Environment-friendly stainless steel polishing solution and preparation method and polishing process thereof

A polishing liquid and stainless steel technology, applied in polishing process and chemical polishing liquid field of stainless steel, can solve the problems of difficult control of process parameters, short polishing liquid life and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

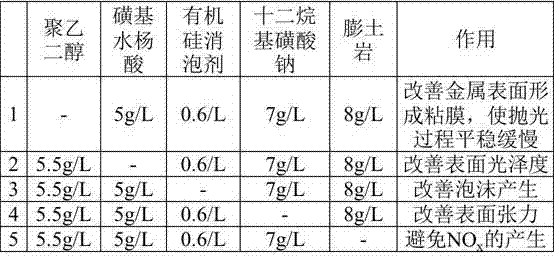

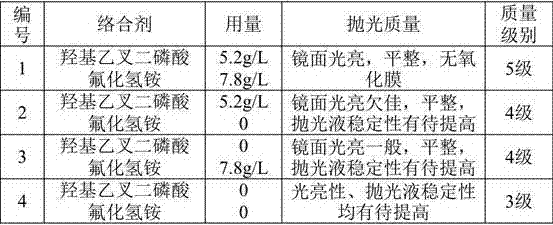

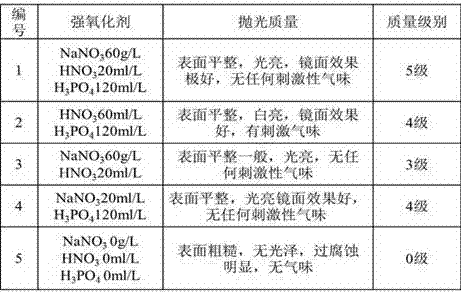

Method used

Image

Examples

Embodiment 1

[0032] An environmentally-friendly stainless steel polishing liquid, characterized in that the polishing liquid includes:

[0033] Strong oxidizer: NaNO 3 40g / L, HNO 3 10ml / L and H 3 PO 4 100ml / L;

[0034] Corrosive acid: HCl 50ml / L;

[0035] Compound complexing agent: hydroxyethylidene diphosphoric acid and ammonium bifluoride, mass ratio 1:1.5, total 12g / L;

[0036] Corrosion inhibitor: Na 2 MoO 4 . 10H 2 O, 2g / L;

[0037] Rare earth additives: La(NO 3 ) 3 . 6H 2 O, 1g / L;

[0038] Viscosity modifier: polyethylene glycol, 4g / L;

[0039] Brightener: sulfosalicylic acid, 3g / L;

[0040] Defoamer: Silicone defoamer, 0.1g / L;

[0041] Surfactant: sodium dodecyl sulfonate, 5g / L;

[0042] NO x Remover: 1600~2000 mesh bentonite in ethanol, 3g / L;

[0043] The remainder is deionized water.

[0044] The method steps for preparing the polishing liquid are: (1) Grind the bentonite particles to a fineness of 1600-2000 mesh, then dissolve them in ethanol, add an appropriate amount of surfactant, o C ultra...

Embodiment 2

[0047] An environmentally-friendly stainless steel polishing liquid, characterized in that the polishing liquid includes:

[0048] Strong oxidizer: NaNO 3 50g / L, HNO 3 20ml / L and H 3 PO 4 110ml / L;

[0049] Corrosive acid: HCl 80ml / L;

[0050] Compound complexing agent: hydroxyethylidene diphosphoric acid and ammonium bifluoride, mass ratio 1:1.5, total 13g / L;

[0051] Corrosion inhibitor: Na 2 MoO 4 . 10H 2 O, 2.6g / L;

[0052] Rare earth additives: La(NO 3 ) 3 . 6H 2 O, 1.3g / L;

[0053] Viscosity modifier: gelatin, 6g / L;

[0054] Brightener: Saccharin, 4.5g / L;

[0055] Defoamer: high-carbon alcohol defoamer 0.5g / L;

[0056] Surfactant: Span 60, 6g / L;

[0057] NO x Remover: 1600~2000 mesh bentonite ethanol solution, 3~10g / L;

[0058] The remainder is deionized water.

Embodiment 3

[0060] An environmentally-friendly stainless steel polishing liquid, characterized in that the polishing liquid includes:

[0061] Strong oxidizer: NaNO 3 50g / L, HNO 3 15ml / L and H 3 PO 4 110ml / L;

[0062] Corrosive acid: HCl 75ml / L;

[0063] Compound complexing agent: Hydroxyethylidene diphosphate and ammonium bifluoride, mass ratio 1:1.75, total 13.5g / L;

[0064] Corrosion inhibitor: Na 2 MoO 4 . 10H 2 O, 2.5g / L;

[0065] Rare earth additives: La(NO 3 ) 3 . 6H 2 O, 1.25g / L;

[0066] Viscosity modifier: propylene glycol, 6g / L;

[0067] Brightener: Sulfonamide, 5g / L;

[0068] Defoamer: Polyether modified silicon defoamer, 0.5g / L;

[0069] Surfactant: sodium lauryl sulfate, 6g / L;

[0070] NOx remover: ethanol solution of bentonite below 1600~2000 mesh, 6g / L;

[0071] The remainder is deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com