Method for preparing surface-enhanced Raman scattering (SERS) matrix

A Raman scattering matrix and surface enhancement technology, applied in Raman scattering, instruments, analytical materials, etc., to achieve uniform particle size and gap, and uniform distribution of hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

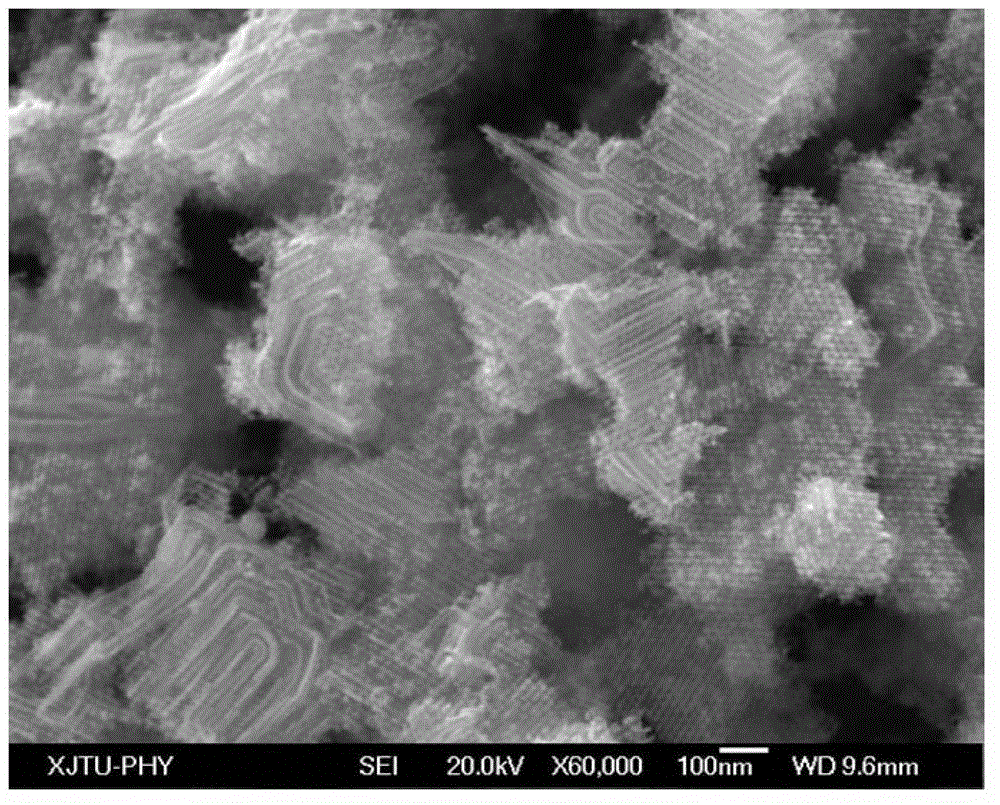

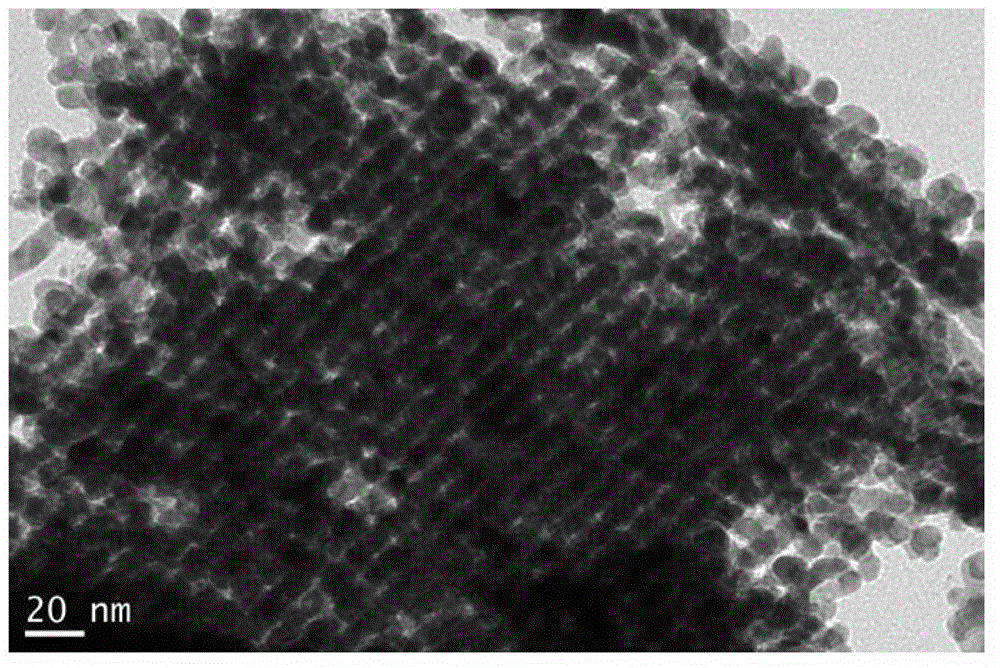

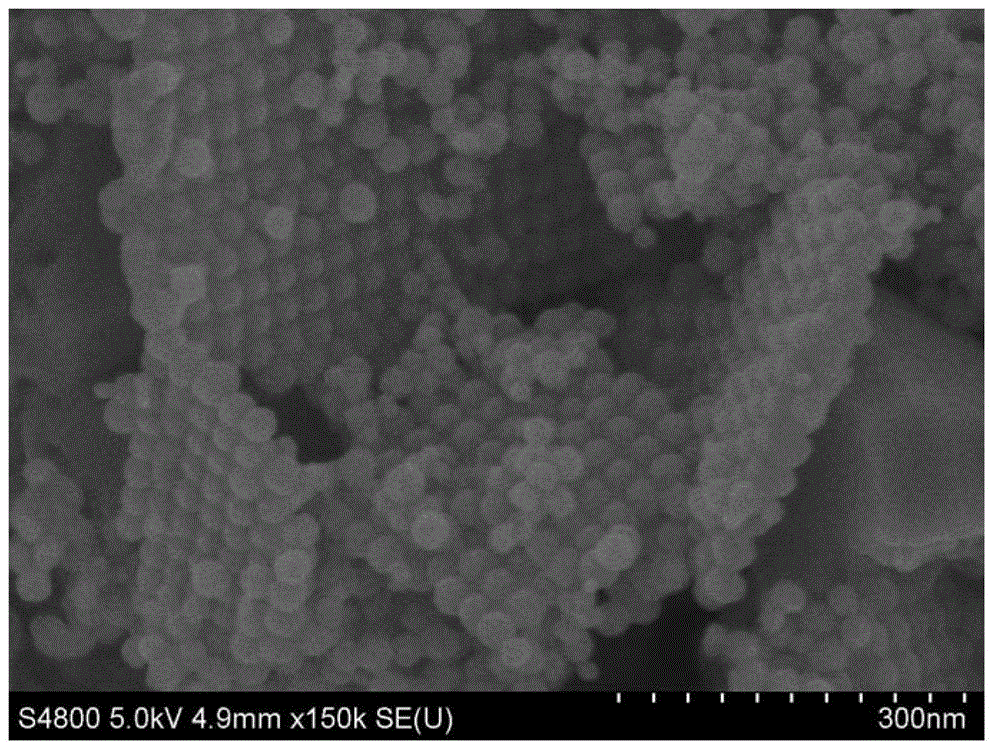

[0037]Example 1: First, weigh the molecular sieve porous silicon KIT-6 template, put it into a three-necked bottle, add n-hexane and modifier hexamethyldisilazane, the organic solvent is based on the dissolved molecular sieve template, and the molecular sieve and modifier The mass ratio is 5.18:1. After stirring evenly, reflux for 1 hour. The product after centrifugation is washed with ethanol three times to remove the organic solvent n-hexane, and dried at 80 degrees to obtain the modified template KIT-6-HMDS. Weigh the modified template, add a silver nitrate solution with a mass concentration of 11.7% into the molecular sieve template, the mass ratio of the molecular sieve template to silver nitrate is 1:1, keep stirring for 1 hour, and then put it in a dry box at 40°C Drying, the drying time is 2 days, after drying, put it into a porcelain boat and transfer it to an atmosphere furnace for calcination under the protection of argon for 2 hours, and then wash it three times wit...

Embodiment 2

[0038] Example 2: First, weigh the molecular sieve ordered mesoporous silicon OMS template, put it into a three-necked bottle, add toluene and the modifier trimethylchlorosilane, the organic solvent is based on the dissolved molecular sieve template, the quality of the molecular sieve and the modifier The ratio is 3:1. After stirring evenly, reflux for 1 hour. The product after centrifugation is washed with ethanol three times to remove the organic solvent toluene, and dried at 80 degrees to obtain the modified template ordered mesoporous silicon OMS. Weigh the modified template, add a silver nitrate solution with a mass concentration of 2% into the molecular sieve template, the mass ratio of the molecular sieve template to silver nitrate is 0.1:1, keep stirring for 1 hour, and then put it in a dry box at 40°C Drying, the drying time is 2 days, after drying, put it into a porcelain boat and transfer it to the atmosphere furnace for calcination under the protection of argon for ...

Embodiment 3

[0039] Example 3: First, weigh the molecular sieve ordered mesoporous silicon OMS template, put it into a three-necked bottle, add toluene and modifier 3-aminopropyltriethoxysilane, the organic solvent is based on dissolving the molecular sieve template, and the molecular sieve The mass ratio to the modifier is 4.13:1. After stirring evenly, reflux for 1 hour. The product after centrifugation is washed with ethanol three times to remove the organic solvent toluene, and dried at 80 degrees to obtain the modified template ordered mesoporous silicon OMS. Weigh the modified template, add a silver nitrate solution with a mass concentration of 10% to the molecular sieve template, the mass ratio of the molecular sieve template to silver nitrate is 3:1, keep stirring for 1 hour, and then put it in a dry box at 40°C Drying, the drying time is 2 days, after drying, put it into a porcelain boat and transfer it to the atmosphere furnace for calcination under the protection of argon for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com