Method for preparing U-shaped seamless steel pipe of high-pressure feedwater heater

A technology of high-pressure water supply and seamless steel pipes, which is applied to chemical instruments and methods, cleaning methods and utensils, containers, etc., can solve problems such as too thick pipe walls, thick pipe diameters, and poor surface quality, and achieve uniform pipe walls and clean pipes. The effect of thin wall and long line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

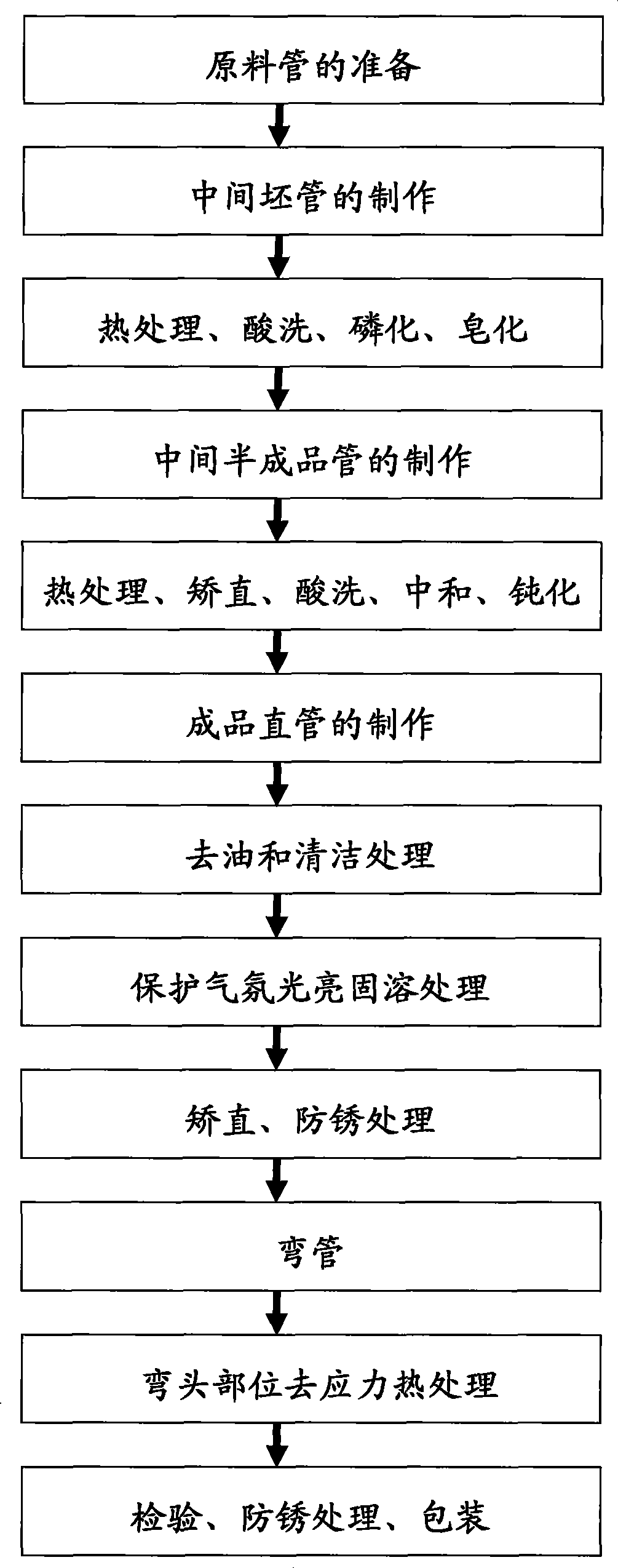

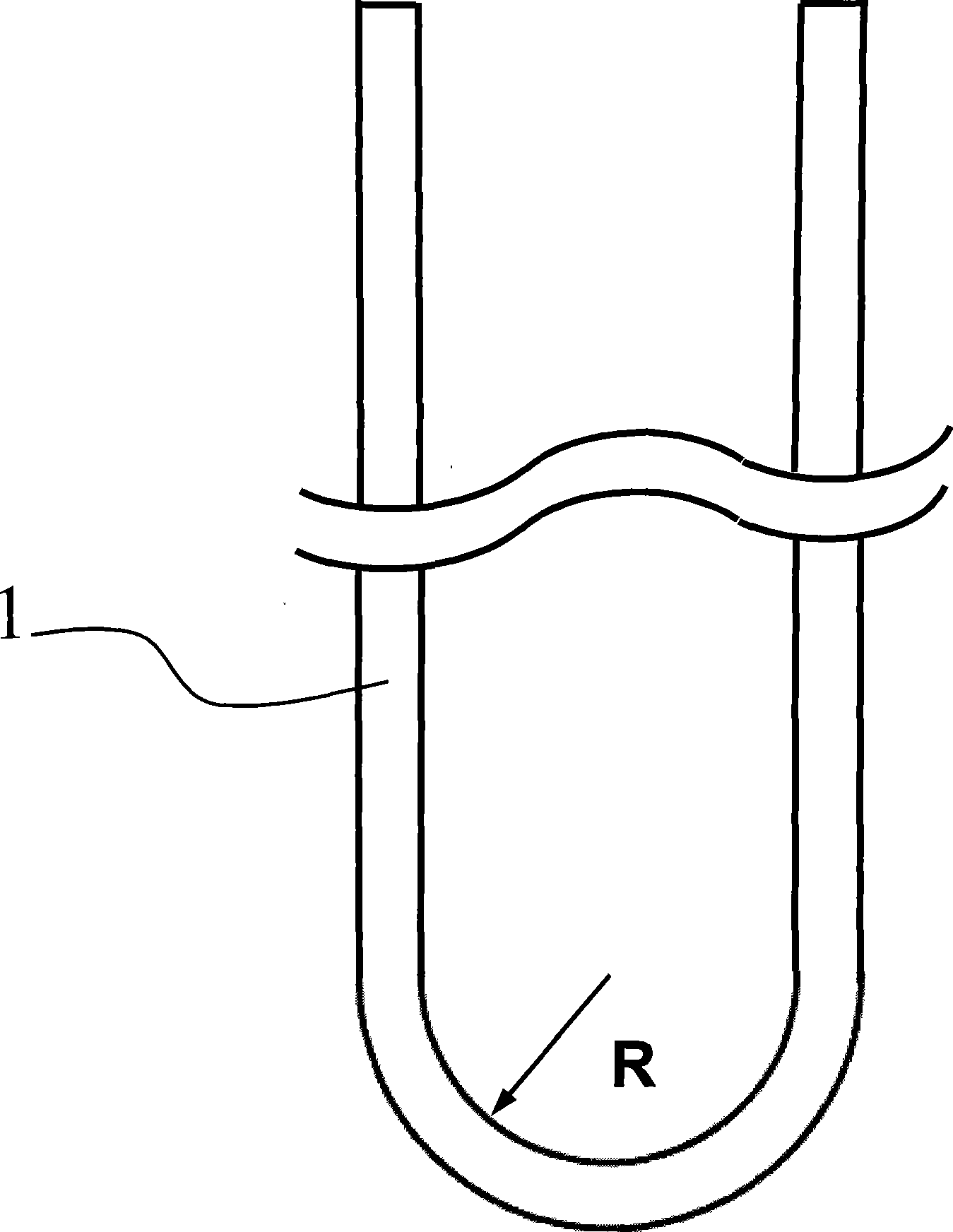

[0046] like figure 1 Shown, making small-diameter, thin-walled, extra-long U-shaped seamless high-plus pipe comprises the following steps:

[0047] 1) After the tube blank of Φ51mm×4.25mm obtained after perforation is trimmed, headed, smoothed, pickled, phosphated, saponified, and ground, the raw material tube is obtained;

[0048] 2) The raw material pipe is cold drawn twice through the cold drawing equipment and the inner mold head, and the outer diameter of the steel pipe is reduced to 45±0.50mm and 38±0.40mm successively, and the wall thickness is successively reduced to 3.45±0.30mm and 2.95±0.30mm , to make the intermediate blank tube;

[0049] 3) Carry out annealing heat treatment to the intermediate blank tube in step 2), carry out straightening, pickling, phosphating, saponification after heat treatment:

[0050] 4) The intermediate blank tube after annealing heat treatment, straightening, pickling, phosphating and saponification treatment is further emptied by cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com