Process and apparatus for heating feedwater in a heat recovery steam generator

a heat recovery and feedwater technology, applied in the field of boilers, can solve the problems of sulfuric acid condense on the surface of sulfuric acid, corrode the low temperature surfaces of boilers, and increase the cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

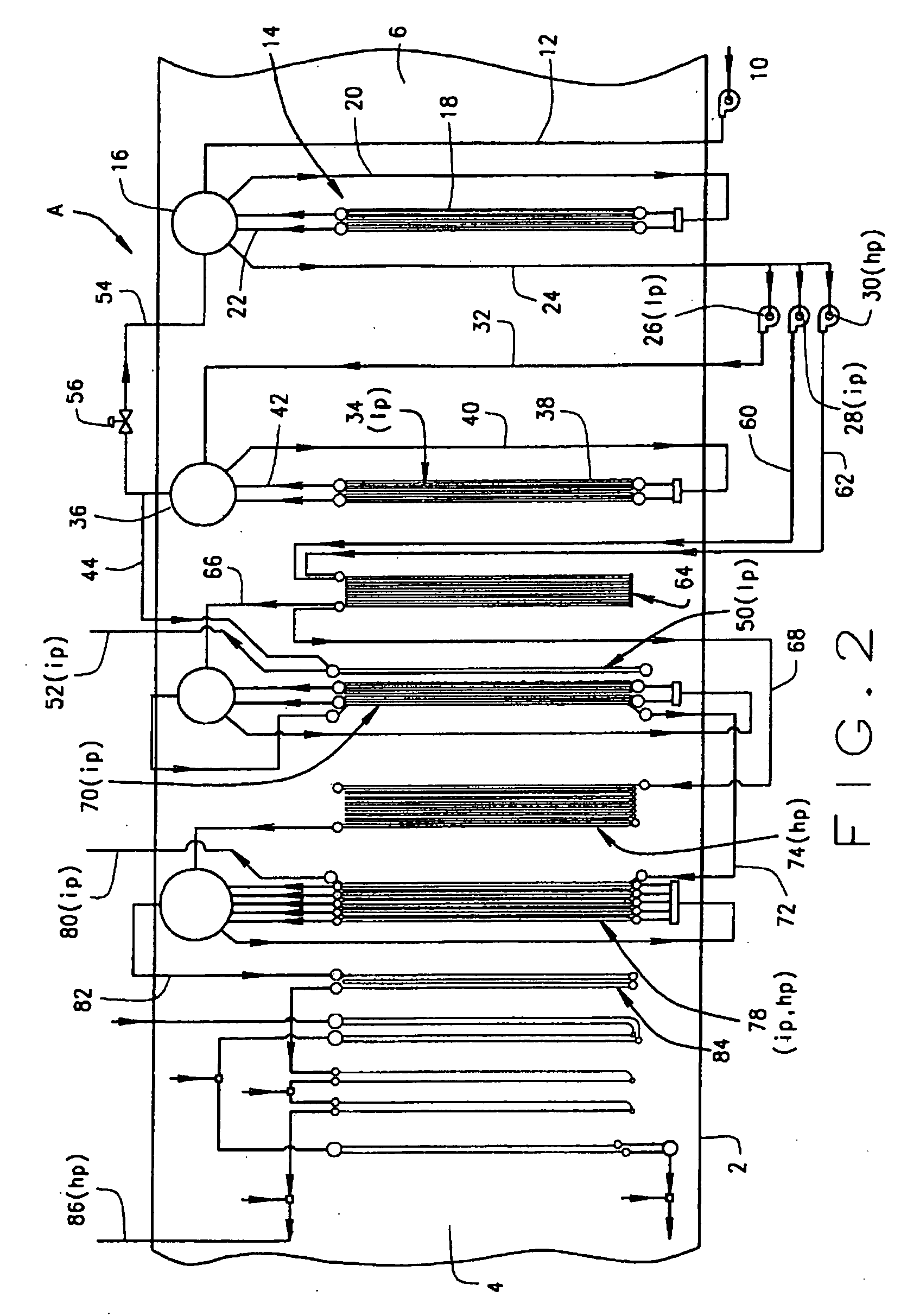

[0016]Referring now to the drawings, a heat recovery steam generator (HRSG) A (FIG. 2) that extracts heat from a hot gas flow provides superheated steam at several pressure levels. That steam may be directed to a steam turbine to power it. After passing through the turbine the steam discharges at a lower pressure and temperature and is condensed into subcooled liquid water which is circulated back to the HRSG A to again be converted into superheated steam.

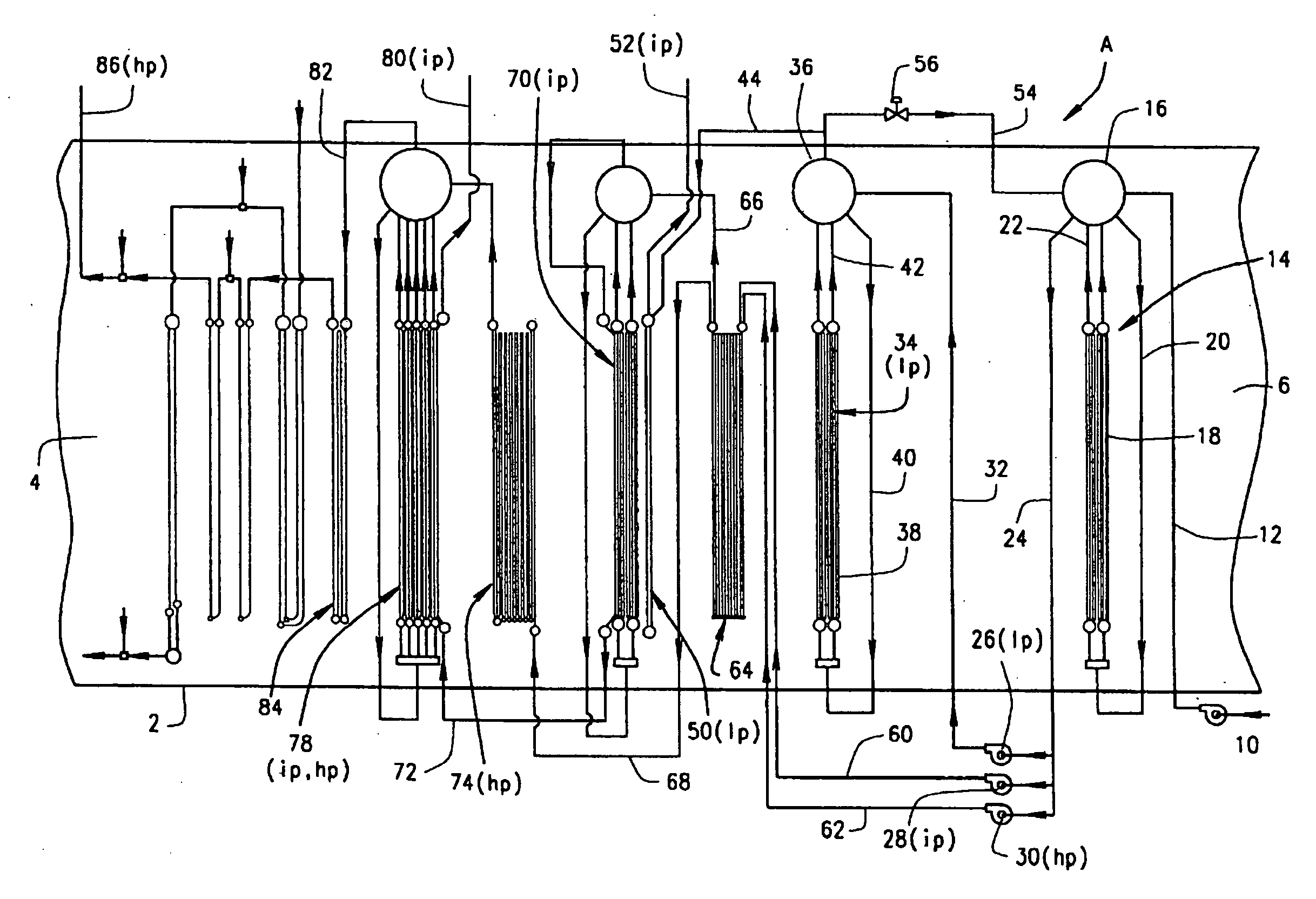

[0017]The HRSG A includes (FIG. 2) a housing 2 that is basically a duct having an inlet 4 and an outlet 6. The HRSG A also includes a series of heat exchangers contained within the housing 2, and their functions are to a large measure described by their names. In addition, the HRSG A includes pumps, valves, and lines or conduits connecting the heat exchangers, pumps and valves together into the functioning HRSG A. Hot exhaust gas derived from the combustion of a fossil fuel enters the housing 2 at its inlet 4, passes through the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com