Coal-fired secondary reheating steam turbine generator unit integrated with supercritical CO2 circulation

A turbo-generator set, double reheating technology, applied in the direction of steam engine device, machine/engine, steam application, etc., can solve the problems of large heat exchange temperature difference, increased irreversible loss, economic impact of the unit, etc., to achieve superheat Effect of reduction, loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

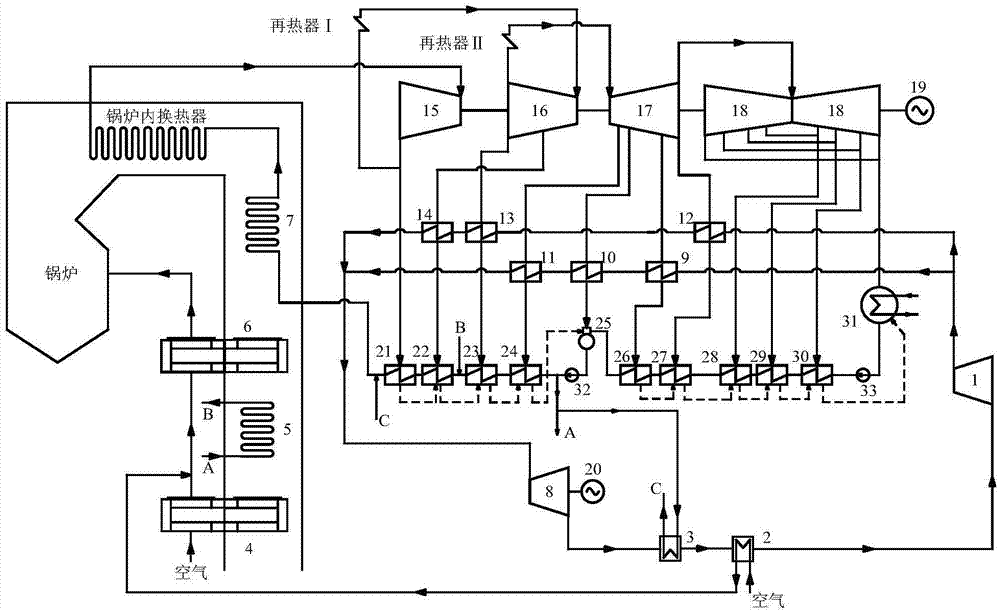

[0014] The purpose of the invention is to provide an integrated supercritical CO 2 Circulating coal-fired secondary reheat turbogenerator set, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0015] figure 1 for the integrated supercritical CO 2 Schematic diagram of the composition of a cycle coal-fired double reheat turbogenerator unit. The integrated supercritical CO 2 The cycle coal-fired double reheat turbo-generator set is mainly composed of a coal-fired boiler, a double-reheat turbo-generator set, supercritical CO 2 Composition of power generation cycle system; in the double reheat turbogenerator set, ultra-high pressure cylinder 15, high-pressure cylinder 16, medium-pressure cylinder 17, low-pressure cylinder 18 are sequentially connected with the first generator 19, ultra-high pressure cylinder 15, high-pressure cylinder 16 , The extraction steam of the medium pressure cylinder 17 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com