Process without opening cylinder for quickly removing carbon deposition of combustion chamber of engine

A technology of engine and combustion chamber, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of engine damage, affecting the performance of the whole vehicle, and low efficiency, so as to prolong the design life, improve maintenance work efficiency, reduce The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

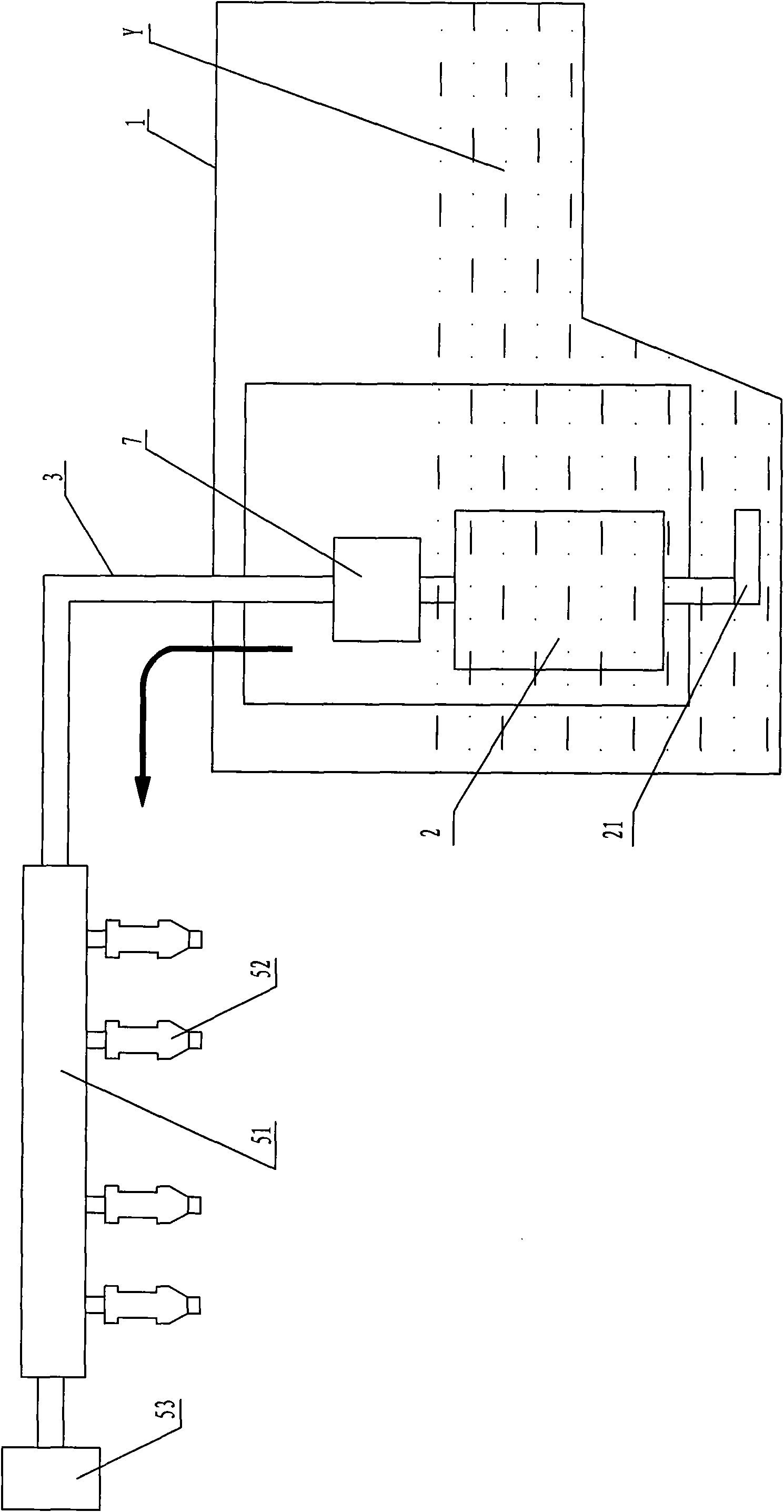

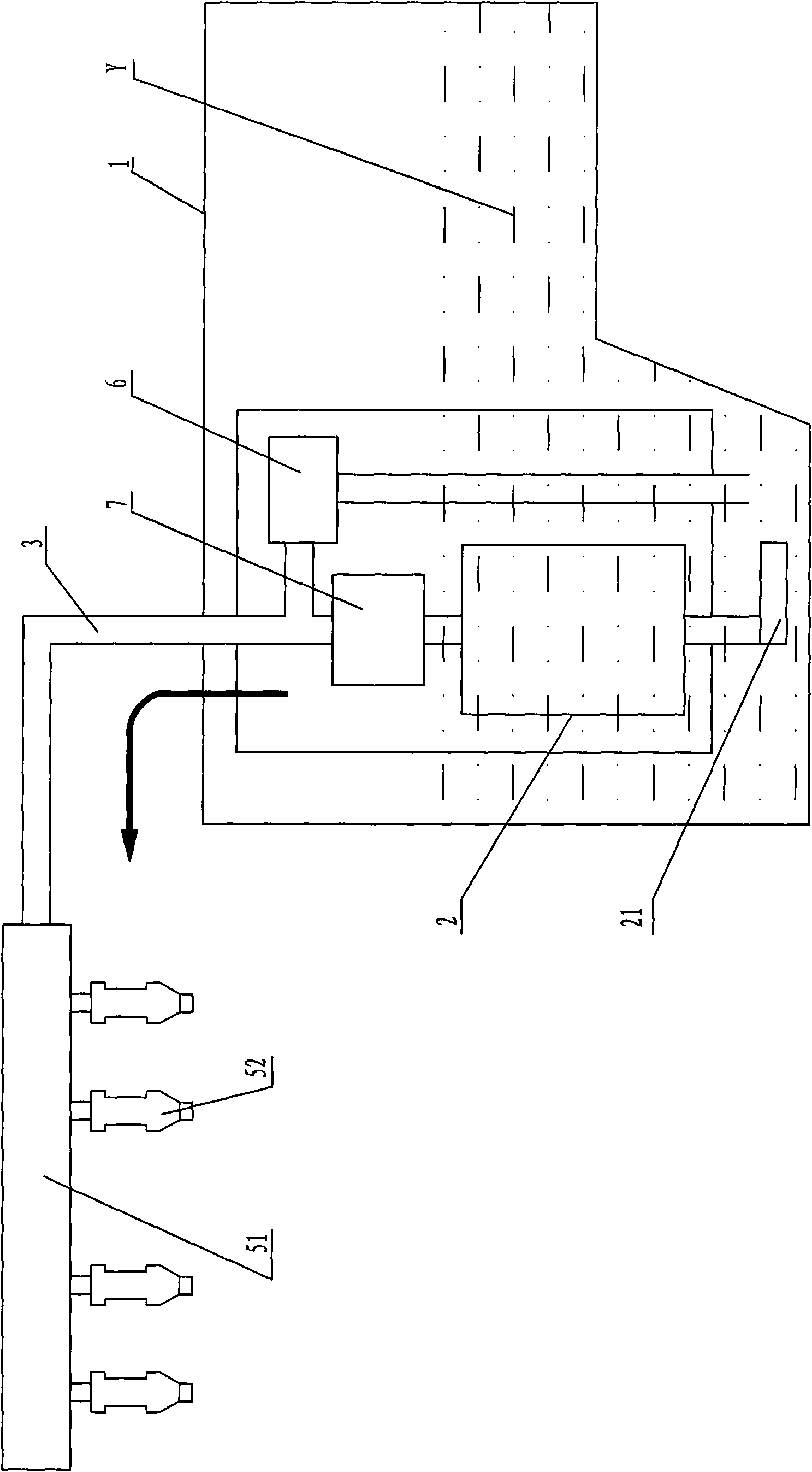

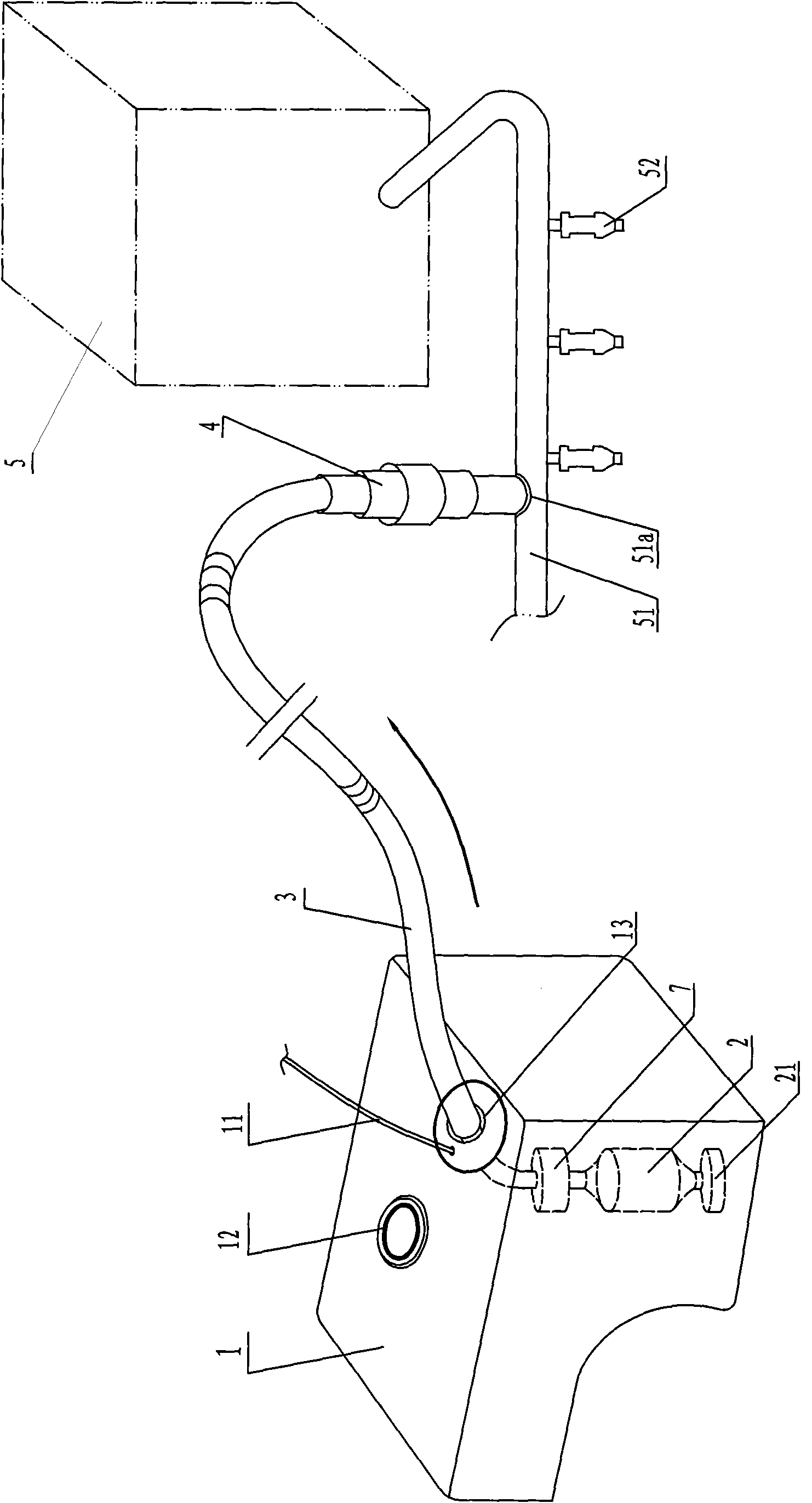

[0033] see figure 1 , 2 , with reference to image 3 , The invention relates to a process for rapid removal of carbon deposits in engine combustion chambers without opening cylinders. The additive gasoline Y involved in this process is formed by uniformly mixing an appropriate amount of fuel detergent with the maximum additive amount allowed by the cleaned engine 5 without shutting down, and ordinary vehicle gasoline, and is filled in the additive gasoline tank 1 .

[0034] Because the fuel detergent used in the present invention has the characteristics of mild drug property, it has almost no damage to the parts of the engine after use.

[0035] Such as image 3 As shown, the structural feature of the dosing gasoline tank involved in the present invention is that an electric fuel pump 2 and its power supply lead-out line are arranged in the casing 1 of the dosing gasoline tank, and a fuel pump filter is provided at the inlet end of the electric fuel pump 2 21, the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com