Painting apparatus

A coating and coating machine technology, applied in the direction of spraying devices, liquid spraying devices, spraying devices with movable outlets, etc., can solve the problems of high operating costs, achieve good coating quality, reduce the scope, and stabilize the supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

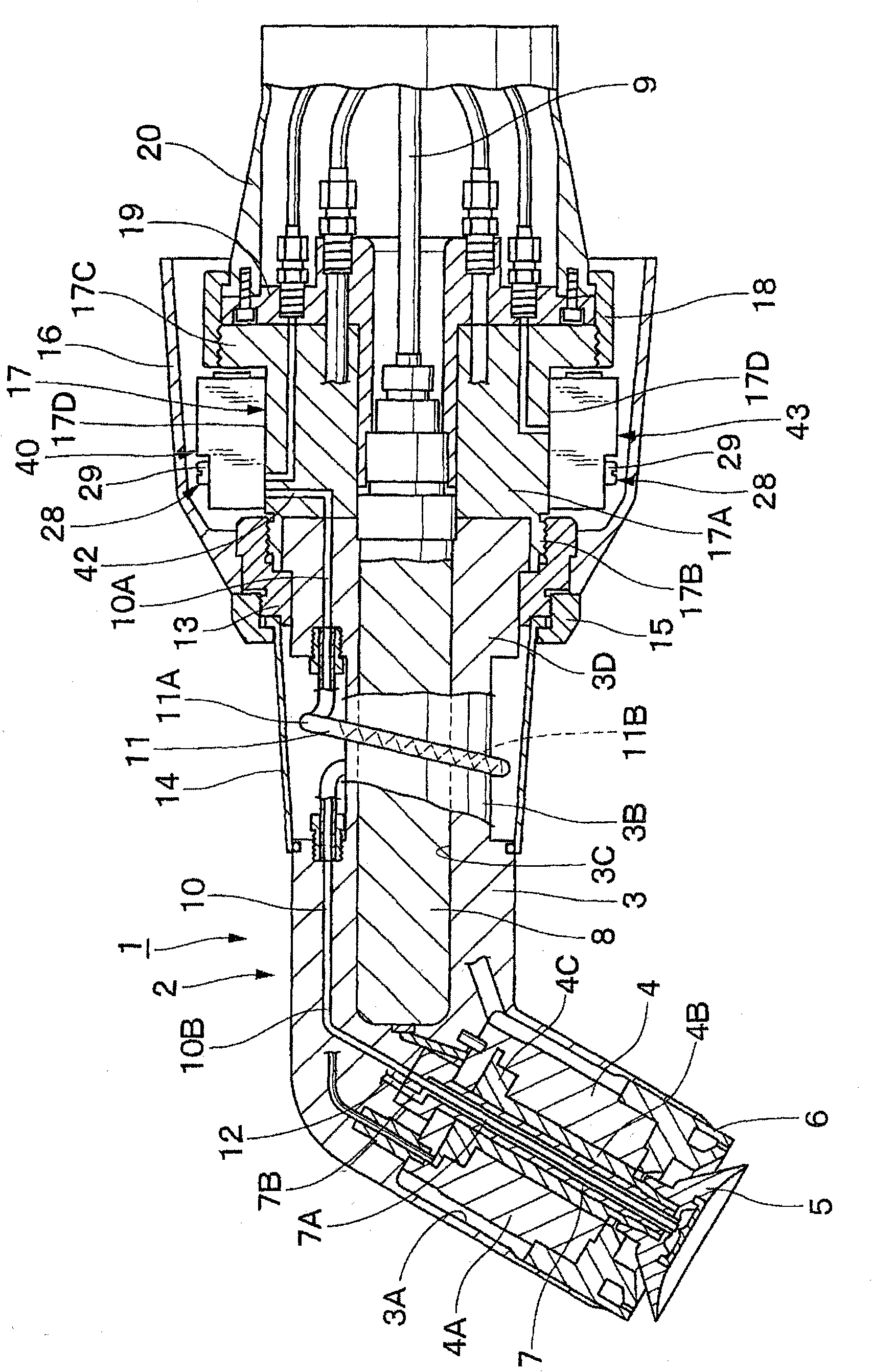

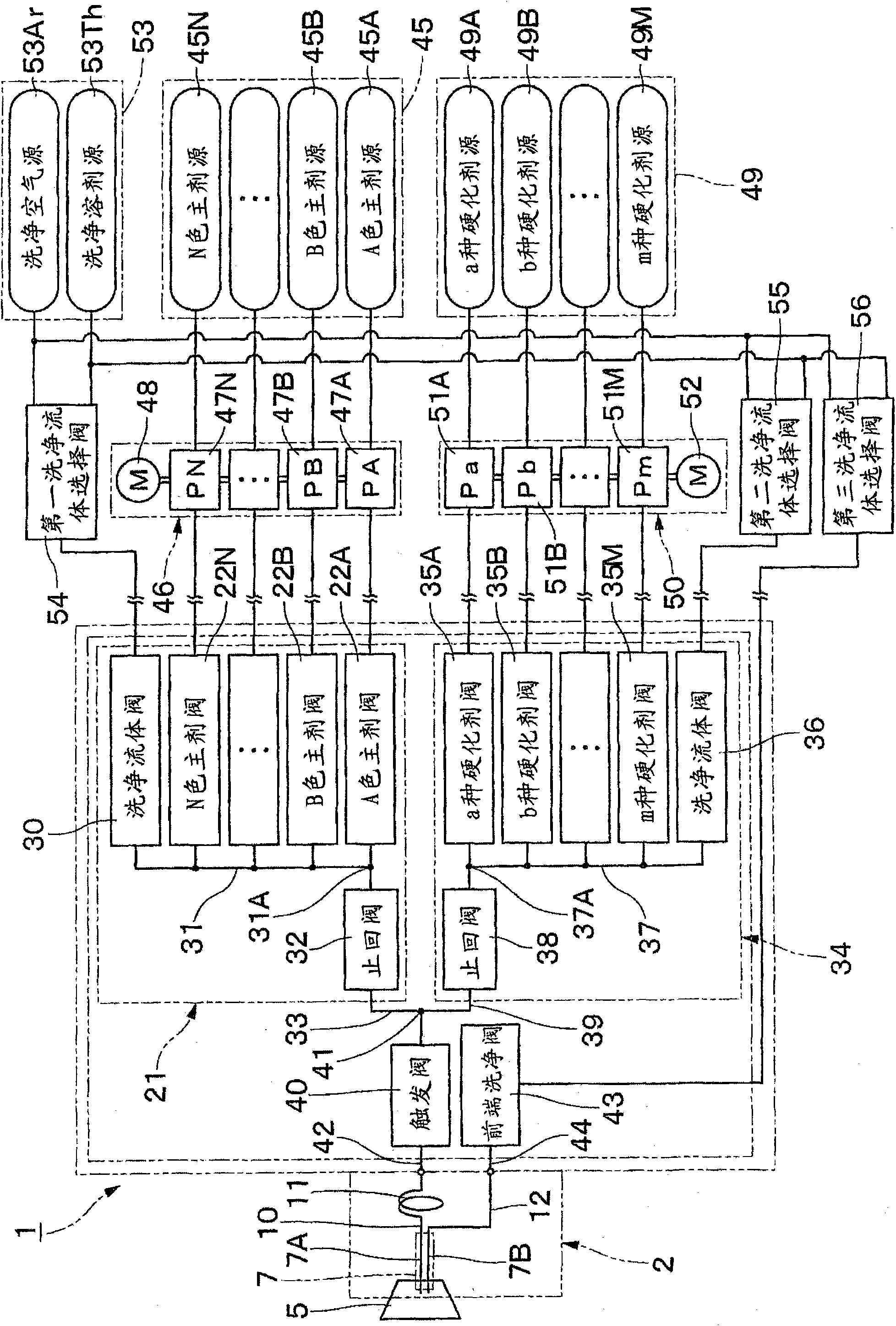

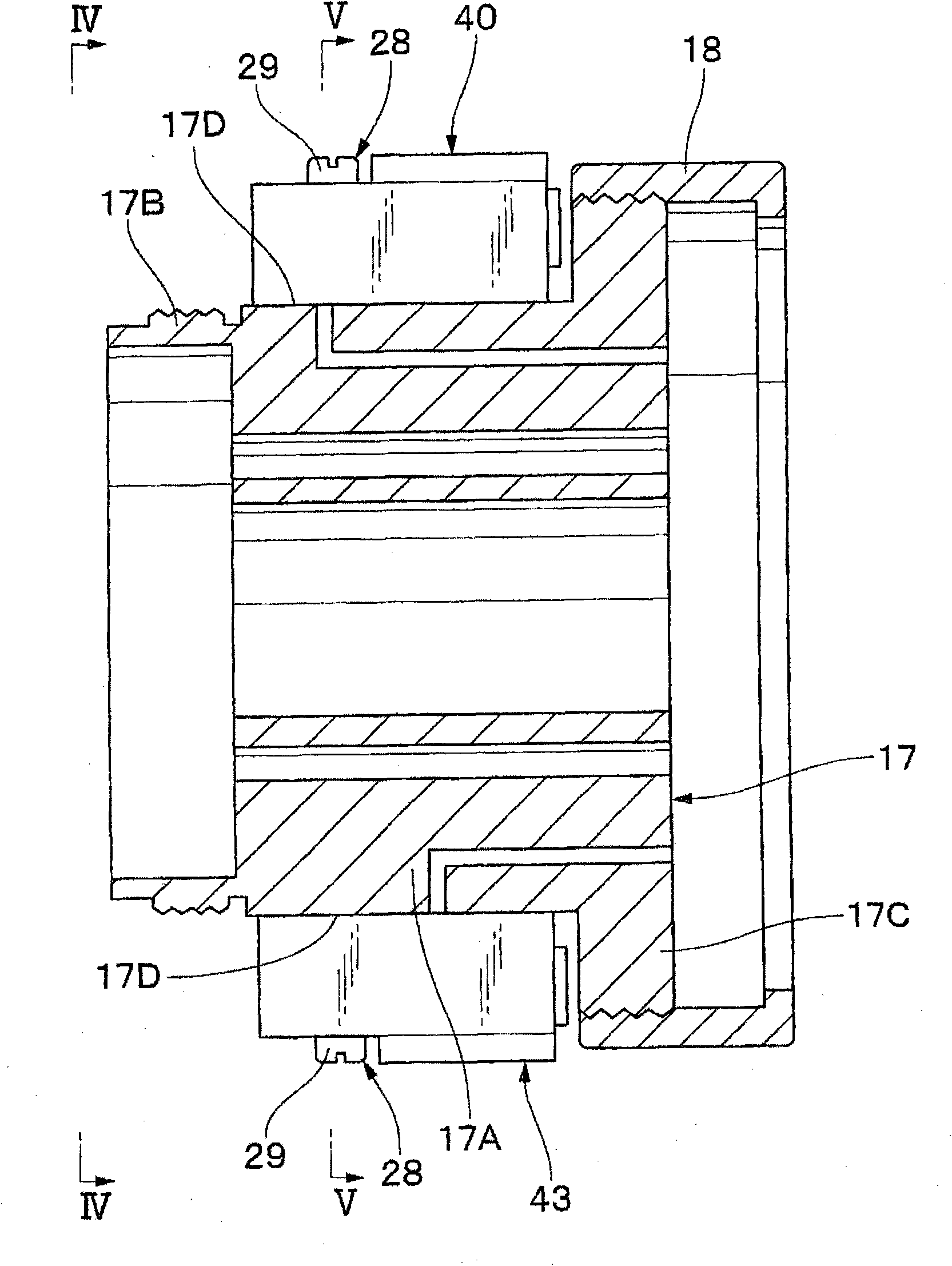

[0052] Hereinafter, a coating device according to an embodiment of the present invention will be described in detail with reference to the drawings, taking a rotary atomizing head type coating device including a rotary atomizing head as a representative example.

[0053] first, Figure 1 to Figure 8 The first embodiment of the coating apparatus of the present invention is shown.

[0054] exist figure 1 In , reference numeral 1 denotes a rotary atomizing head type coating device (hereinafter referred to as coating device 1 ) of the first embodiment. The coating device 1 mixes a pigment main ingredient and a curing agent as a hardening catalyst to harden the main ingredient in a predetermined ratio to form a two-component paint, and applies the two-component paint using a rotary atomizing head 5 described later. coating. In addition, this painting apparatus 1 is attached to the front-end|tip of the arm part (not shown) of a painting robot, a reciprocating type, etc., for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com