Semi-automatic fixed-quantity filling equipment for liquid

A filling equipment and semi-automatic technology, applied in liquid bottling, liquid treatment, packaging, etc., can solve problems affecting product functions, high production costs, energy waste, etc., and achieve stable product quality, high filling efficiency, and labor intensity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

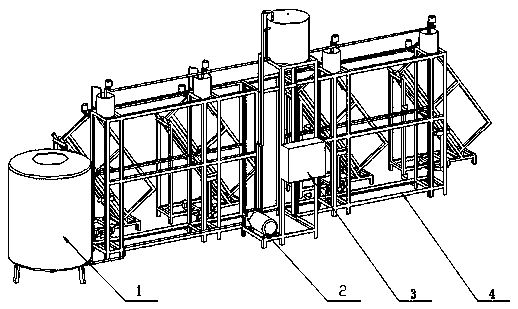

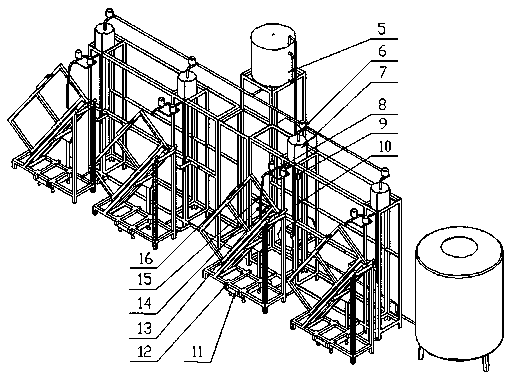

[0021] Such as figure 1 As shown, a semi-automatic liquid quantitative filling equipment consists of a liquid dispensing storage container 1, a booster pump 2, an electrical control box 3, a frame body 4, a shunt storage container 5, a quantitative pre-installed solenoid valve 6, and a quantitative pre-installed Container 7, split filling control device 8, filling control valve time controller 9, sensor control head adjustment and scale device 10, product holder 11, electronic scale 12, filling start switch 13, quantitative filling start button 14, The infusion hose 15 and the fixed baffle plate 16 are constituted. The booster delivery pump 2, the electrical control box 3 and the shunt storage container 5 are fixedly installed on the rear side of the frame body 4, and the liquid dispensing storage container 1 is installed on the frame body 4, the shunt storage container 5 is installed at the top of the frame body 4, the booster pump 2 connects the liquid dispensing storage conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com