Patents

Literature

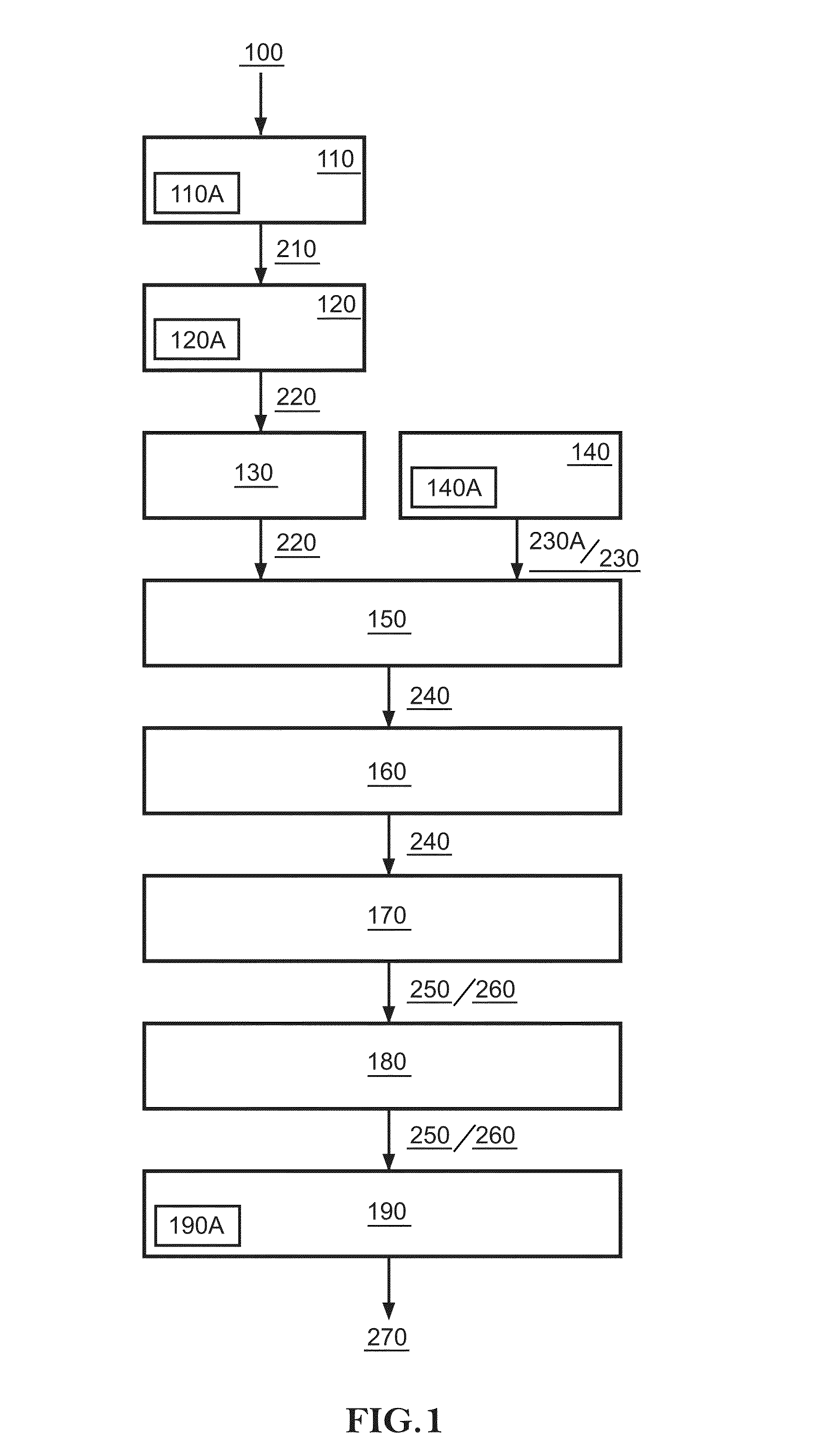

35results about How to "Avoid easy discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

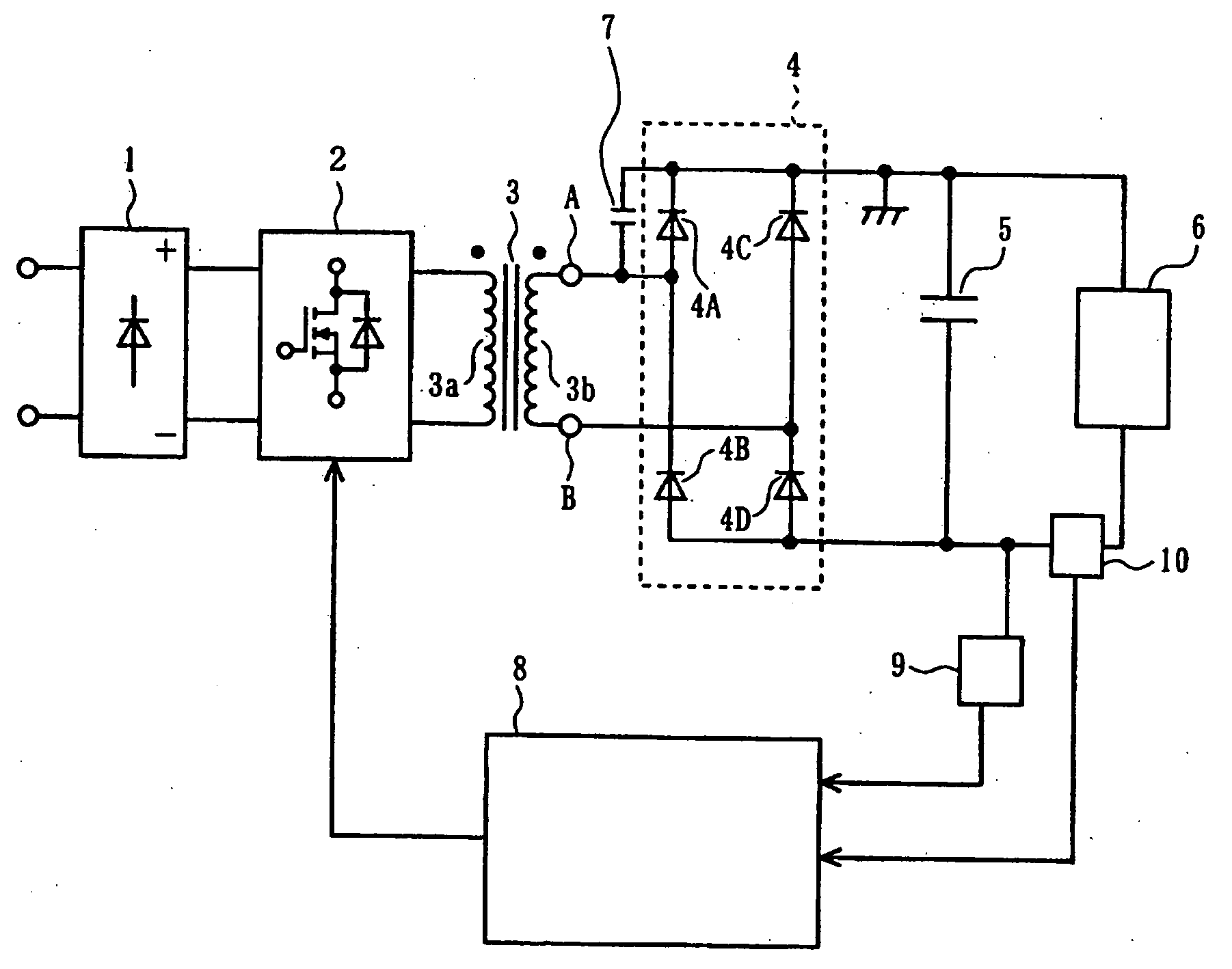

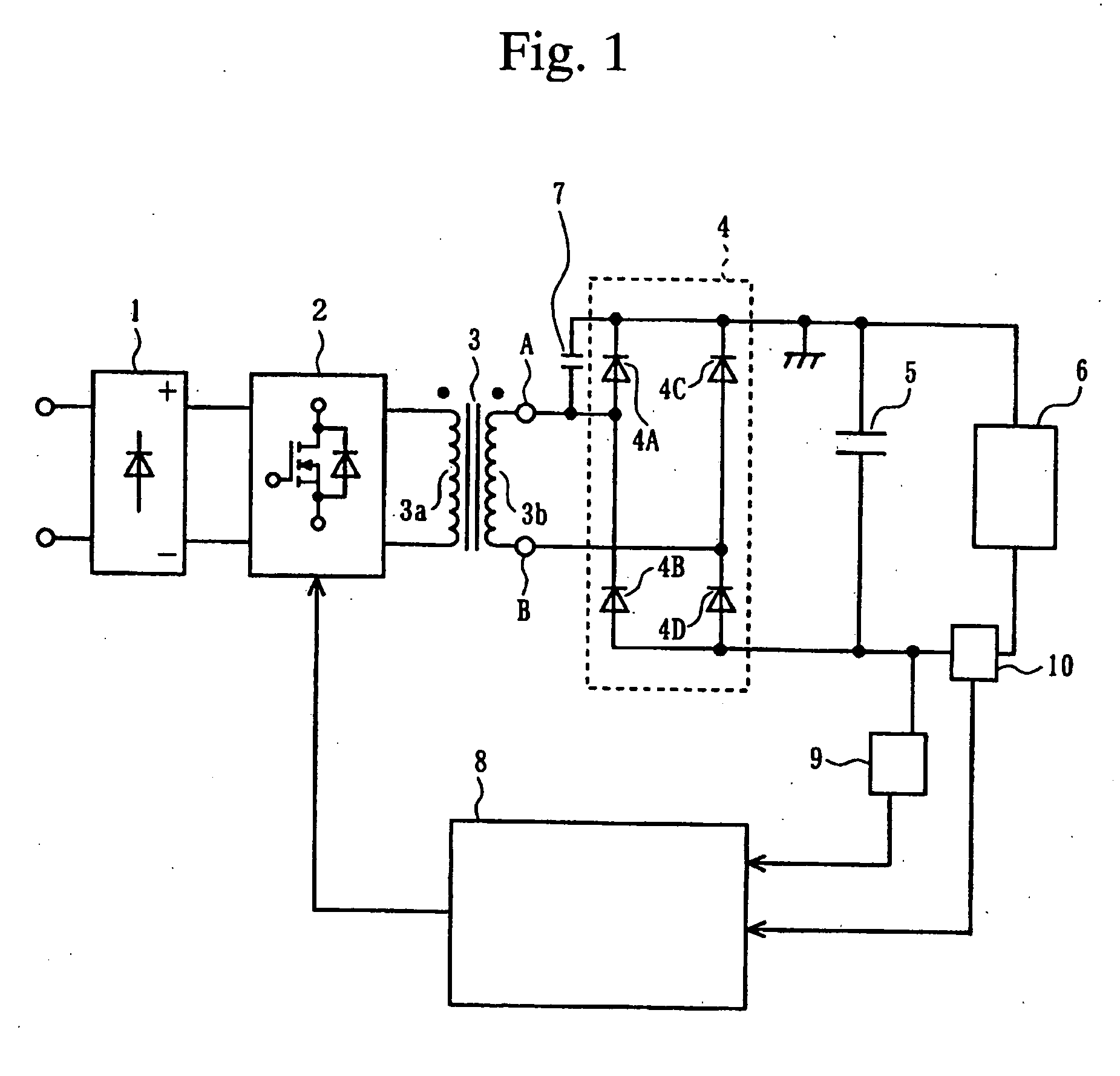

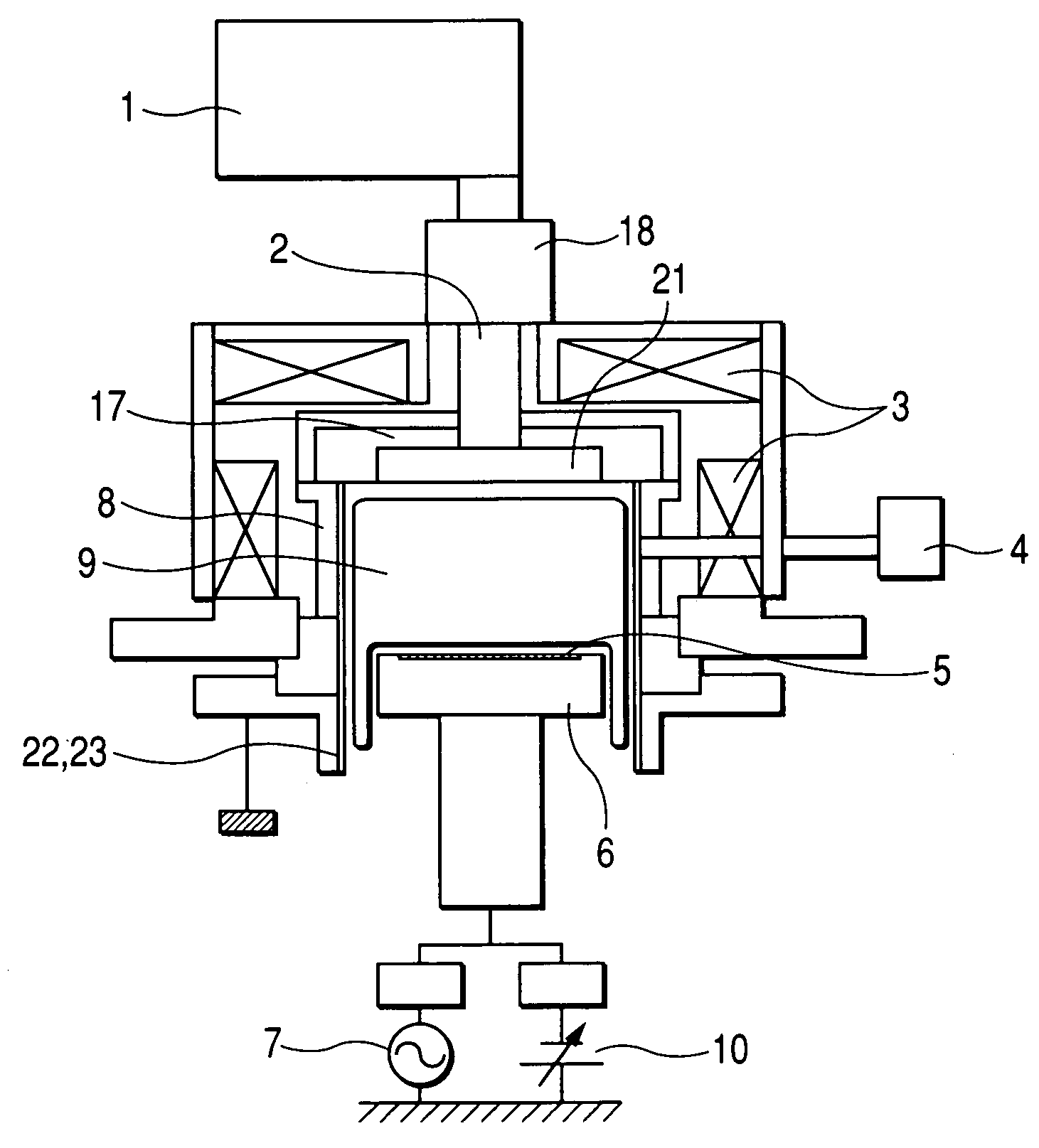

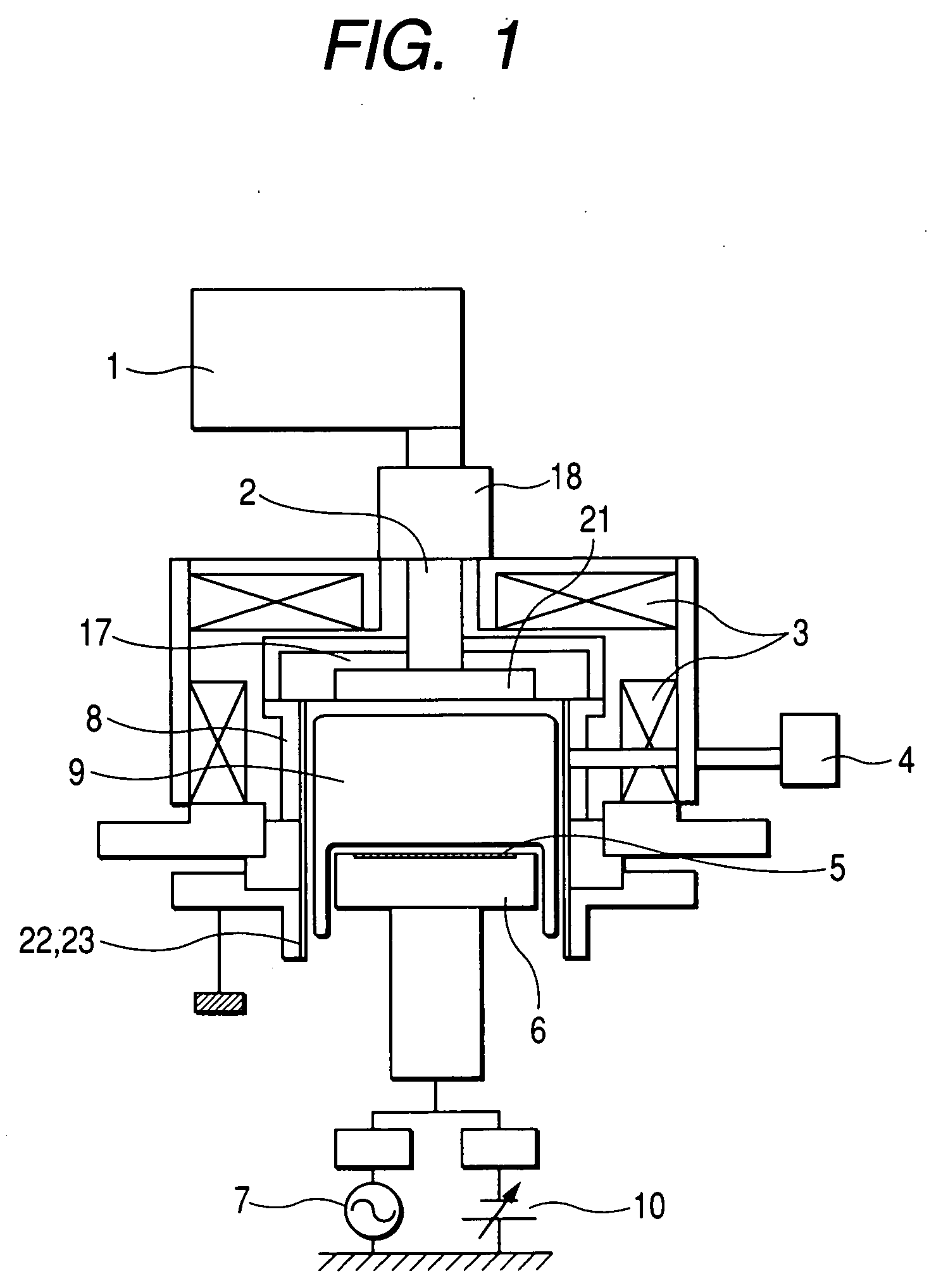

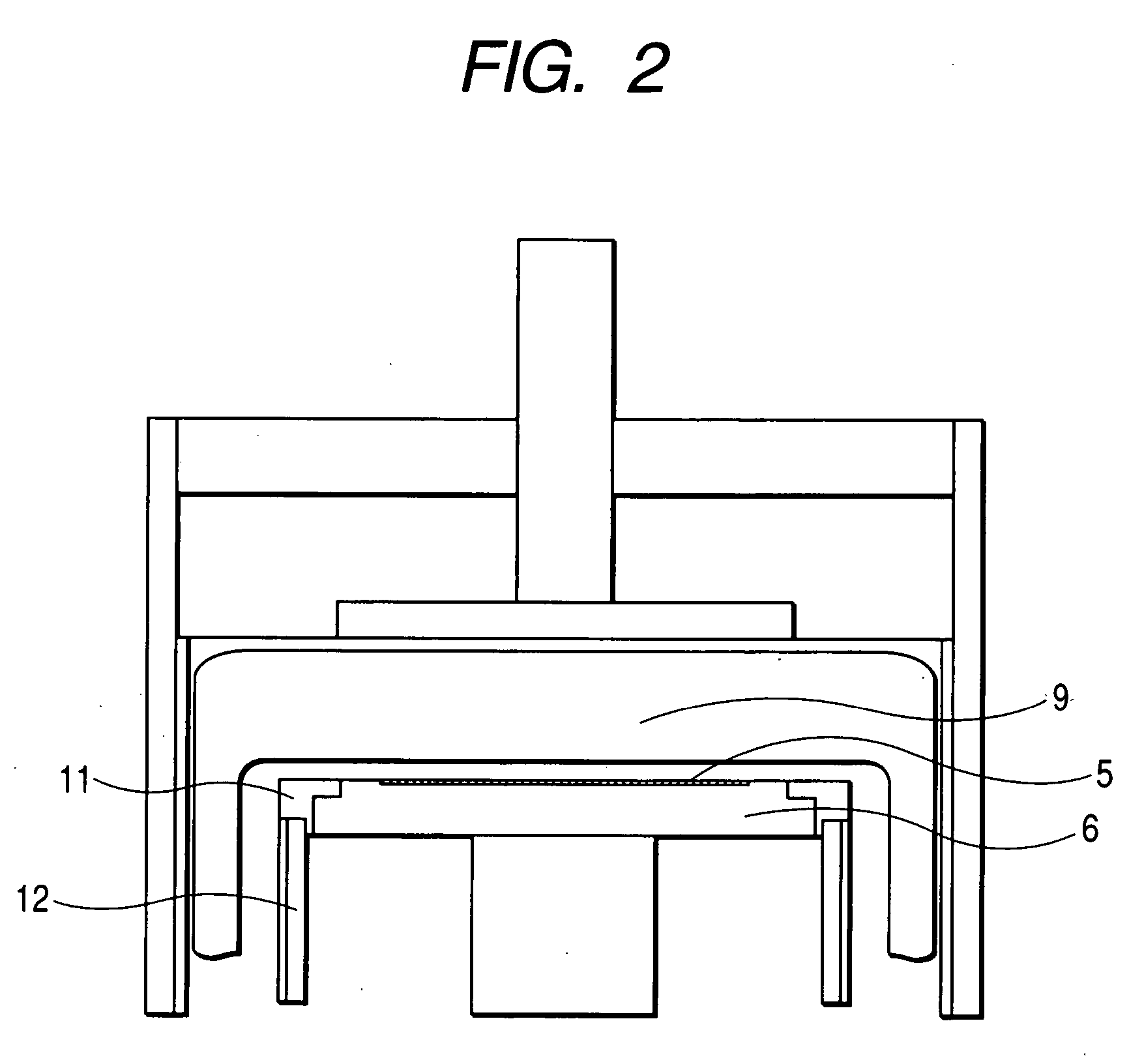

Discharge power supply apparatus

ActiveUS20050007034A1Suppress power lossAvoid easy dischargeAc-dc conversion without reversalElectric light circuit arrangementEngineeringConductor Coil

This discharge power supply apparatus is for supplying a D. C. voltage to a discharge load 6 and discharging the same. The discharge power supply apparatus includes an inverter circuit 2 that converts D. C. voltage to A. C. voltage; a transformer 3 having a primary winding 3a to which the A. C. voltage output by the inverter circuit 2 is supplied and a secondary winding 3b; a full-wave rectifier circuit 4 that has a plurality of diodes 4A to 4D and rectifies the A. C. voltage generated by the secondary winding 3b; and a trigger capacitor 7 connected in parallel to a part of the diodes of the full-wave rectifier circuit 4.

Owner:ORIGIN CO LTD

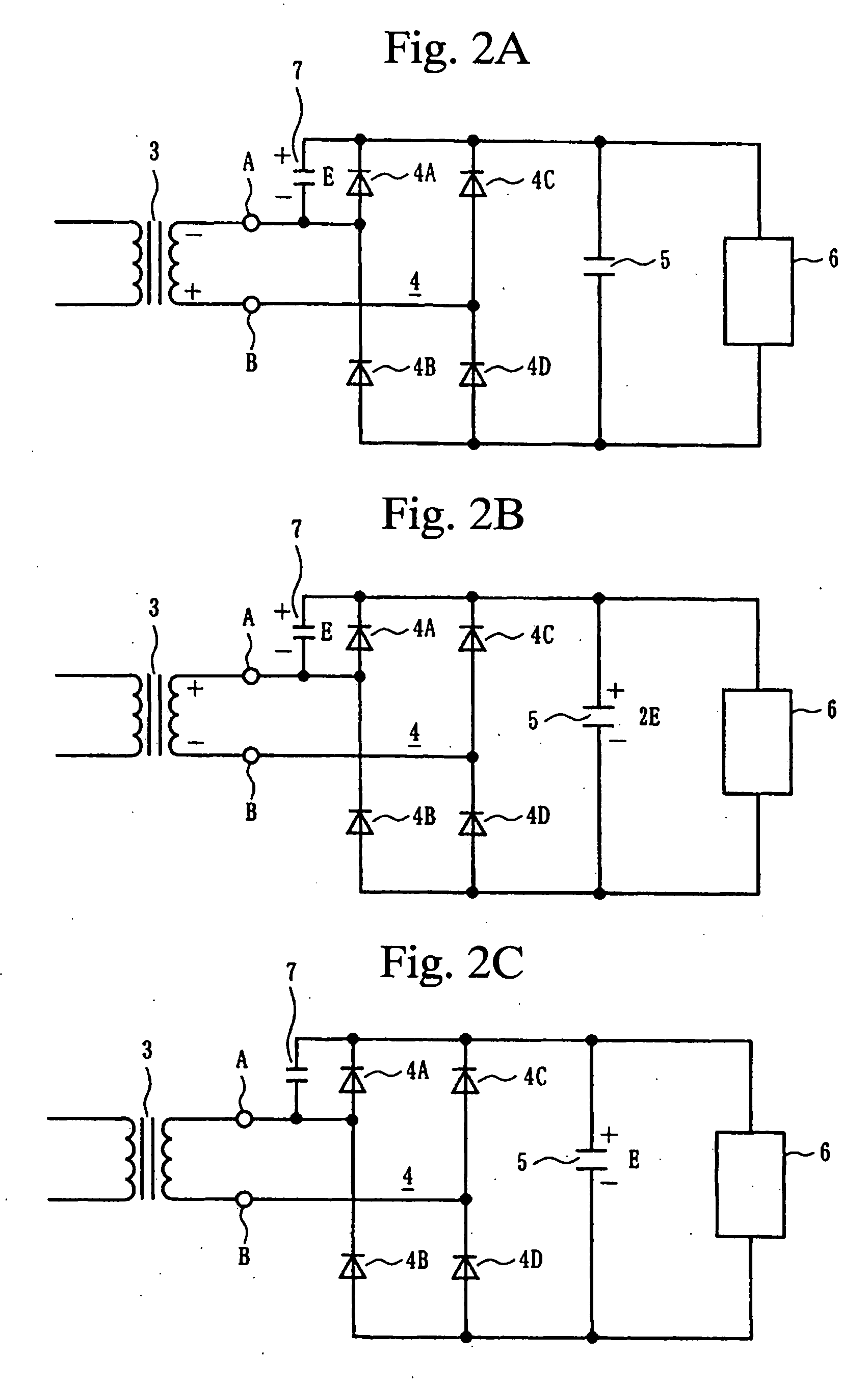

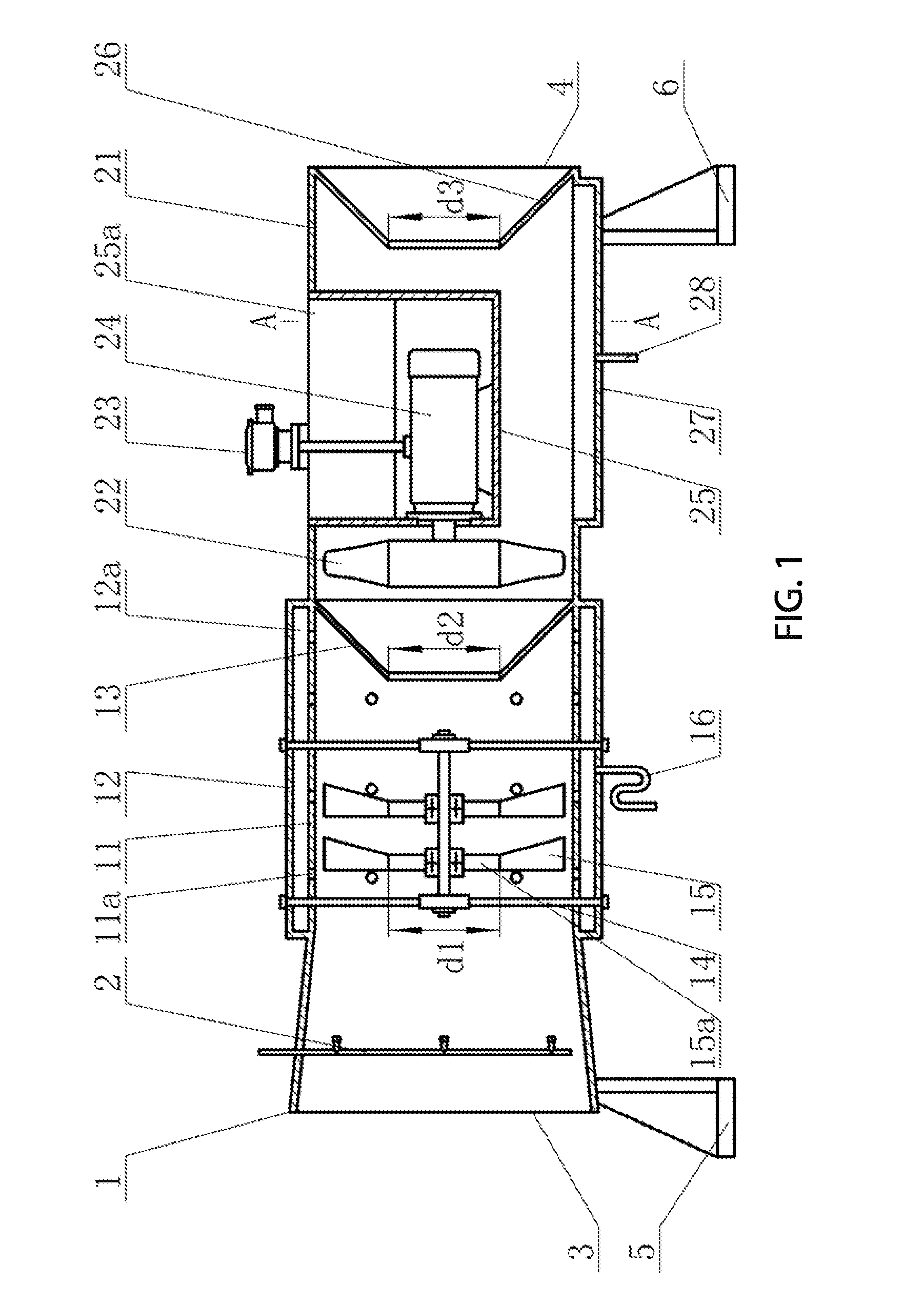

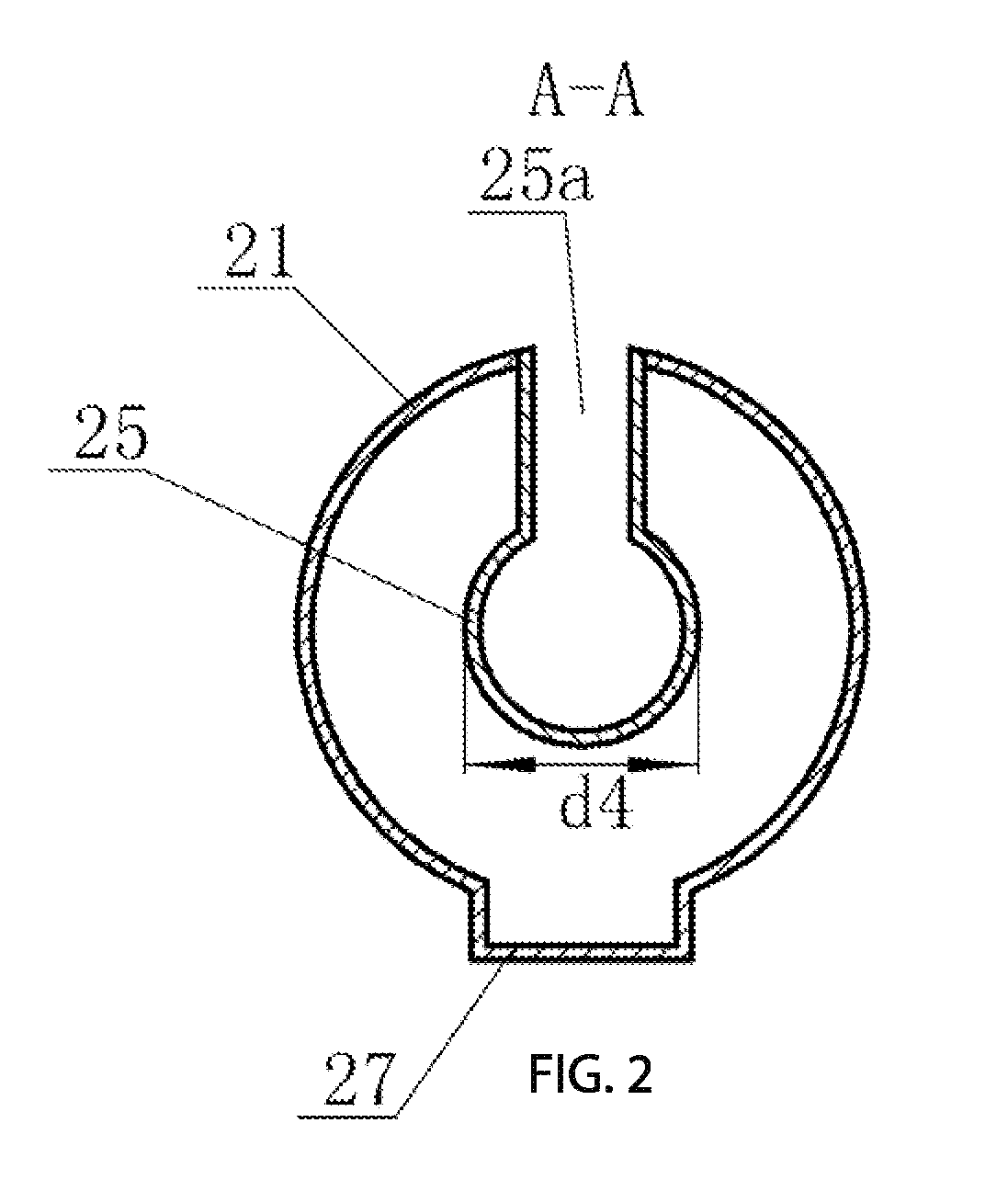

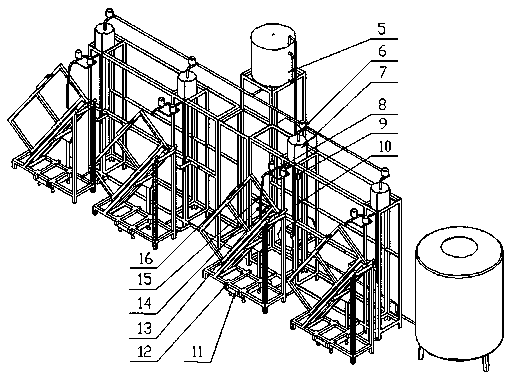

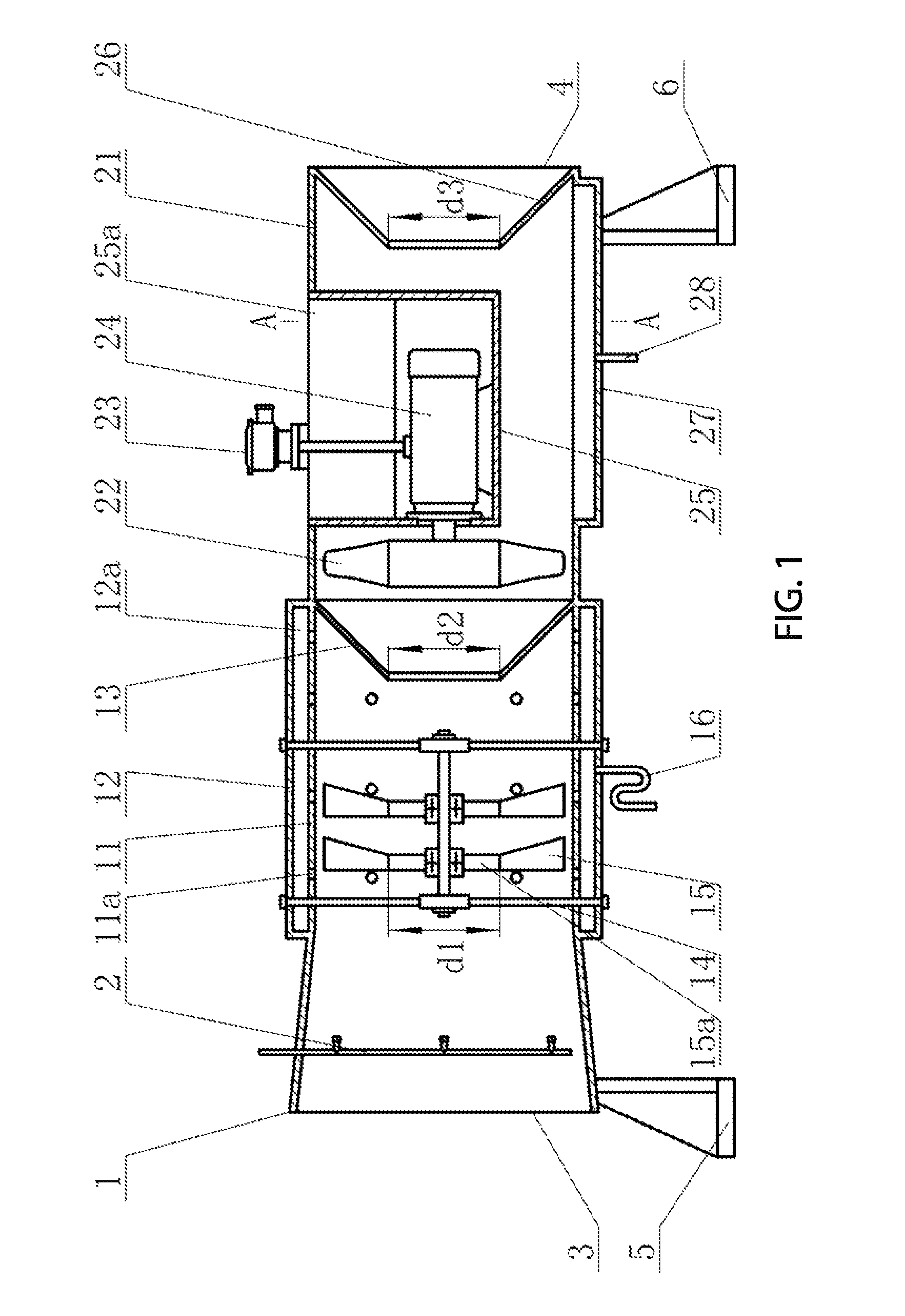

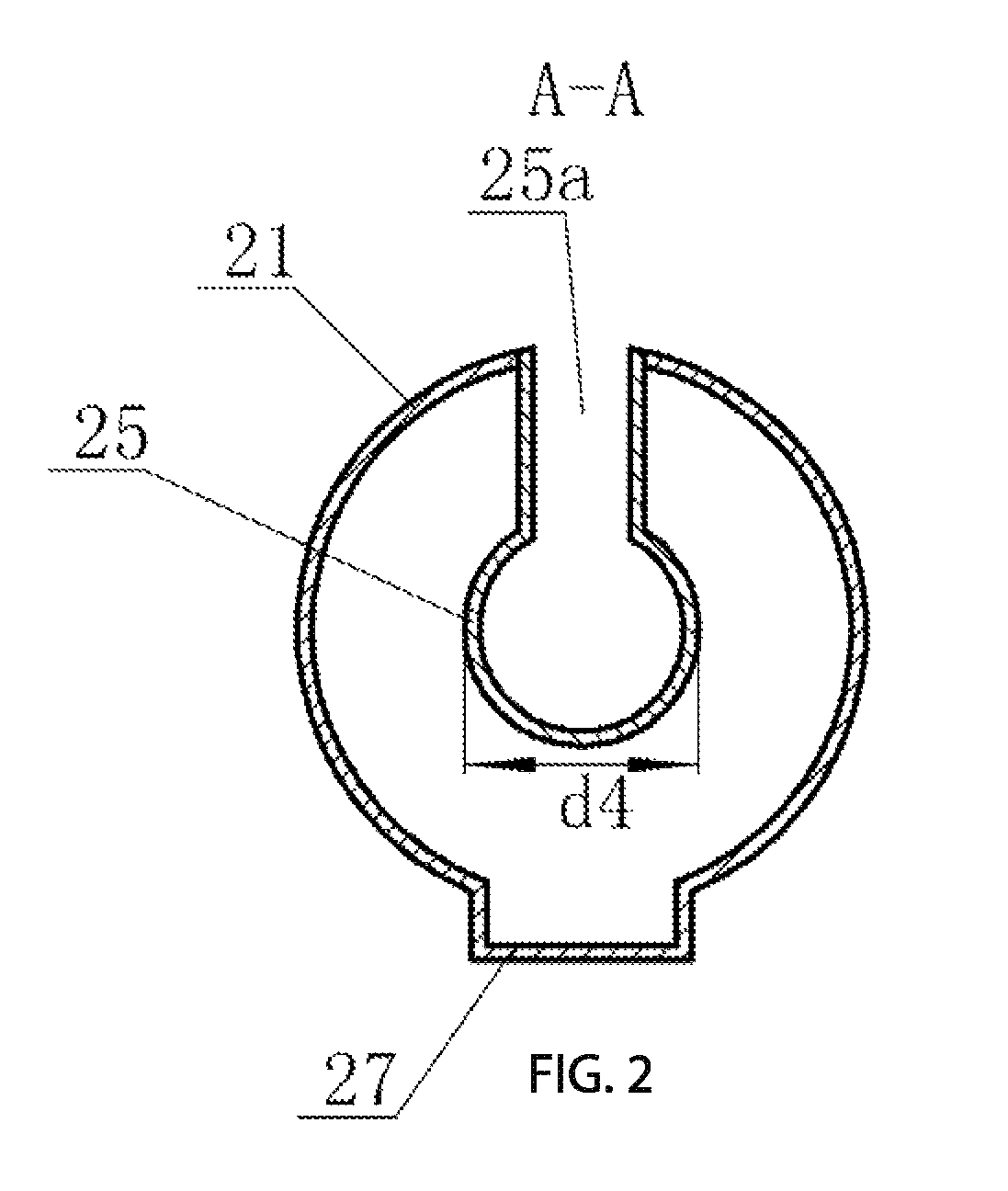

Spray Centrifugal Dedusting Fan

ActiveUS20110277271A1Great air circulation resistanceLow dedusting efficiencyCombination devicesLighting and heating apparatusImpellerHigh energy

The invention provides a spray centrifugal dedusting fan, including an air cylinder consisting of a spray cylinder, a centrifugal cylinder and a fan cylinder; the left end and the right end of the air cylinder are respectively provided with an air inlet and an air outlet communicated with each other; a spraying device is installed in the spray cylinder; a plurality of through holes are arranged on the wall of the centrifugal cylinder; a bracket is installed inside the centrifugal cylinder; at least one centrifugal impeller is installed on the bracket; a fan is installed inside the fan cylinder; an outer cylinder is installed on the external wall of the centrifugal cylinder 11; an empty chamber is arranged between the centrifugal cylinder and the outer cylinder; the lower end of the outer cylinder is connected with a water seal elbow; the water seal elbow is communicated with the empty chamber, the trumpet-shaped first water-blocking shield is connected to the right part inside the centrifugal cylinder; the left port diameter of the first water-blocking shield is smaller than the right port in diameter; the left port of the first water-blocking shield corresponds to the centrifugal impeller and the right port corresponds to the fan. The invention adopts the spray centrifugal form to remove dust in air, which solves the problems of great air circulation resistance, low dedusting efficiency, high energy consumption and easy breakage of fan motor etc. in the prior art.

Owner:TAIAN SANYUAN VENTILATION DUST EQUIP CO LTD

Ink composition and ink jet recording method using same

ActiveUS20180030298A1Improve dispersion stabilityImprove discharge stabilityDuplicating/marking methodsInksVitrificationEmulsion

Provided is an aqueous ink jet-use ink composition which includes a binder resin, a surfactant, a pigment, a solvent and, if necessary, a pigment-dispersing resin. The binder resin has a glass transition temperature of 40-90° C. and is dispersed as resin emulsion particles. The value of A, which is defined as the sum of the product of the acid value and the content in terms of parts by mass of the binder resin and pigment-dispersing resin, is 0-200 mg KOH / g. The surfactant is a non-ionic compound represented by formula (1), and the content of solvents having boiling points of 250° C. or higher is less than 5 parts by mass relative to 100 parts by mass of the ink composition.R1O—(R2O)n—H (1)R1 is a straight-chain or branched chain alkyl group having 12-22 carbon atoms. R2 is an ethylene group or propylene group.n is an integer between 10 and 50.

Owner:DNP FINE CHEMICALS CO LTD

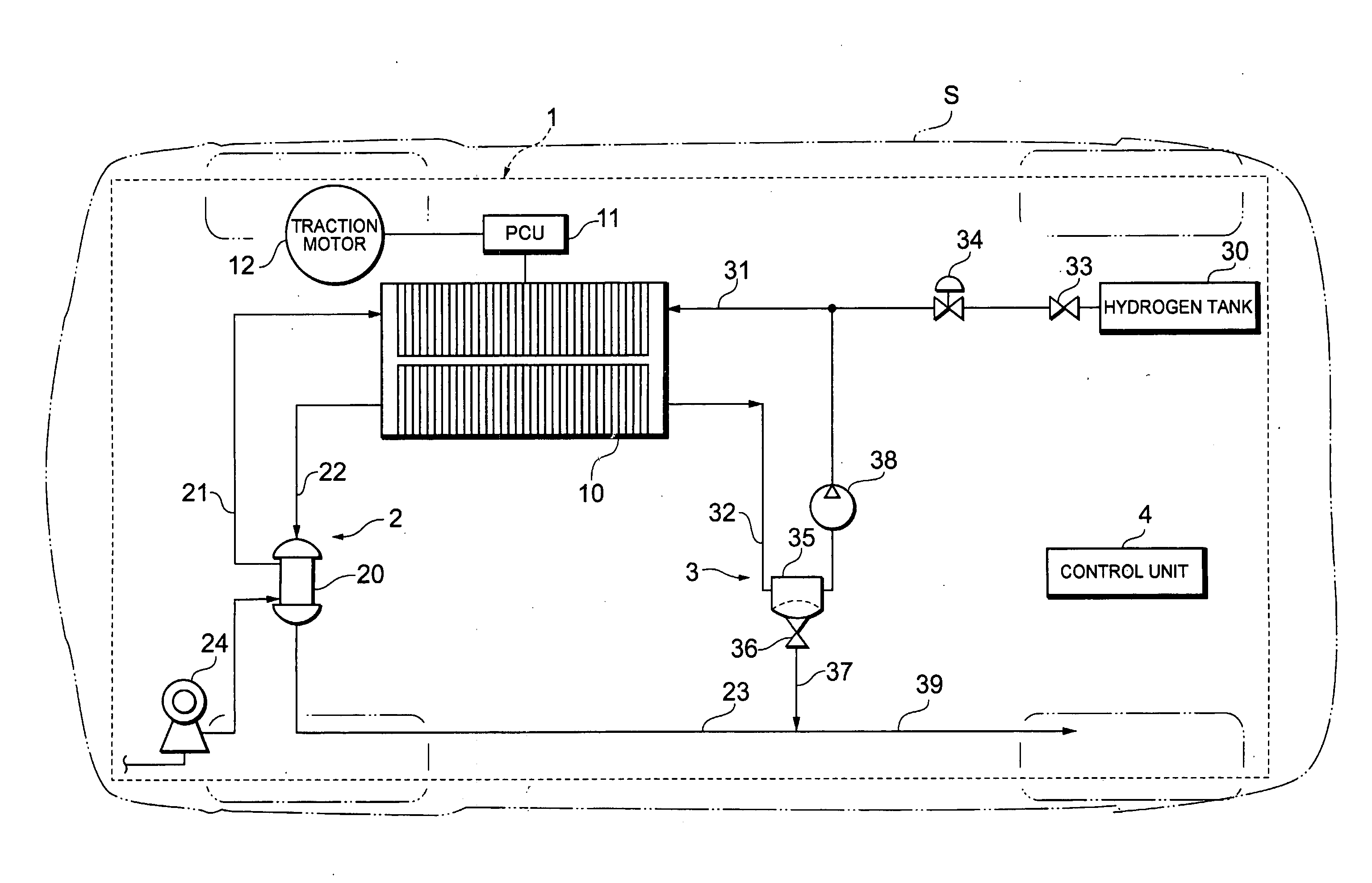

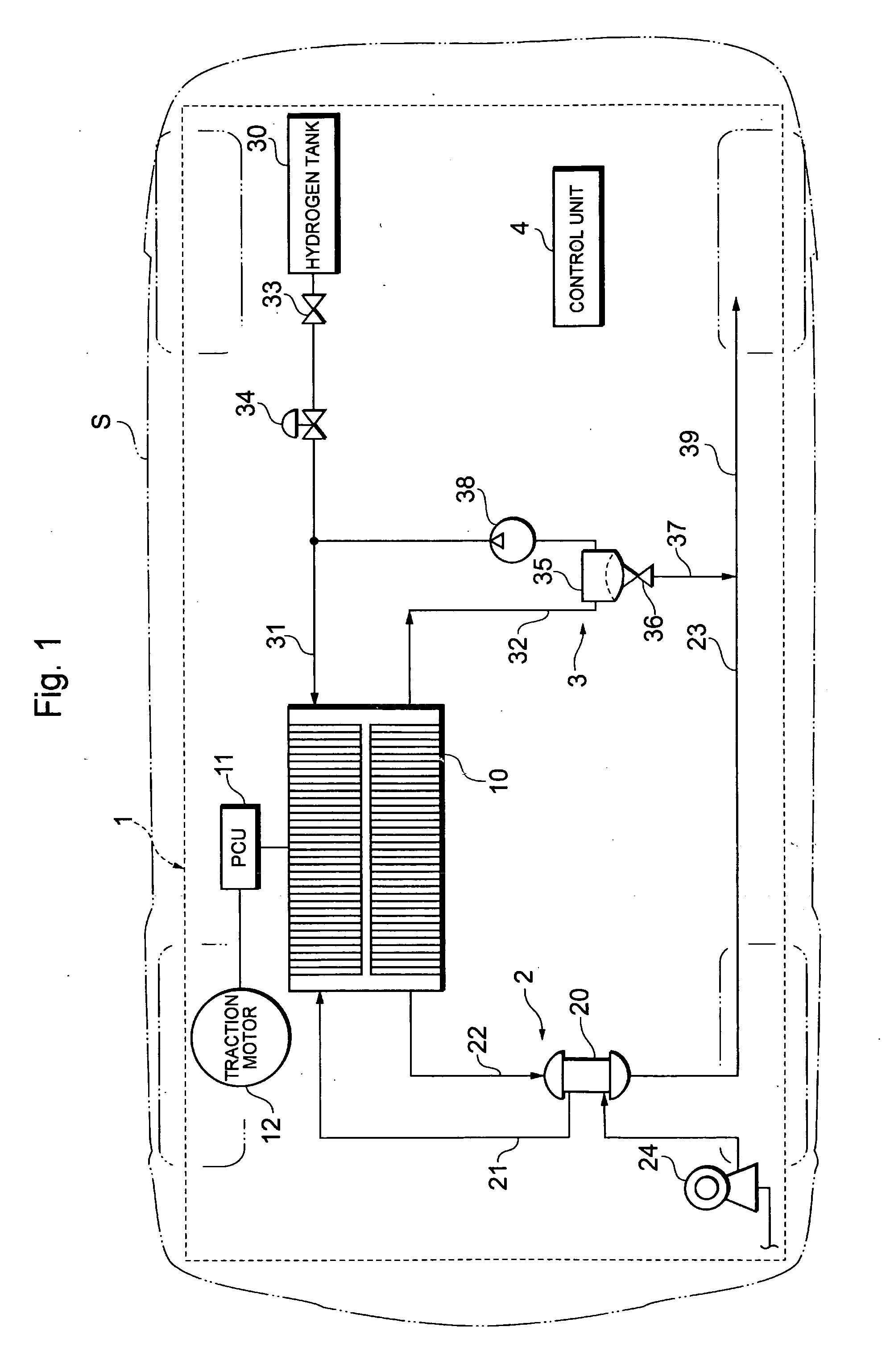

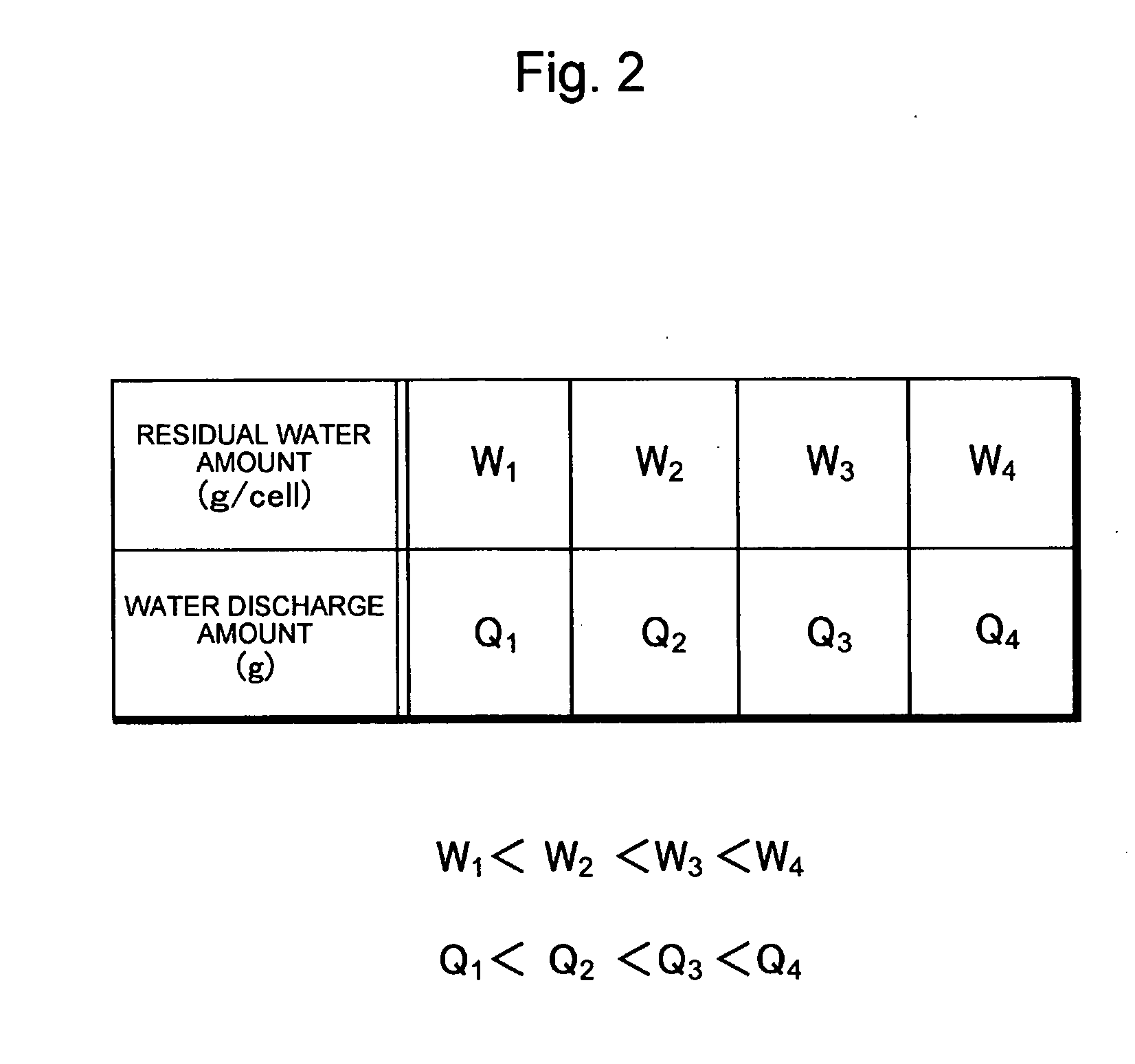

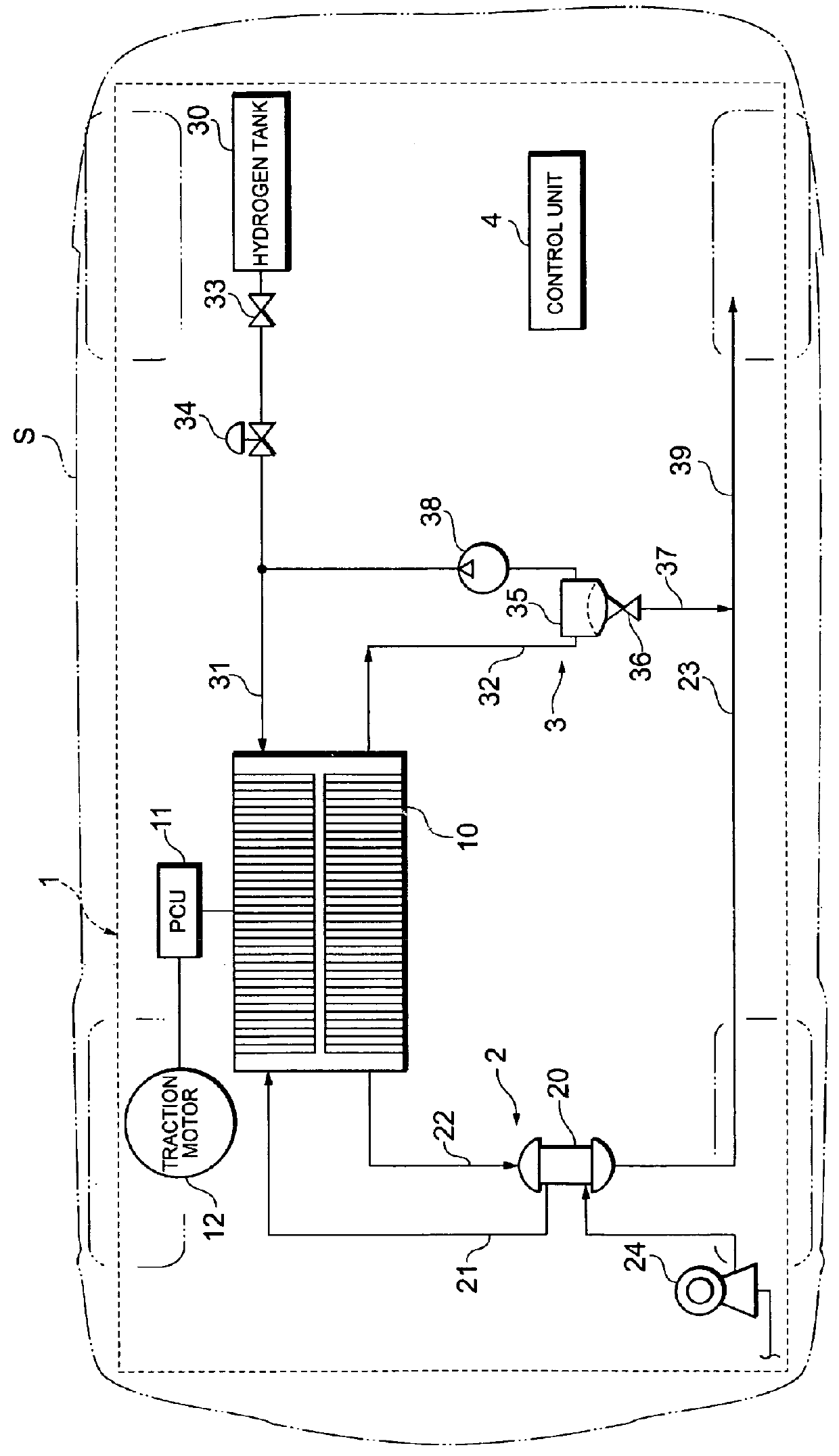

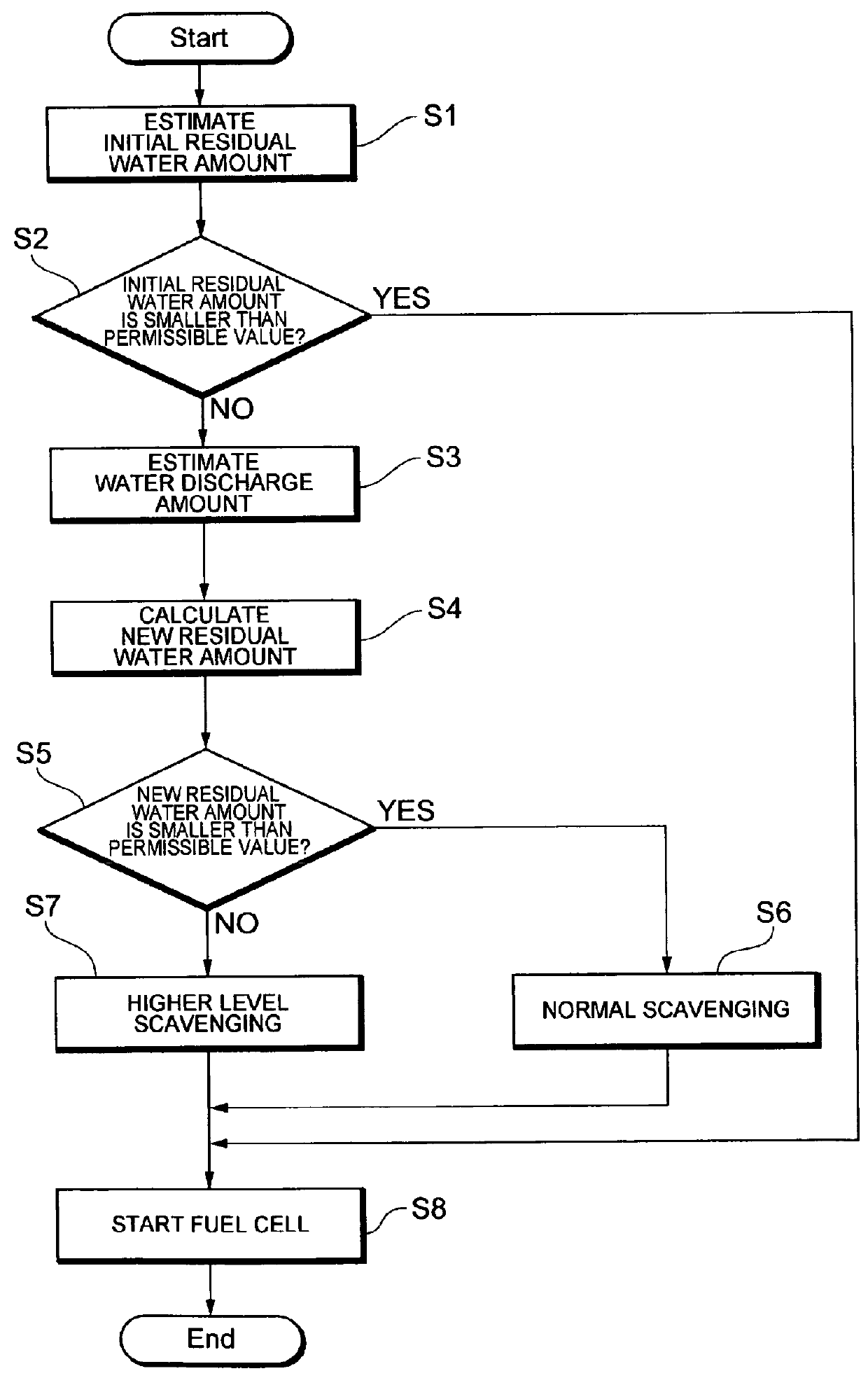

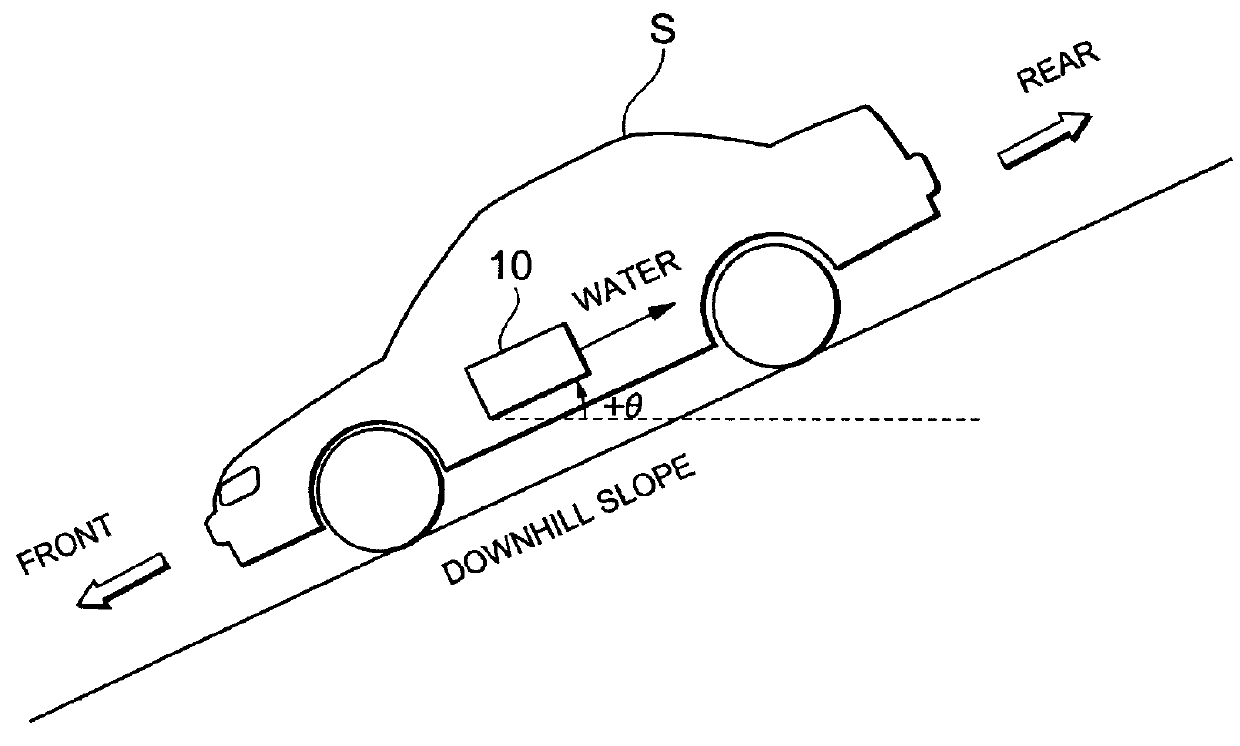

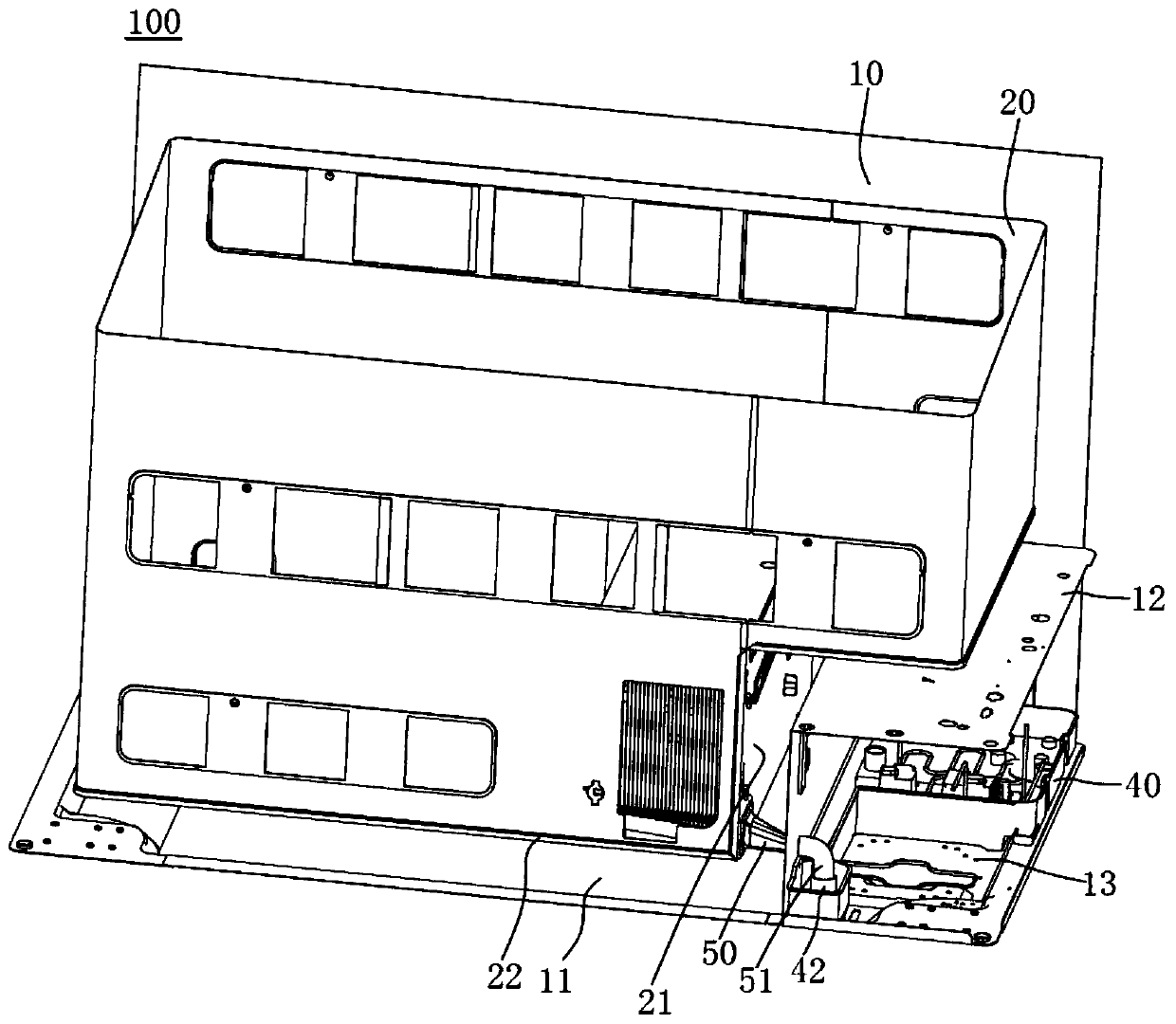

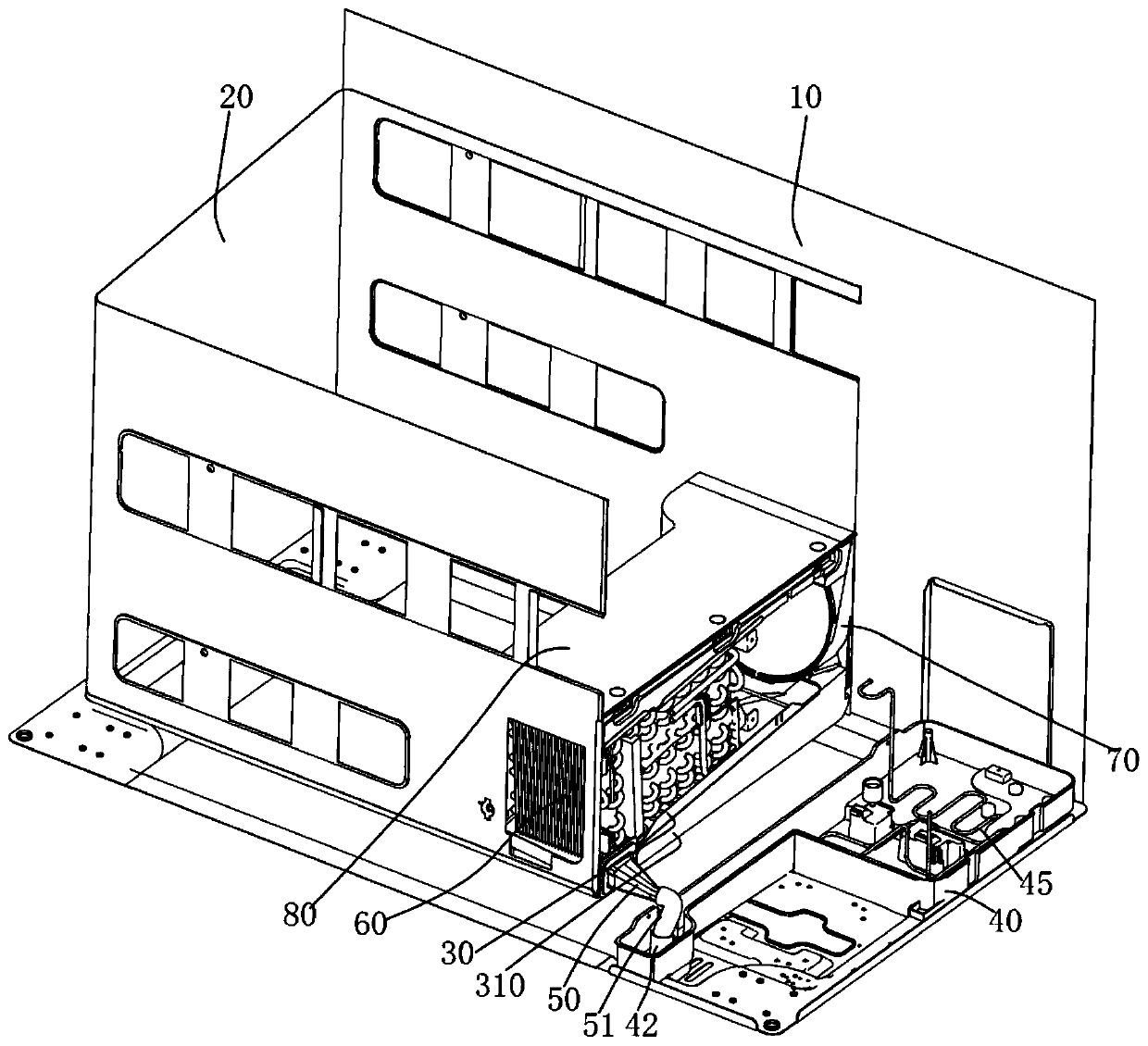

Fuel Cell System and Mobile Article

ActiveUS20090142633A1Superior starting functionReduce the amount requiredFuel cell auxillariesVehicular energy storageFuel cellsProduct gas

A fuel cell system, which includes a fuel cell for generating electric power and which discharges externally water remaining in the fuel cell by supplying a gas to the fuel cell, includes discharge amount estimating means, for estimating, based on the state of the fuel cell (the amount of residual water or an inclination angle), the amount of water to be discharged from the fuel cell.

Owner:TOYOTA JIDOSHA KK

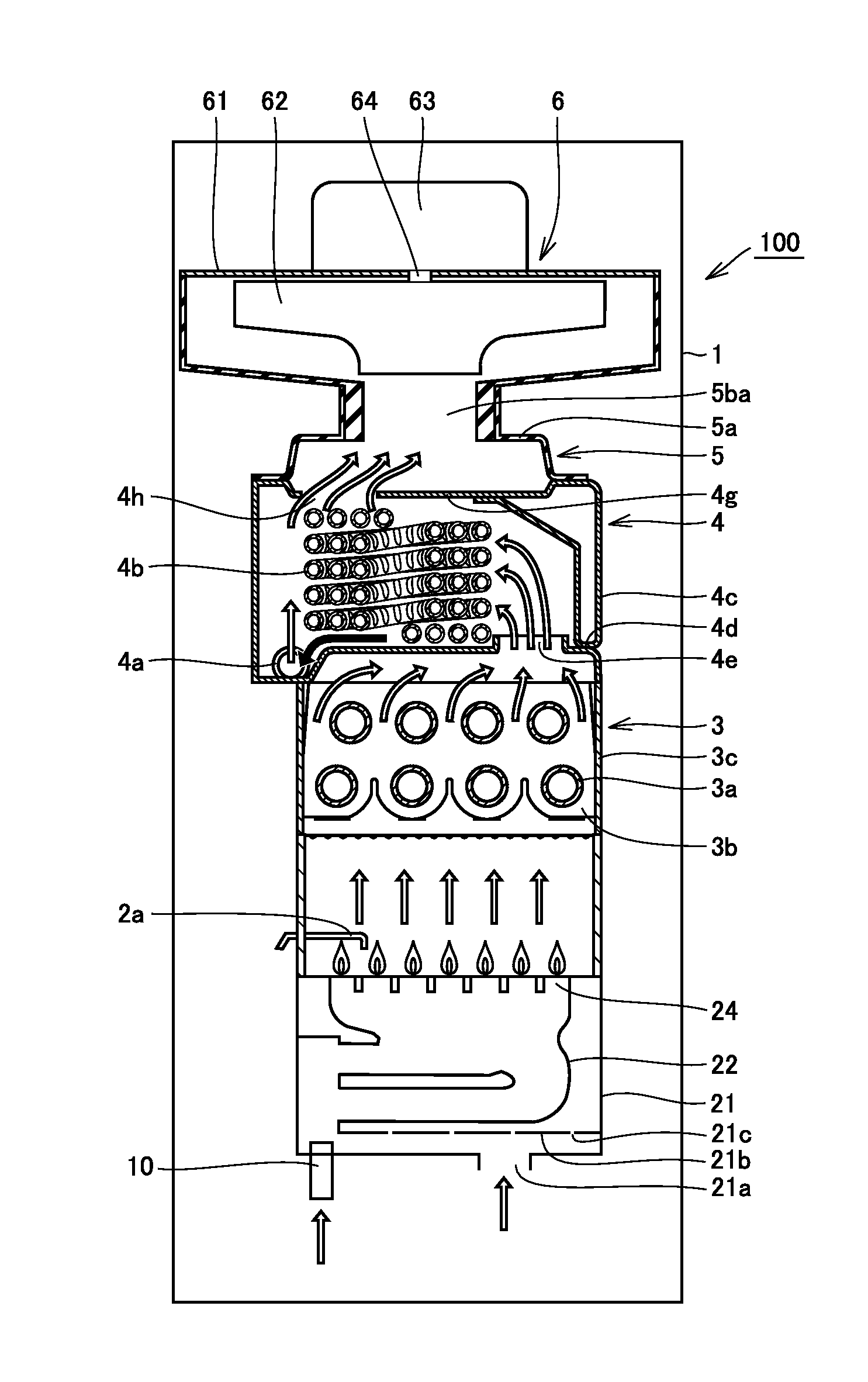

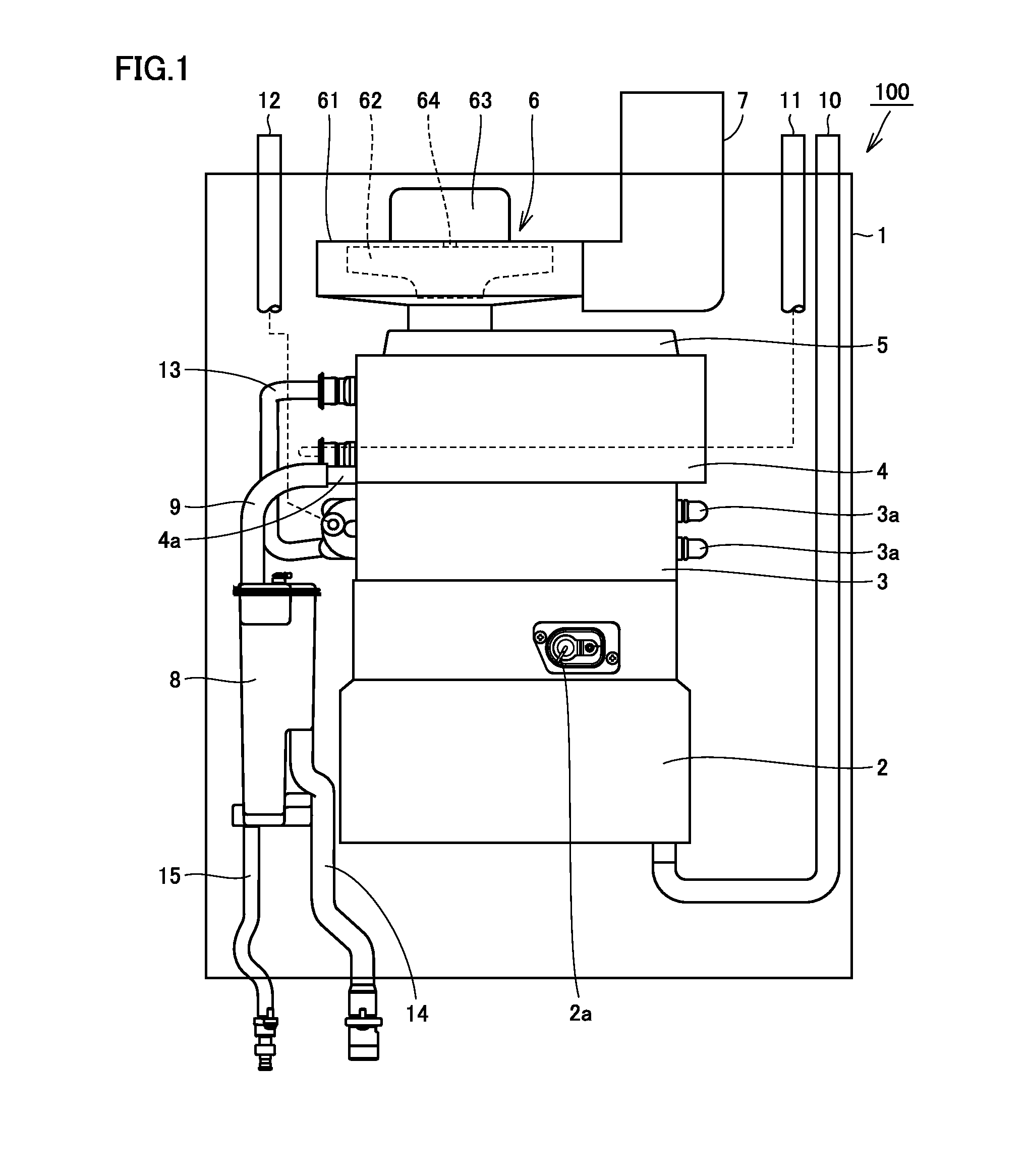

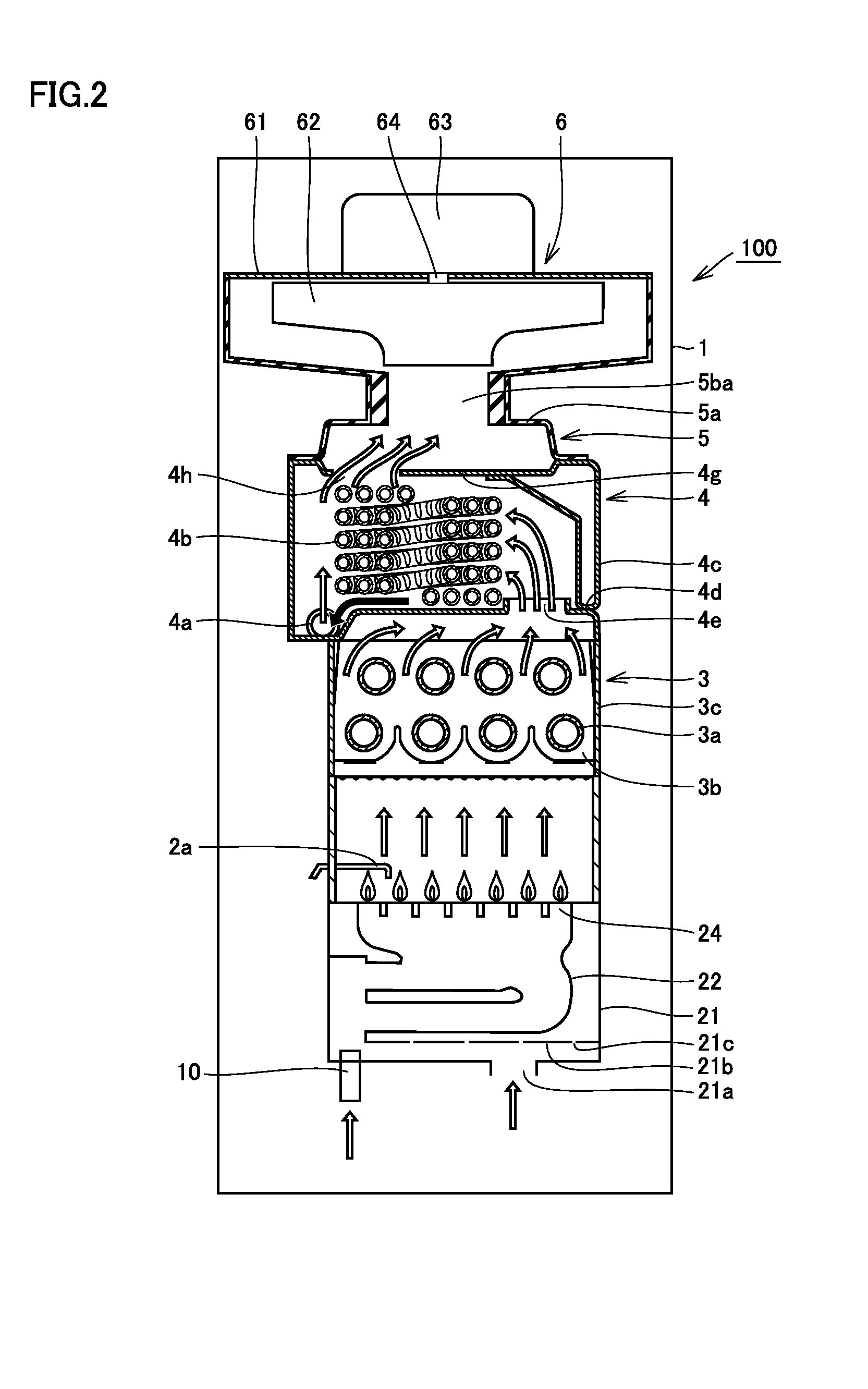

Water heater

ActiveUS20160010892A1Avoid dischargeAvoid easy dischargeAir heatersIndirect heat exchangersCombustorWater discharge

A water heater includes: a burner; a heat exchanger; a fan for supplying air to the burner and emitting combustion gas having passed through the heat exchanger to outside of the water heater; and a drainage water discharge path connected to the heat exchanger. The drainage water discharge path has a water-sealing structure that is water-sealed by drainage water. The water heater further includes a control unit: having a water-seal determination unit giving permission that the water heater can operate in a normal mode based on a condition that the drainage water discharge path has been water-sealed; and issuing an instruction to cause the burner to intermittently operate for a time period until the water-seal determination unit gives the permission.

Owner:NORITZ CORP

Member for plasma processing apparatus and plasma processing apparatus

InactiveUS20060157198A1Reduce impactImproving stability and reliabilityElectric discharge tubesSemiconductor/solid-state device manufacturingConductive materialsQuartz

Provided is a plasma processing apparatus, which comprises, as a member facing plasma in a plasma processing chamber, a member composed of a material prepared by incorporating a conductive material in quartz or germanium which is an amorphous base material.

Owner:HITACHI HIGH-TECH CORP

Sn-Sb-Ni Ternary Compound And Method For Forming the same

ActiveUS20130126053A1Improve charging capacityImprove cycle performanceCell electrodesWelding/cutting media/materialsDiffusion methodsSkutterudite

The invention discloses a novel method to prepare the Ni(Sn, Sb)3 skutterudite compound. Skutterudite compounds are thermoelectric materials, which can transform heat into electric energy. Besides, the Ni(Sn, Sb)3 compound is also an anode material of Li ion battery. The solid state diffusion method is used to prepare the Ni(Sn1-x, Sbx)3 compound. Compared to traditional physical or chemical processes, the method disclosed in the invention is simpler and operates at a lower temperature. By the method according to the invention, the composition of the Ni(Sn, Sb)3 compound can be adjusted to fulfill variety requirements for different applications. It is noteworthy that the invention can prepare ternary compounds. In comparison with the frequently used binary compounds such as Ni3Sn4 or Cu6Sn5, the invention can produce materials with better performance.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

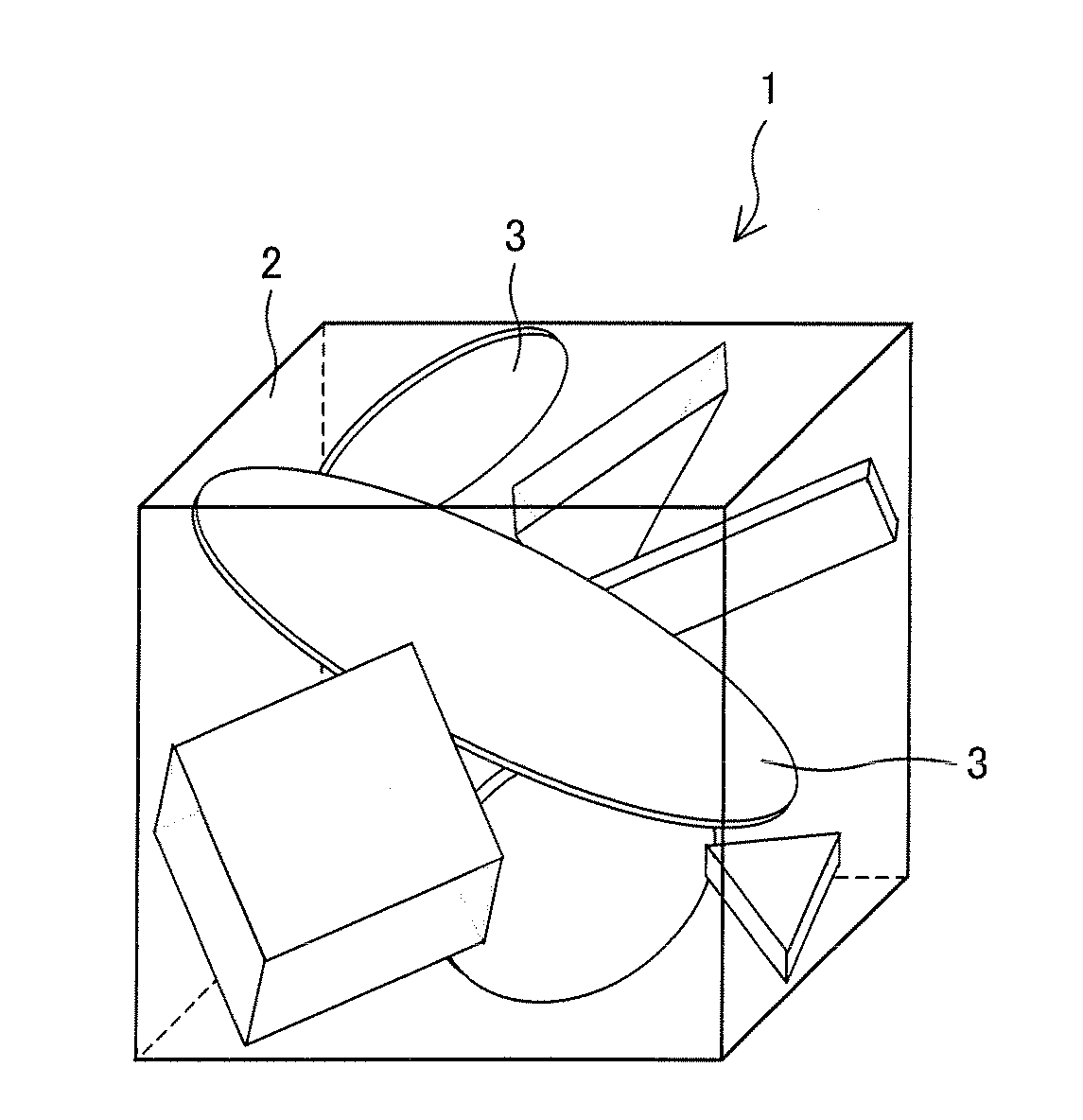

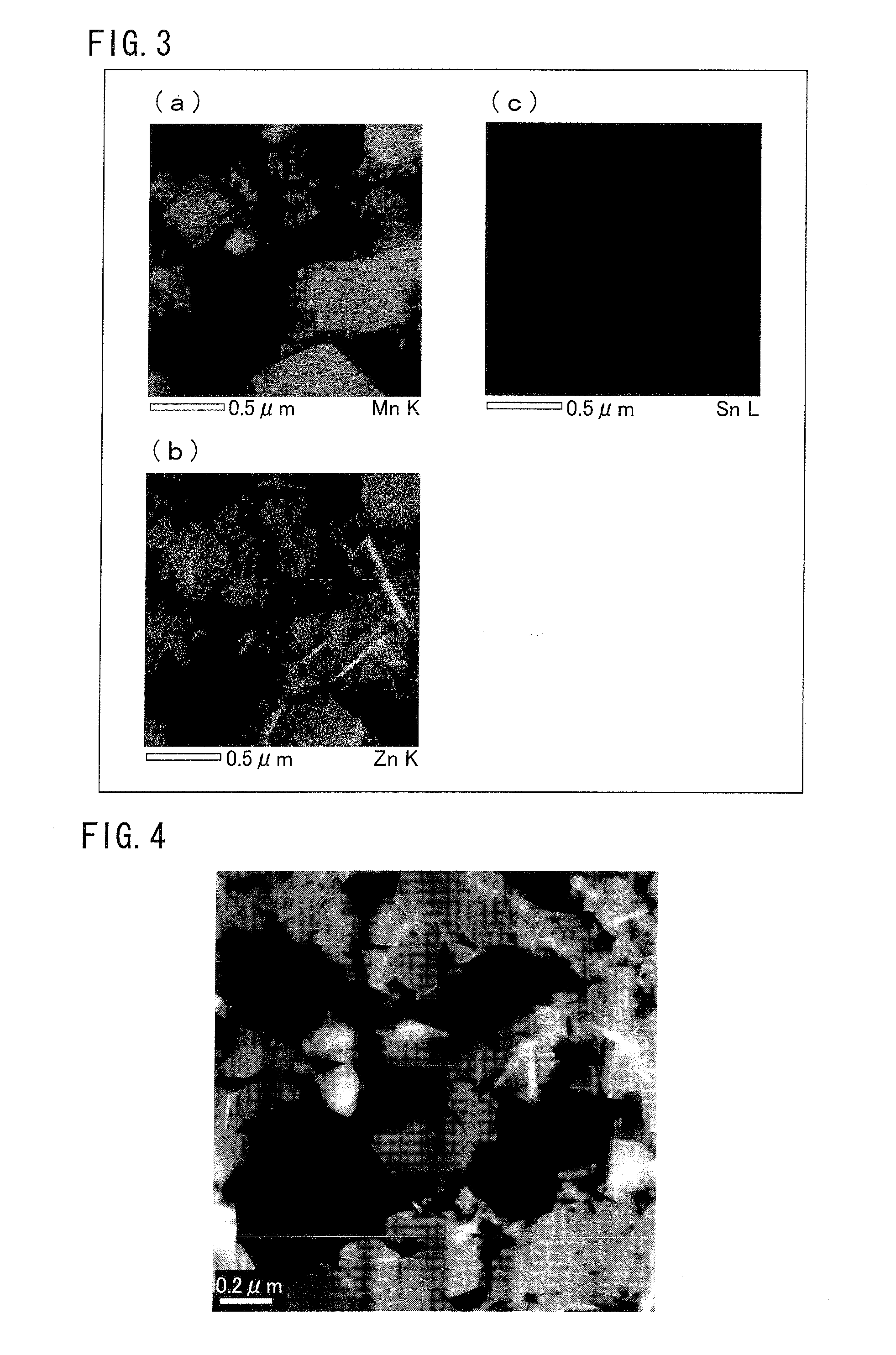

Cathode active material, and nonaqueous secondary battery having cathode including cathode active material

InactiveUS20110171530A1Excellent cycle characteristicsDischarge capacity difficult can be in capacityNon-aqueous electrolyte accumulator electrodesLithiumManganese

A cathode active material (1) of the present invention includes: a main crystalline phase (2) including a lithium-containing transition metal oxide containing manganese and having a spinel structure, and in the cathode active material used in a nonaqueous secondary battery, the main crystalline phase (2) includes a layer-shaped sub crystalline phase (3) which is different in elementary composition from that of the lithium-containing transition metal oxide but having an oxygen arrangement identical to that of the lithium-containing transition metal oxide and which has a spinel structure.

Owner:SHARP KK

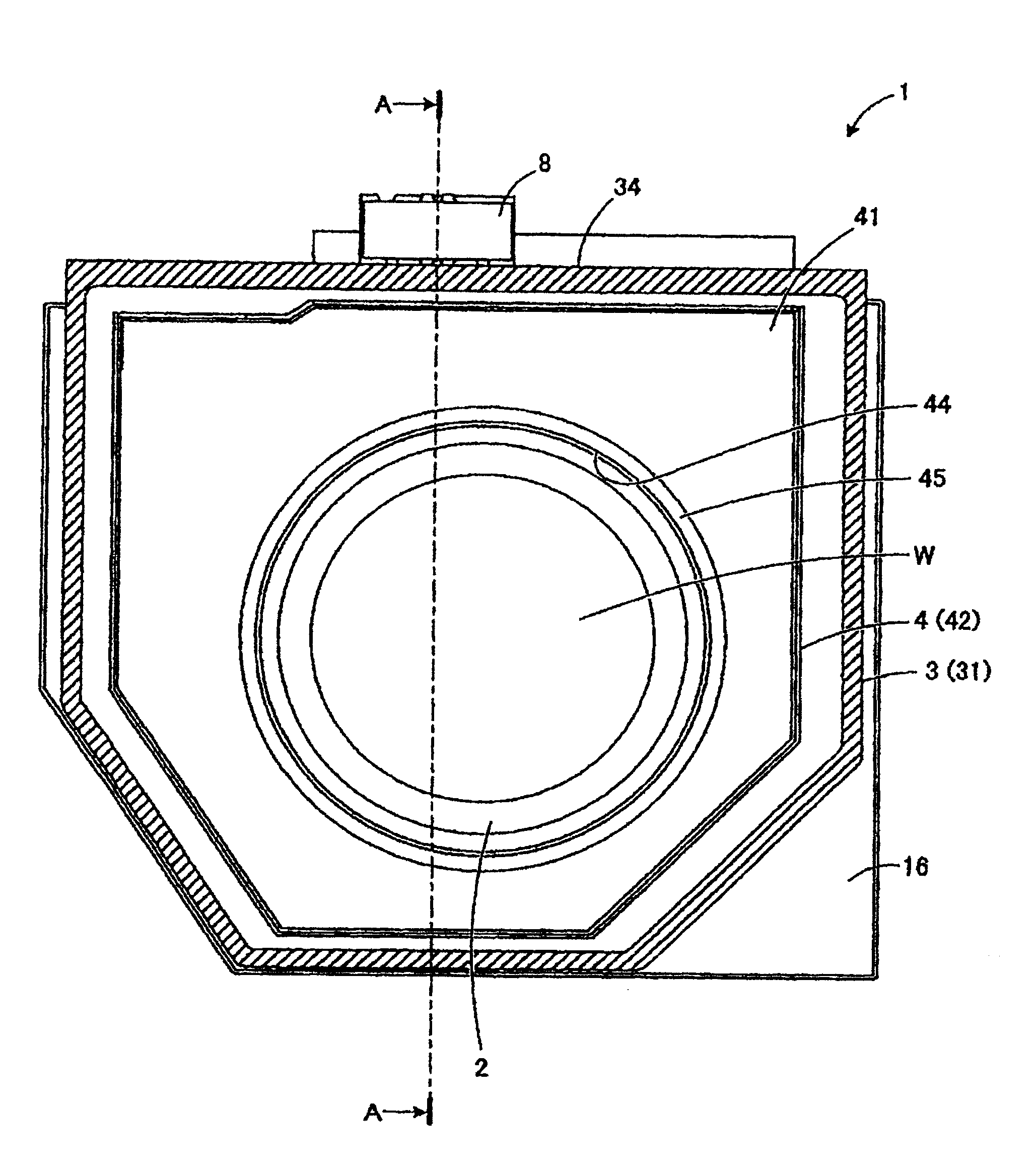

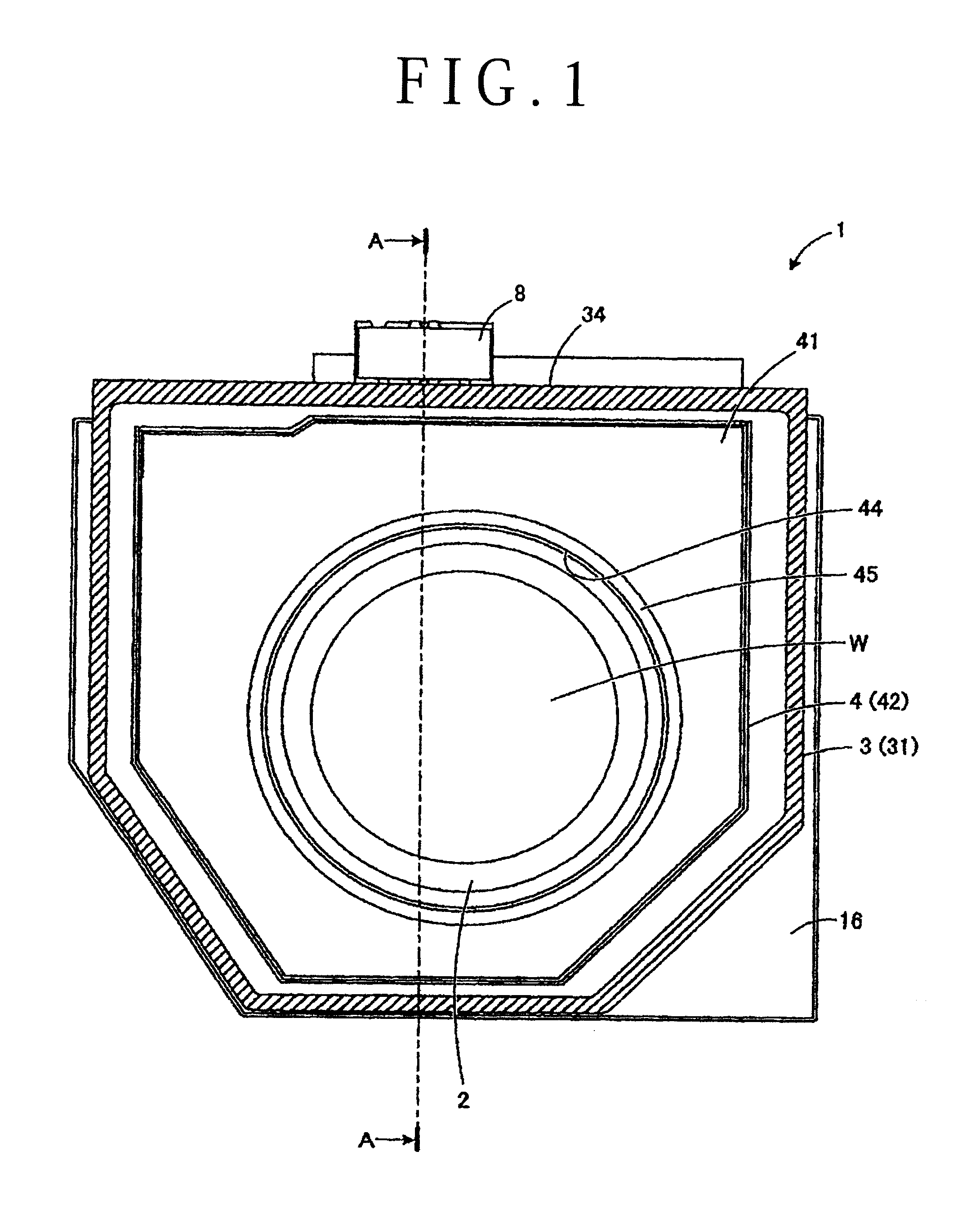

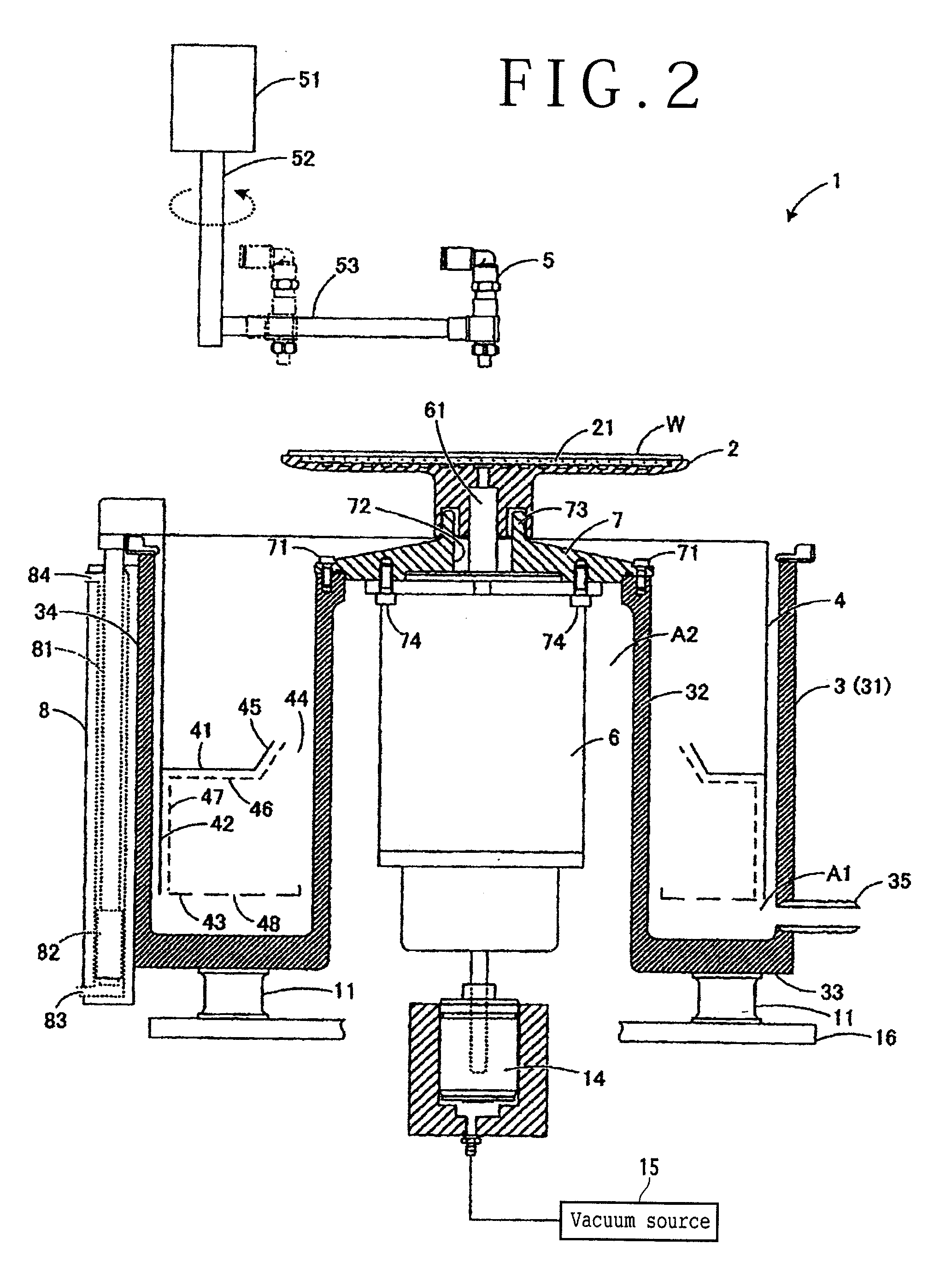

Cleaning apparatus

ActiveUS20150020853A1Promote absorptionAvoid easy dischargeSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringNozzle

A cleaning apparatus including a holding table for holding a plate-shaped workpiece, a cleaning nozzle for spraying a cleaning fluid to the plate-shaped workpiece, and a table cover for covering a circumference of the holding table. The table cover includes a top plate for covering an upper side of the holding table and a side plate for covering the circumference of the holding table. The table cover is provided with a netlike mesh sheet spaced from a lower surface of the top plate and another netlike mesh sheet spaced from an inner surface of the side plate.

Owner:DISCO CORP

Solder paste

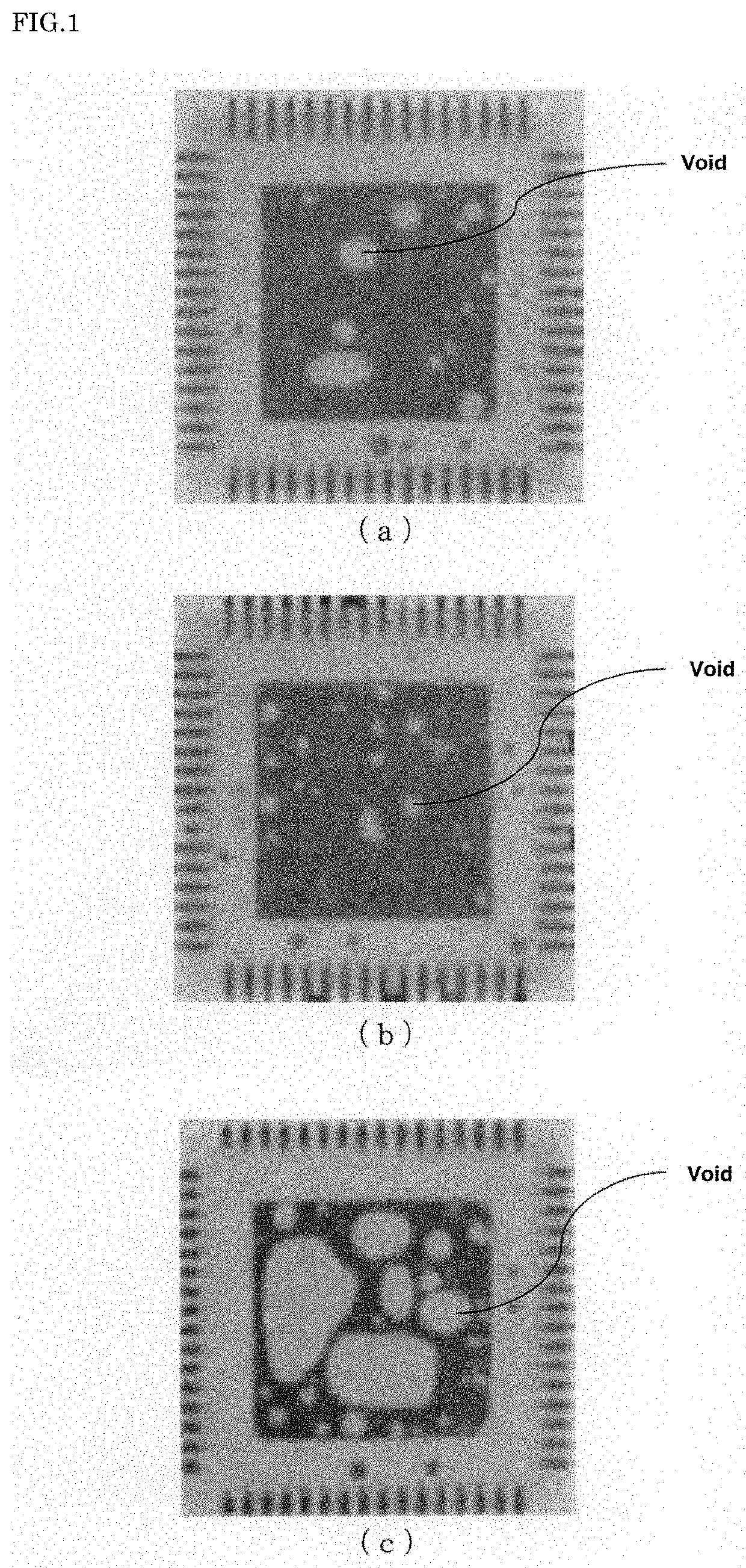

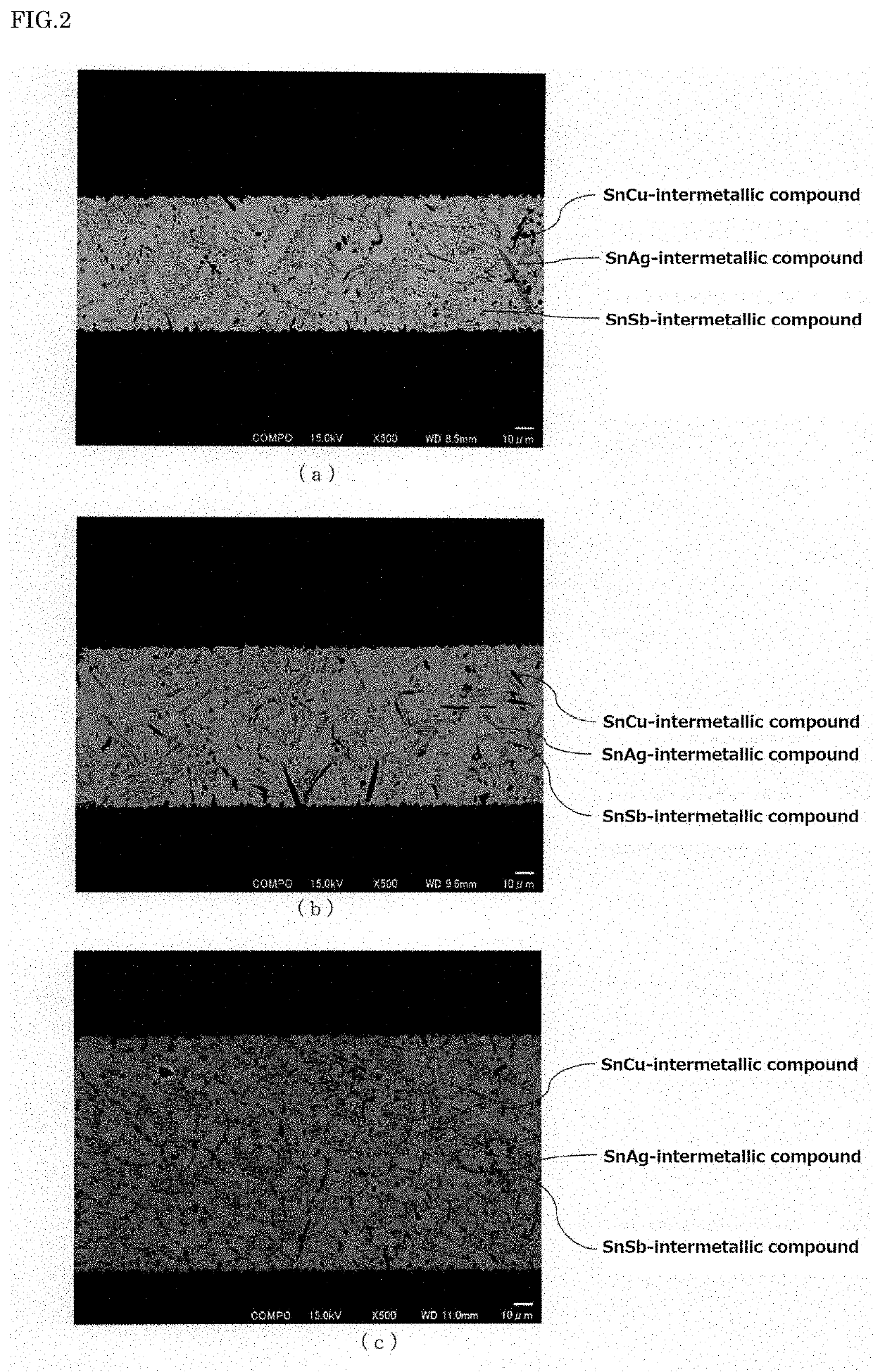

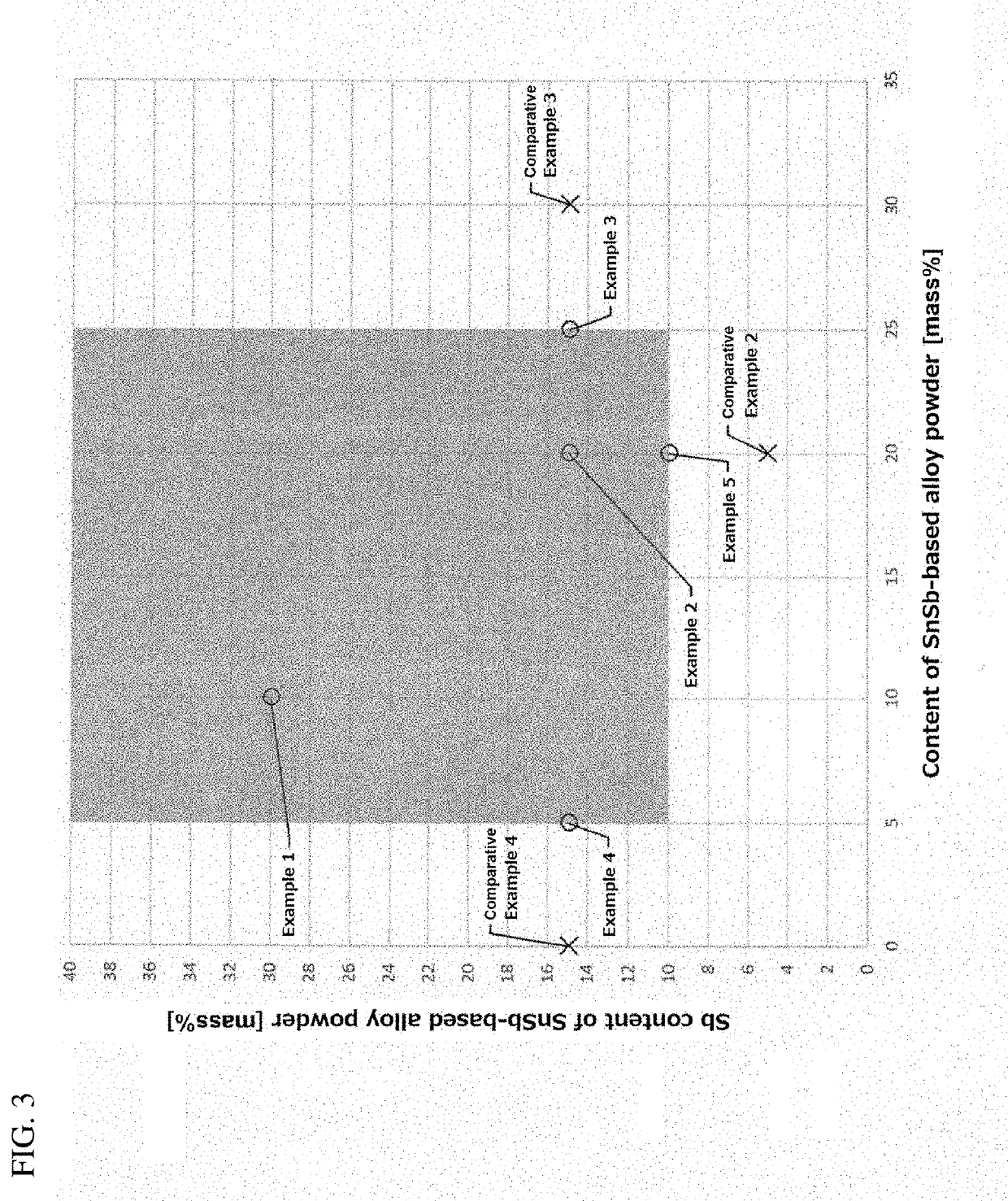

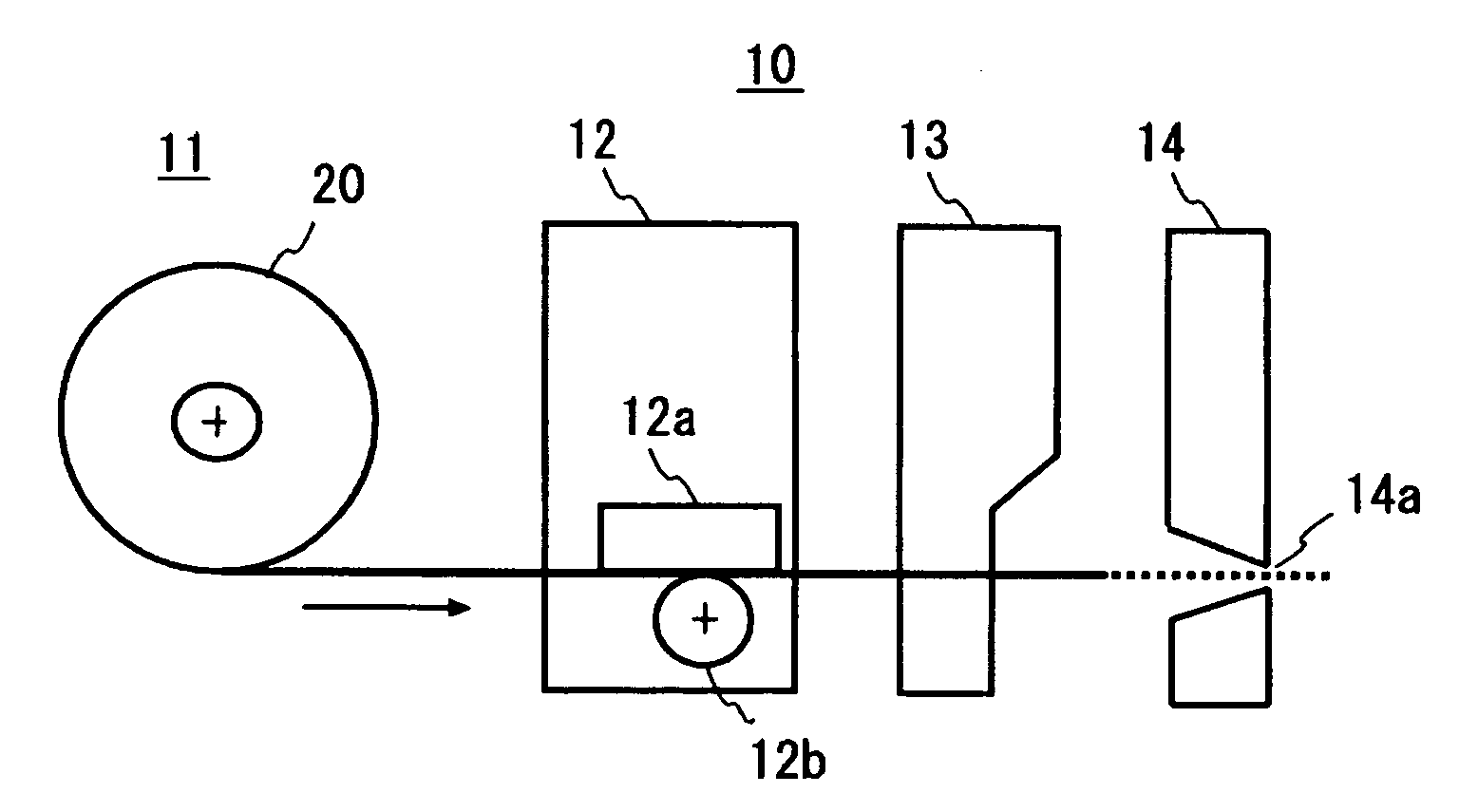

PendingUS20200398382A1Easy to oxidizeLow wettabilityWelding/cutting media/materialsSoldering mediaFluid phaseSolder paste

The present invention provides a solder paste that suppresses generation of voids and has excellent reliability. A solder paste contains Sn-based powder, SnSb-based alloy powder with Sn and 10 mass % or more of Sb, and flux, wherein a liquidus temperature of the SnSb-based alloy powder is higher than a liquidus temperature of the Sn-based powder, and a content ratio of the Sn-based powder and the SnSb-based alloy powder is 75:25 to 95:5. Preferably, the content ratio of the Sn-based powder to the SnSb-based alloy powder is 80:20 to 90:10.

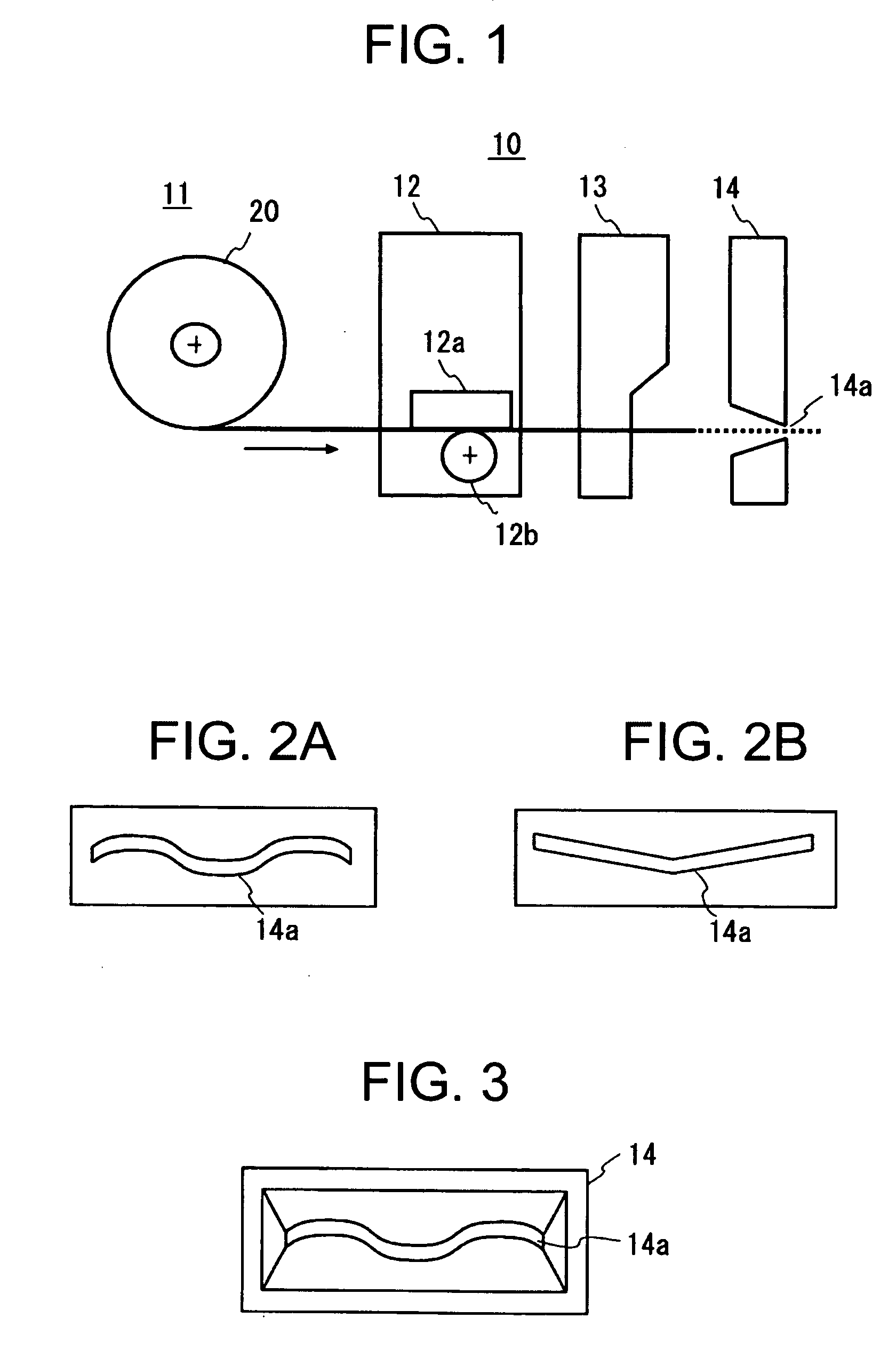

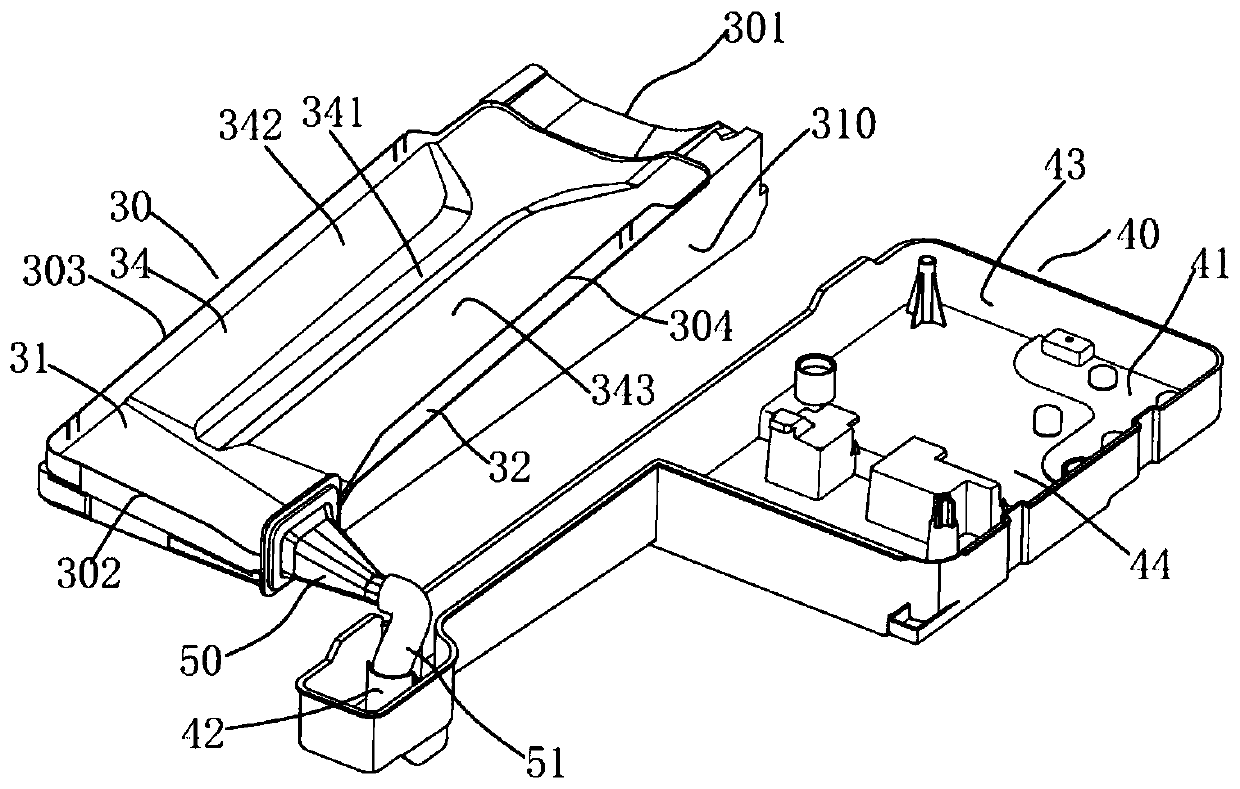

Printer and issuing apparatus

InactiveUS20090090774A1Increase elasticityPrevent insertionVisual presentation using printersOther printing apparatusEngineeringMechanical engineering

In order to provide a printer and an issuing apparatus for effectively preventing a user from mistakenly inserting a card into a discharge port of tickets or the like without increasing the number of components, in the printer or the issuing apparatus having the printer built-in, an outlet of a discharge port (14a) for discharging a printed sheet is formed into a shape other than a linear shape, such as a corrugated shape or a “dogleg” shape when seen from a front thereof. Further, it is desirable that the discharge port be formed to be gradually reduced in opening area from an inlet side thereof to an outlet side thereof.

Owner:SEIKO INSTR INC

Ink composition and ink jet recording method using same

ActiveUS9944810B2Low water absorptionImprove dispersion stabilityMeasurement apparatus componentsDuplicating/marking methodsVitrificationEmulsion

Owner:DNP FINE CHEMICALS CO LTD

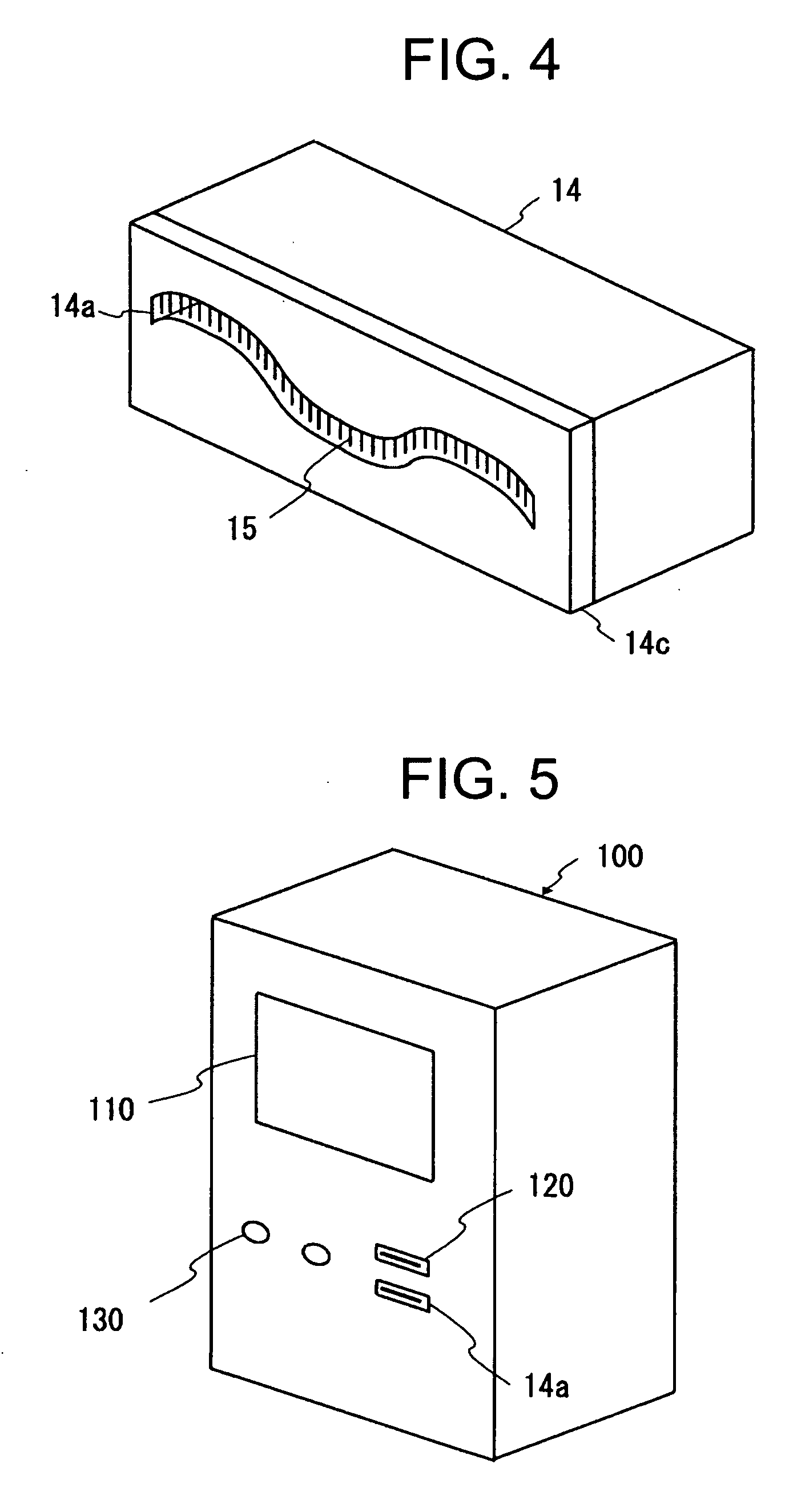

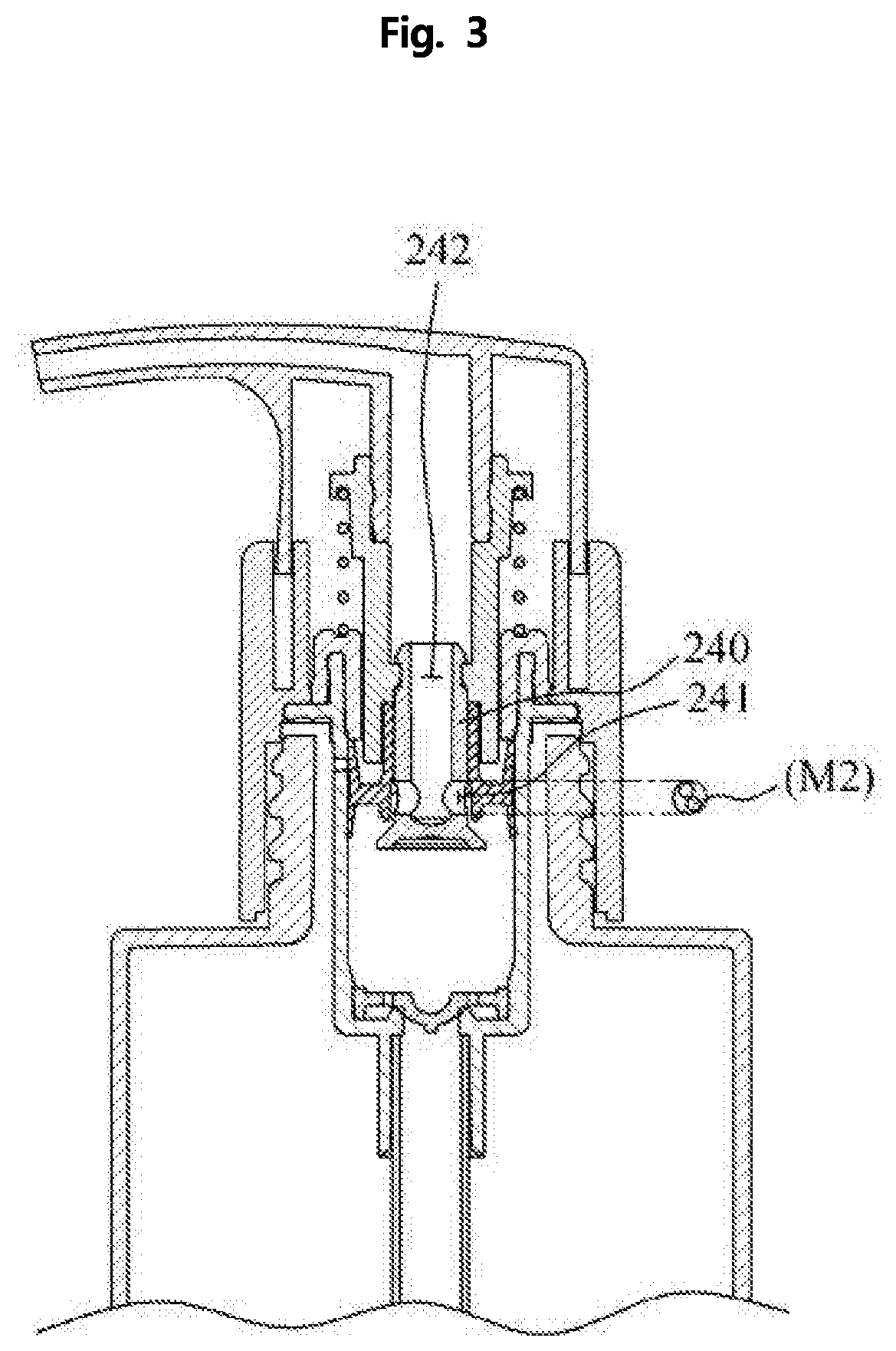

Bead Discharge Pump Container

ActiveUS20200008557A1Avoid easy dischargeSmall article dispensingPowdered material dispensingEngineeringCheck valve

The present invention disclosed herein relates to a bead discharge pump container, in particular, a bead discharge pump container, which has a cylinder-type pump structure having a check valve and designed by changing a check valve structure, a piton rod structure, a gap between a piston rod and a seal cap, and the like such that the bead contents are easily discharged without being burst.

Owner:YONWOO CO LTD

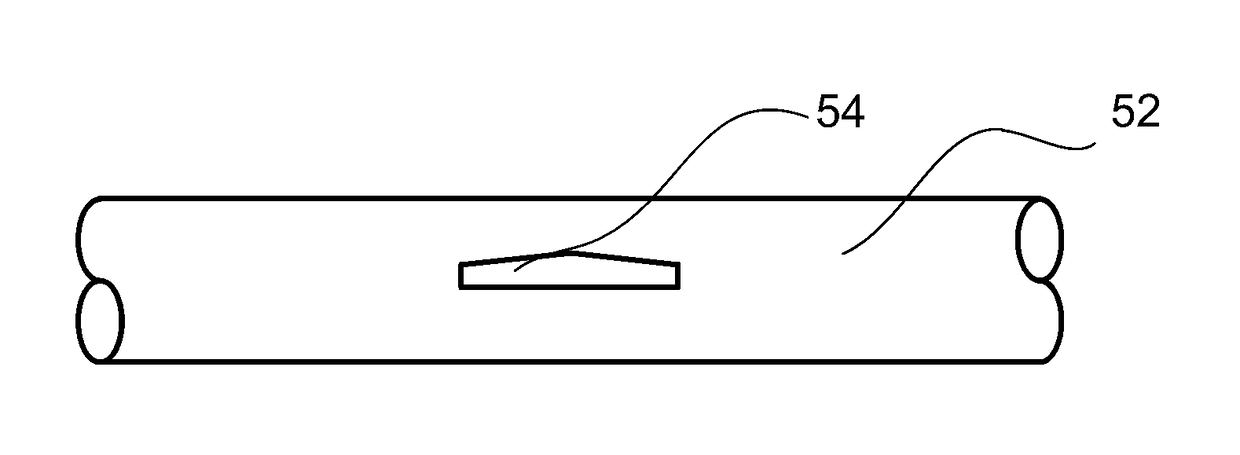

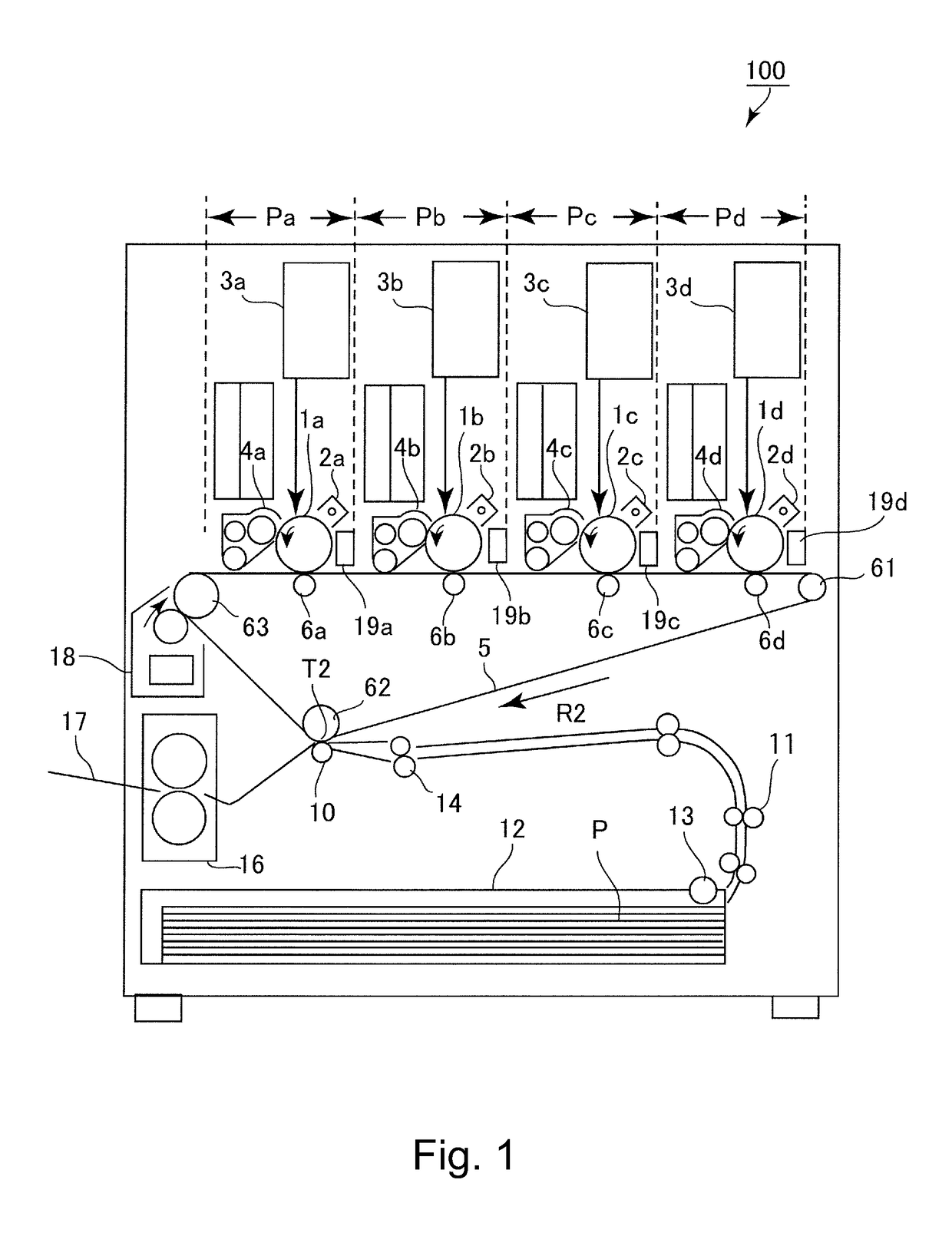

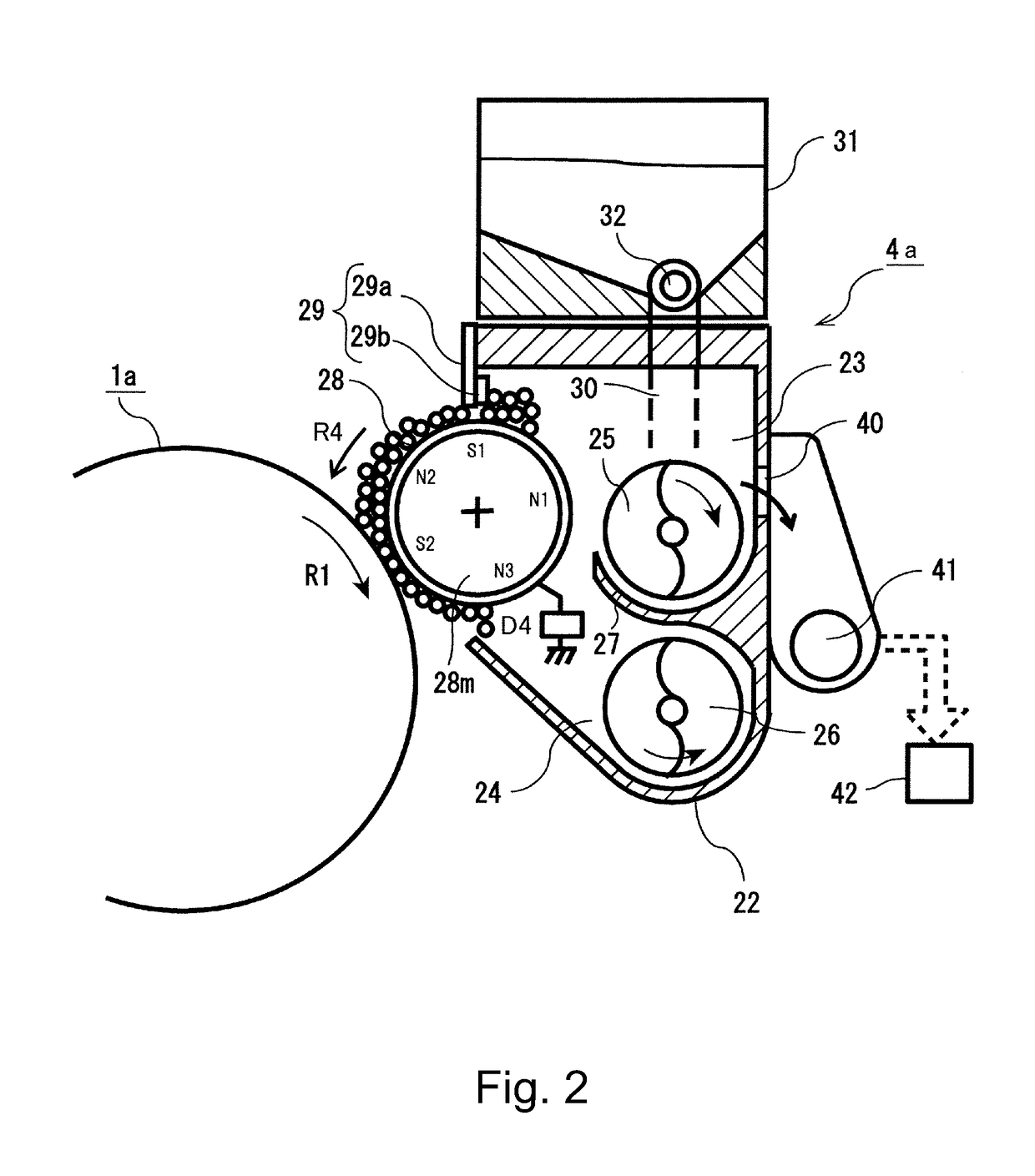

Developing device having rotating feeding member

ActiveUS9841704B2Avoid easy dischargeDecrease in flowabilityElectrographic process apparatusEngineeringMechanical engineering

A developing device includes a developer carrying member for carrying a developer; a circulation path along which the developer is circulated; a carrier supplying portion; a discharge opening, provided in the circulation path, through which a portion of the developer is to be overflowed and discharged; and a feeding member comprising a rotation shaft and a blade portion including a helical portion. An outer diameter of the blade portion formed in a first region including at least a portion opposing the discharge opening is smaller than that in a second region adjacent to the first region with respect to a rotation shaft direction. A smaller average angle formed between the rotation shaft and a developer feeding surface of the blade portion in the first region is smaller than that in the second region.

Owner:CANON KK

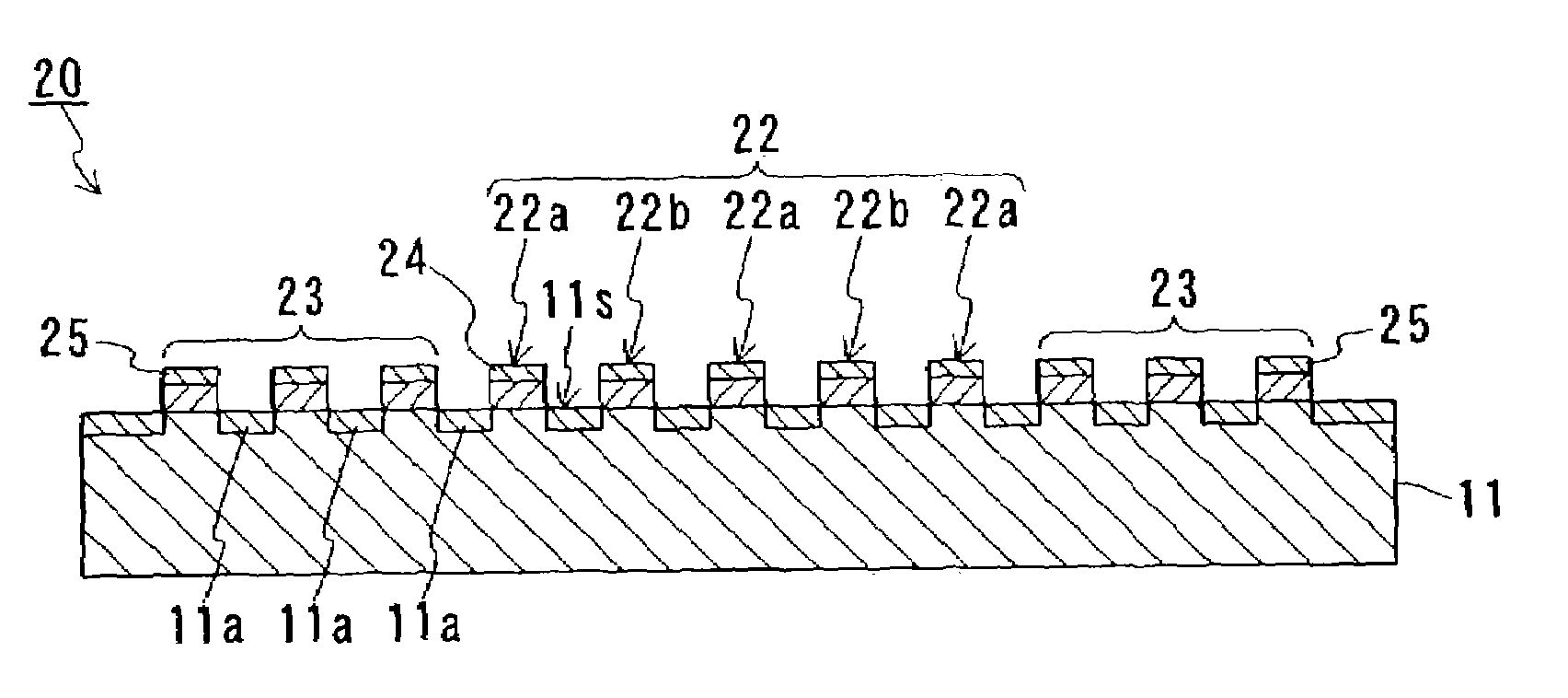

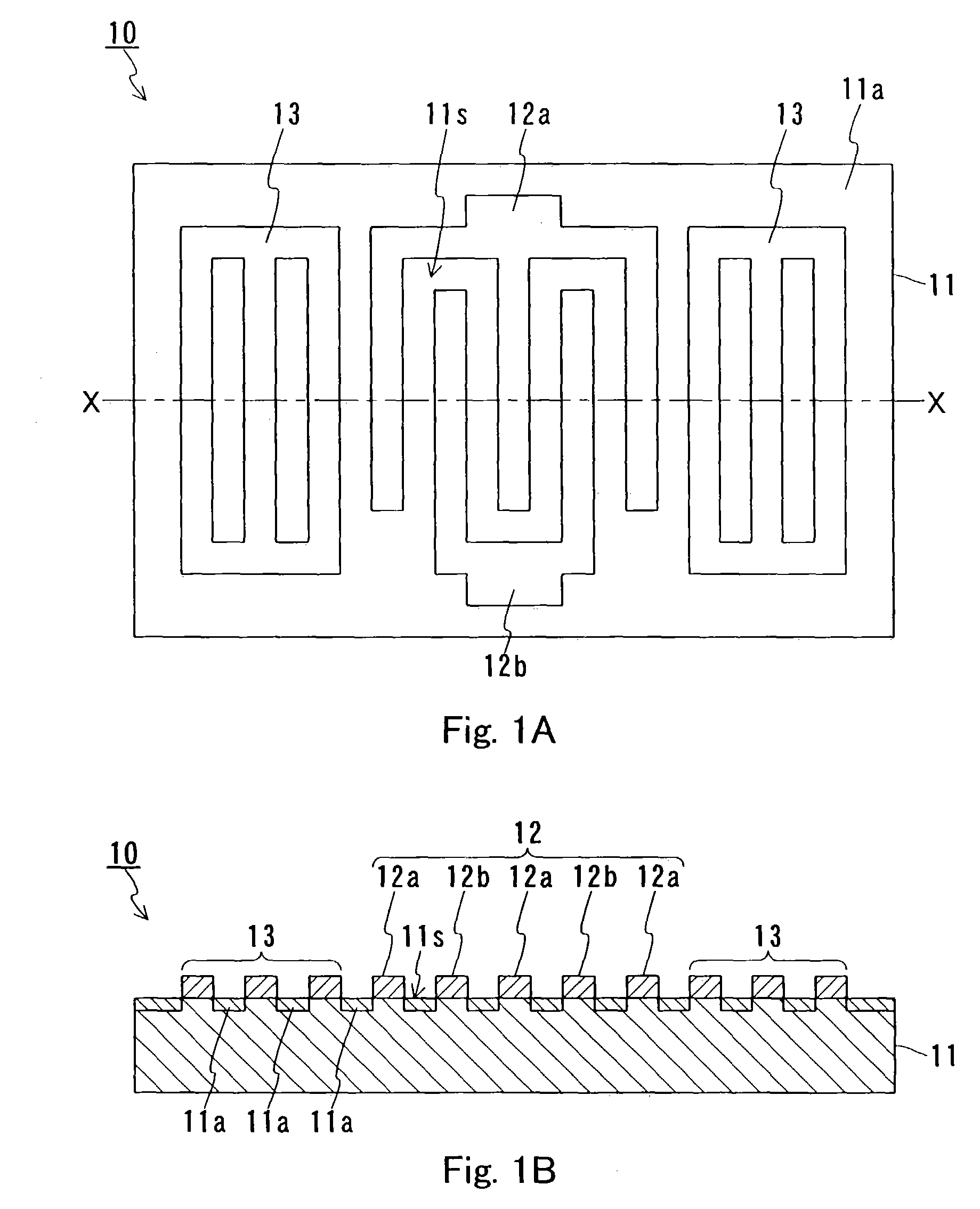

Surface acoustic wave device and method for producing the same

InactiveUS6984540B2Fine surfaceGood characteristic for propagationImpedence networksSolid-state devicesInterdigital transducerPiezoelectric substrate

A surface acoustic wave device includes a piezoelectric substrate, a first interdigital transducer and a second interdigital transducer formed on the substrate so that the first and second interdigital transducers are opposed to each other. The substrate includes a doping region that is doped with a substance in at least one form selected from the group consisting of atoms, molecules and clusters in a surface between the first and second interdigital transducers.

Owner:PANASONIC CORP

Display device

InactiveUS20070013289A1Prevent luminance from deterioratingGood effectDischarge tube luminescnet screensCathode ray tubes/electron beam tubesDisplay deviceElectron

The object of the invention is to provide a display device, particularly to provide a display device that inhibits discharge caused in the operation of the display device utilizing field emission and enables image display for a long time. Discharge between a metal-backed film and an electron emission element is inhibited by forming a plurality of spacers arranged in a display area between a front board and a back board by an insulating material, providing a conductive metallic film on side walls of the spacer and integrating a convex portion protruded on the side of the front board with the conductive metallic film.

Owner:HITACHI DISPLAYS

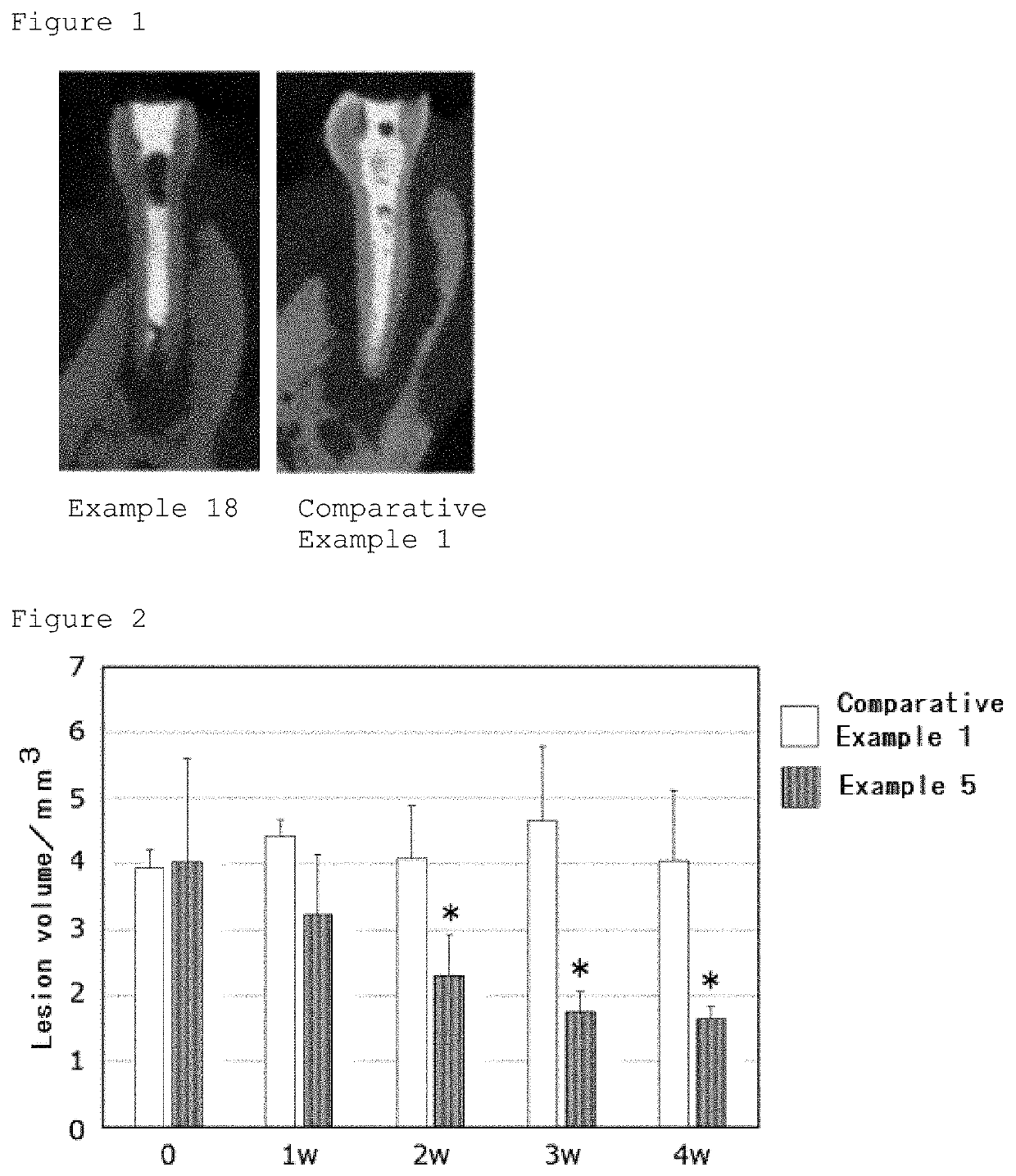

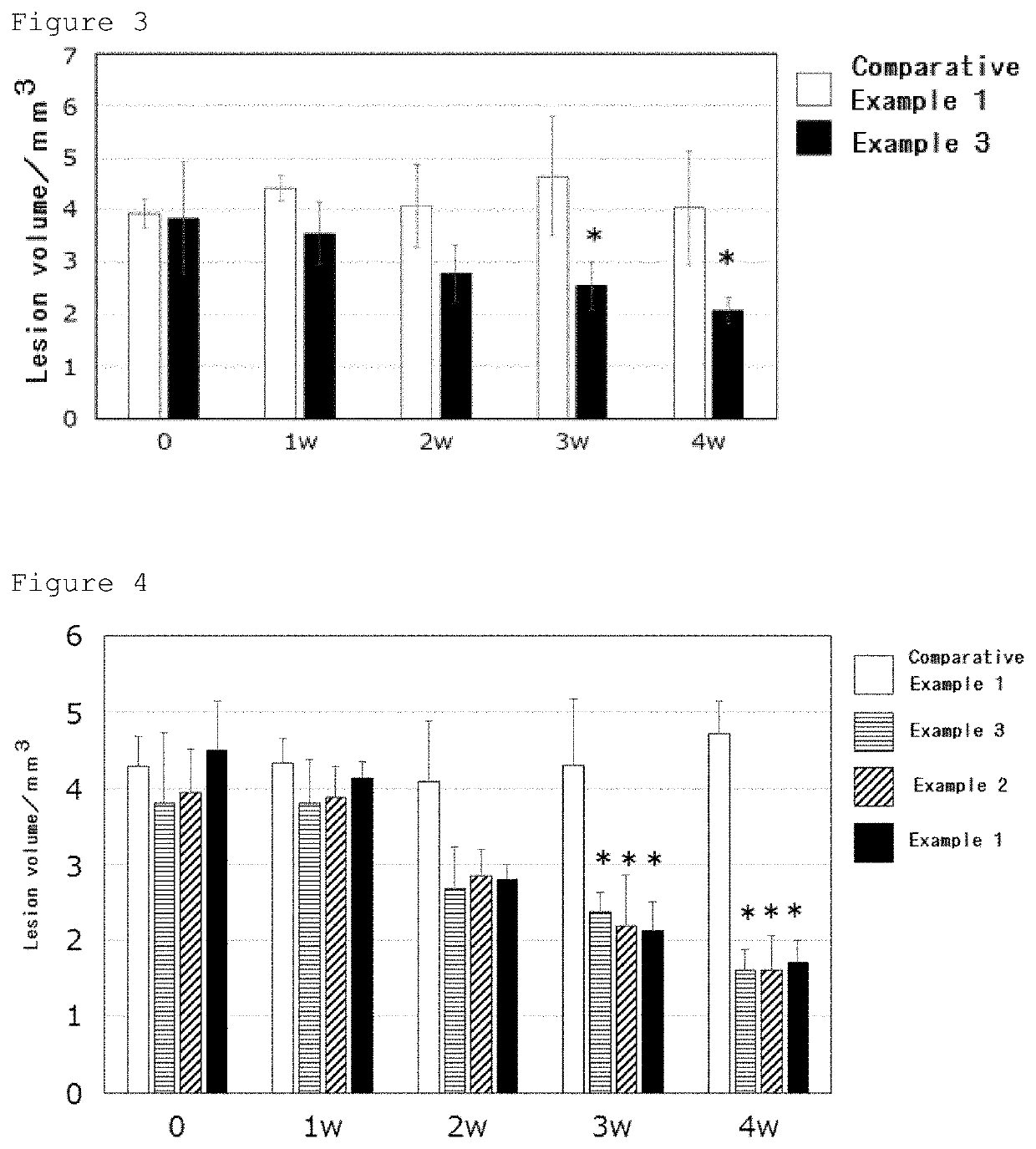

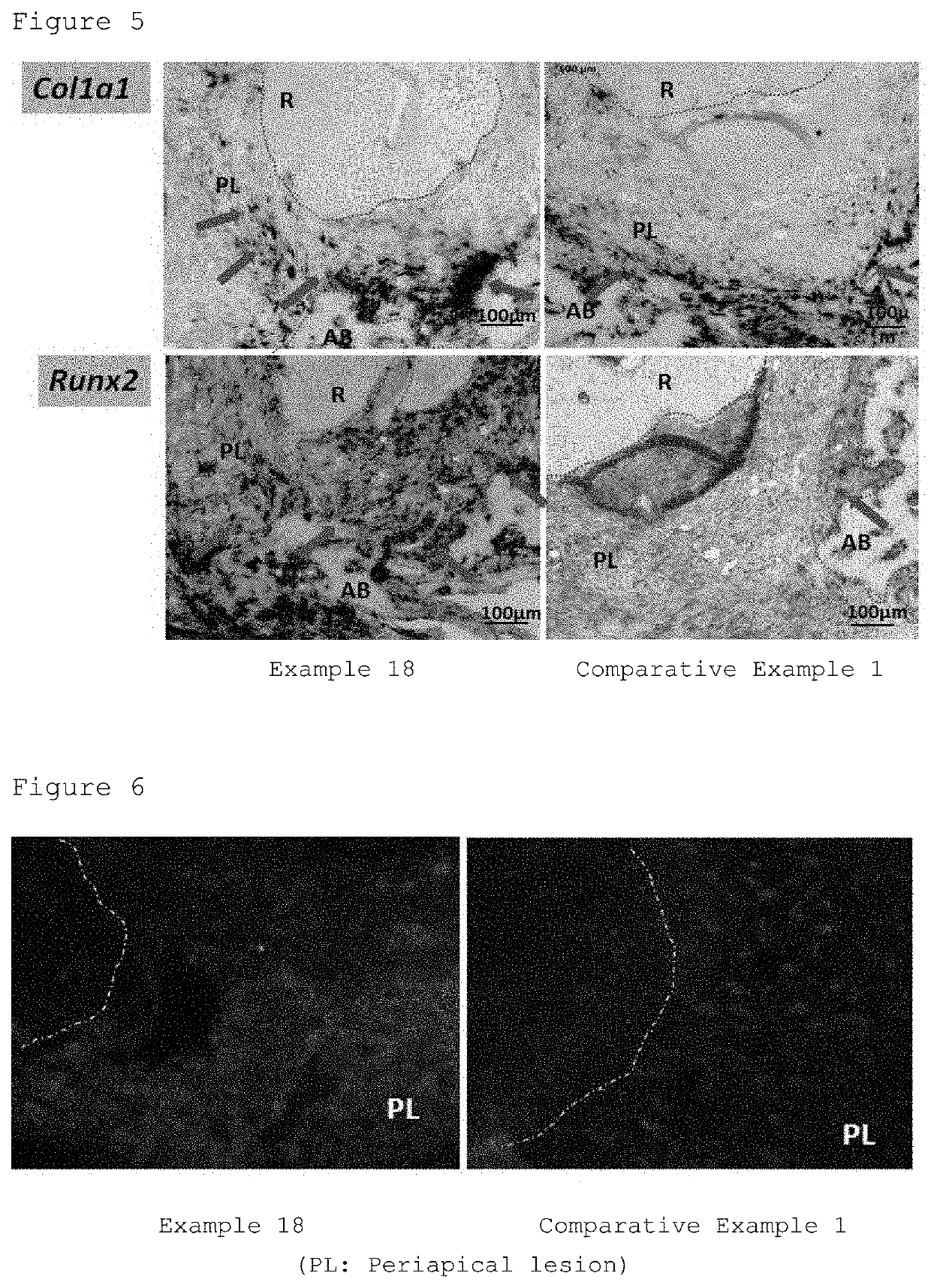

Dental root canal filling material composition

PendingUS20220211586A1Promotes and induces differentiationImprove immunityImpression capsTeeth fillingCalcium hydroxideVegetable oil

A root canal filling material composition comprising a lithium salt has higher healing promoting activity than conventional root canal filling material compositions. Preferable compositions are (1) a composition further comprising a calcium hydroxide, (2) a combination composition of a paste A containing a higher fatty acid and rosin and a paste B containing magnesium oxide and a vegetable oil, and one or both of the paste A and the paste B comprise the lithium salt, and (3) a combination composition of a paste A and a paste B and hardens by mixing the paste A and the paste B, one or both of the paste A and the paste B comprise the lithium salt, one or both of the paste A and the paste B comprise a glass powder, the glass powder contains calcium oxide and silicon dioxide in a total amount of 50 to 100% by weight relative to a total amount of the glass powder, and in the glass powder, a weight ratio of the calcium oxide to the silicon dioxide (calcium oxide:silicon dioxide) is 6:4 to 3:7.

Owner:NIPPON SHIKA YAKUHIN

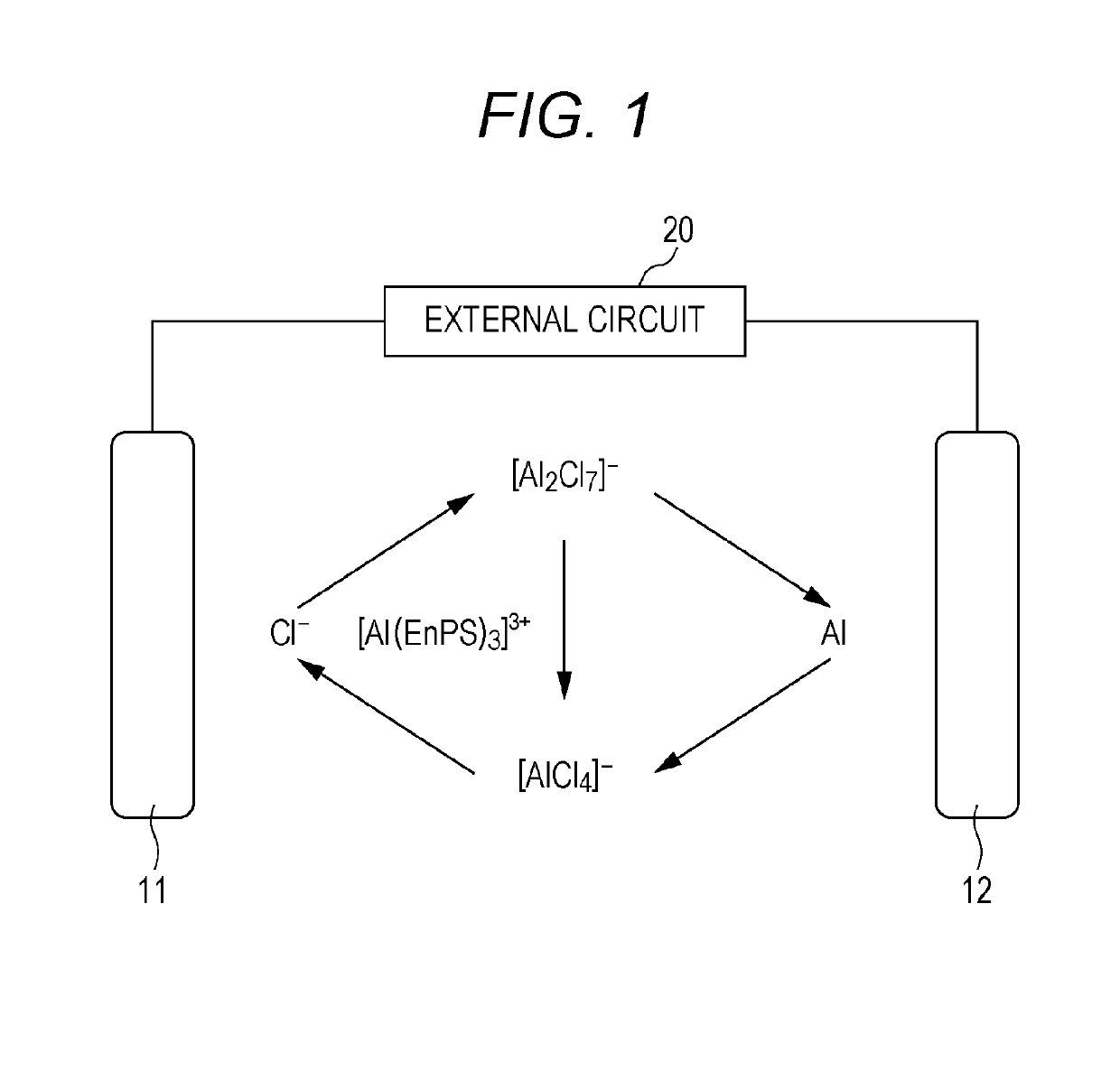

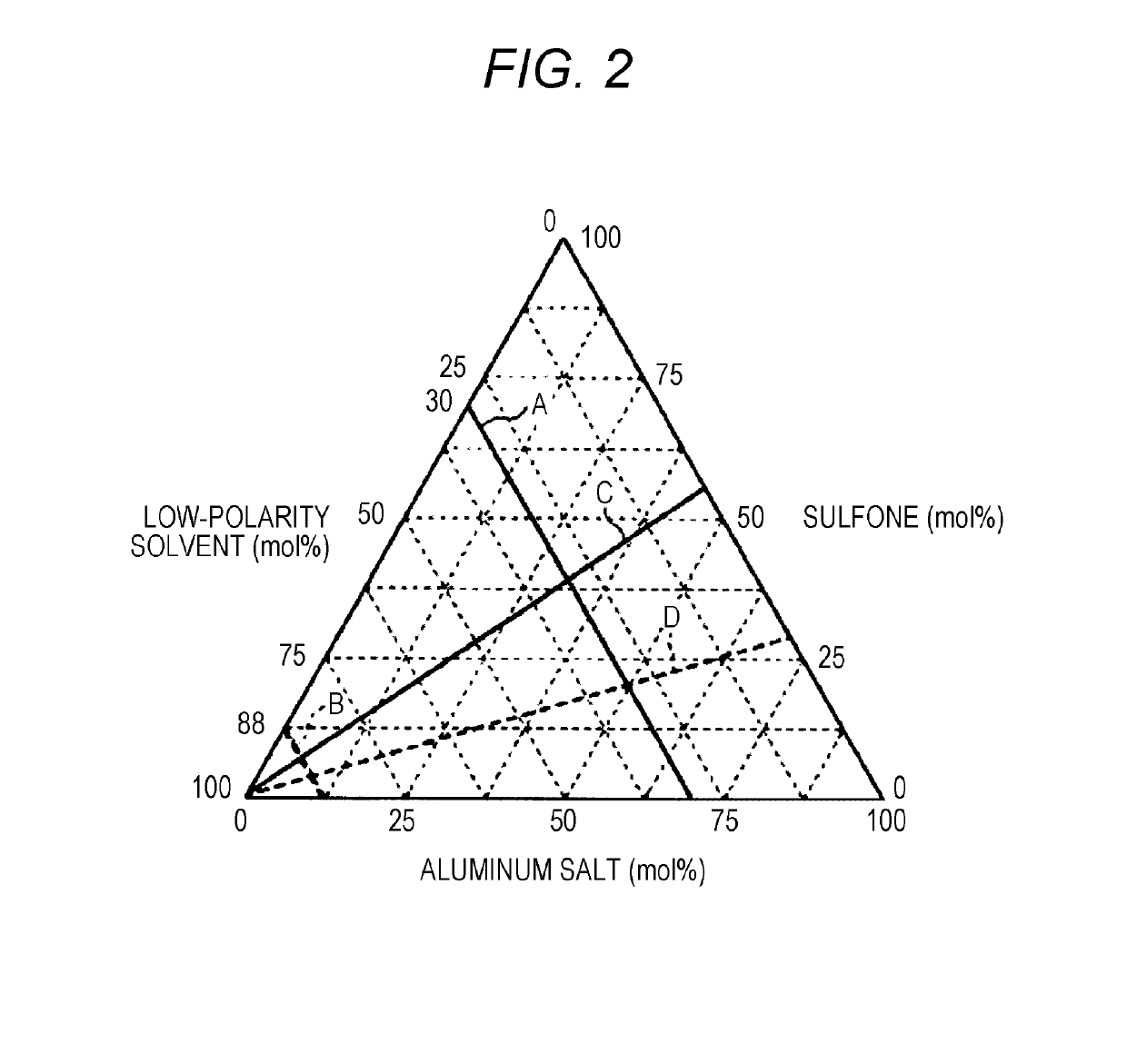

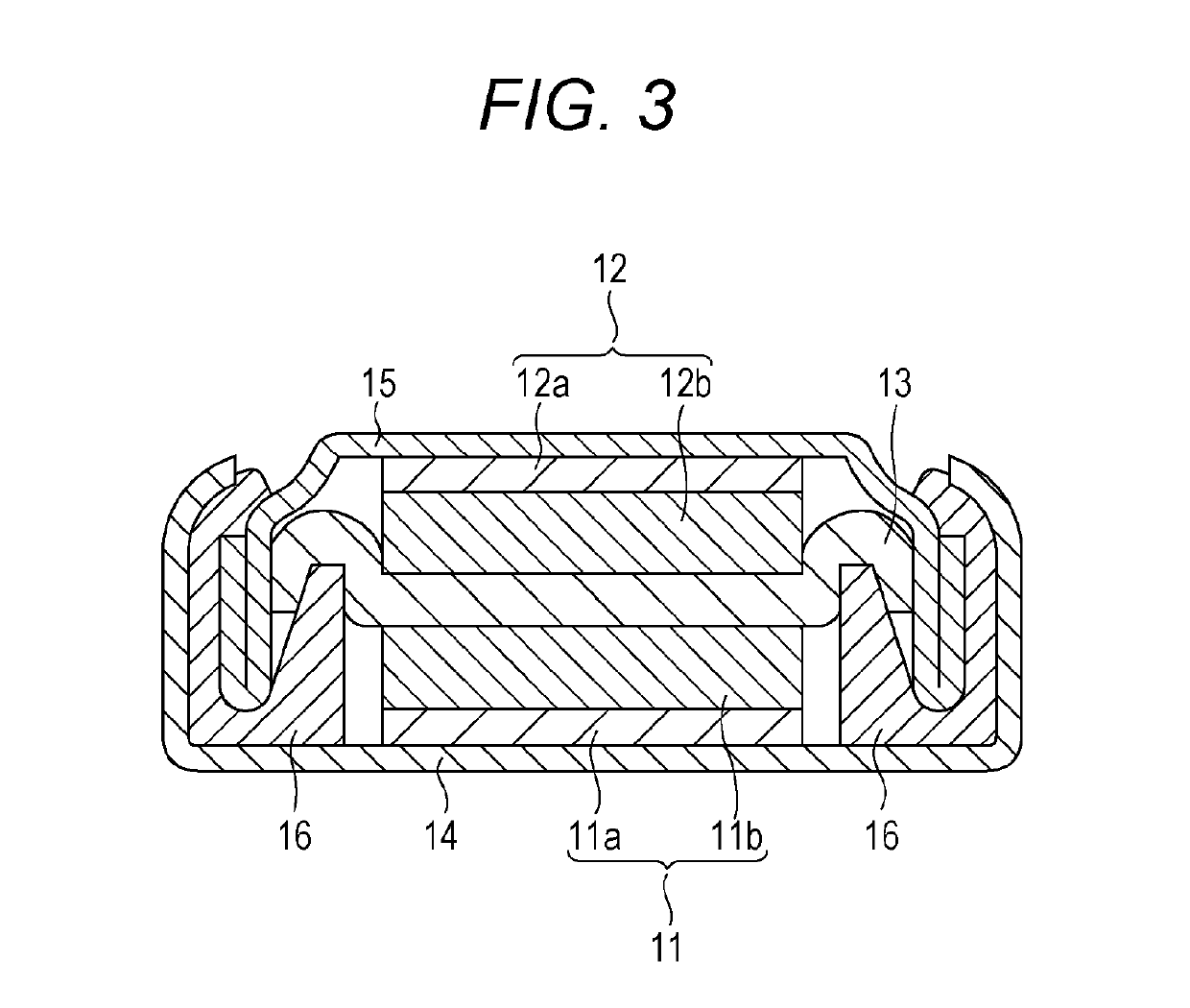

Aluminum secondary battery and electronic device

ActiveUS10355307B2Efficient charge and dischargePrevent materialSecondary cellsPositive electrodesSolventPolyaniline

An aluminum secondary battery includes a positive electrode 11, a negative electrode 12, and an electrolyte, wherein the positive electrode 11 includes an anion receptor such as polyaniline, the negative electrode 12 includes aluminum or an aluminum alloy, the electrolyte includes an aluminum salt, a sulfone, and a solvent with a dielectric constant of 20 or less, wherein the aluminum salt is typically AlCl3 or the like, the sulfone is typically ethyl n-propyl sulfone or the like, and the solvent with a dielectric constant of 20 or less is typically toluene or the like.

Owner:MURATA MFG CO LTD

Fuel cell system and mobile article

ActiveUS10008728B2The right amountAccurately determineFuel cell auxillariesVehicular energy storageFuel cellsBattery system

A fuel cell system, which includes a fuel cell for generating electric power and which discharges externally water remaining in the fuel cell by supplying a gas to the fuel cell, includes discharge amount estimating means, for estimating, based on the state of the fuel cell (the amount of residual water or an inclination angle), the amount of water to be discharged from the fuel cell.

Owner:TOYOTA JIDOSHA KK

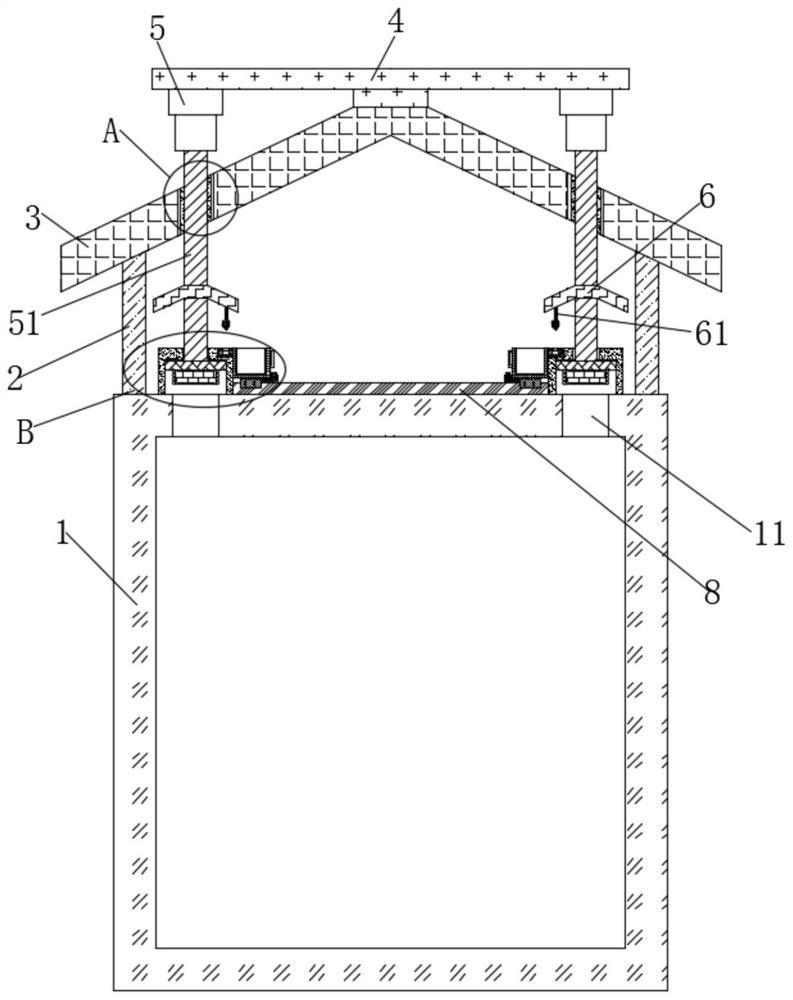

Quick power recovery mechanism

PendingCN113507046AAchieve a blocking effectAvoid problems with access to the interior of the enclosureSubstation/switching arrangement casingsEngineeringMechanical engineering

The invention relates to the technical field of power recovery mechanisms, in particular to a quick power recovery mechanism which comprises a box body, heat dissipation holes are formed in the positions, close to the two sides, of the outer surface of the top end of the box body, mounting rods are fixedly mounted at the positions, close to the two sides, of the top end of the box body, and the top ends of the two mounting rods are fixed to the outer surface of the bottom end of a waterproof cover. Two movable grooves are formed in the waterproof cover, sponge layers are arranged on the inner walls of the two movable grooves, a top plate is fixedly installed at the top end of the waterproof cover, and electric pushing machines are fixedly installed at the positions, close to the two sides, of the bottom end of the top plate. Under the action of two groups of electric pushers, the corresponding push rods can move downwards, so that the corresponding mounting plates and pistons can move downwards until the corresponding mounting plates and pistons move into the corresponding heat dissipation holes, and finally the effect of blocking the corresponding heat dissipation holes is achieved; and therefore, the problem that rainwater enters the box body through the heat dissipation holes is avoided.

Owner:麦美月

Sn—Sb—Ni ternary compound and method for forming the same

ActiveUS9299983B2Improve charging capacityImprove cycle performanceCell electrodesWelding/cutting media/materialsDiffusion methodsSkutterudite

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

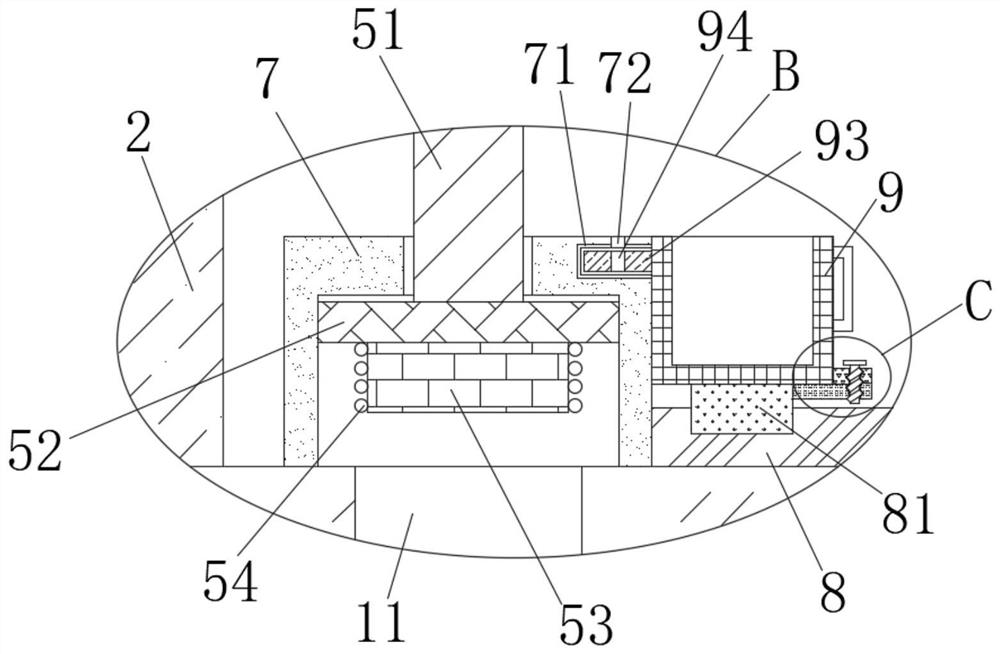

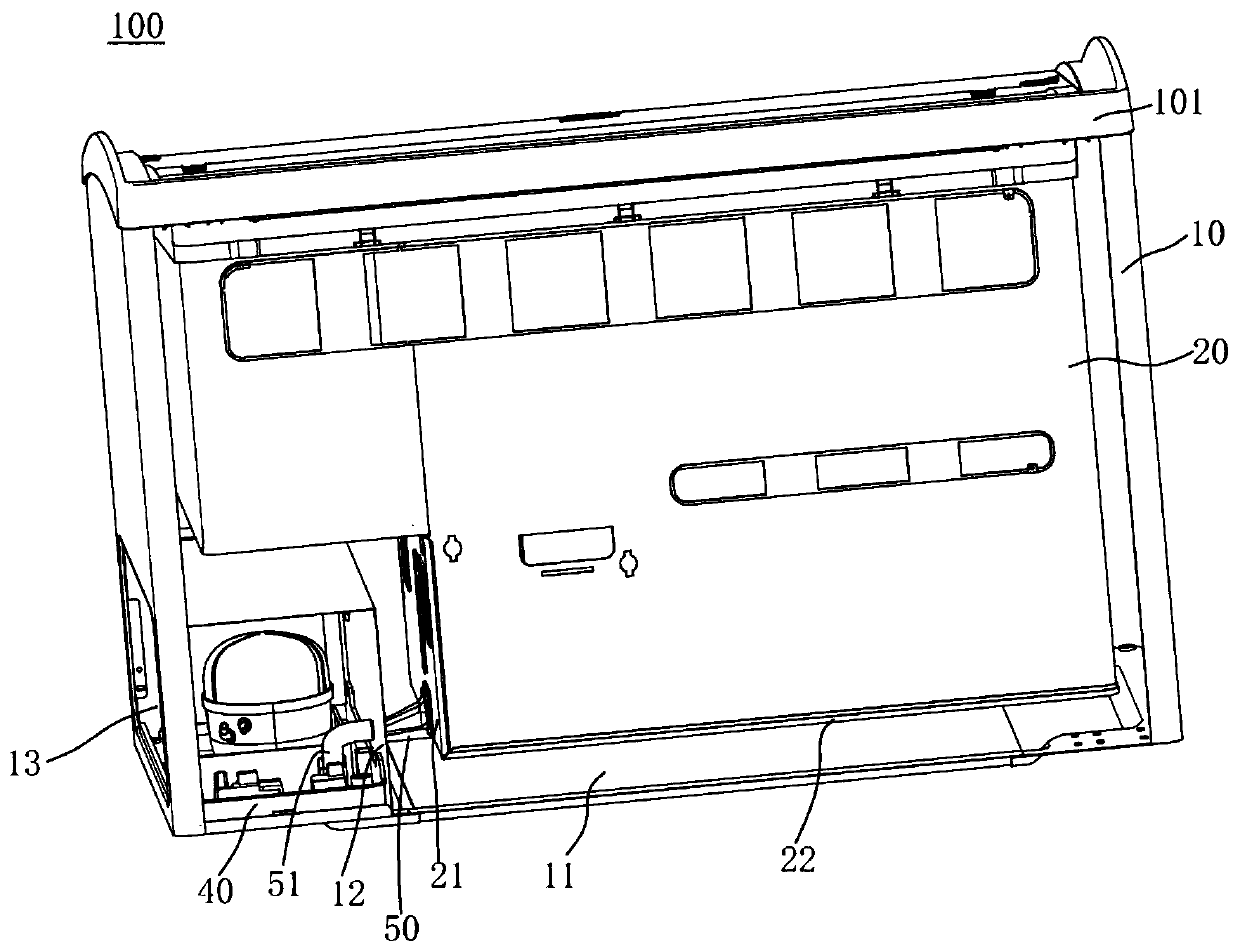

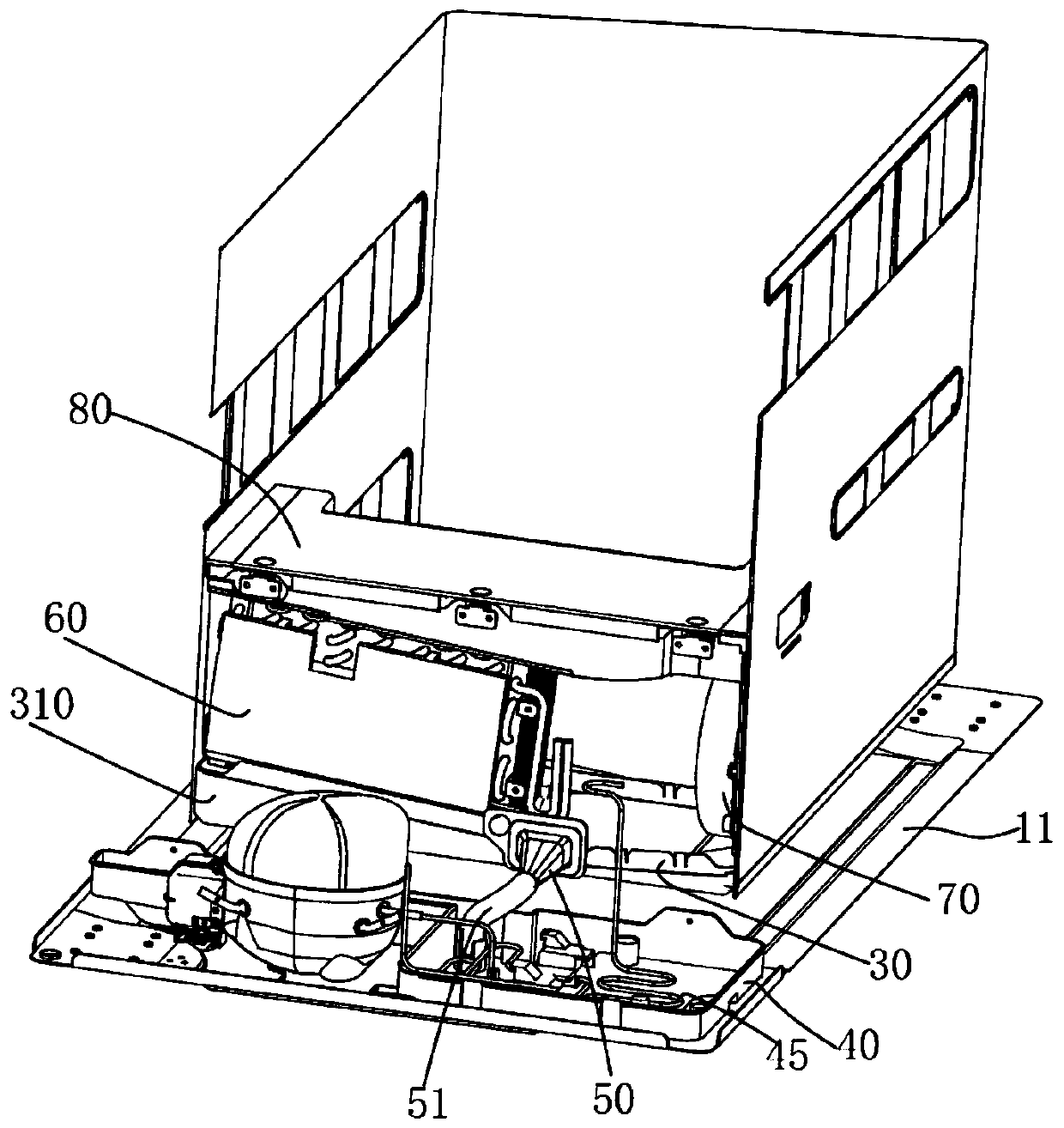

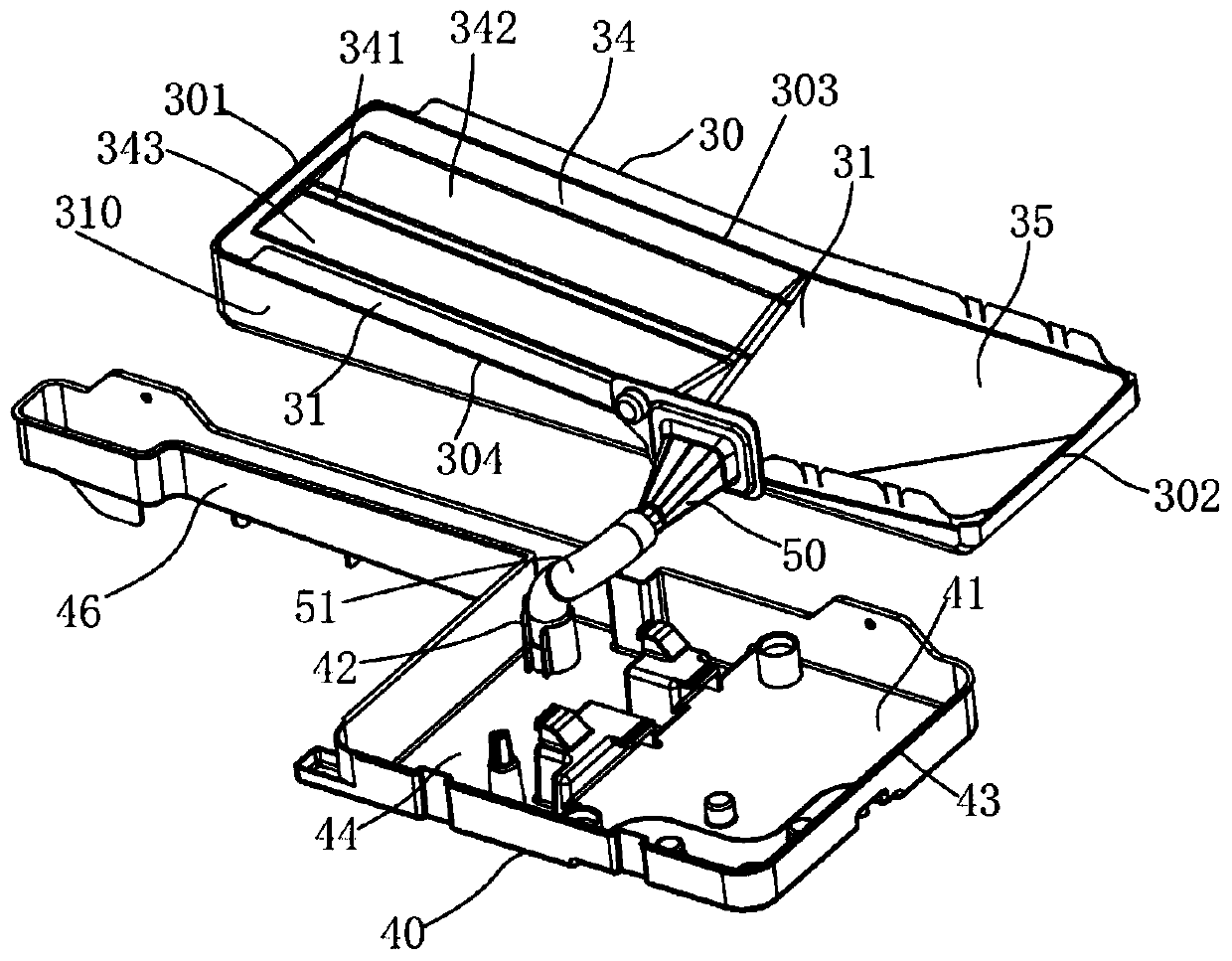

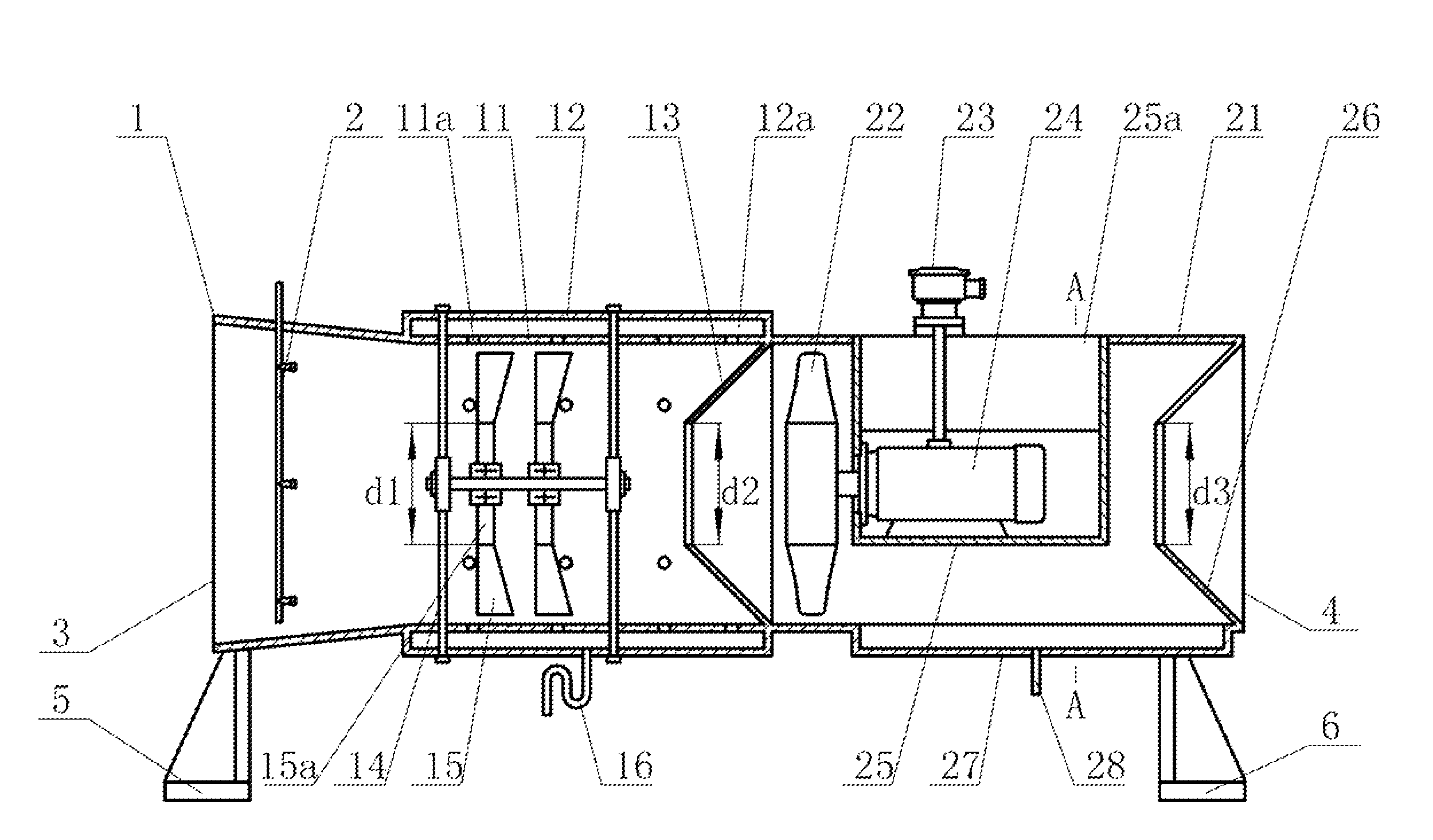

Drainage structure and horizontal refrigerator

PendingCN111380271AAvoid easy dischargeConvenient physical examinationLighting and heating apparatusDomestic refrigeratorsEvaporating dishStructural engineering

The invention provides a drainage structure and a horizontal refrigerator. The horizontal refrigerator comprises a refrigerator shell and an inner container, and the inner container is arranged in therefrigerator shell; the drainage structure comprises a water receiving box, an evaporating dish, a partition plate and a drainage pipe assembly; the water receiving box is arranged in the inner container; the evaporating dish is arranged in a compressor bin of the refrigerator shell and is fixed on a refrigerator shell bottom plate of the refrigerator shell; the partition plate is arranged in thecompressor bin and located between the water receiving box and the evaporating dish; the drainage pipe assembly communicates with the water receiving box and the evaporating dish, and the drainage pipe assembly comprises a drainage connecting pipe; the inner container comprises an inner container bottom plate, a step part is formed on the inner container bottom plate, and the step part is locatedbetween the water receiving box and the partition plate; and the drainage connecting pipe is located between the step part and the partition plate.

Owner:QINGDAO HAIER SPECIAL ICEBOX

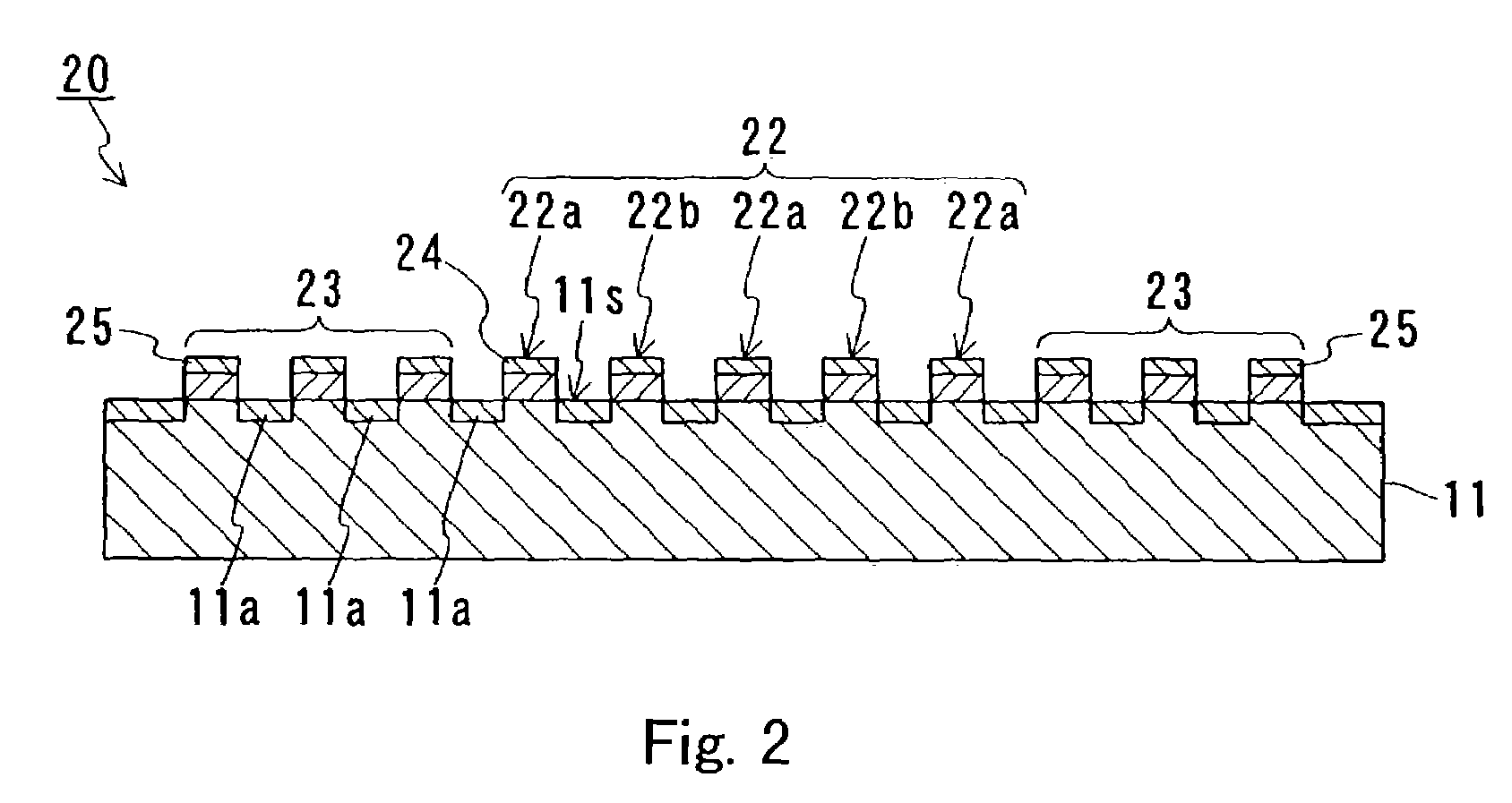

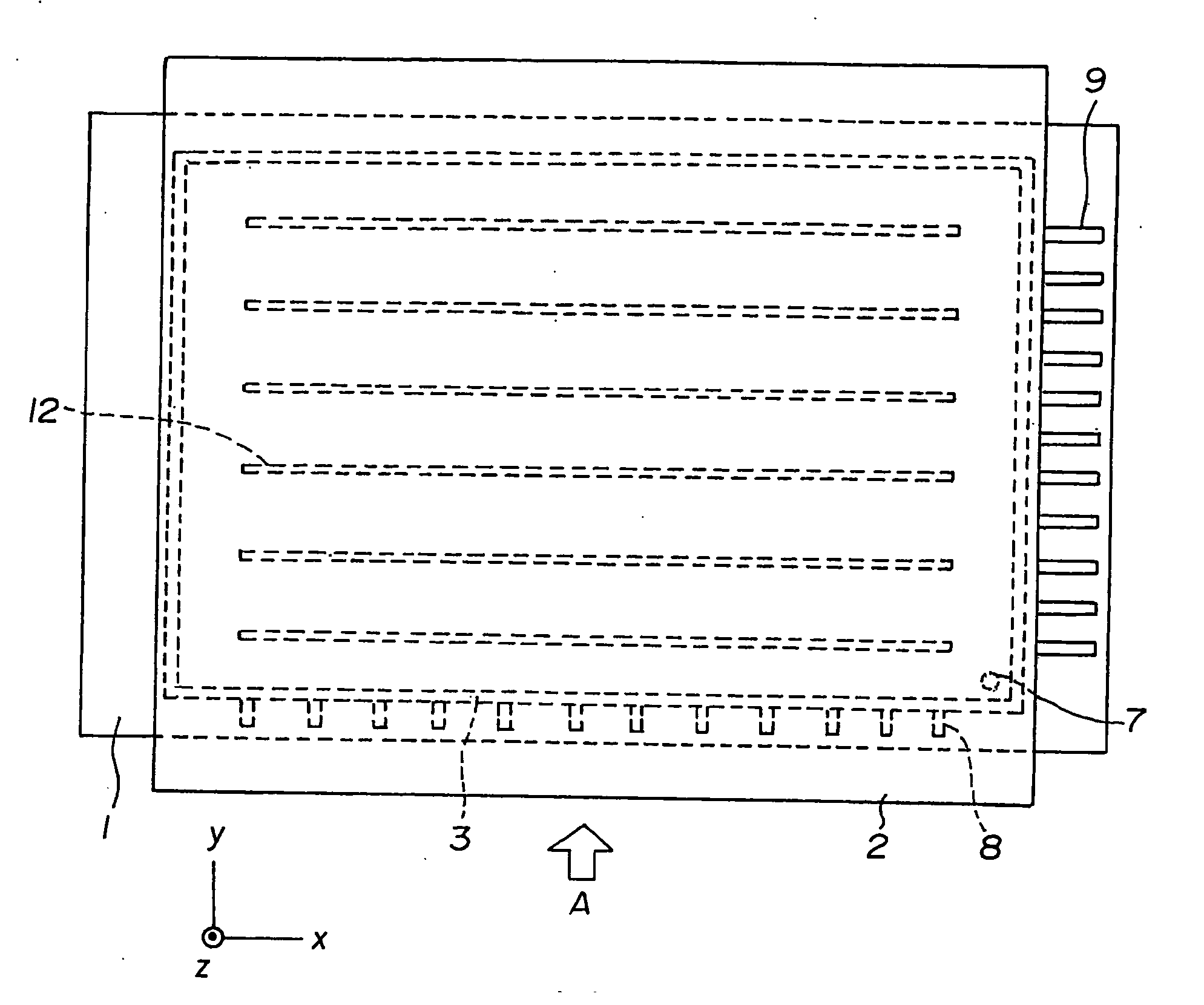

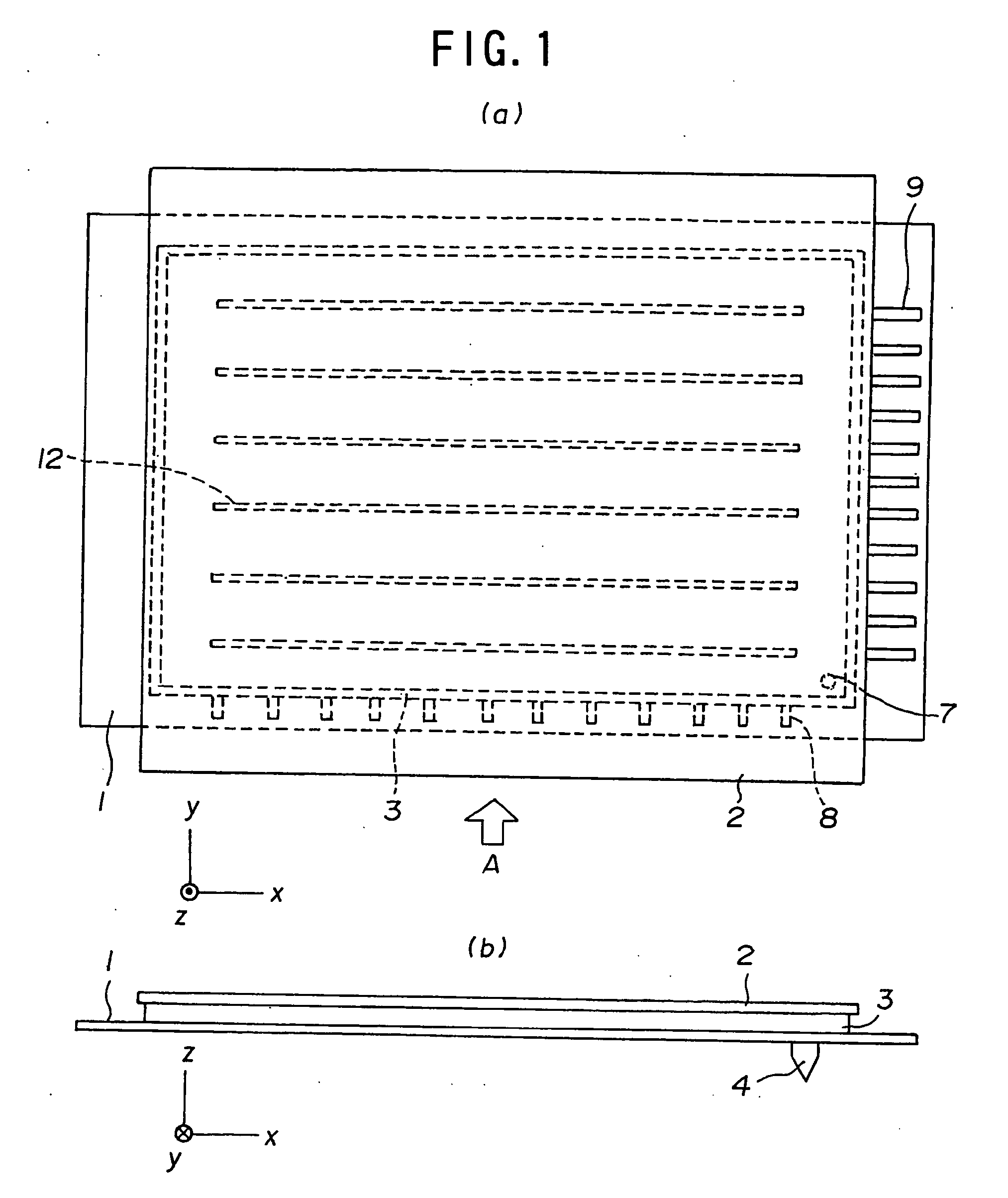

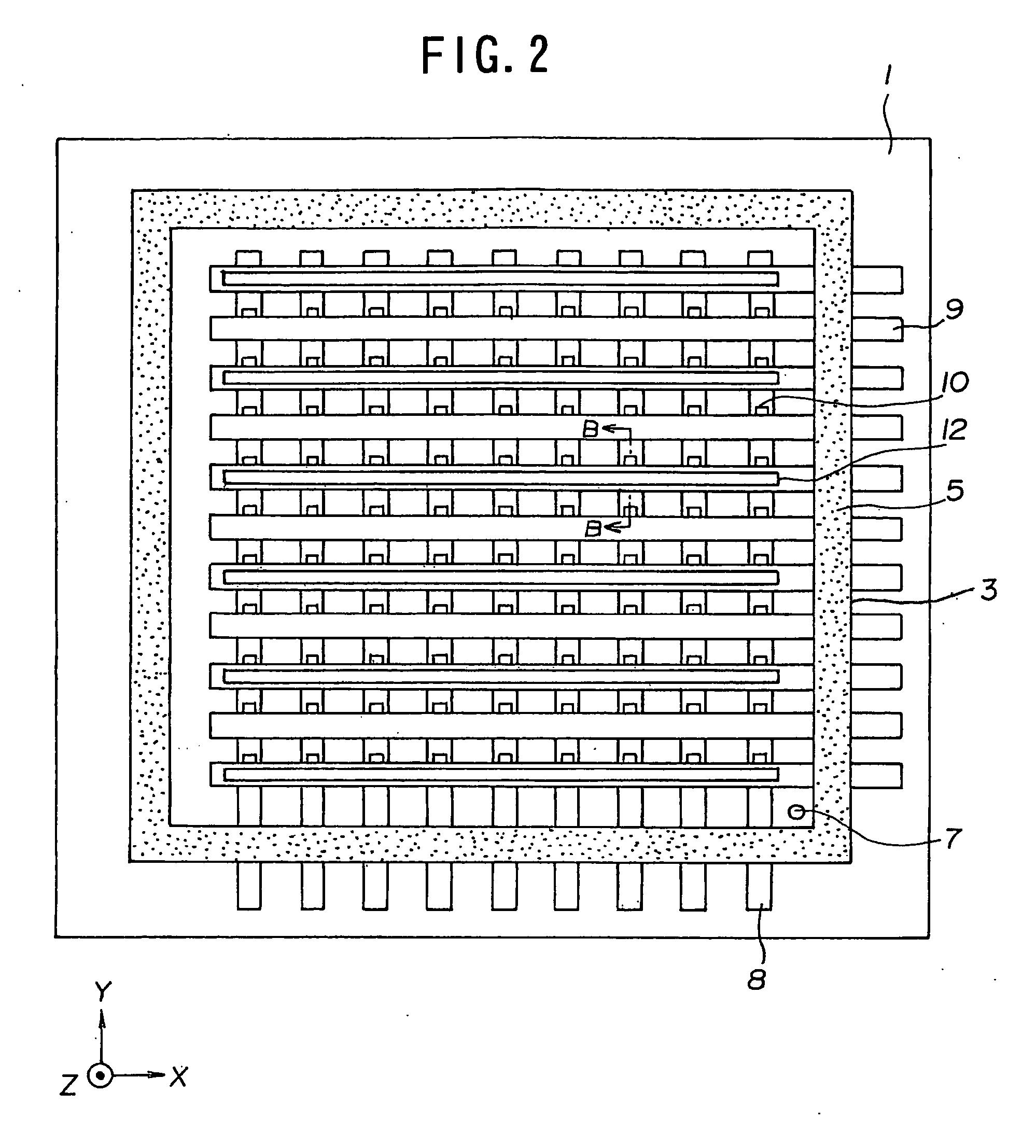

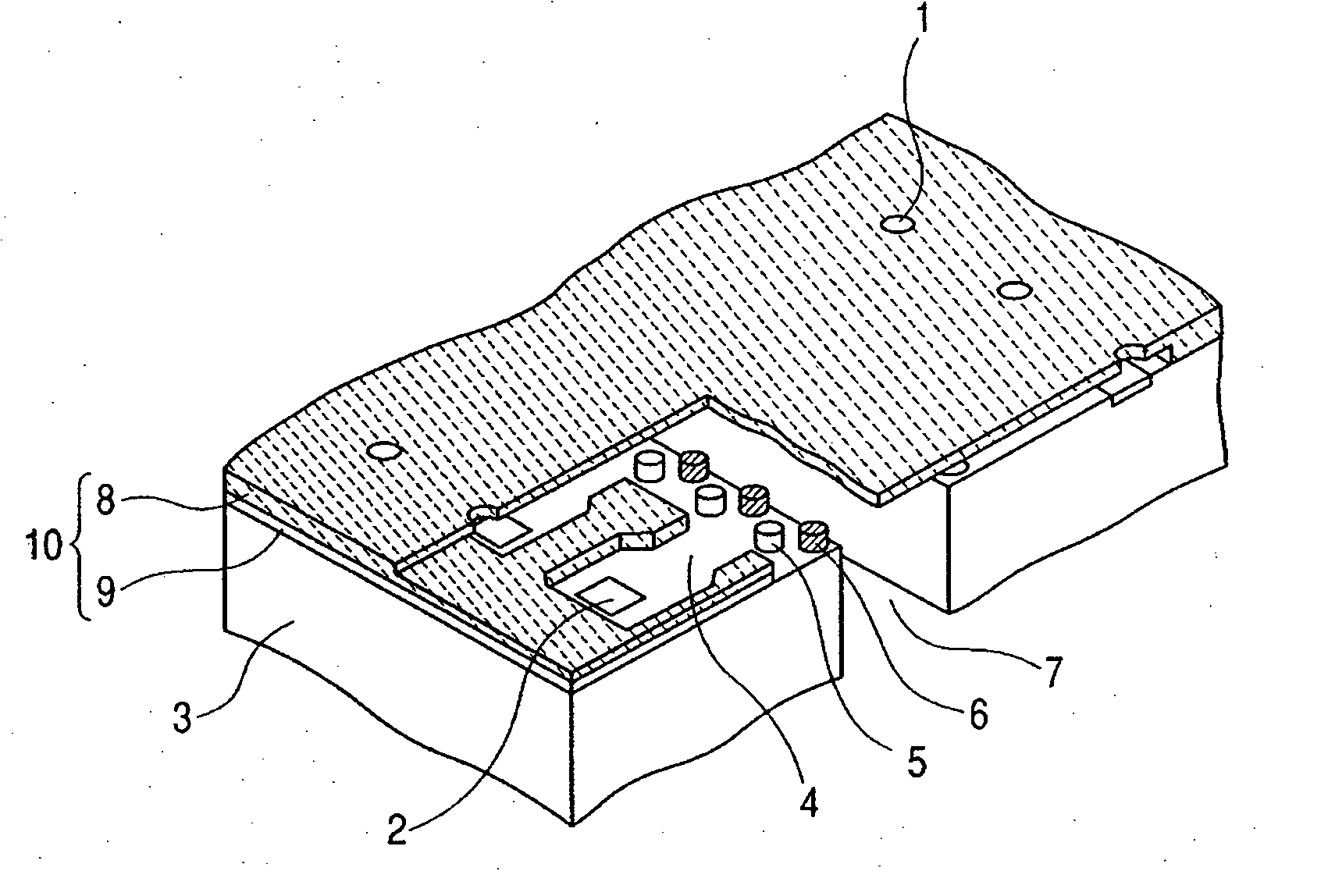

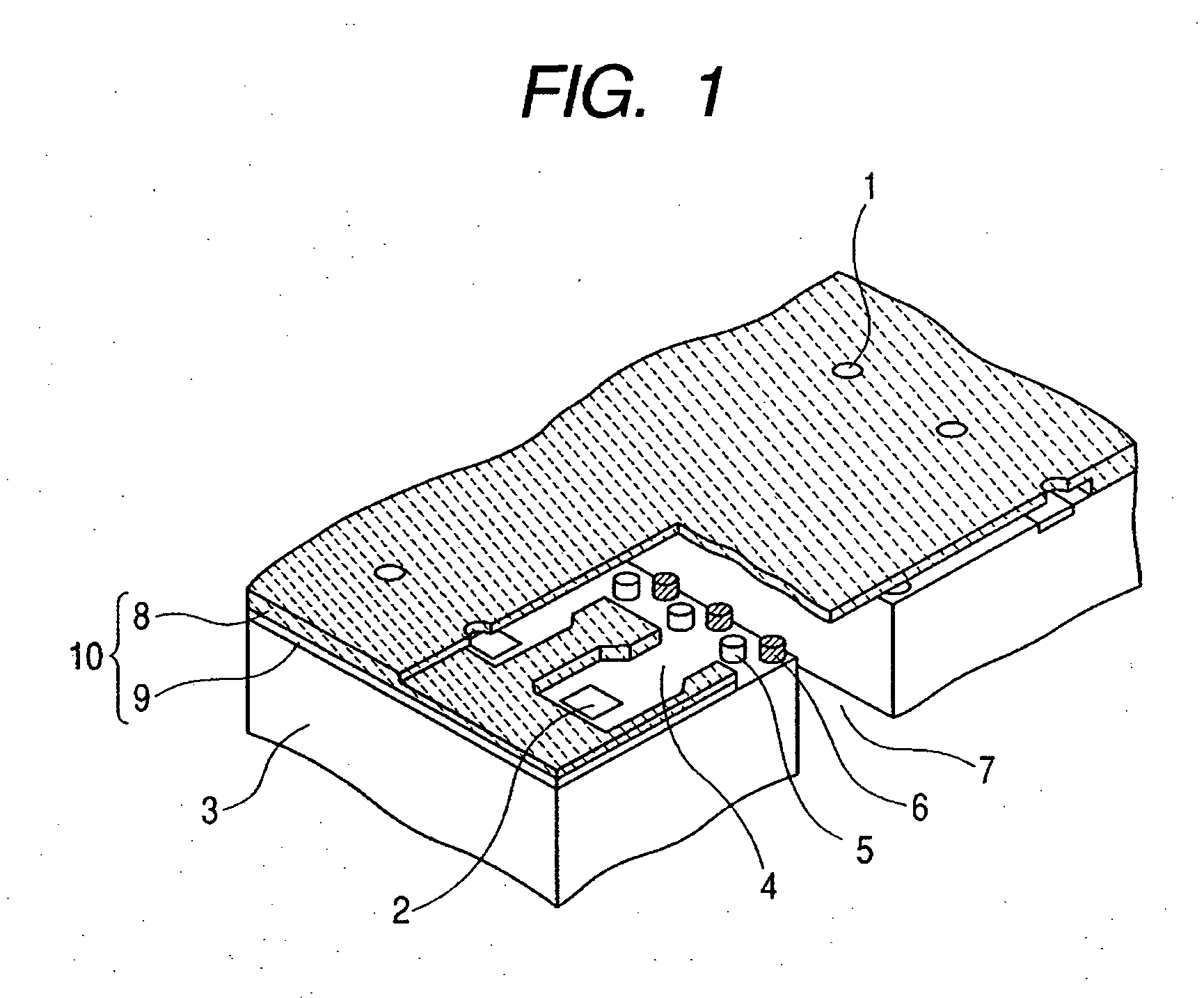

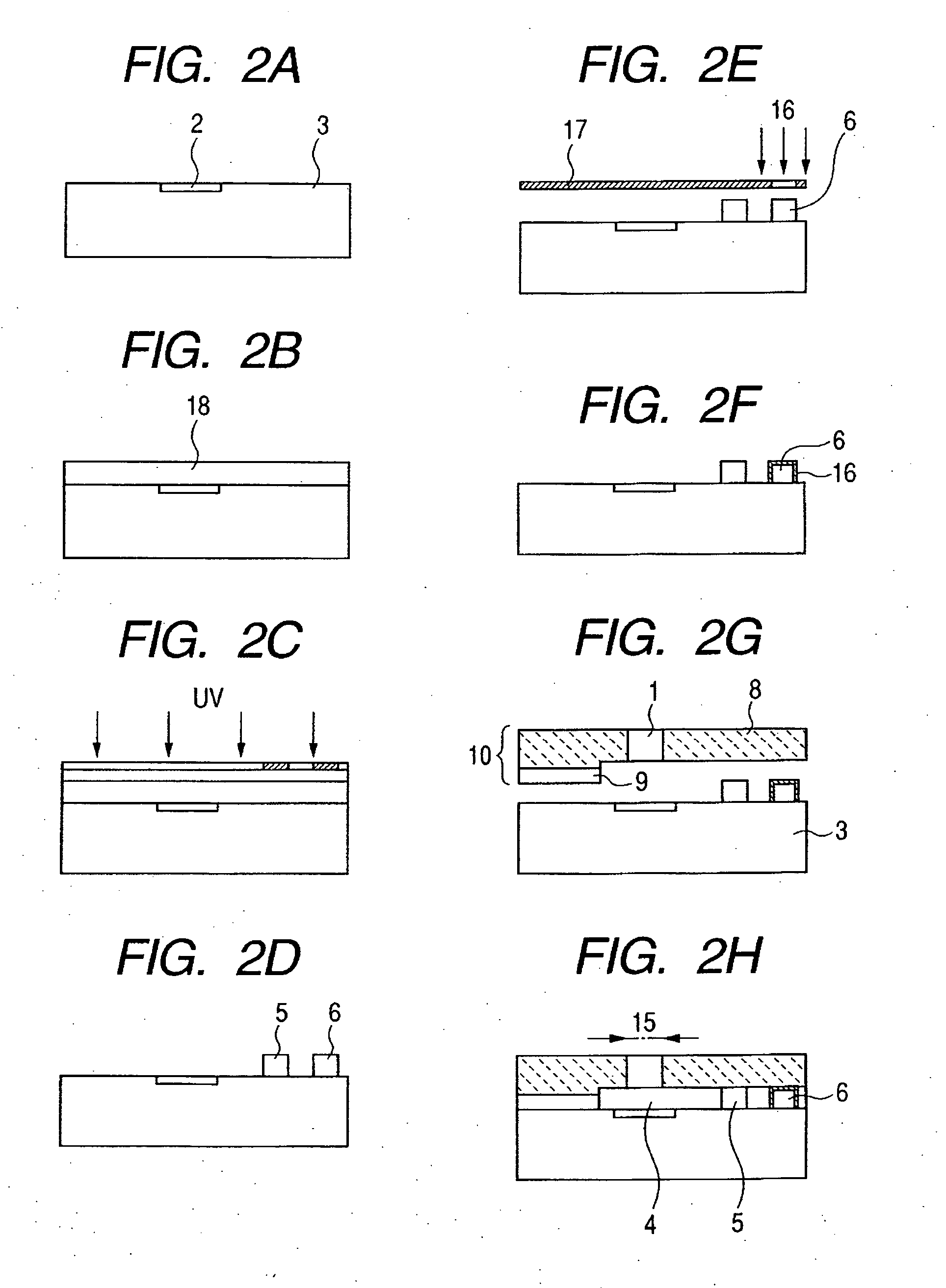

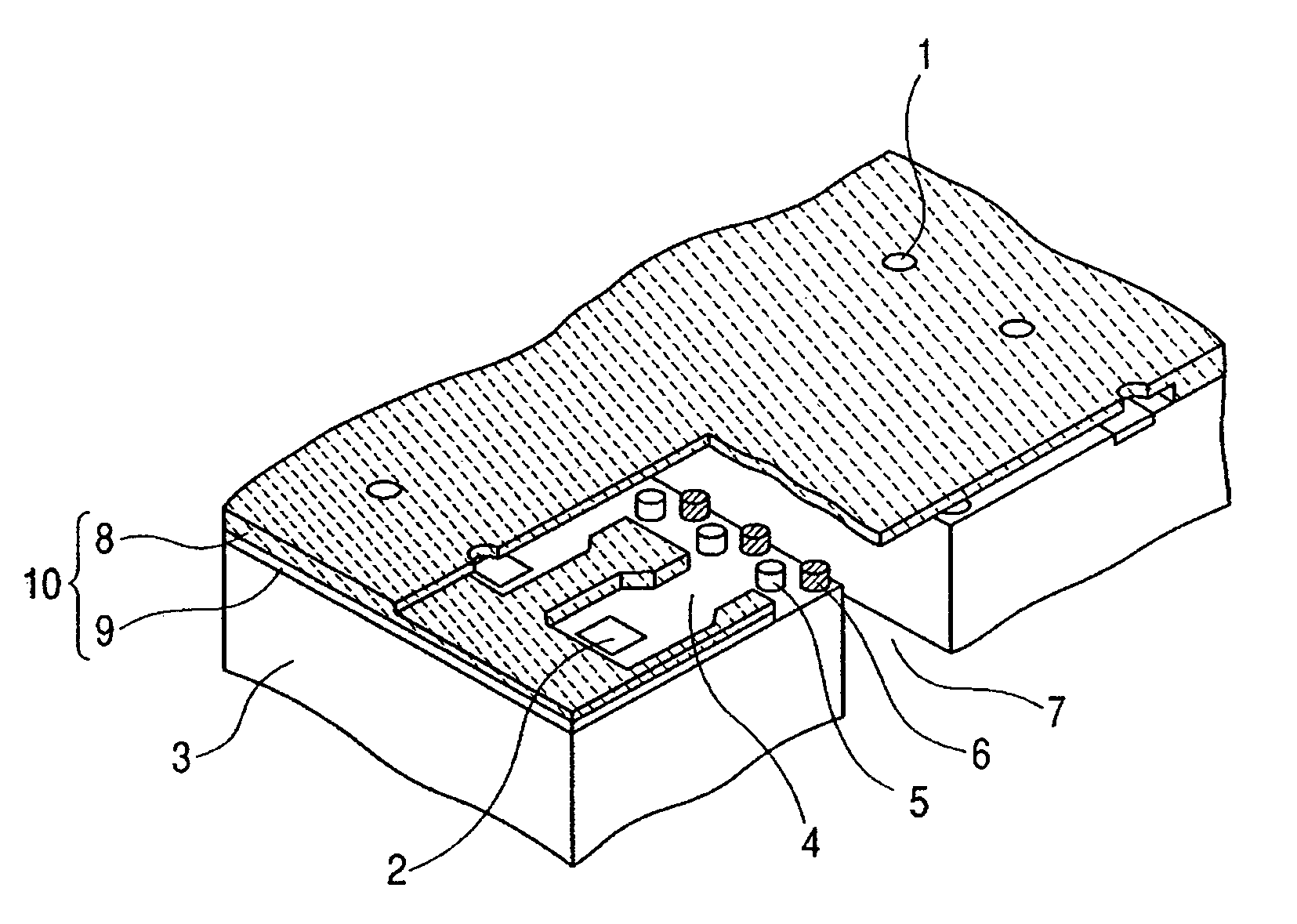

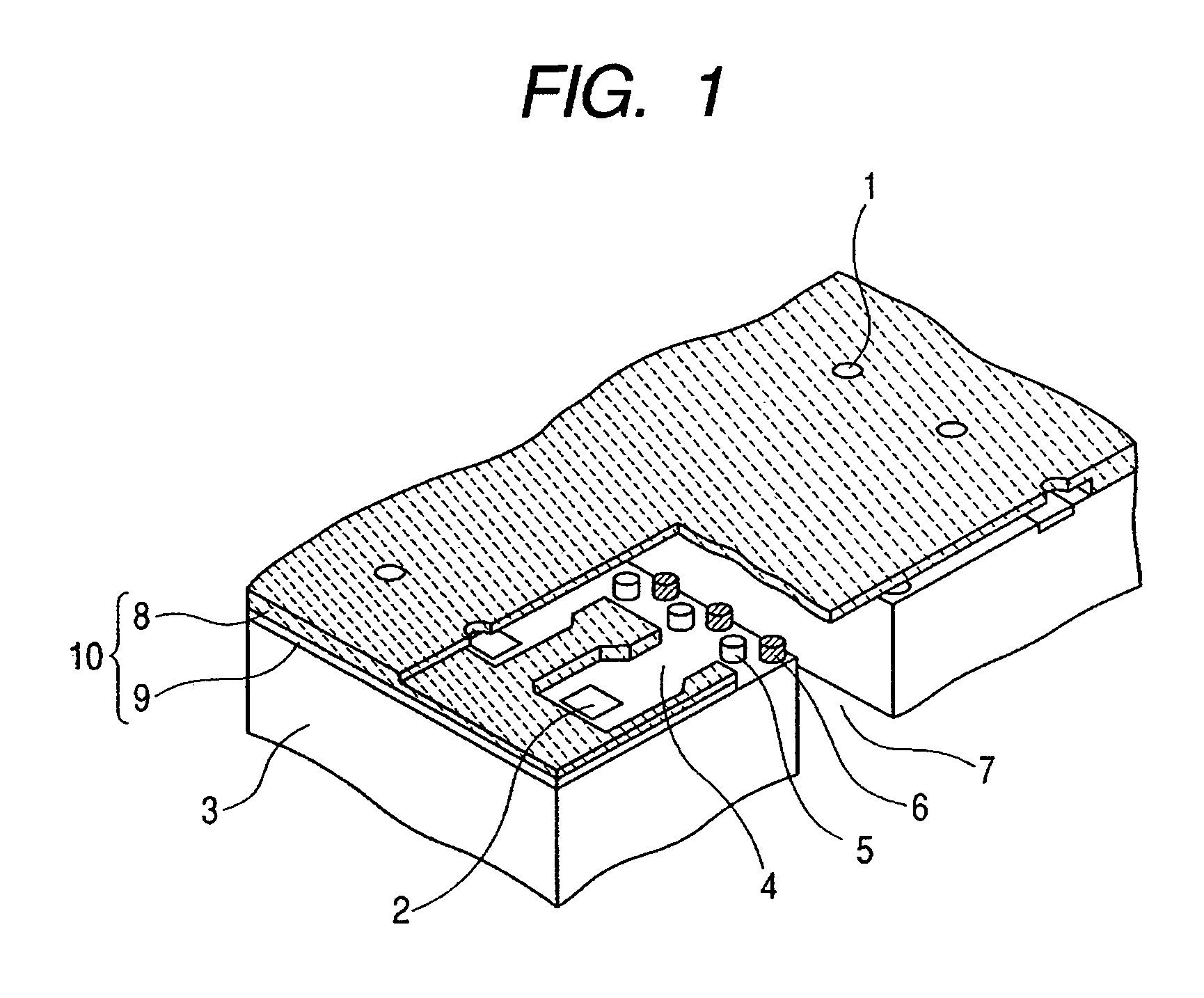

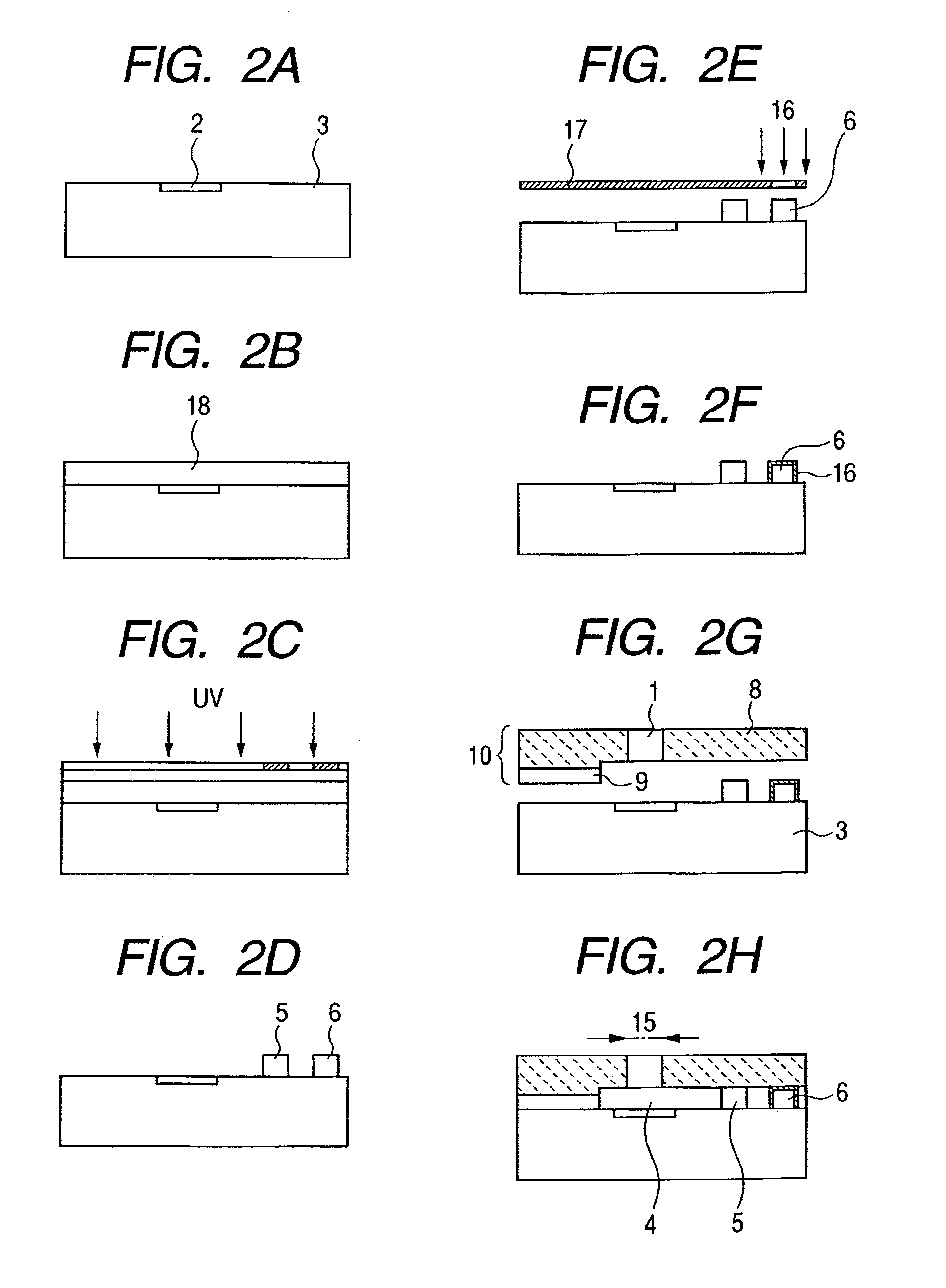

Ink jet recording head and method of manufacturing the same

An ink jet recording head which makes it difficult for any bubble and solid matter such as dust existing in supplied ink to reach the vicinity of a nozzle includes a plurality of energy generating elements 2 for generating energy for discharging the ink, a plurality of discharge ports 1 provided at locations opposed to the respective energy generating elements to discharge the ink there through, a plurality of ink flow paths 4 communicating with the respective discharge ports 1, and an ink supplying port 7 for supplying the ink to the plurality of ink flow paths 4. Water repellent protruding portions 6 having their surfaces formed of a material having surface energy smaller than the interfacial energy between them and the ink are provided upstream of the discharge ports 1 with respect to an ink flow direction in which the ink flows from the ink supplying port 7 into the ink flow paths 4 and is discharged from the discharge ports 1.

Owner:CANON KK

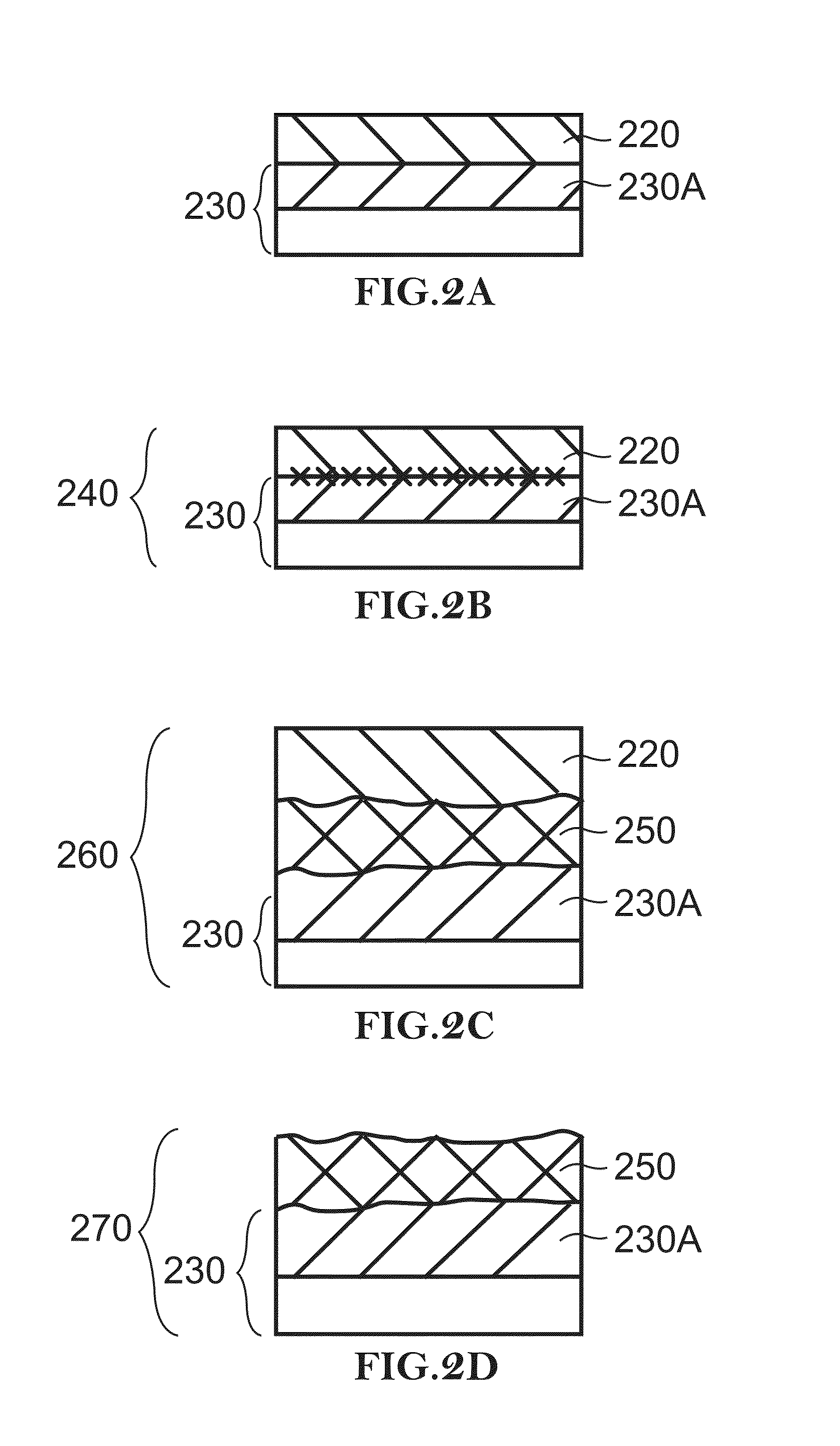

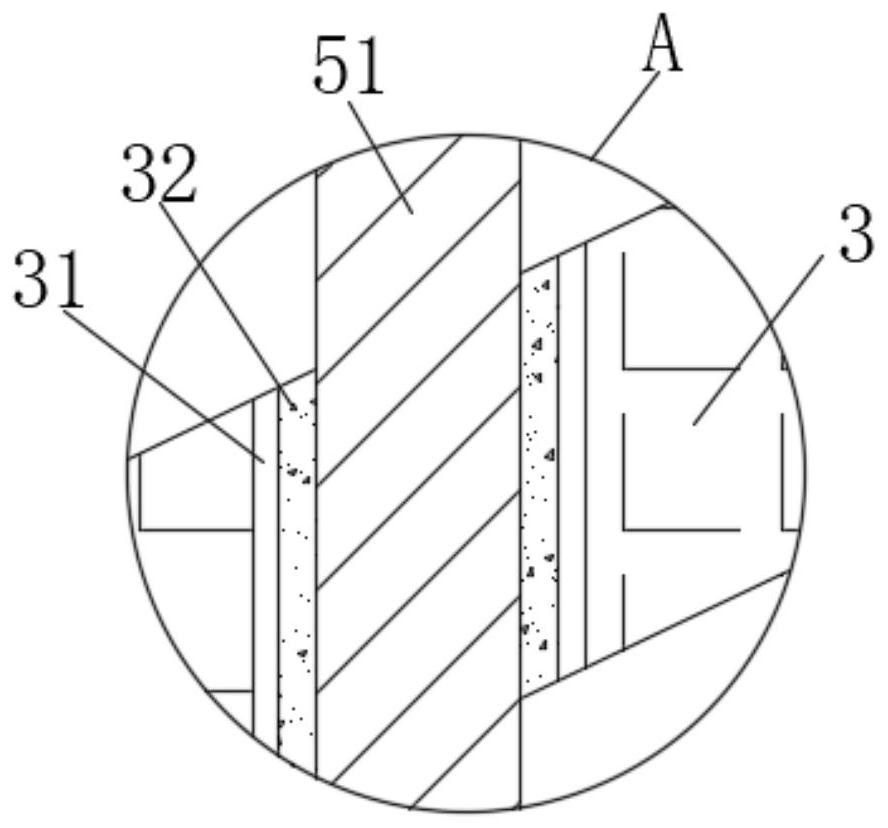

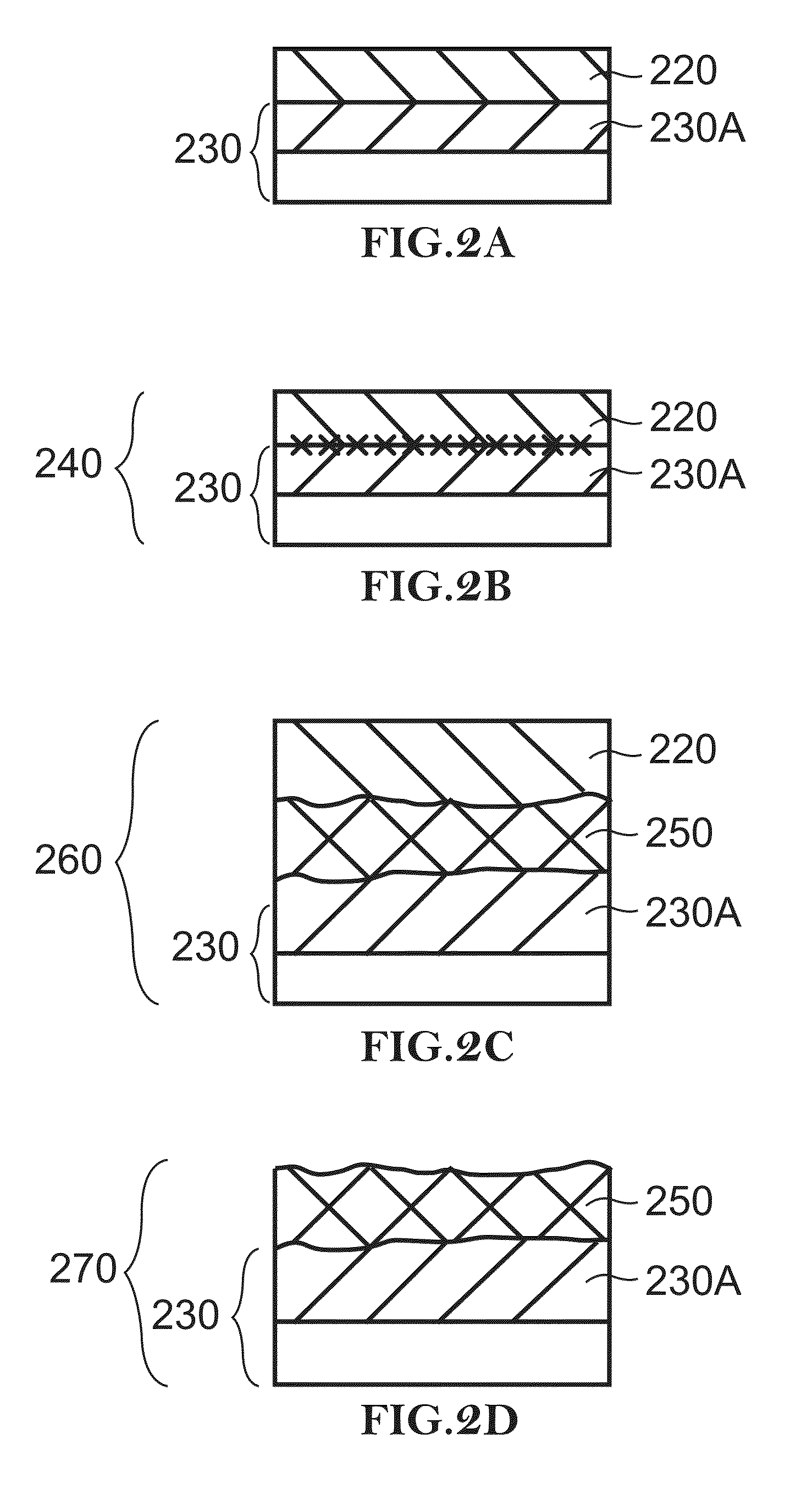

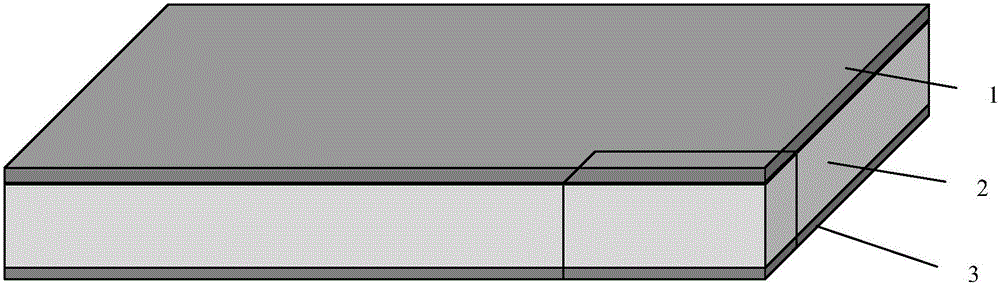

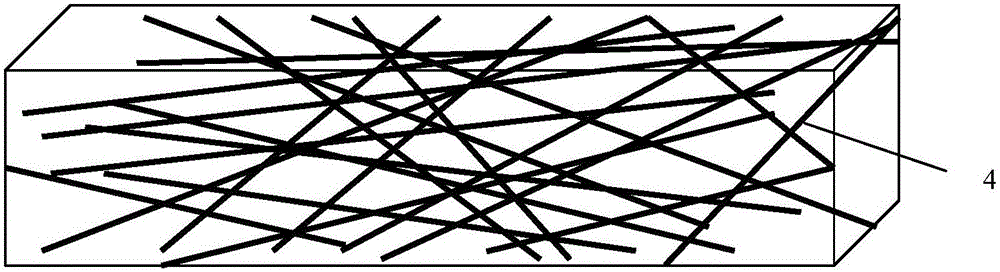

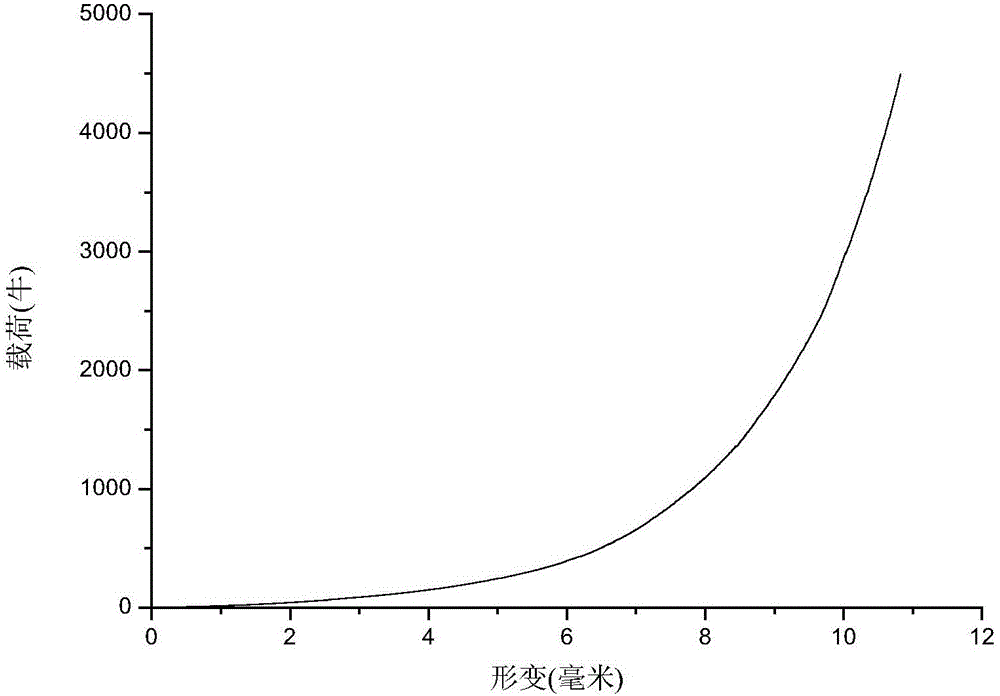

A glass fiber random structure sandwich material and its preparation method

ActiveCN103978749BSimple manufacturing processWeaknesses to Avoid Rapid Collapse DestructionLamination ancillary operationsLaminationGlass fiberFiber bundle

The invention relates to a glass fiber irregular architecture sandwiched material as well as a preparation method thereof. The glass fiber irregular architecture sandwiched material is composed of an upper panel (1), a lower panel (3) and a chopped glass fiber bundle core material (2) with an irregular architecture; the chopped glass fiber bundle core material (2) with the irregular architecture forms an irregular polyhedral hollow structure by mutually overlapping chopped glass fiber bundles (4) at different angles and is fixedly connected with the upper panel (1) and the lower panel (3). The glass fiber irregular architecture sandwiched material provided by the invention cannot generate plastic yielding in a flat pressing loading process; the glass fiber irregular architecture sandwiched material without plastic yielding changes the common properties of the traditional sandwiched material, and overcomes the weakness that the traditional core material is rapidly collapsed and damaged; the preparation technology is simpler and more feasible.

Owner:NANJING TECH UNIV

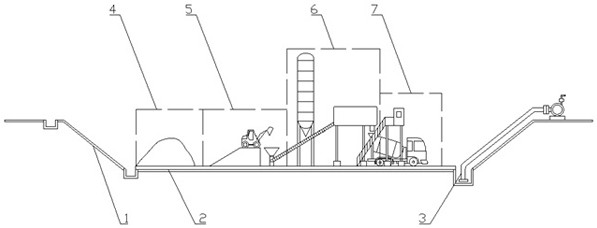

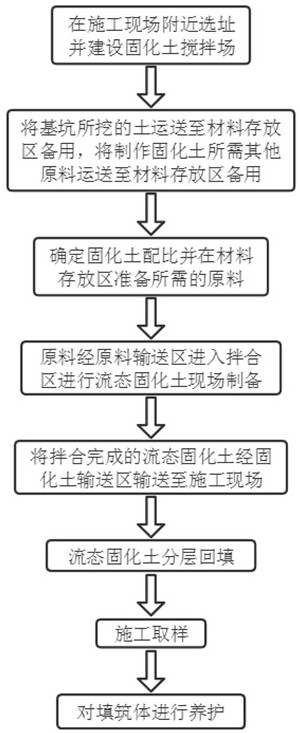

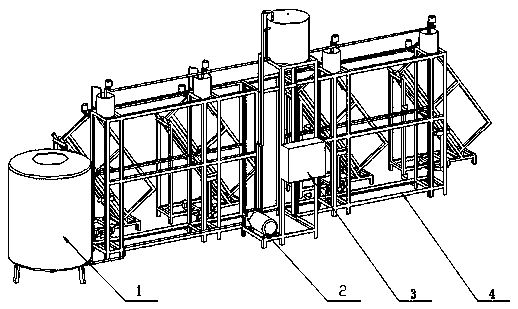

Solidified soil stirring field and solidified soil backfill construction method in narrow high backfill area

PendingCN114351728AReduce transshipment costsProtect environmentExcavationsOrganic fertilisersSoil scienceEcological environment

The invention relates to a stabilized soil mixing plant and a stabilized soil backfill construction method in a narrow high backfill area, the stabilized soil mixing plant is arranged at a flat position near a construction plant, a slope subjected to slope making treatment is arranged on the periphery of the stabilized soil mixing plant, and a concrete hardened layer with a high middle and a low periphery and a drainage system are arranged on the bottom surface of the stabilized soil mixing plant; a material storage area, a raw material conveying area, a mixing area and a solidified soil conveying area are arranged in the stirring field, soil excavated from a foundation pit is processed on site in the solidified soil stirring field to be prepared into flow-state solidified soil, the flow-state solidified soil is backfilled into a narrow high backfilling area, a large amount of transfer cost is saved, the ecological environment is protected, and the construction efficiency is improved. The problems that in backfilling construction, the backfilling area is narrow, the backfilling depth is high, and personnel and machinery cannot conduct construction are solved, the solidified soil has a waterproof effect after being solidified, the hidden danger of leakage of the outer wall is solved, meanwhile, the solidified soil has quite high strength and does not need to be compacted, the tamping procedure is omitted, the construction efficiency is improved, and the construction cost is reduced.

Owner:CHINA CONSTR EIGHTH ENG DIV

Ink jet recording head and method of manufacturing the same

An ink jet recording head, which can effectively prevent any bubble and solid matter such as dust existing in supplied ink to reach the vicinity of a nozzle, includes a plurality of energy generating elements for generating energy for discharging the ink, a plurality of discharge ports provided at locations opposed to the respective energy generating elements to discharge the ink therethrough, a plurality of ink flow paths communicating with the respective discharge ports, and an ink supplying port for supplying the ink to the plurality of ink flow paths. Water repellent protruding portions having their surfaces formed of a material having surface energy smaller than the interfacial energy between them and the ink are provided upstream of the discharge ports with respect to an ink flow direction in which the ink flows from the ink supplying port into the ink flow paths and is discharged from the discharge ports.

Owner:CANON KK

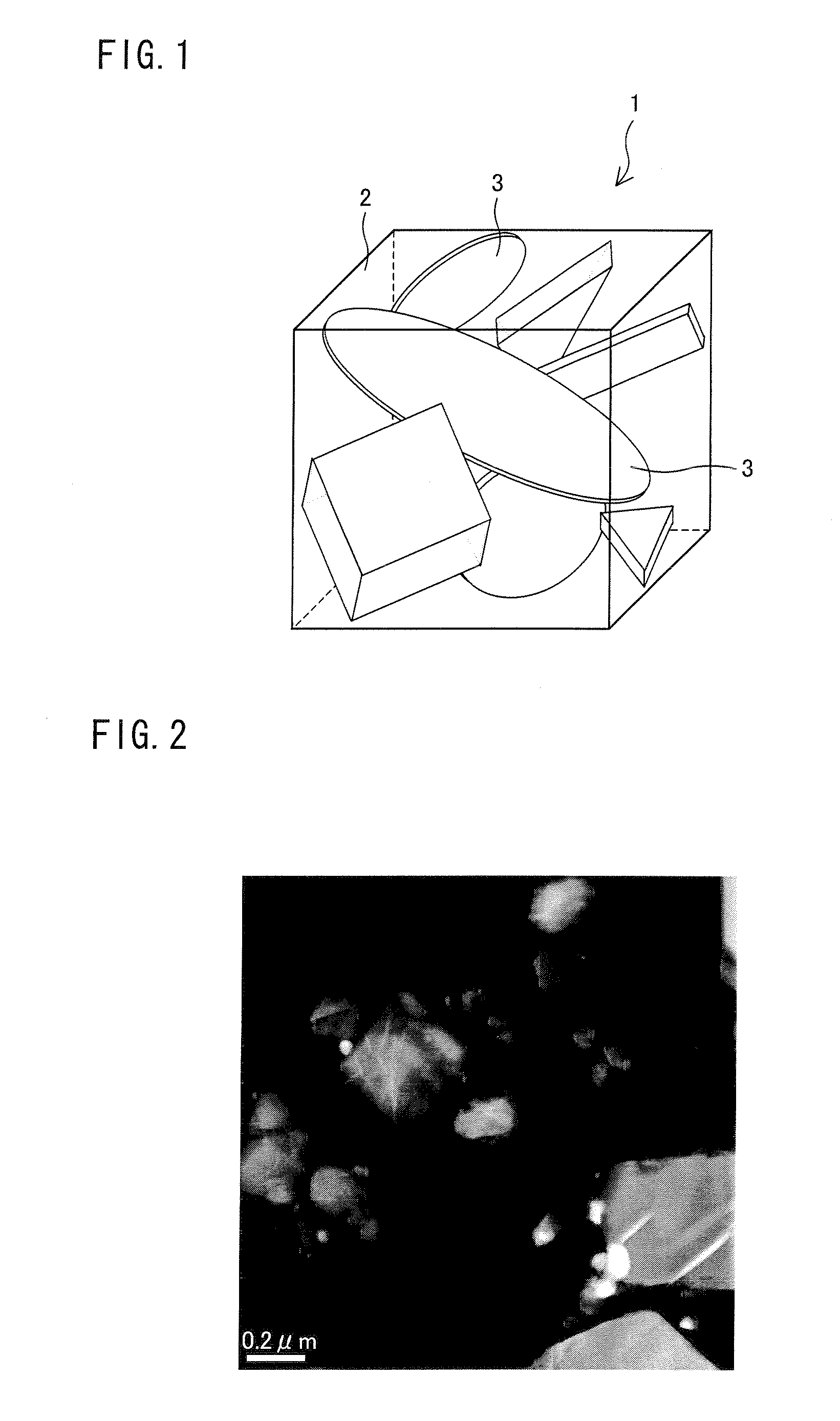

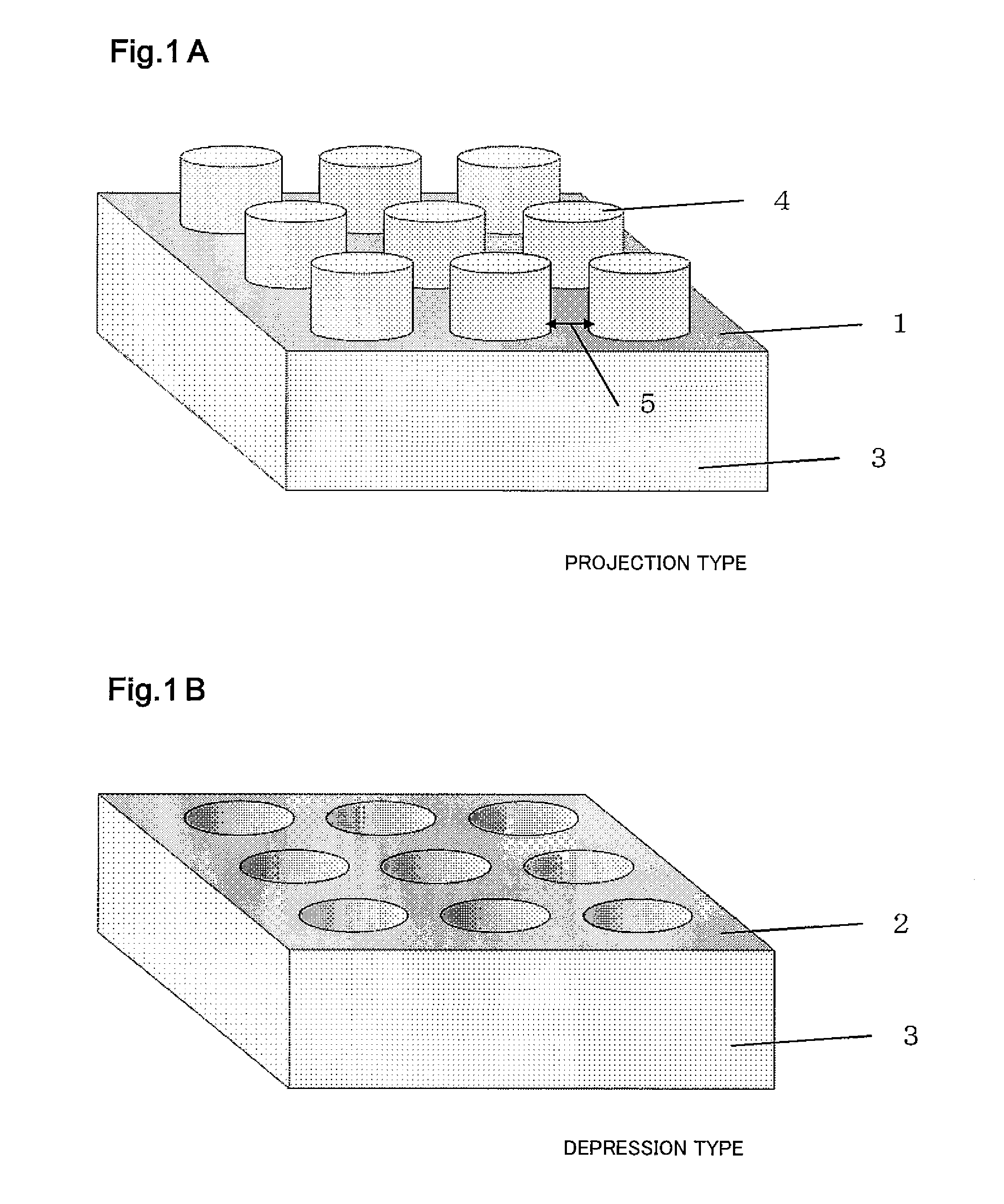

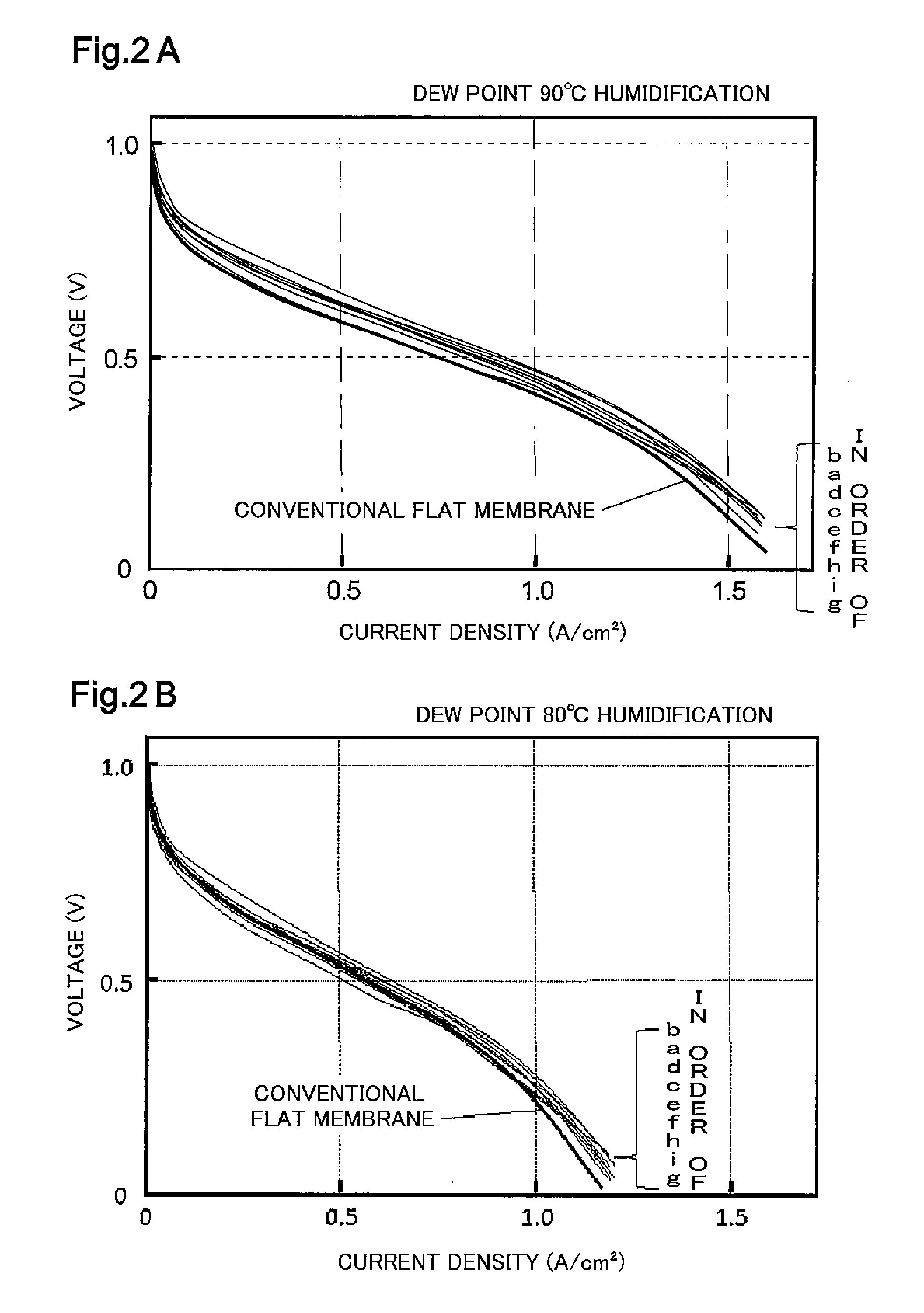

Method of operating polymer electrolyte fuel cell

InactiveUS20120189924A1Increase surface areaIncrease supplyCell electrodesSolid electrolyte fuel cellsFuel cellsOxygen

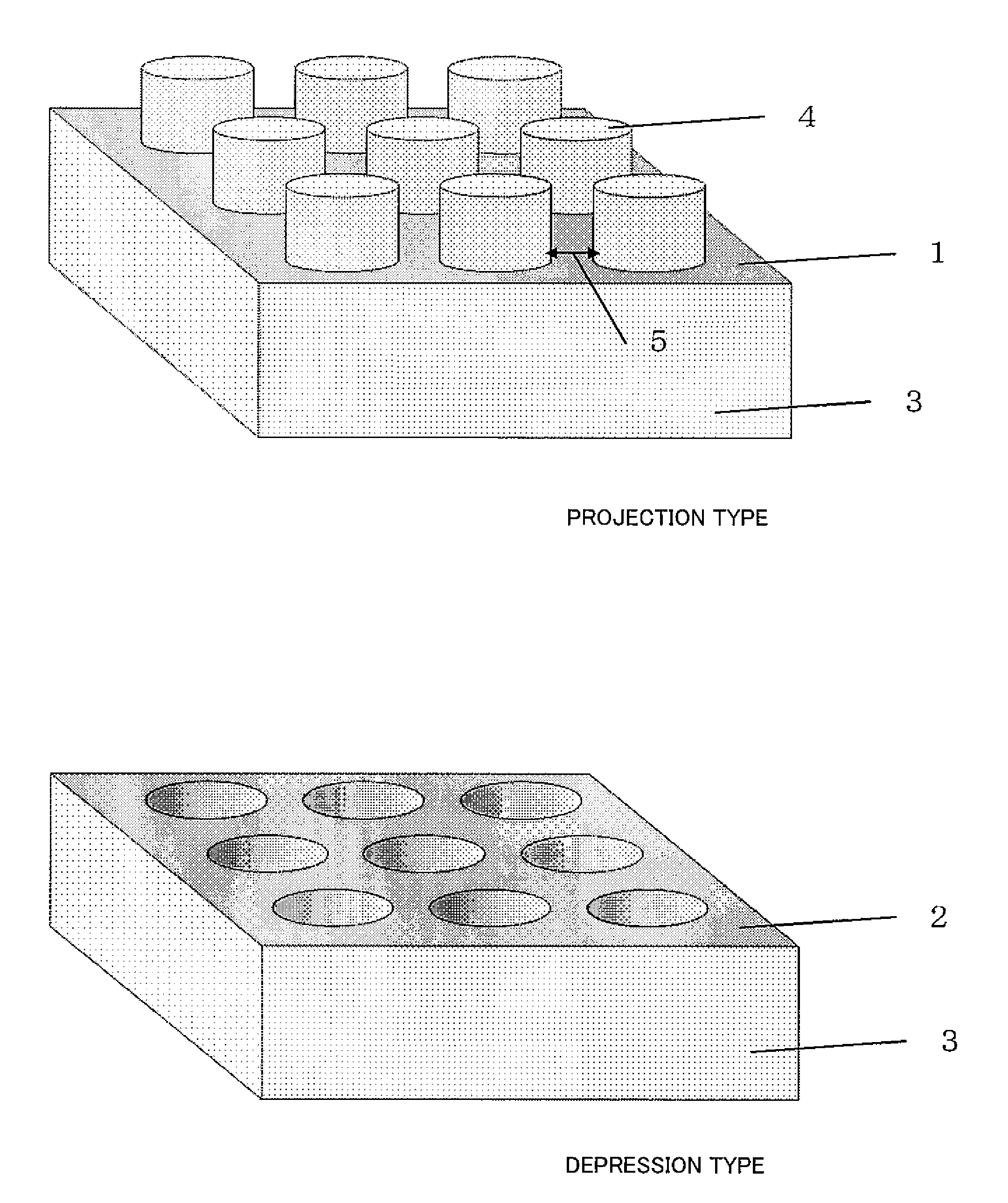

A polymer electrolyte fuel cell includes a cathode, an anode, and an electrolyte membrane sandwiched between the cathode and the anode. A plurality of projections each having a height of 5 to 15 μm or a plurality of depressions each having a depth of 5 to 15 μm are formed on a surface of the electrolyte membrane, the surface being opposed to the cathode. The cathode is constituted by a catalyst layer formed to tightly contact the surface of the electrolyte membrane and having a maximum thickness that is one to three times the height of the projection or the depth of the depression. An oxygen-containing gas having a relative humidity of 10% or less is supplied to the cathode, and electric power is generated by using the polymer electrolyte fuel cell.

Owner:PANASONIC CORP

Drainage structure and horizontal refrigerator

ActiveCN111380269AAvoid easy dischargeConvenient physical examinationLighting and heating apparatusDomestic refrigeratorsThermodynamicsEngineering

The invention provides a drainage structure and a horizontal refrigerator. The horizontal refrigerator comprises a refrigerator shell and an inner container, and the inner container is arranged in therefrigerator shell; the drainage structure comprises a water receiving box, an evaporating dish, a partition plate and a drainage pipe assembly; the water receiving box is arranged in the inner container; the evaporating dish is arranged in a compressor bin of the refrigerator shell and is fixed on a refrigerator shell bottom plate of the refrigerator shell; the partition plate is arranged in thecompressor bin and located between the water receiving box and the evaporating dish; the drainage pipe assembly communicates with the water receiving box and the evaporating dish, and the drainage pipe assembly comprises a drainage connecting pipe; the inner container comprises an inner container bottom plate, a step part is formed on the inner container bottom plate, and the step part is locatedbetween the water receiving box and the partition plate; the drainage connecting pipe is located between the step part and the partition plate; and an evaporator and a fan set are arranged in the inner container, the evaporator and the fan set are arranged above the water receiving box, the water receiving box is provided with a water outlet, and the water outlet is correspondingly located in theend port, away from the fan set, of the evaporator.

Owner:QINGDAO HAIER SPECIAL ICEBOX

Semi-automatic fixed-quantity filling equipment for liquid

The invention discloses semi-automatic fixed-quantity filling equipment for liquid and belongs to filling equipment for liquid in cavities of heat dissipaters or drying racks. The semi-automatic fixed-quantity filling equipment is composed of a proportioned liquid storage container, a pressurization conveying pump, an electrical equipment control cabinet, a machine frame body, a flow division storage container, a fixed-quantitypre-filling solenoid valve, a fixed-quantitypre-filling container, a flow division filling control device, a filling control valve time controller, an inductive probe adjustment and ruler device, a product fixing frame, an electronic scale, a filling start switch, a fixed-quantityfilling start button, an infusion hose and a fixed baffle. The semi-automatic fixed-quantity filling equipment is simple and novel in structure, high in practicality, low in investment, low in labor intensity and high in filling efficiency and can be provided with a plurality of filling positions; the flow division filling control device is adopted, the highest filling speed is realized, the phenomenon that false filling or excessive filling occurs because air in cavities of products to be filled cannot be exhausted easily is avoided, and the product quality of the heat dissipaters is stable.

Owner:JIANGXI AVONFLOW HVAC TECH CO LTD

Spray centrifugal dedusting fan

ActiveUS8528165B2Easily brokenImprove the immunityCombination devicesLighting and heating apparatusImpellerHigh energy

The invention provides a spray centrifugal dedusting fan, including an air cylinder consisting of a spray cylinder, a centrifugal cylinder and a fan cylinder; the left end and the right end of the air cylinder are respectively provided with an air inlet and an air outlet communicated with each other; a spraying device is installed in the spray cylinder; a plurality of through holes are arranged on the wall of the centrifugal cylinder; a bracket is installed inside the centrifugal cylinder; at least one centrifugal impeller is installed on the bracket; a fan is installed inside the fan cylinder; an outer cylinder is installed on the external wall of the centrifugal cylinder 11; an empty chamber is arranged between the centrifugal cylinder and the outer cylinder; the lower end of the outer cylinder is connected with a water seal elbow; the water seal elbow is communicated with the empty chamber, the trumpet-shaped first water-blocking shield is connected to the right part inside the centrifugal cylinder; the left port diameter of the first water-blocking shield is smaller than the right port in diameter; the left port of the first water-blocking shield corresponds to the centrifugal impeller and the right port corresponds to the fan. The invention adopts the spray centrifugal form to remove dust in air, which solves the problems of great air circulation resistance, low dedusting efficiency, high energy consumption and easy breakage of fan motor etc. in the prior art.

Owner:TAIAN SANYUAN VENTILATION DUST EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com