Patents

Literature

205 results about "Feedwater heater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A feedwater heater is a power plant component used to pre-heat water delivered to a steam generating boiler. Preheating the feedwater reduces the irreversibilities involved in steam generation and therefore improves the thermodynamic efficiency of the system. This reduces plant operating costs and also helps to avoid thermal shock to the boiler metal when the feedwater is introduced back into the steam cycle.

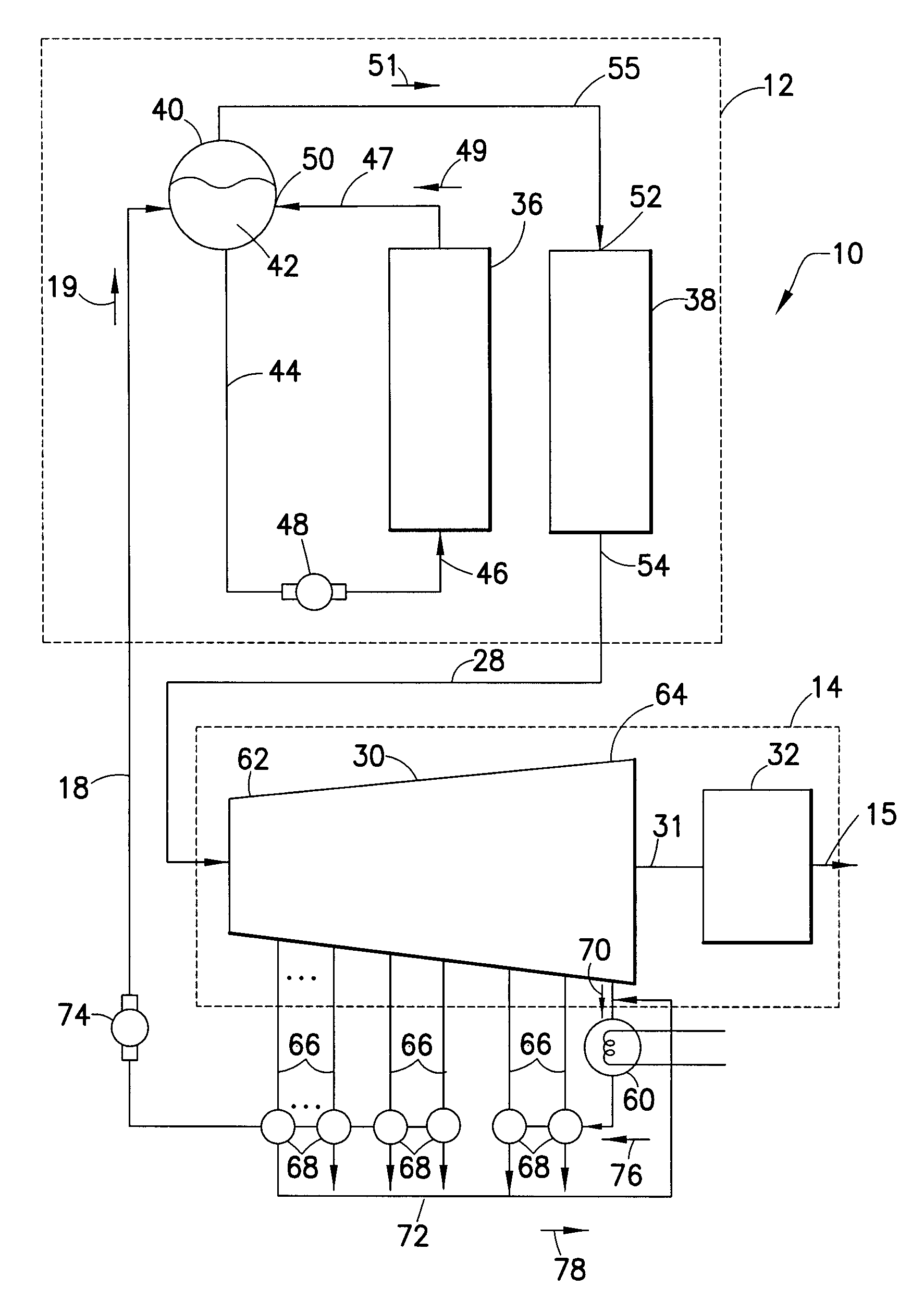

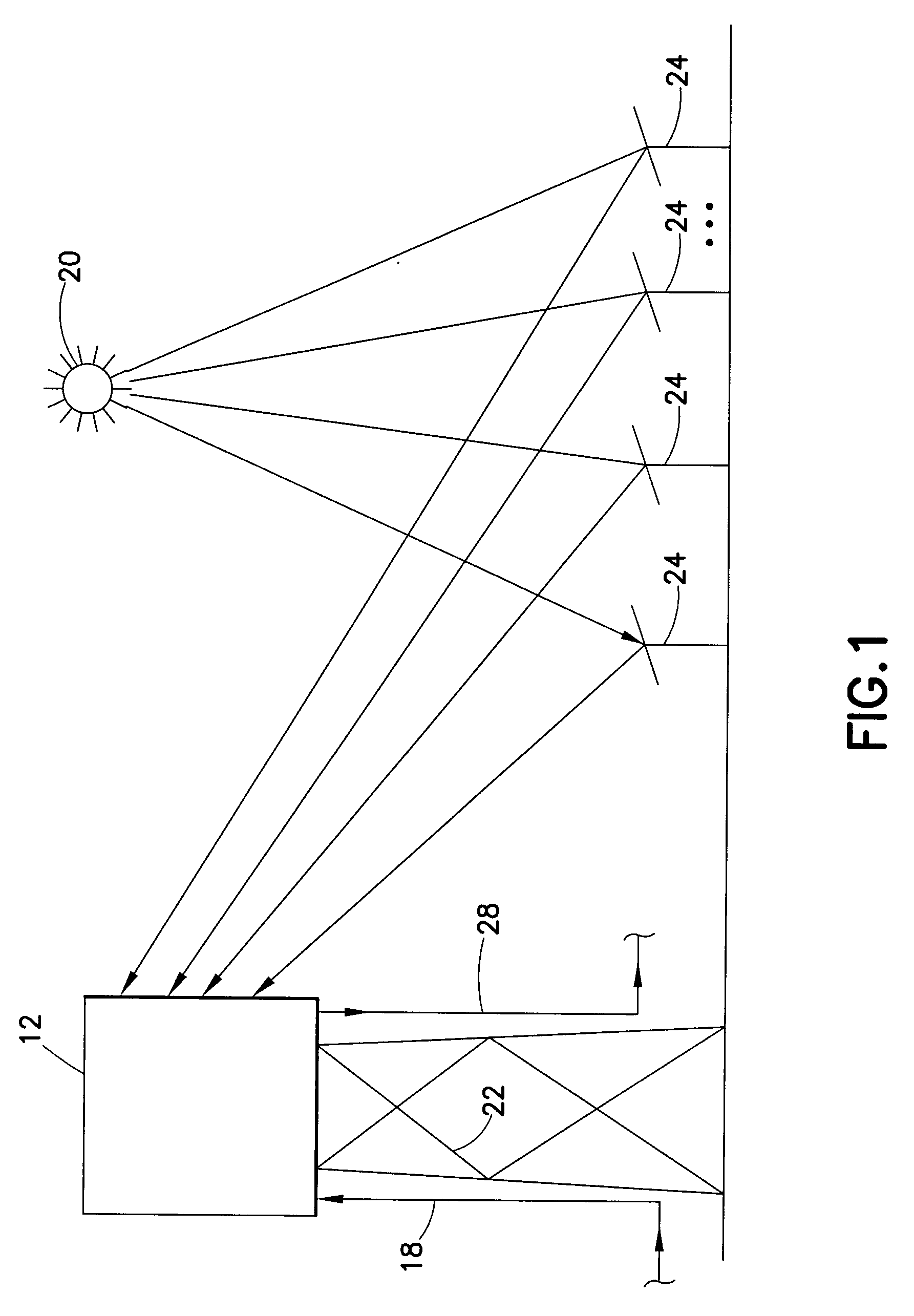

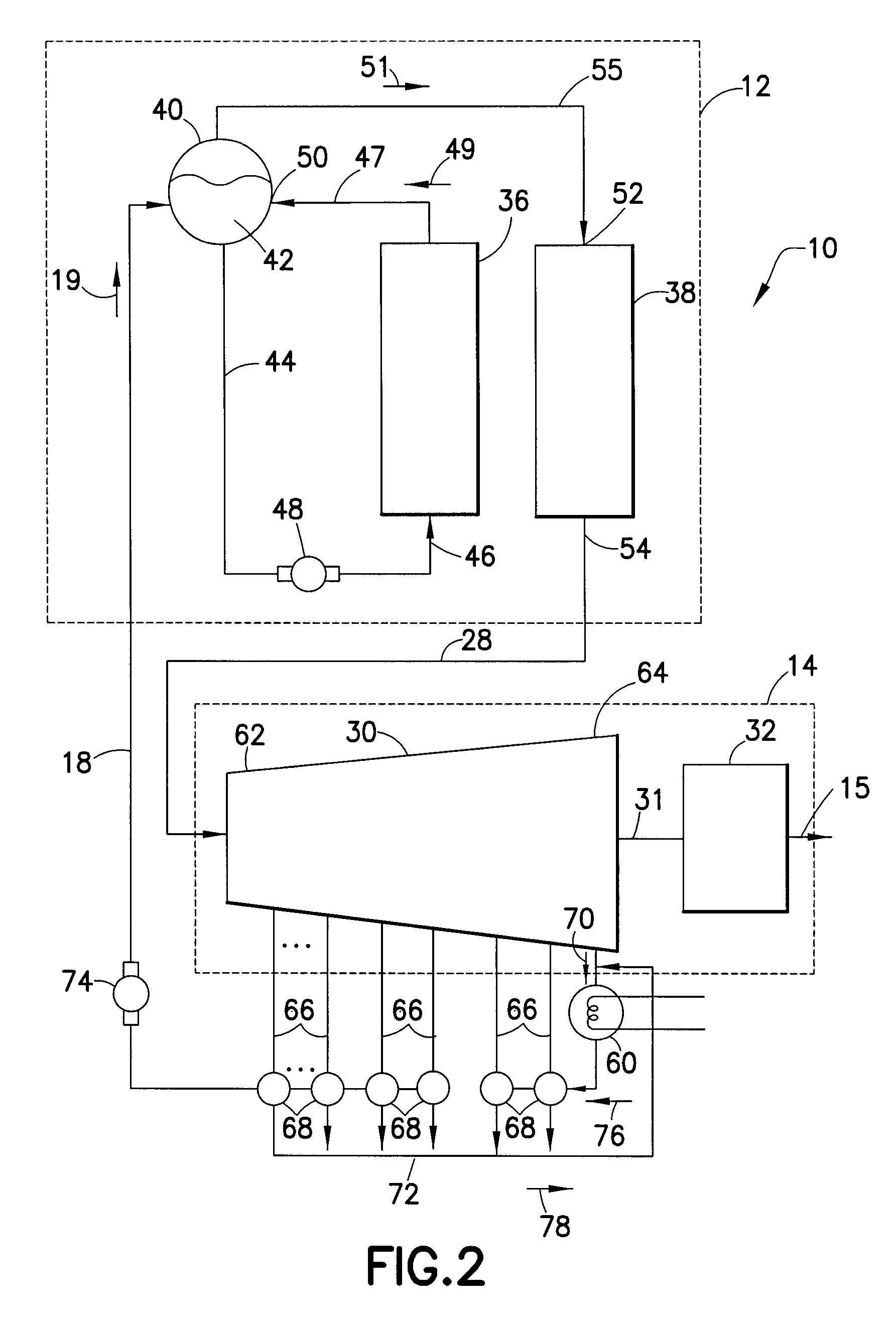

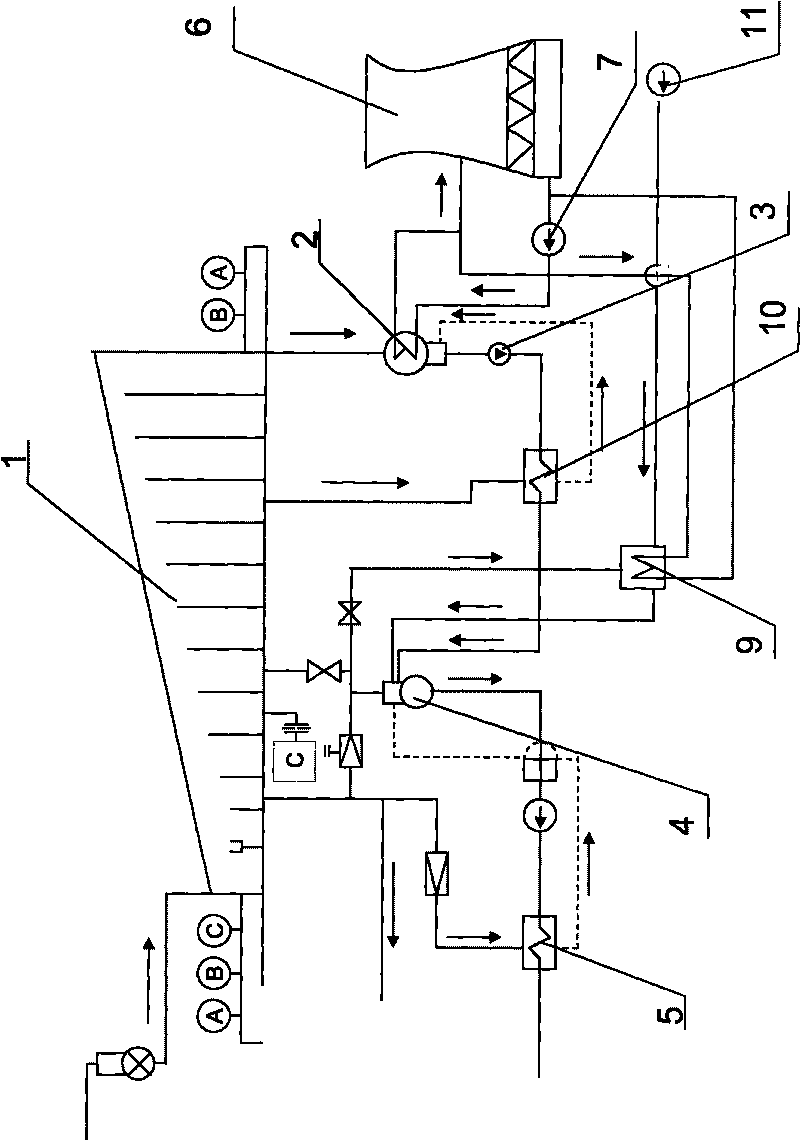

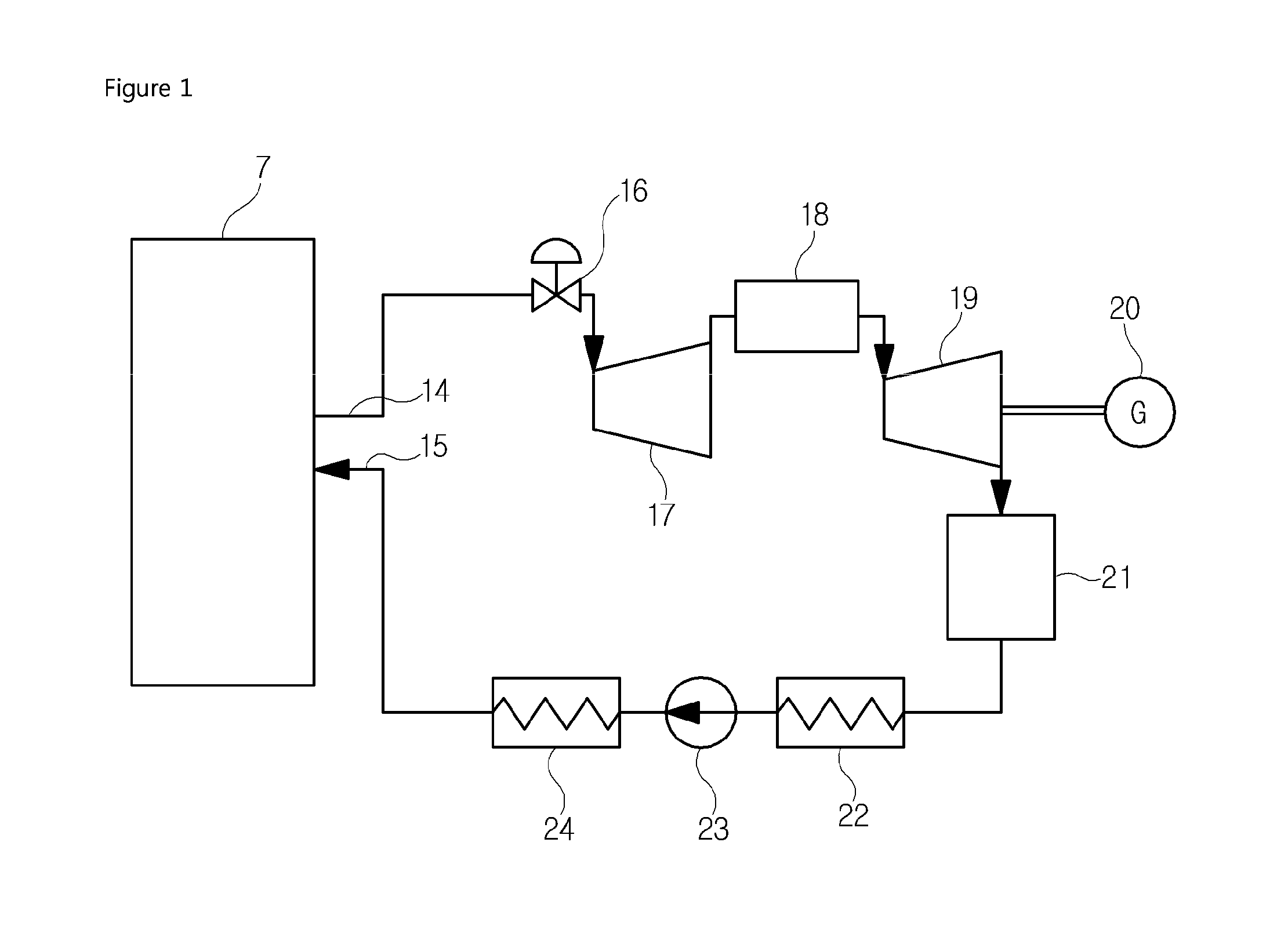

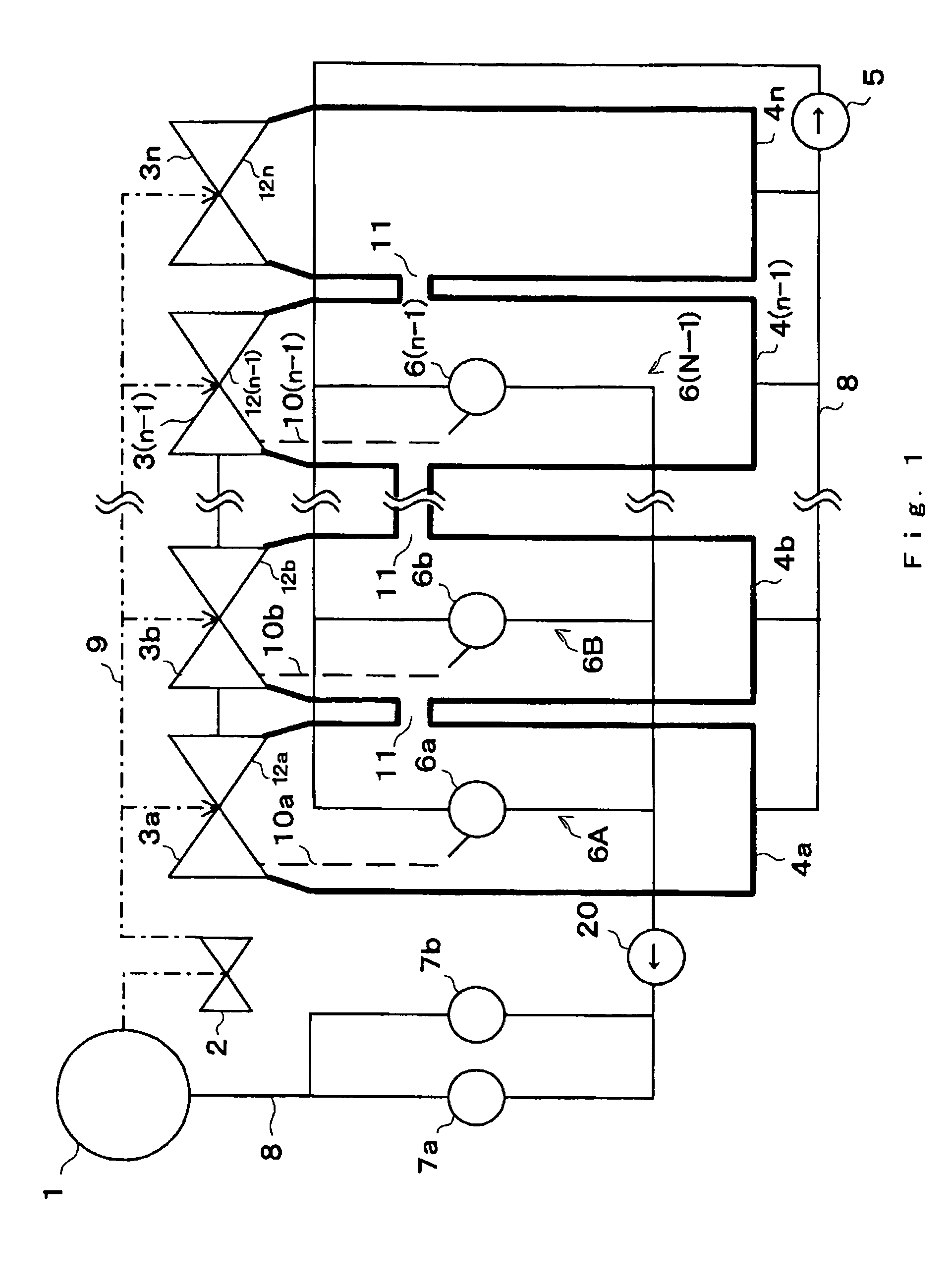

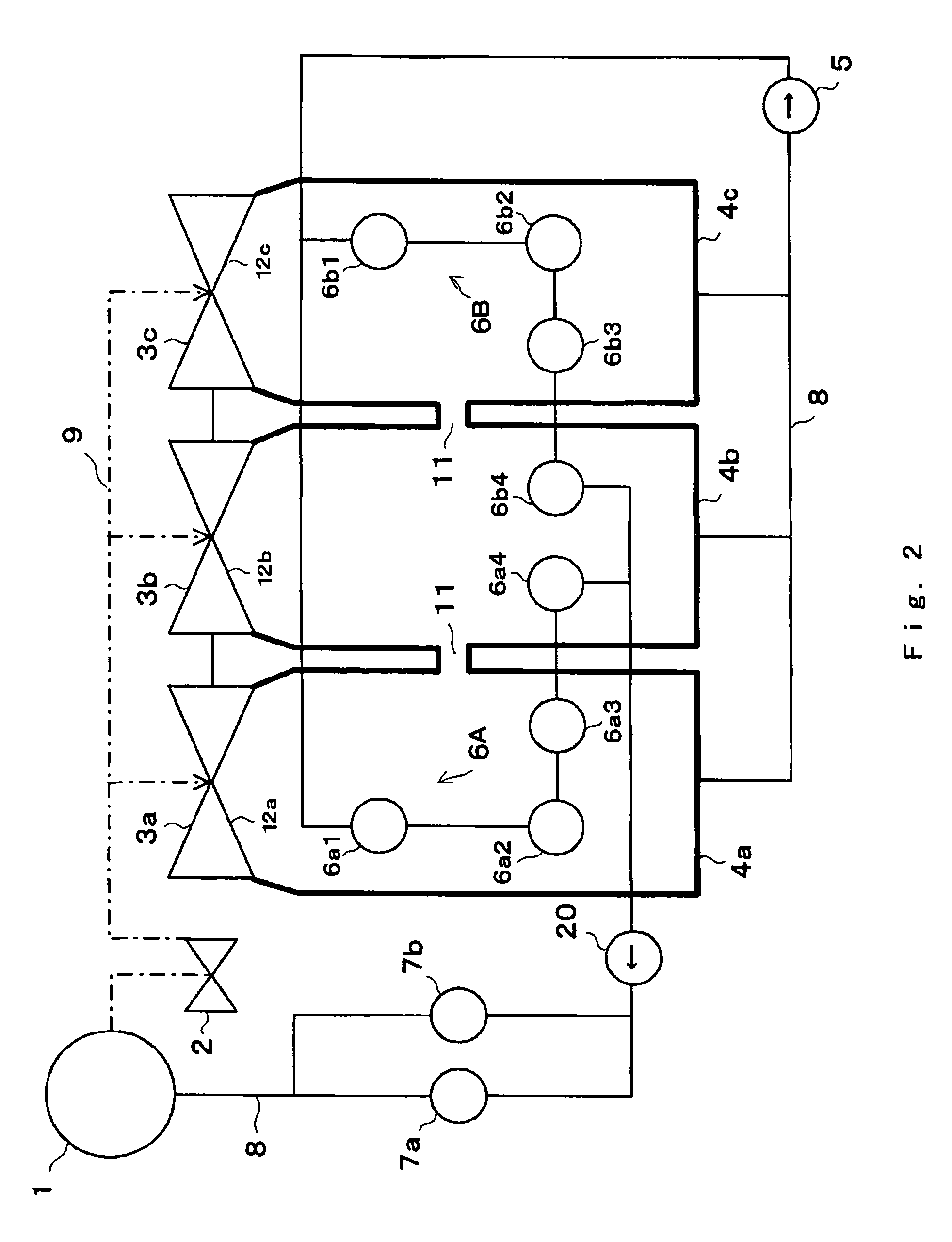

Solar thermal power plant

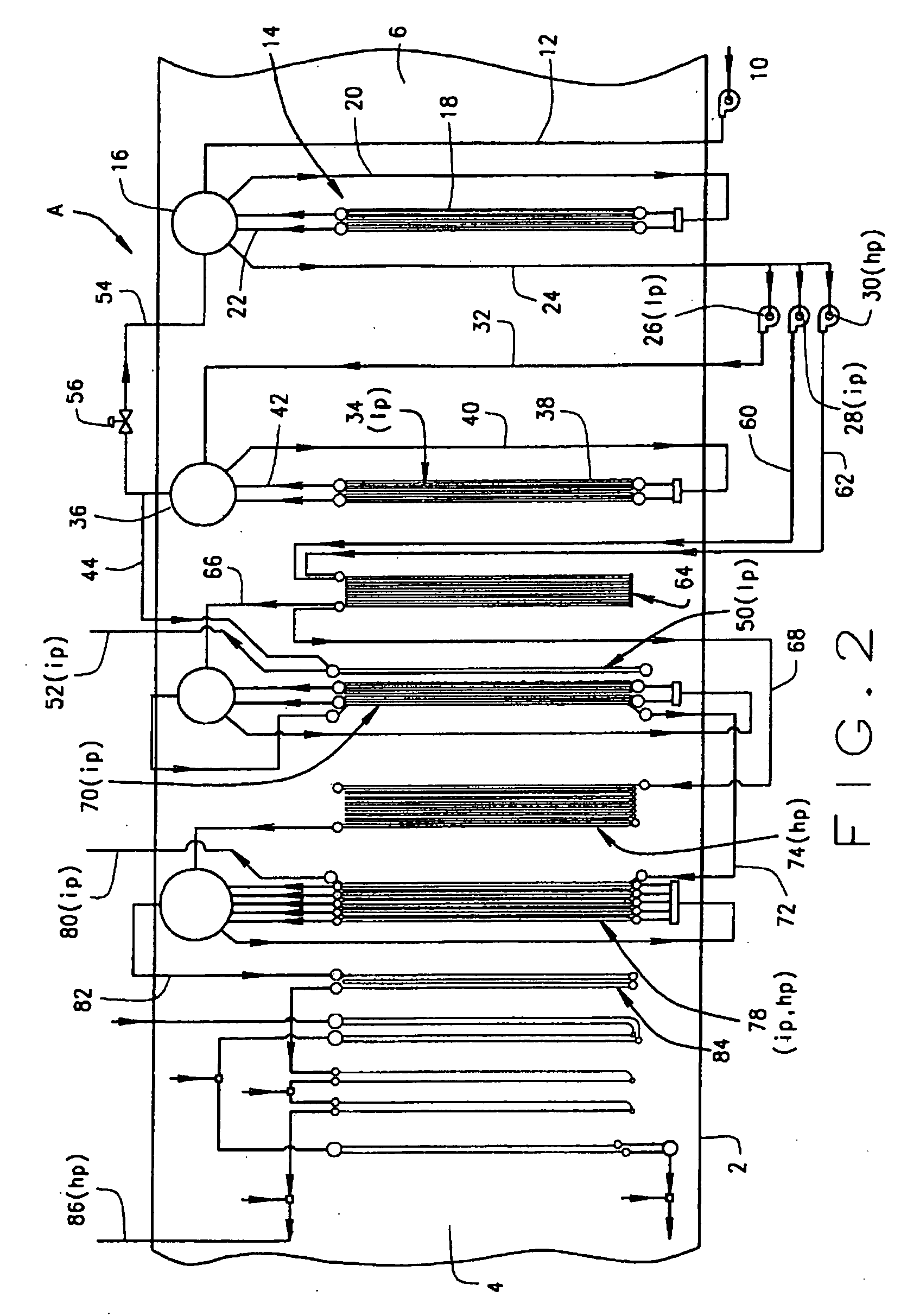

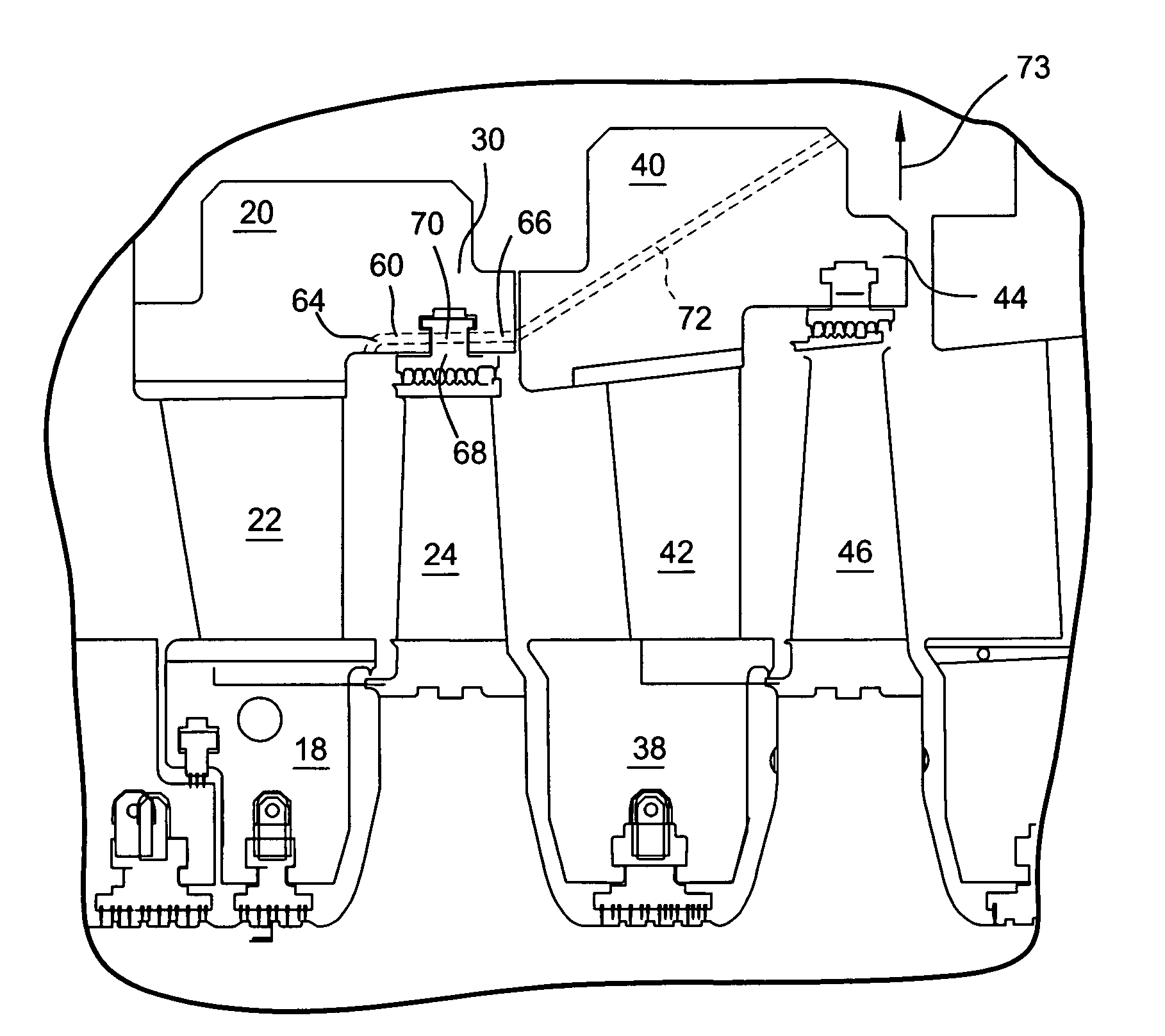

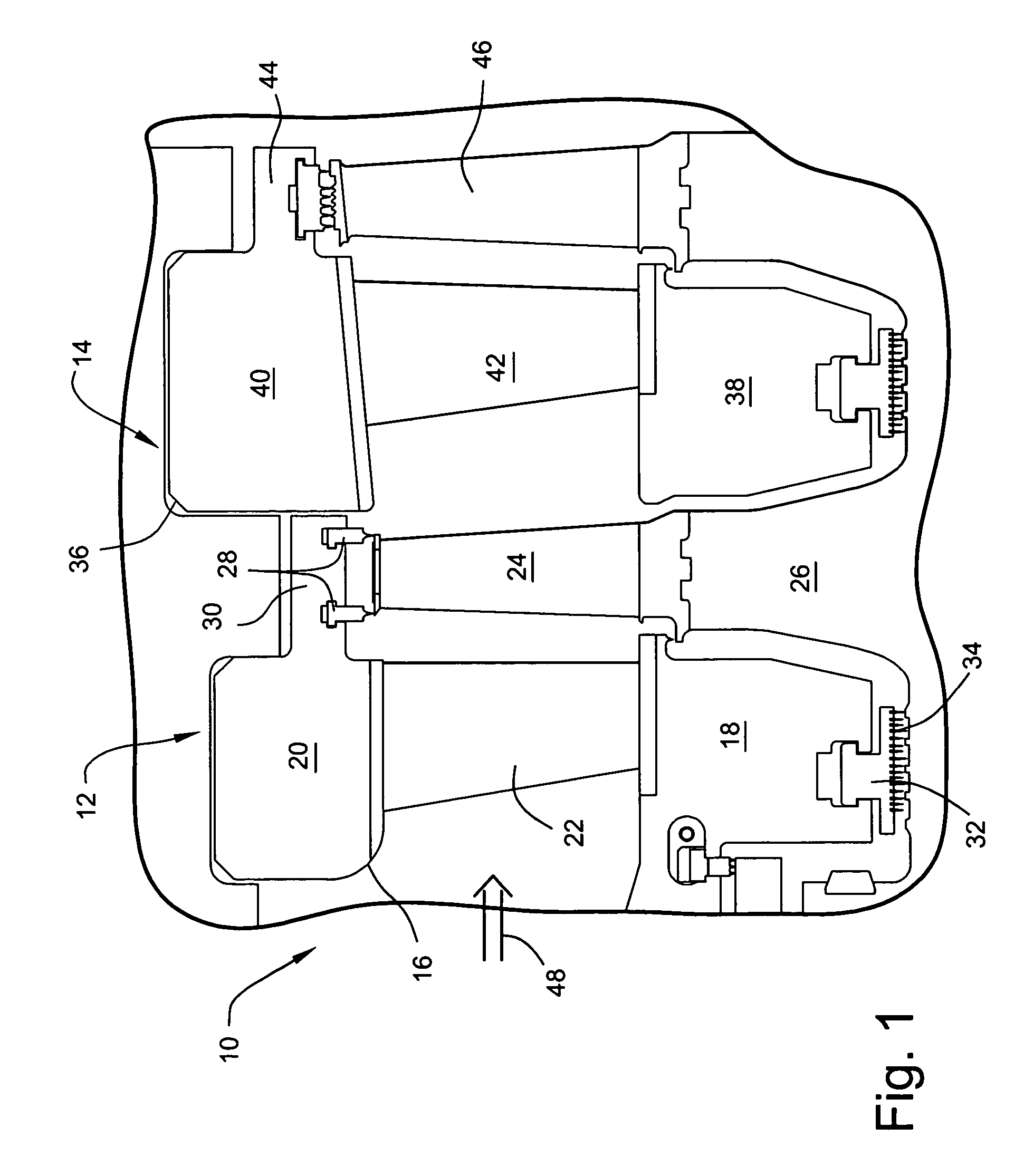

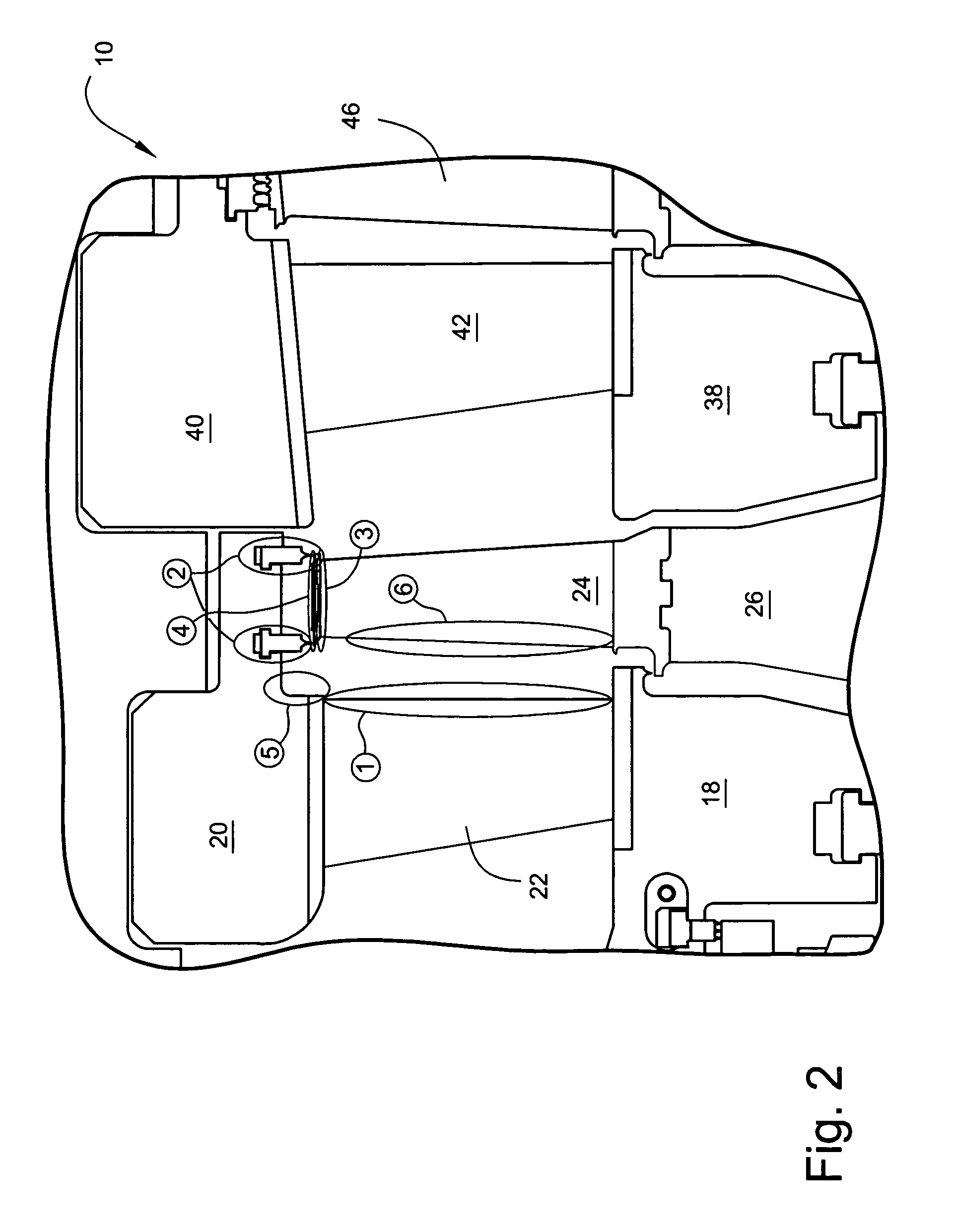

A solar thermal power plant 10 includes a steam generation portion 12 and a turbine 30. The steam generation portion 12 includes a steam drum 50 that separates water and steam, and an evaporator 36 and super heater 38 in fluid communication with the steam drum. The evaporator 36 receives and heats a portion of a flow of water from the steam drum 50 to provide the steam using solar energy provided thereto. The super heater 38 heats the steam from the evaporator 36 to provide super heated steam. A turbine 30 receives the super heated steam from the steam generation portion 12 to rotate the turbine. A plurality of extraction stages 66 extracts steam from the turbine 30 and provides the steam to a plurality of feedwater heaters 68. The feedwater heaters 68 heat the feedwater provided by the turbine 30, wherein the heated feedwater is provided to the steam generation portion 12.

Owner:ALSTOM TECH LTD

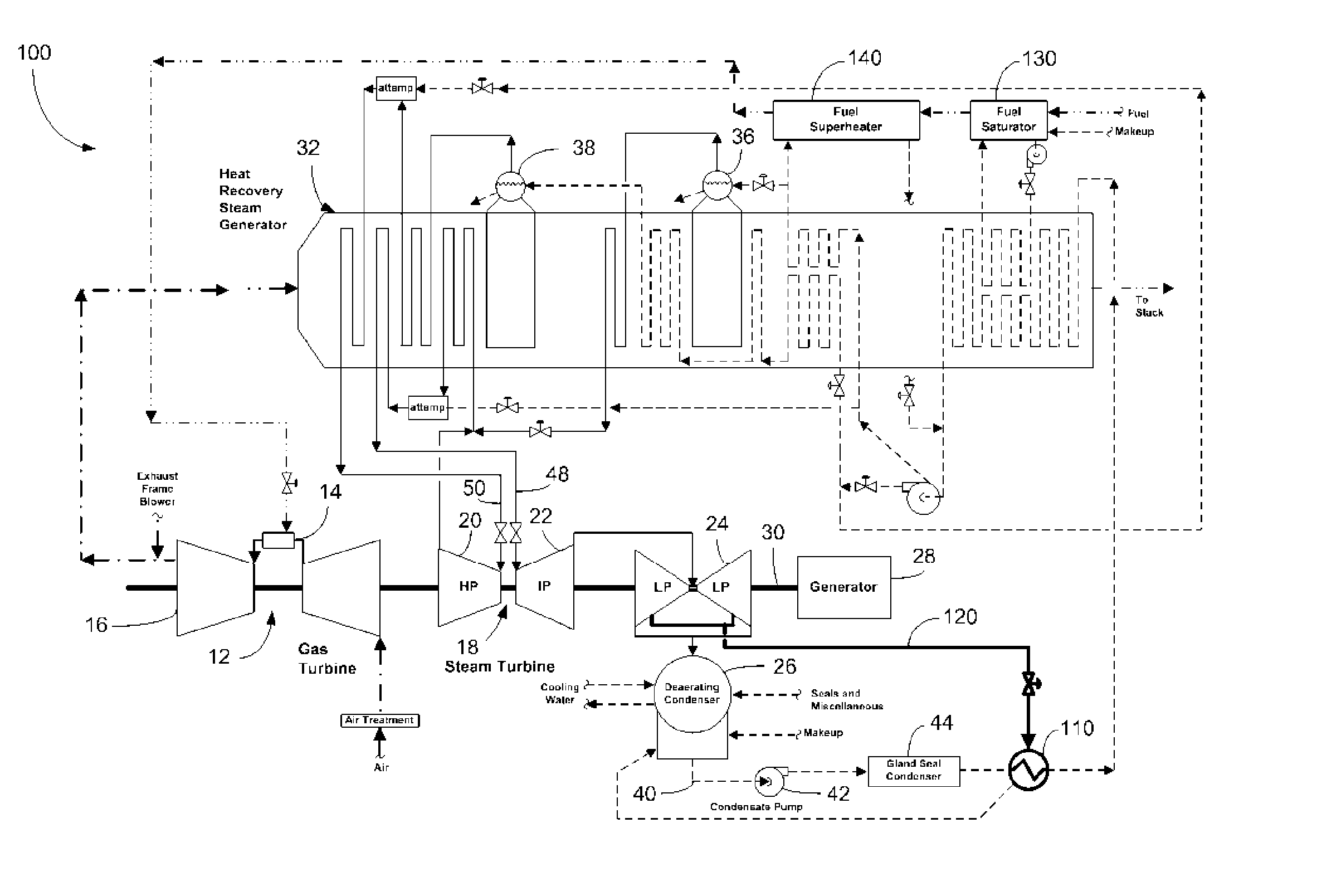

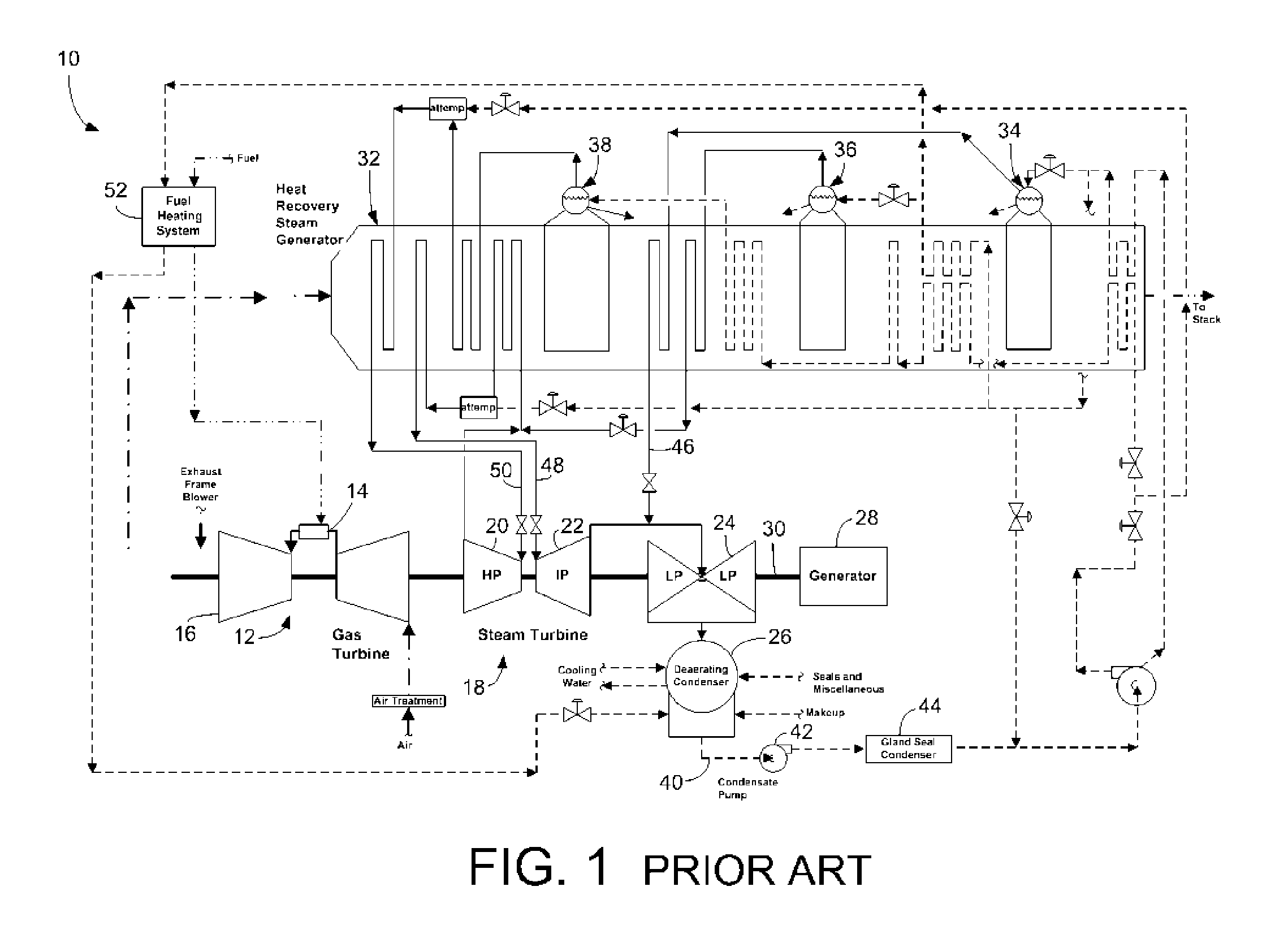

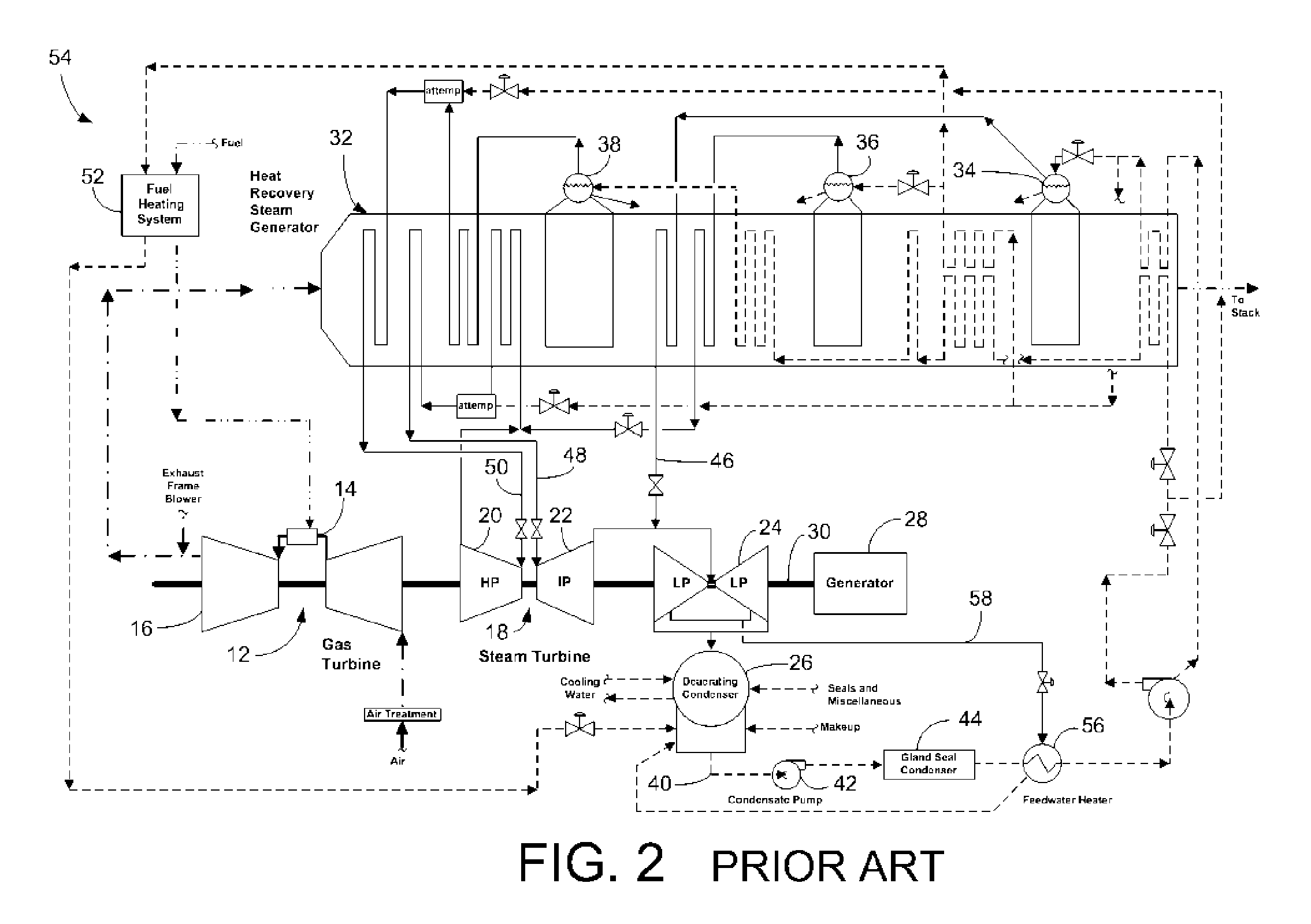

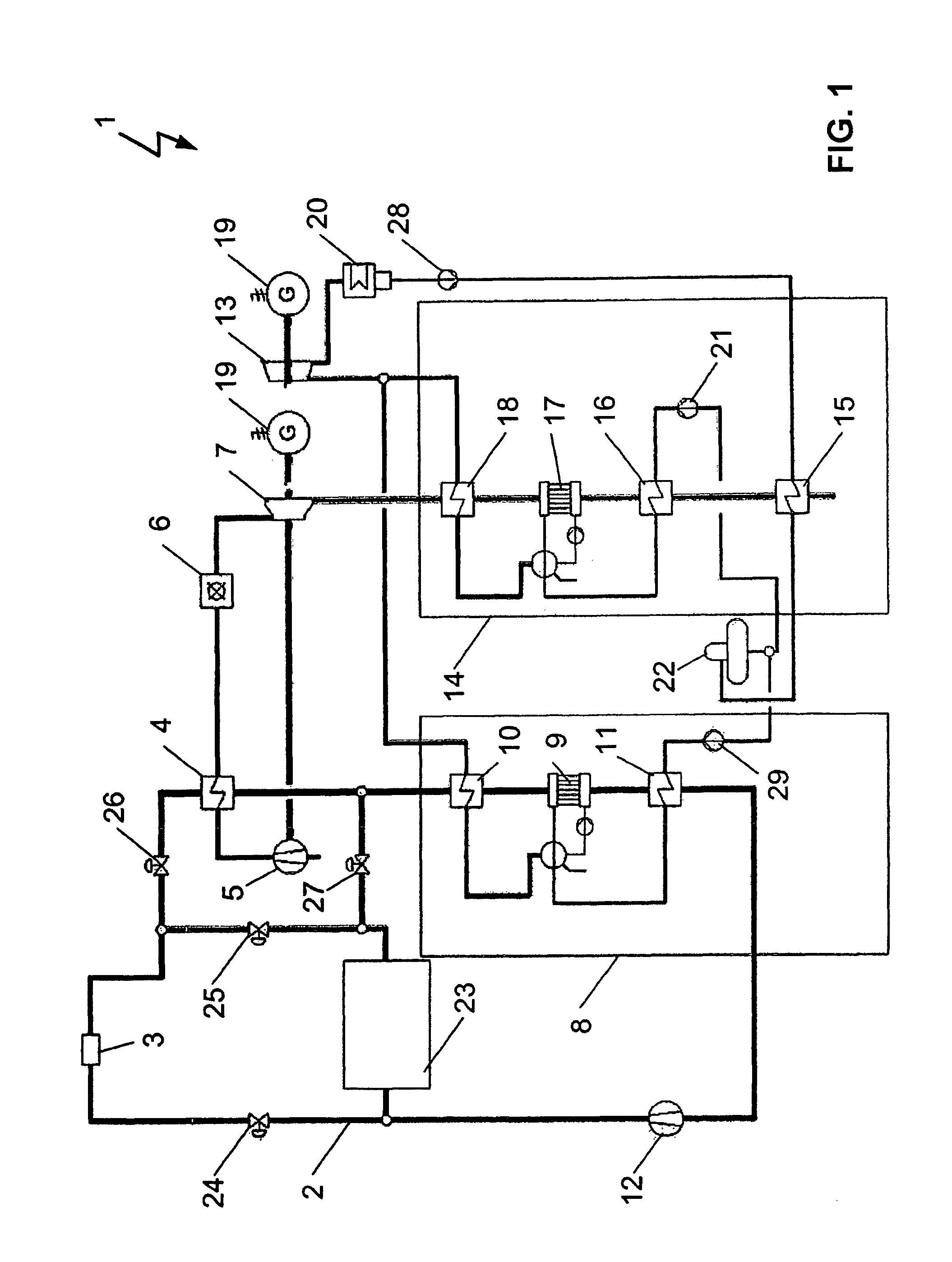

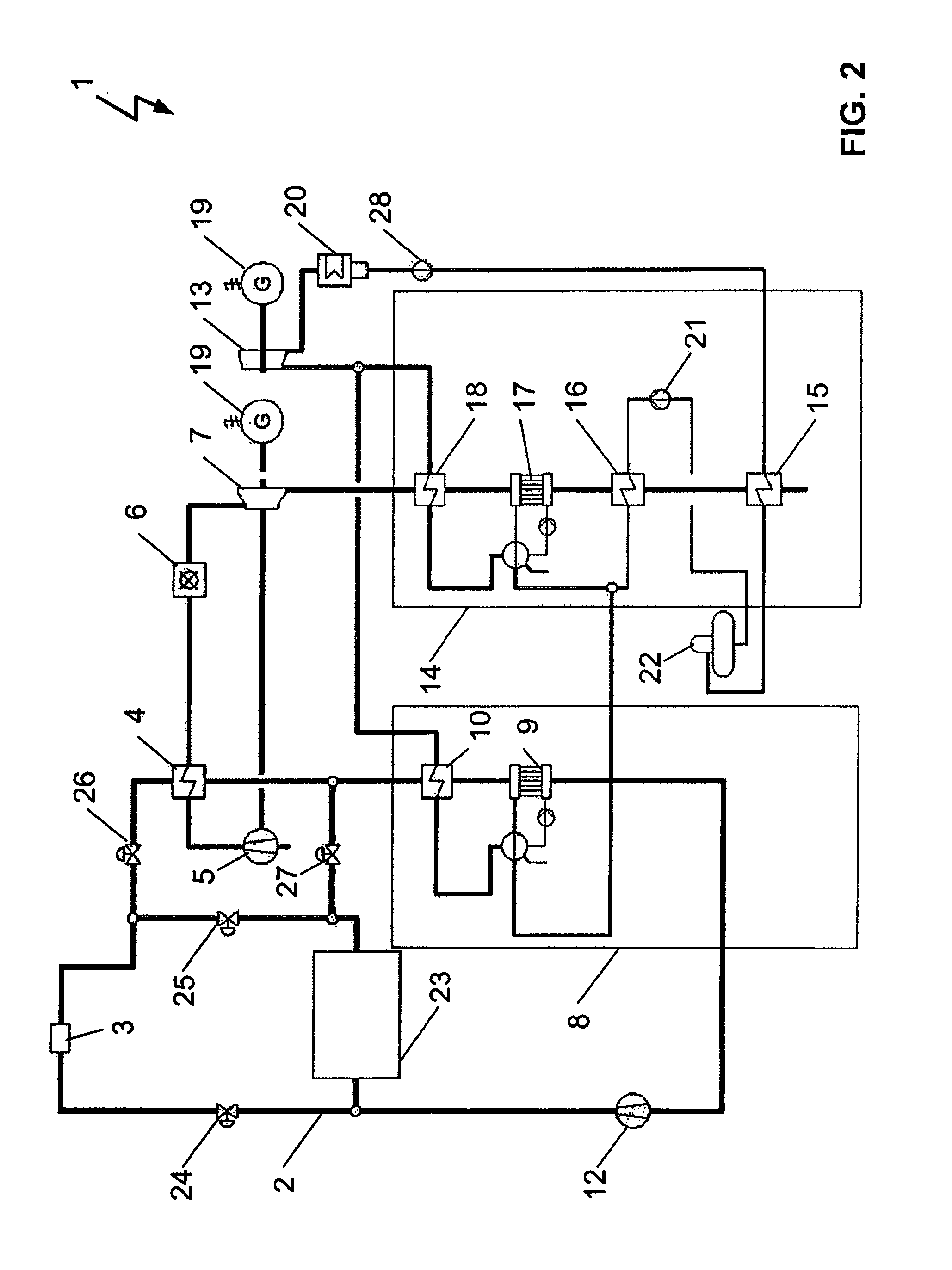

Combined Cycle Power Plant

InactiveUS20070017207A1Gas turbine plantsCombined combustion mitigationPower stationProcess engineering

A combined cycle power plant including a gas turbine, a steam turbine, and a heat recovery steam generator. The power plant also includes a feedwater heater positioned downstream of the steam turbine and a fuel moisturization system in communication with the heat recovery steam generator.

Owner:GENERAL ELECTRIC CO

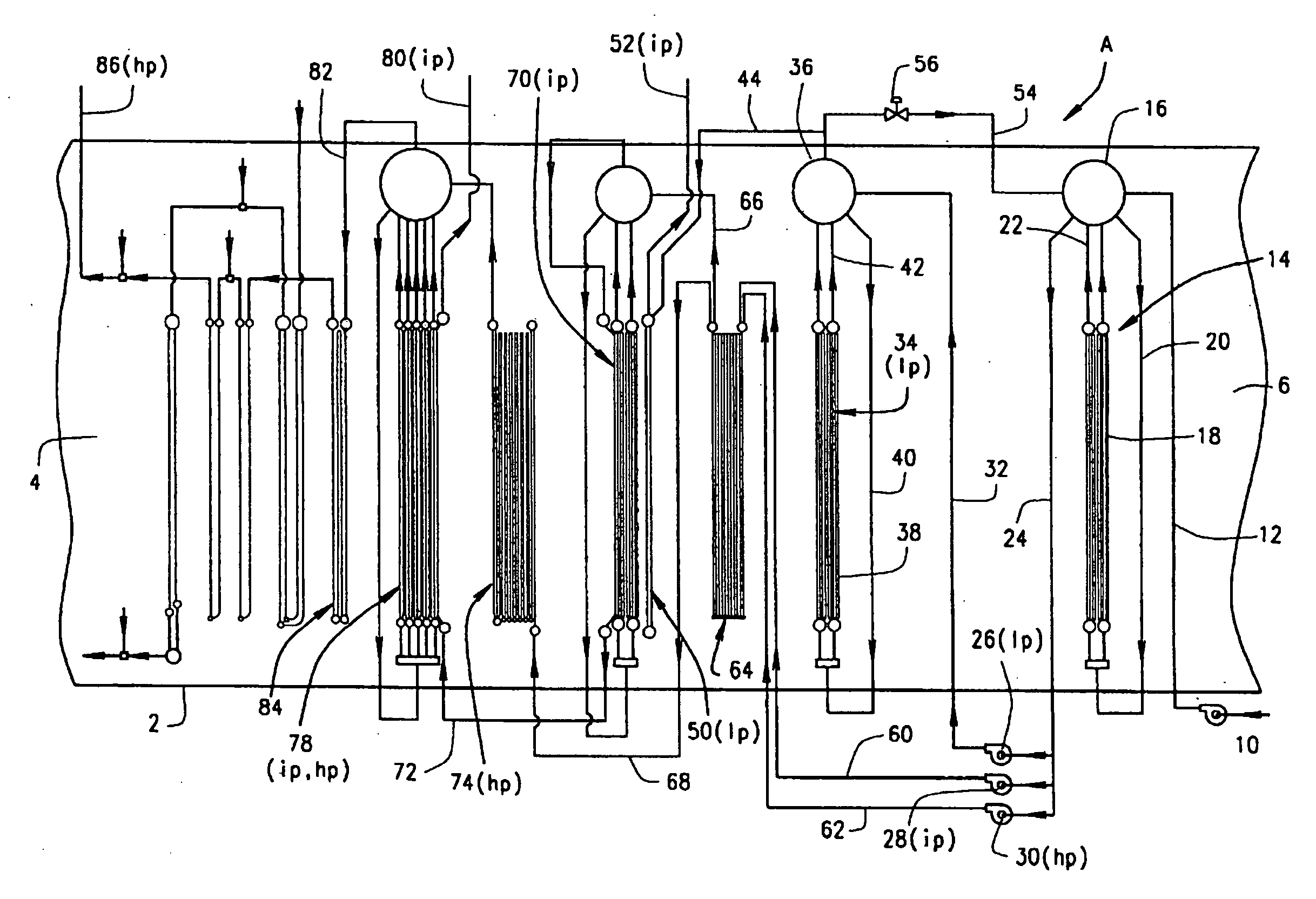

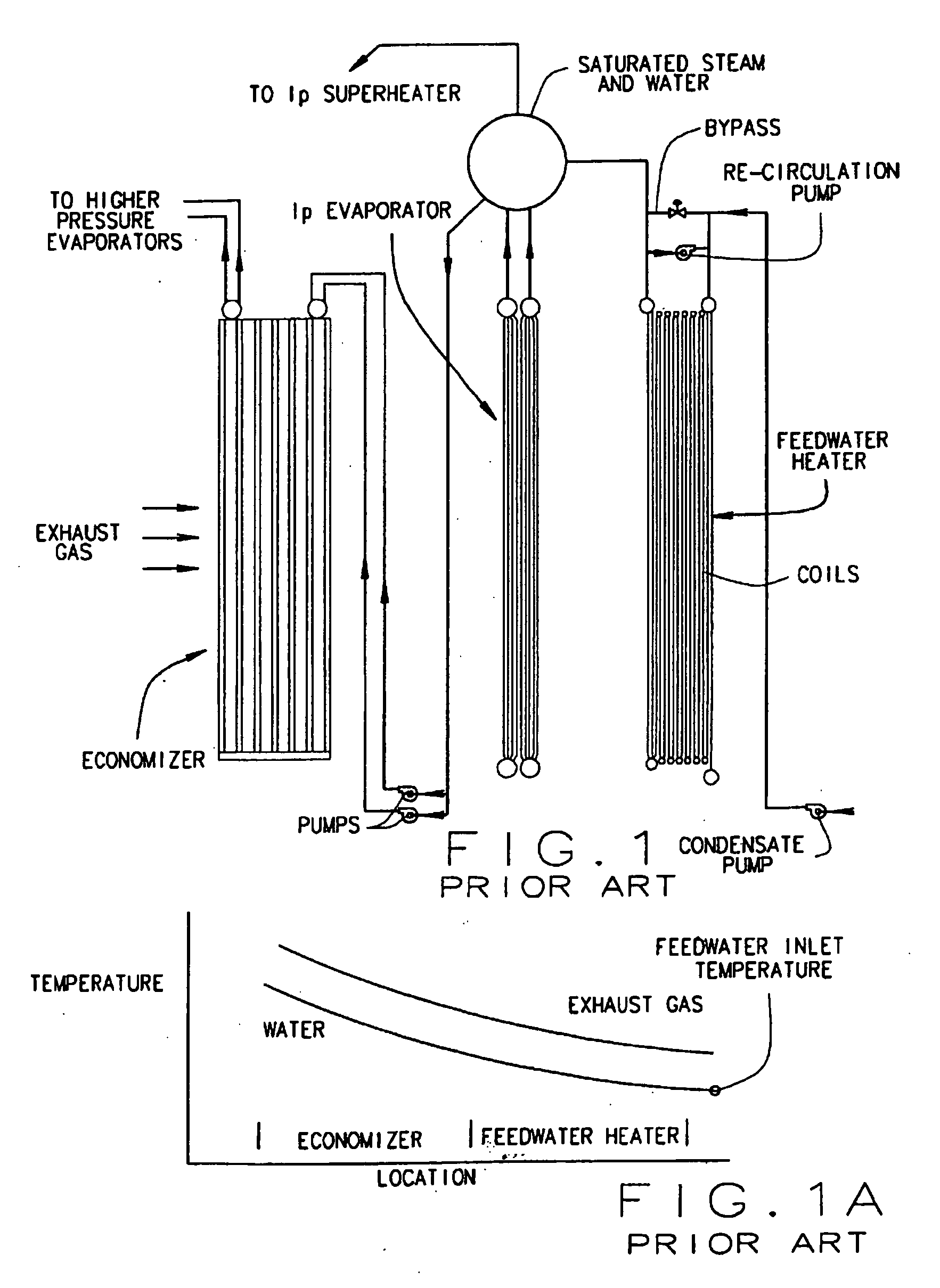

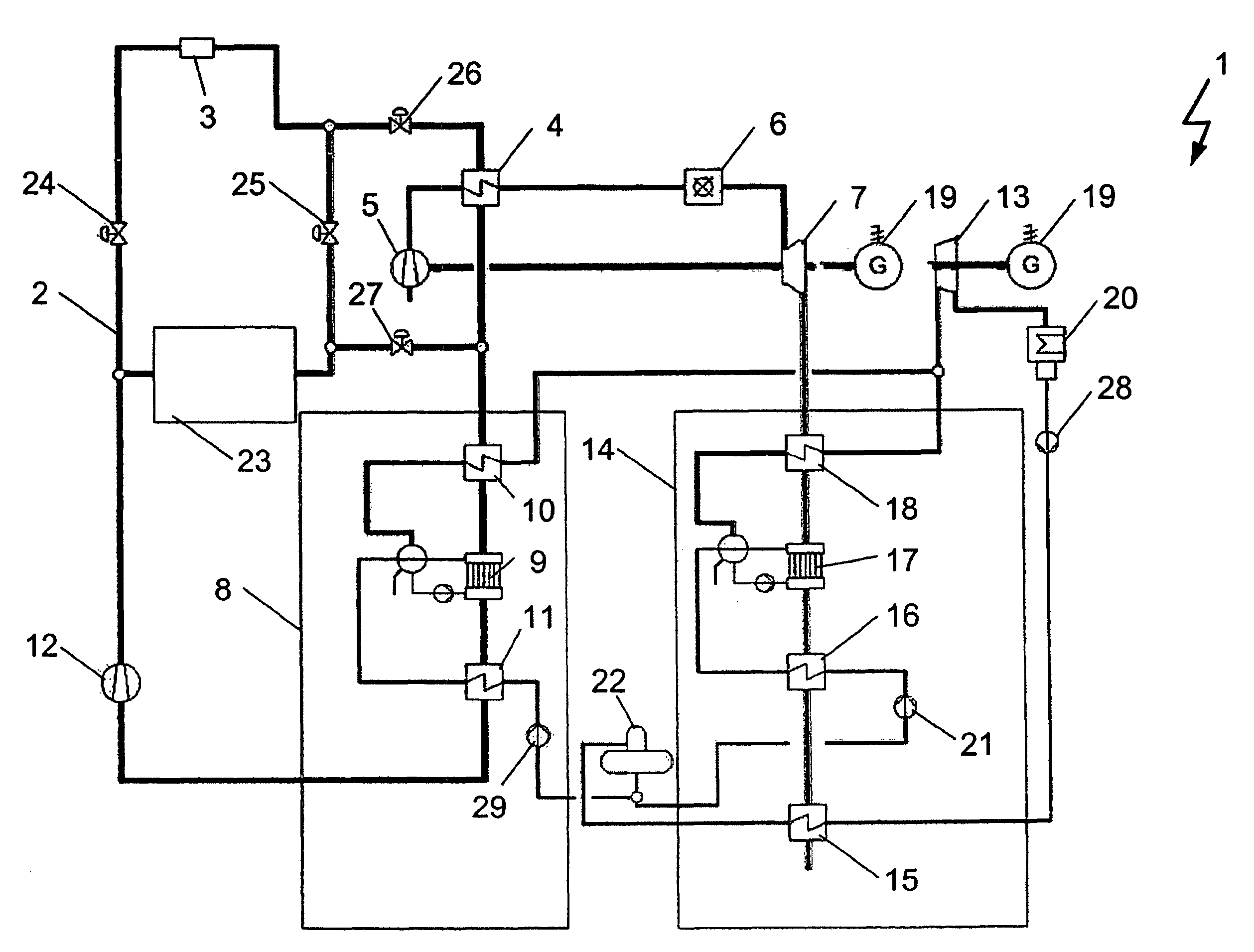

Process and apparatus for heating feedwater in a heat recovery steam generator

InactiveUS20120312019A1Steam generation heating methodsSteam accumulatorsCorrosive acidExhaust fumes

A feedwater heater (14) in a heat recovery steam generator (A,B) lies within a flow of hot exhaust gas. The feedwater heater (14) converts subcooled feedwater into saturated feedwater water, the temperature of which is only lightly above the acid dew point temperature of the exhaust gas so that corrosive acids do not condense on coils (18) of the feedwater heater (14). Yet the temperature of the saturated feedwater lies significantly below the temperature of the exhaust gas at the coils (18), so that the coils (18) operate efficiently and require minimal surface area. Pumps (26, 28, 30) elevate the pressure of the saturated feedwater and direct it into an economizer (64, 90) where, owing to the increase in pressure, the water is again subcooled. The economizer (64, 90) elevates the temperature still further and delivers the higher pressure feedwater to evaporators (34, 70, 78) that convert it into saturated steam that flows on to the superheaters (50, 78, 84). Higher pressure pegging stem admitted to the feedwater heater (14) controls the pressure—and temperature—of saturated steam and water in the feedwater heater (14).

Owner:NOOTER ERIKSEN INC

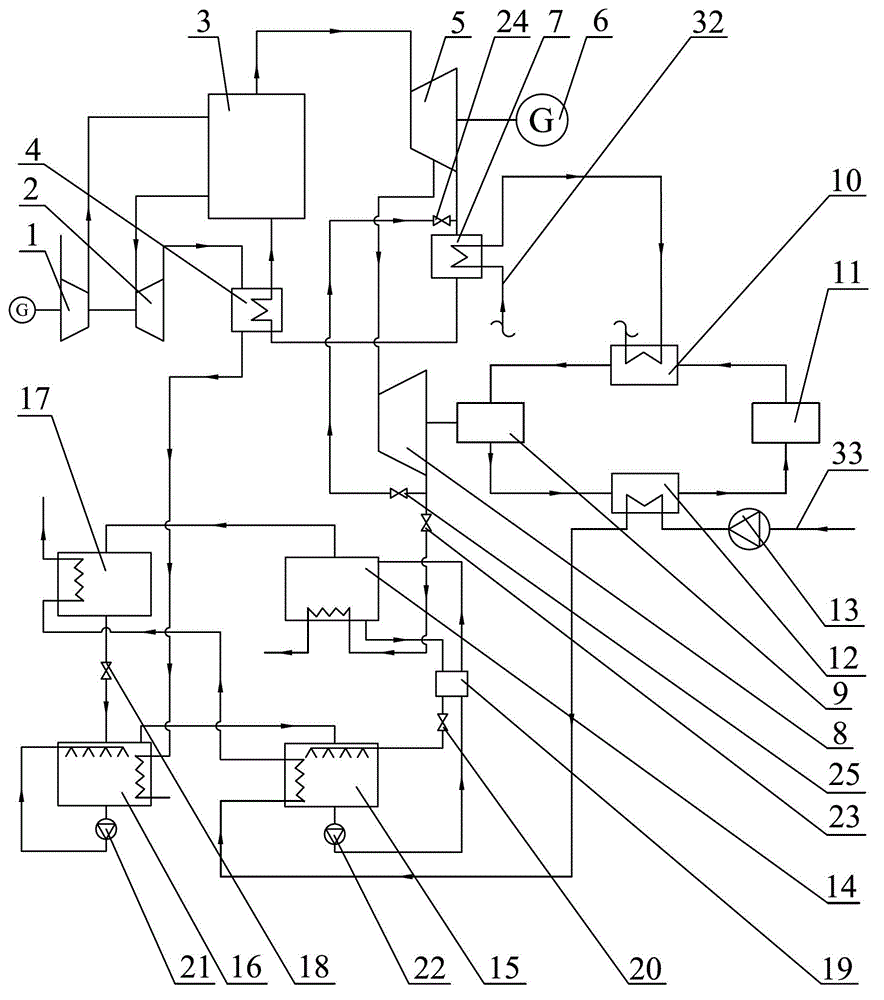

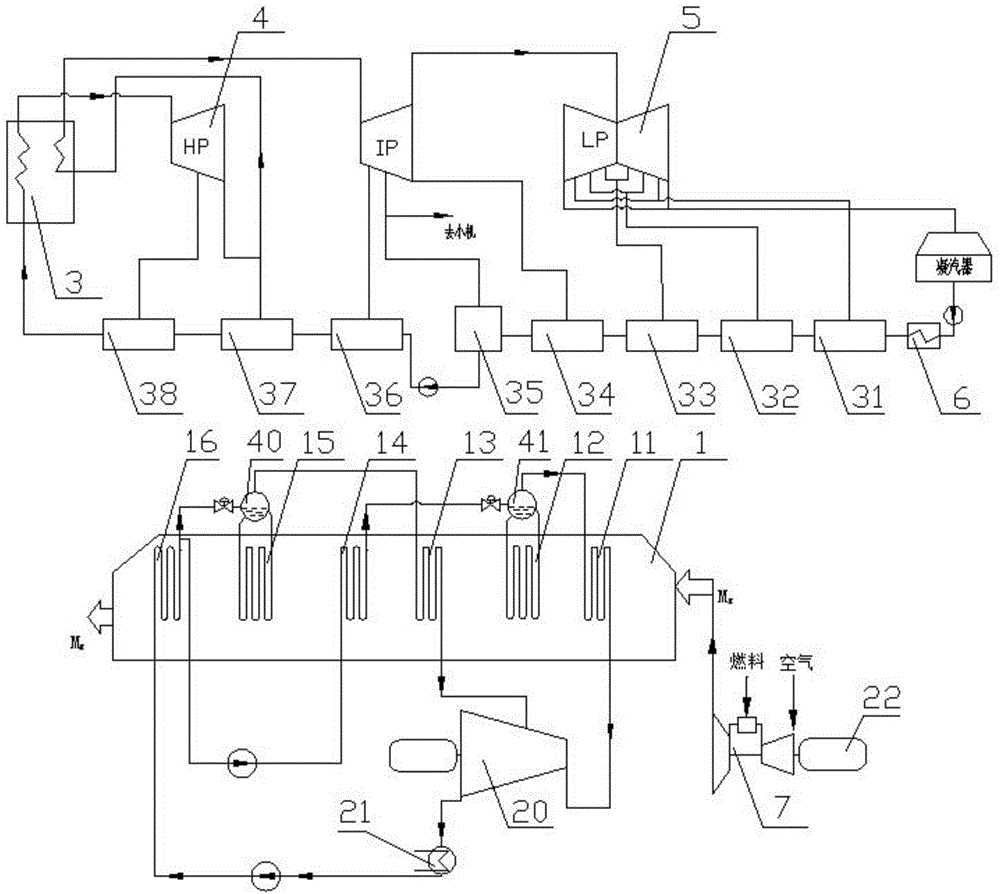

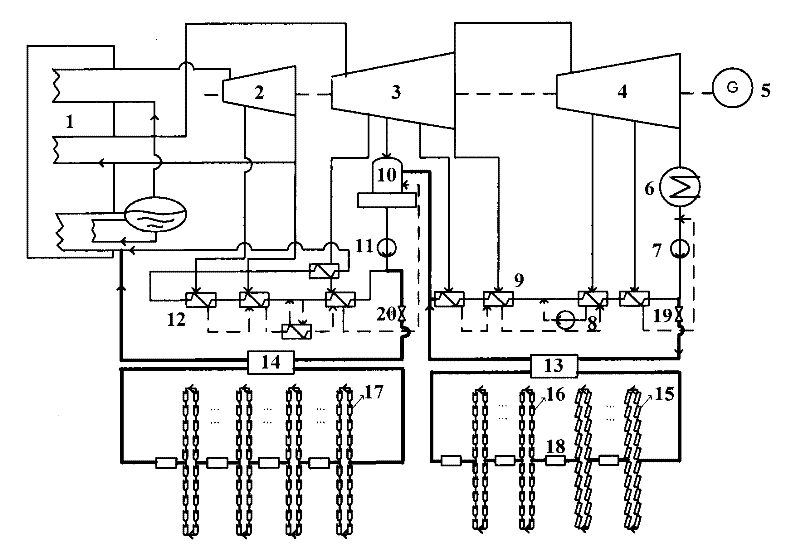

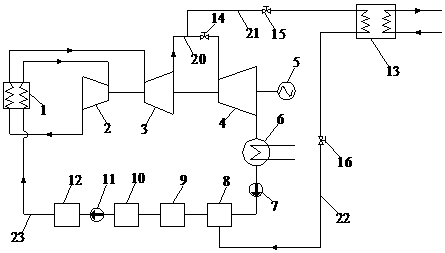

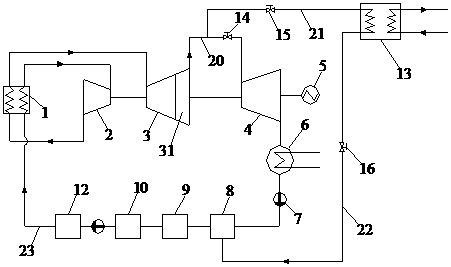

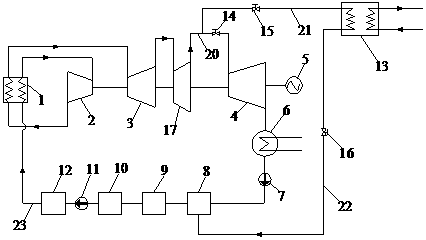

Adjustable feed water heat regenerative system for turbo generator unit

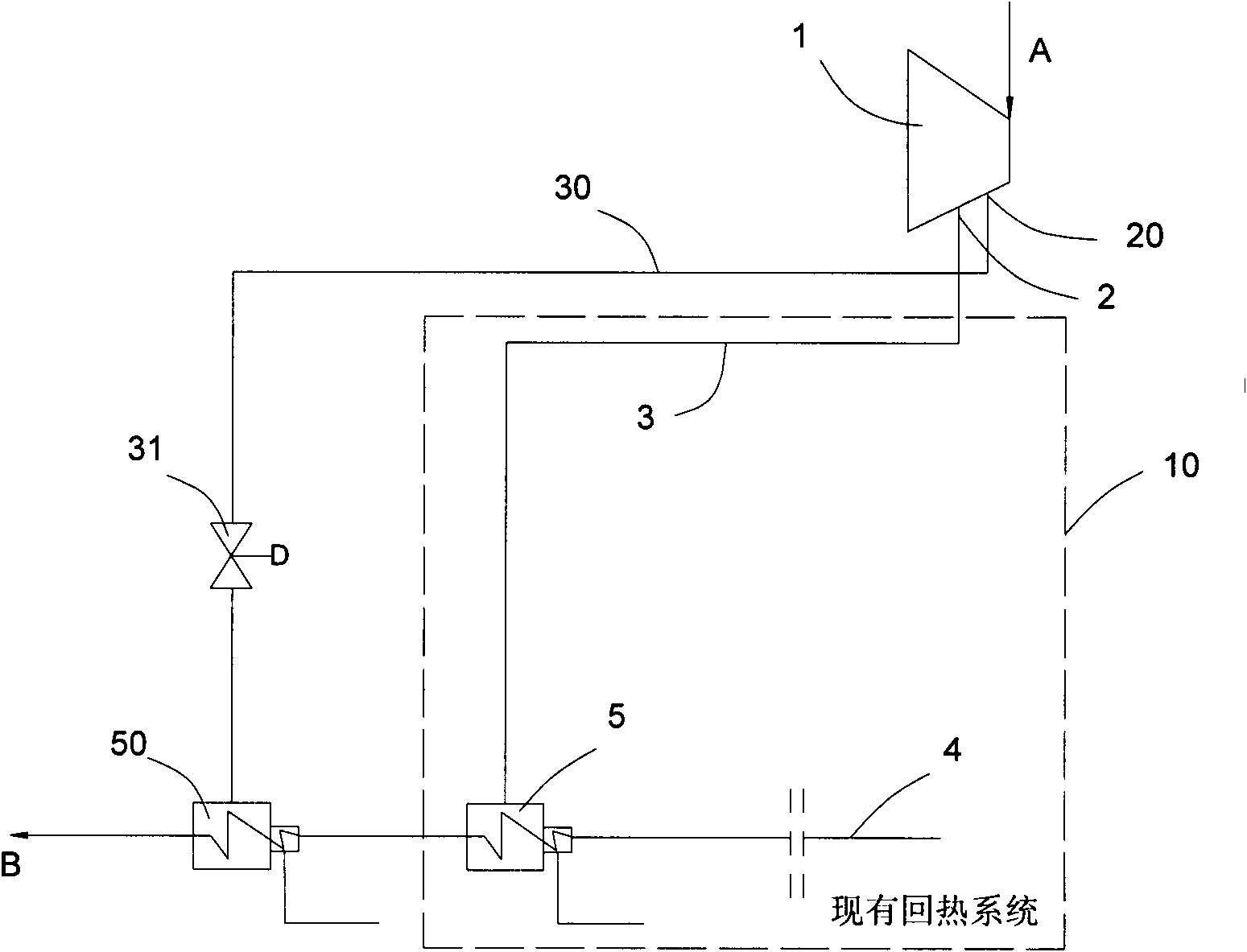

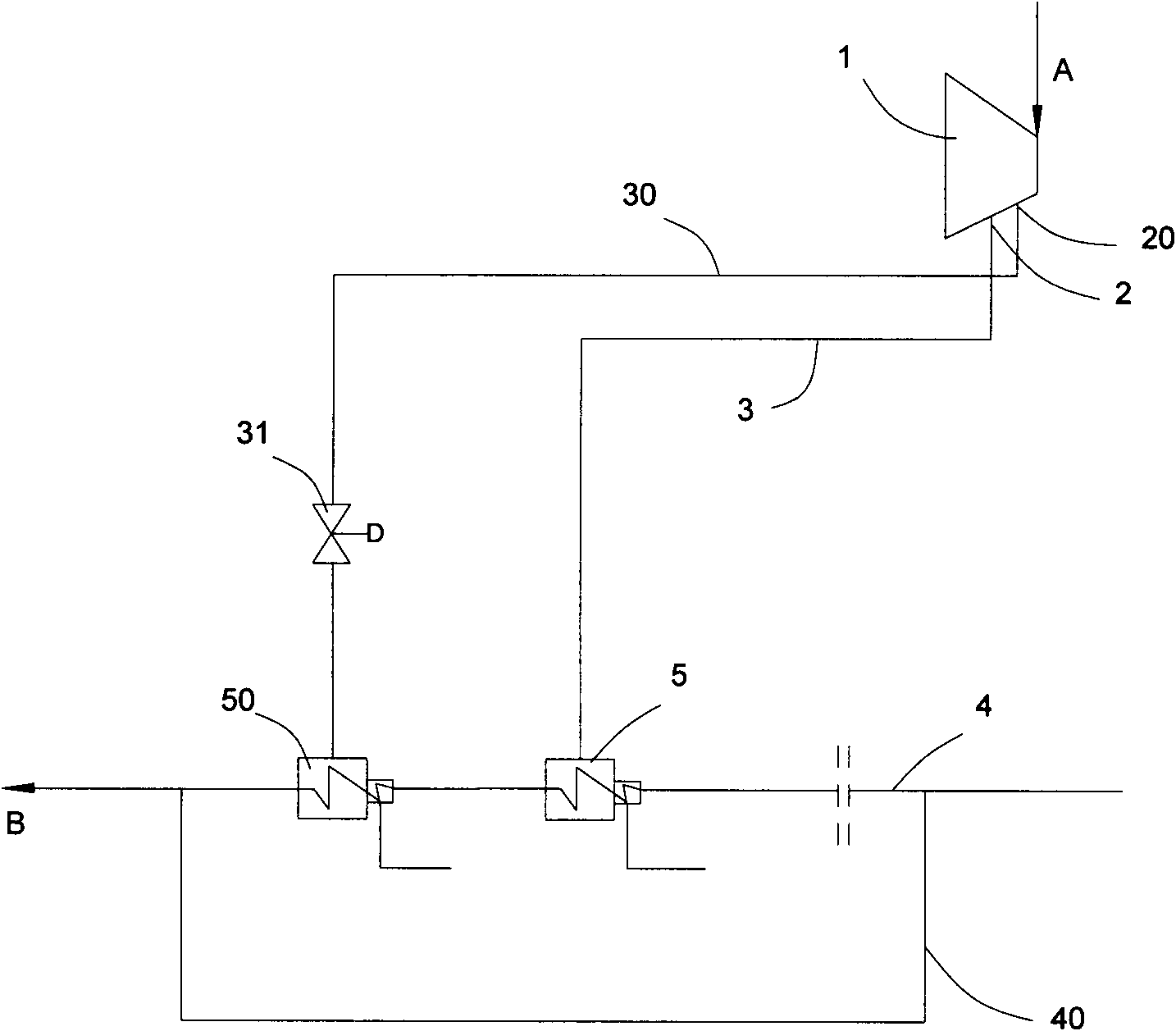

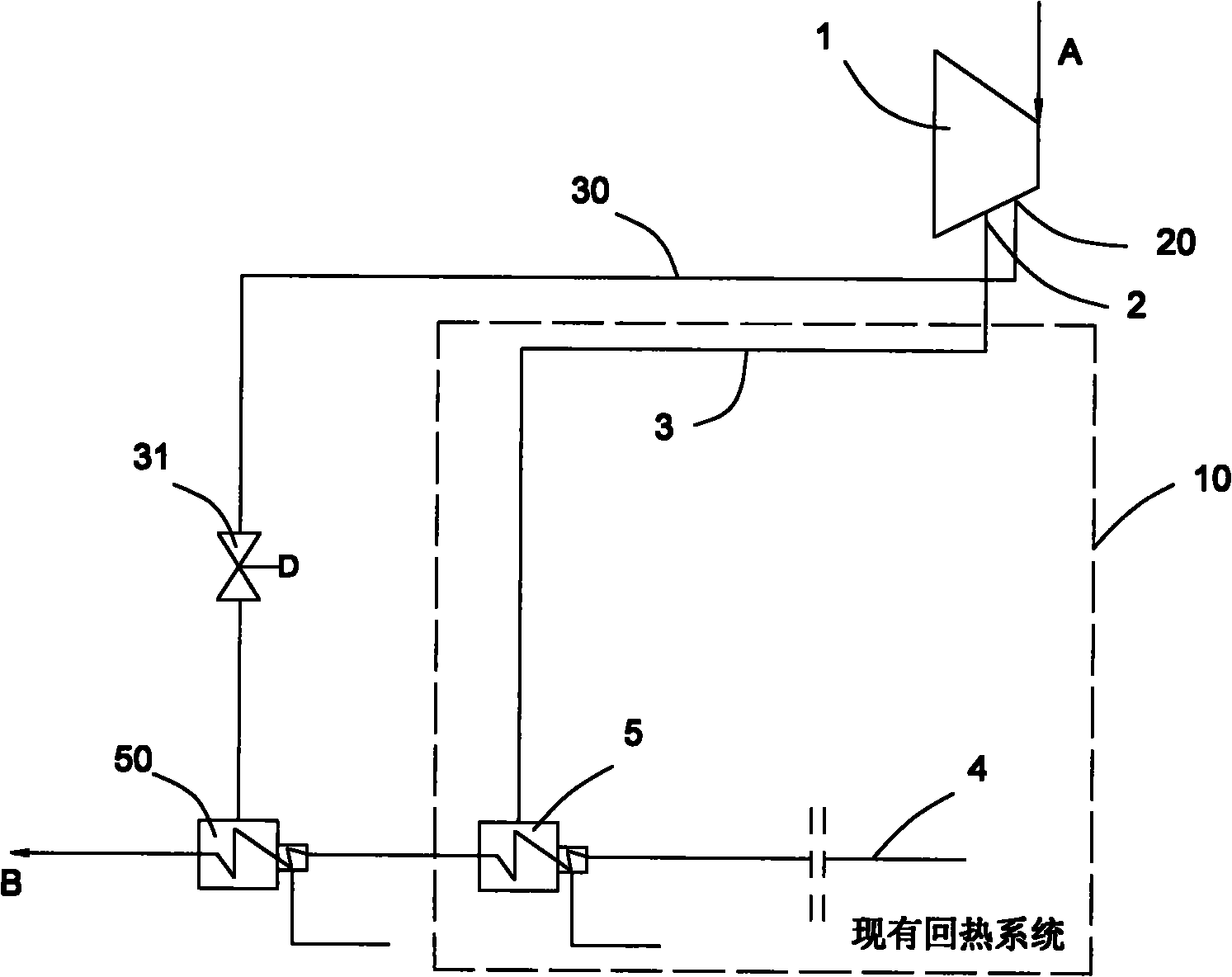

ActiveCN102537933APromote environmental protectionImprove economyMachines/enginesFeed-water heatersEngineeringHigh pressure

The invention provides an adjustable feed water heat regenerative system for a turbo generator unit, which comprises a high pressure cylinder of a steam turbine, a final-stage extraction opening, a final-stage feed water heater, a steam extraction pipe and a regulating valve, wherein the final-stage extraction opening is additionally arranged on the high pressure cylinder; the steam extraction pressure of the final-stage extraction opening is much higher than the common highest extraction pressure; additionally extracted steam is used as a heat source of the final-stage feed water heater; the steam extraction pipe is connected with the final-stage extraction opening and the final-stage feed water heater; and the regulating valve is arranged on the steam extraction pipe. Part of steam which does work is guided to the feed water heater through the final-stage steam extraction pipe so as to further heat feed water of a boiler. The heat regenerative system provided by the invention is an elastic heat regenerative system. The temperature of the feed water can be maintained or changed under the variable load condition of the unit, so that the environmental friendliness, the economy and the safety of the unit are improved and the frequency modulation characteristic is perfected.

Owner:冯伟忠

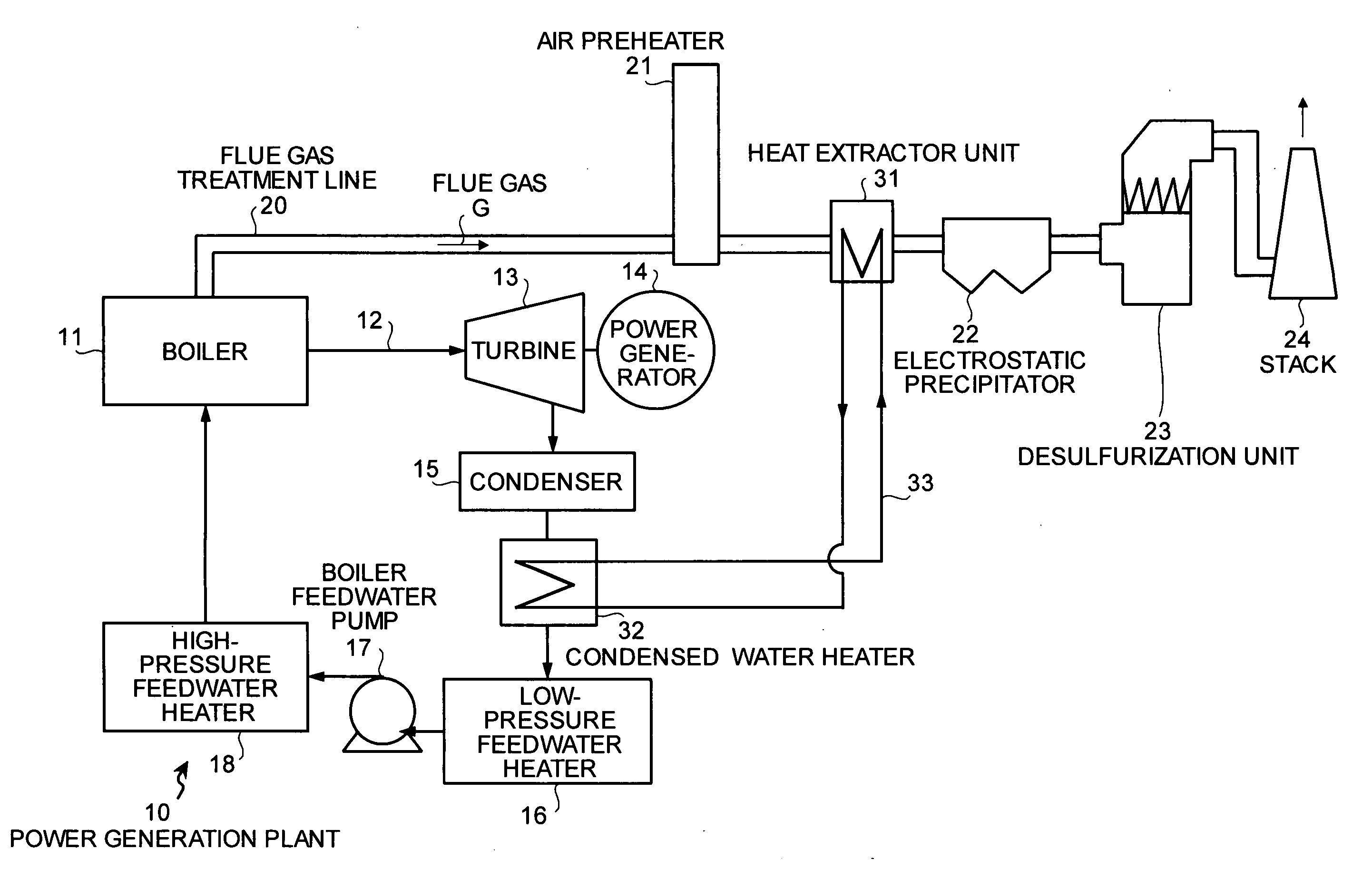

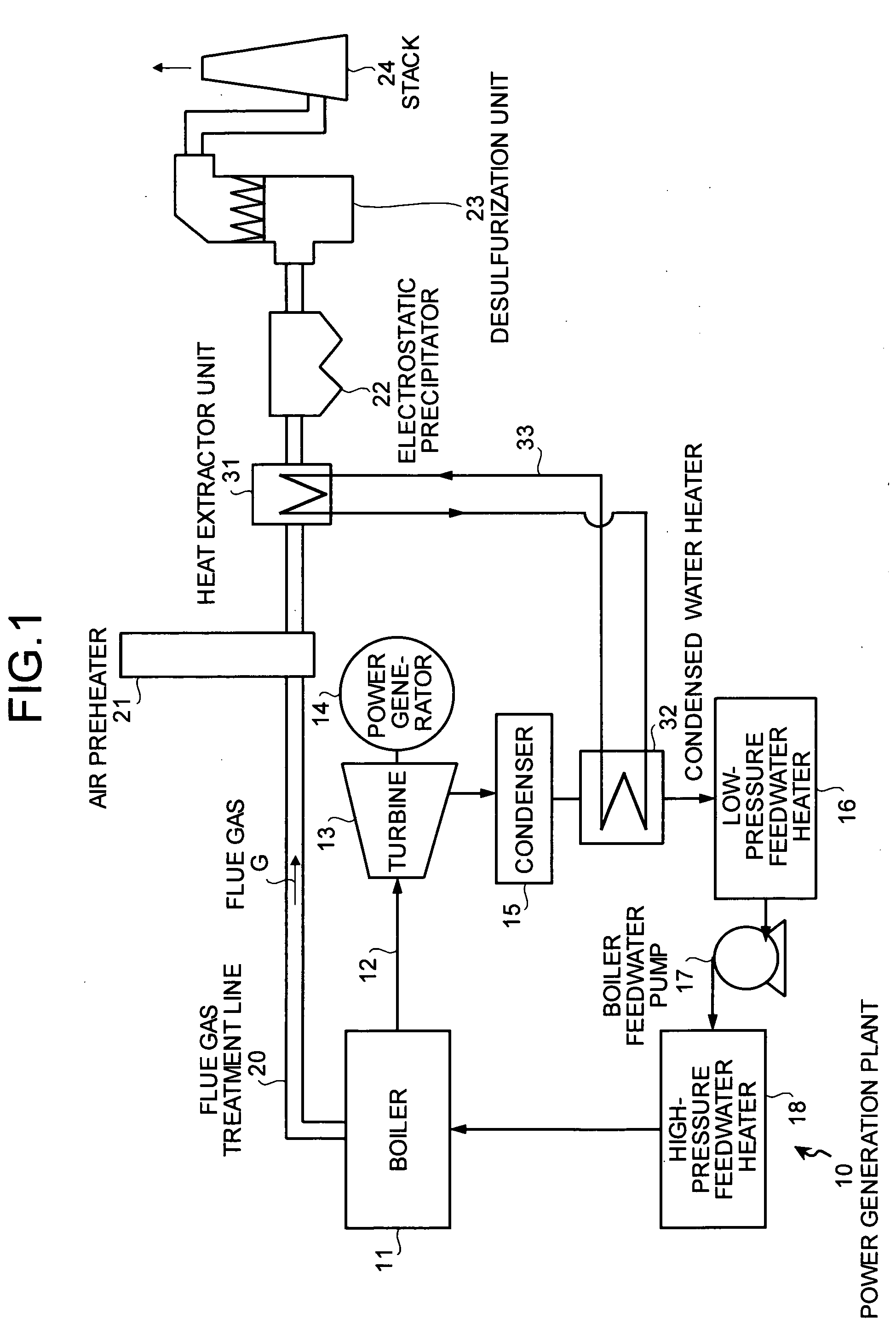

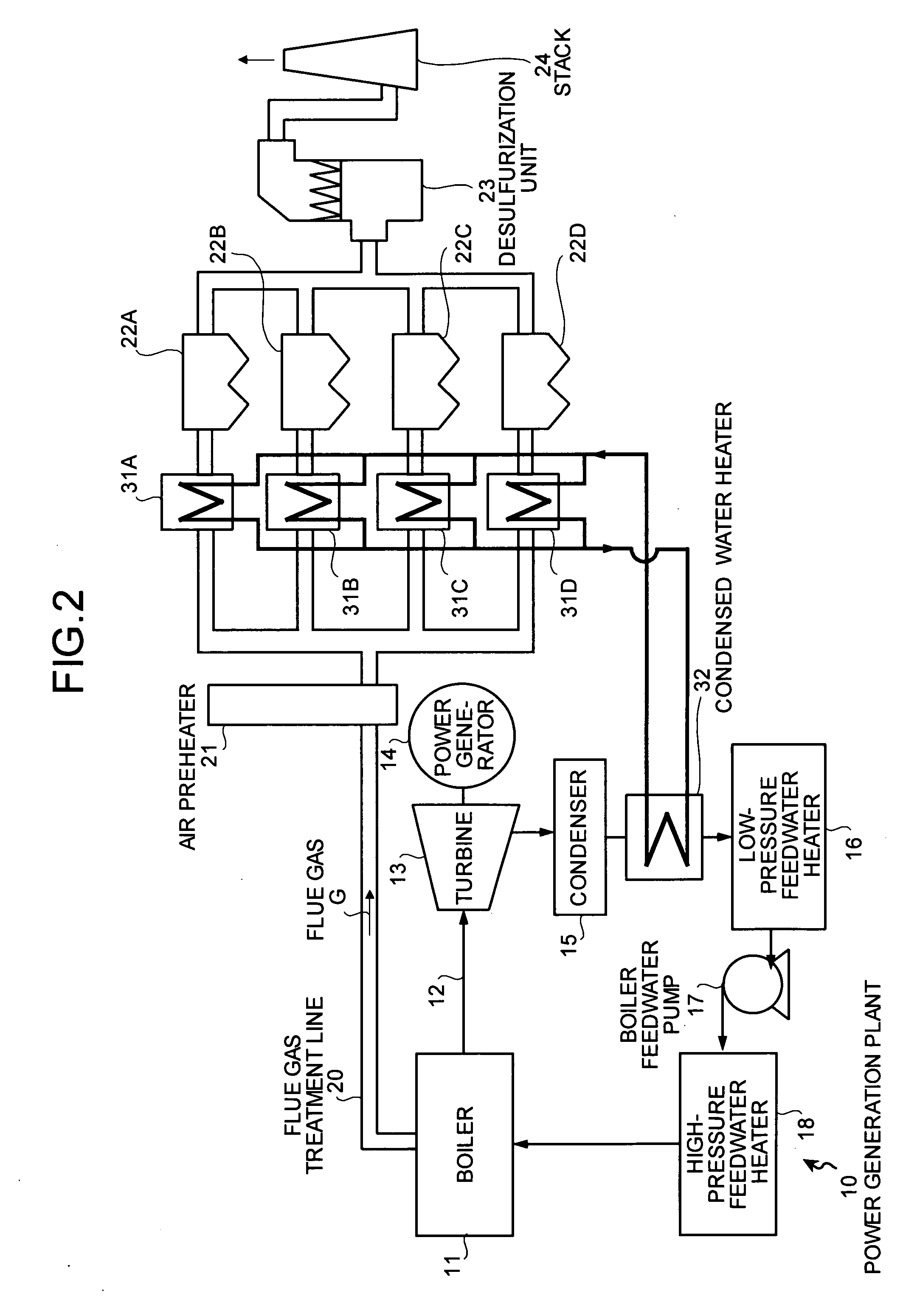

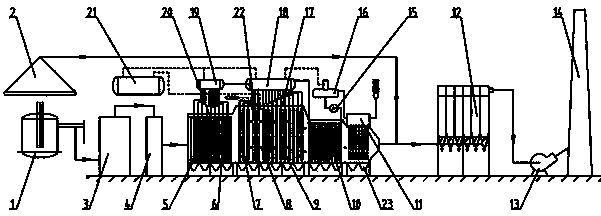

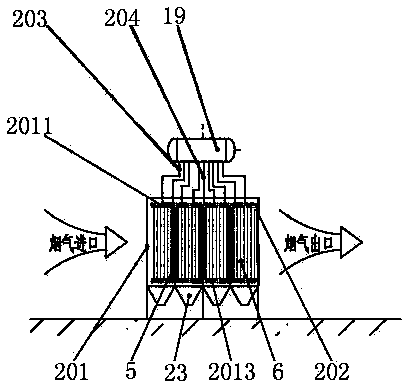

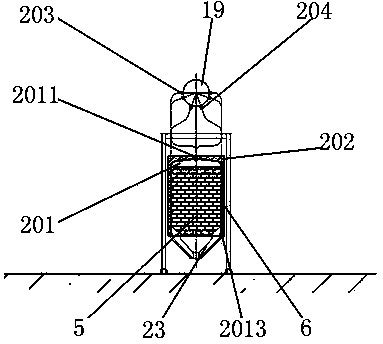

Heat recovery equipment

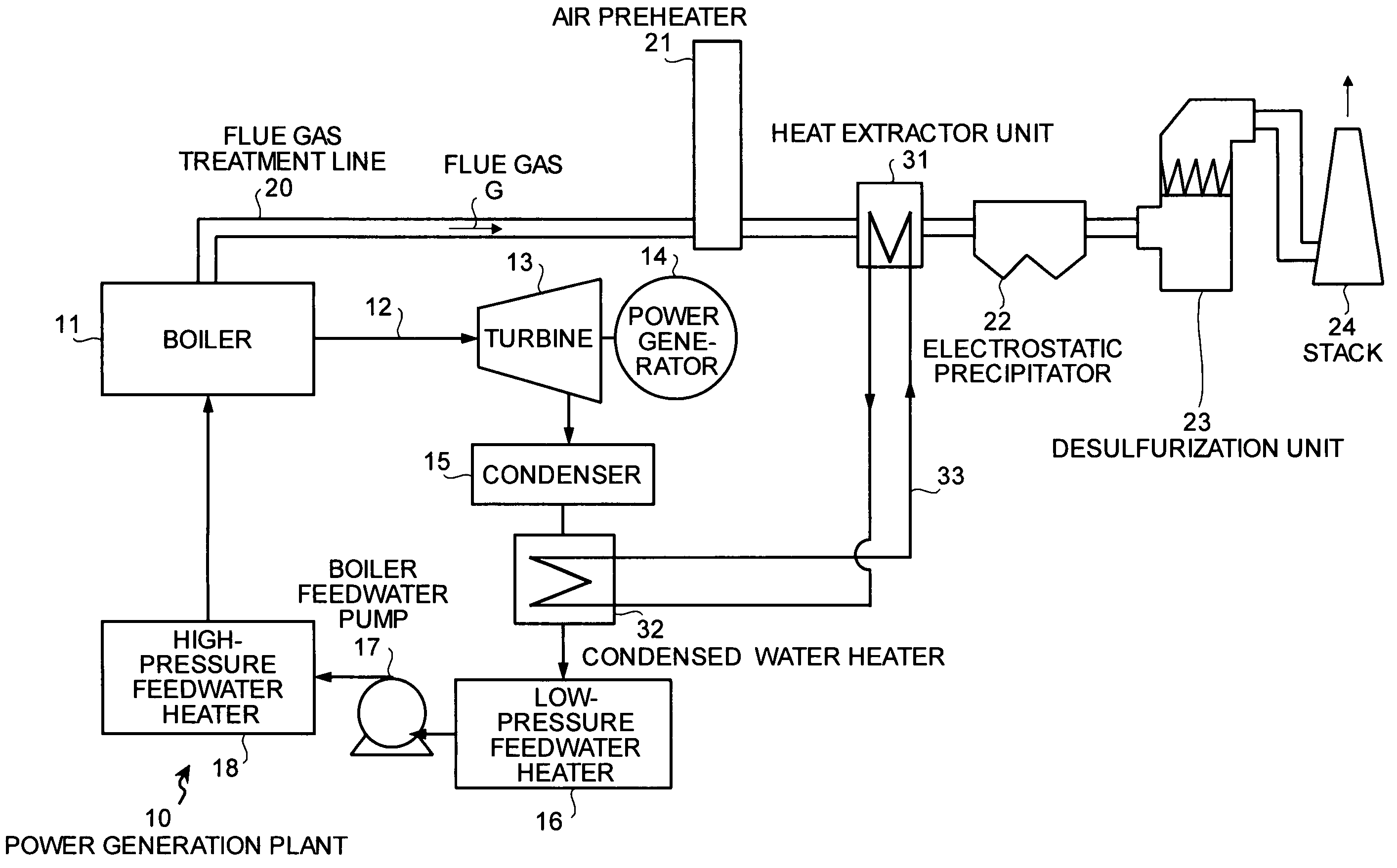

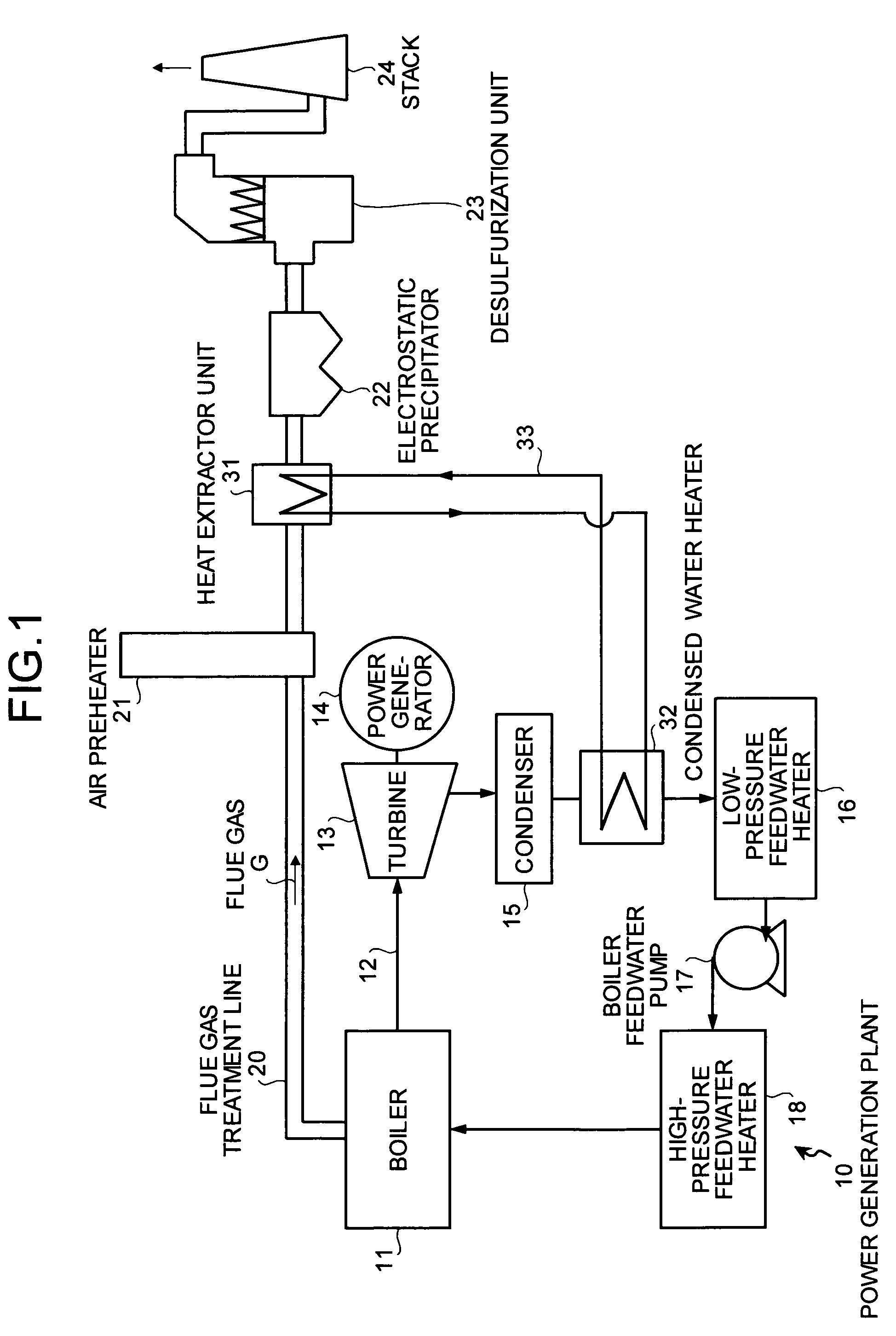

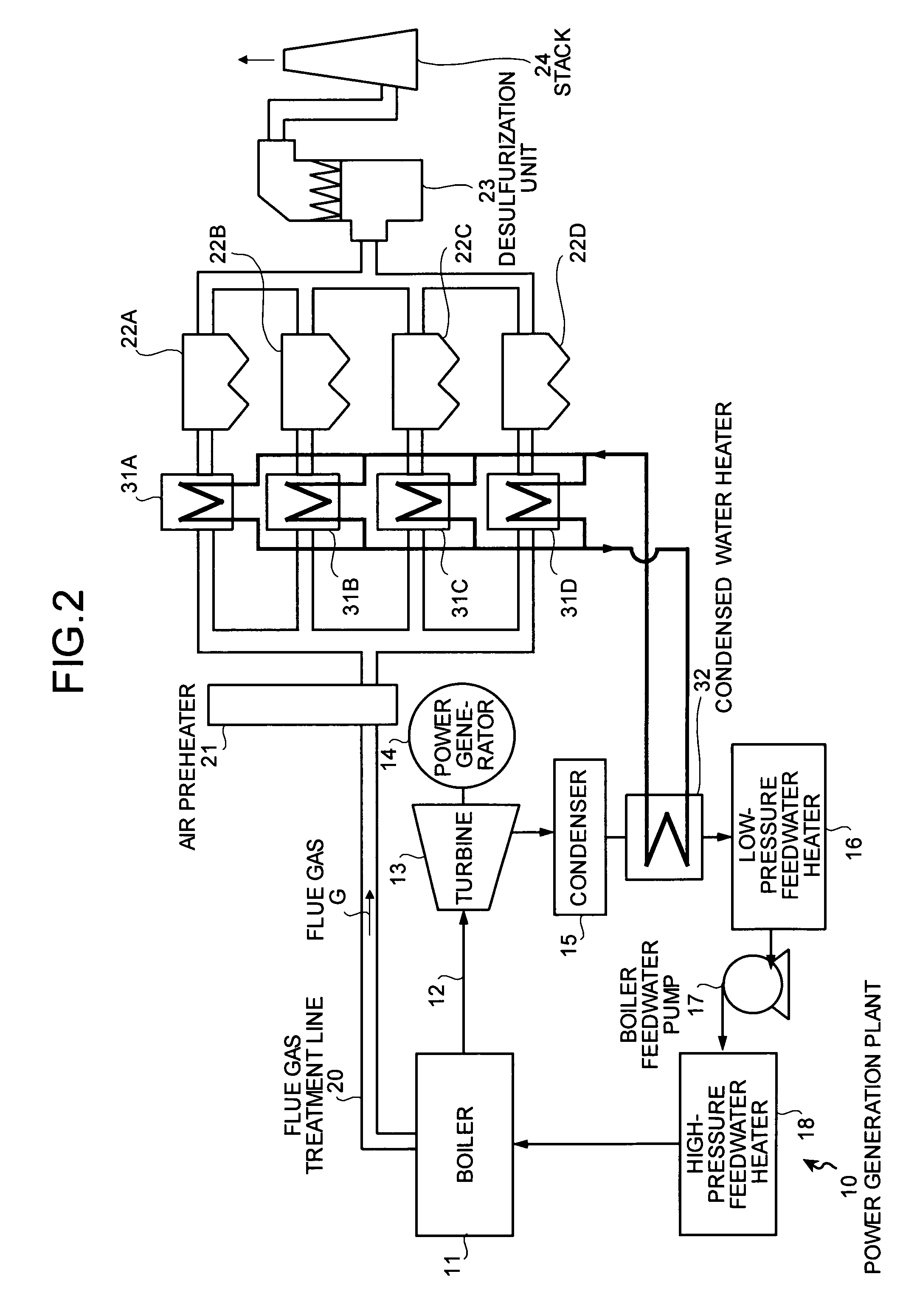

Heat recovery equipment recovers heat from flue gas. The heat recovery equipment includes a power generation plant that drives a steam turbine by superheated steam produced in a boiler, and an exhaust-gas treatment line that treats flue gas output from the boiler. The exhaust-gas treatment line includes a first air preheater, a heat extractor unit, and a dry electrostatic precipitator. The power generation plant includes a condensed water line. The condensed water line includes a condenser, a condensed water heater, and a low-pressure feedwater heater. The condensed water heater heats water condensed by the condenser with the heat recovered by the heat extractor unit.

Owner:MITSUBISHI POWER LTD

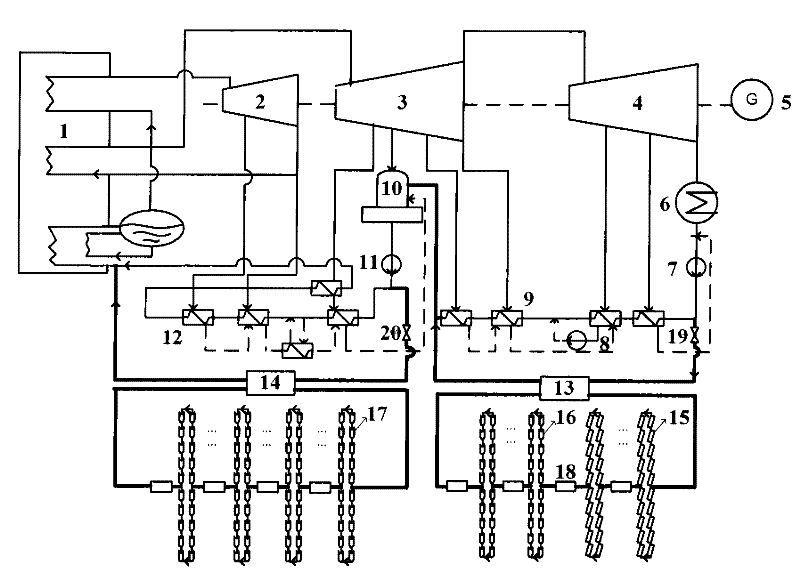

Gas-steam circulation combined double-stage coupling heat pump heat supply device

InactiveCN102878603AImprove work efficiencyImprove cycle efficiencyLighting and heating apparatusHot-water central heatingWater vaporGas compressor

The invention relates to a gas-steam circulation combined double-stage coupling heat pump heat supply device and belongs to the technical field of heat supply equipment. The gas-steam circulation combined double-stage coupling heat pump heat supply device can supply a low-temperature cooling working medium for gas-steam circulation, recycle condensation heat of steam, gradiently utilize energy for supplying heat and extracting steam and recycle heat of cooling water. A gas compressor is communicated with a boiler; the boiler is communicated with a gas turbine; the gas turbine is communicated with the boiler through a feed water heater; the feed water heater is communicated with an evaporator; the boiler is communicated with a power generation turbine; the power generation turbine is communicated with a small turbine and a steam condenser respectively; the steam condenser is communicated with the feed water heater; the feed water heater is communicated with the boiler; the steam condenser is communicated with the evaporator; the power generation turbine is communicated with the small turbine; the small turbine coaxially drives a compressor to rotate; the small turbine is communicated with a generator; the small turbine is communicated with a steam pipeline; a condenser is communicated with an absorber; and the absorber is communicated with the condenser. The gas-steam circulation combined double-stage coupling heat pump heat supply device is mainly applied to afterheat utilization of a gas-steam circulation power plant in the field of heat pump heat supply.

Owner:HARBIN INST OF TECH

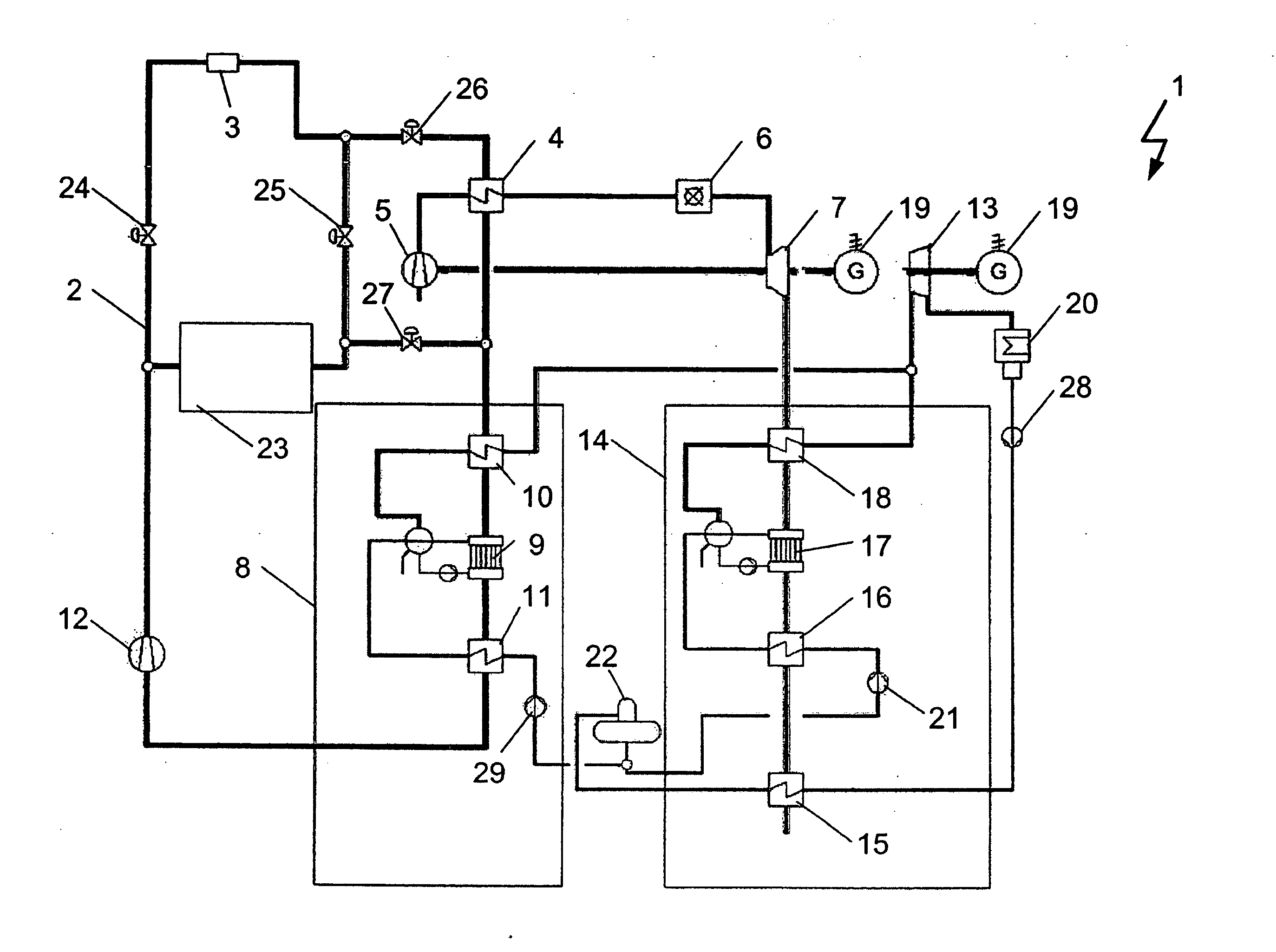

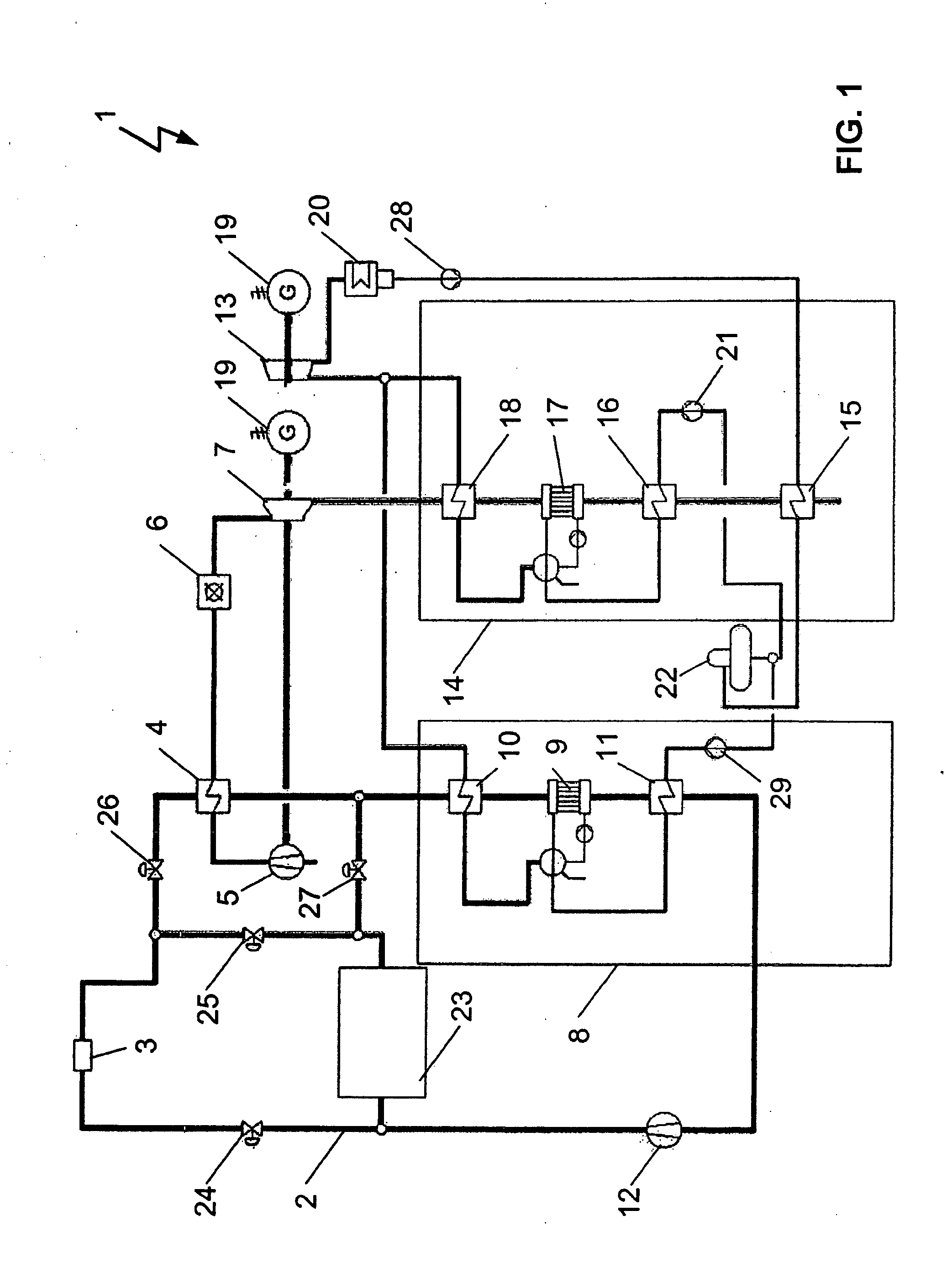

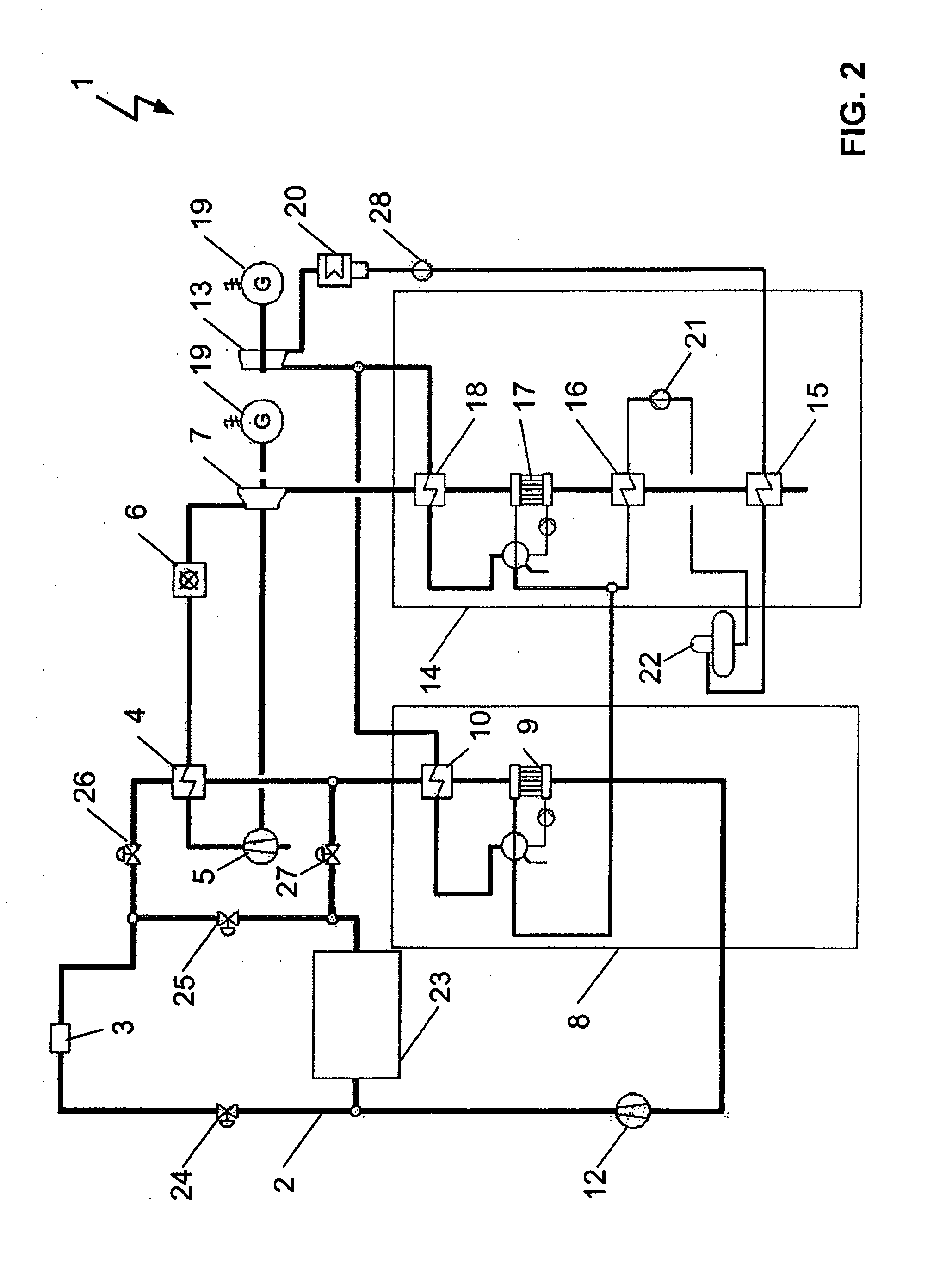

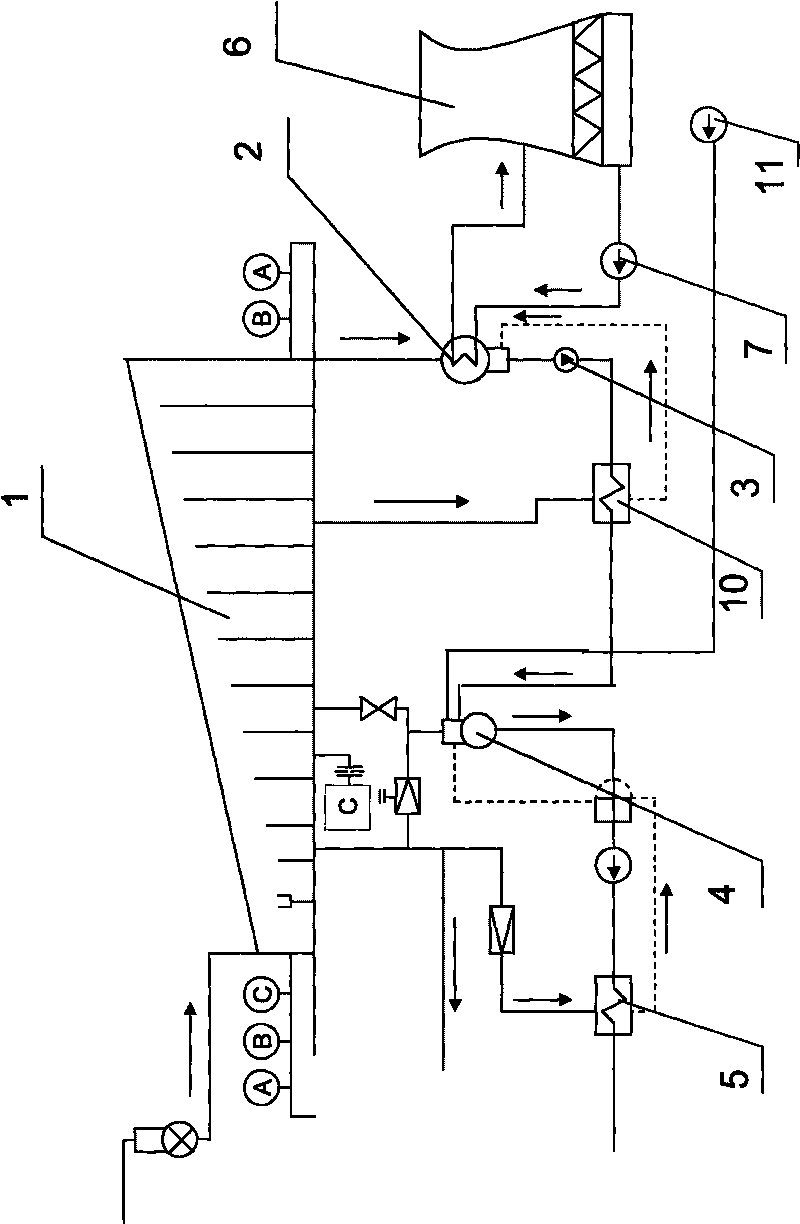

Solar hybrid combined cycle gas and steam power plant

ActiveUS20110185742A1Easy to installFacilitate heat transfer and coupling of heatAuxillary drivesFrom solar energyPower stationSteam power

A solar hybrid combined cycle gas-steam power plant and method including a solar unit, a gas turbine unit and a steam turbine unit. The solar unit includes a receiver. The gas turbine unit includes a gas turbine with a waste heat boiler arranged downstream, and a steam turbine with a feed water heater. The power plant includes a heat transfer medium cycle for transferring solar heat. The heat transfer medium cycle is coupled to the gas turbine unit through a gas turbine heat exchanger and to the steam turbine unit through a solar boiler. Alternatively to the gas turbine unit and the steam turbine unit, the solar hybrid combined cycle power plant includes an integrated gas-steam turbine having a waste heat boiler arranged downstream, wherein the heat transfer medium cycle is coupled to the integrated gas-steam turbine through the gas turbine heat exchanger and through the solar boiler.

Owner:DRESDEN UNIVERSITY OF TECHNOLOGY

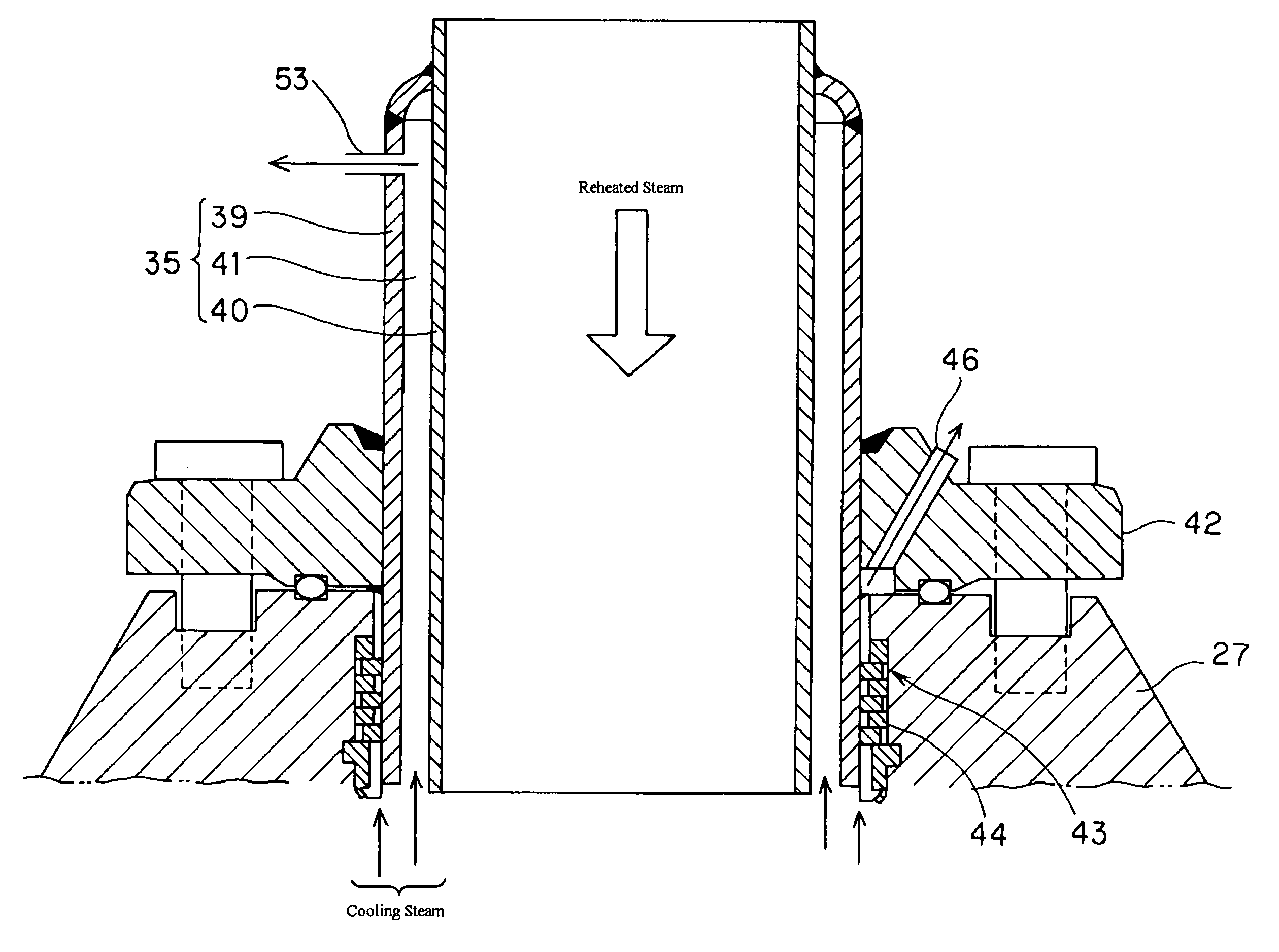

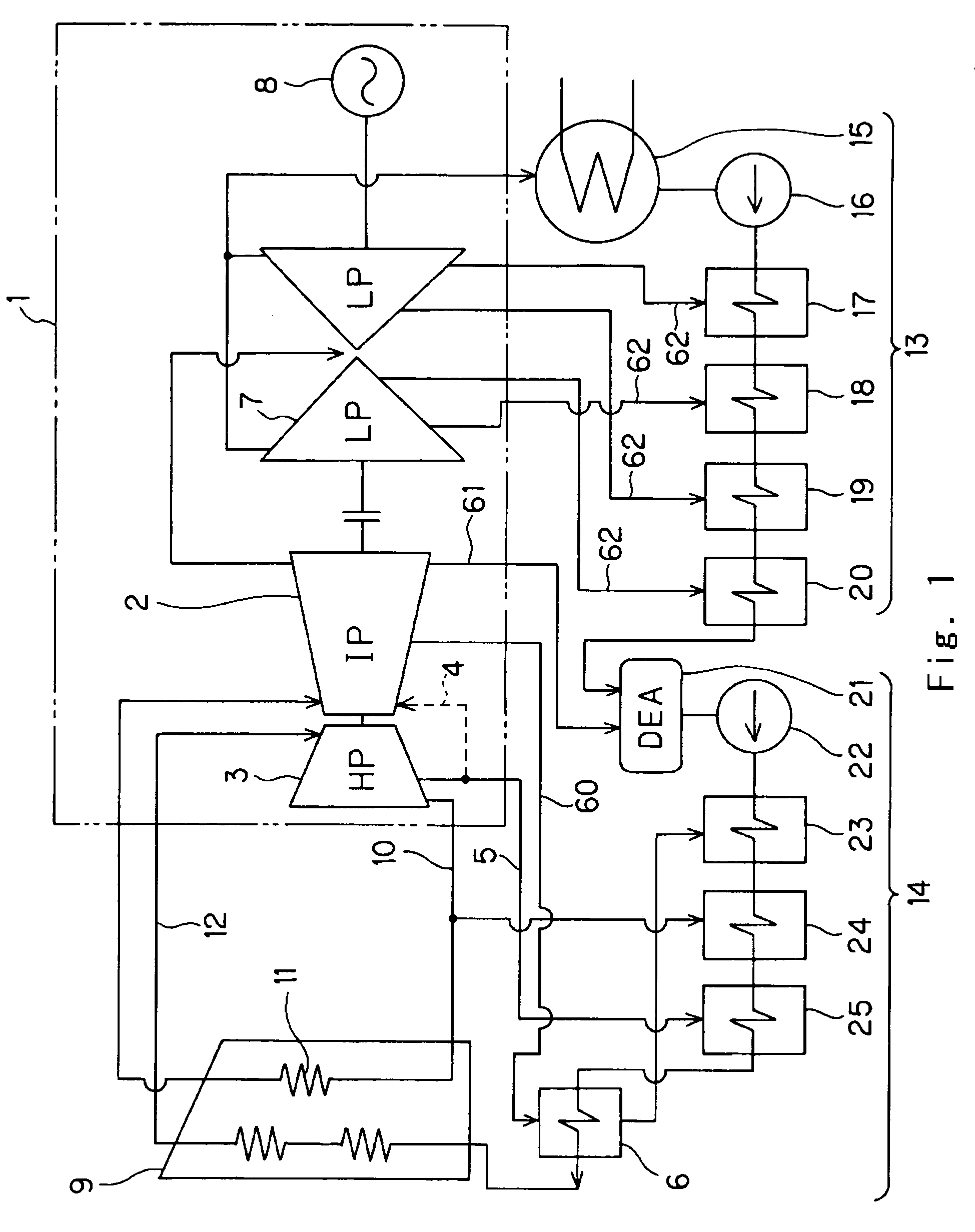

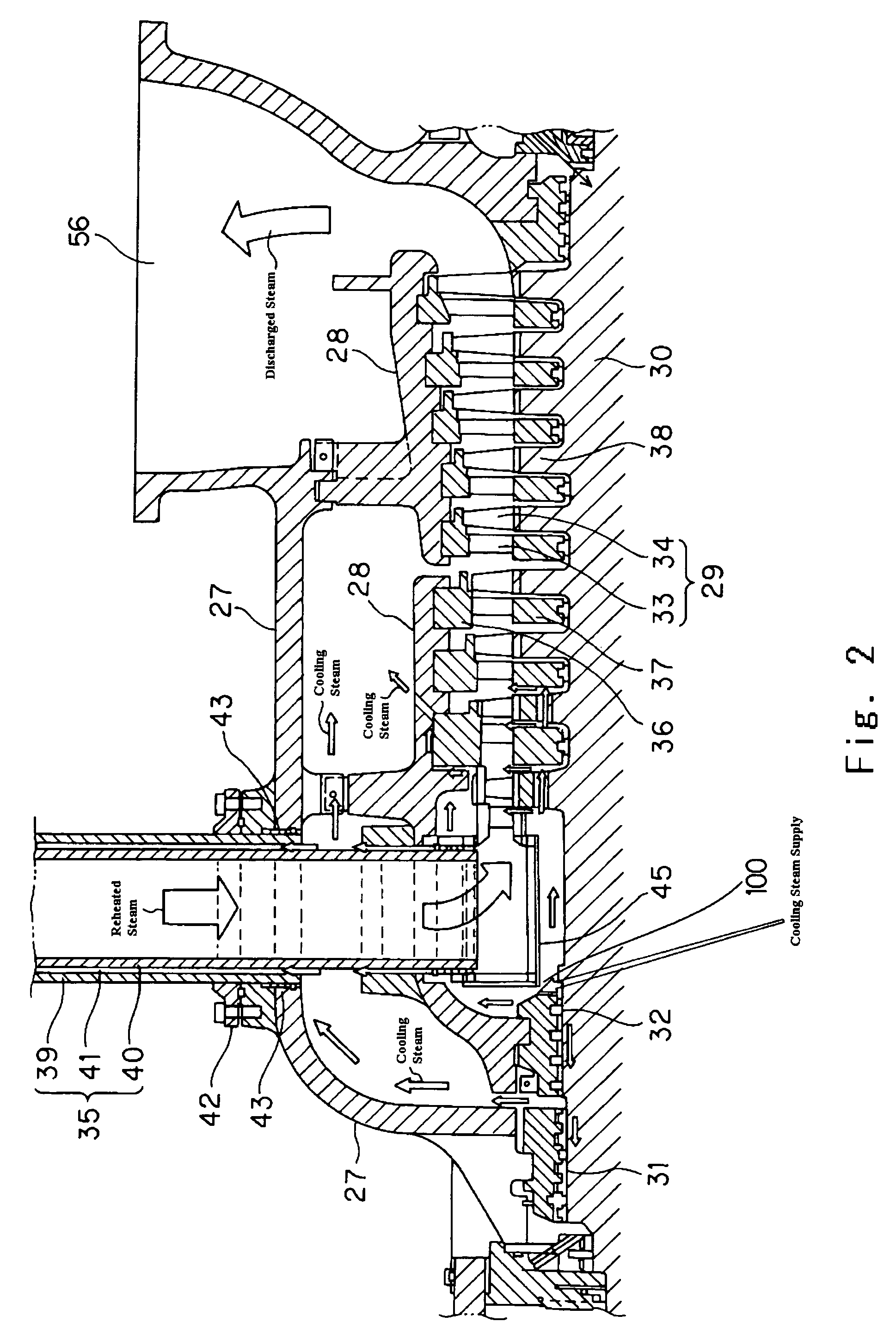

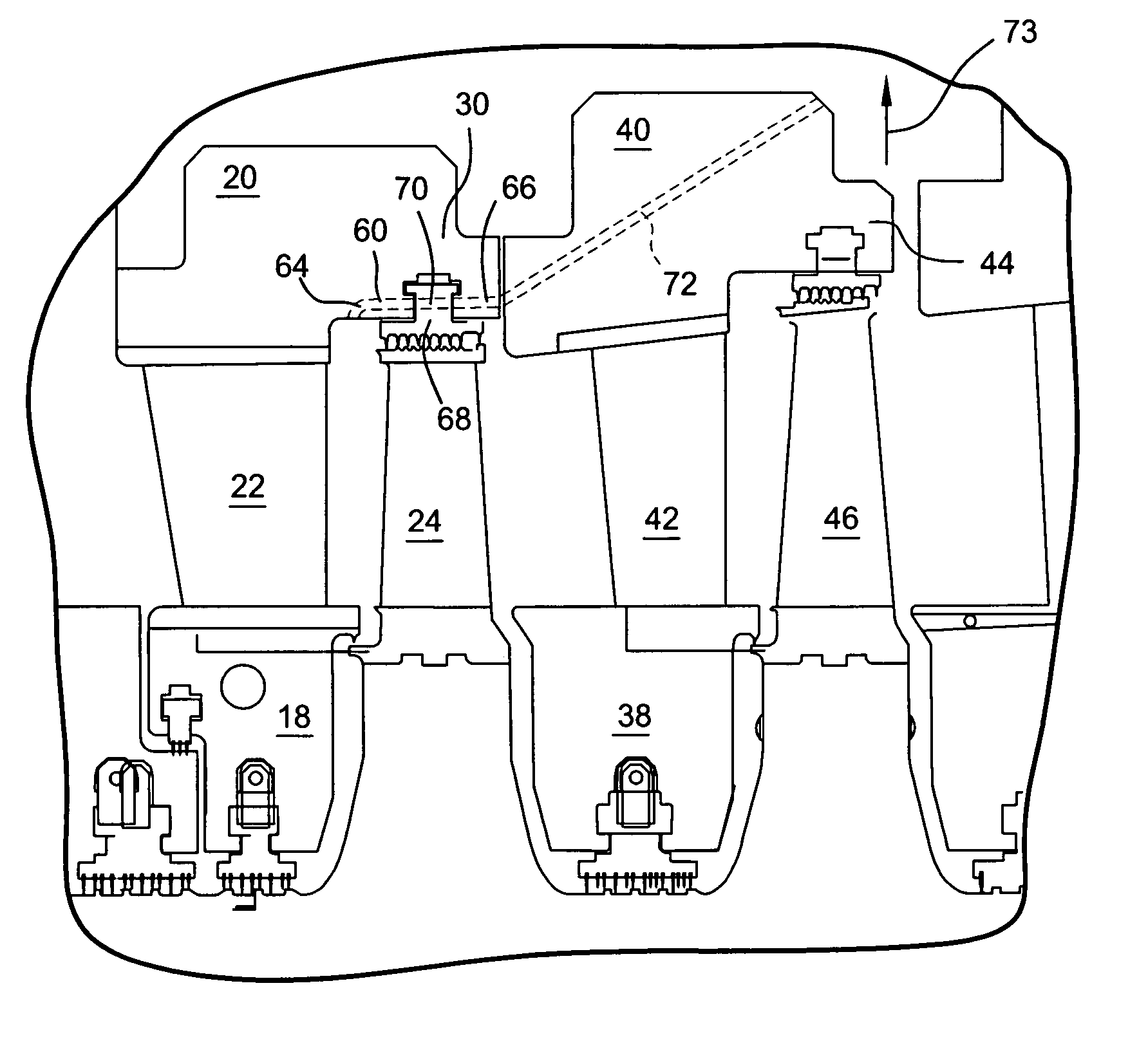

Steam turbine, steam turbine plant and method of operating a steam turbine in a steam turbine plant

ActiveUS7003956B2Improves plant thermal efficiencyIncrease temperatureLiquid degasificationPump componentsSteam condensationEngineering

A steam turbine and steam turbine plant that can utilize a relatively higher reheated steam, such as about 1300 degrees Fahrenheit or higher, is provided. A steam turbine plant includes a steam generator generating high pressure steam and reheated steam, a high pressure turbine driven by the high pressure steam generated by the steam generator, and an intermediate pressure turbine driven by the reheated steam. A steam bleed line coupled with the high pressure turbine bleeds steam from the high pressure turbine as cooling steam. The intermediate pressure turbine includes a heated steam inlet for receiving the reheated steam, and a cooling steam inlet for receiving the cooling steam. The cooling steam cools components of the intermediate pressure turbine that receive the reheated steam. A low pressure turbine is driven by steam discharged from the intermediate pressure turbine, and a condenser condenses steam discharged from the low pressure turbine into water as a condensate. A plurality of feedwater heaters heat the condensate to produce feedwater provided to the steam generator.

Owner:KK TOSHIBA

Low-temperature heat energy recovering apparatus of heat and electricity co-generation and recovering method thereof

ActiveCN101696643AIncrease small loopReduce heat transfer irreversible lossLiquid degasificationSteam regenerationCooling towerAutomatic control

The invention relates to a low-temperature heat energy recovering apparatus of heat and electricity co-generation and a recovering method thereof. The apparatus comprises a steam boiler, a steam turbine, a generator, a condenser, a deaerator, a high-pressure heater, a cooling tower and a demineralized water pump. The steam turbine is connected with the condenser through an exhaust cylinder. The condenser is connected with the cooling tower through pipelines to form a water channel large circulation. The device is characterized by also comprising a water supplementing mixer and a heat pump type feed water heater, wherein the water supplementing mixture is respectively connected with the condenser and the demineralized water pump through pipelines, the heat pump type feed water heater is respectively connected with the water supplementing mixer and the deaerator through the pipelines. The condenser and the feed water heater are connected with the cooling tower through pipelines to form water channel small circulation. The heat pump type feed water heater is driven by steam extracted by the steam turbine. The apparatus further comprises an automatic control apparatus. The invention can reduce the cold source loss and improve the comprehensive heat efficiency.

Owner:联合优发生物质能源徐州有限公司

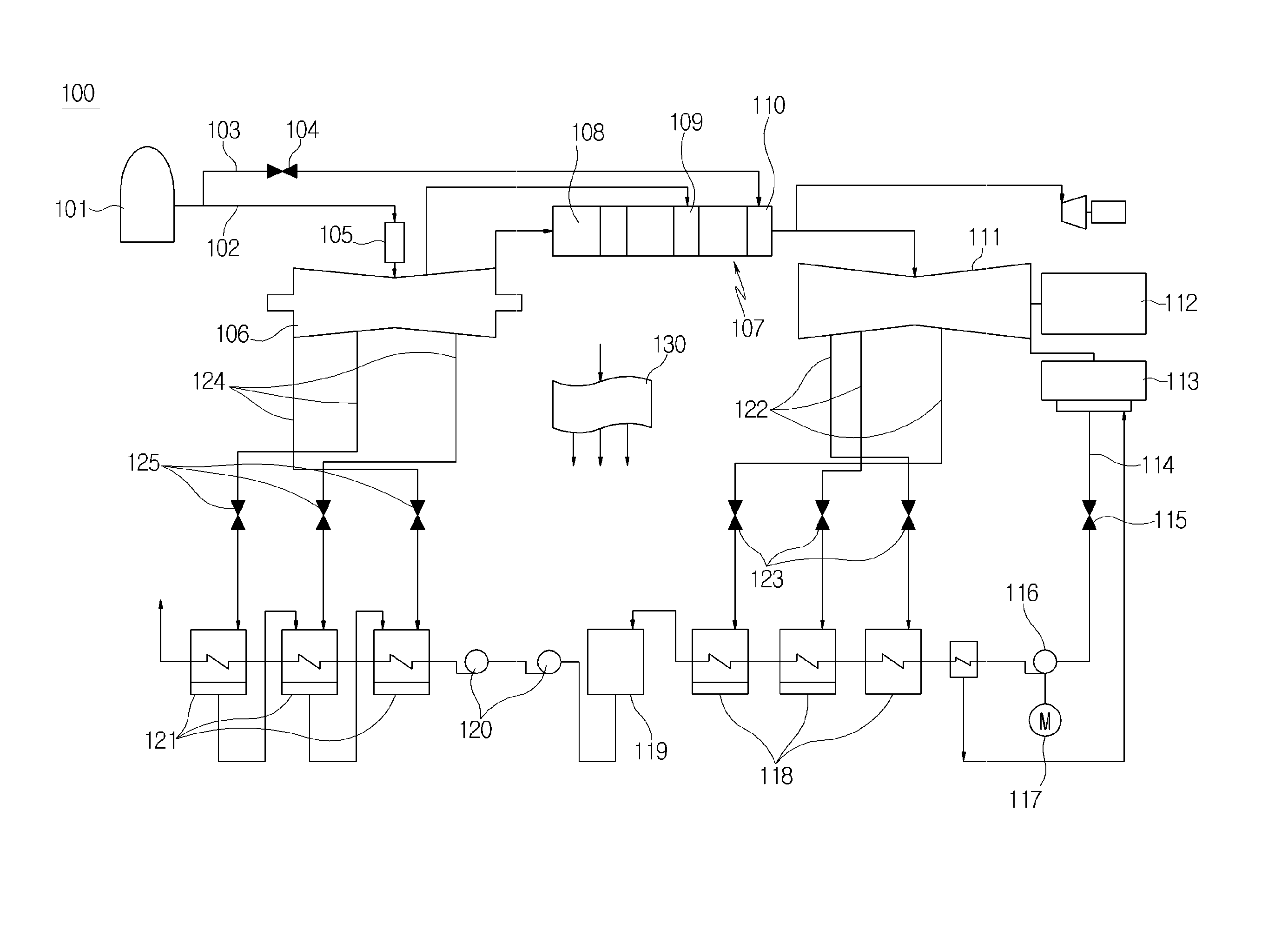

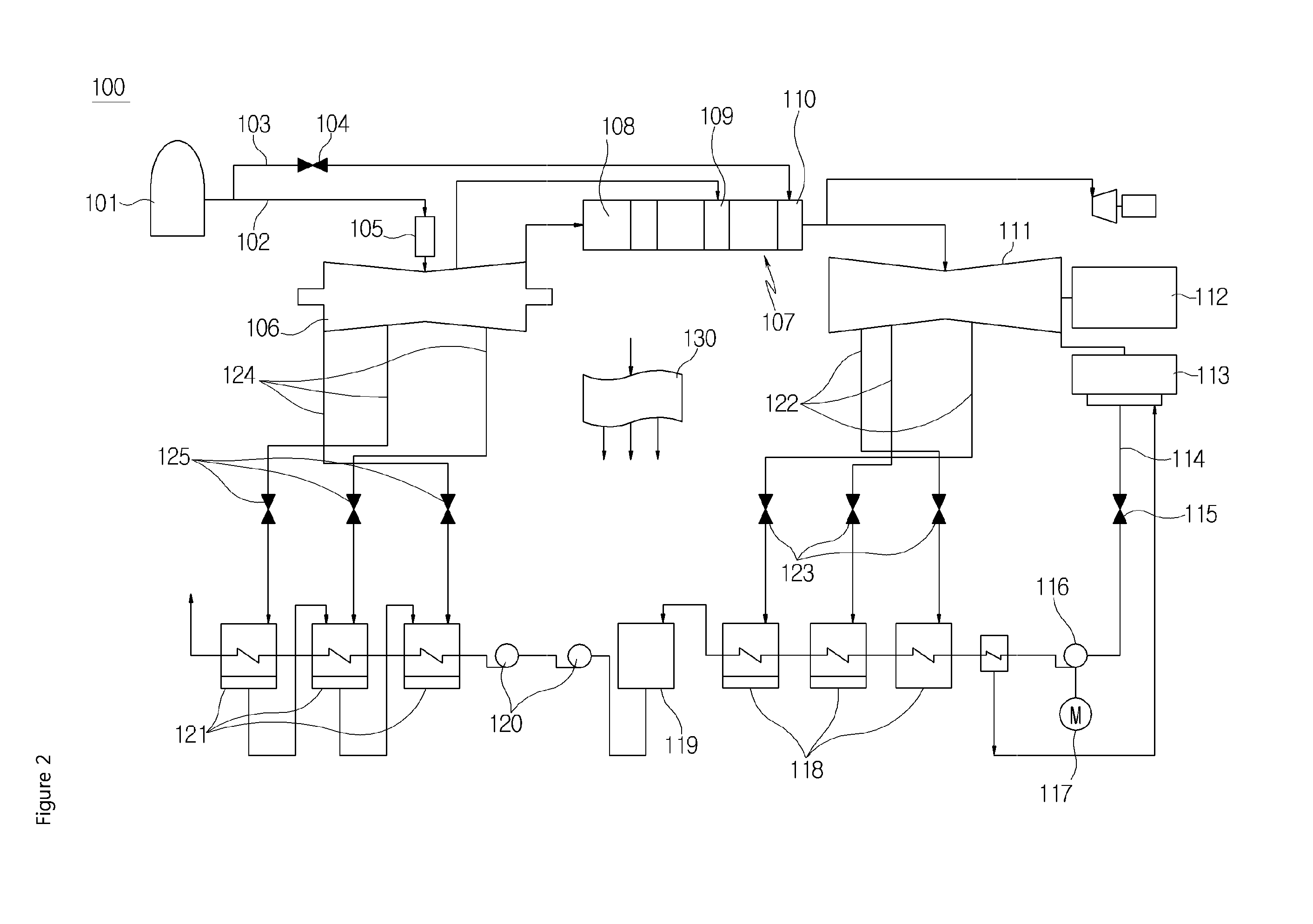

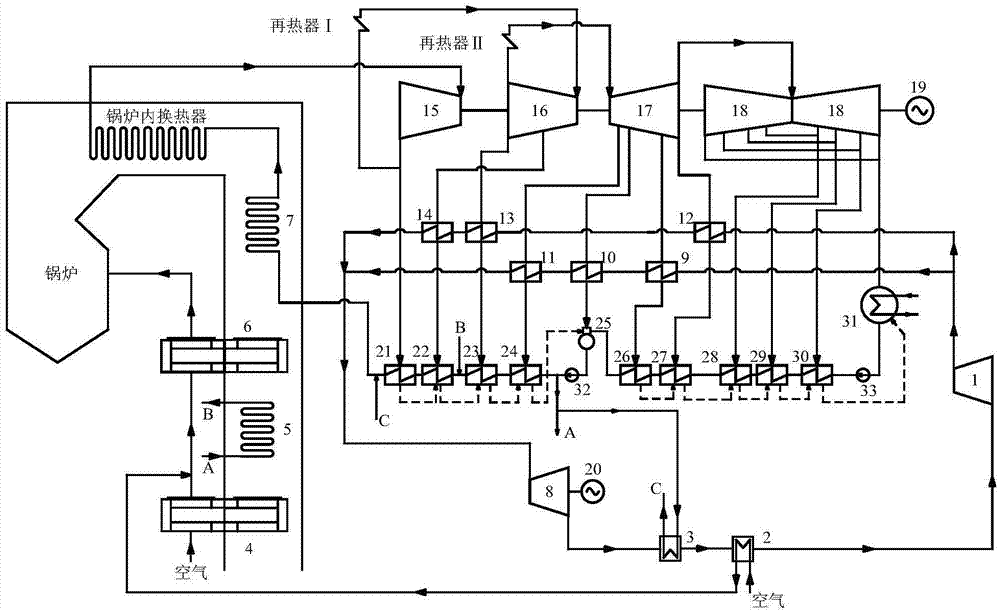

Coal-fired unit and gas turbine combined type power generation system

ActiveCN104314628AImprove power generation efficiencyImprove energy efficiencySteam useCombined combustion mitigationEngineeringHigh pressure

The invention relates to a coal-fired unit and gas turbine combined type power generation system, and belongs to the field of combined power generation. The coal-fired unit and gas turbine combined type power generation system comprises a coal-fired unit, a gas turbine, a residual heat boiler and a water feeding heater, wherein the water feeding heater is integrated in the residual heat boiler, a high-pressure heater system of the coal-fired unit is provided with an outlet bypass, and is connected with the water feeding heater, the other end of the water feeding heater is connected with a coal-fired boiler of the coal-fired unit, a shaft seal heater of the coal-fired unit is provided with a bypass, condensate enters the residual heat boiler through the bypass, and is heated to form steam, and then the steam is supplemented into a steam turbine of the coal-fired unit. The coal-fired unit and gas turbine combined type power generation system has the advantages that the heat circulating efficiency is greatly improved, the utilization rate of energy source is improved, the coal consumption of power generation enterprises is reduced, and the energy-saving and emission-reduction purposes are realized.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Apparatus and methods for minimizing solid particle erosion in steam turbines

Solid particle erosion in a steam turbine is minimized by diverting through holes in appendages of outer rings of the diaphragms, a portion of the steam from the steam flow path thereby bypassing downstream rotating components. The hole through the first stage appendage lies in communication with a passage through a downstream outer ring of a following stage such that the diverted solid particle containing steam may be extracted from the steam flow path and passed to the feed water heater of the turbine. The hole in the second stage appendage diverts steam from between the first and second stages and about the second stage. Solid particle erosion in various regions, i.e., the trailing edge of the stator vanes, along the surfaces of the buckets and in the regions of the cover and its connection with the buckets as well as the sealing devices are thereby minimized.

Owner:GE INFRASTRUCTURE TECH INT LLC

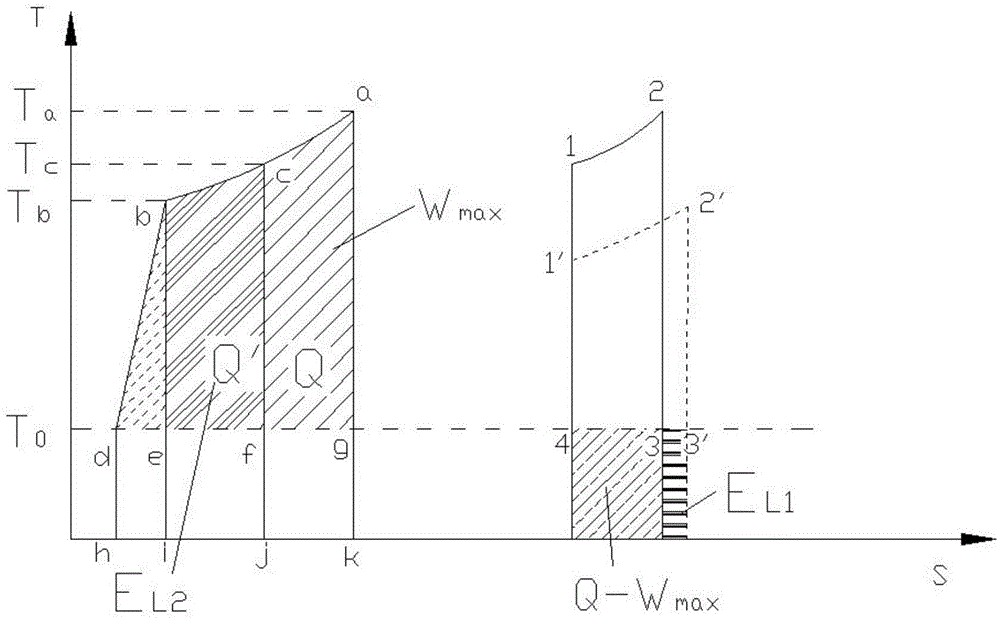

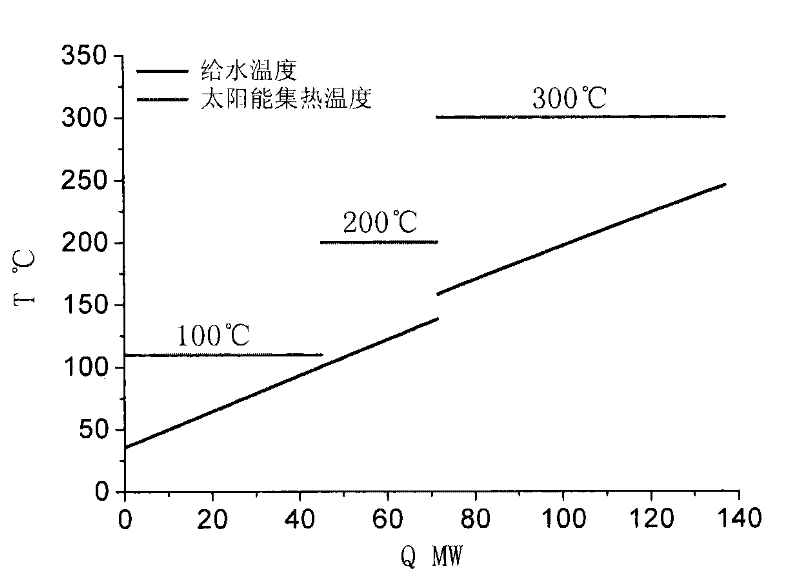

Board slot combined solar energy and thermal power station complementary generating system

ActiveCN102454440AReduce irreversibilityHigh thermal efficiencySteam generation heating methodsSolar heat devicesWater vaporDeaerator

The invention discloses a board slot combined solar energy and thermal power station complementary generating system which comprises a coal-fired boiler, a steam turbine, a generator, a condenser, a condensate pump, an oil-water heat exchanger of a low-pressure solar feed water heater, a flat-plate solar collector, a first parabolic trough type solar collector, a deaerator, a high-pressure water pump, an oil-water heat exchanger of a high-pressure solar feed water heater and a second parabolic trough type solar collector, wherein the steam turbine comprises a high-pressure cylinder, an intermediate-pressure cylinder and a low-pressure cylinder; high-temperature and high-pressure steam generated in the coal-fired boiler does work by expansion in the high-pressure cylinder, the intermediate-pressure cylinder and the low-pressure cylinder of the steam turbine to drive a generator to rotate and output an electrical load externally. The generating system can be used for realizing the capacity expansion and consumption reduction of thermal power stations and solving the problem that the solar energy is unstable and discontinuous, and is beneficial to low-cost transformation of the thermal power stations and large-scale application and popularization of a solar energy technology.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

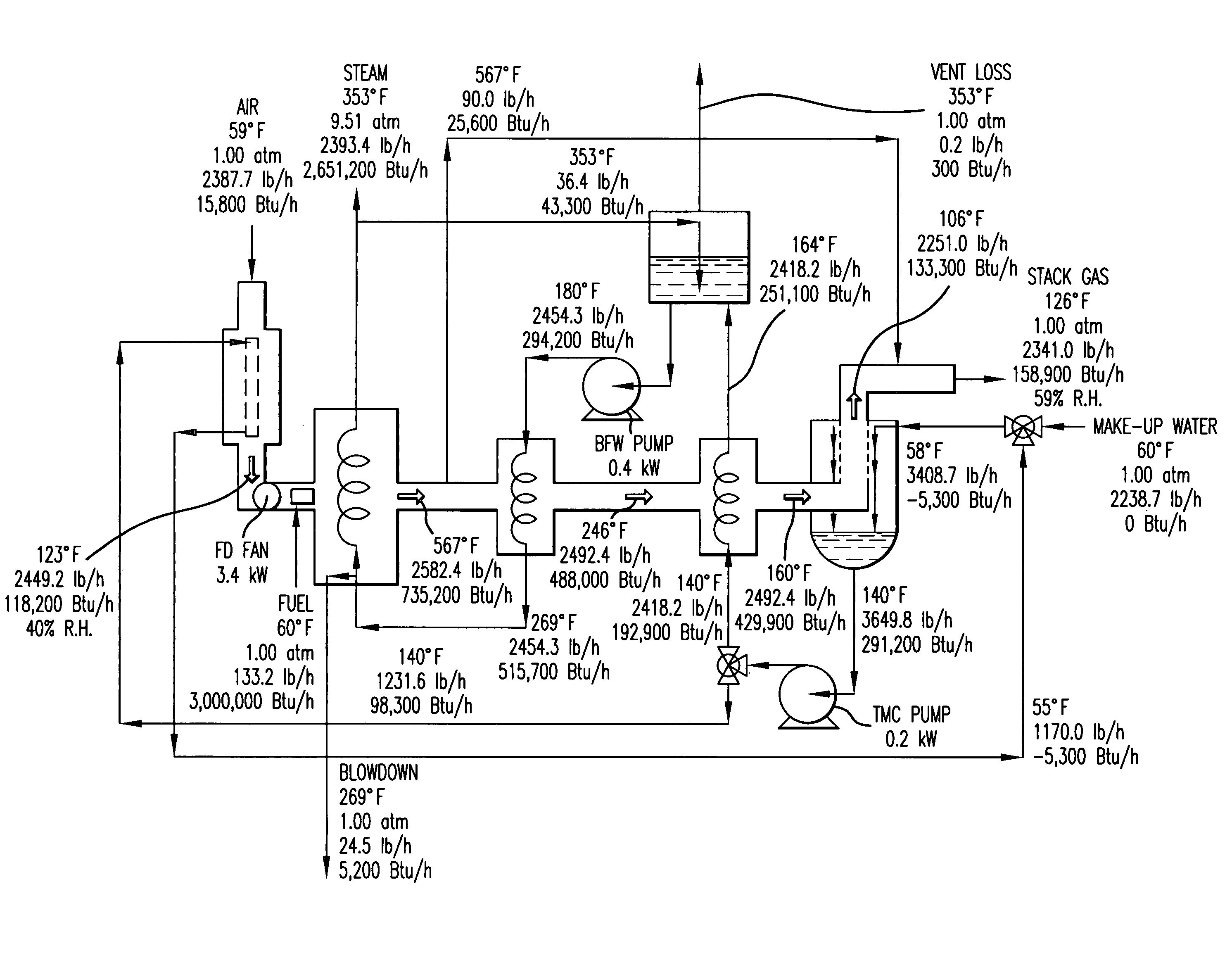

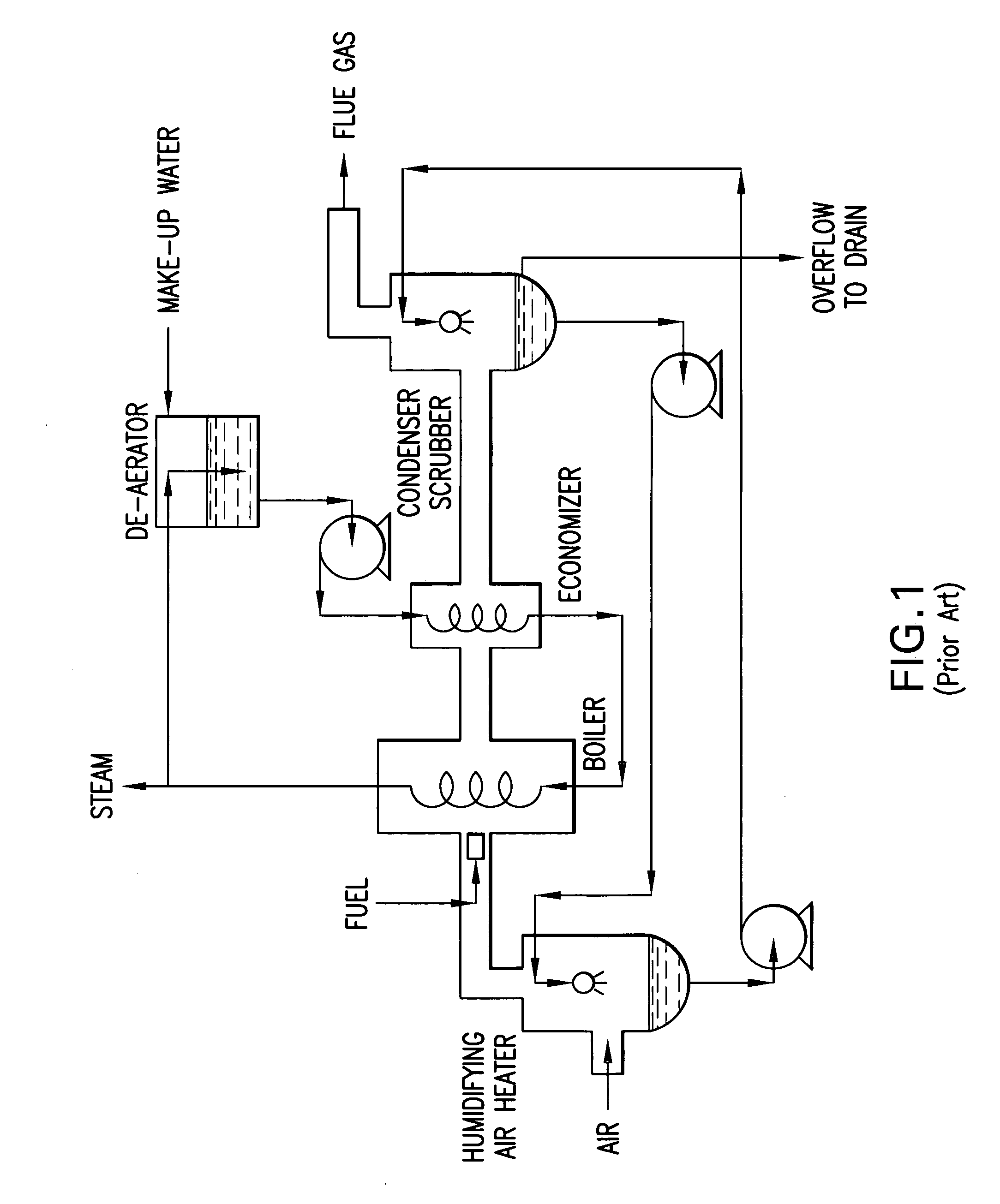

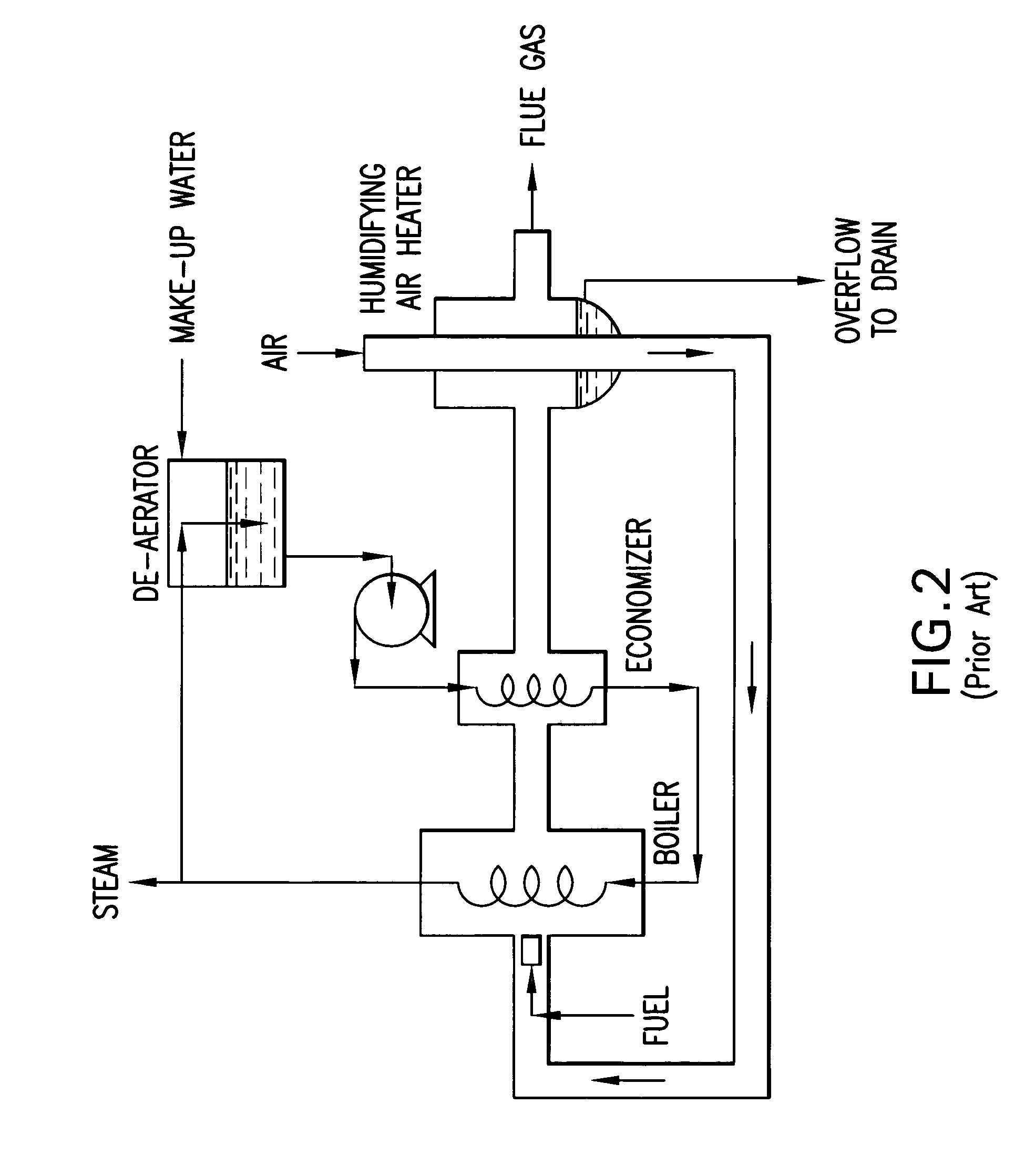

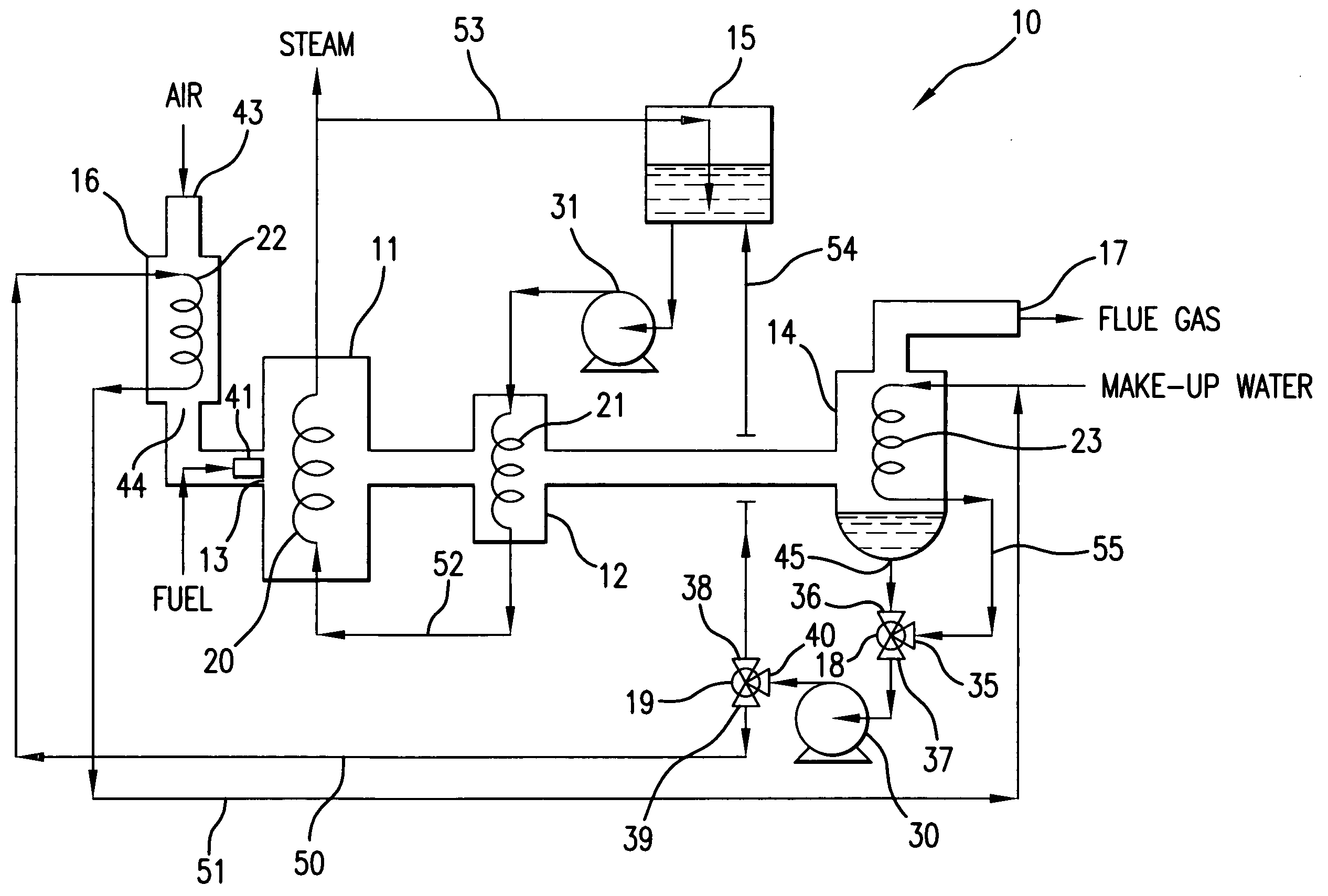

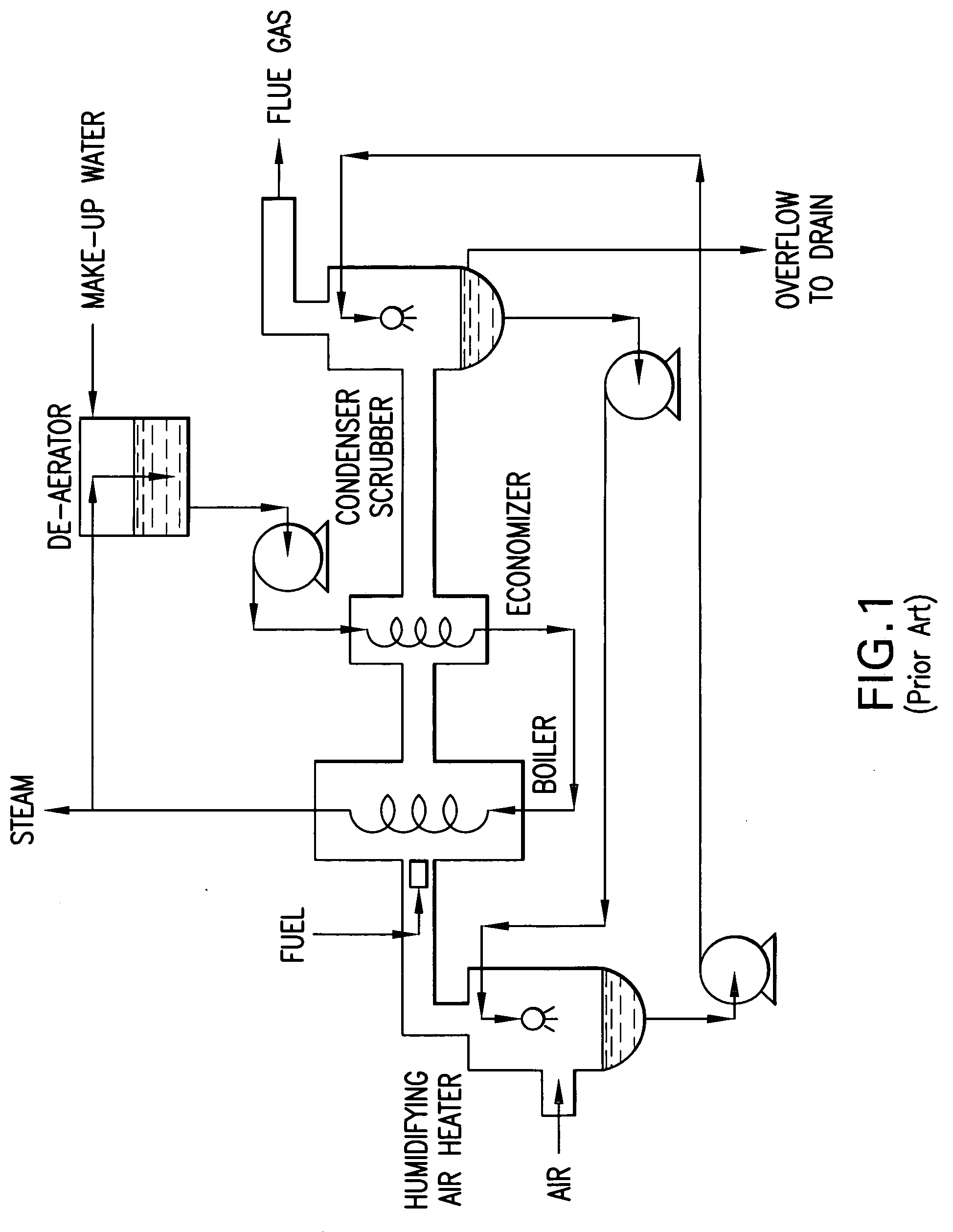

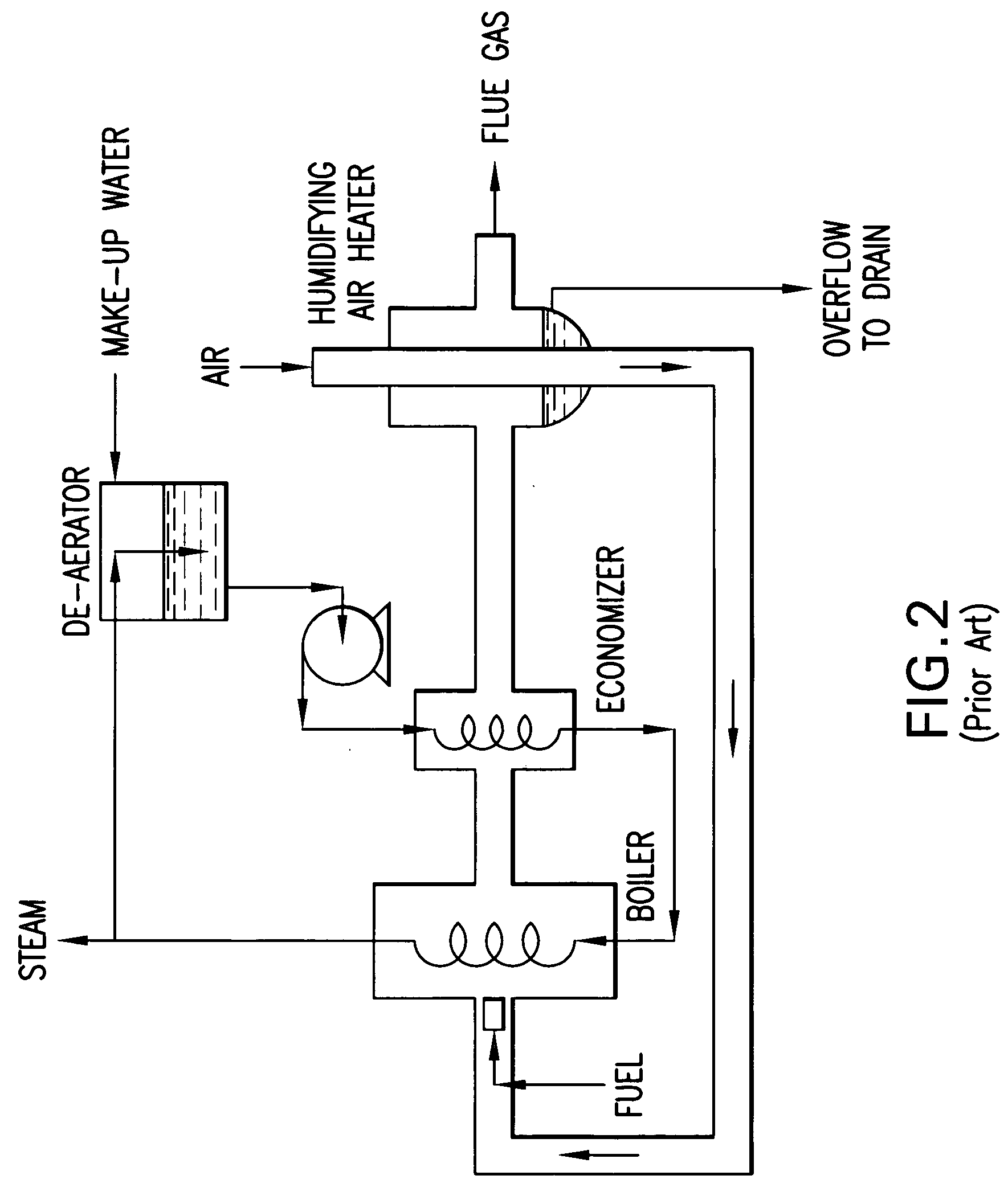

Method and apparatus for enhanced heat recovery from steam generators and water heaters

A heating system having a steam generator or water heater, at least one economizer, at least one condenser and at least one oxidant heater arranged in a manner so as to reduce the temperature and humidity of the exhaust gas (flue gas) stream and recover a major portion of the associated sensible and latent heat. The recovered heat is returned to the steam generator or water heater so as to increase the quantity of steam generated or water heated per quantity of fuel consumed. In addition, a portion of the water vapor produced by combustion of fuel is reclaimed for use as feed water, thereby reducing the make-up water requirement for the system.

Owner:UNITE STATES DEPT OF ENERGY

Heat recovery equipment

Heat recovery equipment recovers heat from flue gas. The heat recovery equipment includes a power generation plant that drives a steam turbine by superheated steam produced in a boiler, and an exhaust-gas treatment line that treats flue gas output from the boiler. The exhaust-gas treatment line includes a first air preheater, a heat extractor unit, and a dry electrostatic precipitator. The power generation plant includes a condensed water line. The condensed water line includes a condenser, a condensed water heater, and a low-pressure feedwater heater. The condensed water heater heats water condensed by the condenser with the heat recovered by the heat extractor unit.

Owner:MITSUBISHI POWER LTD

Heat accumulation type electric furnace flue gas waste heat recovery system

ActiveCN103940248AImprove waste heat utilization efficiencyReduce the impact of volatilityEnergy industryIncreasing energy efficiencyAtmospheric airDeaerator

The invention provides a heat accumulation type electric furnace flue gas waste heat recovery system which comprises a perpendicular type connecting flue, a heat accumulation type water-cooling settling chamber, a heat convection waste heat boiler, a feed water heater, a steam heat accumulator and the like. After flue gas inside a combustion settling chamber passes through the perpendicular type connecting flue, the temperature and the flow rate of the flue gas are preliminarily integrated through the heat accumulation type water-cooling settling chamber, and then the flue gas sequentially enters the heat convection waste heat boiler and is exhausted to the atmosphere after the flue gas is cooled through the feed water heater and dust of the flue gas is removed through a dust remover. Raw water is heated through the feed water heater and then enters a deaerator for removing oxygen in the raw water. Then, the raw water flows through the heat convection waste heat boiler and the heat accumulation type water-cooling settling chamber and generates saturated steam to be fed into the steam heat accumulator. The steam enters a superheater after being buffered by the steam heat accumulator, and the superheated steam is output stably in a superheated mode. According to the heat accumulation type electric furnace flue gas waste heat recovery system, due to the fact that the two peak clipping trough levelling measures of the heat accumulation type water-cooling settling chamber and the steam heat accumulator are set, flue gas waste heat, generated by an electric furnace, with unstable fluctuations passes through the heat accumulation type electric furnace flue gas waste heat recovery system so as to stably and efficiently output the superheated steam.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

Apparatus and methods for minimizing solid particle erosion in steam turbines

Solid particle erosion in a steam turbine is minimized by diverting through holes in appendages of outer rings of the diaphragms, a portion of the steam from the steam flow path thereby bypassing downstream rotating components. The hole through the first stage appendage lies in communication with a passage through a downstream outer ring of a following stage such that the diverted solid particle containing steam may be extracted from the steam flow path and passed to the feed water heater of the turbine. The hole in the second stage appendage diverts steam from between the first and second stages and about the second stage. Solid particle erosion in various regions, i.e., the trailing edge of the stator vanes, along the surfaces of the buckets and in the regions of the cover and its connection with the buckets as well as the sealing devices are thereby minimized.

Owner:GENERAL ELECTRIC CO

Method and apparatus for enhanced heat recovery from steam generators and water heaters

A heating system having a steam generator or water heater, at least one economizer, at least one condenser and at least one oxidant heater arranged in a manner so as to reduce the temperature and humidity of the exhaust gas (flue gas) stream and recover a major portion of the associated sensible and latent heat. The recovered heat is returned to the steam generator or water heater so as to increase the quantity of steam generated or water heated per quantity of fuel consumed. In addition, a portion of the water vapor produced by combustion of fuel is reclaimed for use as feed water, thereby reducing the make-up water requirement for the system.

Owner:UNITE STATES DEPT OF ENERGY

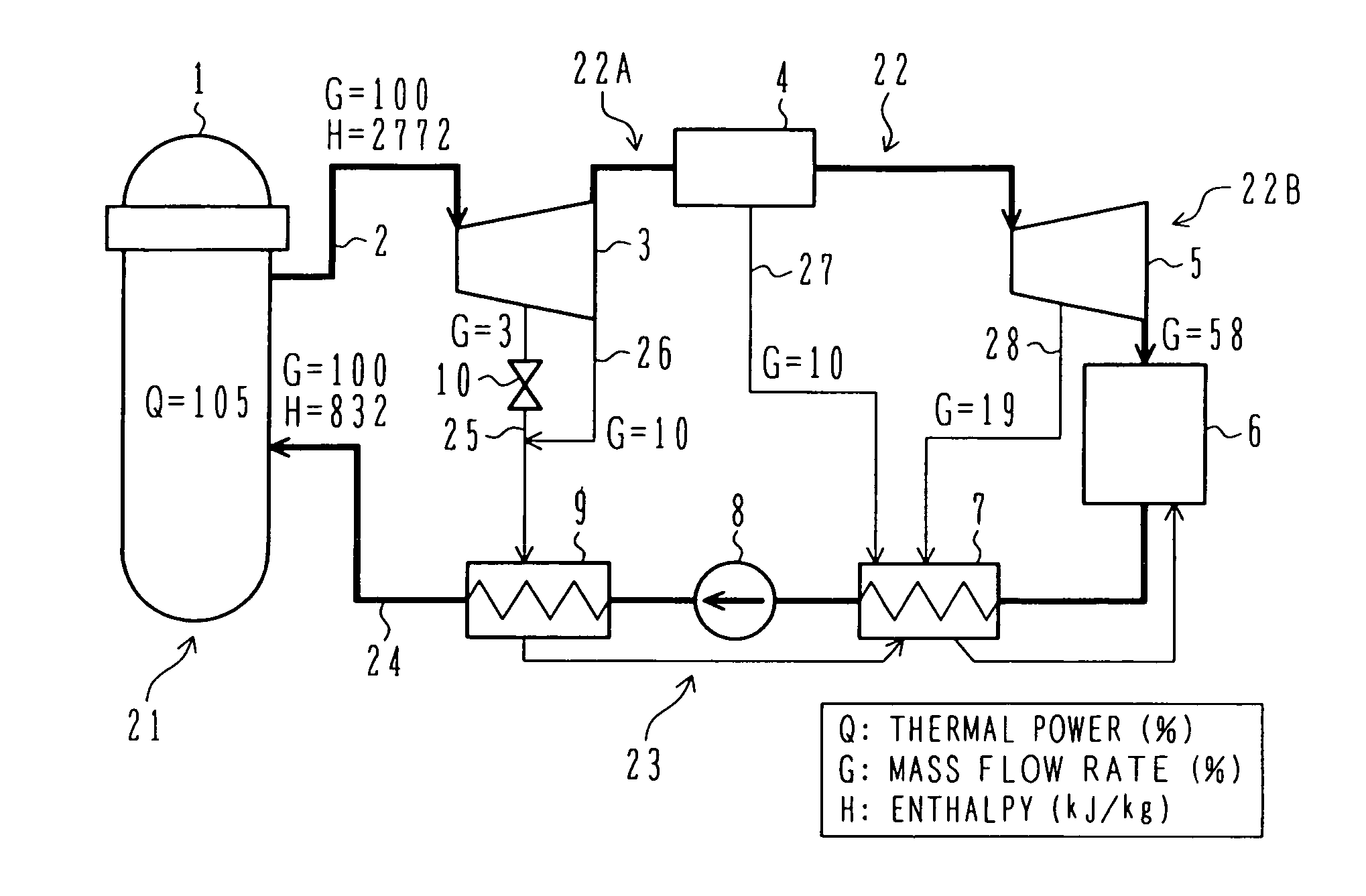

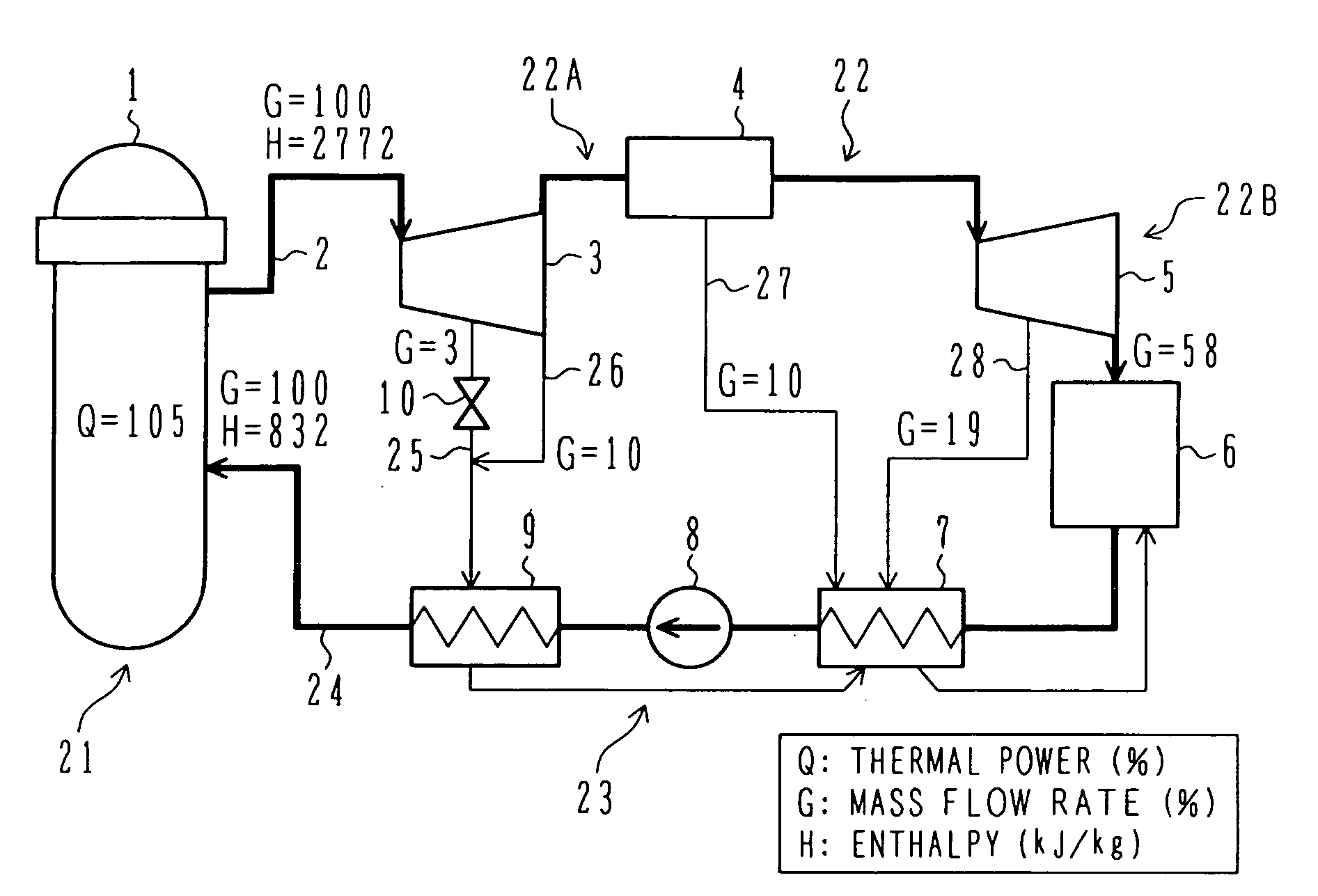

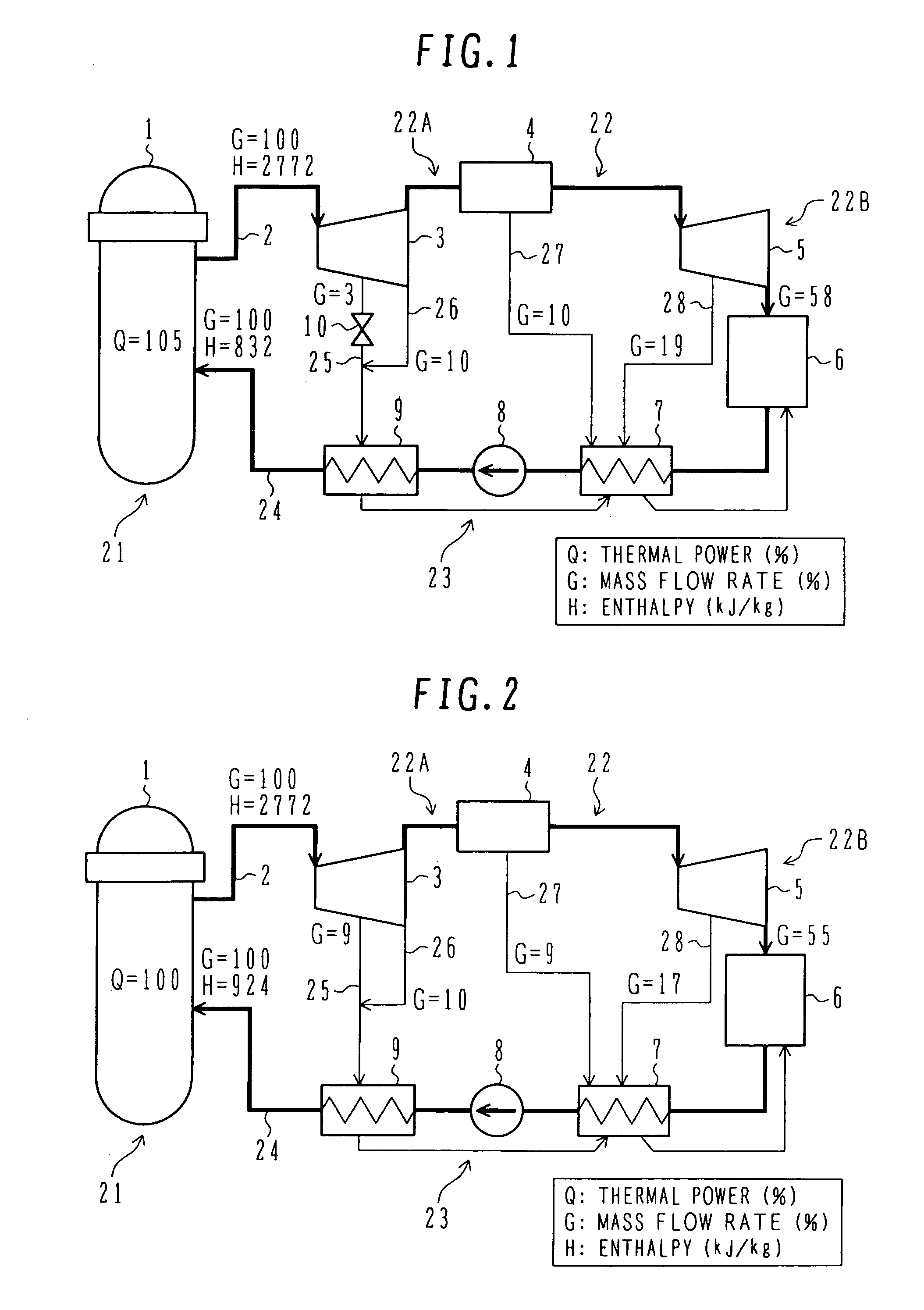

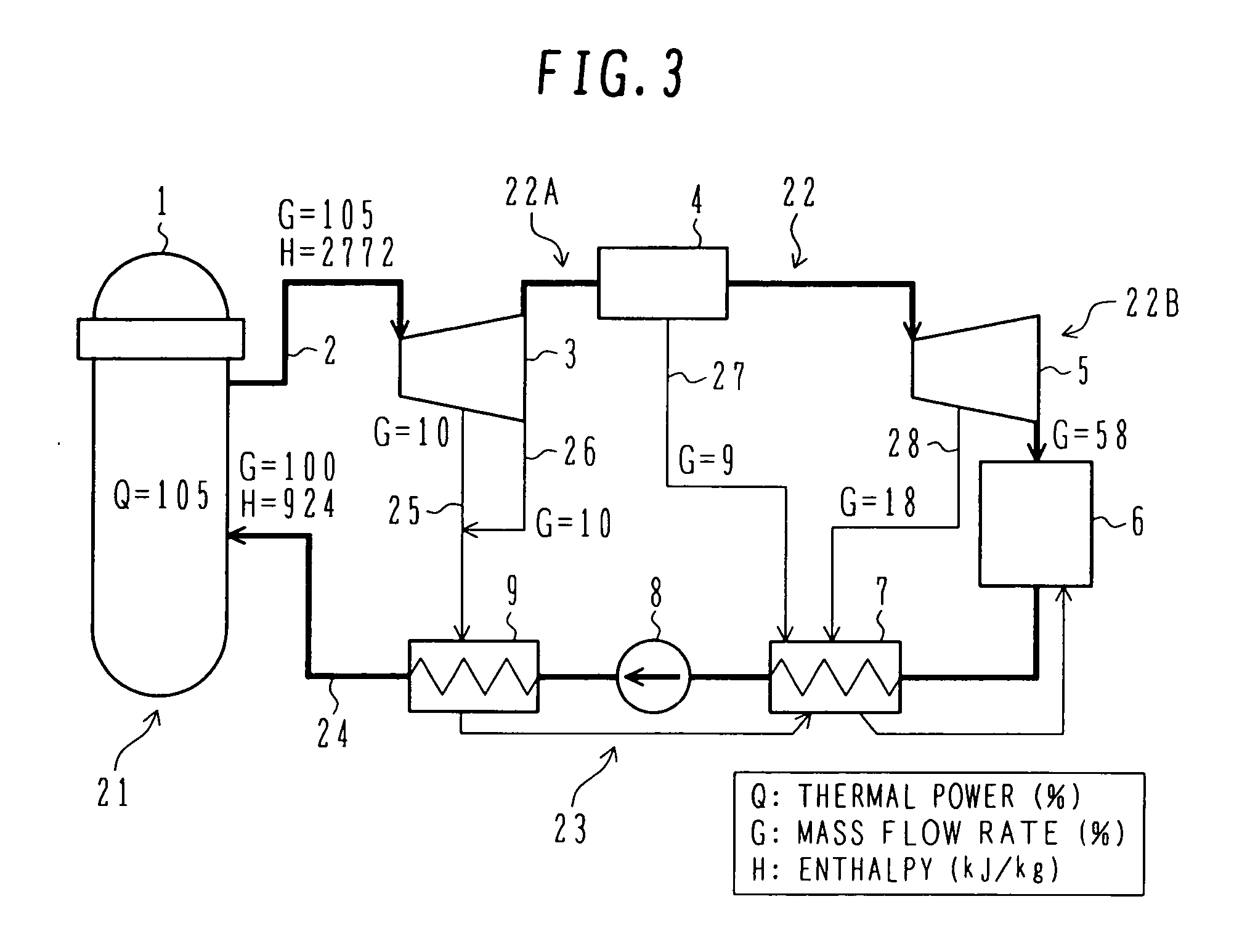

Operation method of nuclear power plant

ActiveUS7614233B2Increase thermal powerIncrease flow rateNuclear energy generationNuclear power plant controlNuclear reactorNuclear power

In a nuclear power plant, thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle by at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam, is reduced in the second operation cycle from that in the first operation cycle such that the temperature of feedwater discharged from the feedwater heater is lowered by 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Apparatus and method for reactor power control of steam turbine power generation system

ActiveUS20150218970A1Improve follow-up performanceSteam generation heating methodsEngine controllersEngineeringHigh pressure

Disclosed herein is an apparatus for reactor power control of a steam turbine power generation system including a reactor, a high-pressure turbine to which steam is supplied from the reactor through a main steam pipe, a low-pressure turbine to which the steam discharged from the high-pressure turbine is supplied via a moisture separator reheater, a branch pipe branched from the main steam pipe to be connected to the moisture separator reheater, a generator connected to the low-pressure turbine, a condenser for condensing the steam discharged from the low-pressure turbine, a condensate pump for feeding condensate condensed by the condenser, and feed water heaters for heating the condensate, the apparatus including a branch pipe control valve provided on the branch pipe and a control unit for controlling an opening degree of the branch pipe control valve.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

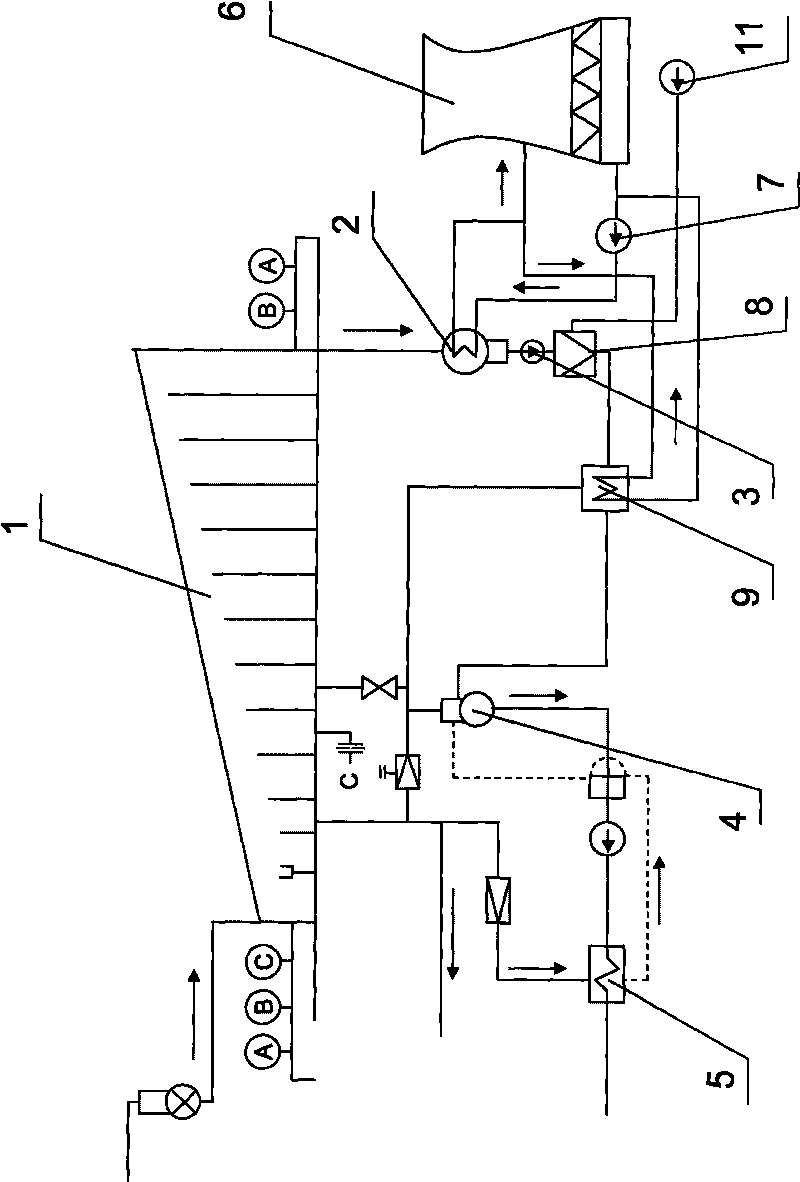

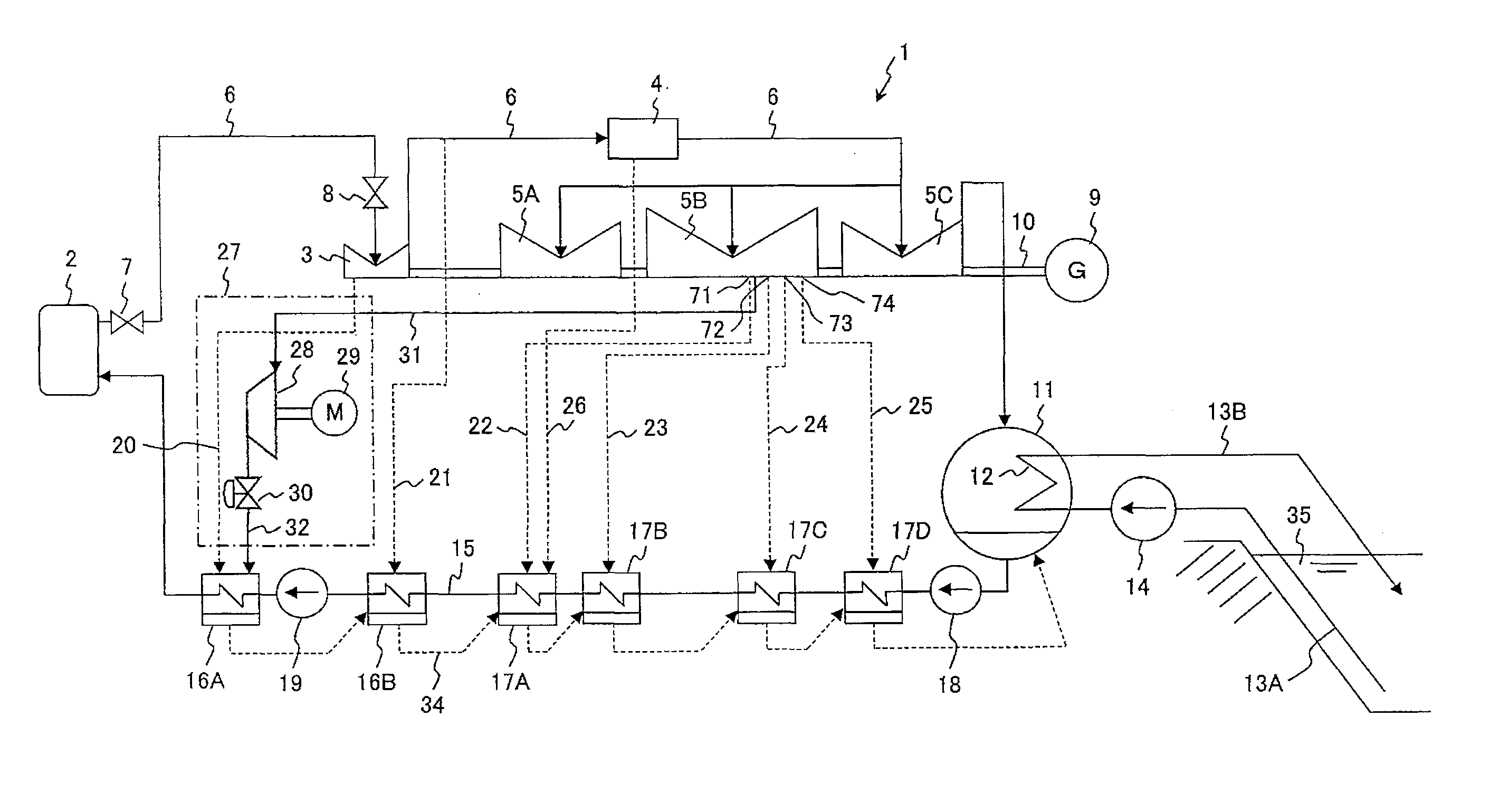

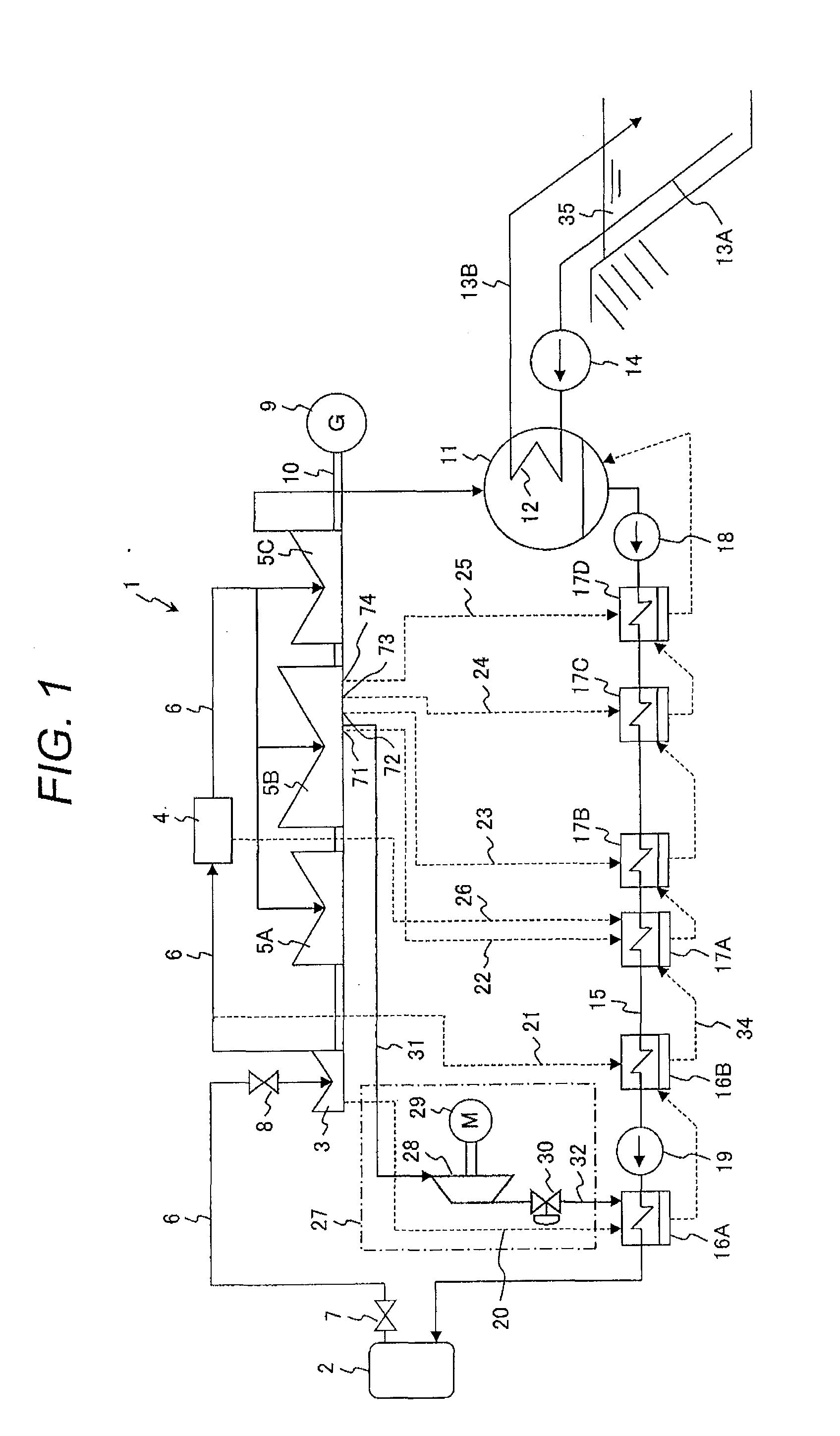

Solar hybrid combined cycle gas and steam power plant

ActiveUS8286429B2Facilitate heat transfer and coupling of heatReduce fossil fuel consumptionAuxillary drivesFrom solar energyPower stationSteam power

A solar hybrid combined cycle gas-steam power plant and method including a solar unit, a gas turbine unit and a steam turbine unit. The solar unit includes a receiver. The gas turbine unit includes a gas turbine with a waste heat boiler arranged downstream, and a steam turbine with a feed water heater. The power plant includes a heat transfer medium cycle for transferring solar heat. The heat transfer medium cycle is coupled to the gas turbine unit through a gas turbine heat exchanger and to the steam turbine unit through a solar boiler. Alternatively to the gas turbine unit and the steam turbine unit, the solar hybrid combined cycle power plant includes an integrated gas-steam turbine having a waste heat boiler arranged downstream, wherein the heat transfer medium cycle is coupled to the integrated gas-steam turbine through the gas turbine heat exchanger and through the solar boiler.

Owner:DRESDEN UNIVERSITY OF TECHNOLOGY

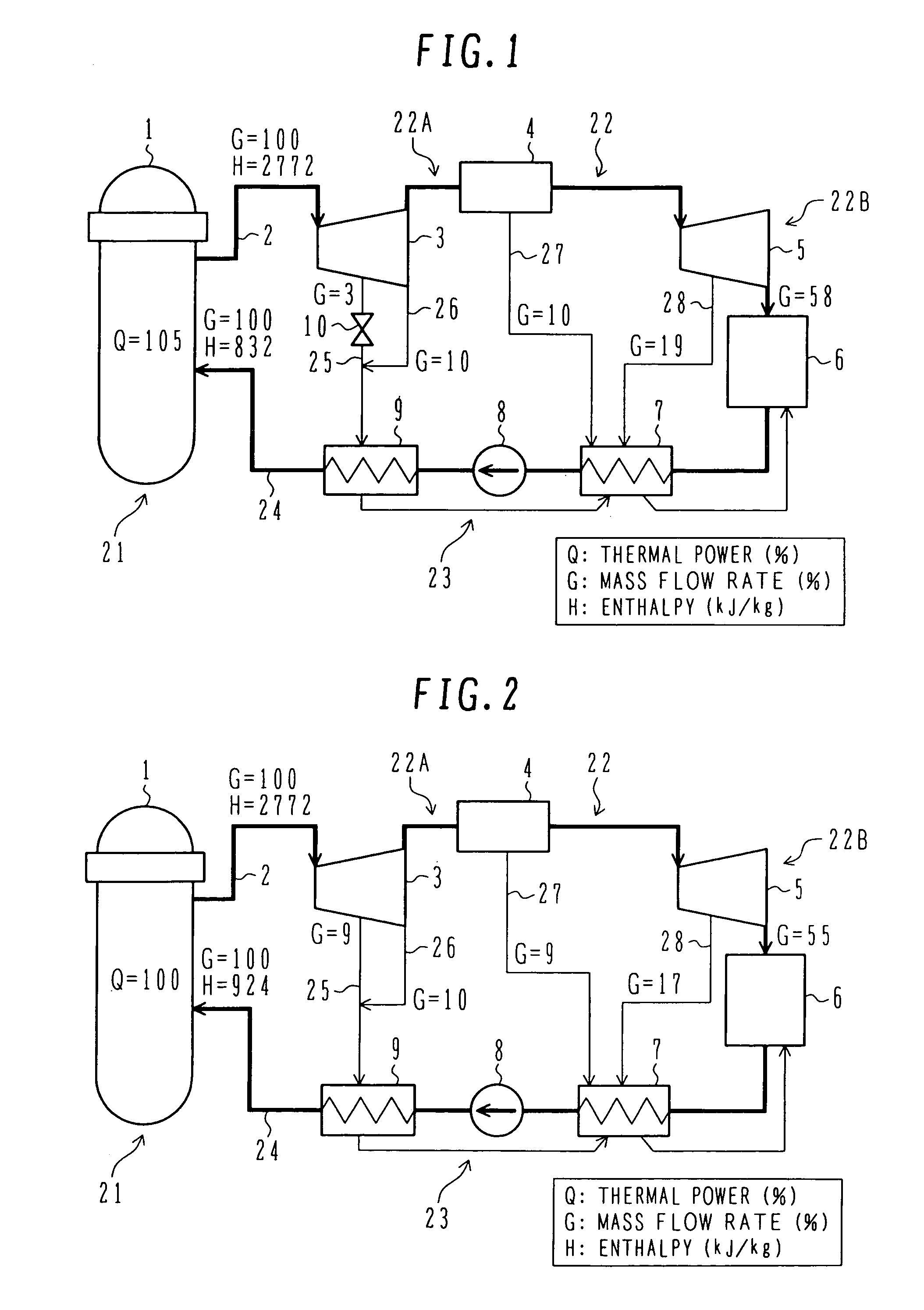

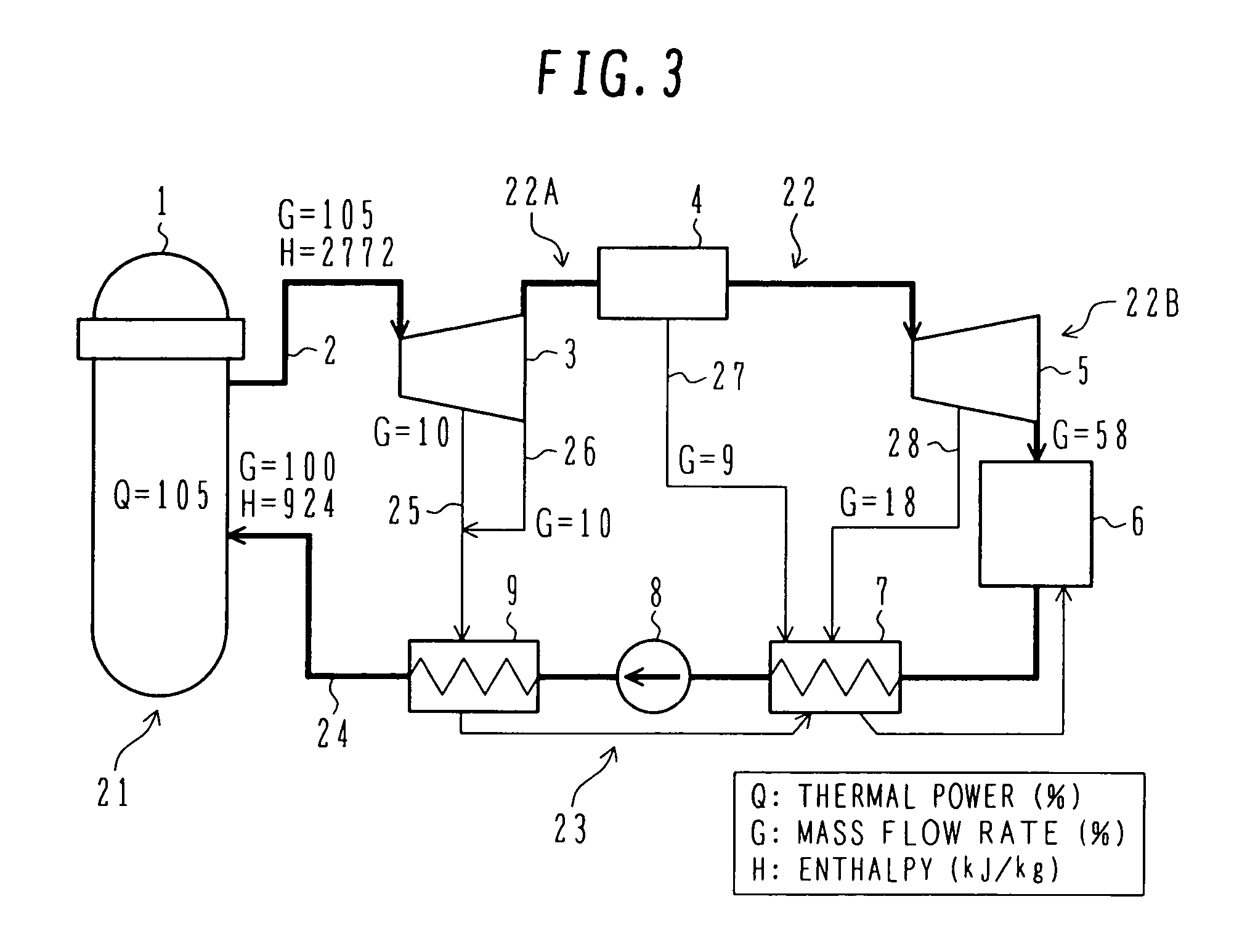

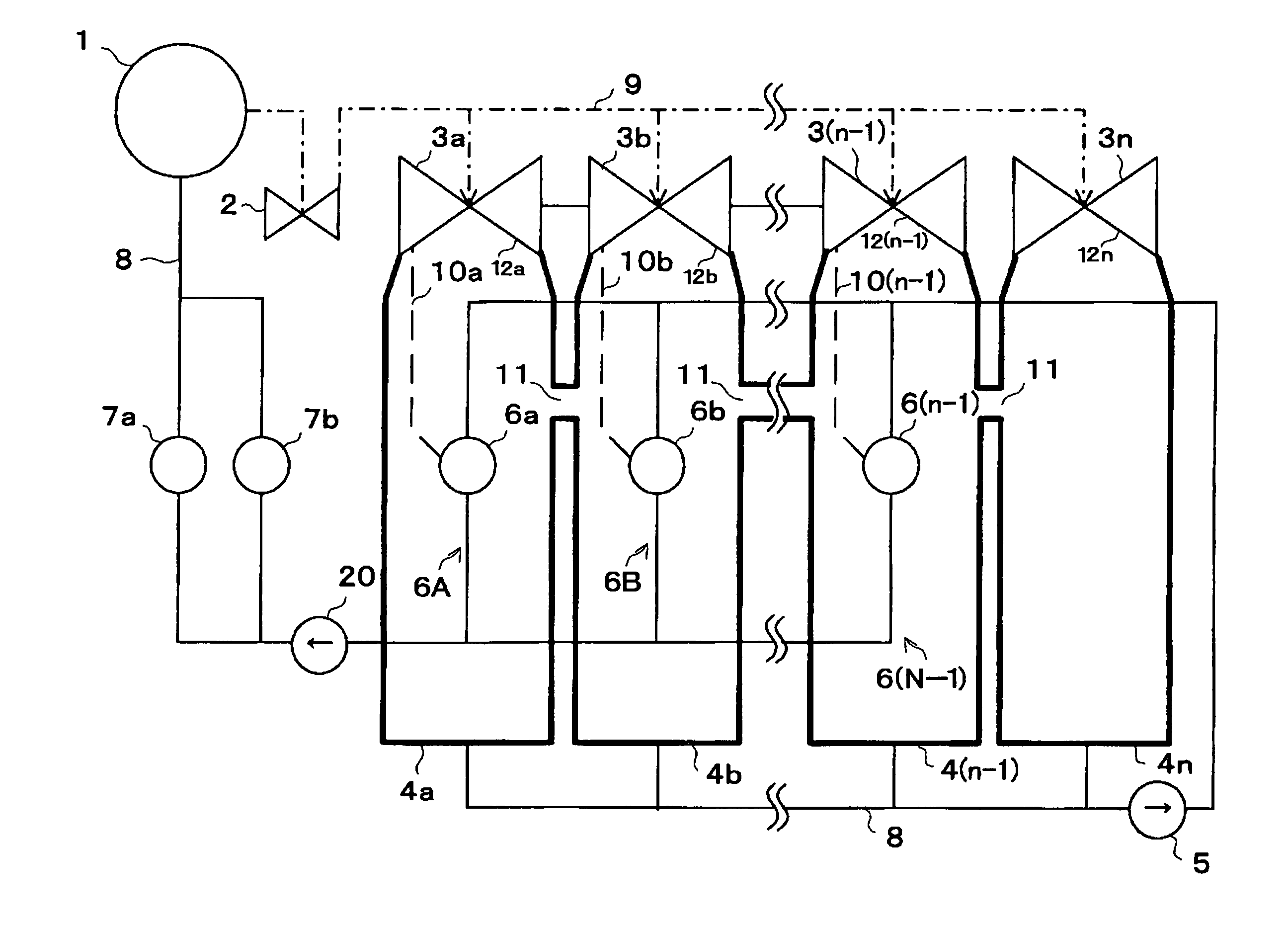

Electric Power Plant, and Method for Running Electric Power Plant

ActiveUS20110005225A1Improve thermal efficiencyHigh power outputSteam useReactor heat to mechanical energyWater flowHigh pressure

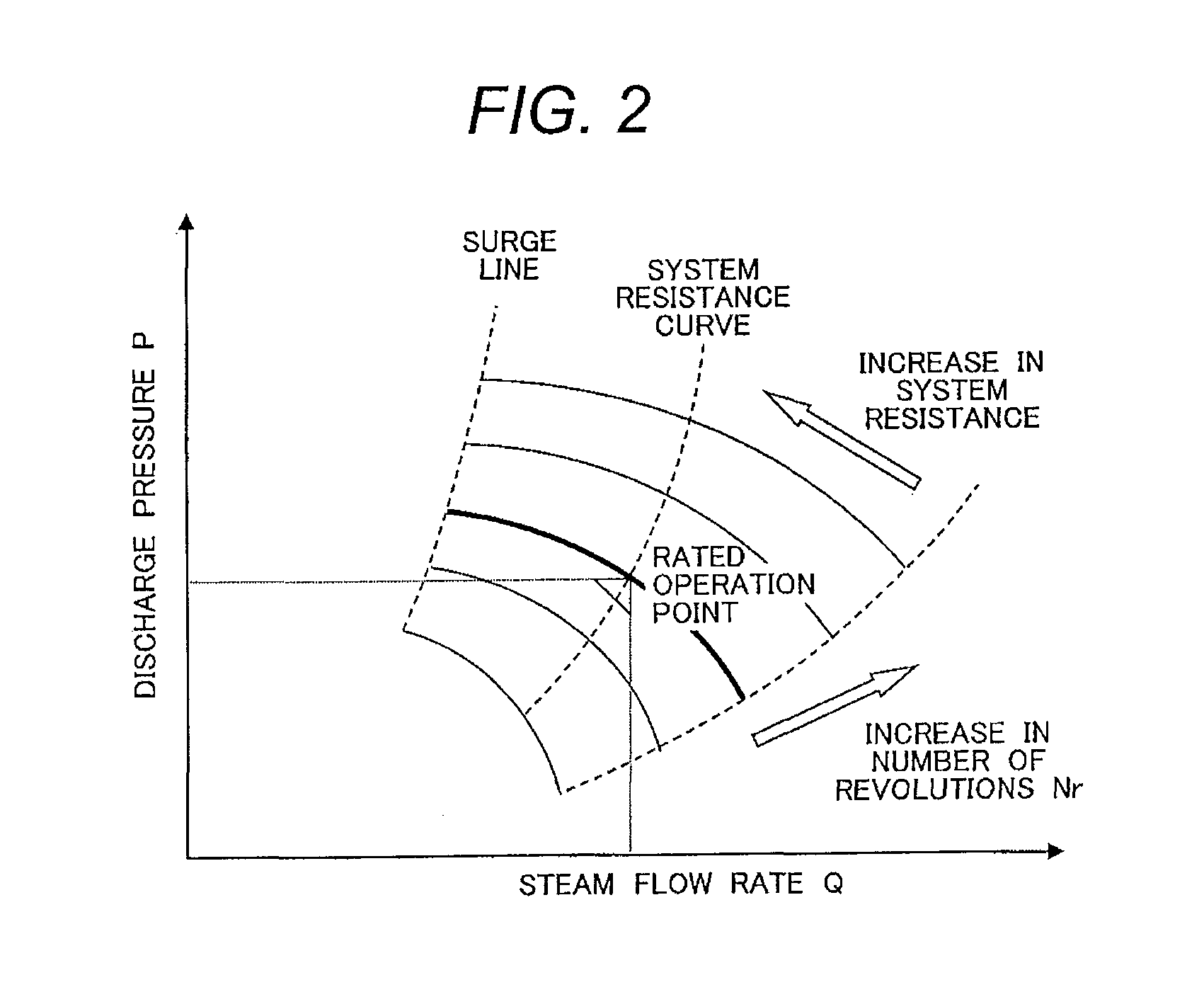

An electric power plant, e.g., a boiling water reactor nuclear power plant supplies steam generated in a nuclear reactor to a high-pressure turbine and a low-pressure turbine. The steam discharged from the low-pressure turbine is condensed with a condenser. Water generated with the condenser, used as feed water, flows through a feed water pipe, is heated with a low-pressure feed water heater and a high-pressure feed water heater, and then supplied to the nuclear reactor. The steam extracted from the high-pressure turbine is supplied to the high-pressure feed water heater. The steam extracted from the low-pressure turbine is compressed with a steam compressor, and the steam whose temperature has been increased is then supplied to the high-pressure feed water heater. The feed water to be directed to the nuclear reactor is heated in the high-pressure feed water heater by both the steam extracted from the high-pressure turbine and the steam compressed with the steam compressor. Because the feed water is heated by both the extracted steam and the compressed steam in the high-pressure feed water heater, the amount of plant service power consumed by the steam compressor can be reduced. Therefore, it is possible to increase thermal efficiency in the electric power plant when increasing the power output.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Water heater preheating method and water heater

PendingCN107990560AImprove experienceGuaranteed water temperatureFluid heatersHeating timeAppointment time

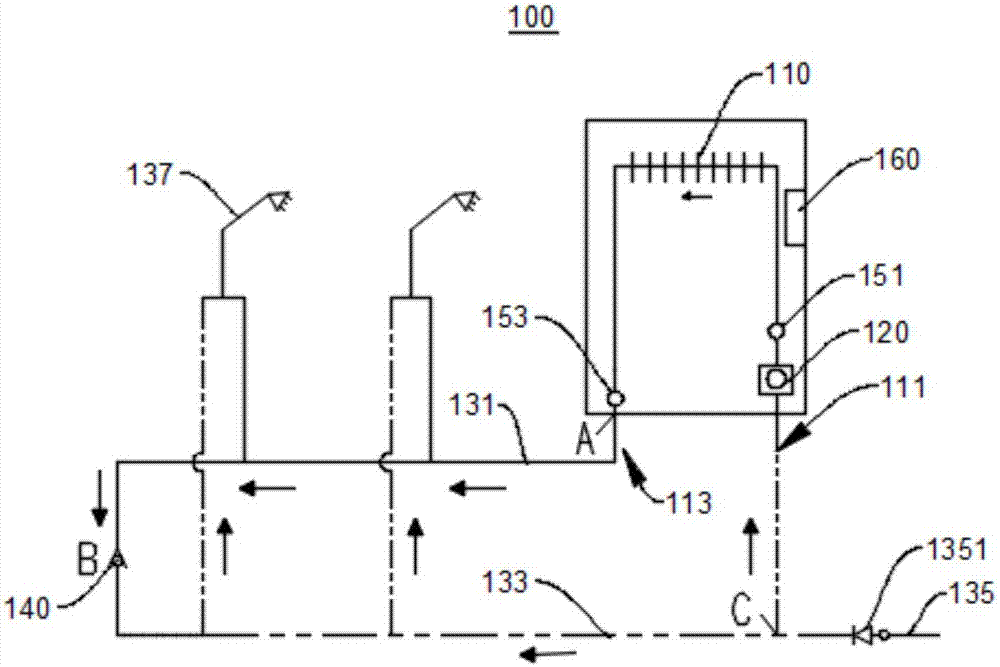

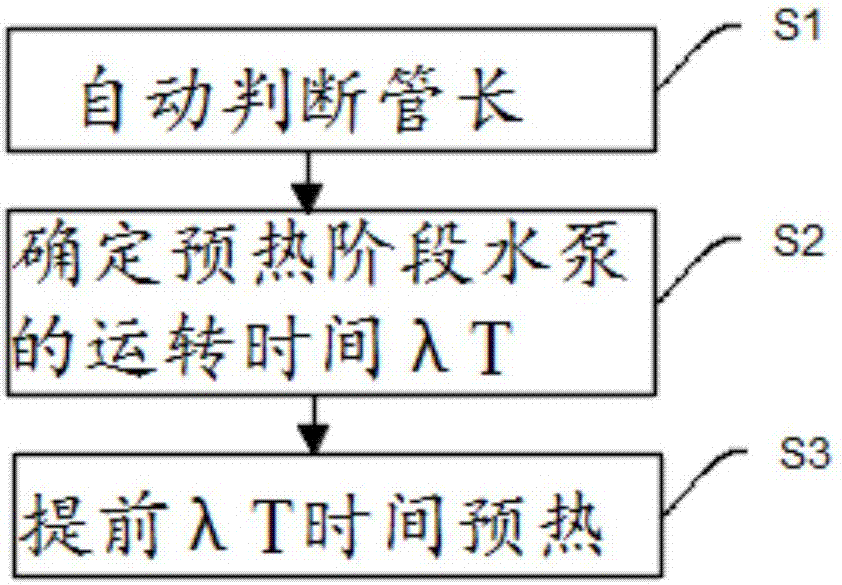

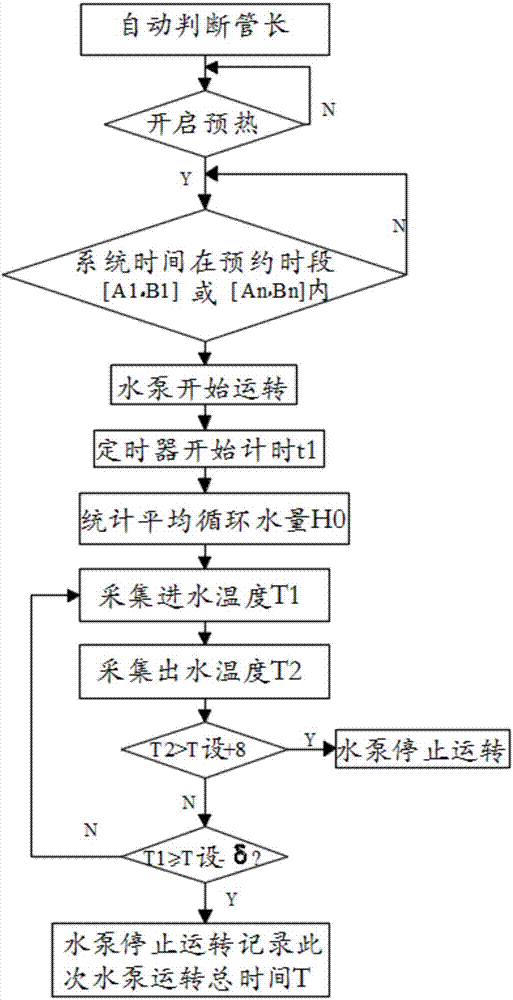

The invention provides a water heater preheating method and a water heater and relates to the technical field of water heaters. The water heater preheating method comprises the steps that the length of a water flow pipeline is judged at first, running of a water pump runs and heating of a heater as well as a full-pipeline preheating cycle T allowing the water temperature of the whole water flow pipeline to reach the preset water temperature are determined, then a half-pipeline preheating cycle delta T for heating water in a hot water pipeline to the preset water temperature is determined, after a user starts the preheating function, the water heater starts preheating delta T earlier than the appointment time interval of the user so that the water temperature in the hot water pipeline can meet the preset water temperature when the user uses the water, water is hot instantly when needed, and user experience is improved. According to the water heater provided by the invention, the preheating method is adopted, the water flow pipeline is provided with a one-way valve, the hot water pipeline and a cold water pipeline are separated, and only water in the hot water pipeline is heated whenthe water heater carries out preheating, so that the heating time is shortened, energy consumption is reduced, and user experience is great.

Owner:GUANGDONG MACRO GAS APPLIANCE

Operation method of nuclear power plant

ActiveUS20070000250A1Increase thermal powerIncrease flow rateNuclear energy generationNuclear power plant controlNuclear powerHigh pressure

A nuclear power plant and an operation method of the nuclear power plant, which can uprate plant power without greatly modifying the construction of plant equipment, while keeping a core's pressure loss characteristic, a safety margin, and a design margin in the transient state substantially the same as those before the power uprate. Thermal power in a second operation cycle of a nuclear reactor is uprated from thermal power in a first operation cycle preceding the second operation cycle at least one operation cycle. A proportion of steam extracted from a steam system and introduced to a feedwater heater, which is in particular extracted from an intermediate point and an outlet of a high pressure turbine, with respect to a flow rate of main steam is reduced in the second operation cycle from that in the first operation cycle such that temperature of feedwater discharged from the feedwater heater lowers in the range of 1° C. to 40° C. in the second operation cycle.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Steam turbine plant

InactiveUS7032384B2Improve space efficiencyLow costFeed water supplySteam accumulatorsEngineeringTurbine

Steam turbine plant includes a steam generator, a plurality of low pressure turbines being driven by steam from the steam generator, a plurality of steam condensers to condense the steam from the low pressure turbines into condensed water and a feedwater line which supplies the condensed water to the steam generator as feedwater. The feedwater line including a plurality of feedwater heating lines connected in parallel. A number of feedwater heating lines being less than a number of steam condensers. Each of the feedwater heating lines includes at least one low pressure feedwater heater provided in at least one of the steam condensers to heat the condensed water by steam bled from the low pressure turbines.

Owner:KK TOSHIBA

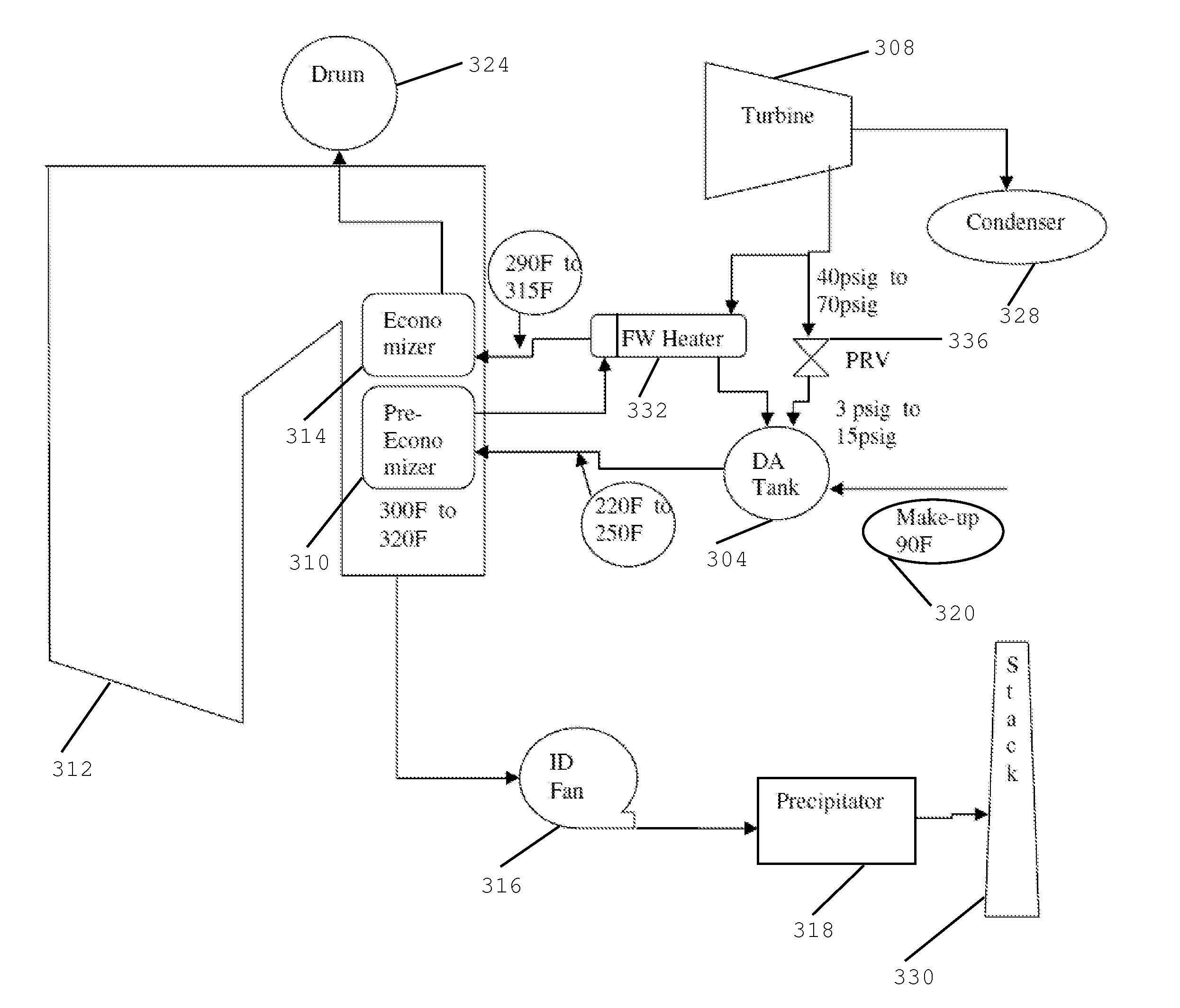

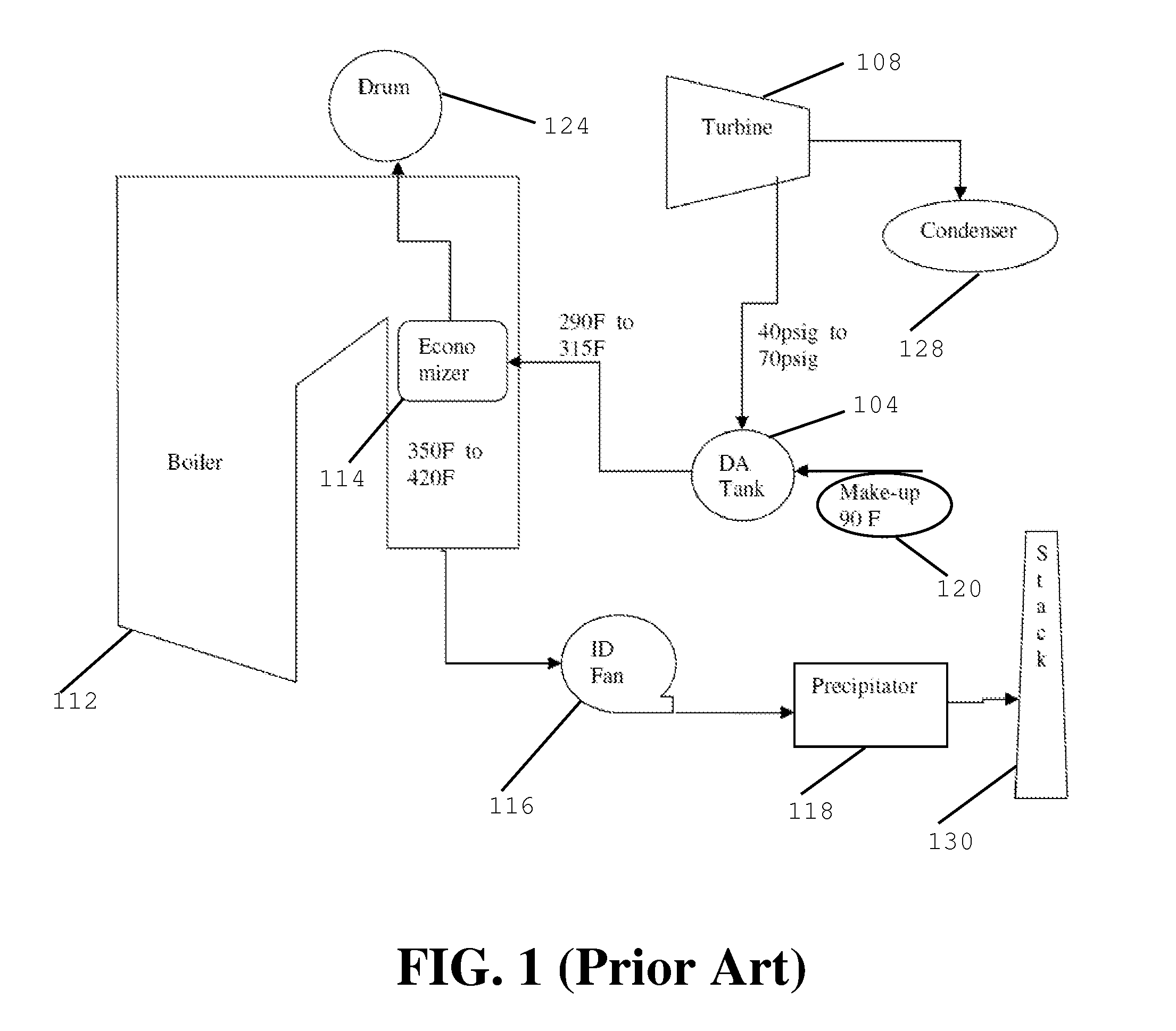

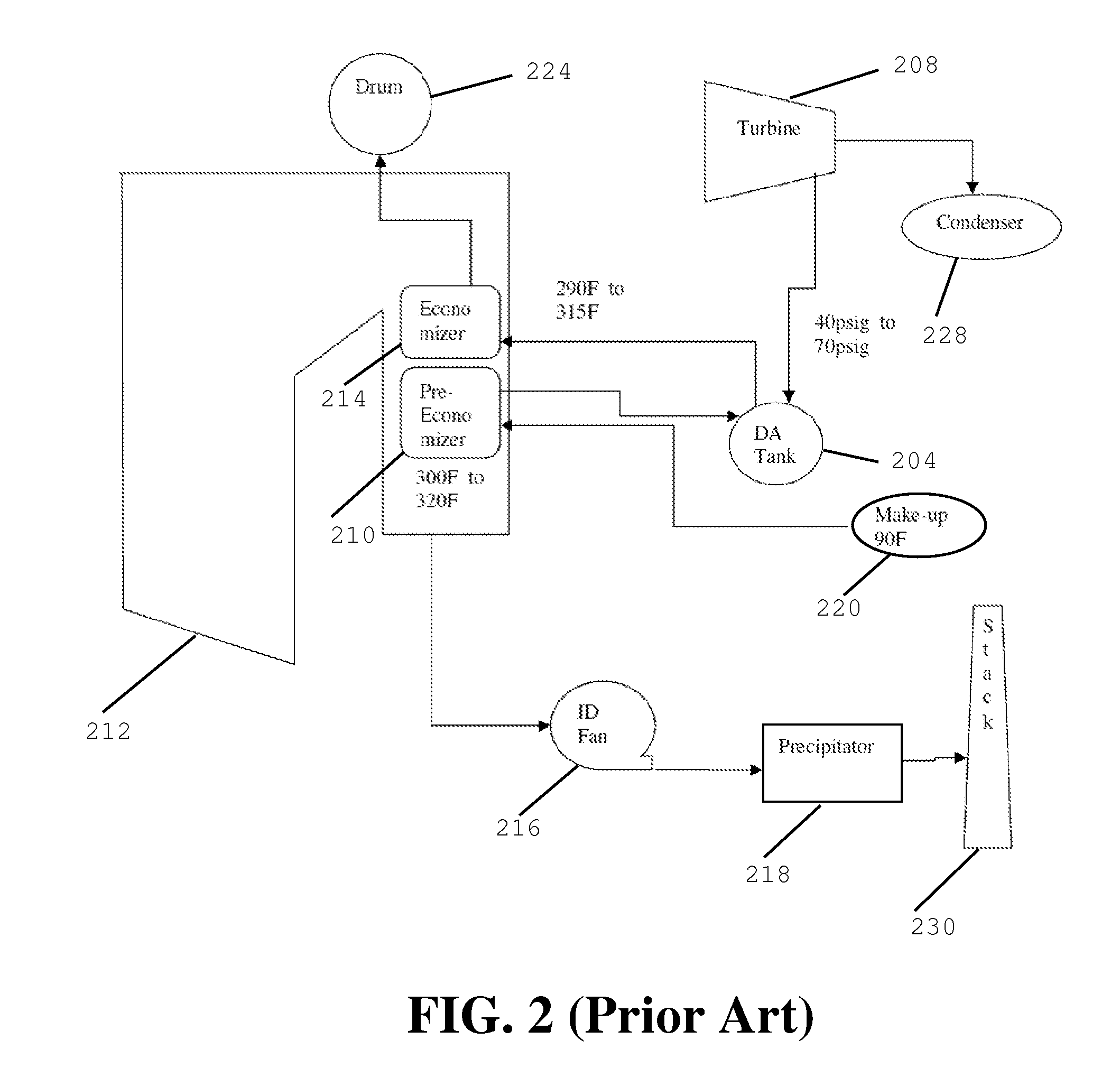

Steam cycle efficiency improvement with pre-economizer

InactiveUS20120048215A1Increase available low-pressure steamCost-effectiveDryer sectionSteam boilersEngineeringCycle efficiency

A method for improving pulp mill steam cycle efficiency includes the steps of providing at least one deaerator tank having a first pressure, and lowering the pressure of said deaerator tank to a second pressure. Feedwater is supplied to a pre-economizer, where it is heated. The water is then delivered to at least one feedwater heater, where it is heated. The water is then delivered to an economizer. By this method boiler steam rate is increased while boiler efficiency is maintained and turbine extraction for deaerator and feedwater heating is minimized.

Owner:THE BABCOCK & WILCOX CO

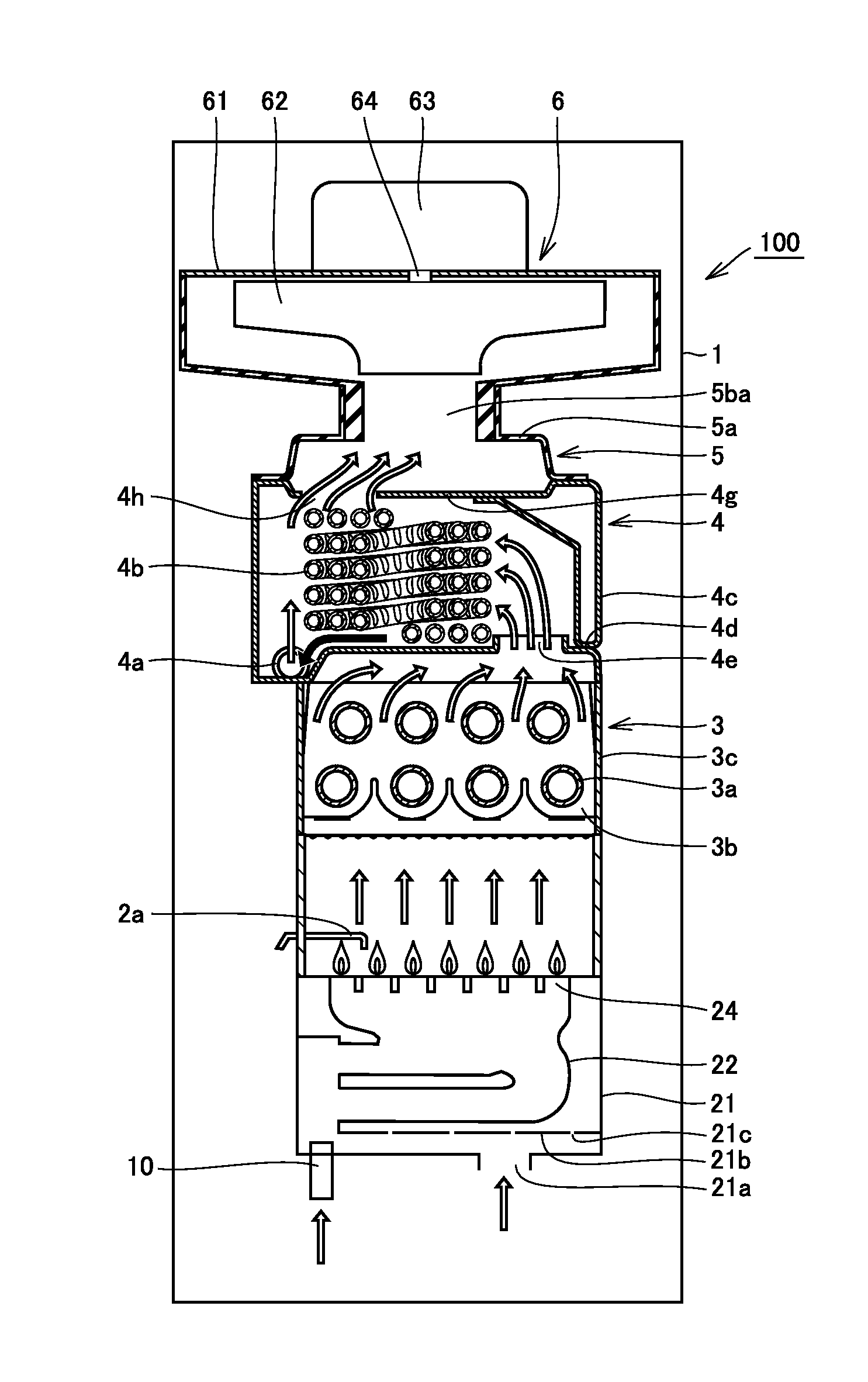

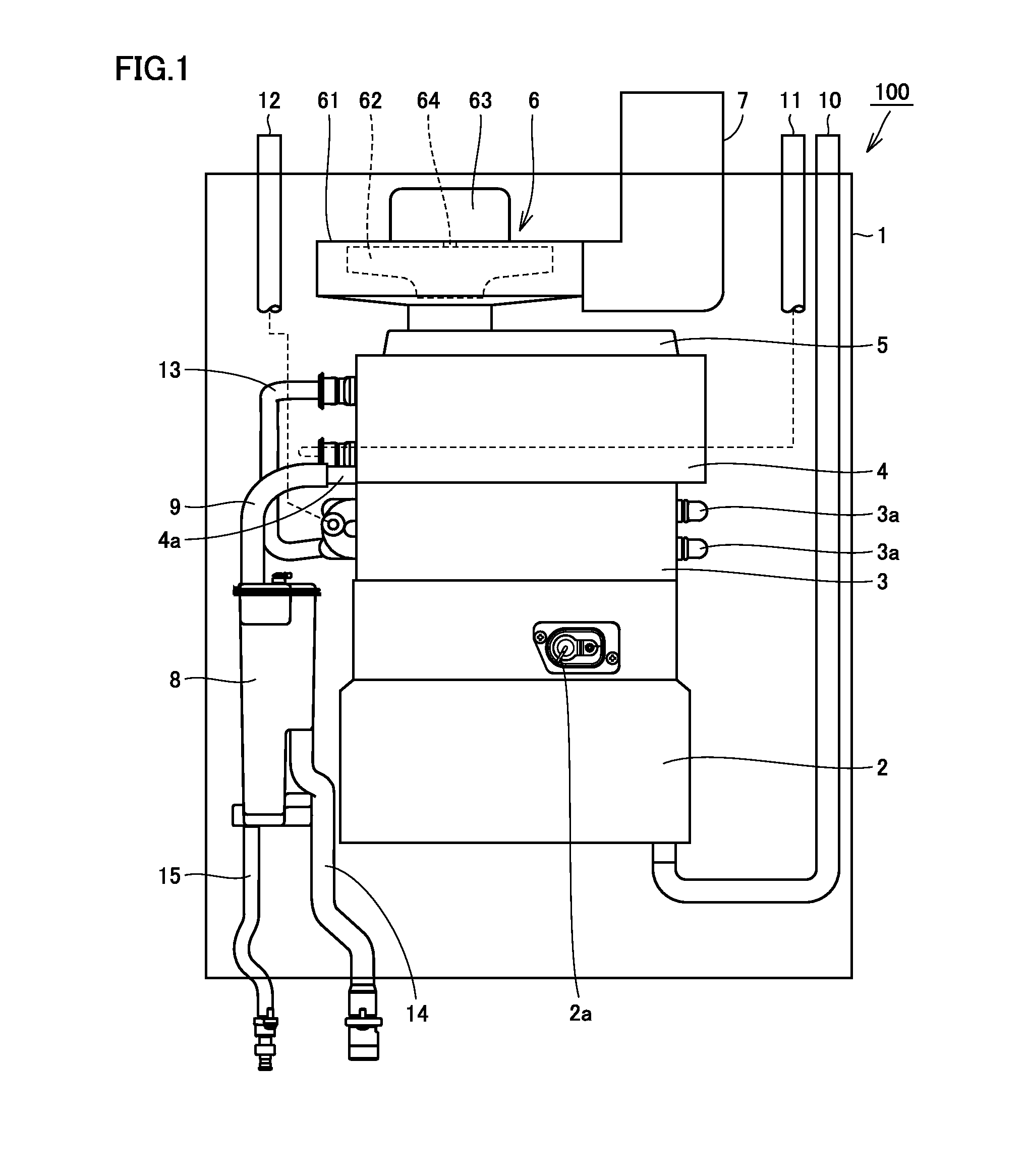

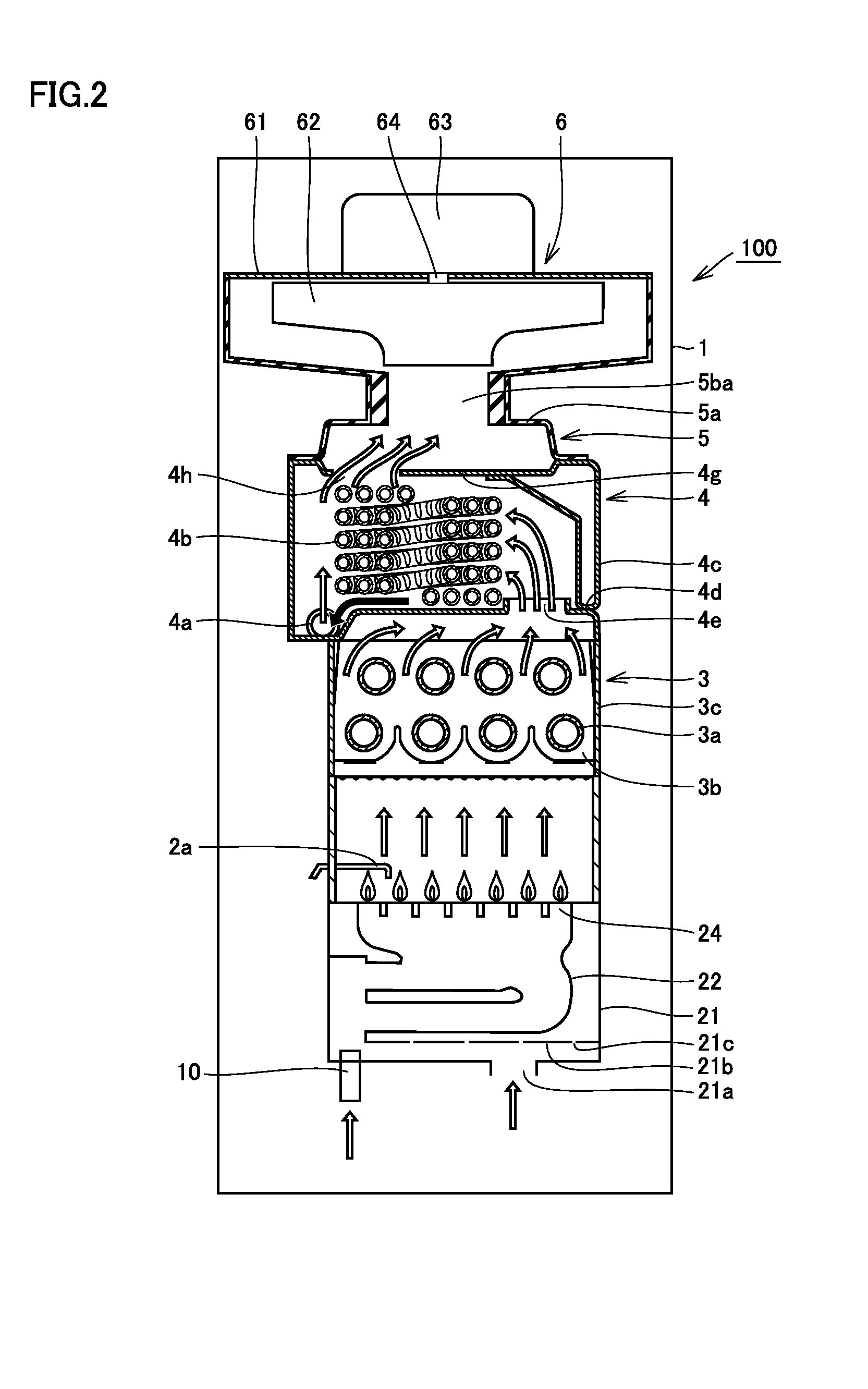

Water heater

ActiveUS20160010892A1Avoid dischargeAvoid easy dischargeAir heatersIndirect heat exchangersCombustorWater discharge

A water heater includes: a burner; a heat exchanger; a fan for supplying air to the burner and emitting combustion gas having passed through the heat exchanger to outside of the water heater; and a drainage water discharge path connected to the heat exchanger. The drainage water discharge path has a water-sealing structure that is water-sealed by drainage water. The water heater further includes a control unit: having a water-seal determination unit giving permission that the water heater can operate in a normal mode based on a condition that the drainage water discharge path has been water-sealed; and issuing an instruction to cause the burner to intermittently operate for a time period until the water-seal determination unit gives the permission.

Owner:NORITZ CORP

Coal-fired secondary reheating steam turbine generator unit integrated with supercritical CO2 circulation

ActiveCN107989667ALower extraction temperatureReduce superheatSteam useIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention belongs to the technical field of secondary reheating steam turbine generating and energy saving and discloses a coal-fired secondary reheating steam turbine generator unit integrated with supercritical CO2 circulation. The unit comprises a coal-fired boiler, a secondary reheating steam turbine generator unit and a supercritical CO2 circulating generation system. Six-stage extractionsteam connected with a high pressure cylinder and an intermediate pressure cylinder is connected with steam-CO2 heat exchangers and enters corresponding feed water regenerative heaters after heatingCO2; in the CO2 circulating generation system, CO2 at an outlet of a compressor is divided into two streams, the two streams are heated by three stages of steam-CO2 heat exchangers respectively and are converged to enter a CO2 turbine for working, and CO2 exhaust enters the compressor after passing through a CO2-feed water heater and a CO2-air preheater sequentially; in a flue at the tail of the boiler, air is divided into two streams, and the two streams are preheated by the CO2-air preheater and a low-temperature air preheater respectively and are converged to enter a main air preheater. Bythe aid of the integrated system, the superheat degree of regenerative extraction steam of the secondary reheating unit and the exergy loss of air preheating are substantially reduced, the work of a steam turbine is increased, and the efficiency is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

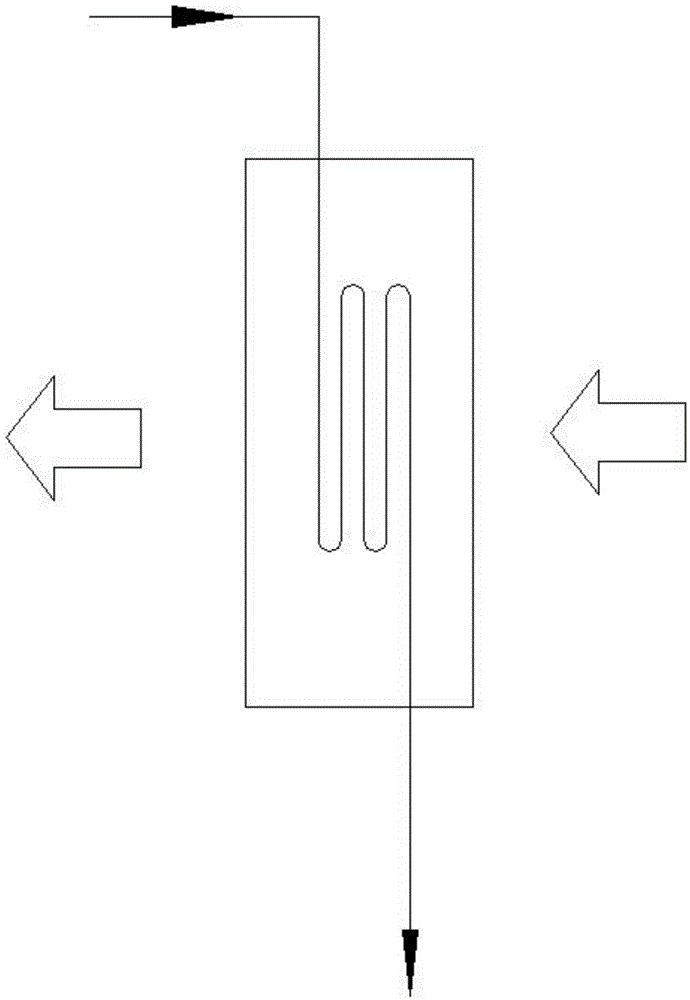

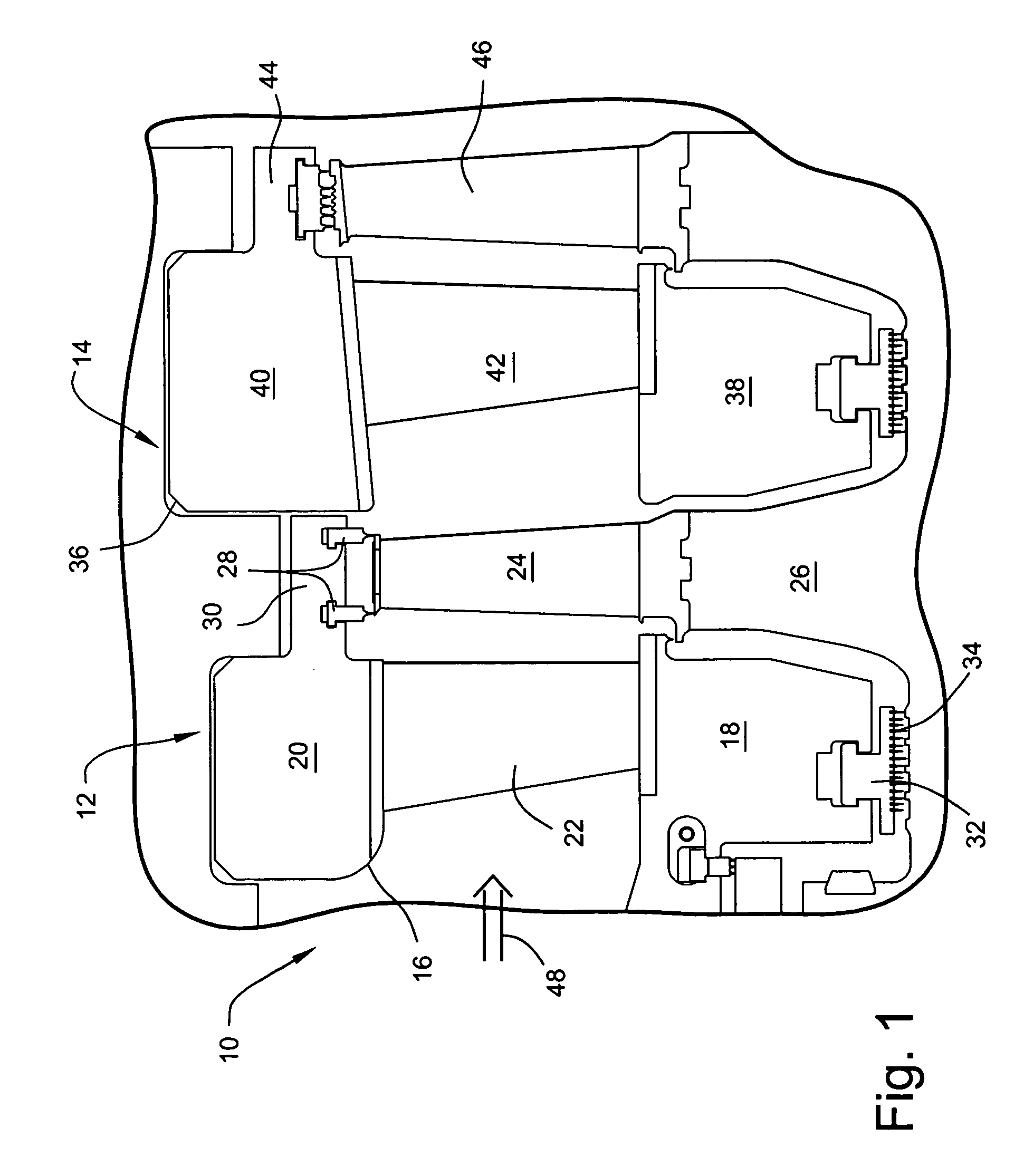

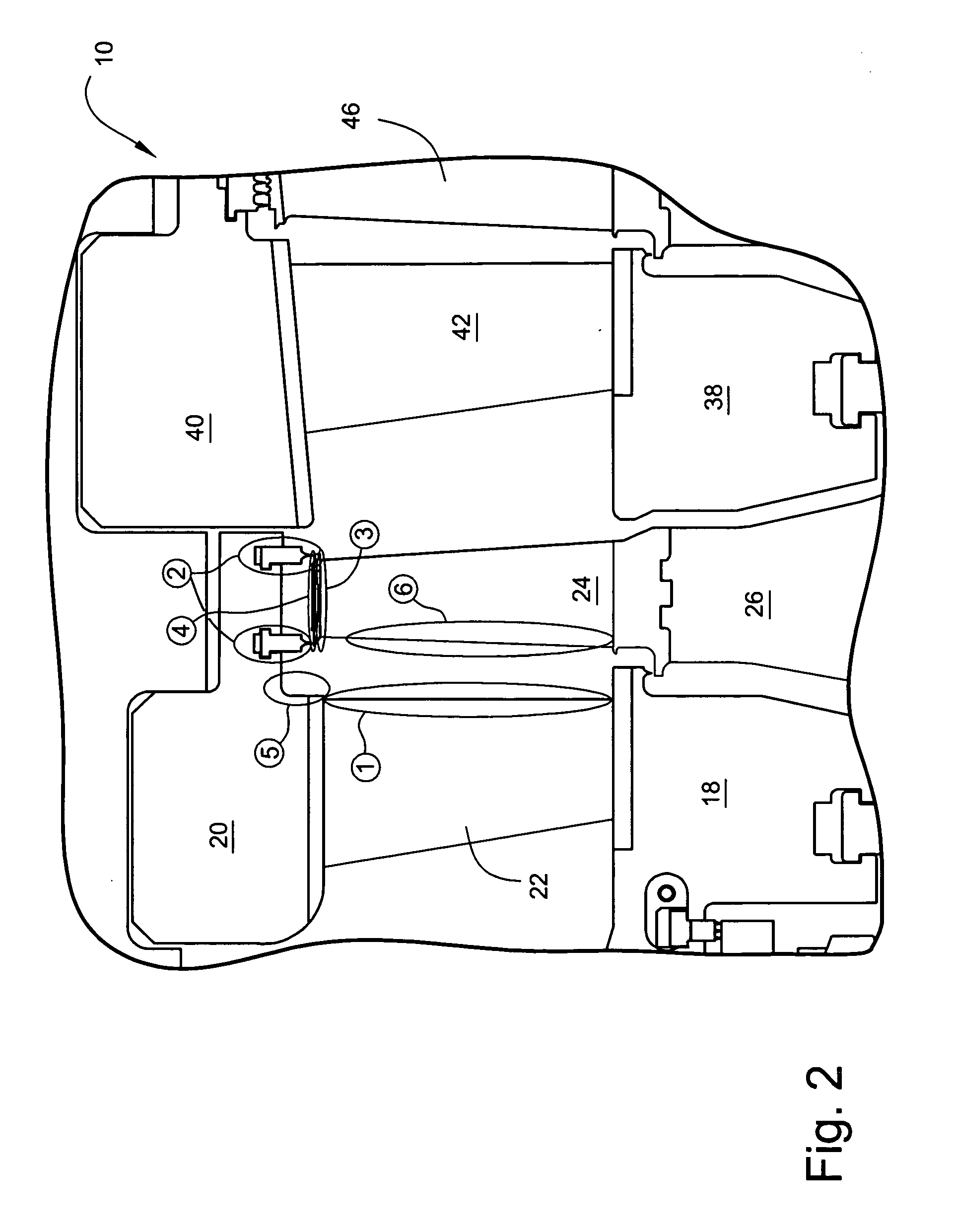

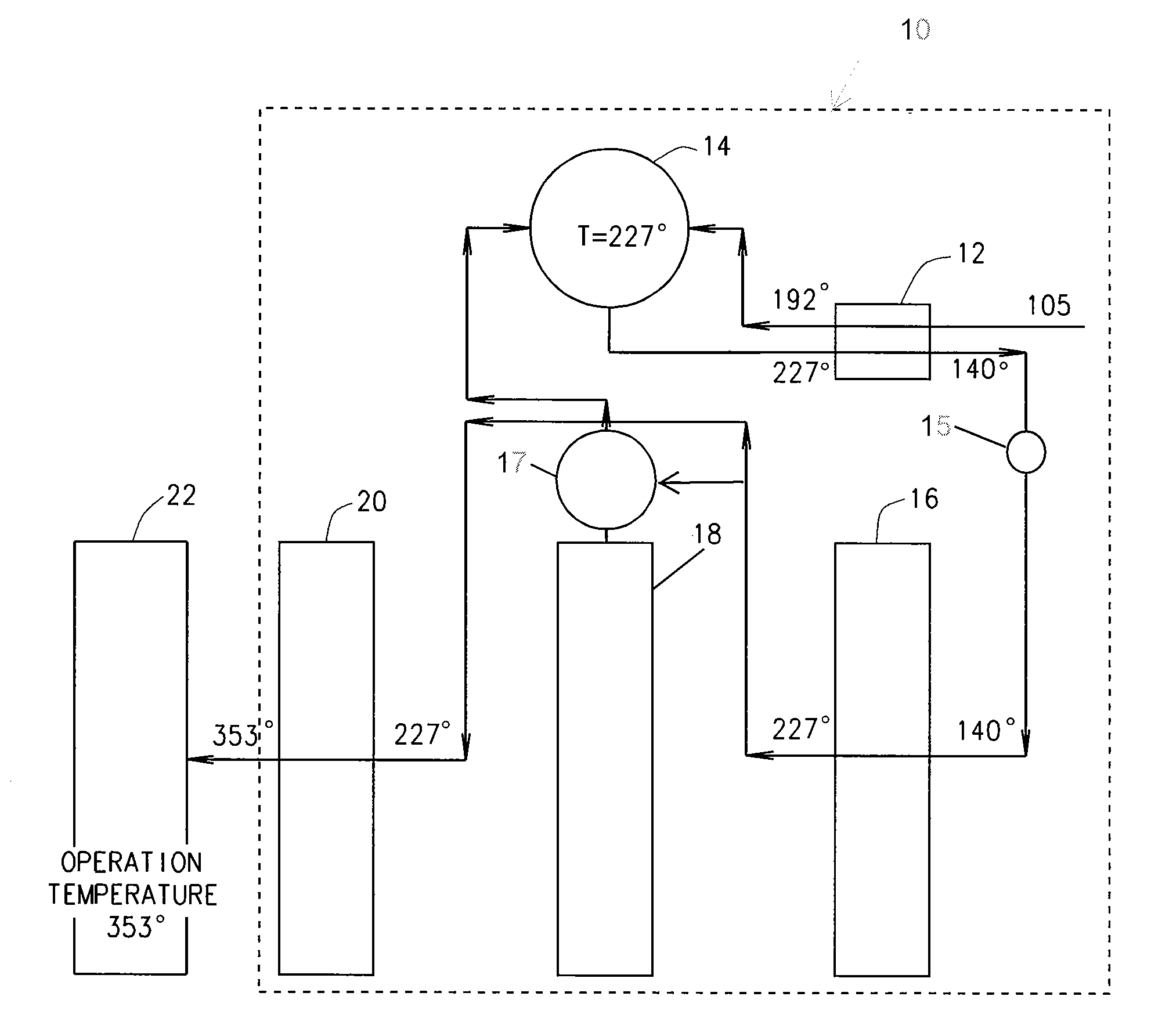

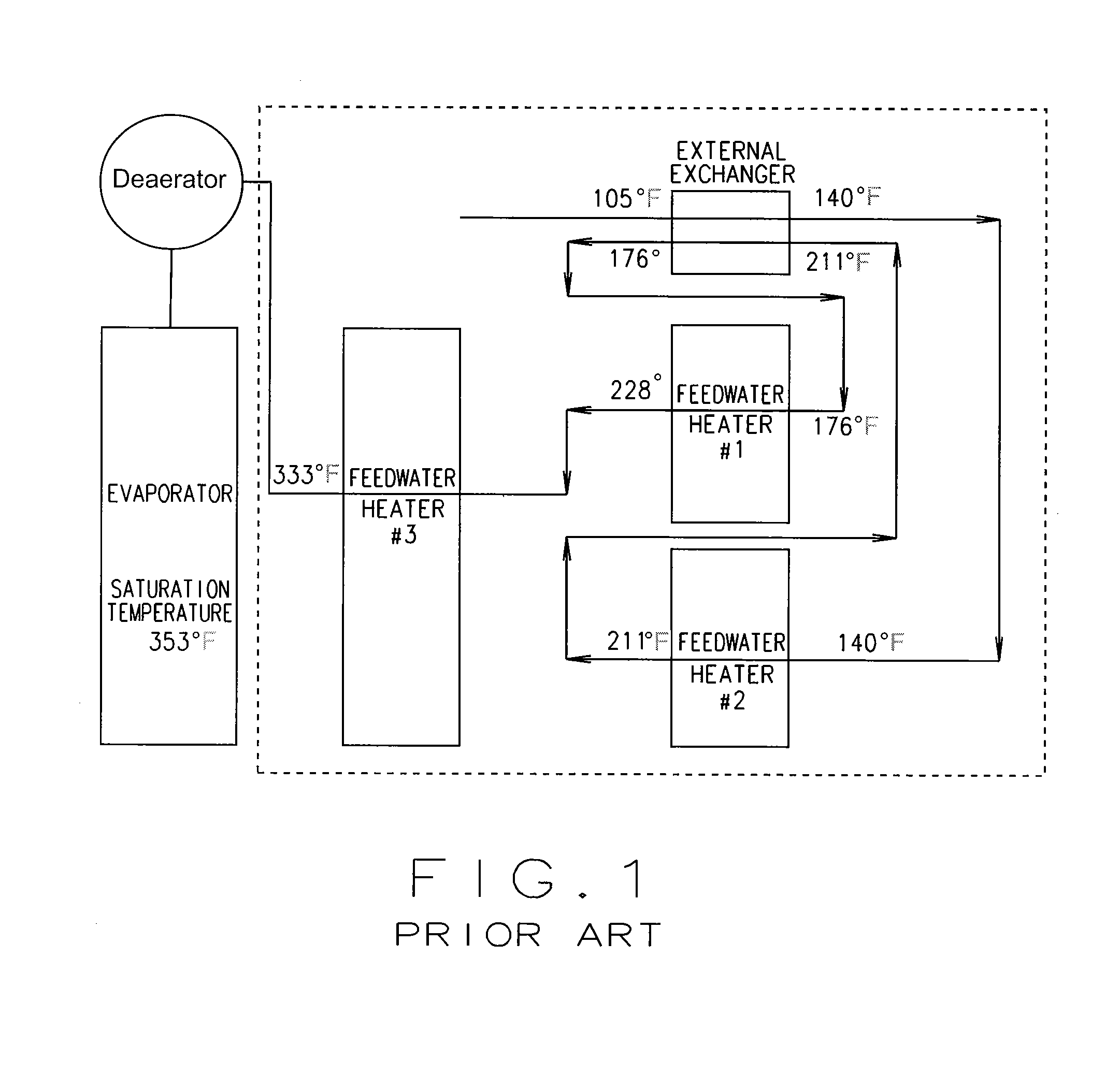

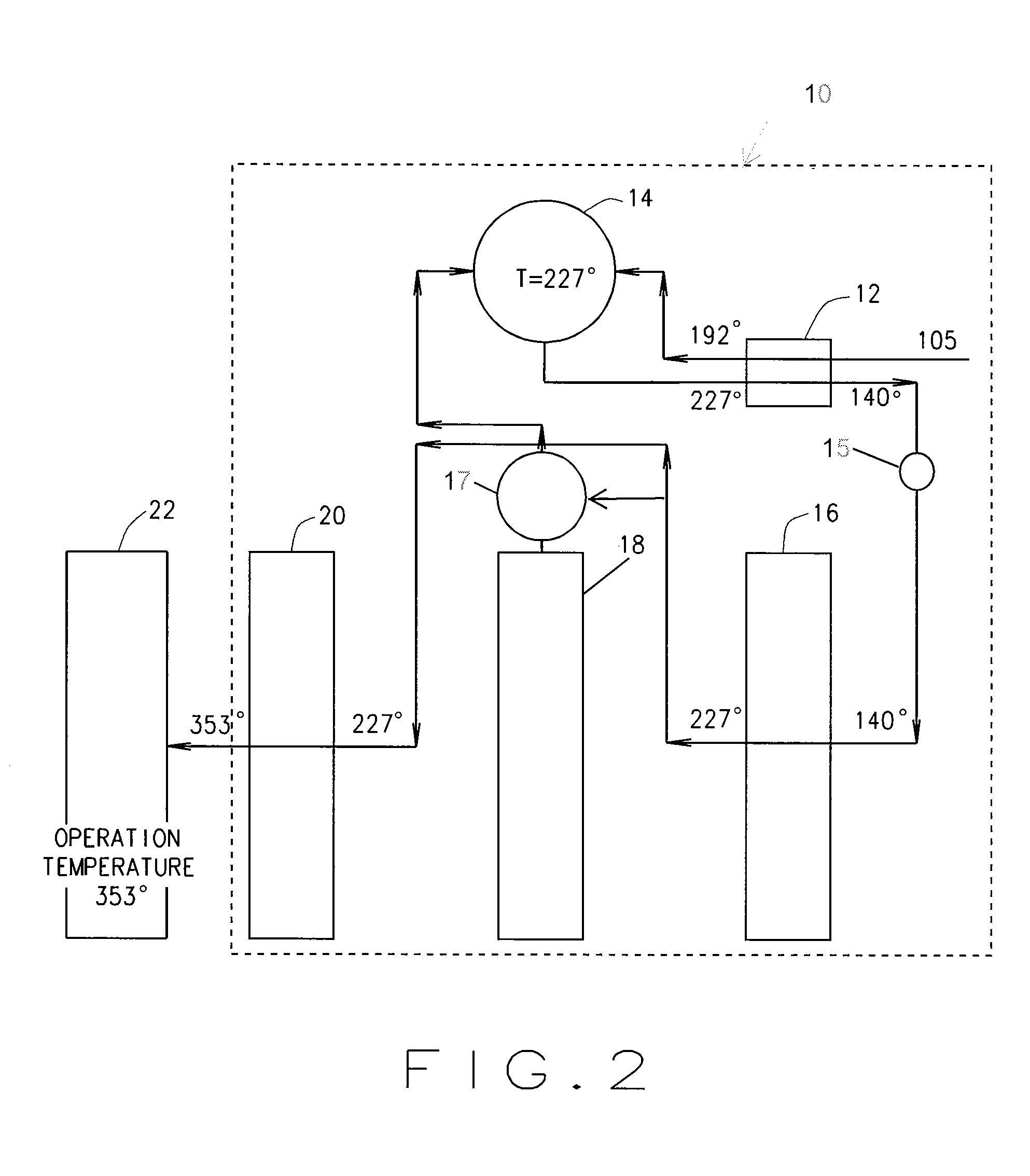

High efficiency feedwater heater

A feedwater heater (10) for a steam generator communicating feedwater through an external heat exchanger (12), a deaerator (14) that allows the use of carbon steel feedwater tubes, a first heater (16), an evaporator section (18) and steam drum (17) for communicating a portion of the feedwater in the form of steam to the deaerator (14), and a second heater (20).

Owner:NOOTER ERIKSEN INC

Combined heat and power generation system for condensing-extracting-backpressure heat supply and operation method thereof

PendingCN107859538AReasonable designSimple structureSteam engine plantsCombined combustion mitigationCogenerationDeaerator

The invention relates to a combined heat and power generation system for condensing-extracting-backpressure heat supply and an operation method thereof. A traditional centralized heating mode can cause great available energy loss. In the combined heat and power generation system for condensing-extracting-backpressure heat supply provided by the invention, a boiler, a steam turbine high-pressure cylinder, a steam turbine intermediate-pressure cylinder, a steam turbine low-pressure cylinder, an electric generator and a condenser are sequentially connected through a pipeline; a boiler feed pipe is connected between the condenser and the boiler; the condenser, a condensate pump, a low-pressure heater, a feed water heater, a deaerator, a feed pump and a high-pressure heater are sequentially arranged on the boiler feed pipe; a steam inlet of a heat supply network heat exchanger is connected with a communicating pipe between the steam turbine intermediate-pressure cylinder and the steam turbine low-pressure cylinder; and a dewatering outlet is connected with the low-pressure heater. According to the combined heat and power generation system for condensing-extracting-backpressure heat supply and the operation method thereof provided by the invention, the steam turbine intermediate-pressure cylinder is structurally improved, or a secondary intermediate-pressure cylinder is additionallyarranged behind so as to be adapt to switching operation among three working conditions, i.e. pure condensing, steam extracting and backpressure of a turboset. According to the combined heat and powergeneration system for condensing-extracting-backpressure heat supply and the operation method thereof provided by the invention, the original lost energy is converted into high-quality electric energy through the acting of a turbine, so that the gradient utilization of the energy is realized.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

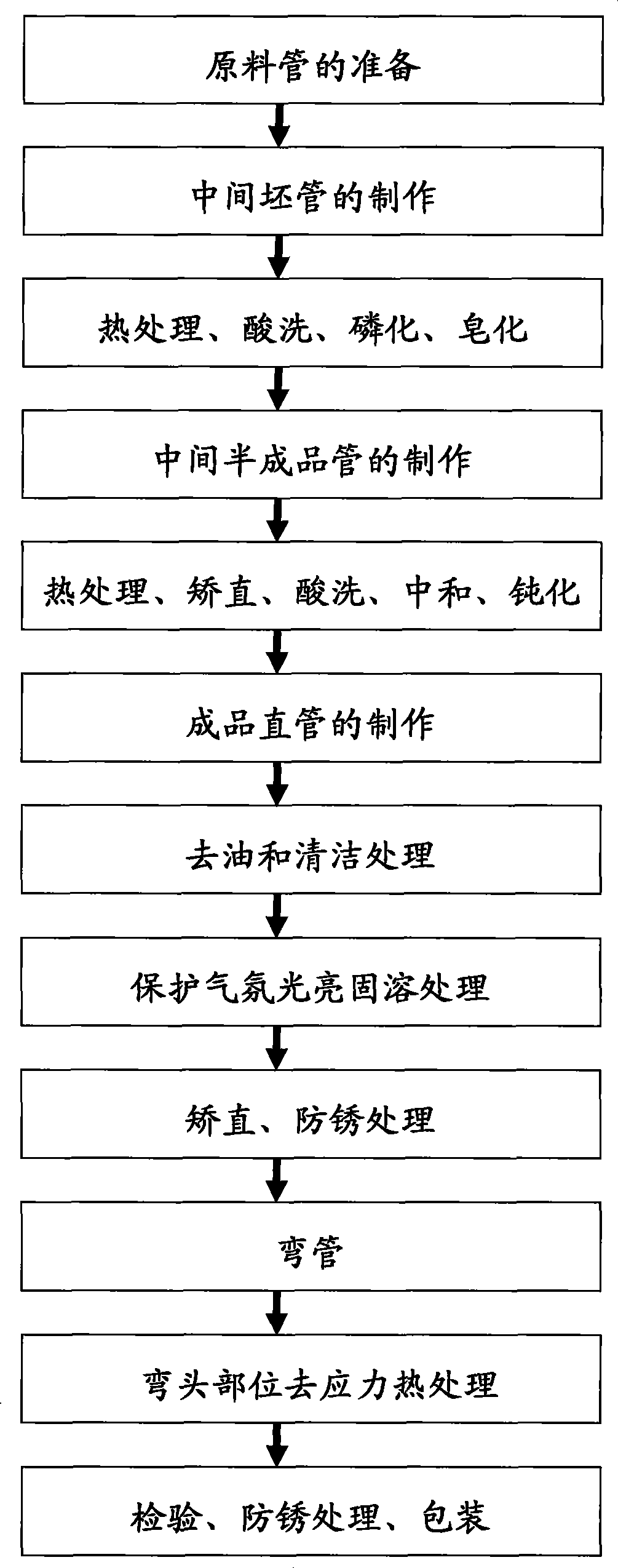

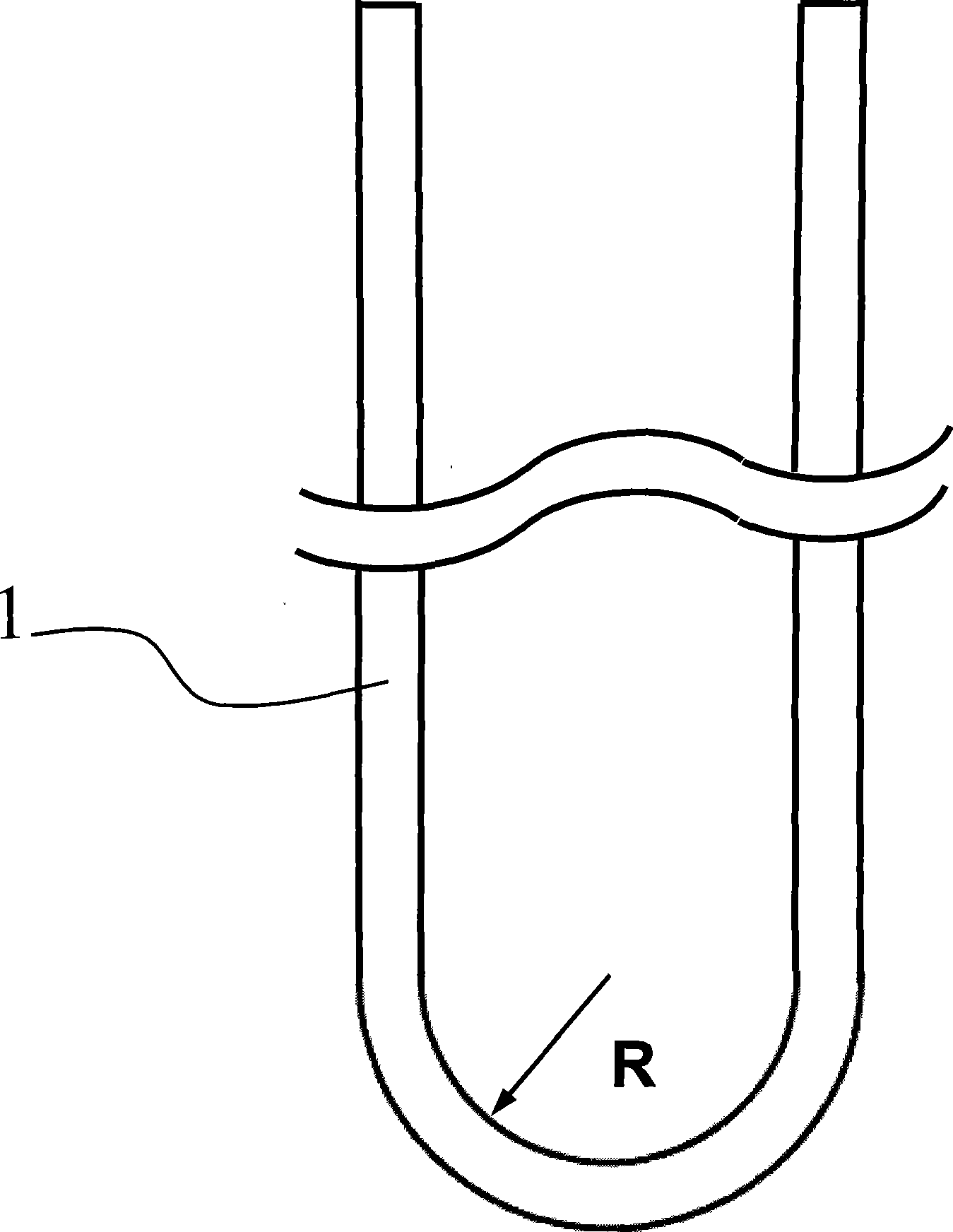

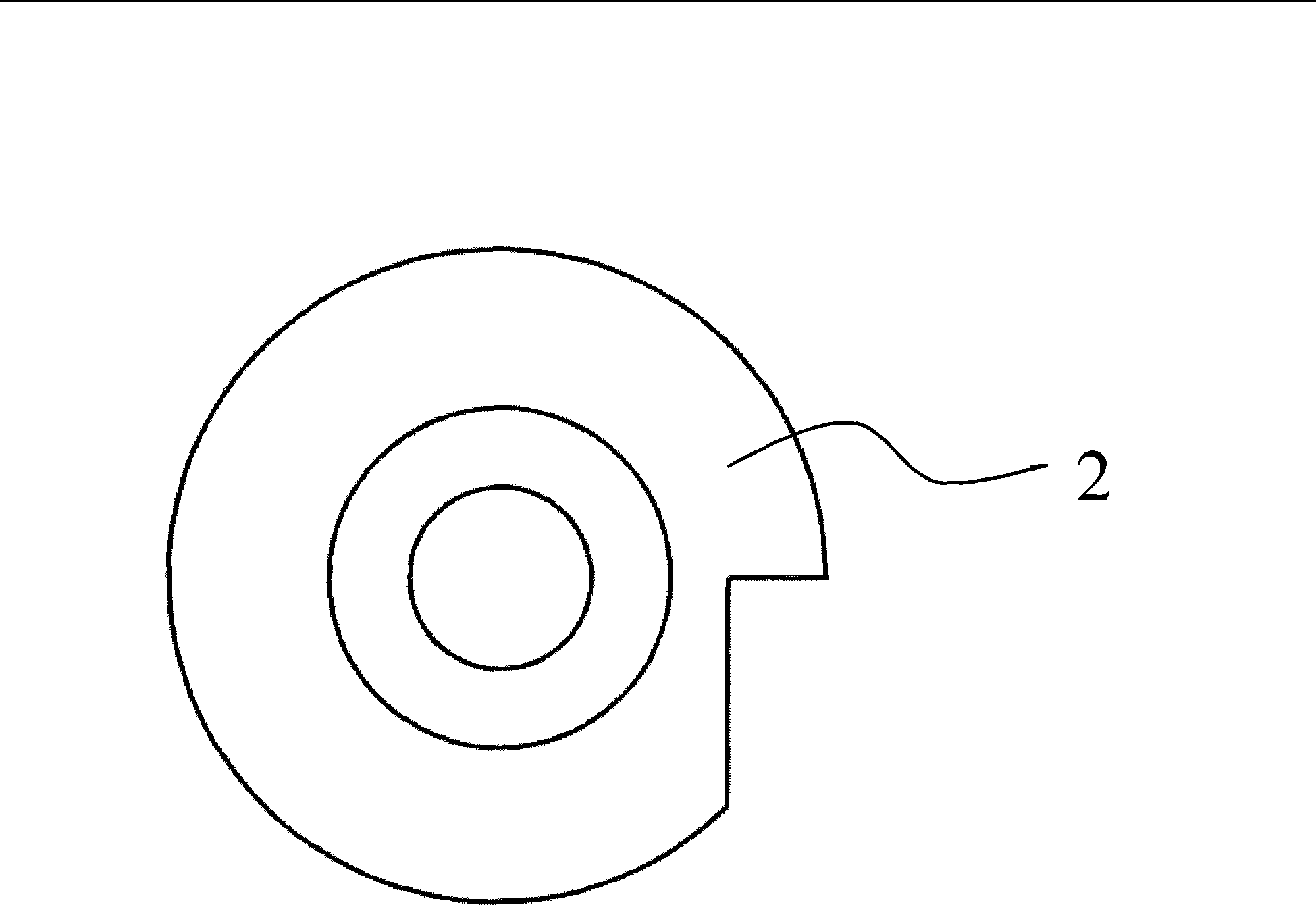

Method for preparing U-shaped seamless steel pipe of high-pressure feedwater heater

InactiveCN101372020AThin and uniform wallMeet the requirementsHollow article cleaningLinings/internal coatingsMetallurgyWork in process

The invention provides a method for preparing a U-shaped seamless steel pipe of a high-pressure feed water heater, relating to the high-pressure feed water heater. The method comprises the steps: the preparation of raw material pipes; the raw material pipes are unceasingly colddrawn by a cold drawing device to form middle parison pipes with the external diameter of 38 plus and minus 0.40mm and the thickness of 2.95 plus and minus 0.3mm; the middle parison pipes are further colddrawn by the cold drawing device to form middle semi-finished products pipes with the external diameter of 30-32mm and the thickness of 3.00-3.80mm; the middle semi-finished products pipes are colddrawn by a ring hole pattern mold and the cold drawing device to form finished products with the external diameter of 16-19mm, the thickness of 1.7-3.0mm and the length of 12-35mm; the finished products are bended into U-shaped pipes by a bent pipe mold; stressrelieving is carried out on the elbow parts of the U-shaped pipes; rust prevention treatment is carried out on the U-shaped pipes, and then U-shaped pipes are packed. The average yield stress of the high tension test of a gawga pipe prepared by the invention is 340MPa; the average tensile strength is 530MPa; the average unit extension is 36.7%; the invention totally meets the use demand of a high-pressure feed water heater and has the advantages of low cost, high performance.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com