Composite type catalyst and preparation method thereof

A catalyst and composite technology, applied in chemical instruments and methods, physical/chemical process catalysts, preparation/purification of sulfur, etc., can solve the problems of easy deactivation, expensive materials, high temperature required, etc. Effects of absorption and decomposition, controllable process parameters, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

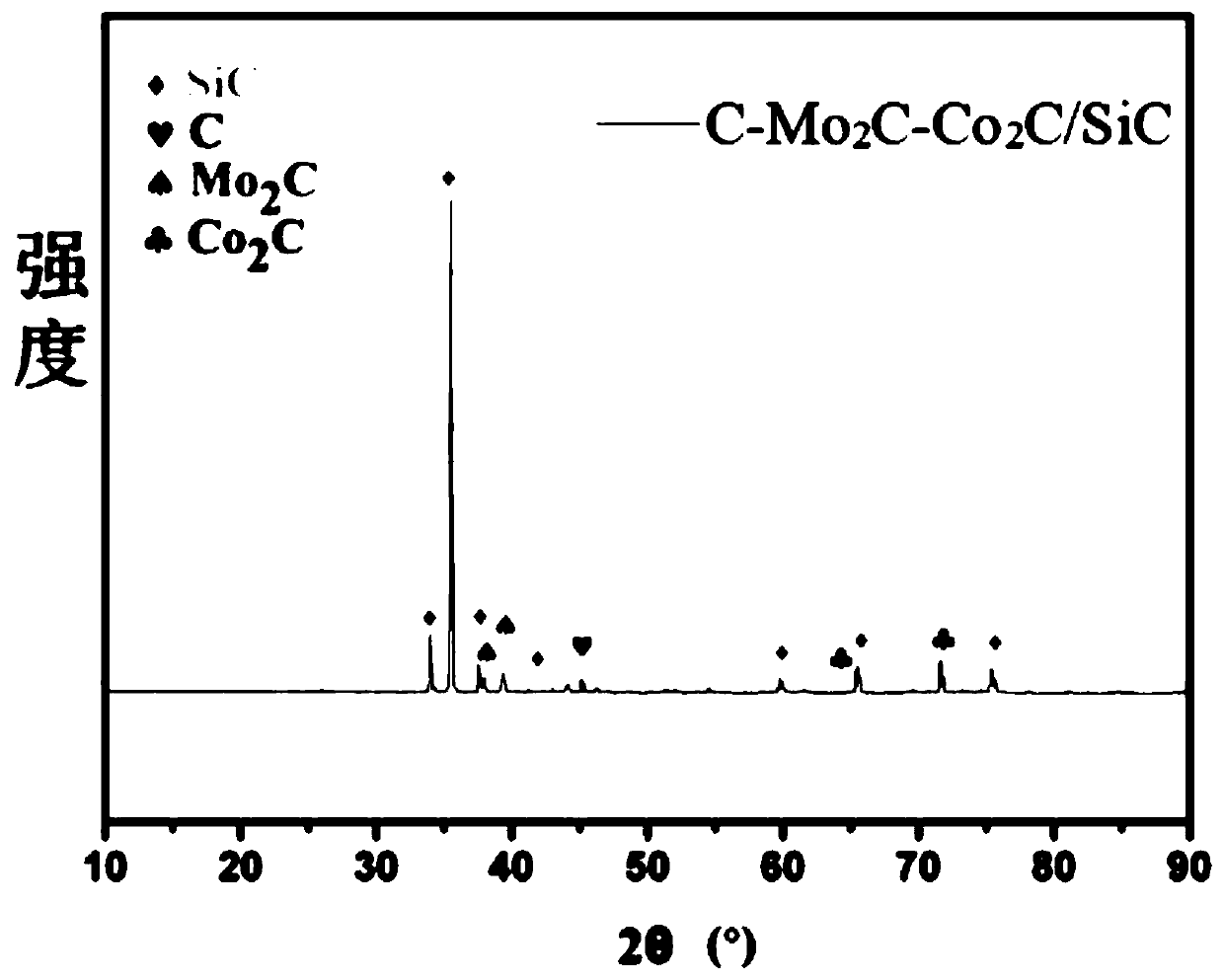

Image

Examples

Embodiment 1

[0021] The specific steps of alkali treatment of silicon carbide: put silicon carbide into an alkali solution of a certain concentration, the treatment temperature is 50-90°C, and the treatment time is 1-6 hours; the alkali solution is sodium hydroxide or potassium hydroxide solution At least one of them, the molar concentration of the alkali solution is 0.2-4 mol / L.

[0022] A kind of preparation method of composite catalyst:

[0023] Step 1: Weigh 0.276g of ammonium molybdate and 0.800g of cobalt nitrate hexahydrate into a beaker, add 40ml of pure water, and stir to dissolve.

[0024] In the second step, 2 g of alkali-treated silicon carbide is weighed and added to the solution in the first step, and stirred on a magnetic stirrer to form a mixed solution.

[0025] The third step is to put the mixed liquid into a constant temperature water bath, firstly age it at 40°C for 30 minutes, then evaporate it at 70°C for 4 hours, and then put it into an oven and dry it at a constant...

Embodiment 2

[0033] The composite microwave catalyst prepared according to Example 1 is applied to the decomposition of catalytic hydrogen sulfide, specifically: first, asbestos is filled in the reaction quartz tube of the microwave reactor to facilitate fixing the catalyst bed, and then the prepared in Example 1 The composite catalyst is placed in a quartz tube to form a microwave catalyst bed, a thermocouple is inserted into the center of the catalyst bed, and then a mixed gas of hydrogen sulfide is introduced to cause a gas-solid phase catalytic reaction to achieve the purpose of decomposing hydrogen sulfide.

[0034] The mixed gas is provided by Dalian Date Gas Co., Ltd., and consists of nitrogen and hydrogen sulfide, wherein the hydrogen sulfide content is 15vol%.

[0035] The gas chromatograph was GC-7890A manufactured by Agilent Corporation, USA.

[0036]The range of microwave power is 0-1350W, preferably 300-800W, and the frequency is 2450MHz.

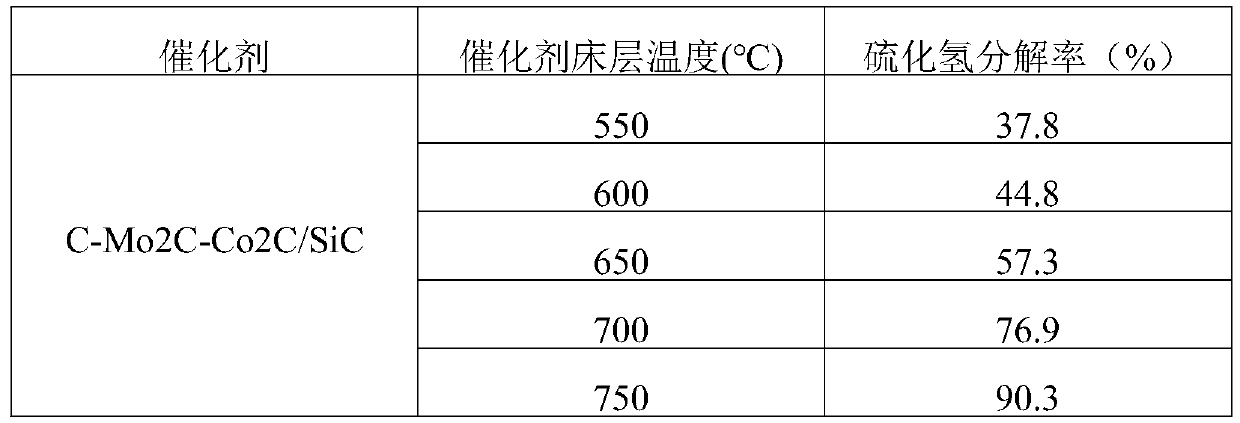

[0037] Details are as follows:

[...

Embodiment 3

[0043] In this example, different kinds of composite catalysts were selected to carry out the hydrogen sulfide decomposition reaction experiment. The dosage of the composite catalyst was 2 g, the mesh size was 40-60 mesh, and the bed temperature of the catalyst was 650°C. The carbonization times were all 1 hour. Hydrogen sulfide mixed gas (use 15vol% H in the present invention 2 S and 85vol% N 2 The mixed gas was tested) the inlet flow rate was 60ml / min, the reaction pressure was normal pressure, and the temperature of the reaction bed was regulated by adjusting the microwave power. The experimental results are shown in Table 2. Table 2 shows the decomposition rate of different catalysts for microwave catalytic decomposition of hydrogen sulfide.

[0044] Table 2

[0045] catalyst

[0046] C-Mo 2 C / SiC, C-Co 2 The decomposition rates of C / SiC and C-WC / SiC catalysts were 50.1%, 49.5%, and 47.3% when the bed temperature was 650°C. This shows that different types o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com