Hollow open lignin nano-sphere and preparation method thereof

A technology of lignin and nanospheres, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of lack of hollow structure and random morphology of nano-lignin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 5 mg of enzymatic lignin in a 250 mL beaker, add 10 mL of tetrahydrofuran, stir at 600 rpm, then titrate with 40 mL of deionized water at a speed of 2 mL / min, and finally transfer the suspension into a dialysis bag for dialysis for 24 h.

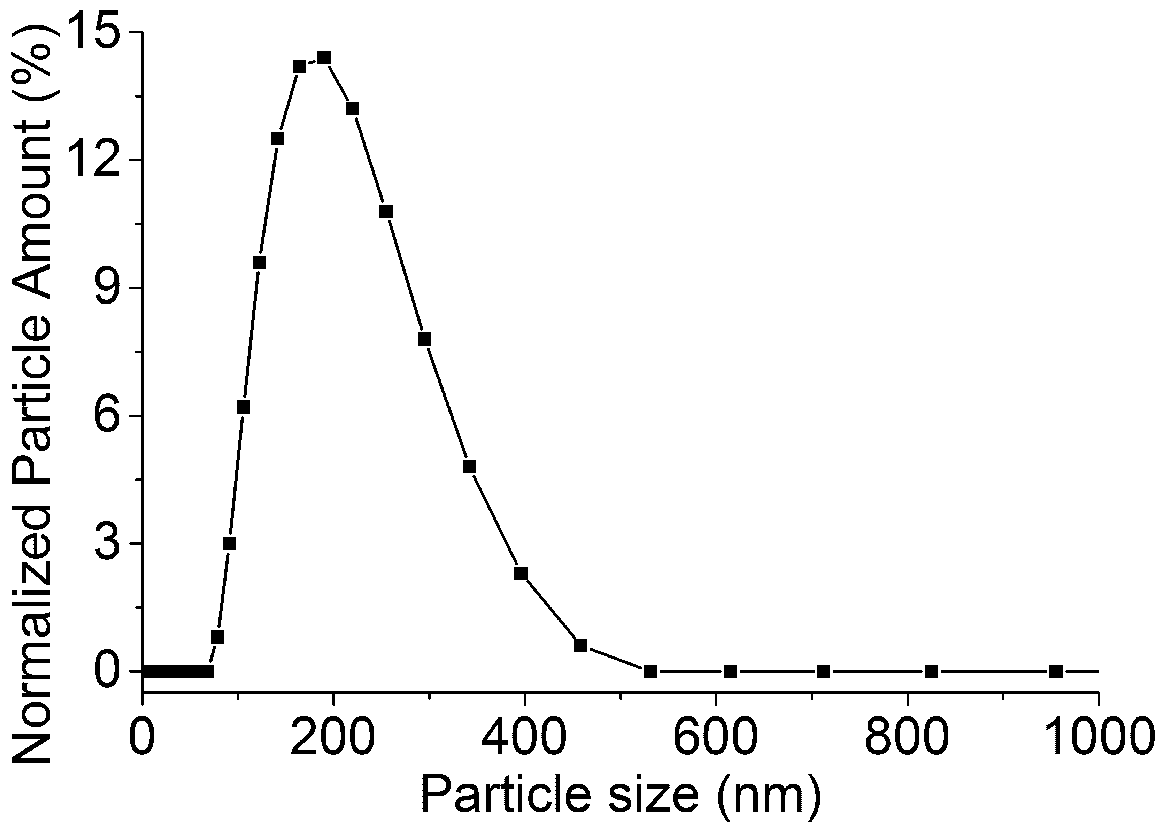

[0022] figure 2 It is the particle size distribution diagram of the hollow open lignin nanospheres measured by the laser particle size analyzer, and the average particle size is 419.2nm.

[0023] image 3 is a scanning electron micrograph of hollow open lignin nanospheres.

[0024] Figure 4 is a transmission electron micrograph of hollow open lignin nanospheres.

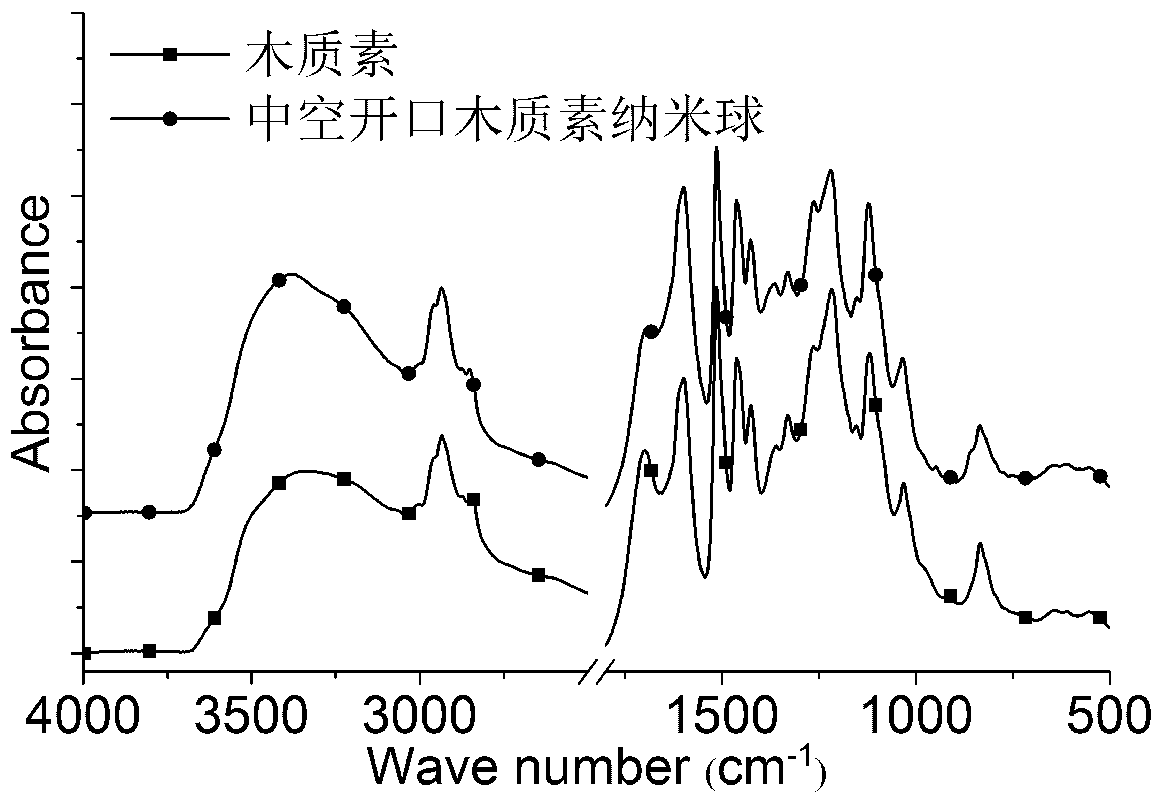

[0025] Figure 5 It is the infrared spectrogram of hollow open lignin nanospheres and lignin raw materials. It can be seen that the characteristic peaks have not changed before and after preparation, indicating that no chemical reaction has occurred before and after preparation.

Embodiment 2

[0027] Take 10 mg of enzymatic lignin in a 250 mL beaker, add 10 mL of tetrahydrofuran, stir at 600 rpm, then titrate 40 mL of deionized water at a speed of 2 mL / min, and finally transfer the suspension into a dialysis bag for dialysis for 24 h.

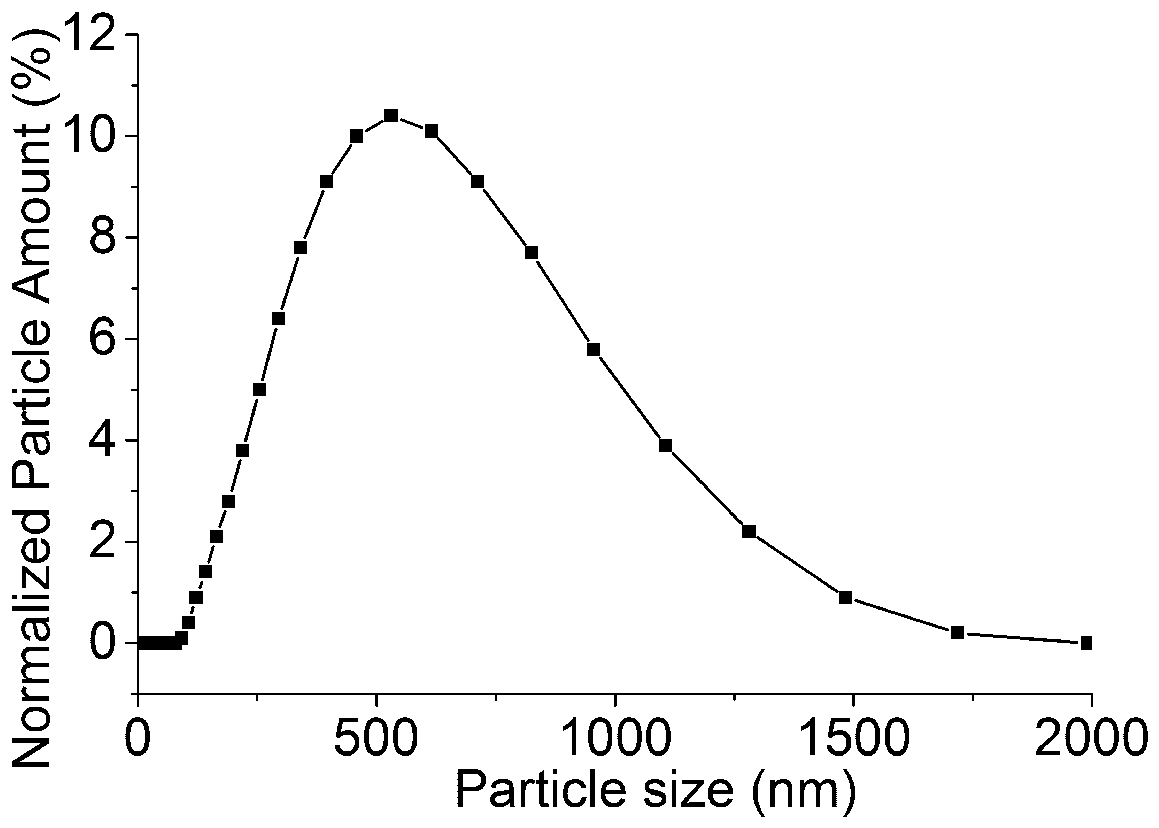

[0028] The average particle size measured by the laser optical particle size analyzer is 502.4 nm, which is larger than that in Example 1. In addition, the opening and hollow diameters are reduced compared to Example 1.

Embodiment 3

[0030] Put 15 mg of enzymatic lignin into a 250 mL beaker, add 10 mL of tetrahydrofuran, stir at 600 rpm, then titrate 40 mL of deionized water at a speed of 2 mL / min, and finally transfer the suspension into a dialysis bag for dialysis for 24 h.

[0031] The average particle size measured by the laser optical particle size analyzer is 515 nm, which is larger than that of Example 1. In addition, the opening and hollow diameters are reduced compared to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com