Water heater preheating method and water heater

A technology for water heaters and hot water pipes, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of poor user experience, insufficient use of energy, waste of energy, etc., and achieve the effect of improving the experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

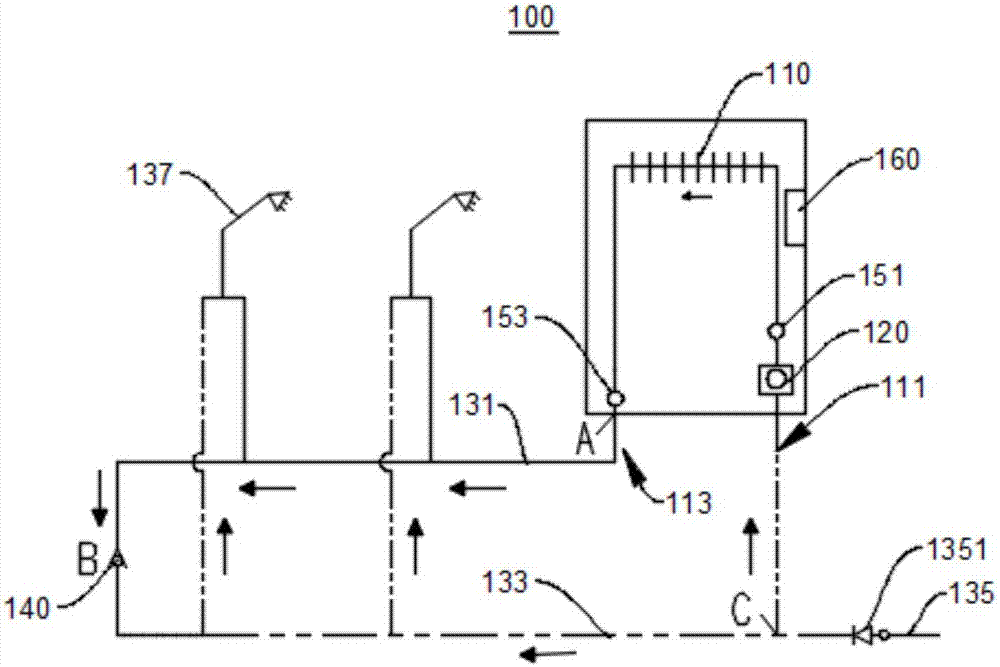

[0044] figure 1 This is a schematic diagram of the structure of the water heater 100 provided by the first embodiment of the present invention, please refer to figure 1 . The dotted line in the figure represents the cold water pipe 133, the solid line represents the hot water pipe 131, and the arrow represents the direction of water flow in the water flow pipe.

[0045] The water heater 100 provided in this embodiment includes a heater 110, a water pump 120, a water flow pipeline, a one-way valve 140, a first temperature sensor 151, a second temperature sensor 153, a timer, a temperature limiter, a flow meter, and a control 器160.

[0046] The heater 110 includes a water inlet 111 and a water outlet 113. The water pump 120 is connected to the water inlet 111. The one-way valve 140 is arranged on the water flow pipe. The first temperature sensor 151 is arranged on the water inlet 111 to detect the temperature of the inlet water. . The second temperature sensor 153 is provided at the...

no. 2 example

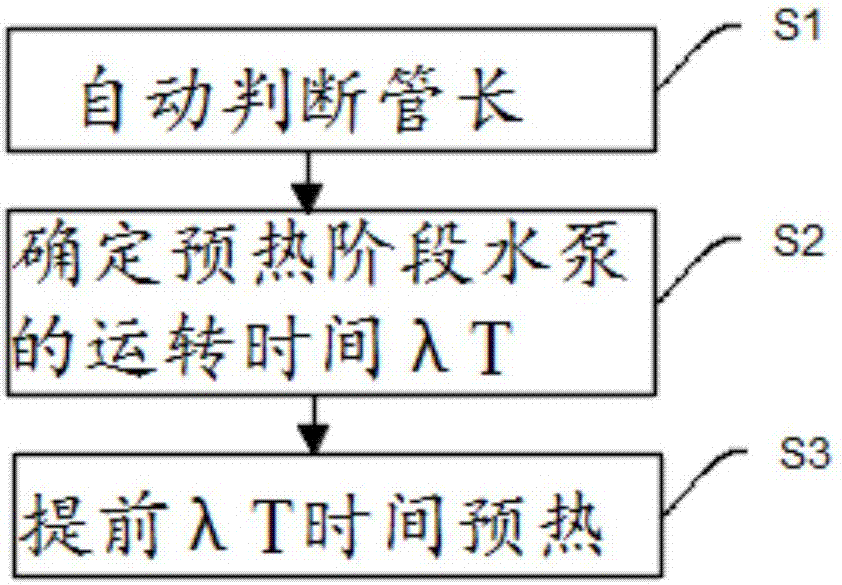

[0060] figure 2 This is the control principle diagram of the water heater preheating method provided by the second embodiment of the present invention, please refer to figure 2 .

[0061] The preheating method for a water heater provided in this embodiment is applied to the water heater 100 in the first embodiment and includes the following steps:

[0062] S1: Automatically judge the tube length. The length of the water flow pipeline of the water heater 100 is judged, and the preheating period T of the entire pipeline is determined.

[0063] S2: Determine the operating time λT of the water pump 120 in the warm-up phase. That is, the preheating period λT of the hot water pipe 131 is determined and the preheating period λT of the hot water pipe 131 is stored.

[0064] S3: Warm up ahead of time λT. When the system time of the water heater 100 is in the reserved time period set by the user and is advanced by λT, and the water temperature in the hot water pipe 131 is lower than the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com