Variable working condition active-control light-coal complementation indirect air-cooling generation system and method

A light-coal complementary and variable working condition technology, applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve the problems of difficult improvement of system economy and waste of fixed investment, so as to avoid idle mirror field and increase system output , is conducive to the effect of making full use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

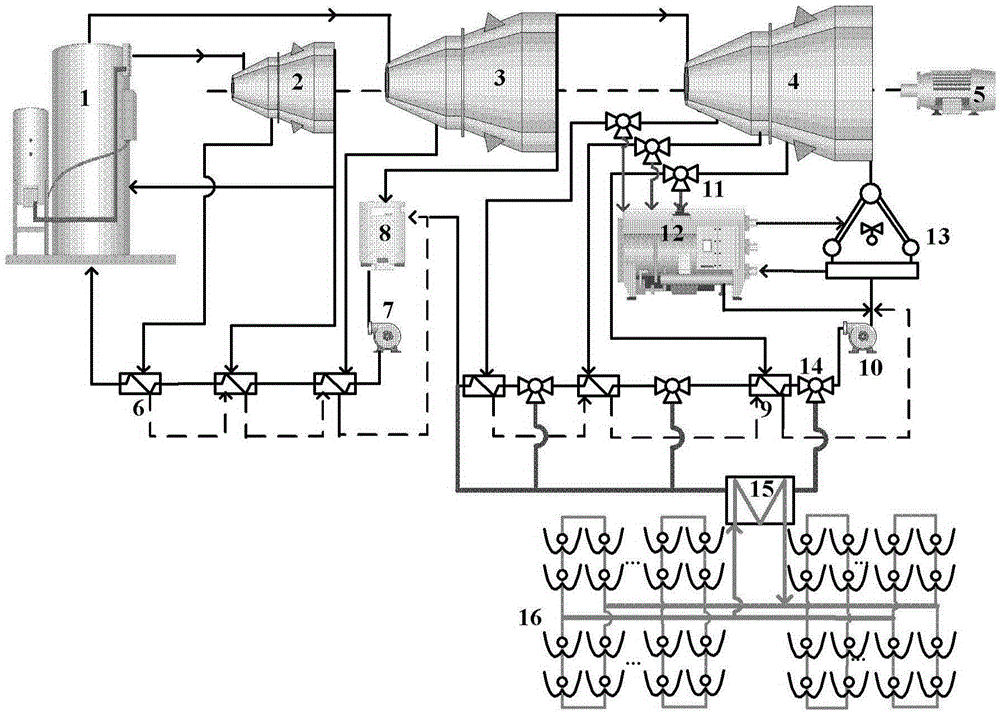

[0039] Such as figure 1 as shown, figure 1 It is a schematic diagram of a light-coal complementary indirect air-cooled power generation system actively regulated under variable working conditions according to an embodiment of the present invention. The system includes a boiler 1, a steam turbine high-pressure cylinder 2, a steam turbine medium-pressure cylinder 3, a steam turbine low-pressure cylinder 4, a generator 5, Feedwater heater 6, high-pressure feedwater pump 7, deaerator 8, low-pressure feedwater heater 9, low-pressure feedwater pump 10, steam extraction flow control valve 11, absorption refrigerator 12, air-cooled condenser 13, feedwater flow control valve 14. Mirror field heat exchanger 15 and compound parabol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com