Device for preparing glass tube and preparation method for device

A technology for preparing a device and a glass tube, which is applied in glass pressing, glass manufacturing equipment, glass forming, etc., can solve the problems of dimensional accuracy affecting secondary drawing accuracy, secondary drawing application and promotion restrictions, etc., and achieve economical savings. Energy and investment costs, the effect of maintaining squeeze and draw, avoiding investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

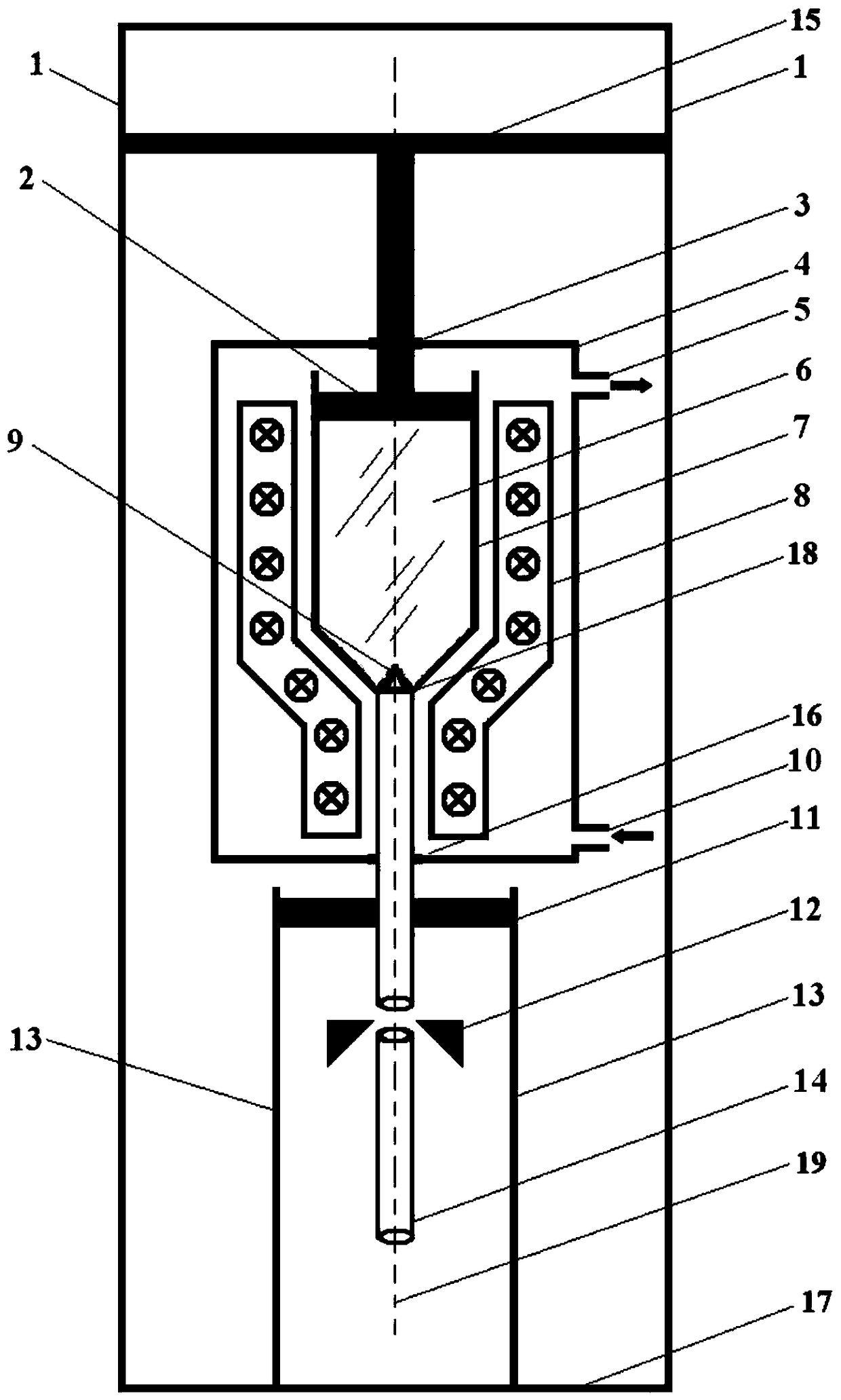

[0049] figure 1 is a structural schematic diagram of an embodiment of the glass preparation device of the present invention, such as figure 1 As shown, the glass tube preparation device provided by the embodiment of the present invention includes: a forming mechanism and an extrusion mechanism, wherein,

[0050] The forming mechanism includes an upper mold 2, a lower mold 7 and a heating furnace;

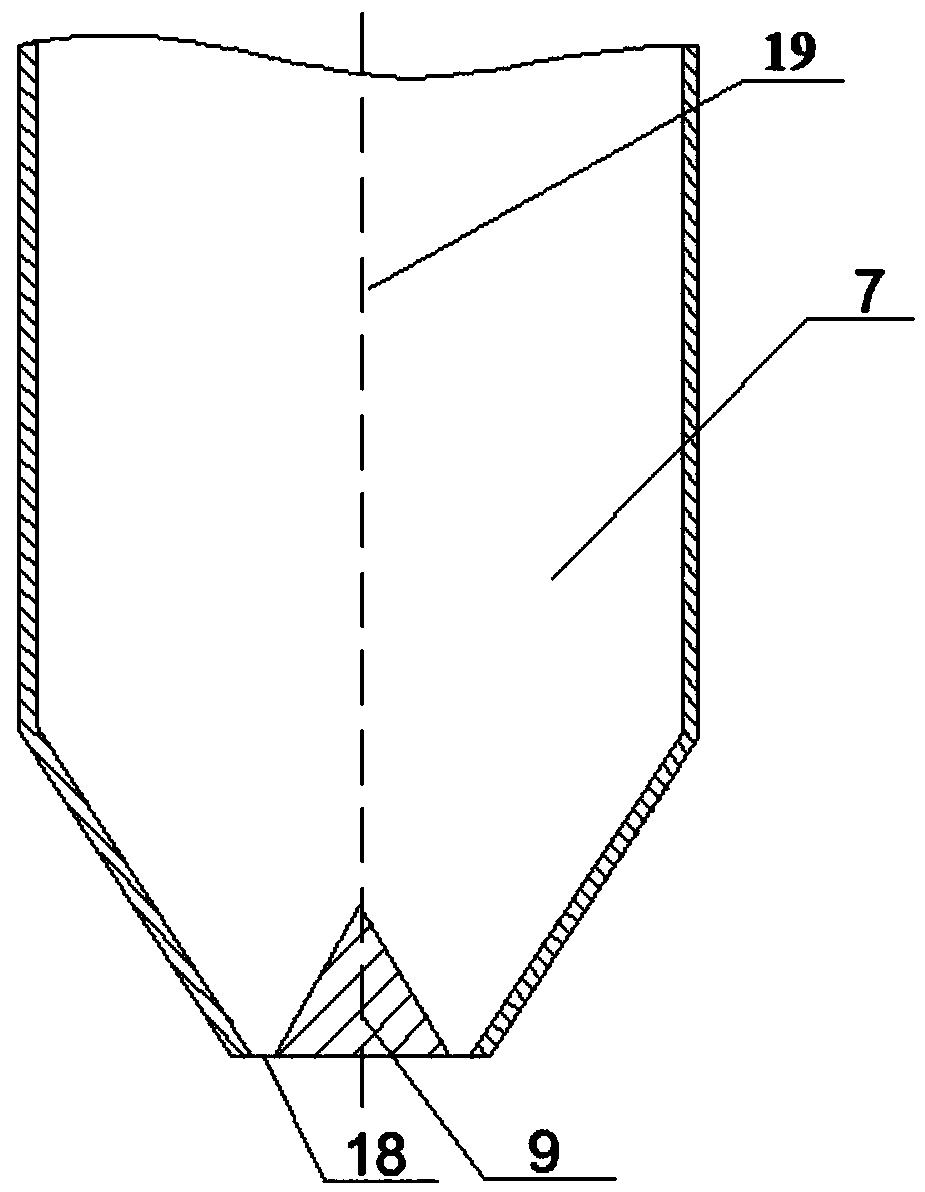

[0051] figure 2 It is a structural schematic diagram of a lower mold of a glass preparation device provided in an embodiment of the present invention, as figure 2 As shown, the lower mold 7 includes a cylindrical cavity of the upper section and an inverted conical cavity of the lower section; the cylindrical cavity communicates with the inverted conical cavity; the inverted conical cavity is provided with an opening 18 at the tip of the cone .

[0052] Forming part 9 is arranged in the inverted conical cavity of lower mold 7, and forming part 9 is used for the shaping of glass...

Embodiment 1

[0105] The present embodiment provides a kind of preparation method of glass tube, adopts such as figure 1 The preparation device of shown glass tube, it comprises the steps:

[0106] (1) Production of glass preforms:

[0107] Select glass raw materials, by weight percentage, include the following components: SiO 2 : 80.6%, B 2 o 3 : 13%, Al 2 o 3 : 2%, Na 2 O: 3.5%, K 2 O: 0.5% and Sb 2 o 3 : 0.4%; make the glass raw material into a glass preform rod with a size of Φ120mm, and the glass preform rod has no defects such as bubbles, streaks and stones;

[0108] (2) Heat treatment of the glass preform: put the above glass preform into the heating furnace body for heat treatment to soften the glass preform; ℃; the temperature of the middle section is 840±1℃; the temperature of the lower section is 520℃;

[0109] (3) Extrusion forming: the softened glass preform is extruded and formed, the extrusion force is 80MPa, the extrusion rate is 0.2mm / min, and the drawing rate is 1...

Embodiment 2

[0112] The present embodiment provides a kind of preparation method of glass tube, adopts such as figure 1 The preparation device of shown glass tube, it comprises the steps:

[0113] (1) making of glass preform: same as embodiment 1;

[0114] (2) Heat treatment of the glass preform: put the above glass preform into the heating furnace body for heat treatment to soften the glass preform; ℃; the temperature of the middle section is 850±1℃; the temperature of the lower section is 480℃;

[0115] (3) Extrusion forming: the softened glass preform is extruded and formed, the extrusion force is 150MPa, the extrusion rate is 0.1m / min, and the drawing rate is 22.2mm / min to obtain a glass tube with an outer diameter Φ 外 =9mm, inner diameter Φ 内 = 4 mm.

[0116] The apparent quality inspection of the glass tube prepared in this example shows that the glass tube has an outer diameter deviation of ±0.05 mm and an inner diameter deviation of ±0.05 mm, which has the advantages of high r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com