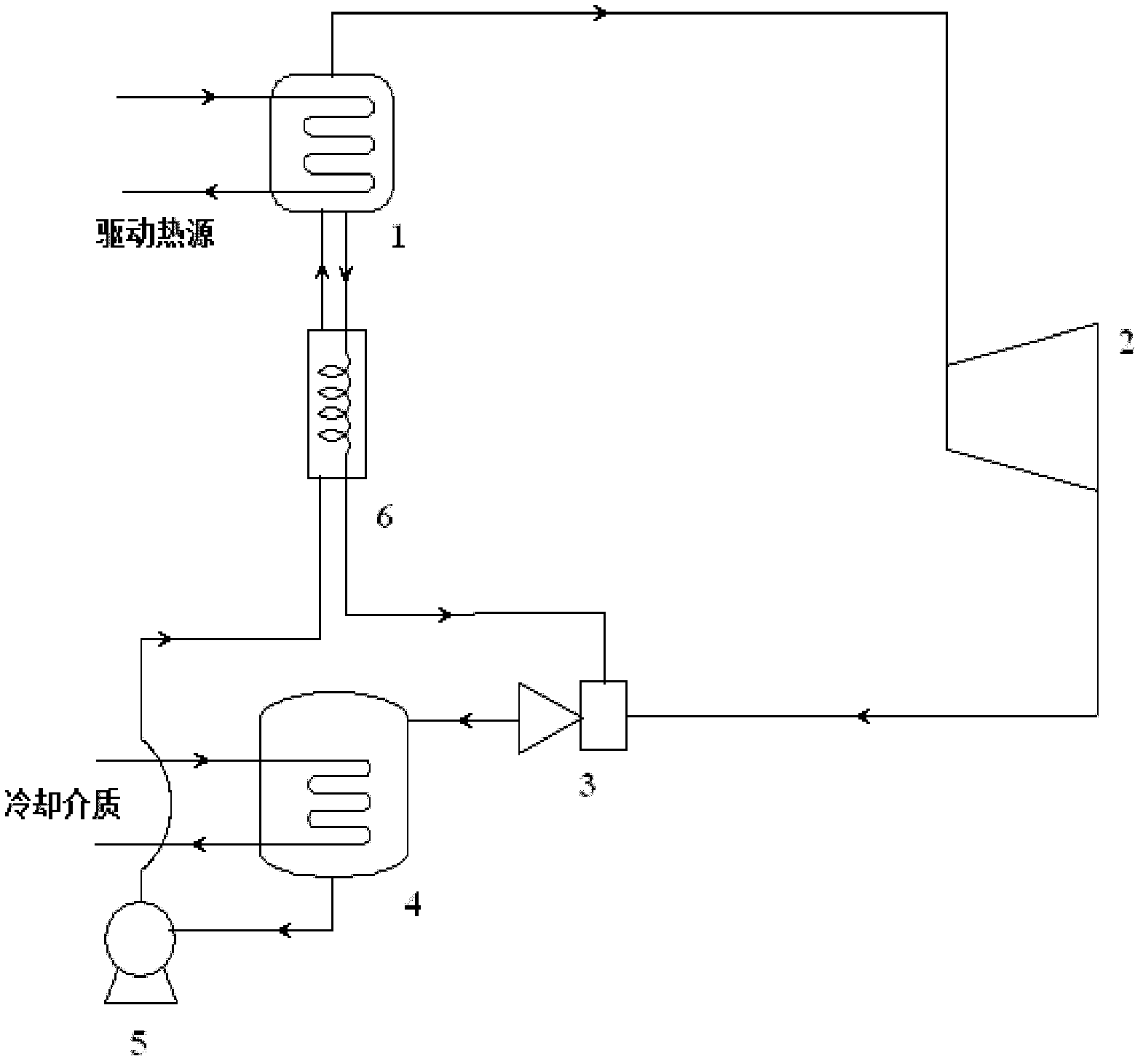

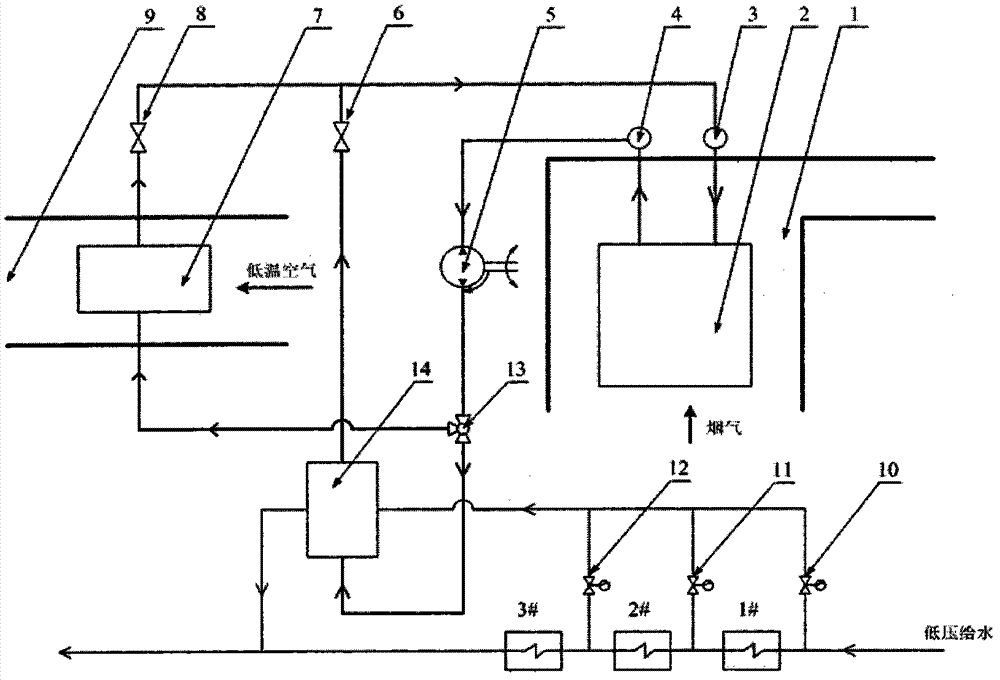

Brown coal pre-drying-air preheating-waste heat utilization composite coal-fired power generation system

InactiveCN103277155AIncrease energy densityStable combustionCombustion processSteam useAir preheaterPower generation system

The invention discloses a brown coal pre-drying-air preheating-waste heat utilization composite coal-fired power generation system, and belongs to the power station energy-saving field. The system is mainly characterized in that a brown coal drying system is connected with a steam turbine regenerative system and an air preheating system, a smoke heat-setting water system is connected with the steam turbine regenerative system and the air preheating system, the steam turbine regenerative system is connected with a steam turbine generating device, the air preheating system is connected between the brown coal drying system and a boiler rear smoke channel, then whole-course heating of air is finished, and brown coal can be directly burned for power generation after being dried. Energy density of the brown coal is increased, boiler efficiency is improved, heat and moisture in dried tail gas are recycled, temperature of air in an inlet of an air pre-heater is increased, meanwhile, a smoke-water heat exchanger arranged in a hearth division smoke channel recycles smoke heat, coal consumption of a unit is expected to be greatly reduced, and therefore the efficient, energy-saving, water-saving and emission-reducing effects are achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

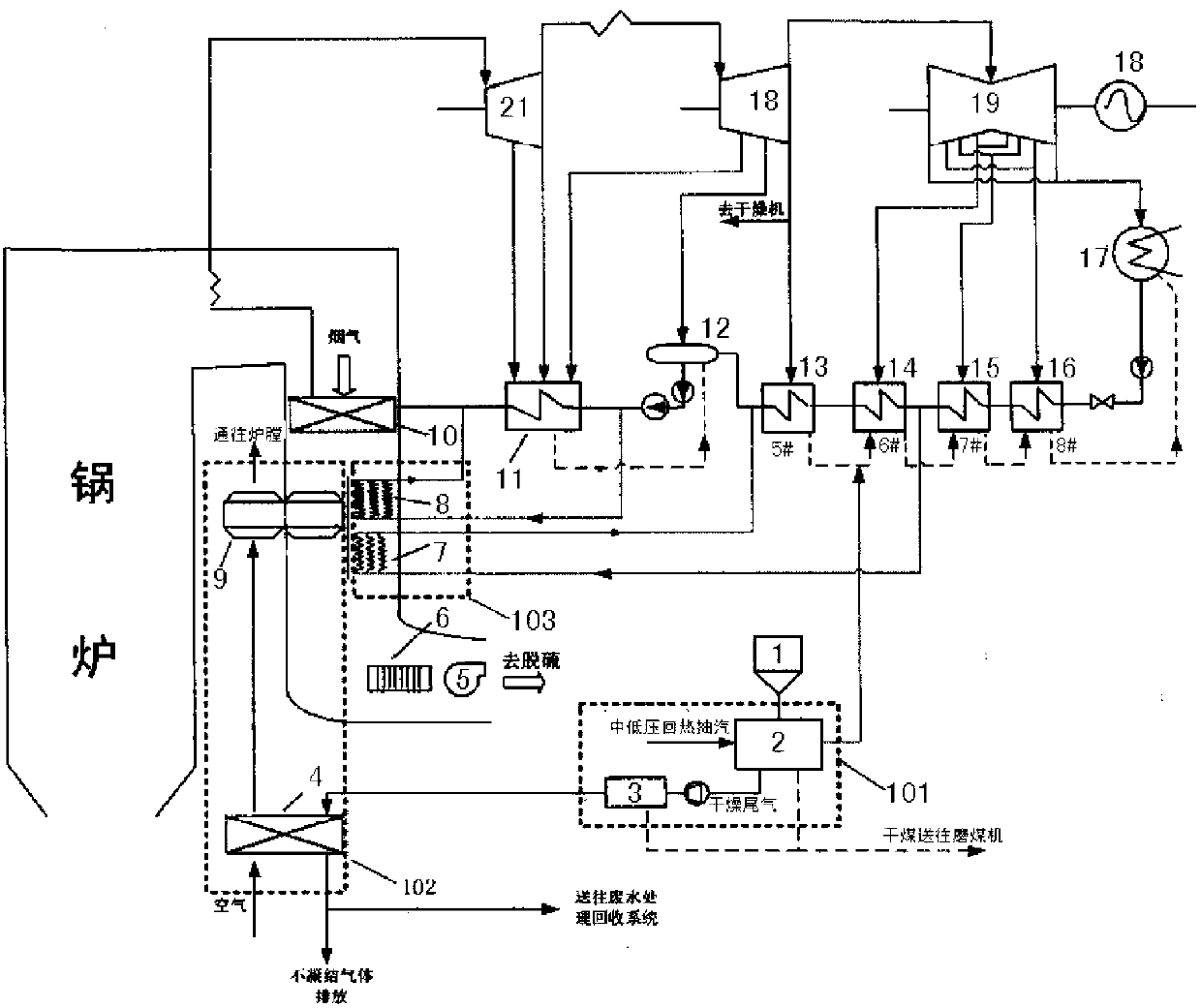

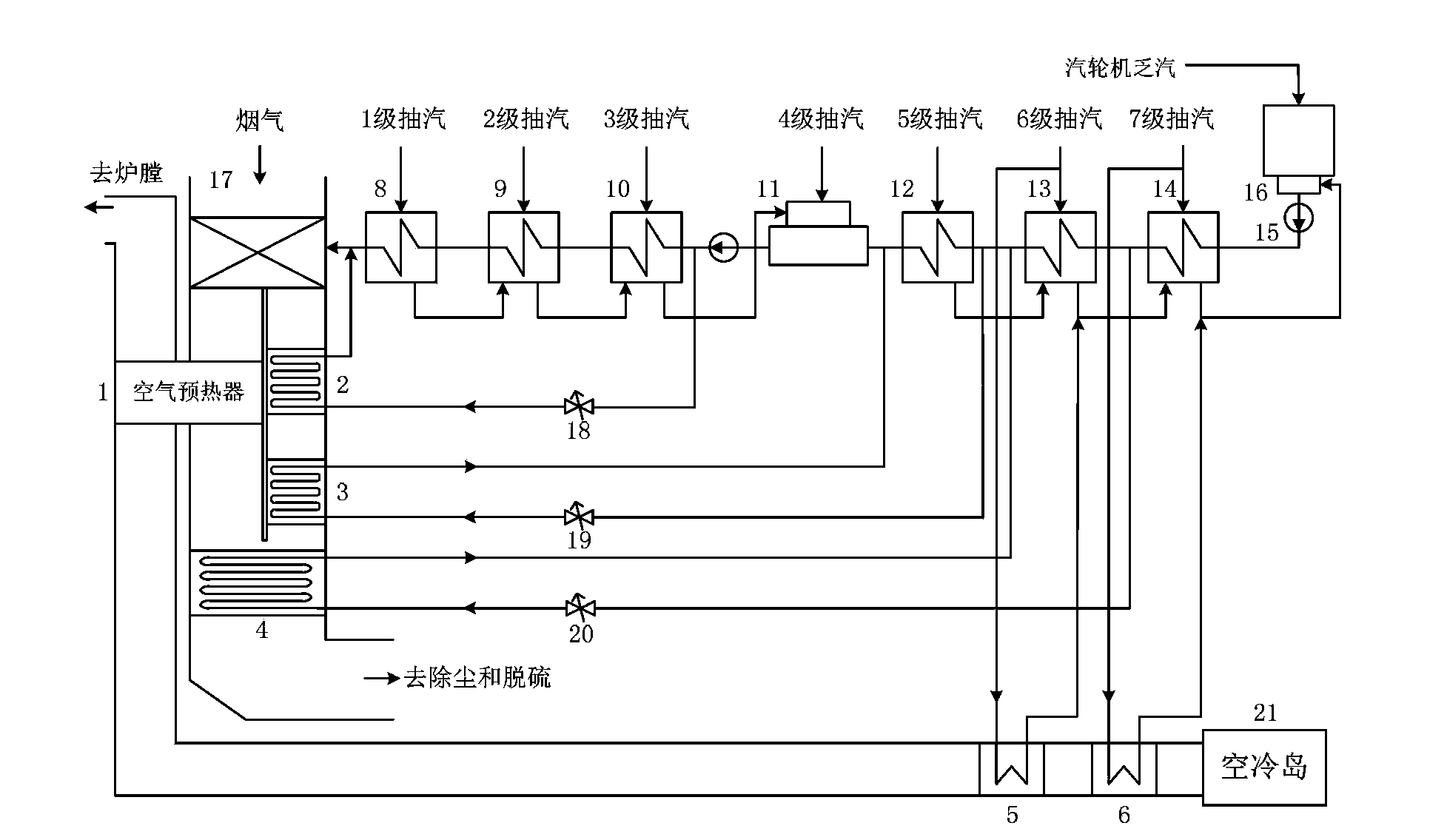

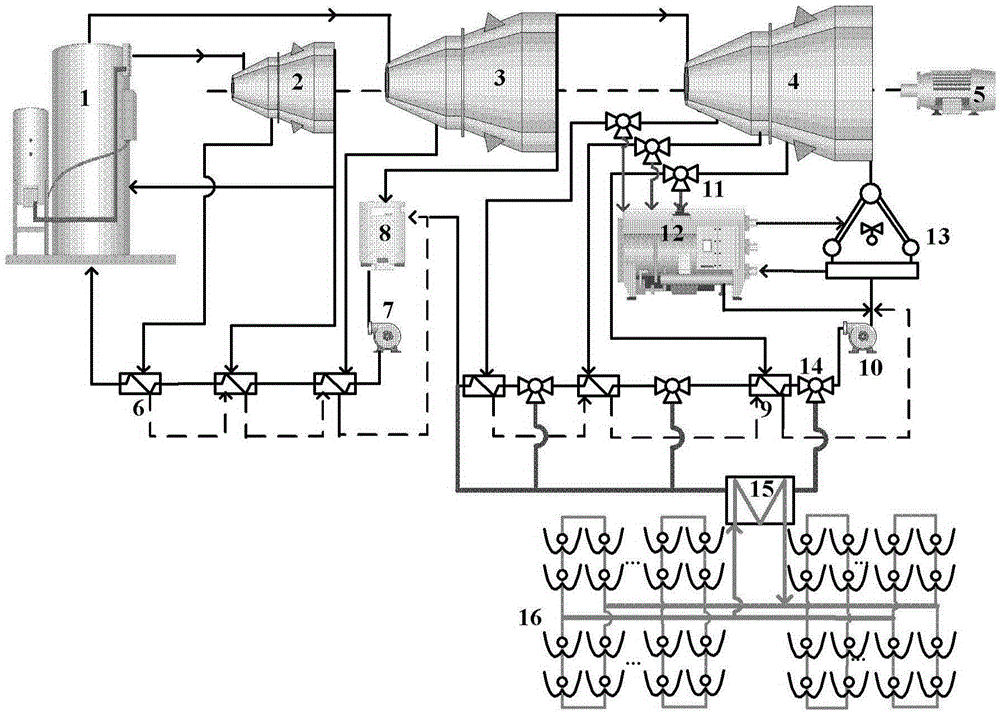

Engine-boiler coupled deep waste heat utilization system for air cooling unit

InactiveCN103375792AIncrease workWaste heat optimizationSteam boilersFeed-water heatersAir preheaterEngineering

The invention belongs to the field of energy conservation and emission reduction of thermal power units, and particularly relates to an engine-boiler coupled deep waste heat utilization system for an air cooling unit. The system mainly comprises an air pre-heater, multistage bled steam type air heaters, a feed water heater, a condensed water heater and a low-temperature economizer, the primary bled steam type air heater uses waste steam preheated air, the other bled steam type air heaters use low-level to high-level turbine bled steam preheated air, the heat absorption capacity of the preheated air in the air pre-heater is decreased, the amount of flue gas needed by the air pre-heater is also decreased, residual flue gas is led to a bypass flue parallelly connected with the air pre-heater, the feed water heater and the condensed water heater are arranged in the bypass flue and used for heating feed water and condensed water respectively, and regenerative extraction steam is squeezed out to increase power of a turbine. The system recycles high-parameter waste steam and waste heat of low-level bled steam of the air cooling unit, improves the grade of heat and has fine energy-saving effects.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

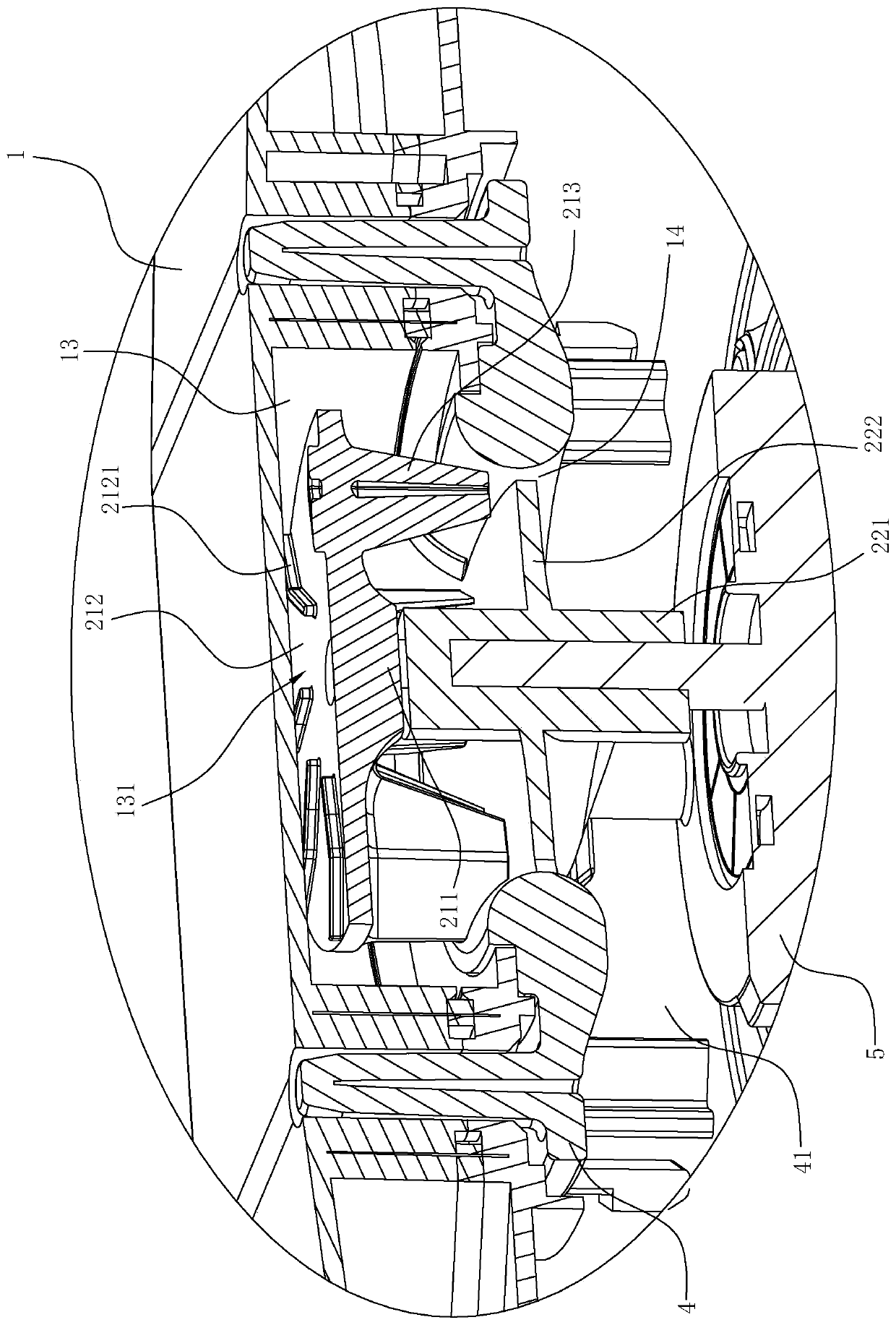

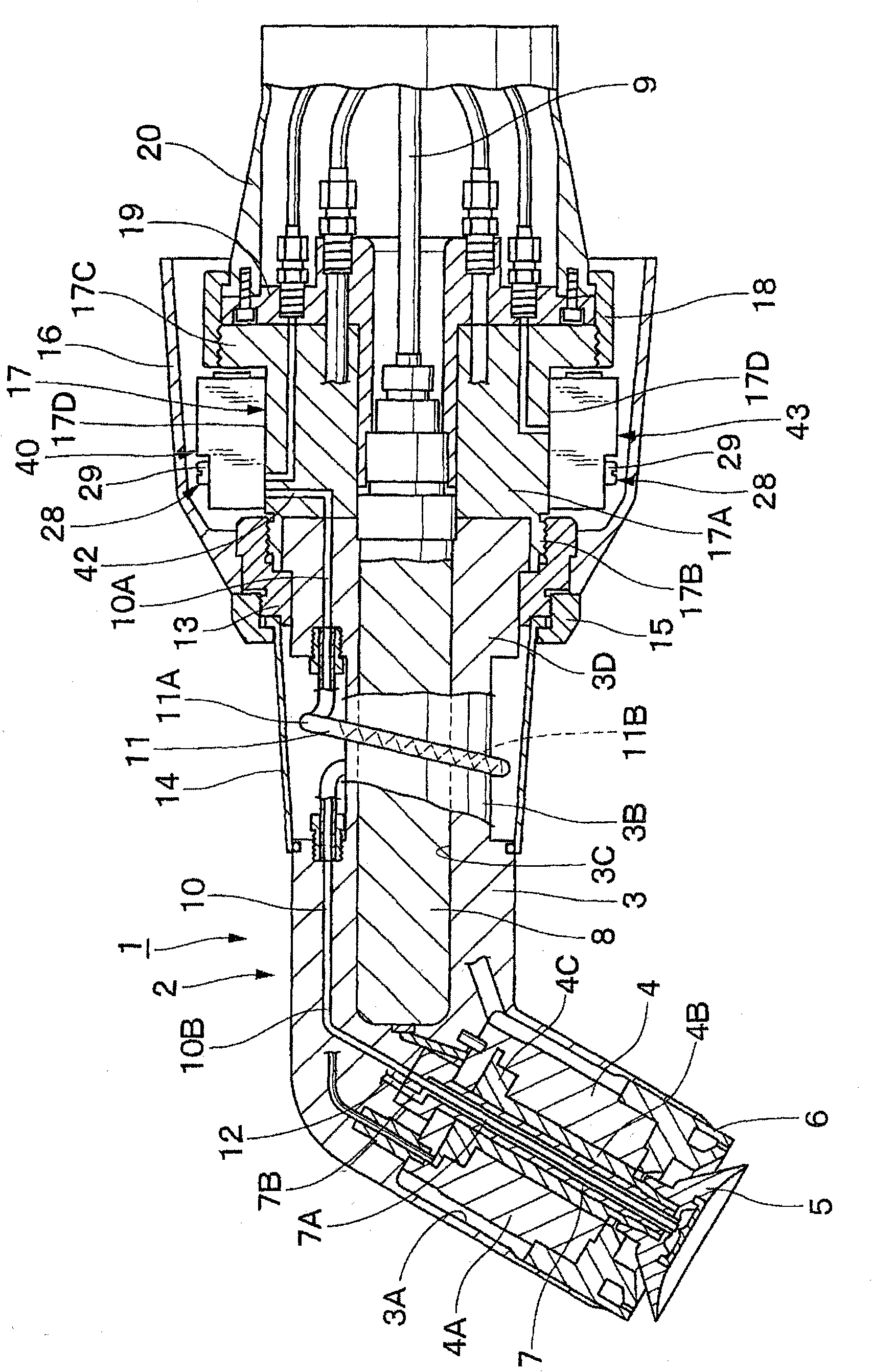

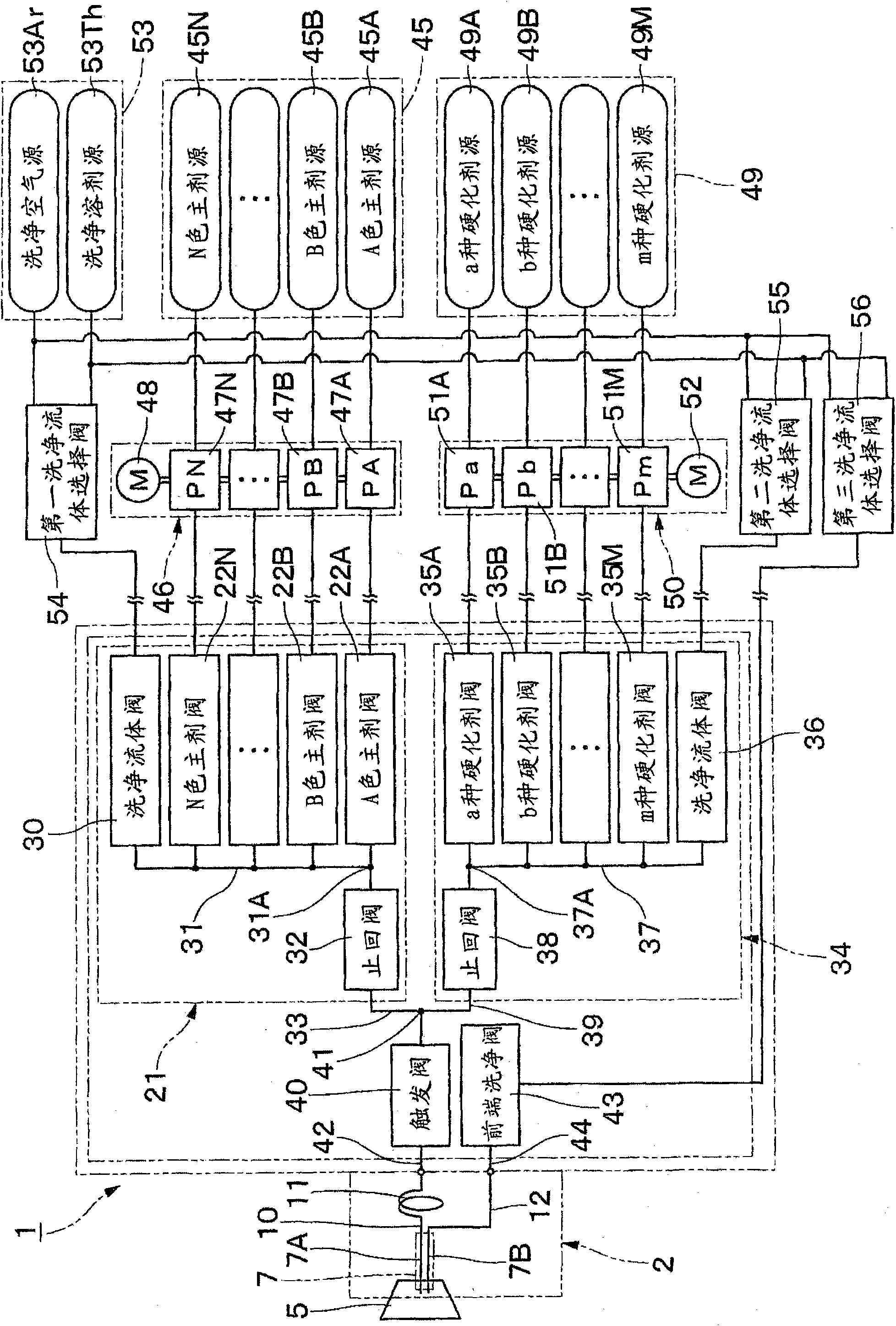

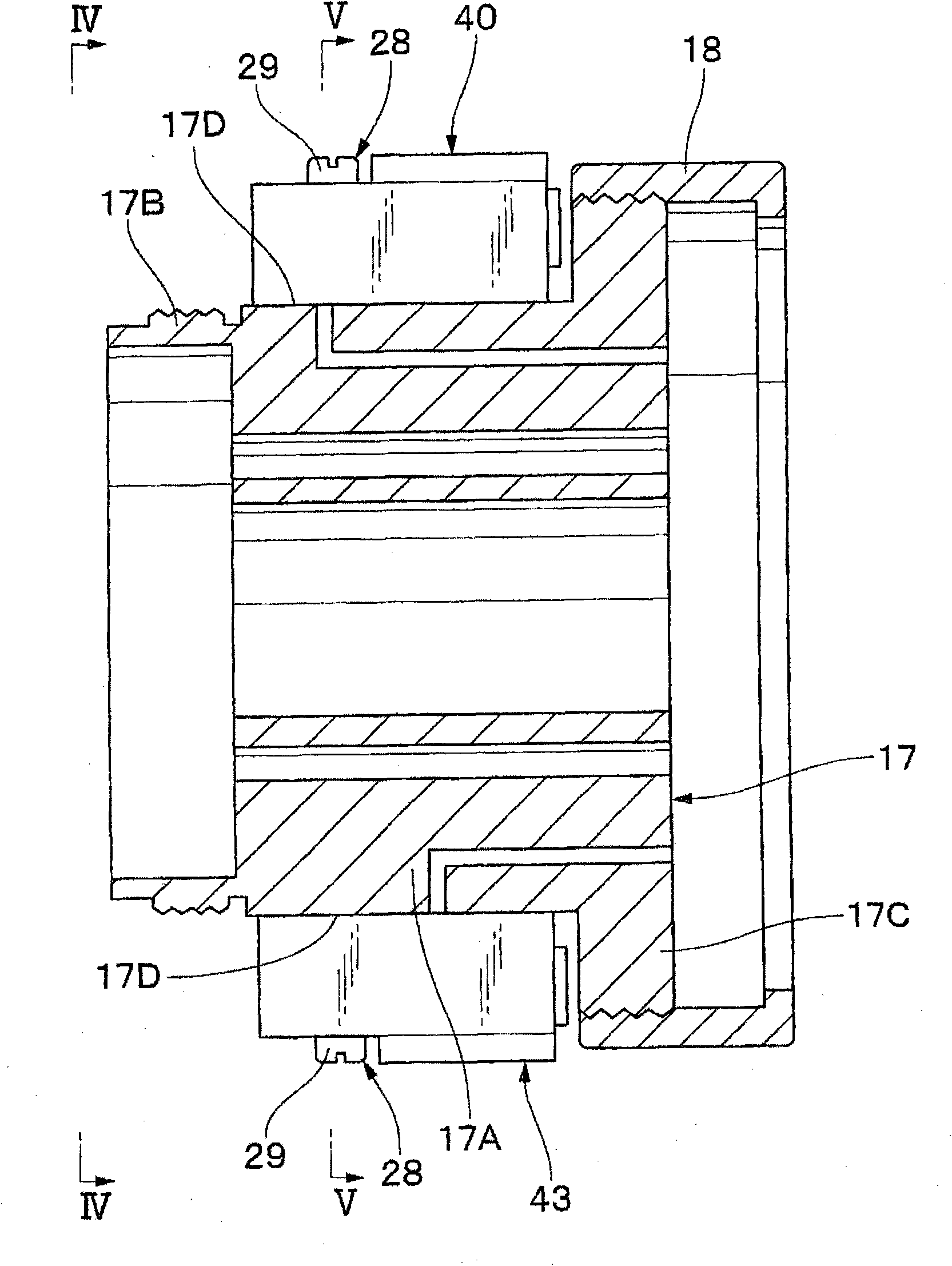

Painting apparatus

InactiveCN101568389AImprove maintenance work efficiencyIncrease workMovable spraying apparatusLiquid spraying apparatusEngineeringMechanical engineering

Owner:ABB株式会社

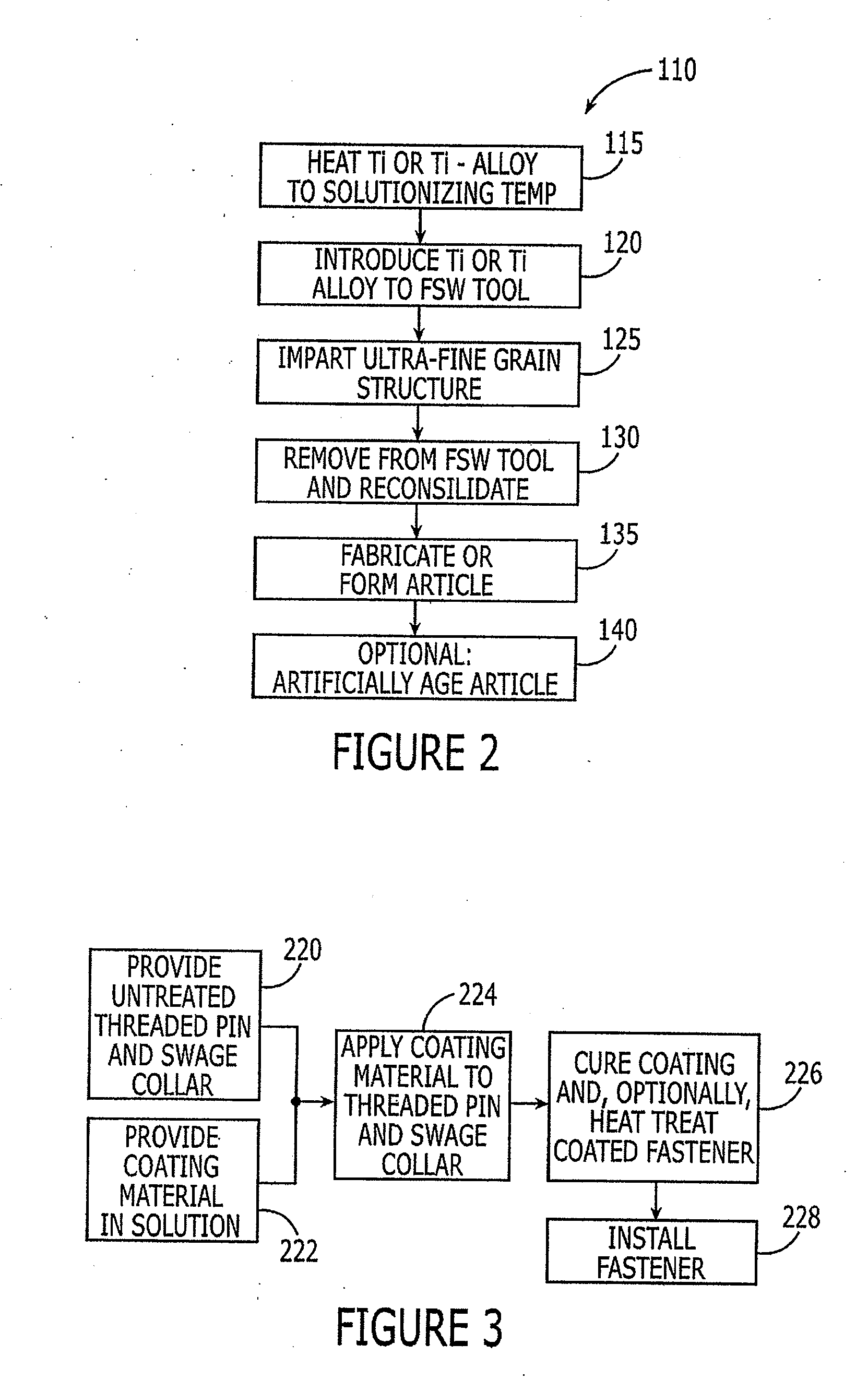

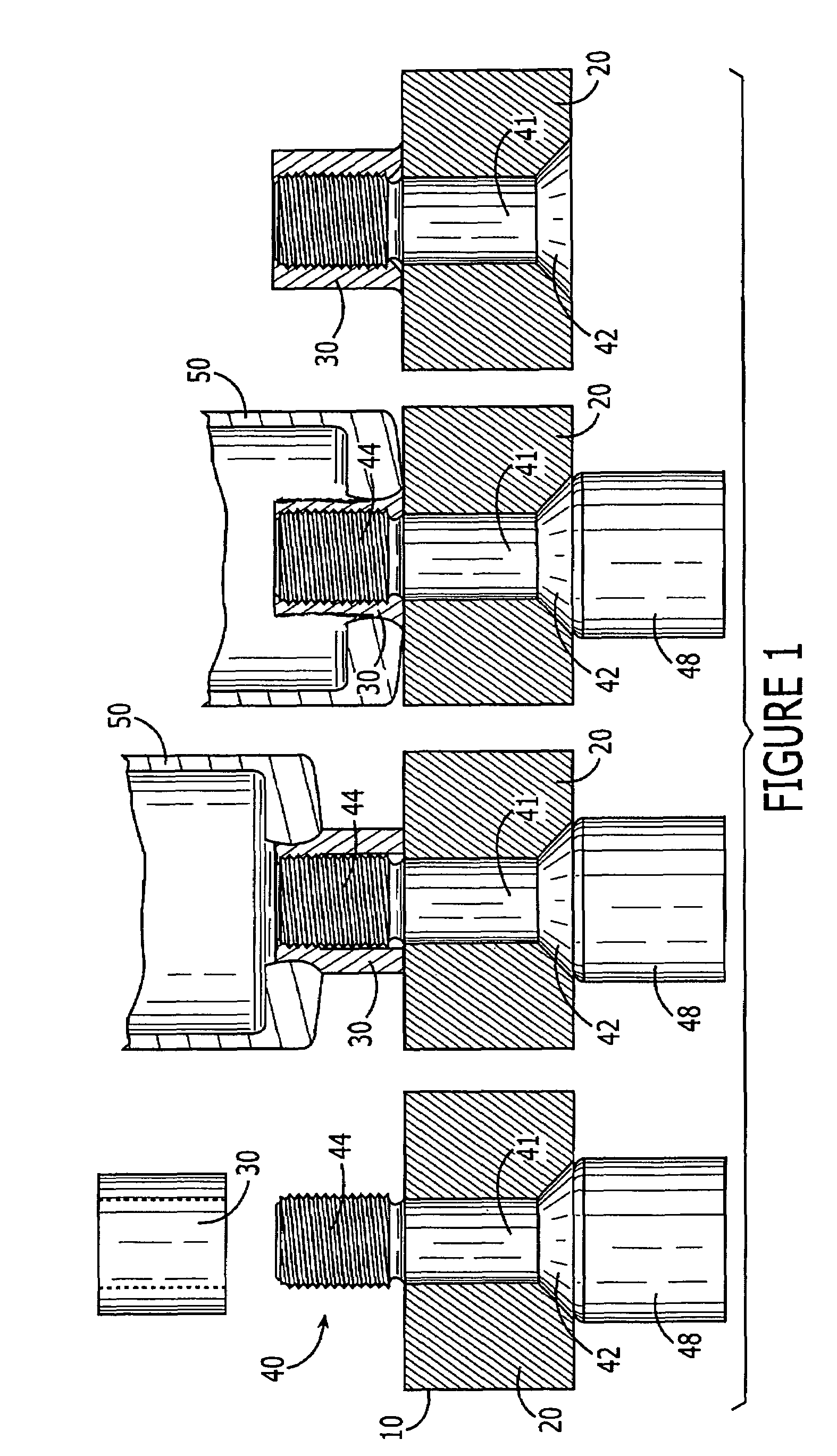

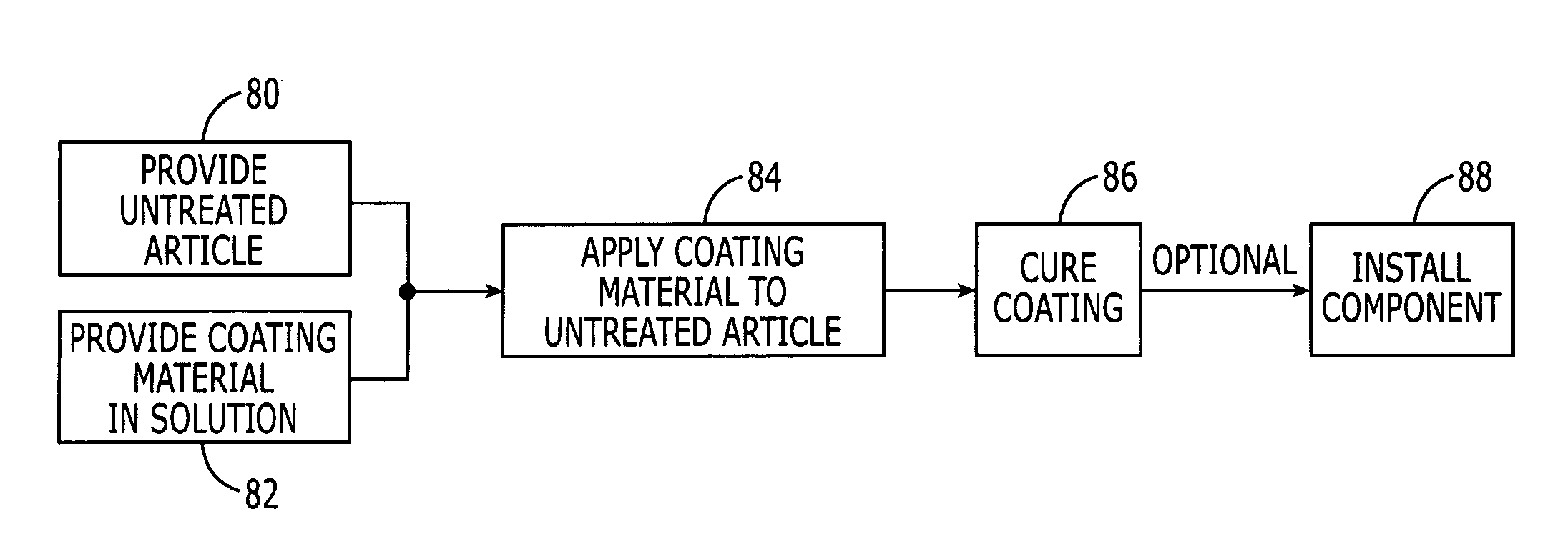

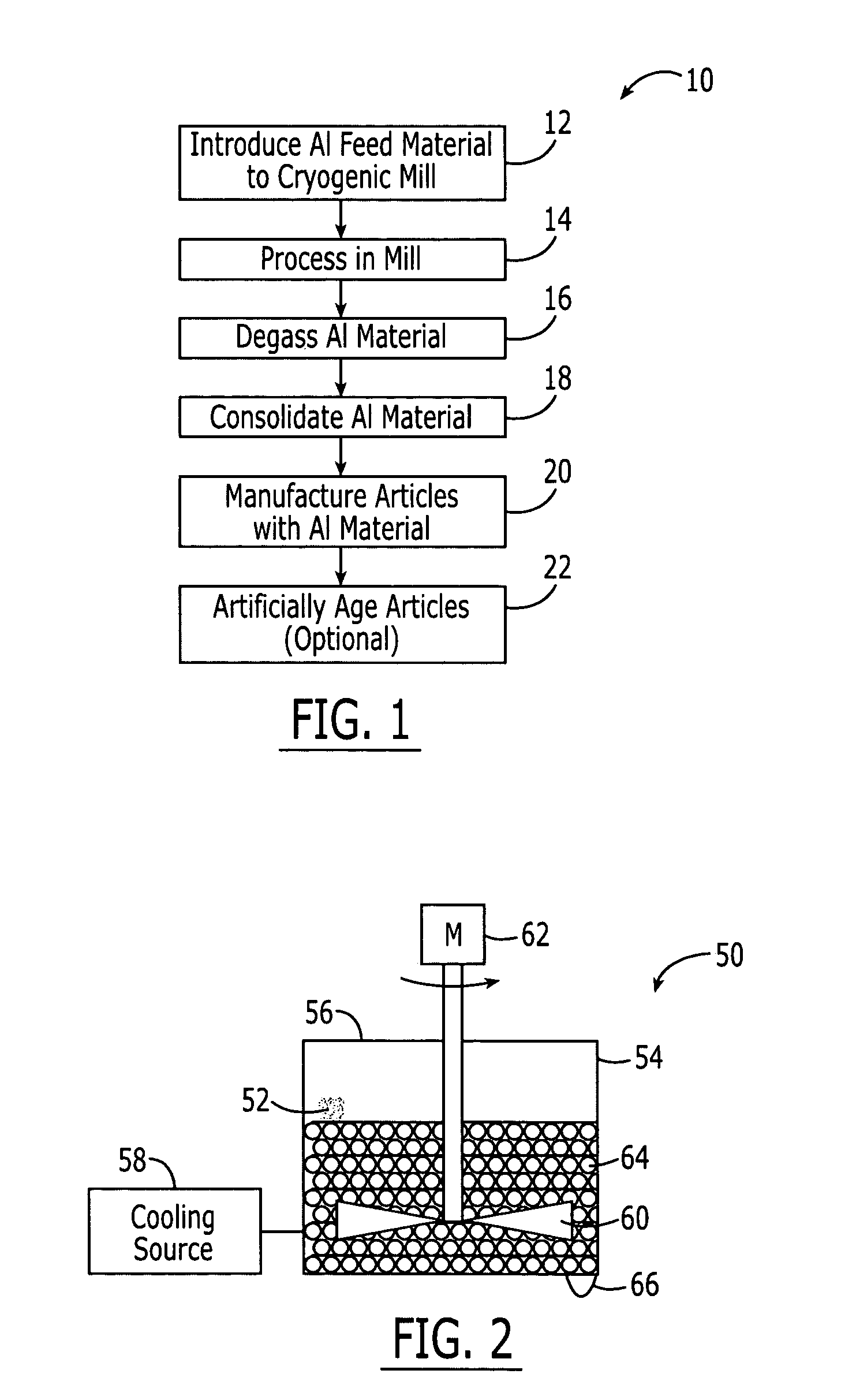

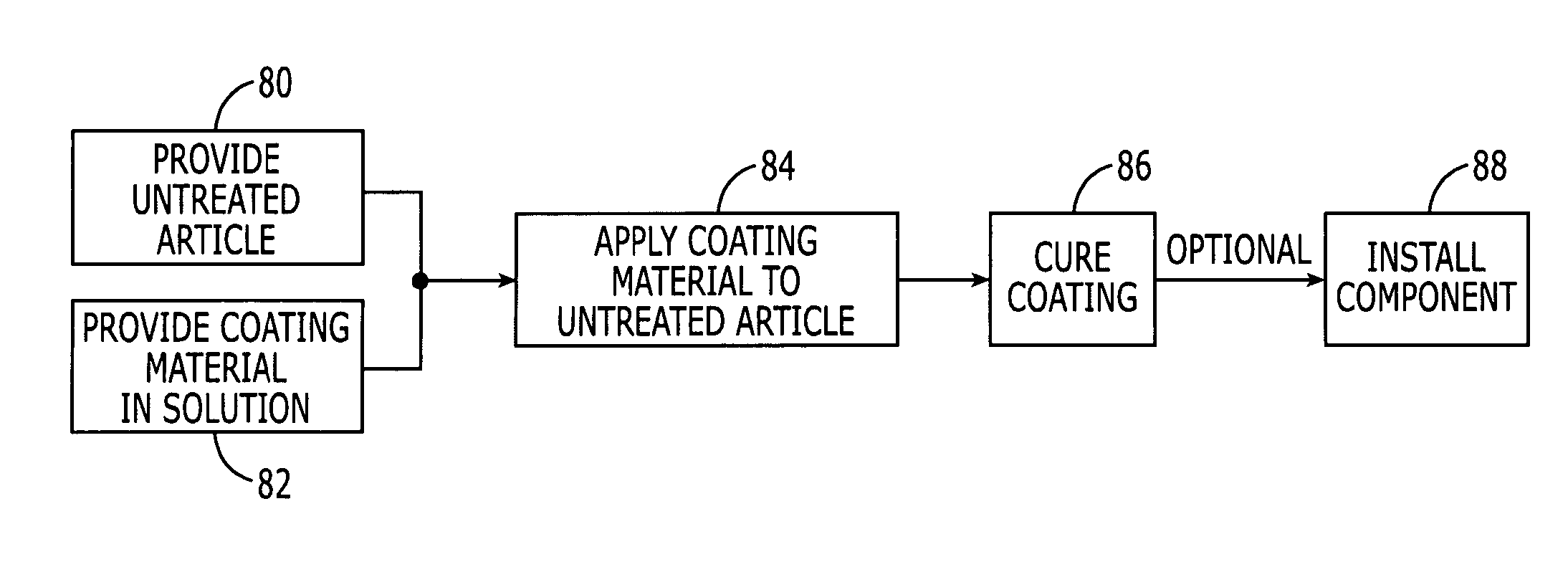

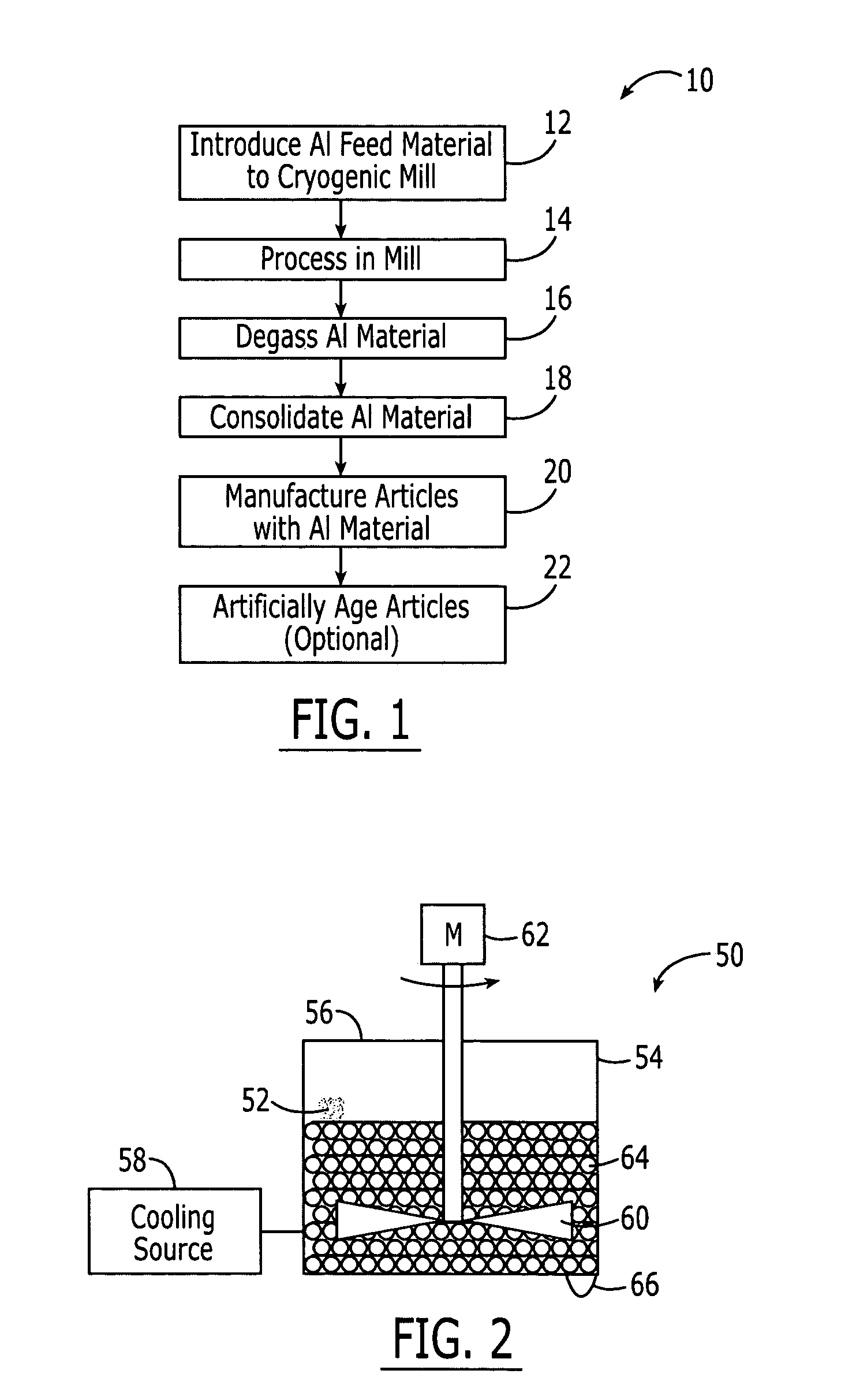

Method for preparing pre-coated, ultra-fine, submicron grain high-temperature aluminum and aluminum-alloy components and components prepared thereby

ActiveUS20060237134A1Improves fatigue life and corrosion resistanceImprove workmanshipRivetsSynthetic resin layered productsCrystalliteUltra fine

The invention is a high-strength, pre-coated, aluminum or aluminum-alloy component comprising an aluminum or aluminum-alloy article having ultra-fine, submicron grain microstructure and an organic coating of phenolic resin applied to the surface of the article. The article is prepared from a coarse grain aluminum or aluminum-alloy material that is cryomilled into an ultra-fine, submicron grain material, degassed, and densified. The densified material is formed into an article, and coated with an organic coating containing phenolic resin prior to installation or assembly.

Owner:THE BOEING CO

Method for preparing pre-coated, ultra-fine, submicron grain high-temperature aluminum and aluminum-alloy components and components prepared thereby

ActiveUS8137755B2High strengthComponents improvedRivetsMetal-working apparatusUltra fineMaterials science

The invention is a high-strength, pre-coated, aluminum or aluminum-alloy component comprising an aluminum or aluminum-alloy article having ultra-fine, submicron grain microstructure and an organic coating of phenolic resin applied to the surface of the article. The article is prepared from a coarse grain aluminum or aluminum-alloy material that is cryomilled into an ultra-fine, submicron grain material, degassed, and densified. The densified material is formed into an article, and coated with an organic coating containing phenolic resin prior to installation or assembly.

Owner:THE BOEING CO

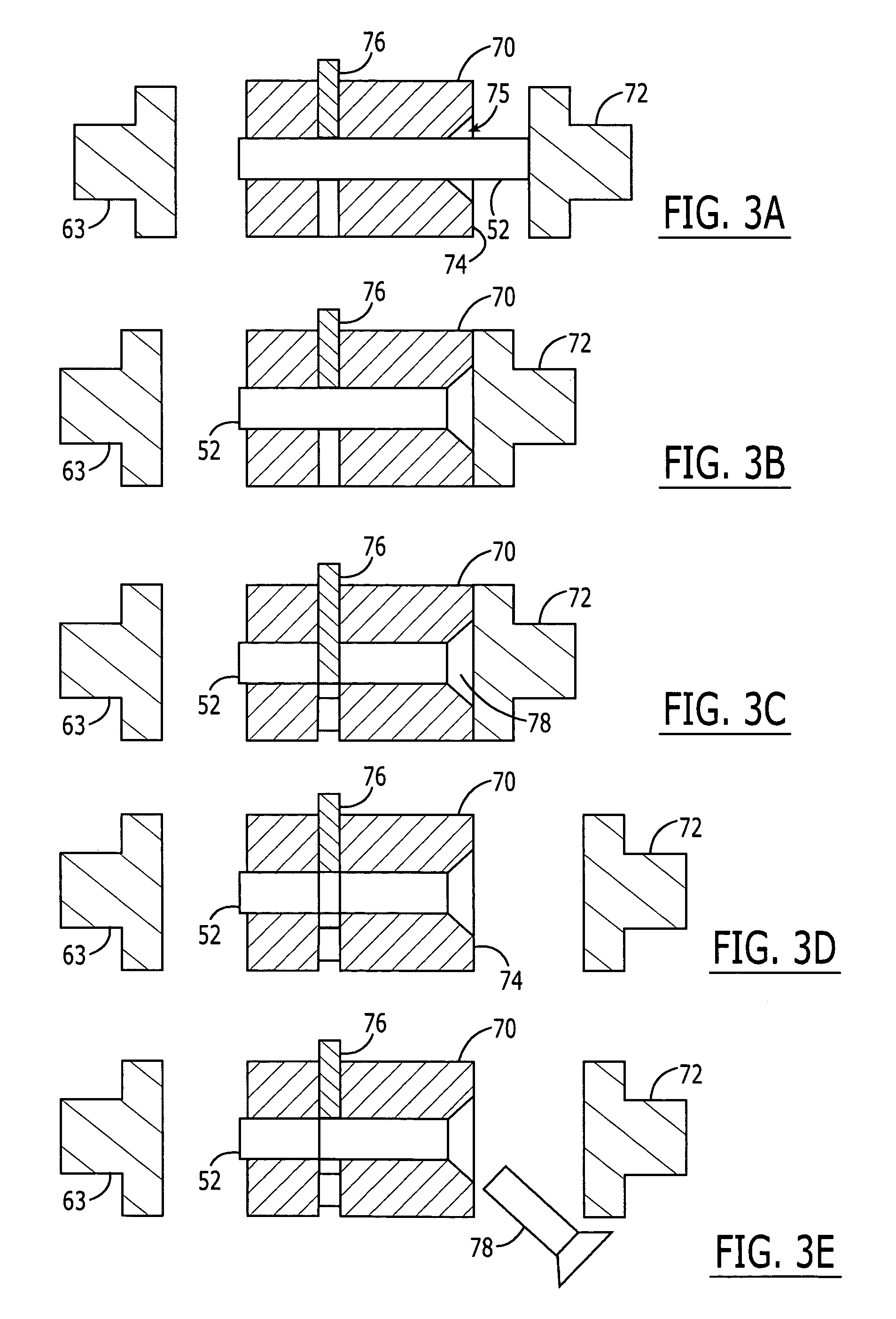

Variable working condition active-control light-coal complementation indirect air-cooling generation system and method

The invention discloses a variable working condition active-control light-coal complementation indirect air-cooling generation system and method. The system comprises a boiler, a turbine, a generator, a high-pressure fed water heater, a low-pressure fed water heater, a deaerator, a steam extraction branch control valve, an absorption type refrigerator, an air-cooling condenser, a fed water branch control valve, a mirror field heat exchanger and a composite paraboloid light condenser. In the daytime in summer, the environmental temperature rises, the back pressure of the turbine rises, the turbine carries out low-pressure steam extraction to drive the absorption type refrigerator to cool air at the inlet of the air-cooling condenser, the back pressure of the turbine is made to reach the design valve, and the light condenser is used for replacing original low-pressure steam extraction to heat fed water. In the daytime in winter, the environmental temperature decreases, the back pressure of the turbine can keep the design value, the turbine carries out low-pressure steam extraction to continue expansion working, and the light condenser is used for replacing original low-pressure steam extraction to heat fed water. By means of the variable working condition active-control light-coal complementation indirect air-cooling generation system and method, the problem of the variable working condition operation efficiency of a traditional air-cooling unit is reduced in summer is solved, the annual average generation efficiency of the unit is improved, and efficient utilization of low-temperature solar energy is achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Comprehensive optimized smoke discharge waste heat deep recycle system of smoke in thermal power plant

InactiveCN102818276AReduce cooling water consumptionReduce the temperatureLiquid degasificationCombustion technology mitigationProcess engineeringTower

The invention relates to a comprehensive optimized smoke discharge waste heat deep recycle system of smoke in a thermal power plant. The system comprises a smoke cooler is arranged at the back of a dust remover and in front of a desulfurizing tower in a smoke channel. A preferable scheme further comprises a smoke discharge waste heat utilizing device used for enabling absorbed heat to heat condensation water or enabling a steam air heater to heat air to improve air supply temperature. Compared with the prior art, the system greatly reduces smoke discharge temperature, simultaneously completely utilizes recycled heat and improves unit efficiency.

Owner:安徽省科捷能源科技有限公司

Method and device for utilizing oxygen-enriched combustion heat

ActiveCN103234213AReduce pumpingIncrease workCombustion processIndirect carbon-dioxide mitigationProcess engineeringFlue-gas condensation

The invention discloses a method and a device for utilizing oxygen-enriched combustion heat. The method comprises step A, dividing outlet flue gas of a boiler (1) into a first part of flue gas, a second part of flue gas and a third part of flue gas, wherein the first part of flue gas preheats oxygen fed into the boiler (1), the second part of flue gas heats circulating flue gas fed into the boiler (1), and the third part of flue gas heats water; and step B, mixing and feeding the first part of flue gas, the second part of flue gas and the third part of flue gas into a flue gas condenser (18) after heat exchange, dividing the flue gas into two parts after the flue gas is dried and condensed to the normal temperature, feeding one part of flue gas into circulating flue gas preheater (3) as circulating flue gas, and feeding the other part of flue gas into a flue gas compressor (11). By means of the method and the device, the power generation efficiency of an oxygen-enriched combustion power station can be improved remarkably, and CO2 trapping costs of coal-fired power plants can be reduced.

Owner:SOUTHEAST UNIV

Compound red sage root freezing-dried powder injection containing tanshinol and its preparation method

InactiveCN101085001AIncrease workIncrease cardiac outputPowder deliveryHydroxy compound active ingredientsGinsenoside Rb1Panax notoginseng extract

Owner:TIANJIN TASLY ZHIJIAO PHARMA

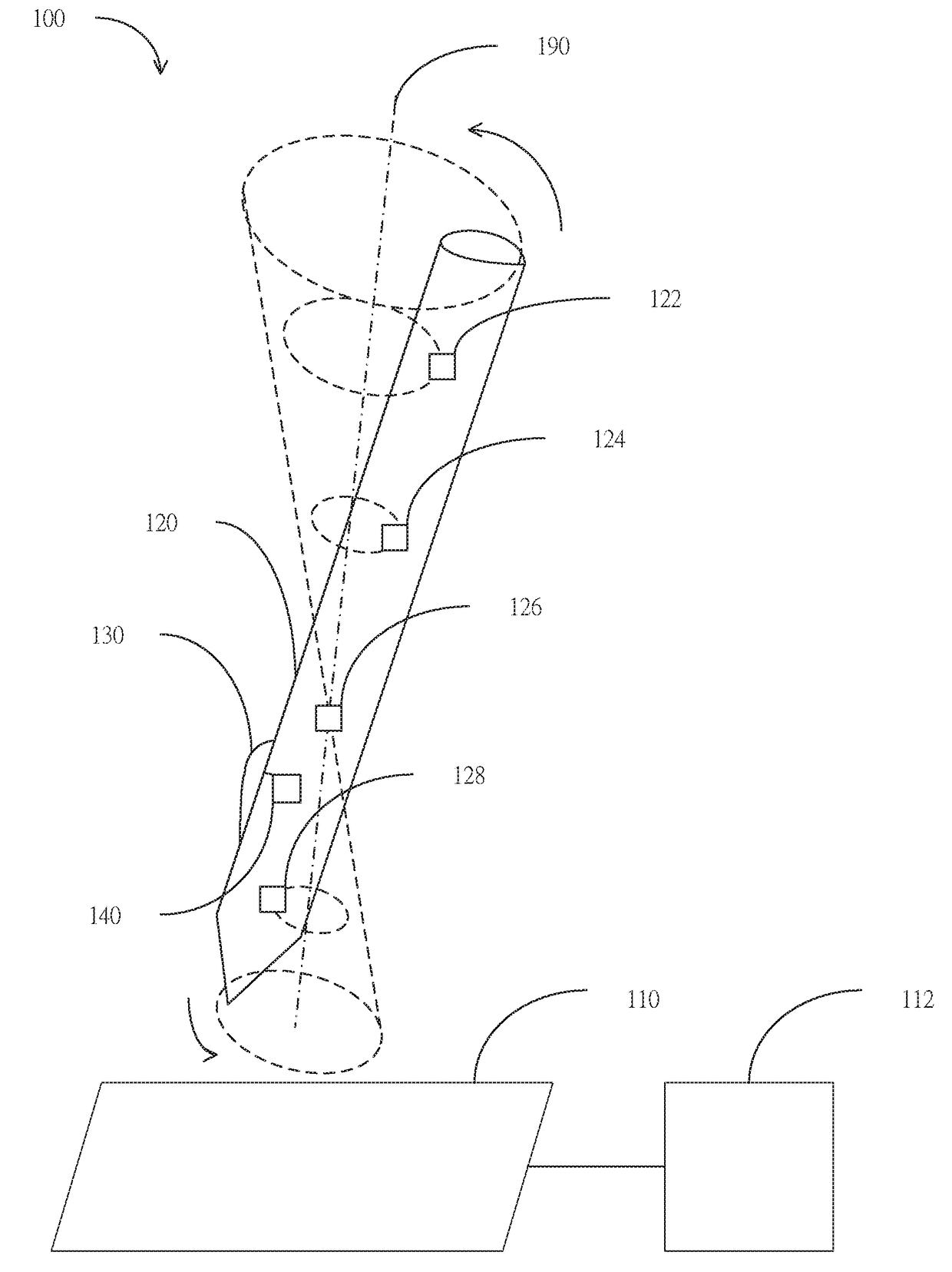

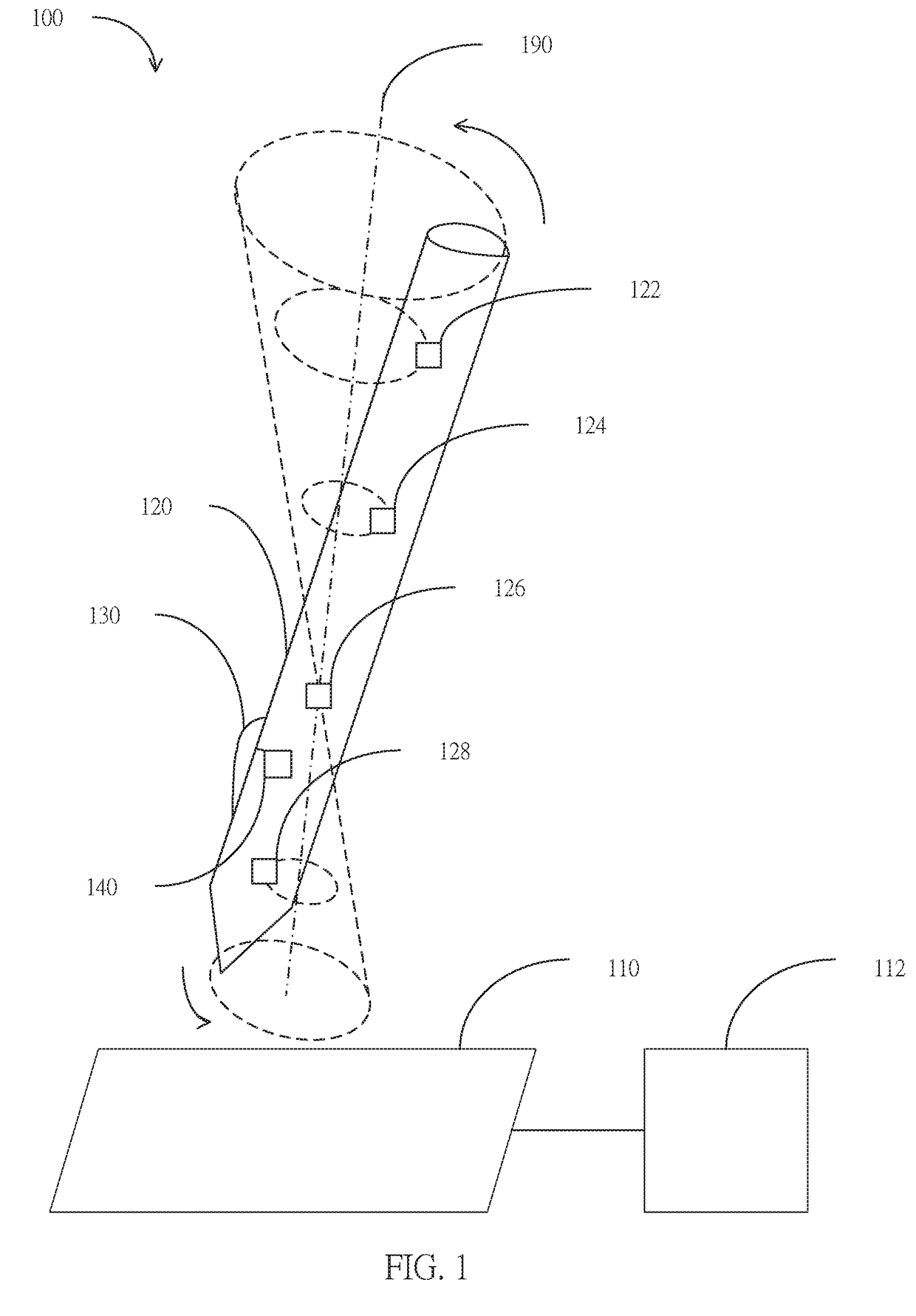

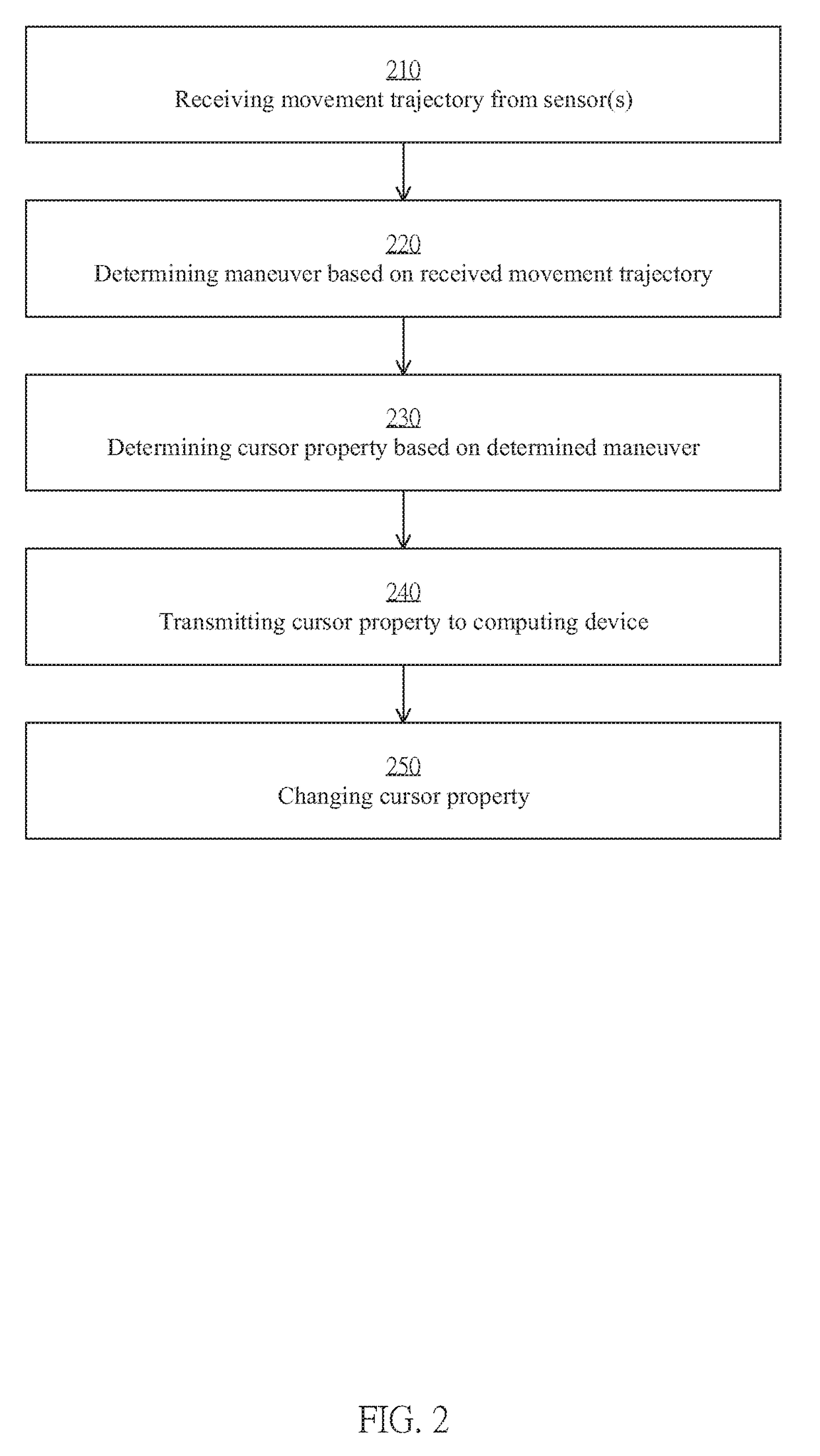

Touch Sensitive System and Stylus for Commanding by Maneuvering and Method Thereof

ActiveUS20170131802A1Increase workReduce fatigueInput/output processes for data processingPostural orientationData library

A stylus for commanding by maneuvering is provided. The stylus includes a communication module for connecting with a computing device. The computing device is equipped with a touch sensitive panel for detecting the location of the stylus on or near the touch sensitive panel. The stylus includes at least one posture sensor; a memory for storing a maneuver database; and a stylus processor. The maneuver database store a plurality of maneuvers, each with associated one or more sets of moving vectors and an associated command. The stylus processor is configured to receive a moving trajectory from the posture sensor and to calculate one or more sets of moving vectors; based on the calculated one or more sets of moving vectors, finding the associated maneuver and the associated command in the maneuver database; and transmitting the command to the computing device via the communication module.

Owner:EGALAX EMPIA TECH INC

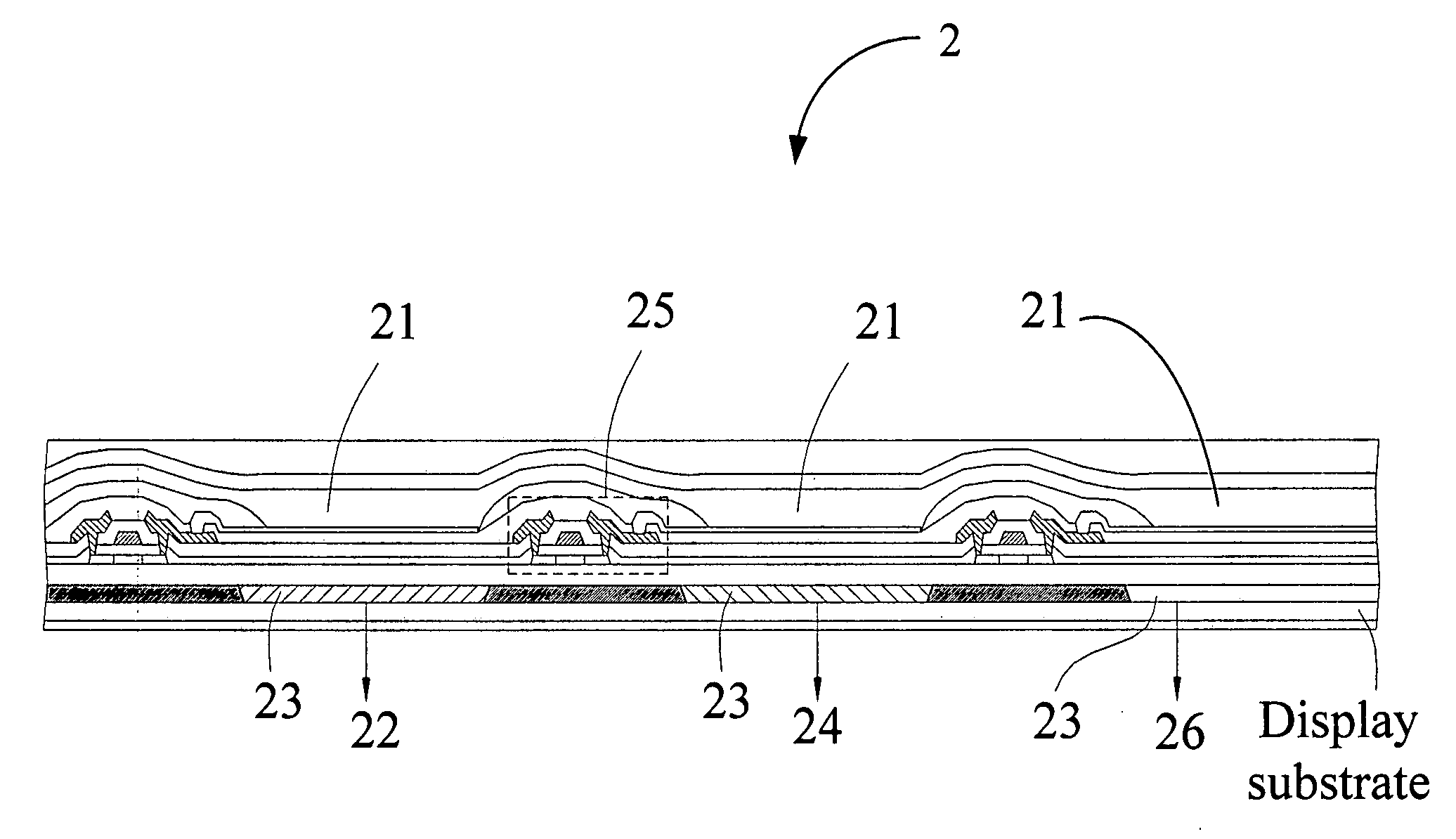

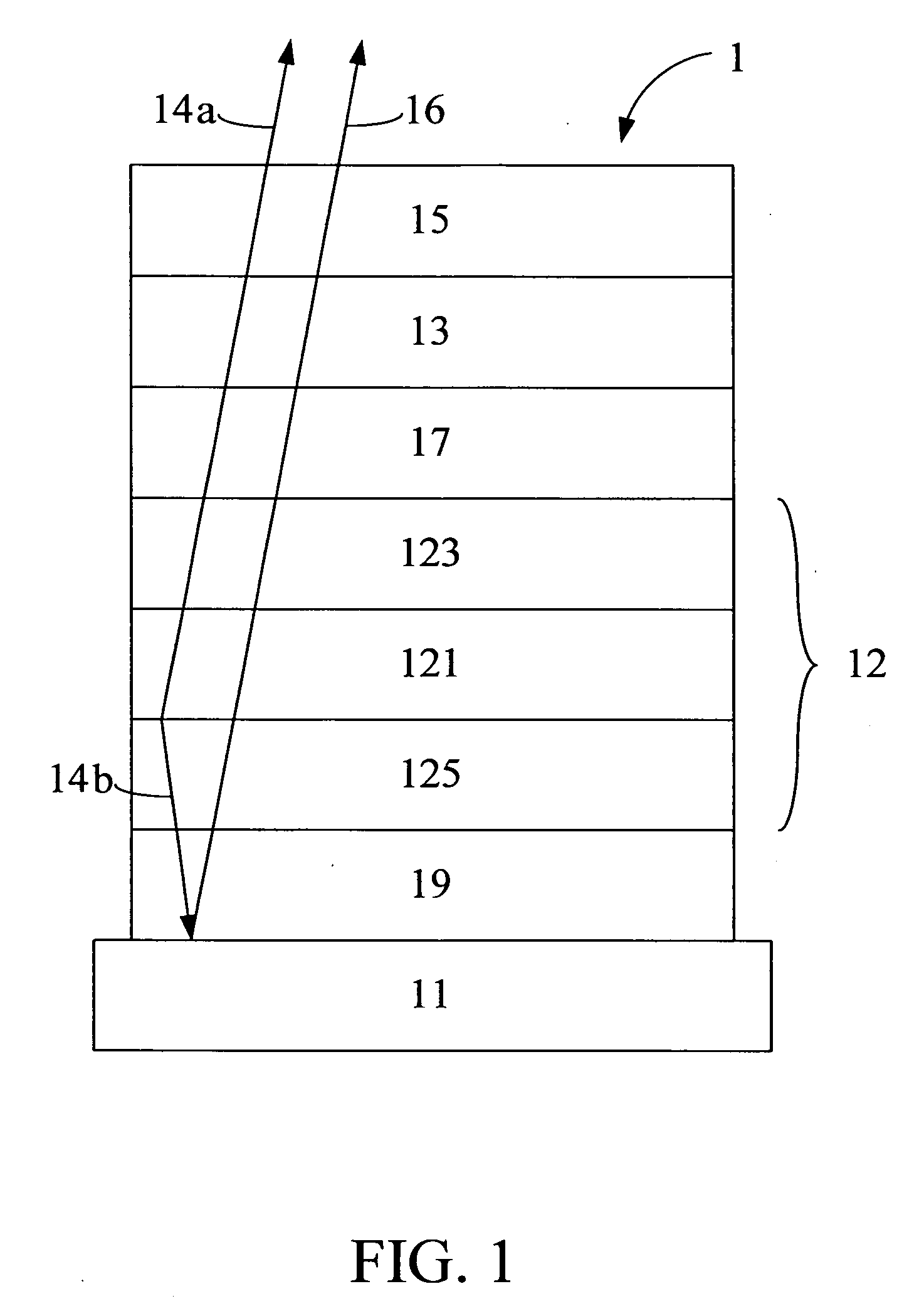

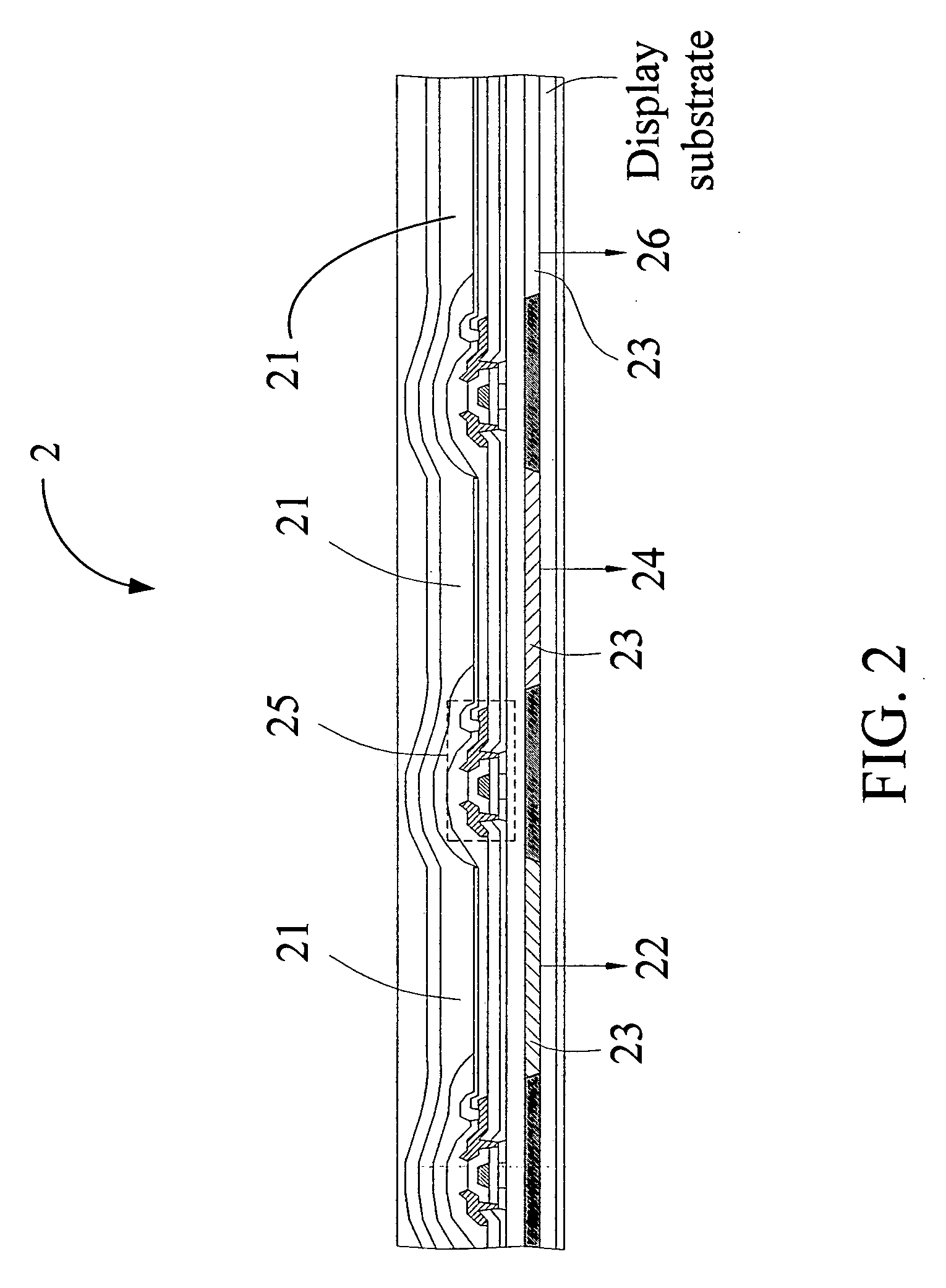

White organic electroluminescent elements and displays using the same

ActiveUS20080070033A1Increase workConvenience to workSolid-state devicesRecord information storageOrganic electroluminescenceChemistry

A white organic electroluminescent element for an organic electroluminescent display and a display using the white organic electroluminescent are provided. The organic electroluminescent display comprises a white organic electroluminescent element and a color filter. The white organic electroluminescent element comprises an anode, a cathode, a capping layer, and an organic layer. The capping layer is disposed on the cathode. The organic layer is disposed between the anode and the cathode, and comprises a blue light emitting layer. The thickness of the organic layer is X+120N nm, wherein 85≦X≦125, and N=0, 1, or 2. The white organic electroluminescent element is configured to emit a white light. The color filter is configured to convert the white light to a first color beam, with the first color beam being either red, blue, or green.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com