Heat accumulation type electric furnace flue gas waste heat recovery system

A flue gas waste heat and recovery system technology, applied in furnaces, waste heat treatment, steam superheating, etc., can solve the problems of low waste heat recovery efficiency, difficult to match steam users, affecting the actual effect of electric furnace waste heat recovery, etc., to improve the utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Referring to the drawings showing the present embodiment, it will be described in more detail below. However, the invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In these drawings, the size and relative sizes of layers and regions may be exaggerated for clarity.

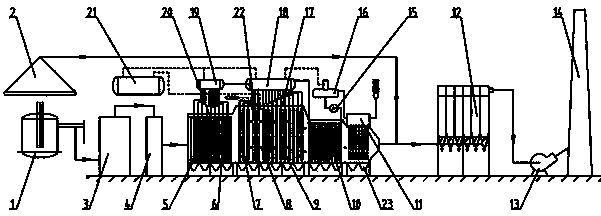

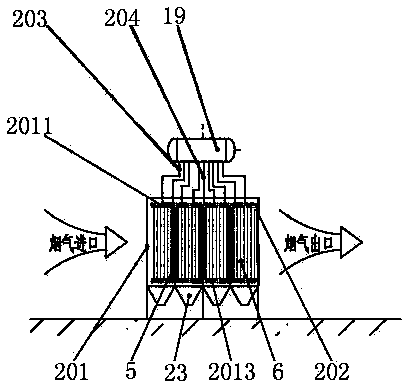

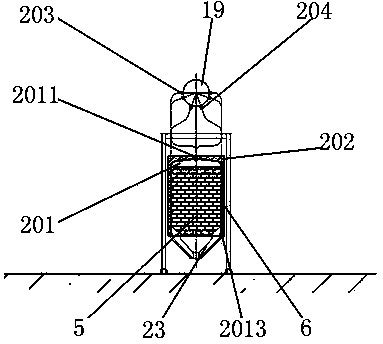

[0061] refer to Figure 1-3 As shown, the present invention provides a regenerative electric furnace flue gas waste heat recovery system, which is used to recover intermittent electric furnace flue gas waste heat to generate stable and continuous superheated steam, mainly including electric furnace 1, regenerative water-cooled settling chamber 20, convective heat exchange Waste heat boiler 17, feed water heater 11, steam accumulator 21, etc. This system can effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com