Engine-boiler coupled deep waste heat utilization system for air cooling unit

An air-cooled unit and machine-furnace technology, which is used in preheating, steam boilers, feedwater heaters, etc., can solve the problems of low thermal cycle efficiency and high coal consumption for power generation, achieving significant economic benefits, optimal utilization of waste heat, and increased power output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention proposes a waste heat deep utilization system coupled with an air-cooling unit and a furnace. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

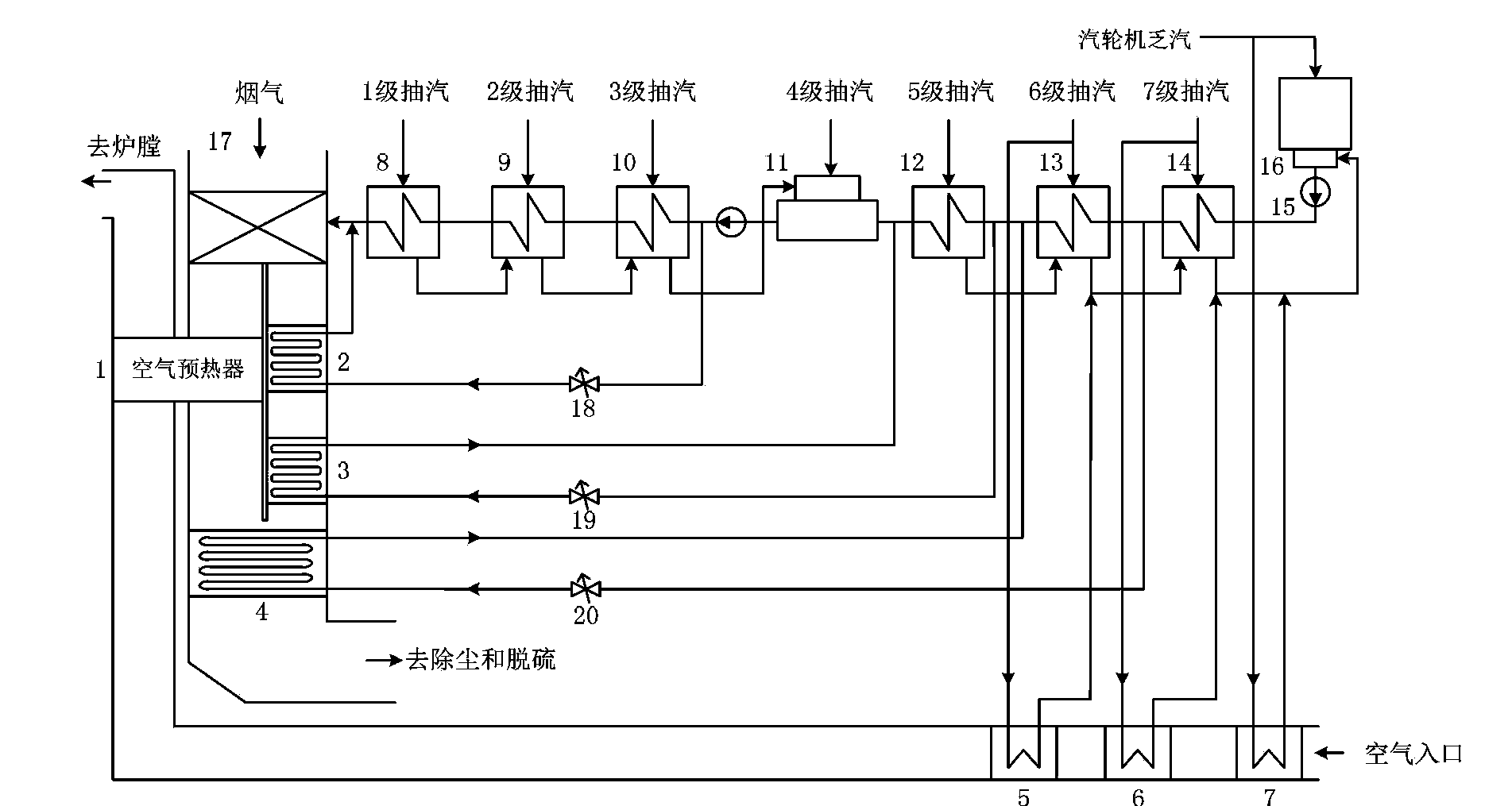

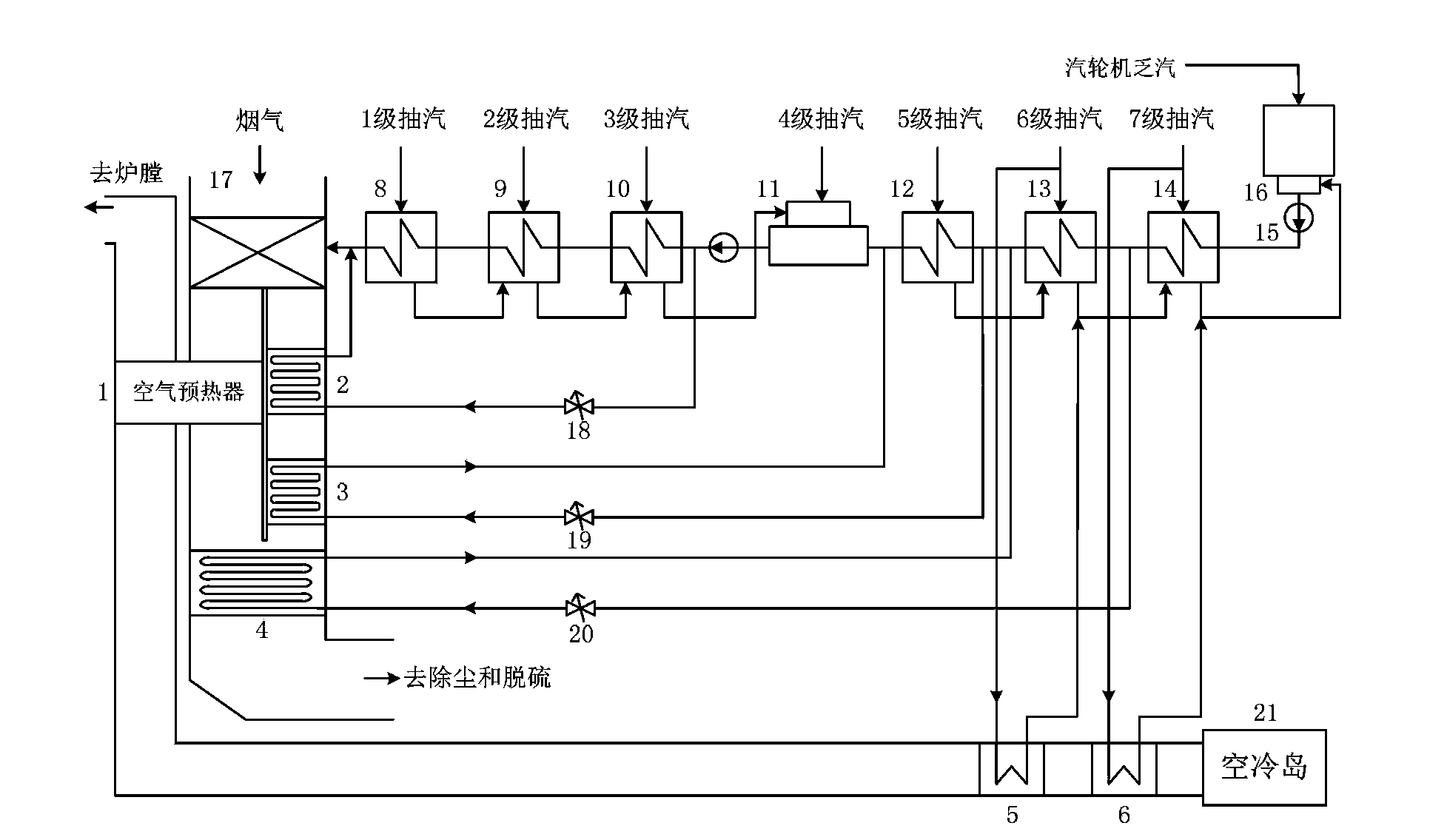

[0017] Such as figure 1 In the schematic diagram of the system structure shown in the first implementation case, an economizer 17, an air preheater 1, a feed water heater 2, and a condensate water heater 3 are arranged in sequence in the boiler flue of the system; exhaust steam from the steam turbine enters the hot well of the condenser 16, and then through the condensate pump 15, 7# heater 14, 6# heater 13, 5# heater 12, deaerator 11, 3# heater 10, 2# heater 9, 1# heater 8 Pass into economizer 17. The principle is: a three-stage extraction air heater is arranged in front of the air preheater 1, and the first-stage extraction air heater 7 uses the exhaust steam at the outlet of the steam turbine to heat the air, and the exhaust steam releases he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com