Patents

Literature

43results about How to "Reduce cooling water consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

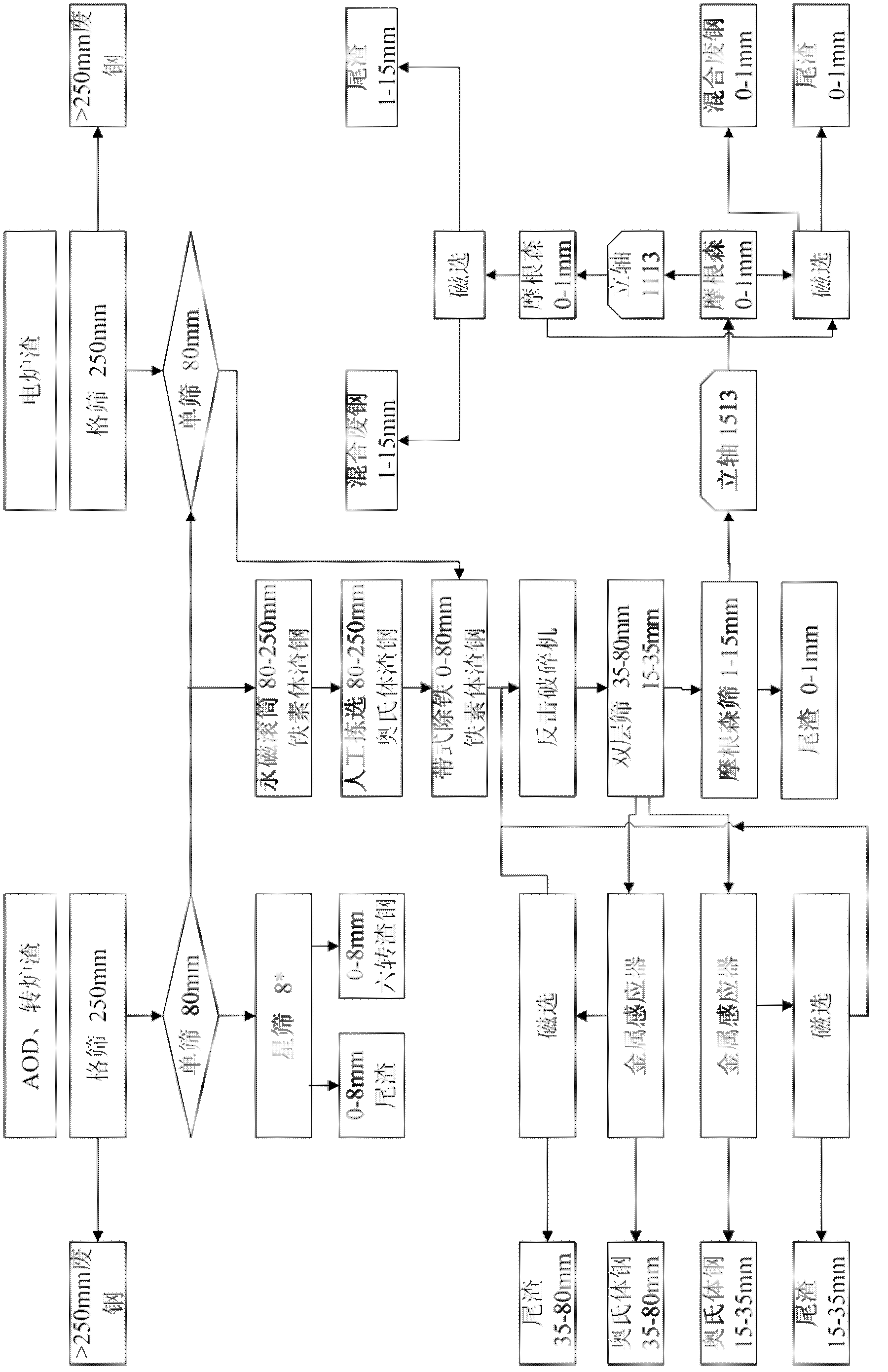

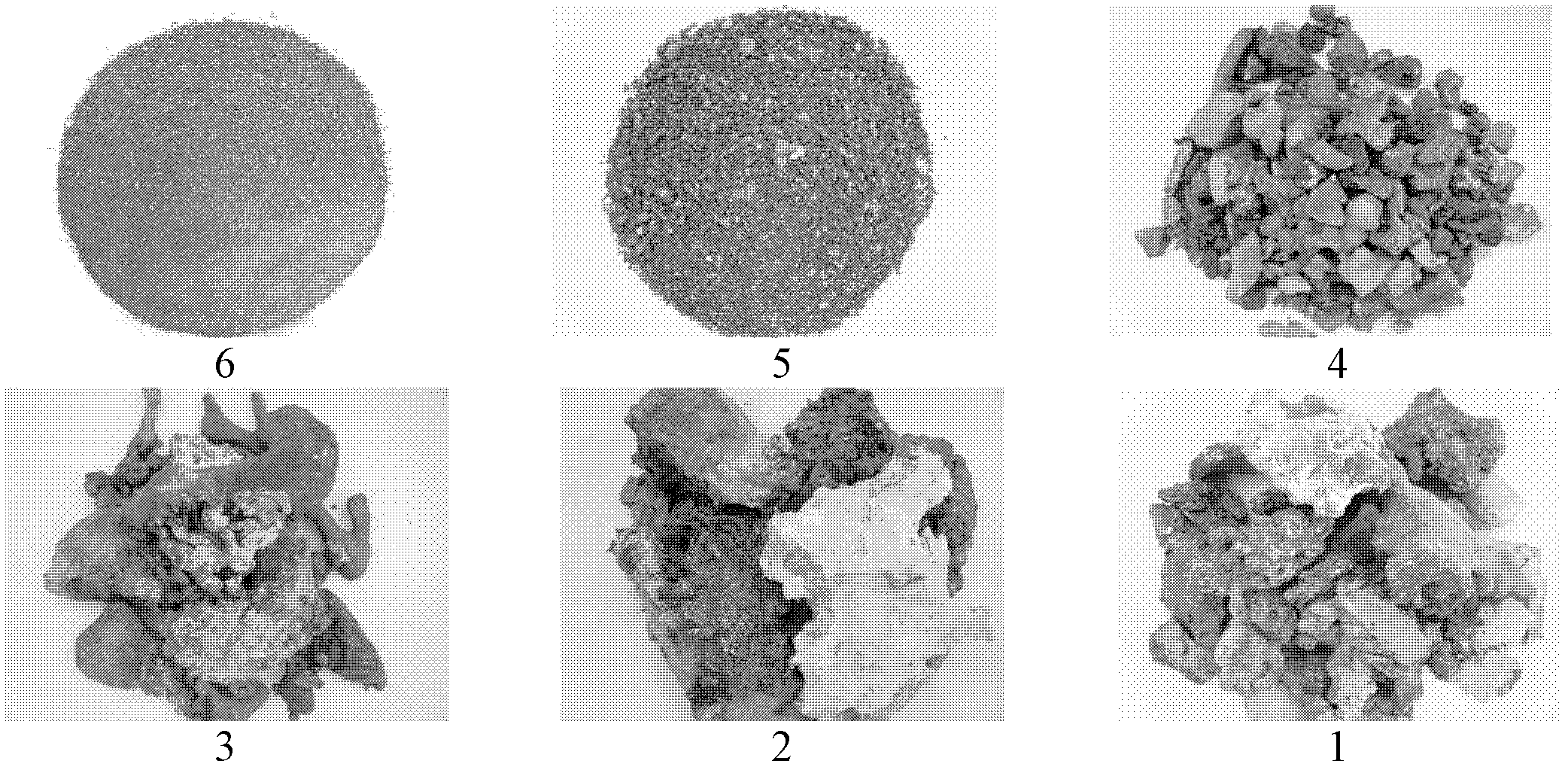

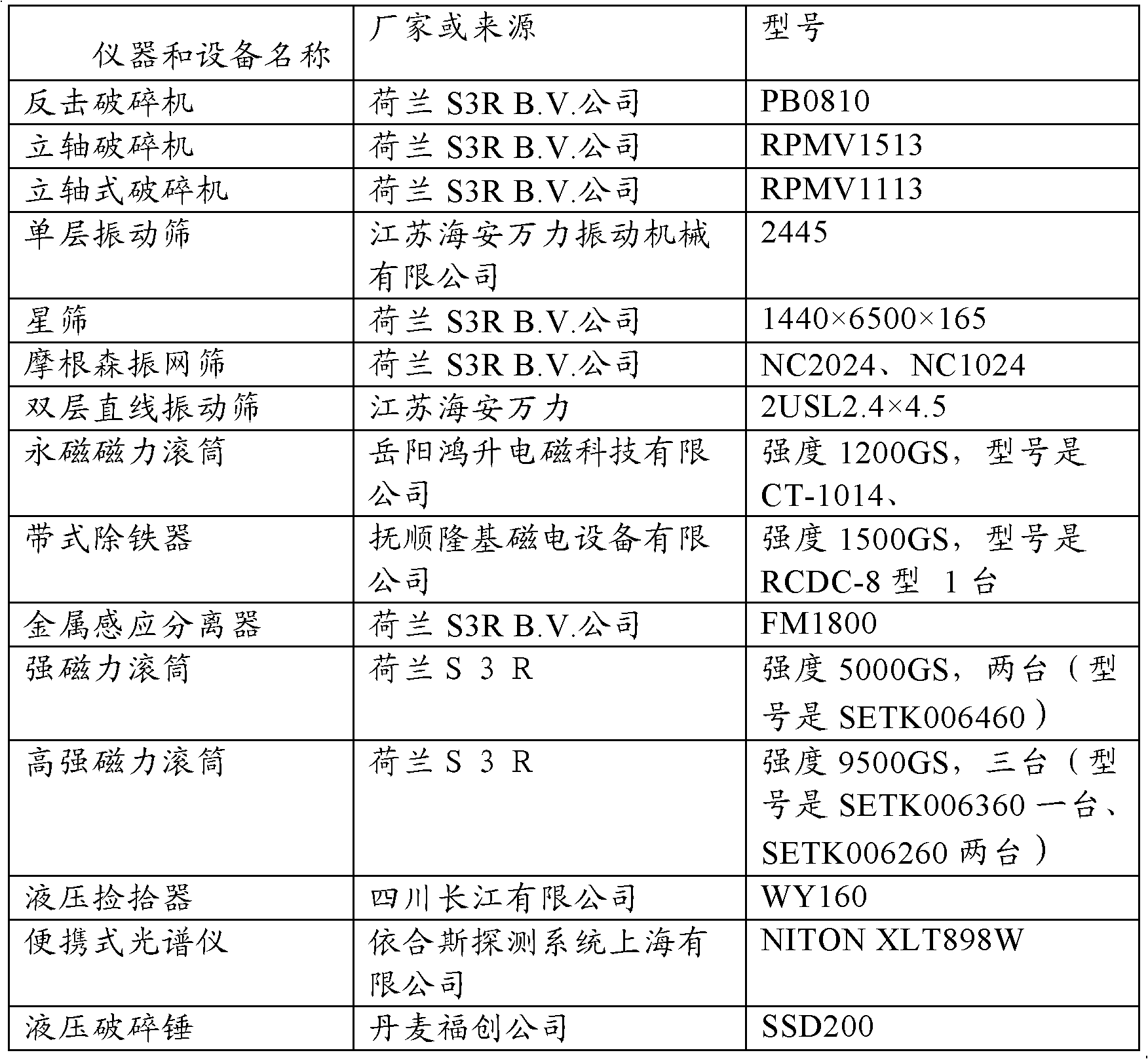

Stainless steel slag treatment method

ActiveCN102586517AMeet energy saving and emission reduction requirementsAchieve slag modificationRecycling and recovery technologiesProcess efficiency improvementSlagBoron

The invention relates to a stainless steel slag treatment method, which comprises the following steps of: (1) adding a modifier: adding a boron modifier into steel slag in the deslagging process; (2) cooling: cooling the steel slag added with the boron modifier to the temperature of below 80DEG C; and (3) grading for multiple times: (31) primarily grading: primarily grading the steel slag into three kinds of steel slag with coarse particles, medium particles and fine particles, applying a first magnetic field to the medium steel slag to separate the medium steel slag into a ferrite slag steel product and mixed waste slag, mixing the fine steel slag and the mixed waste slag obtained through separation in the step (313), applying a second magnetic field to separate into a ferrite slag steel product and mixed waste slag, and separating the mixed waste slag into an austenite slag steel product and mixed waste slag through a spectrograph. By the method, tank cooling and dry-process treatment in the whole process of slag modification, steel slag cooling, crushing, metal sorting and the like is realized, and the energy conservation and emission reduction requirements of iron and steel enterprises are met.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

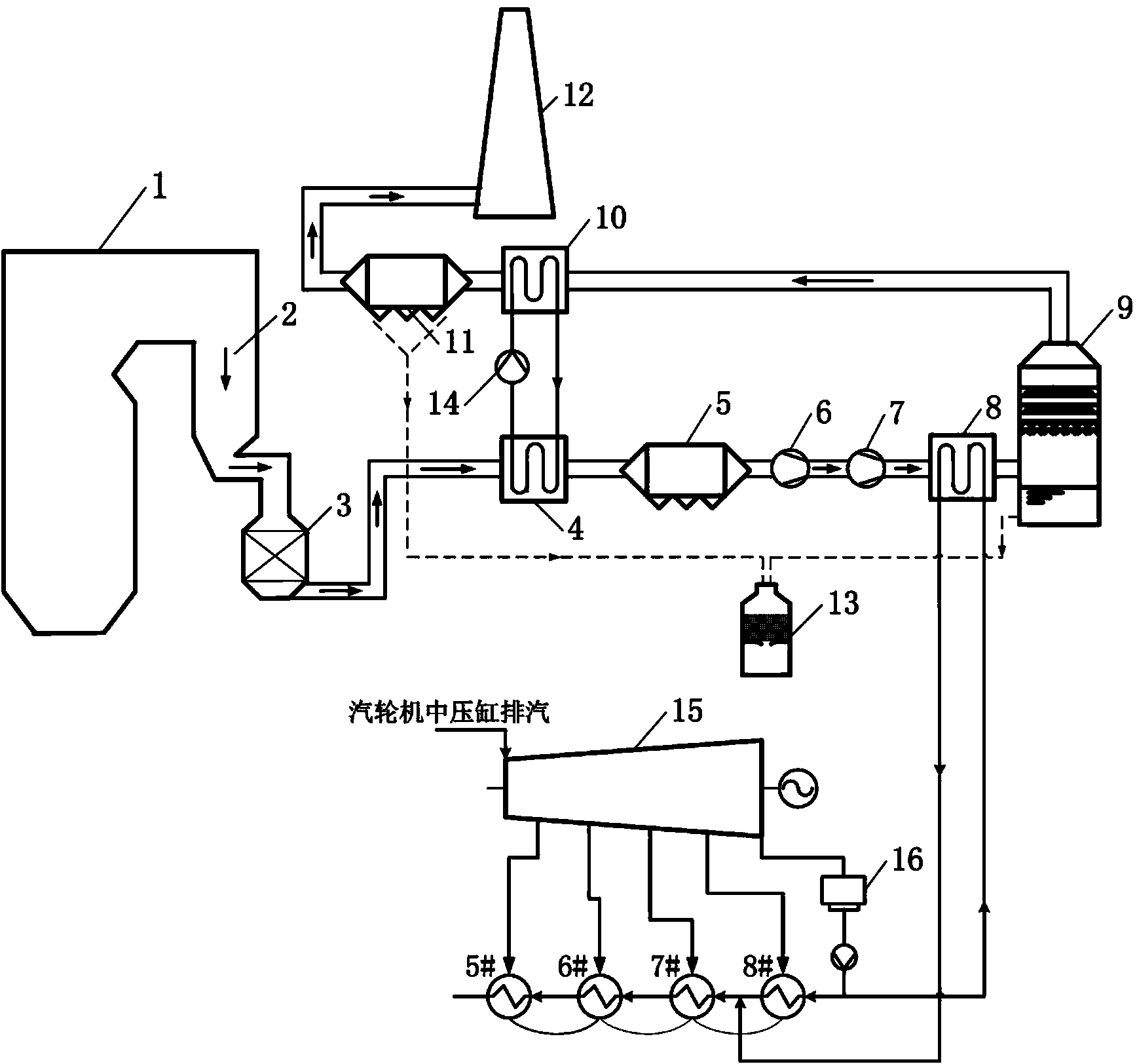

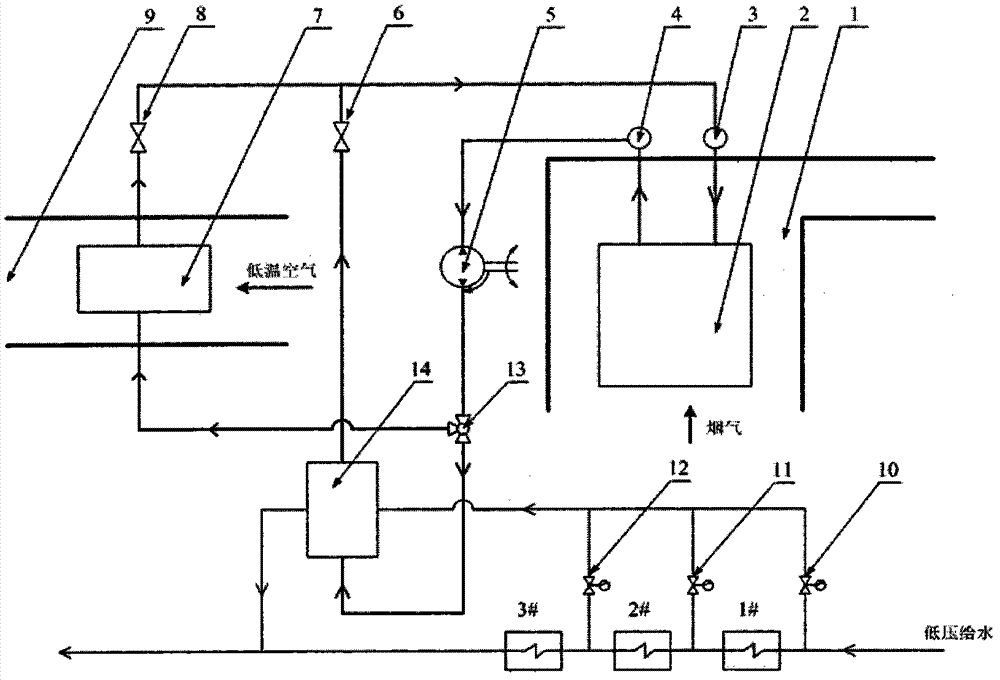

Dedusting, desulfuration and waste-heat utilization integrated system with low PM2.5 emission

ActiveCN103968401APrevention of "Gypsum Rain" PhenomenonEmission controlFeed-water heatersAir preheaterAtmospheric air

The invention discloses a dedusting, desulfuration and waste-heat utilization integrated system with low PM2.5 emission. The system is composed of a boiler rear smoke channel, an air pre-heater, smoke-water heat exchangers, dust extraction devices, a desulphurization device, a low pressure heat regenerative system and a chimney. The outlet of the air pre-heater of the system is connected with the first-level smoke-water heat exchanger, after smoke is cooled through the heat exchanger, large solid particles carried in the smoke are removed through the first-level dust extraction device, then the smoke enters the second-level smoke-water heat exchanger through an induced draft fan and a booster fan to heat a part of power plant condensed water, and finally the smoke enters the desulphurization device. The outlet of the desulphurization device of the system is connected with the third-level smoke-water heat exchanger, after the smoke is heated up, the smoke enters the second-level dust extraction device to remove plaster particles, and finally the smoke is discharged to the atmosphere through the chimney. The dedusting, desulfuration and waste-heat utilization integrated system with the low PM2.5 emission can prevent the phenomenon of plaster rain of coal-fired power plants from occurring, can effectively reduce the emission load of PM2.5 of coal-fired power plants, and has the advantages of being simple in structure, mature in equipment technology and good in dedusting effect.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

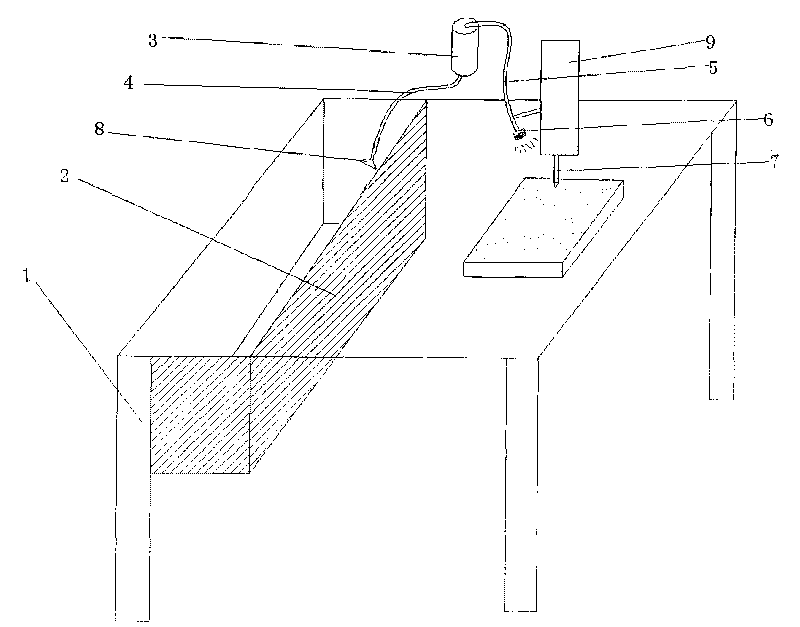

Circulating splash water cooling device of engraving machine

InactiveCN101734068AEffective filteringReduce cooling water consumptionModel makingEngravingEngineeringFluid level

The invention discloses a circulating splash water cooling device of an engraving machine. The cooling device comprises a storage tank fixedly arranged in a chassis and a water pump, wherein the storage tank is loaded with cooling water; the water inlet of the water pump is connected with a water inlet pipe, the water outlet of the water pump is connected with a water outlet pipe, the water inlet pipe extends in the storage tank and below the fluid level of the cooling water, the front end of the water outlet pipe is provided with a nozzle, and the nozzle directly faces to the cutter of the engraving machine. The invention adopts a circulating water system to cooling the cutter of the engraving machine, the water consumption is low, the production cost is reduced, and the production environment is improved.

Owner:晋兵

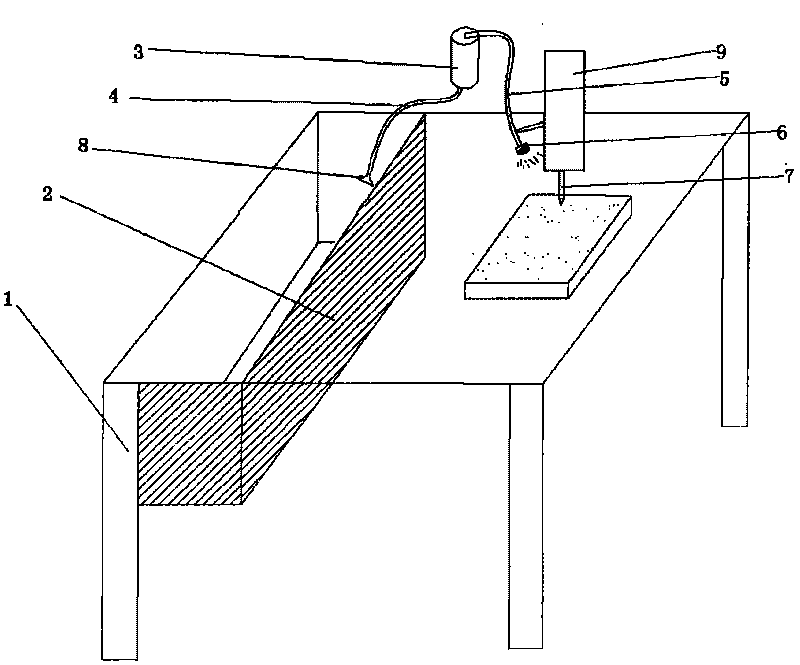

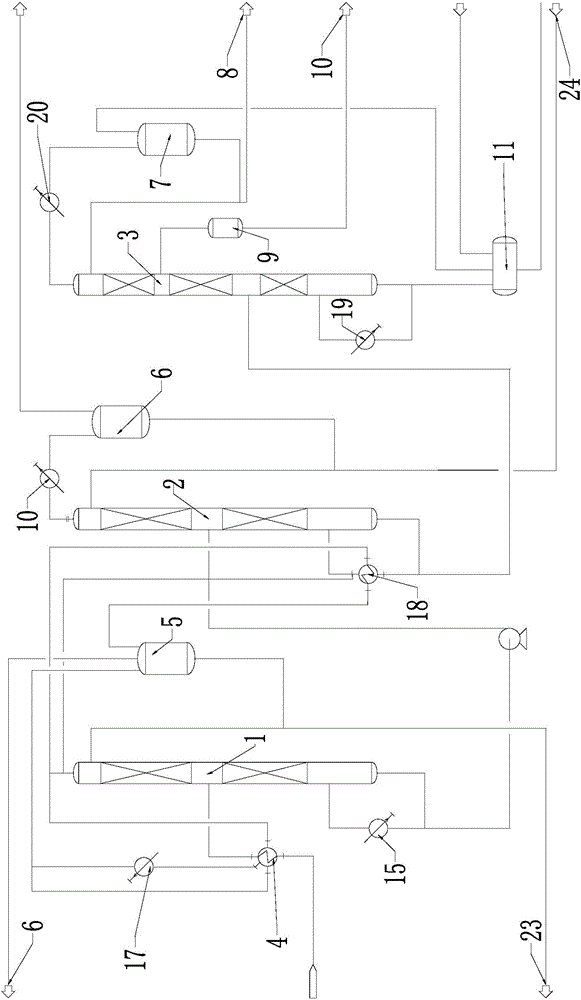

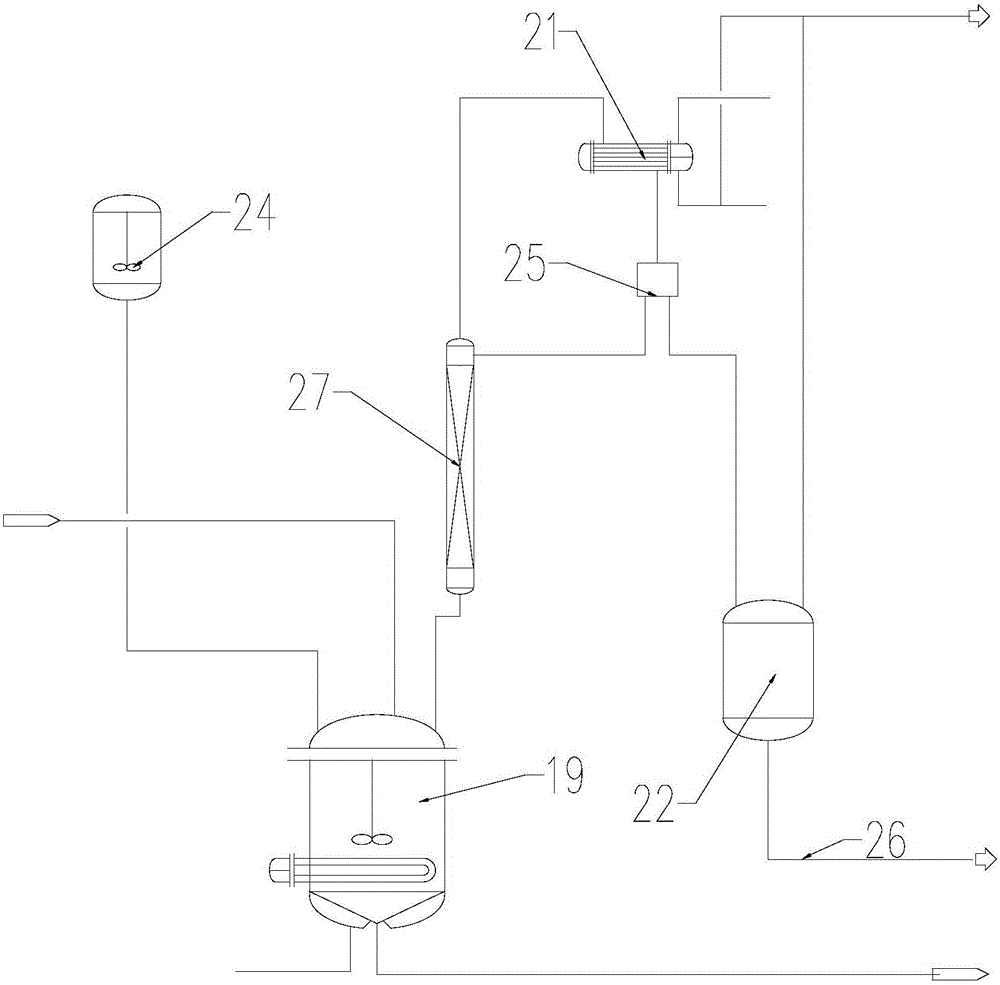

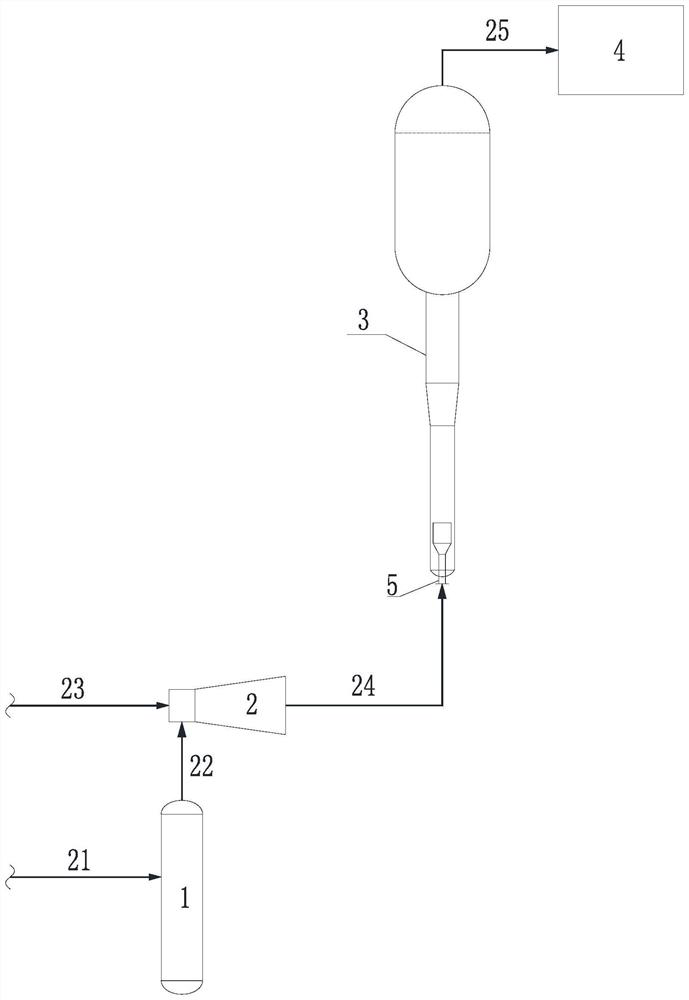

Waste water disposal technique by union of steam recompression evaporation and flue spraying technology

InactiveCN107954560AReduce consumptionLow costElectrostatic separationWater/sewage treatmentVapor–liquid separatorEvaporation

The invention discloses a waste water disposal technique by union of steam recompression evaporation and flue spraying technology. The technique includes steps of removing suspended solid and calciumfrom waste water; then delivering waste water to a raw water tank by a water delivering pump after filtering, delivering waste water to a preheater by a raw water pump and a raw water filter to heat;after preliminarily preheating the waste water, heating in a pipe box at the lower part of the heater without evaporation, and then entering a gas fluid separator to carry out flashing and generate enough steam, absorbing steam to a steam compressor; using the secondary steam compressed and heated by the steam compressor as a new heat source and delivering to a shell side of the heater to releasethe potential heat; closing a steam door and realizing the self-circulation evaporation and heat transfer; drawing waste water without being evaporated in the gas fluid separator at a conical side ofthe lower part; delivering the circulated pump to the heater to circularly absorb heat; after circular evaporation for many times, discharging concentrated waste water from one path of the bottom partof the gas fluid separator to a concentrated water box and then delivering to a flue to spray and evaporate; discharging the other path to the raw water tank to adjust water balance. The waste waterdisposal technique is applicable to the treatment of waste water of a heat-engine plant.

Owner:XIAN XIELI POWER TECH

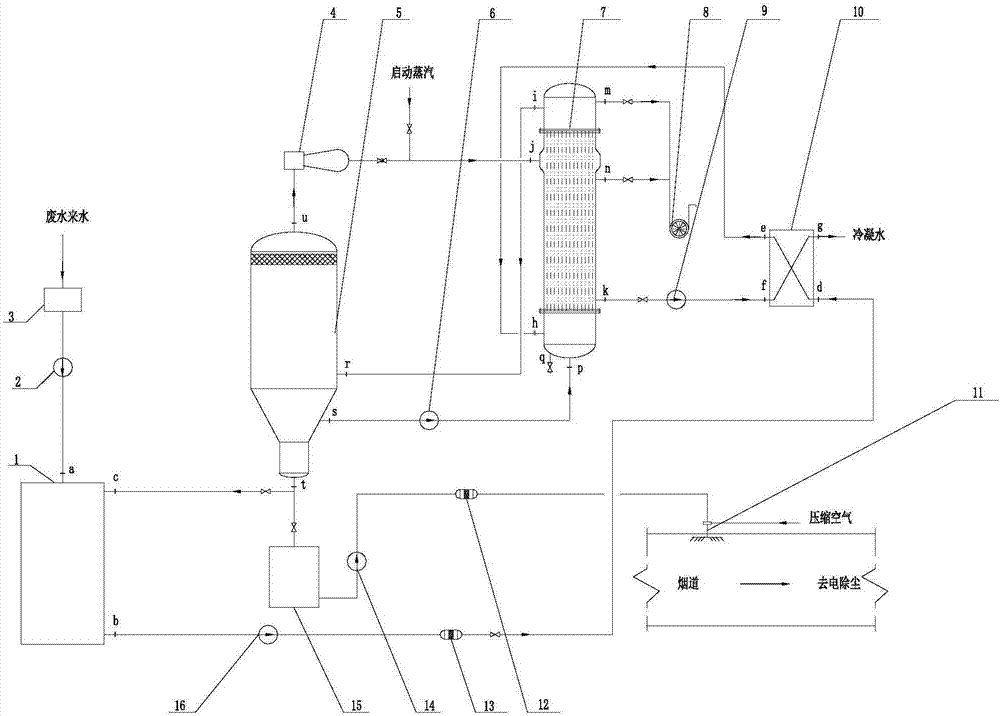

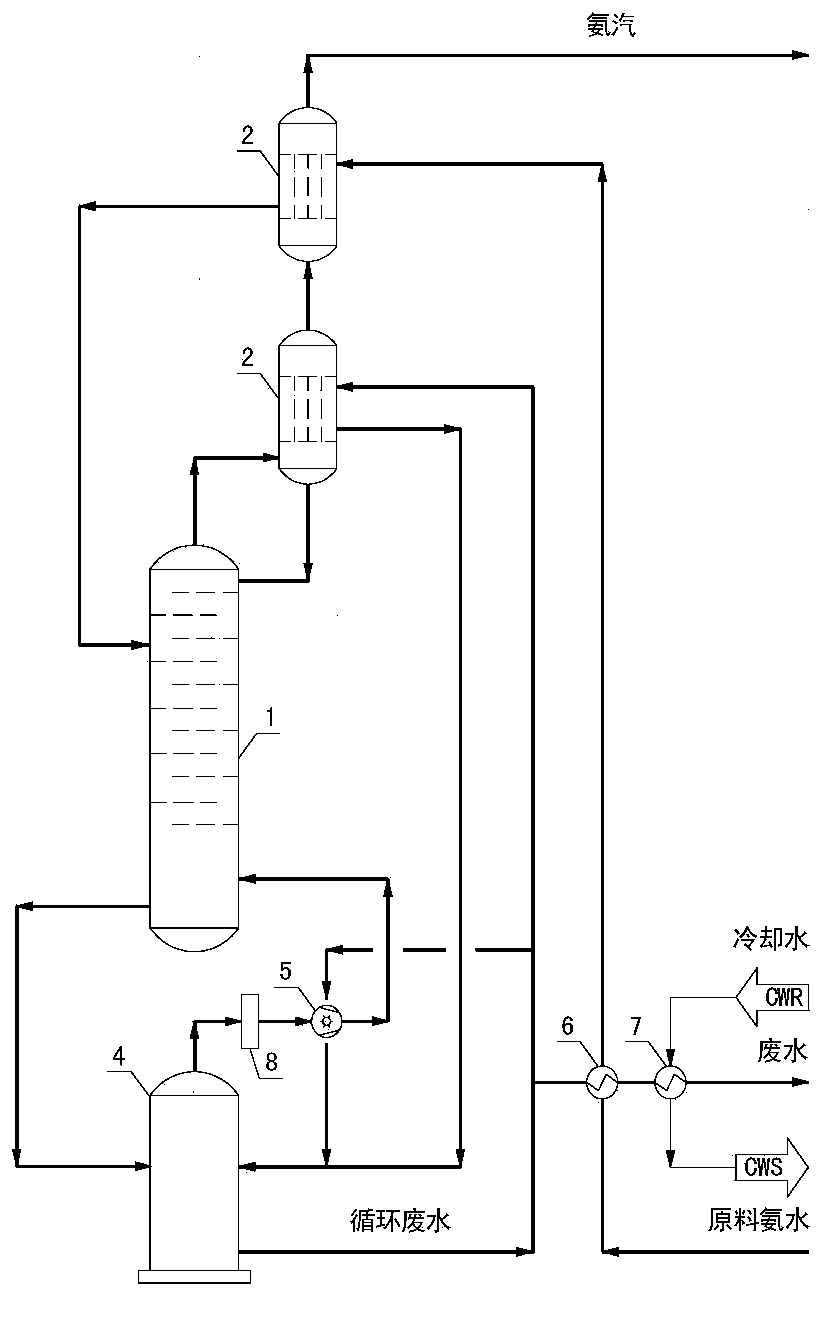

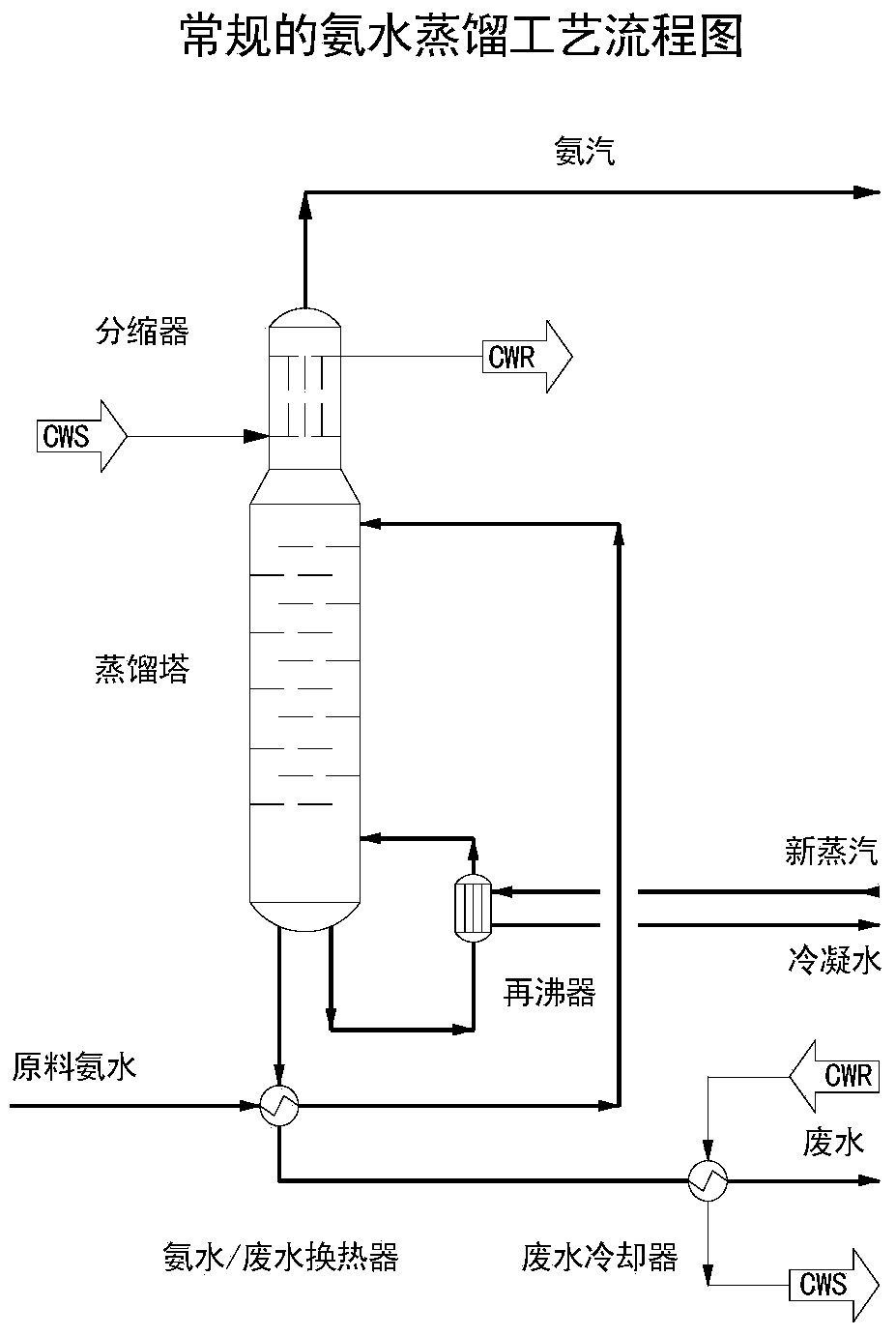

Energy-saving ammonia water distillation technology

ActiveCN103641193AAchieving heat balanceReduce cooling water consumptionChemical industryWater/sewage treatment by heatingChemistryEvaporator

The invention provides an energy-saving ammonia water distillation production method which comprises the following steps: (a) providing raw material ammonia water containing NH3 and impurities generated in the production process of chemical enterprises, wherein the impurities comprise H2S, HCN and / or CO2 impurities; (b) performing heat exchange between high-temperature wastewater at the bottom of a distillation tower and the raw material ammonia water and allowing the high-temperature wastewater to enter an evaporator or directly allowing the high-temperature wastewater to enter the evaporator, and performing partial flashing to generate first low-entropy steam, so that the temperature is reduced to be 55-125 DEG C; (c) circulating and feeding the low-temperature wastewater in the evaporator into a dephlegmator, heating the low-temperature wastewater to the temperature of 70-130 DEG C by ammonia steam, returning the wastewater back to the evaporator, and performing partial flashing to generate second low-entropy steam; (d) compressing the obtained first low-entropy steam and second low-entropy steam in the evaporator into saturated high-entropy steam at the temperature of 103-165 DEG C by an MVR (Mechanical Vapor Recompression) compressor, and feeding the saturated high-entropy steam into the distillation tower to serve as a heat supply source for distillation.

Owner:薛斌

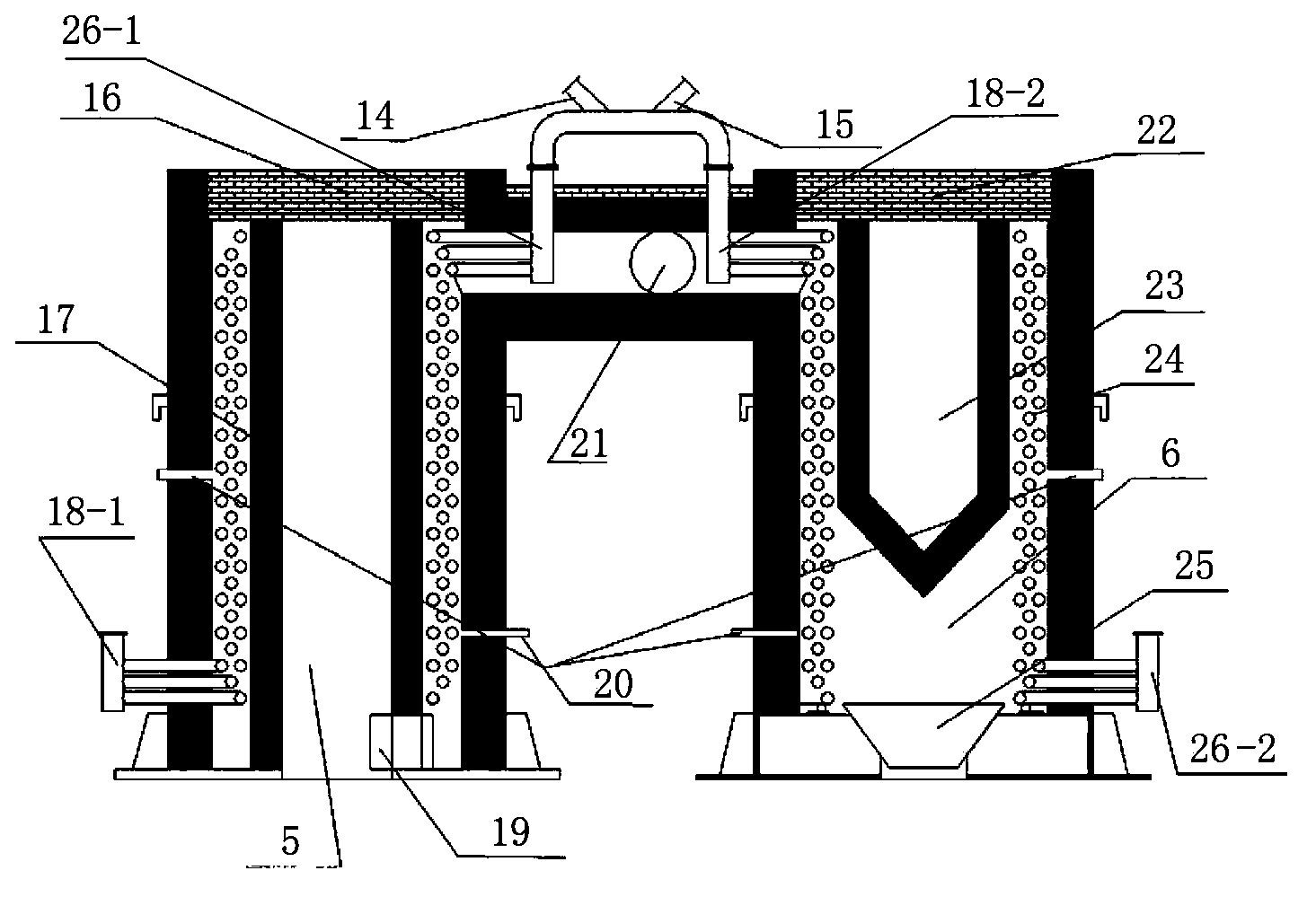

Step heating furnace beam and pole and its construction method

InactiveCN1945187AExtended service lifeGuaranteed service lifeLinings repairFiberOxidation resistant

The present invention is beam and column for walking heating furnace and their construction process. The column includes core pipe, water pipe, anchor hook, fiber blanket and cast layer; and the beam includes water pipe, anchor hook, heat resisting spacer block, fiber blanket and cast layer. The beam and the column feature the fiber blanket capable of resisting high temperature up to 1250 deg.C, the Y-type anchor hook of stainless steel capable of resisting high temperature up to 1050-1150deg.C and coated with asphalt paint, and the cast layer of material with cured strength not lower than 90 MPa at 1400 deg.C. The construction process of the beam and the column includes the steps of welding anchor hook, coating fiber blanket, assembling formwork, casting, demolding and stoving. The beam and the column have high strength, high heat resistance, good antioxidant performance and long service life.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Comprehensive optimized smoke discharge waste heat deep recycle system of smoke in thermal power plant

InactiveCN102818276AReduce cooling water consumptionReduce the temperatureLiquid degasificationCombustion technology mitigationProcess engineeringTower

The invention relates to a comprehensive optimized smoke discharge waste heat deep recycle system of smoke in a thermal power plant. The system comprises a smoke cooler is arranged at the back of a dust remover and in front of a desulfurizing tower in a smoke channel. A preferable scheme further comprises a smoke discharge waste heat utilizing device used for enabling absorbed heat to heat condensation water or enabling a steam air heater to heat air to improve air supply temperature. Compared with the prior art, the system greatly reduces smoke discharge temperature, simultaneously completely utilizes recycled heat and improves unit efficiency.

Owner:安徽省科捷能源科技有限公司

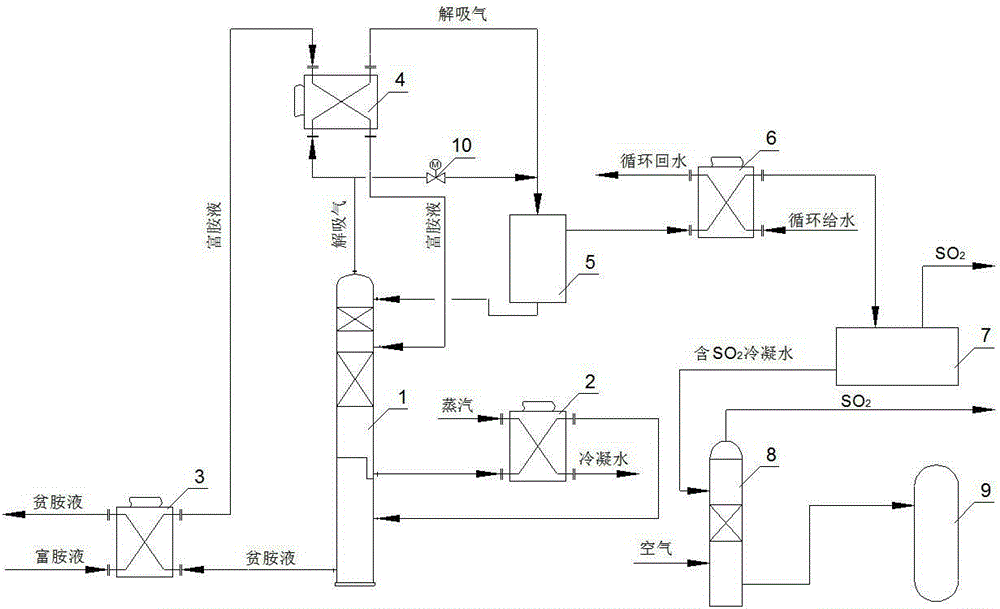

Organic amine wet flue gas desulphurization and desorption system with high-efficiency and low-energy consumption

ActiveCN105233689AReduce usageReduce cooling water consumptionDispersed particle separationReboilerChiller

The invention relates to an organic amine wet flue gas desulphurization and desorption system with high-efficiency and low-energy consumption. The desorption system comprises a desorber, a reboiler, a lean / rich amine liquid heat exchanger, a rich amine heater, a primary separator, a condensation cooler, a secondary separator, a desorption tower, an amine liquid purifying system and an electric regulating valve. A high-temperature saturated steam containing SO2 (desorbed gas for short) at the top of the desorber is directly used as a secondary heating medium of a rich amine liquid, so that the rich amine liquid entering the tower is at bubble point temperature; an integrated process system comprising step-by-step condensation cooling waste heat utilization of the high temperature desorbed gas, charging of the rich amine liquid at bubble point temperature, and backflow of a condensation liquid at bubble point temperature is used, so that effective reuse of the waste heat andreduced amounts of cooling water and heating steam are realized, the SO2 desorption efficiency of the desorber is improved, and the energy-saving effect is substantial.

Owner:TONGLING NON FERROUS METAL GROUP CORP +1

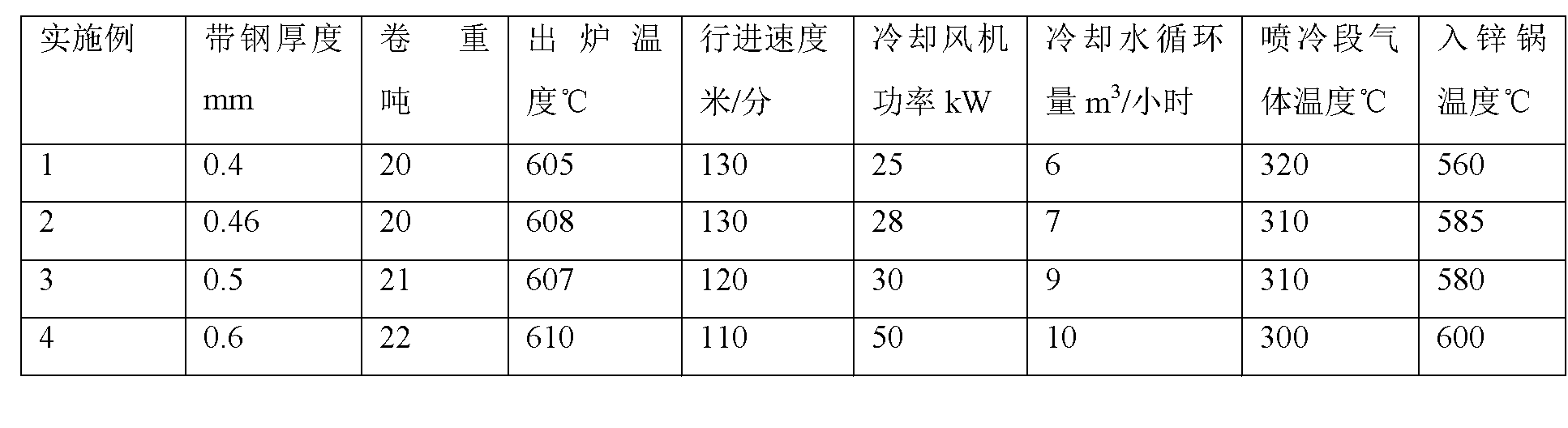

Method for increasing temperature of semi-hardness aluminum-zinc-plating strip steel entering zinc pot

ActiveCN103160767AReduce temperature dropStable temperatureHot-dipping/immersion processesFurnace typesShielding gasHardness

The invention relates to the field of producing semi-hardness aluminum-zinc-plating high-strength steel by using an annealing furnace, and in particular relates to a method for increasing the temperature of semi-hardness aluminum-zinc-plating strip steel entering a zinc pot. The method is characterized in that aiming at the 0.4-0.6nm thin strip steel, the cooling capacity of a cooling system of a cold jetting section is controlled, and the temperature of protective gas at the cold jetting section can be increased, wherein the specific control steps are as follows: (1) the running speed of the strip steel in an area of a heat-preservation and slow-cooling section and the cold jetting section is 110-130m / min; (2) the power of a fan at the cold jetting section is controlled to be within 5-10% of the rated power, and the circulation amount of cooling water is reduced to be 30-50% of the total amount of the cooling water; and (3) the temperature of the protective gas at the cold jetting section is increased to be 300-320 DEG C, and the temperature of the strip steel entering the zinc pot is controlled to be 550-600 DEG C. Compared with the prior art, the method has the beneficial effects that the stability of the temperature of the strip steel entering the zinc pot is ensured, the consumption amount of the cooling water of a cooler at the cold jetting section is saved, the power output of an electric heater is eliminated, and the aim of energy saving can be realized.

Owner:ANGANG STEEL CO LTD

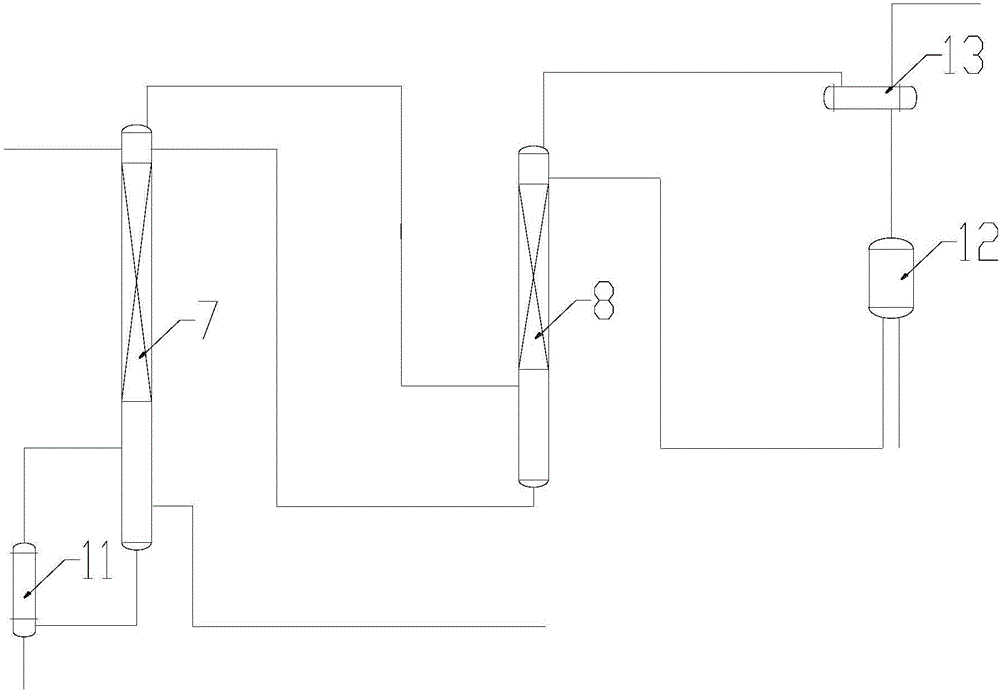

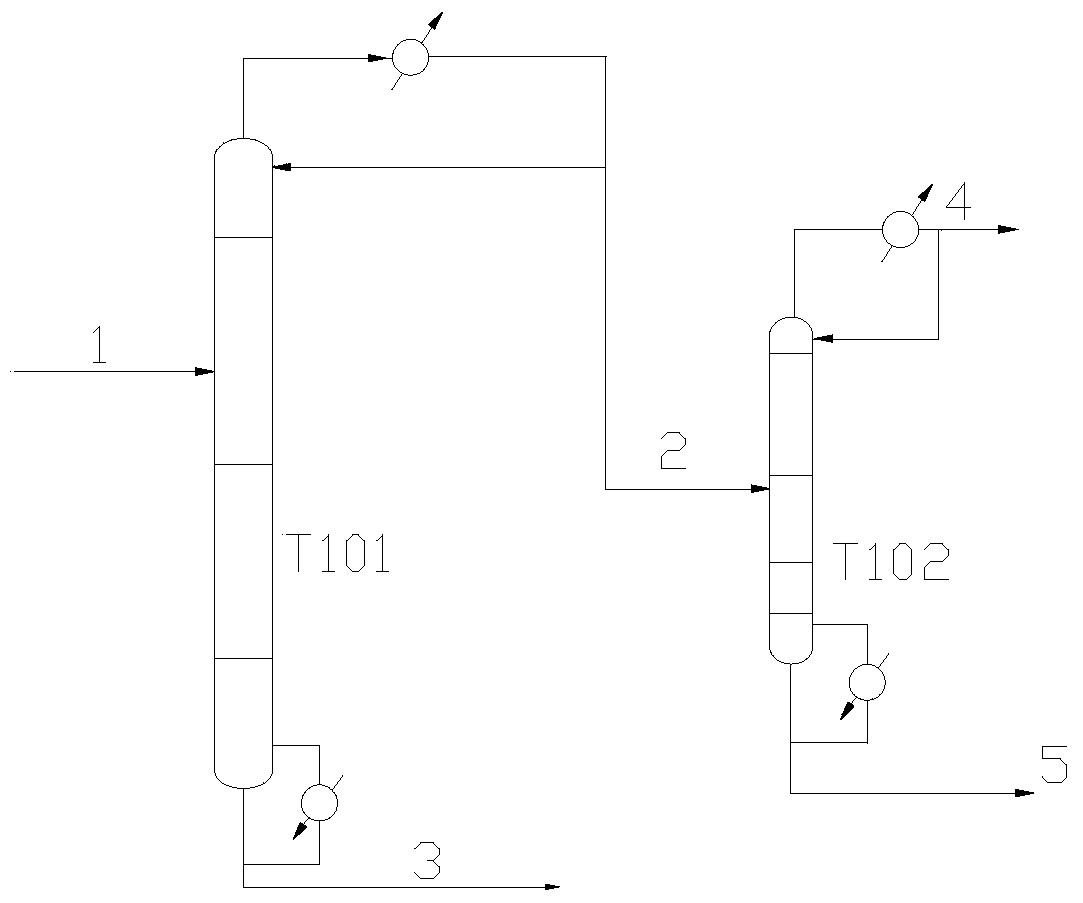

Novel rectification method

InactiveCN106220536AReduce cooling water consumptionReflect the characteristics of energy saving and consumption reductionOrganic chemistryOrganic compound preparationRefluxTower

Provided is a novel rectification method. The method comprises a dehydration process and a product refining process, and the method is suitable for the components that no azeotropy or association exists between two components and is used for solving the problems that a product is prone to thermal decomposition and low in purity in the rectification process of the substances. The method comprises the steps that a waste fluid containing a low-concentration product is pumped into a dehydrating tower, and the waste fluid in a tower kettle of the dehydrating tower is heated to be steam and then condensed into a fluid on the tower top to enter a first reflux tank; the fluid in the tower kettle of the dehydrating tower enters a product tower, and the fluid in a tower kettle of the product tower is heated to be steam and then condensed into a fluid on the tower top to enter a second reflux tank; the fluid in the tower kettle of the product tower enters a product refining tower, the fluid in a tower kettle of the product refining tower is heated to be steam and then condensed into a fluid on the tower top to enter a third reflux tank, and a qualified product is obtained from a liquid phase at the rectifying section of the product refining tower.

Owner:烟台国邦化工机械科技有限公司

Stepwise heating furnace beam and pole and its construction method

InactiveCN100494852CExtended service lifeGuaranteed service lifeLinings repairFiberOxidation resistant

The present invention is beam and column for walking heating furnace and their construction process. The column includes core pipe, water pipe, anchor hook, fiber blanket and cast layer; and the beam includes water pipe, anchor hook, heat resisting spacer block, fiber blanket and cast layer. The beam and the column feature the fiber blanket capable of resisting high temperature up to 1250 deg.C, the Y-type anchor hook of stainless steel capable of resisting high temperature up to 1050-1150deg.C and coated with asphalt paint, and the cast layer of material with cured strength not lower than 90 MPa at 1400 deg.C. The construction process of the beam and the column includes the steps of welding anchor hook, coating fiber blanket, assembling formwork, casting, demolding and stoving. The beam and the column have high strength, high heat resistance, good antioxidant performance and long service life.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for recycling heat energy from returned cooling water in production of polysilicon

InactiveCN101762174AReduce cooling water consumptionSave waterSteam generationIncreasing energy efficiencyLithium bromideEngineering

The invention relates to a method for recycling heat energy from returned cooling water in the production of polysilicon, belonging to the production field of polysilicon. In order to solve technical problem, the invention provides a method for recycling heat energy from returned cooling water in the production of polysilicon, which has high utilization rate of recycling heat energy from the returned cooling water. The method for recycling heat energy from returned cooling water in the production of polysilicon comprises the following steps: a, transfer of heat energy: the returned cooling water is adopted to concentrate lithium bromide dilute solution; b, release of heat energy: the concentrated lithium bromide solution is sprayed by water and the heat discharged therefrom is used to heat water to result in superheated water from 138 to 145 DEG C; and c, preparation of high temperature saturated steam: the superheated water is added to a flash device in order to instantaneously gasify the superheated water to the saturated steam from 128 to 132 DEG C. The method according to the invention has the advantages of: reducing the large use amount of cooling water for plate heat exchange, saving water resource, providing stable and excellent heat source for polysilicon, lowering the use amount of steam, economizing on energy and being favourable for environmental protection.

Owner:LESHAN LEDIAN TIANWEI SILICON TECH CO LTD

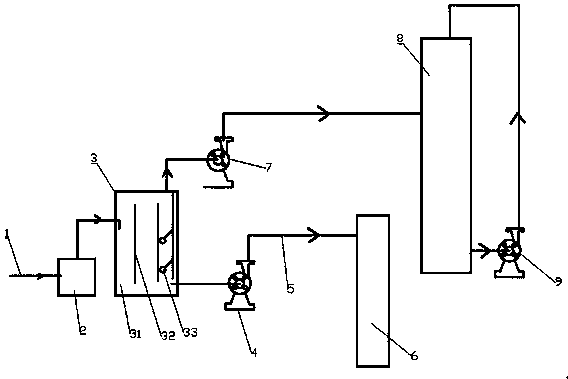

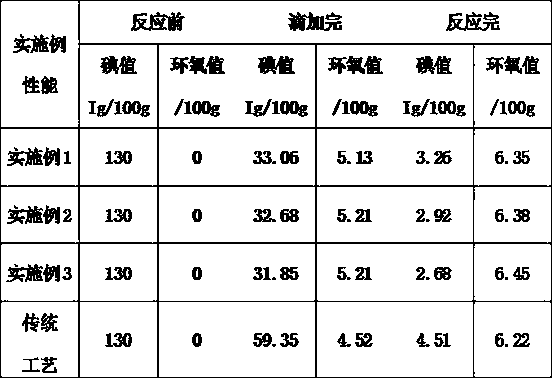

Novel high-temperature reaction process and device for producing epoxidized soybean oil

PendingCN109320478AQuality improvementShorten the dropping timeOrganic chemistryHot TemperatureFormic acid

The invention discloses a novel high-temperature reaction process for producing epoxidized soybean oil. A dripping stage and a continuous reaction stage are sequentially performed. The process comprises the following concrete steps of (1) at the dripping stage, firstly, sufficiently mixing formic acid and soybean oil; then, dripping hydrogen peroxide into the mixture at the dripping temperature of70 to 76 DEG C, and the dripping time is 7 hours; at the continuous reaction stage, firstly heating the materials to 70 to 78 DEG C; performing reaction for 5 hours; then continuously performing heating to 78 to 82 DEG C; identically performing reaction for 3 hours. According to the reaction process and device disclosed by the invention, the work procedures are simple; the reaction efficiency ishigh. Compared with a conventional process, the hydrogen peroxide dripping time is shortened by 1 to 4 hours; the continuous reaction time is shortened by 2 to 4 hours. Under the condition of the samequality of the soybean oil, after the end of the dripping and the continuous reaction, the quality of the epoxidized soybean oil is higher than that of a conventional process.

Owner:NANTONG HAIERMA TECH CO LTD

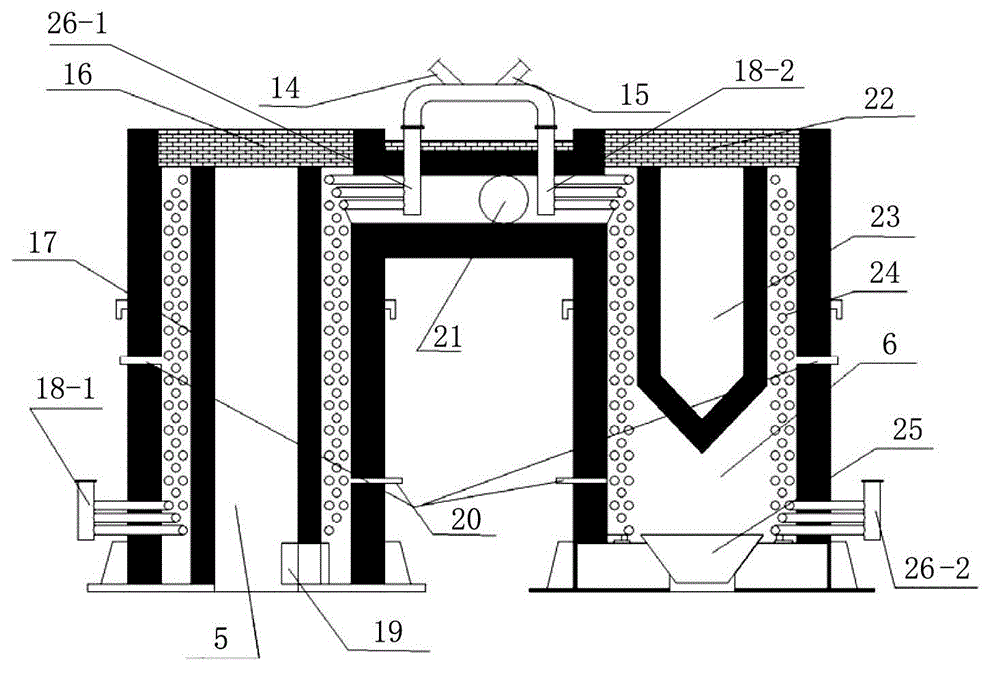

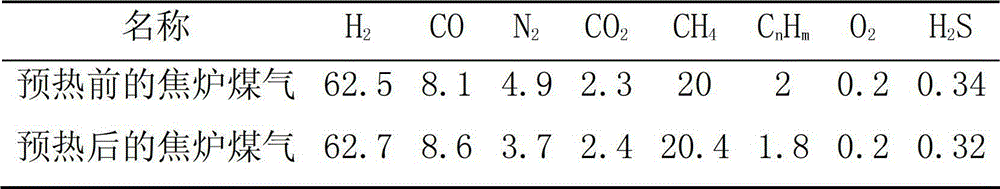

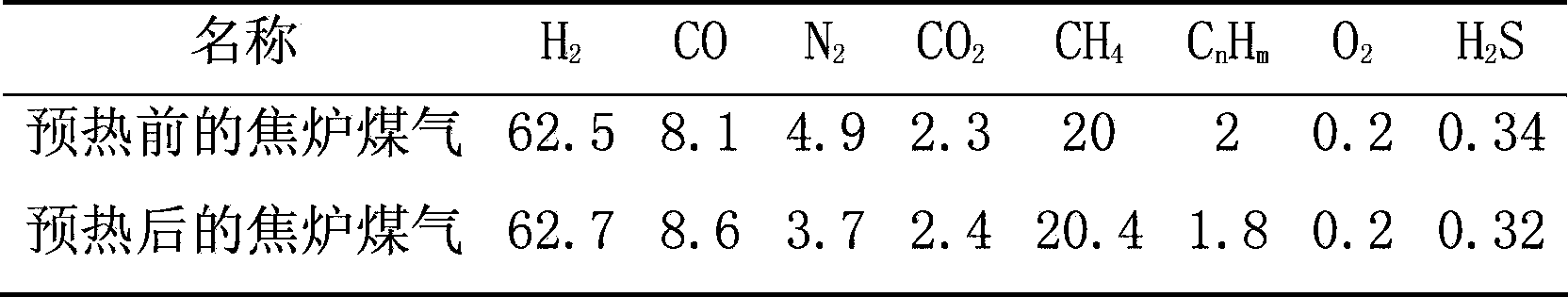

Method for efficiently preheating coke oven gas

InactiveCN102944129AEasy to handleRaise the preheat temperatureStationary tubular conduit assembliesAutomatic controlDecomposition

The invention discloses a method for efficiently preheating coke oven gas. The coke oven gas is subjected to preheating treatment by flue gas or waste gas with the temperature of above 1,150 DEG C, and the flue gas or the waste gas and the coke oven gas are subjected to countercurrent heat exchange, wherein the preheating treatment comprises convection preheating treatment and radiation preheating treatment which are performed sequentially; after the convection preheating treatment, the coke oven gas is preheated to 500 to 600 DEG C; and after the radiation preheating treatment the coke oven gas is continuously preheated to 800 to 950 DEG C. The coke oven gas is preheated by completely utilizing the sensible heat of high-temperature flue gas or tail gas, so that the preheating time is short, the preheating temperature is high, the automatic control can be realized basically, the heat efficiency is high, and operation safety and reliability are achieved. High-temperature decomposition of hydrocarbon in the coke oven gas and carbon deposition can be effectively prevented by adding a trace amount of a carbon deposition inhibitor and a decarbonizer, and the application range is wide.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

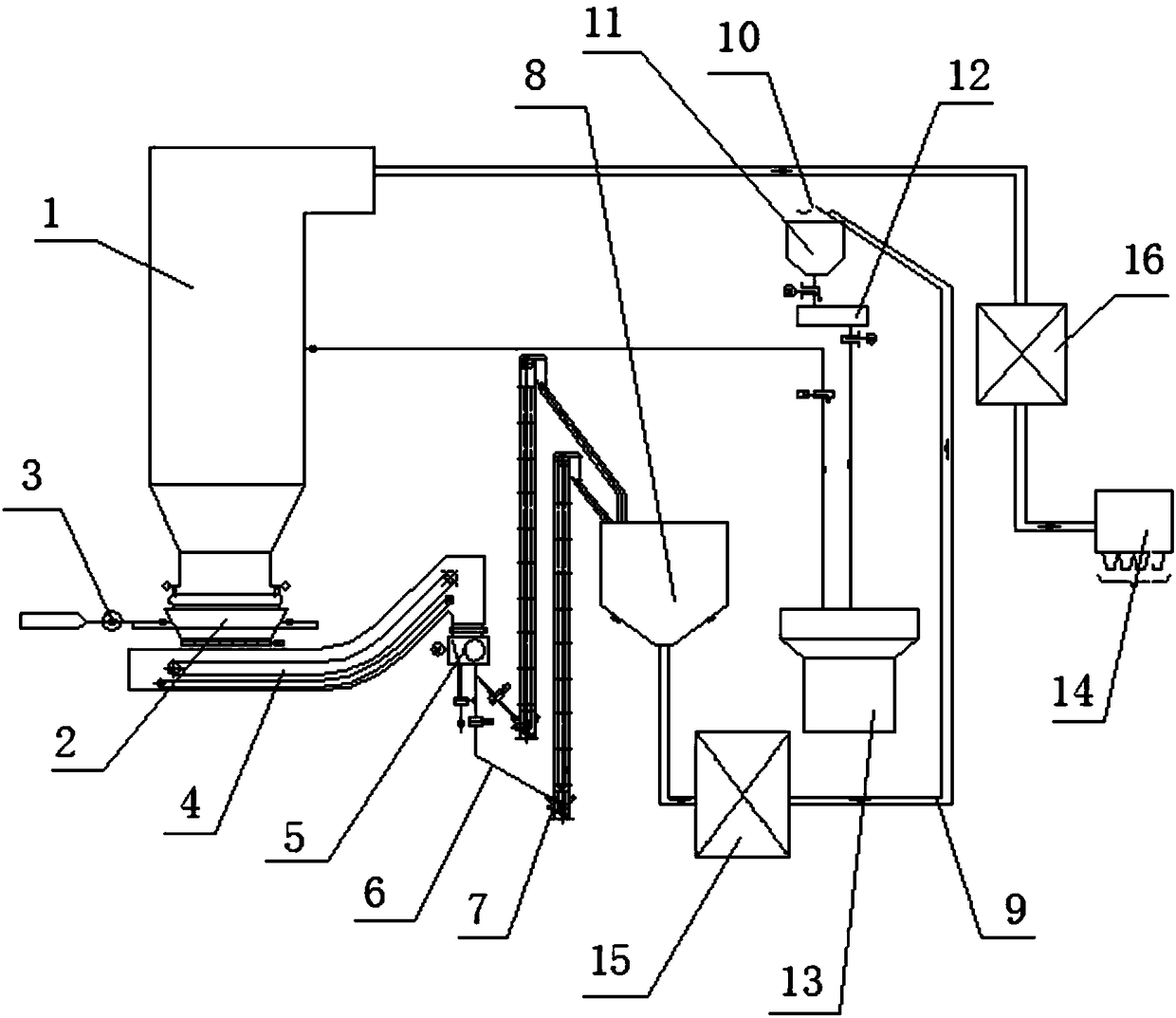

Fire coal sludge coupling power generation system

PendingCN108534168AAchieve re-useReduce pollutionSludge treatment by de-watering/drying/thickeningLump/pulverulent fuel feeder/distributionSludgeSlag

The invention relates to the technical field of power generation equipment, in particular to a fire coal sludge coupling power generation system. The fire coal sludge coupling power generation systemcomprises a boiler, a sludge conveying pump and a slag fetching machine. A slag well is connected to the bottom of the boiler, a sludge discharging opening is formed in the slag well, the sludge conveying pump is communicated with the slag well through the sludge discharging opening, the slag fetching machine is used for conveying sludge and dry slag in the slag well into a feeding opening of a dry slag machine, a discharging opening of the dry slag machine is connected with a feeding opening of a coal bucket, the feeding opening of the coal bucket right faces the coal outlet end of a coal conveying belt, a discharging opening of the coal bucket is communicated with a feeding opening of a coal mill, a discharging opening of the coal mill is communicated with a feeding opening of the boiler, a smoke outlet of the boiler communicates with a smoke inlet of a dust remover, and an ash outlet of the dust remover is communicated with an inlet of an ash storage. The fire coal sludge coupling power generation system saves energy, reduces water consumption, is more environment-friendly, and can achieve energy reutilization.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

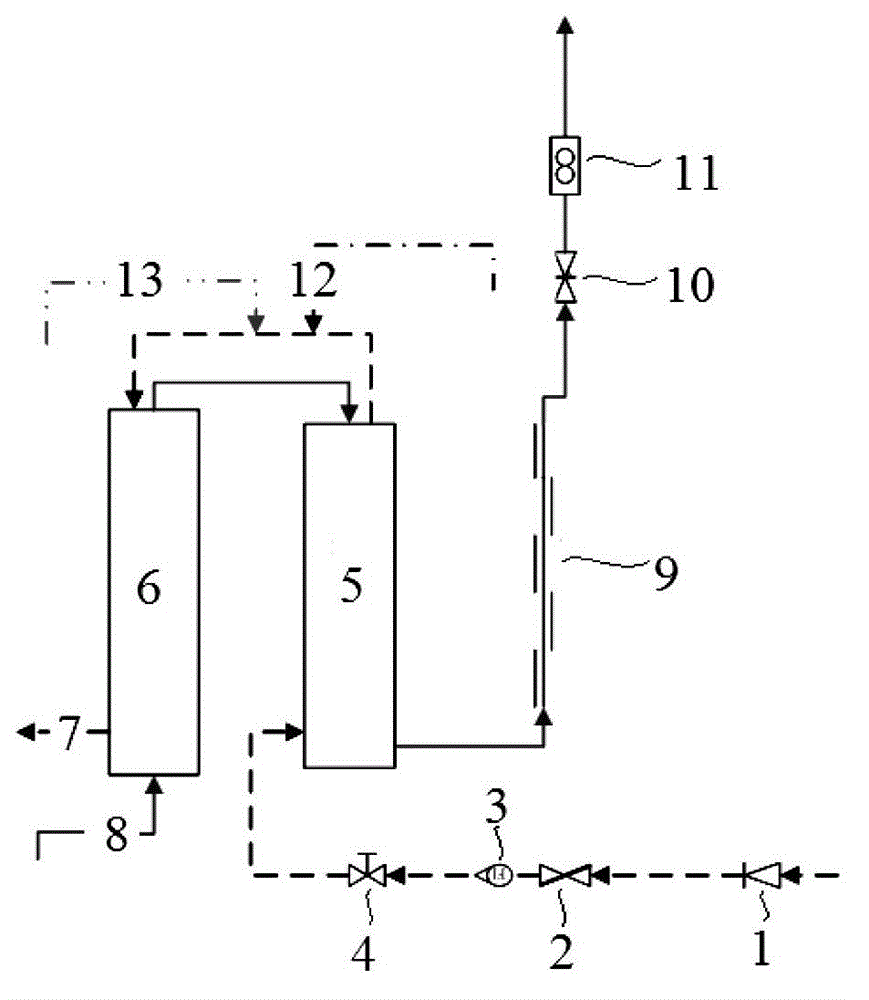

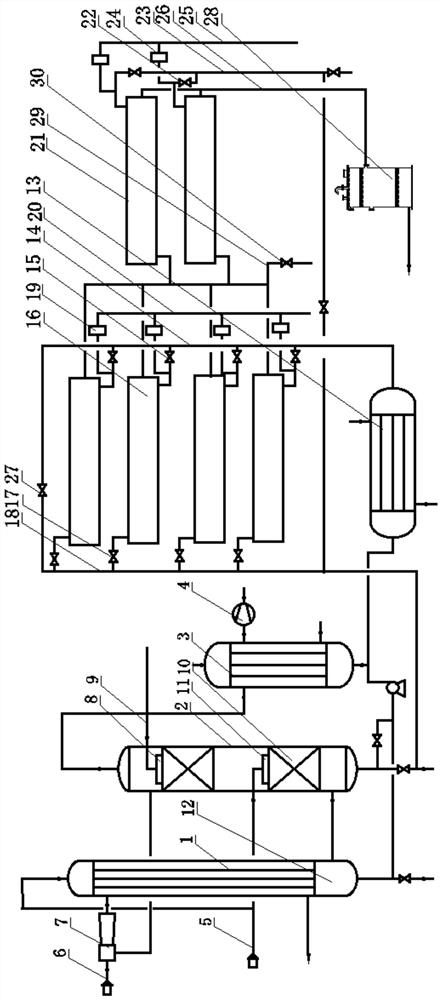

Production method of electronic-grade aqueous hydrogen peroxide solution

PendingCN113912019AReduce condensationReduce cooling water consumptionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesReverse osmosisIon exchange

The invention provides a production method of an electronic-grade aqueous hydrogen peroxide solution. The production method comprises the steps that a part of aqueous hydrogen peroxide solution is fed from the top of an evaporator (1) and heated by the evaporator (1) and then enters a concentrated solution storage area (12) of the evaporator (1); gas generated in the concentrated solution storage area (12) enters a rectifying tower (2), the rest aqueous hydrogen peroxide solution enters the rectifying tower (2) from a second feeding hole of the rectifying tower (2) and is concentrated by the evaporator (1) and the rectifying tower (2); a part of the combined aqueous hydrogen peroxide solution is pumped into a heat exchanger (13) and cooled to normal temperature and then enters a first-stage reverse osmosis mechanism (16); reverse osmosis liquid obtained after reverse osmosis of the first-stage reverse osmosis mechanism (16) enters a second-stage reverse osmosis mechanism (21); and reverse osmosis liquid obtained after reverse osmosis of the second-stage reverse osmosis mechanism (21) is subjected to ion exchange through an ion exchange device (28) to prepare the electronic-stage aqueous hydrogen peroxide solution.

Owner:湖南双阳高科化工有限公司

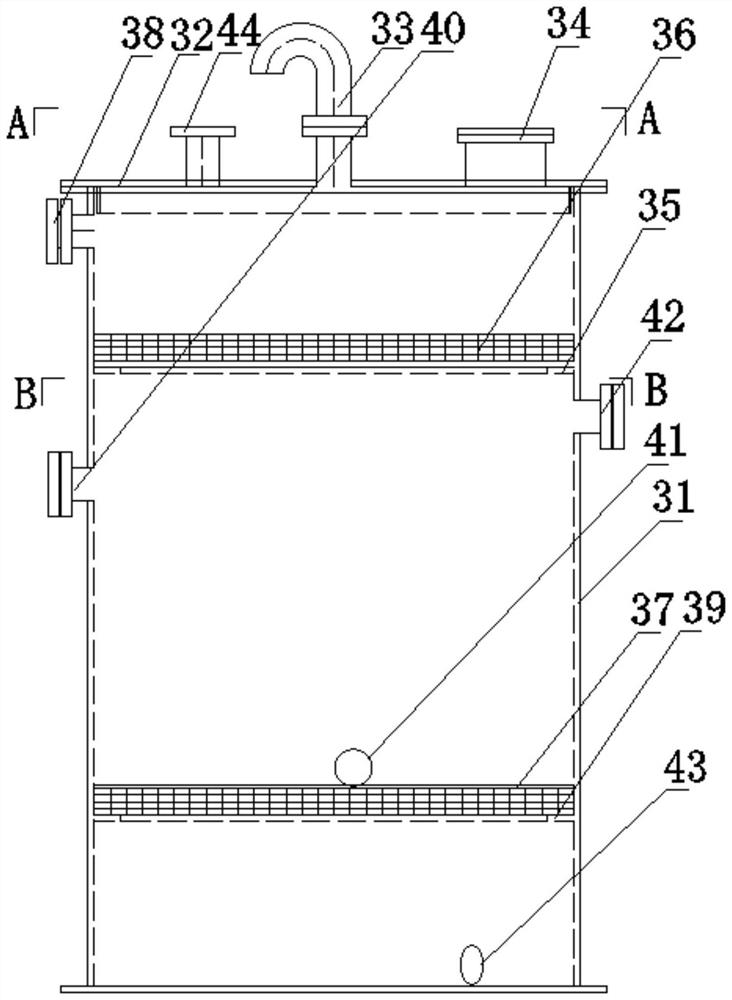

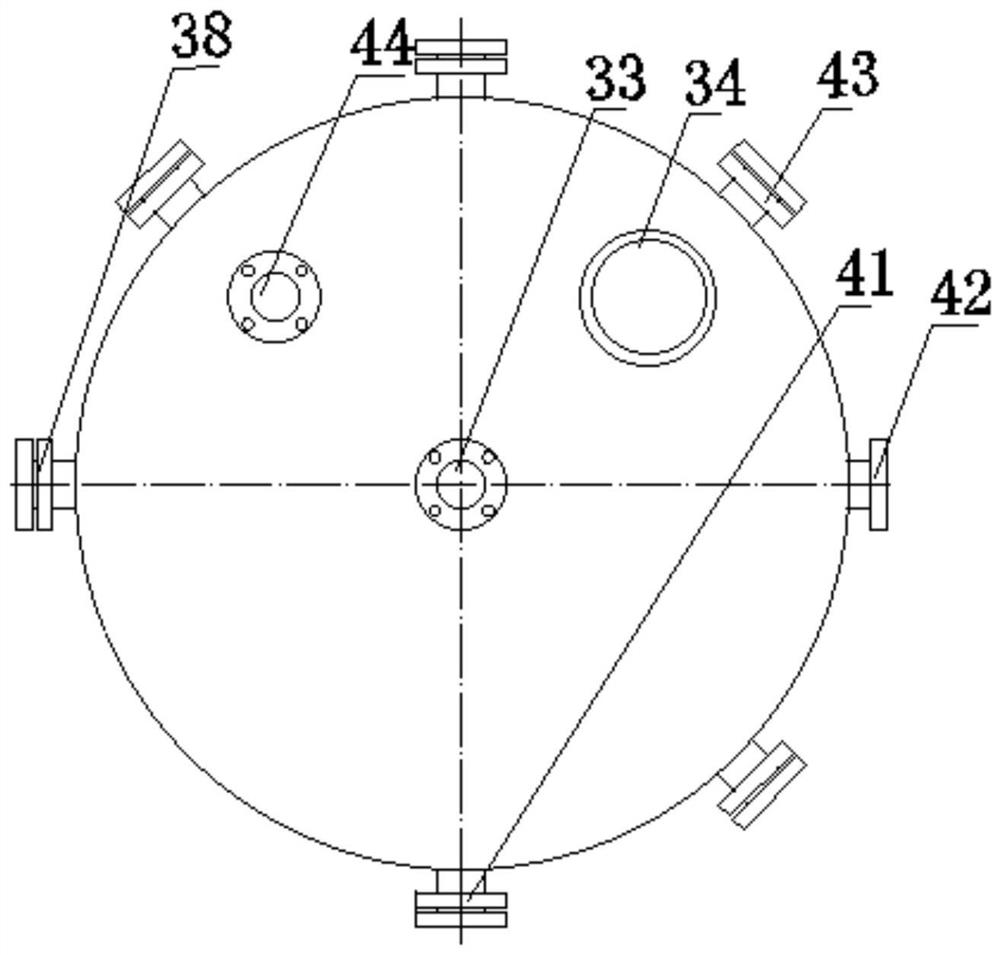

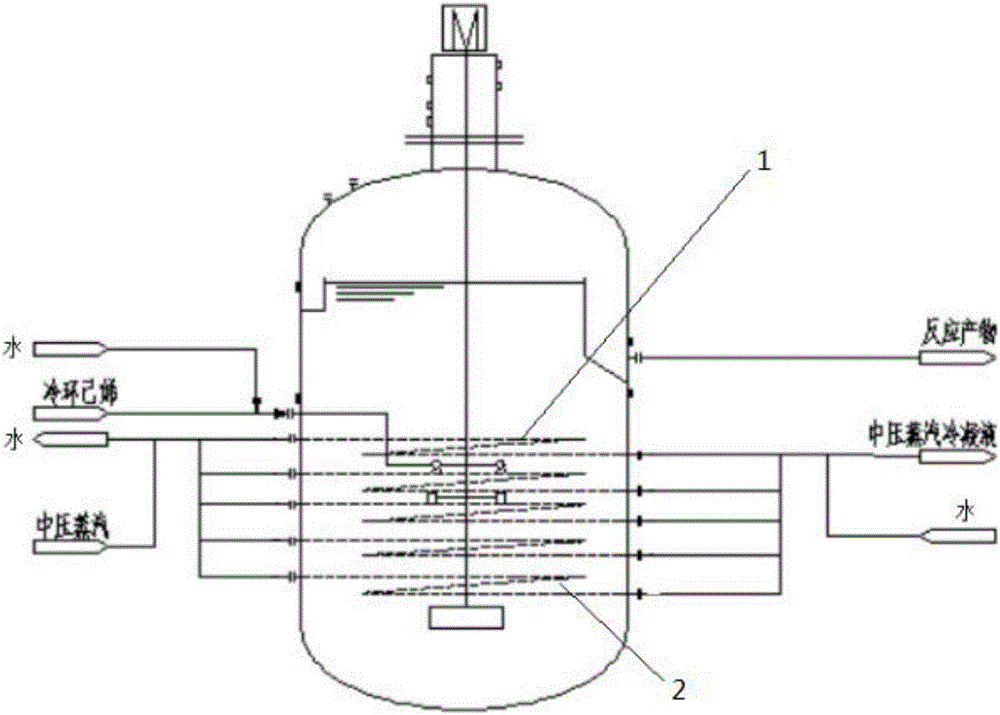

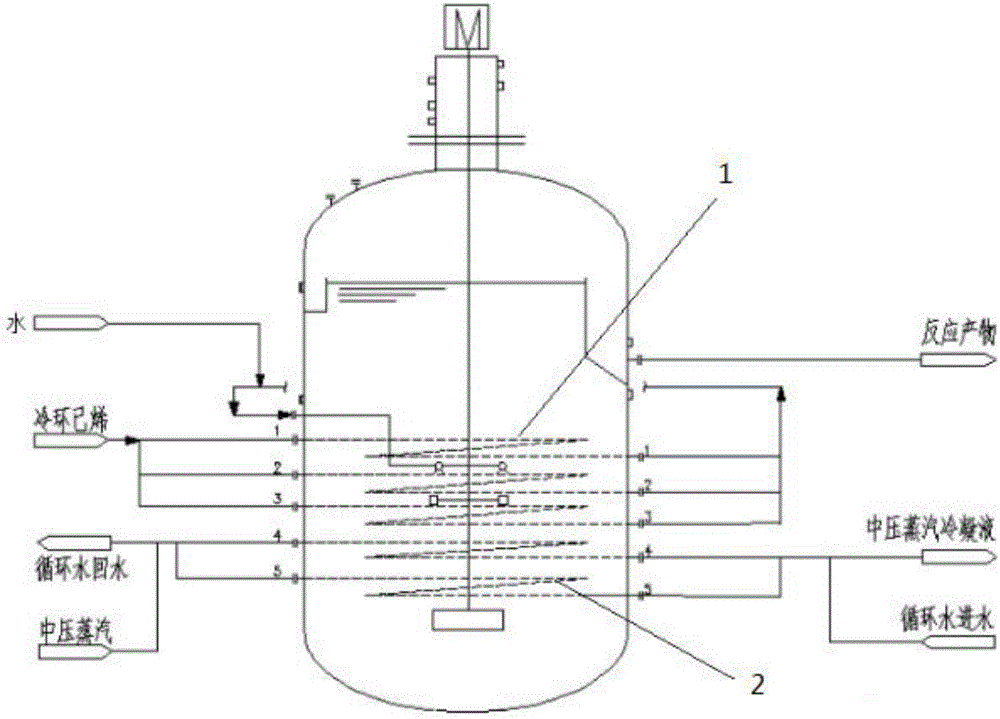

Heat energy synergy method of hydration reactor

InactiveCN105732330AReduce cooling water consumptionReduce water vaporPreparation by hydroxy group additionChemical/physical processesProcess engineeringCyclohexenes

The invention discloses a heat energy synergy method of a hydration reactor. The method is characterized by comprising the following steps: a cooling medium of the hydration reactor is changed into raw material cyclohexene (HE), the cyclohexene moves through an upper coil of the reactor, and water vapor or cooling water moves through a lower coil. The self reaction heat release of the material is used in the hydration reactor, the heat exchange of the coil in the hydration reactor is used for supplying heat energy for the raw material cyclohexene, and meanwhile, the amount of the cooling water consumed for cooling the hydration reactor is reduced, the aims of utilizing the resource and saving energy and reducing consumption are achieved. The method is used for directly supplying heat energy for the raw material cyclohexene, the cooling water dosage is greatly reduced, and the water vapor for warming is saved. Based on the current aim of energy saving and consumption reducing, the cooling medium and equipment for the 120000-ton hydration reactor are technically improved, and energy-saving effect of the patent can achieve 45% or more.

Owner:CHONGQING HUAFON CHEM

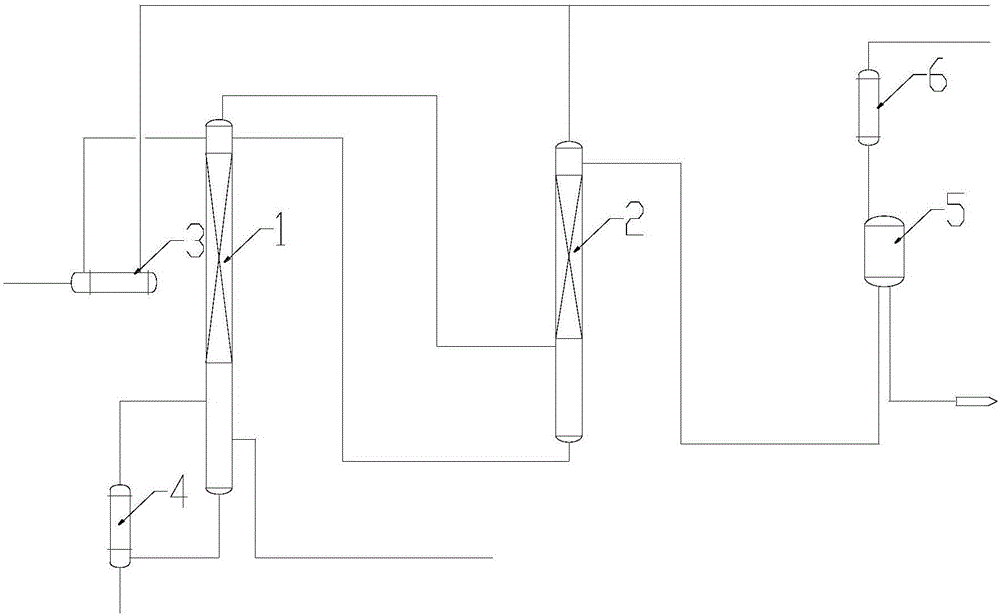

Rectification technology capable of separating rectifying section from stripping section

InactiveCN106220537AReduce cooling water consumptionQuality improvementOrganic compound preparationDistillation regulation/controlDecompositionProcess engineering

The invention relates to a rectification technology capable of separating a rectifying section from a stripping section. The rectification technology comprises a dehydration technology and a refining technology which comprise the following steps: leading target product containing waste liquid to flow in a dehydration tower A for rectifying, leading materials on the top of the dehydration tower A to enter a dehydration tower B, leading materials at the top of the dehydration tower B to enter a product tower A, leading materials on the top of the product tower A to enter the dehydration tower B, leading materials on the top of the dehydration tower B to enter a product refining tower A, leading materials at the top of the product refining tower A to enter a product refining tower B, and condensing to obtain a qualified product. The rectification technology has the following advantages: 1) the installation height of equipment can be reduced; 2) energy-saving purpose is achieved; 3) the decomposition of target products can be inhibited; 4) secondary pollution can be decreased; 5) the corrosion to the equipment can be reduced; 6) the product yield is high; and 7) the deionized water can be recycled.

Owner:烟台国邦化工机械科技有限公司

Method for efficiently preheating coke oven gas

InactiveCN102944129BEasy to handleRaise the preheat temperatureStationary tubular conduit assembliesAutomatic controlDecomposition

The invention discloses a method for efficiently preheating coke oven gas. The coke oven gas is subjected to preheating treatment by flue gas or waste gas with the temperature of above 1,150 DEG C, and the flue gas or the waste gas and the coke oven gas are subjected to countercurrent heat exchange, wherein the preheating treatment comprises convection preheating treatment and radiation preheating treatment which are performed sequentially; after the convection preheating treatment, the coke oven gas is preheated to 500 to 600 DEG C; and after the radiation preheating treatment the coke oven gas is continuously preheated to 800 to 950 DEG C. The coke oven gas is preheated by completely utilizing the sensible heat of high-temperature flue gas or tail gas, so that the preheating time is short, the preheating temperature is high, the automatic control can be realized basically, the heat efficiency is high, and operation safety and reliability are achieved. High-temperature decomposition of hydrocarbon in the coke oven gas and carbon deposition can be effectively prevented by adding a trace amount of a carbon deposition inhibitor and a decarbonizer, and the application range is wide.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

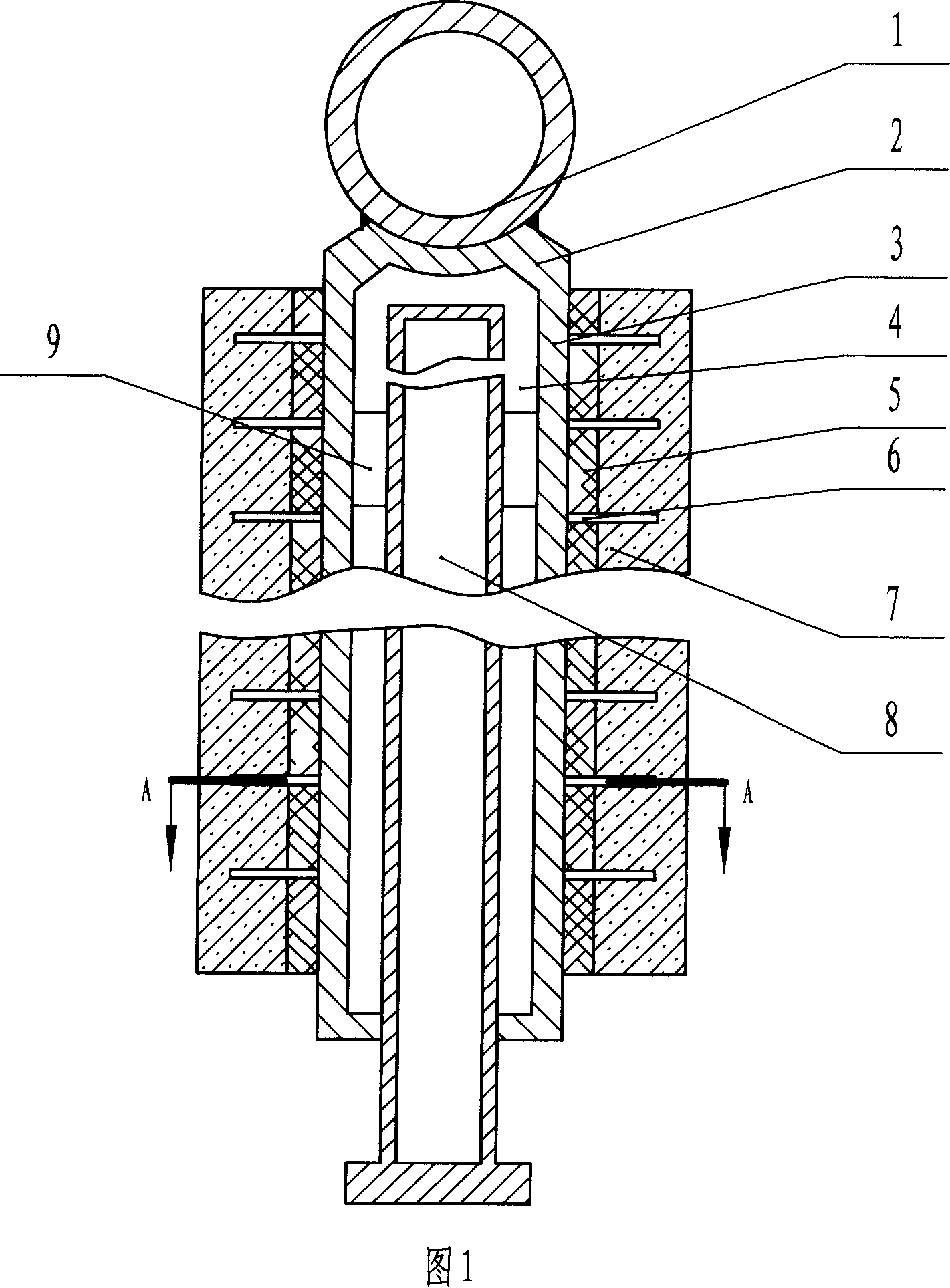

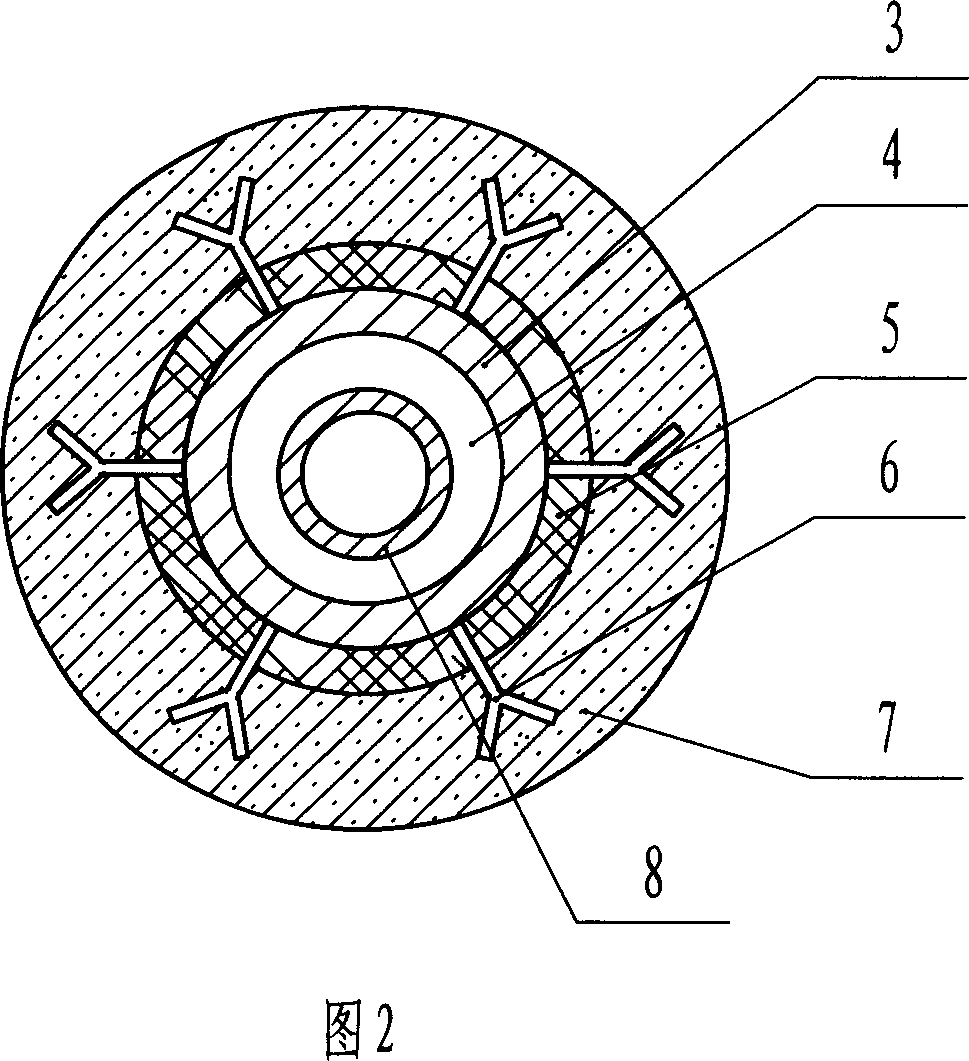

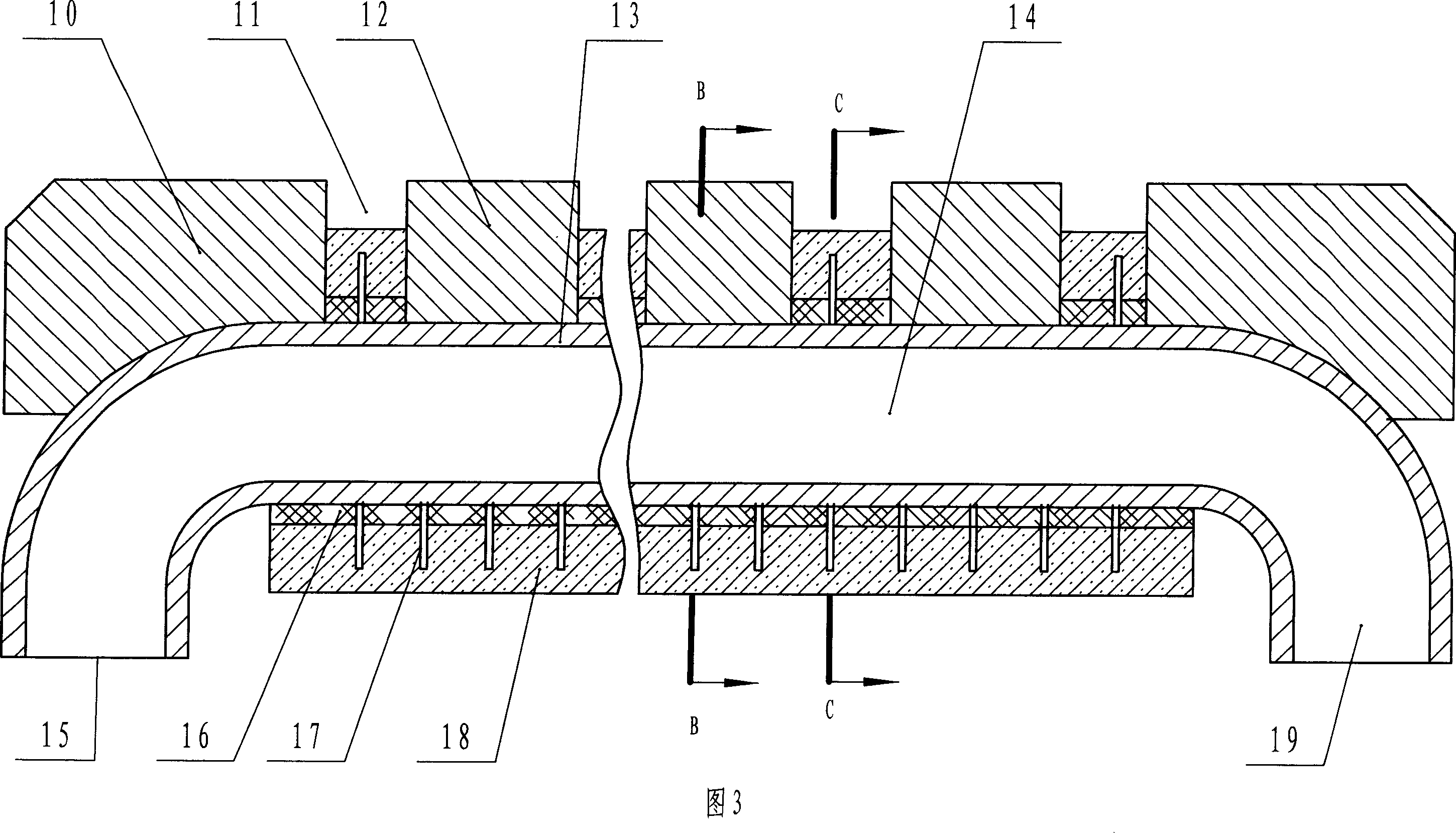

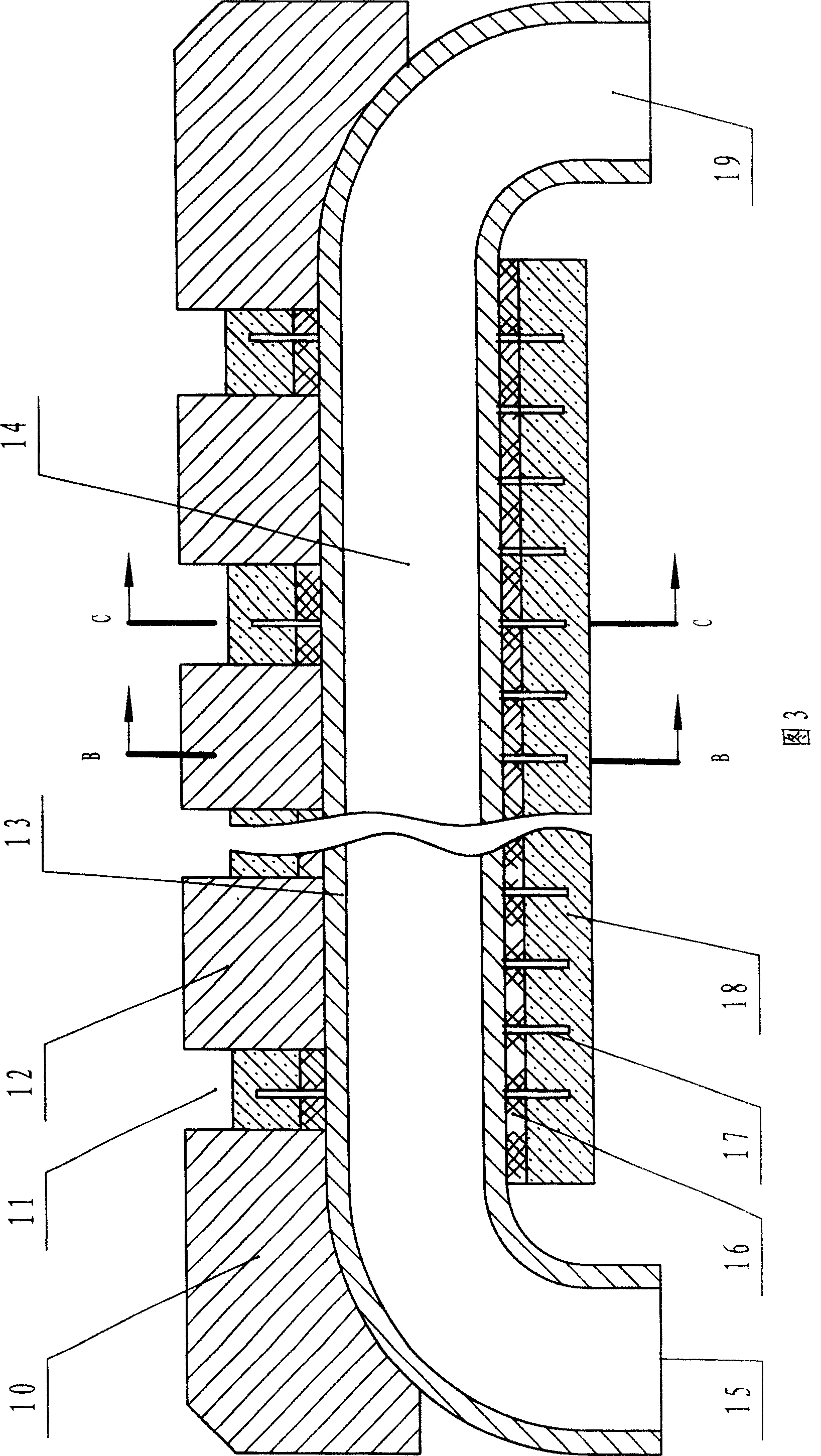

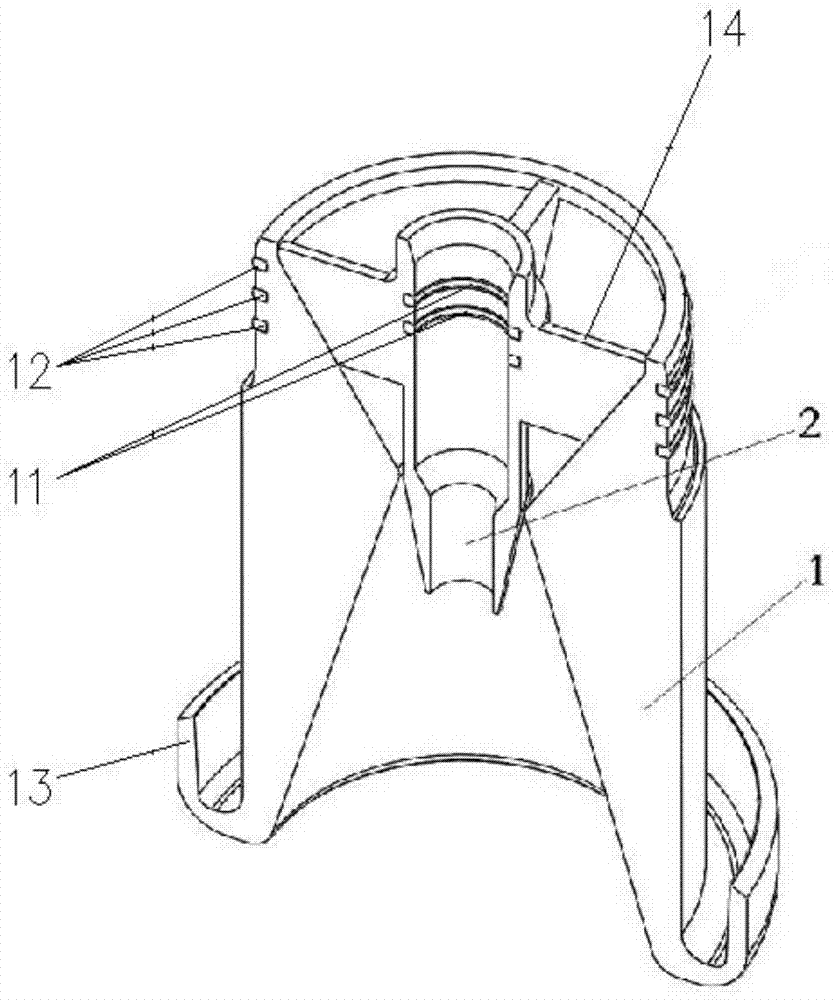

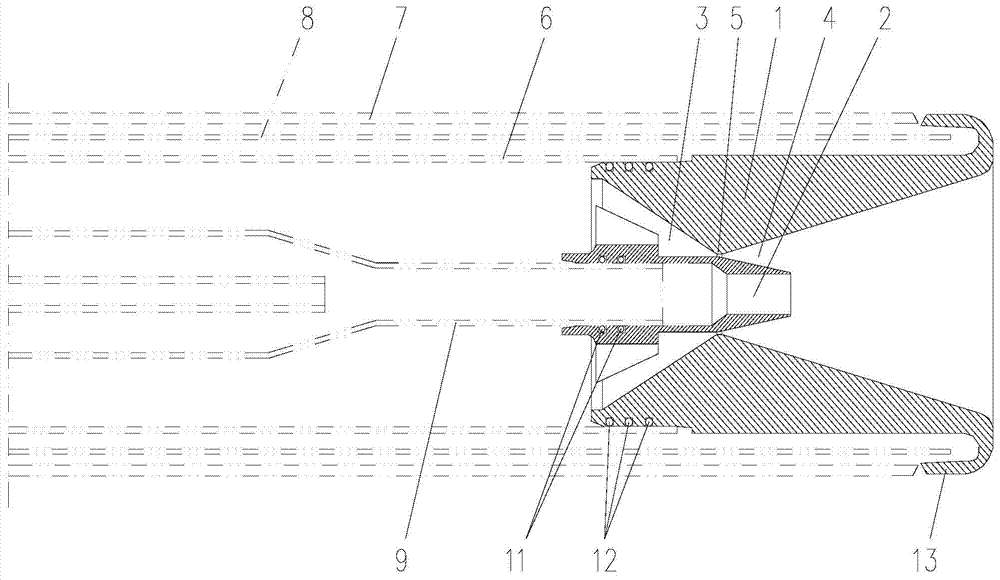

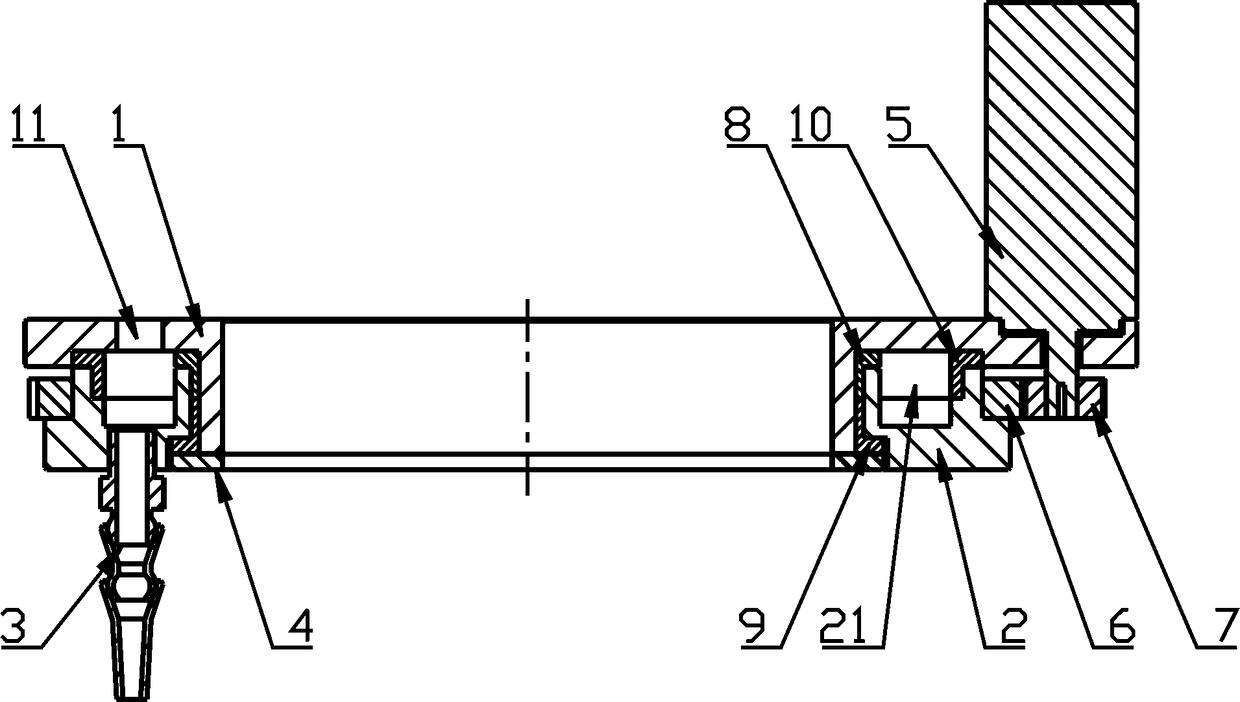

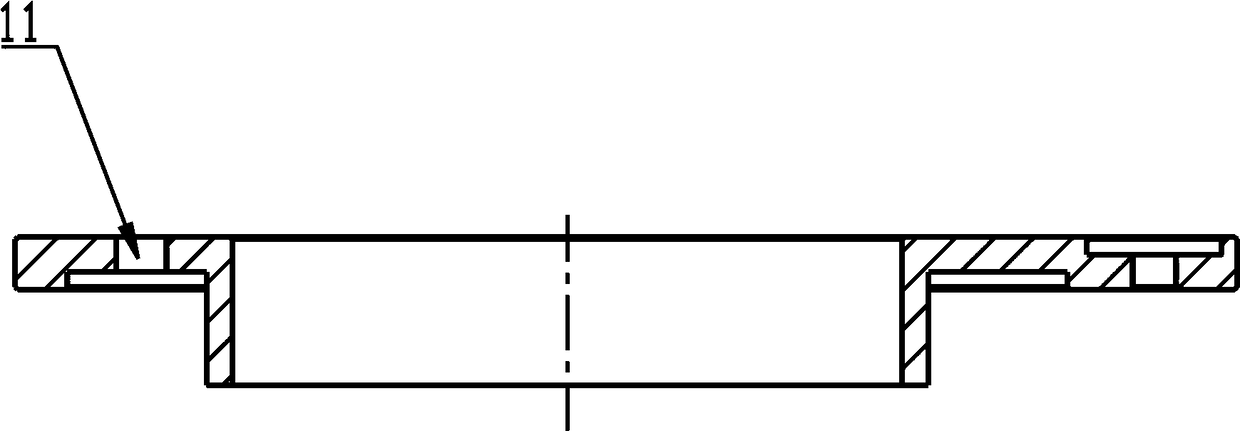

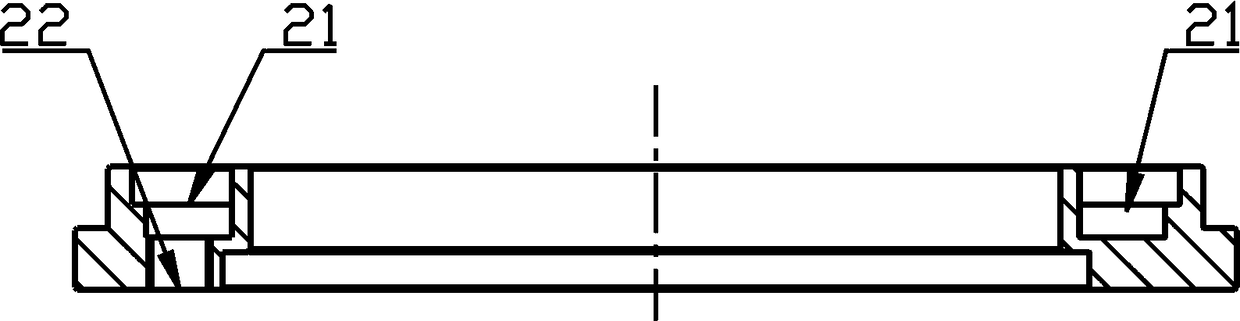

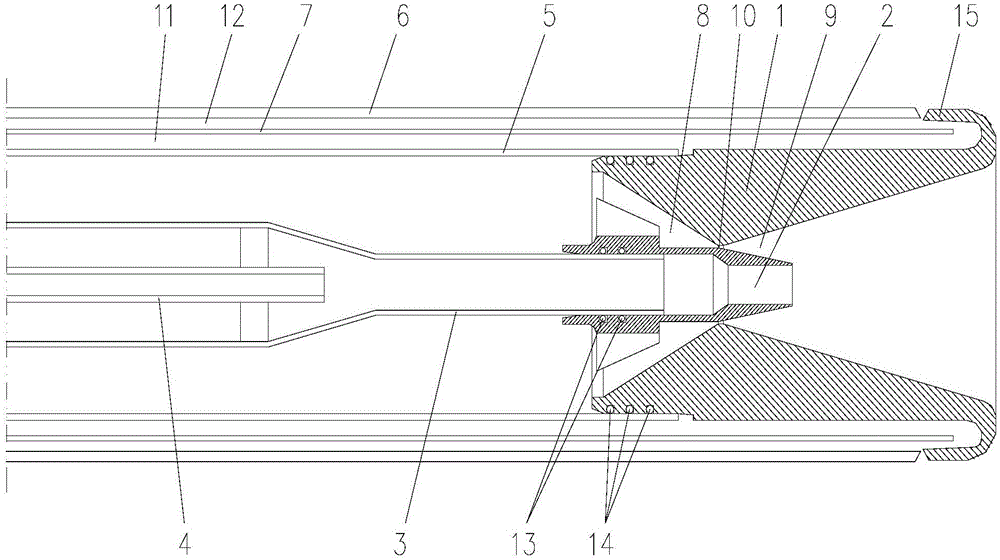

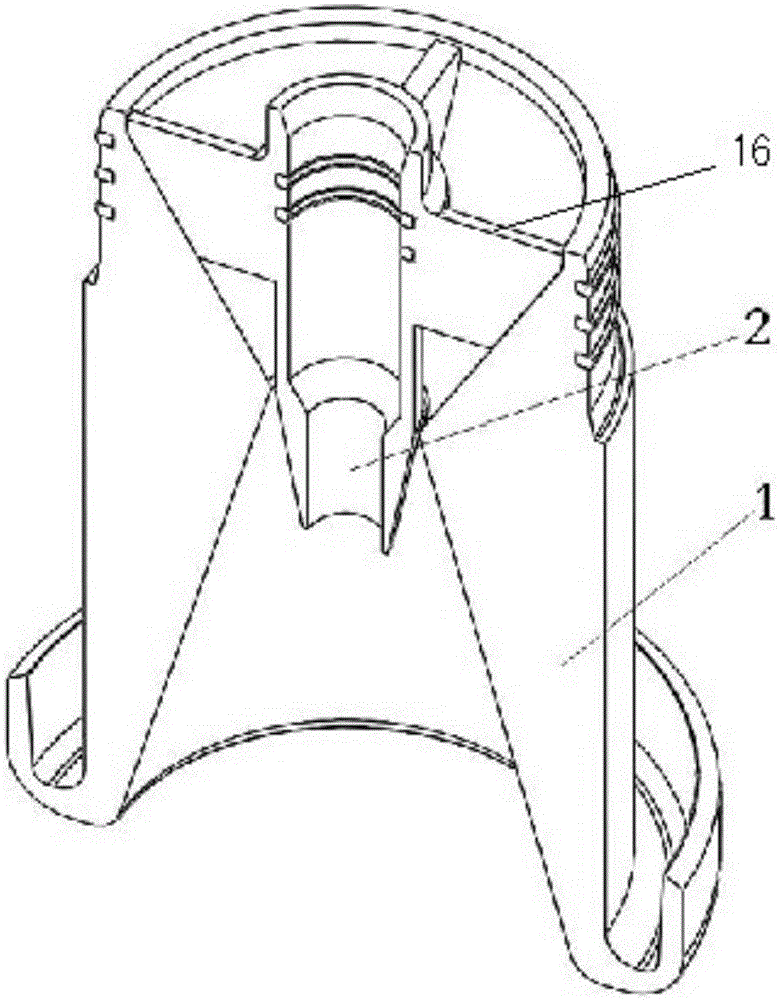

Shower nozzle of RH vacuum refining top lance

ActiveCN104120216AImprove heating efficiencyIncrease the flow rate of oxygen blowingEngineeringLiquid steel

The invention discloses a shower nozzle of an RH vacuum refining top lance. The shower nozzle comprises a Laval tube and a core tube which is coaxially arranged in the Laval tube, wherein a circular contracting tubular section and a circular expanding tubular section are formed between the Laval tube and the core tube. According to the circular contracting tubular section and the circular expanding tubular section provided by the invention, an oxygen flow is sprayed into a vacuum chamber with an ultrasonic speed, so that the working lance position can be lifted to reduce the splashed liquid steel adhering to the lance and reduce the consumption of cooling-water of the shower nozzle. A circular throat can more effectively prevent the lance from being blocked compared with a circular throat of existing shower nozzle of the top lance, so that the shower nozzle is longer in service life. The circular throat can increase the blowing oxygen flow under the condition of maintaining equalness of oxygen pressure and that of the conventional RH vacuum refining equipment, so that the efficiency of blowing oxygen to decarburize and blowing oxygen and adding aluminum to raise the temperature is improved. As the Laval tube, the core tube and the connecting structure therebetween are simple, compared with existing shower nozzle of the top lance, the shower nozzle is not precisely casted and the manufacturing difficulty is remarkably reduced.

Owner:CISDI SHANGHAI ENG CO LTD +1

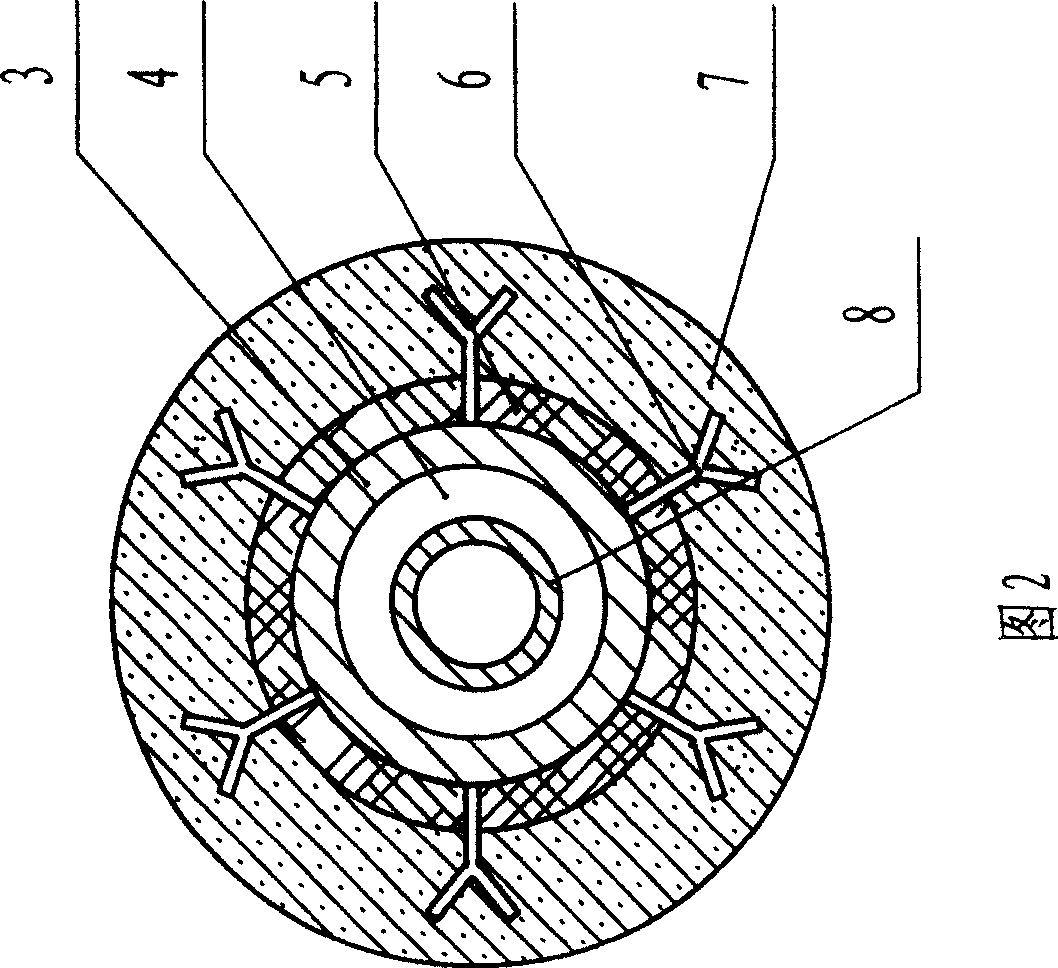

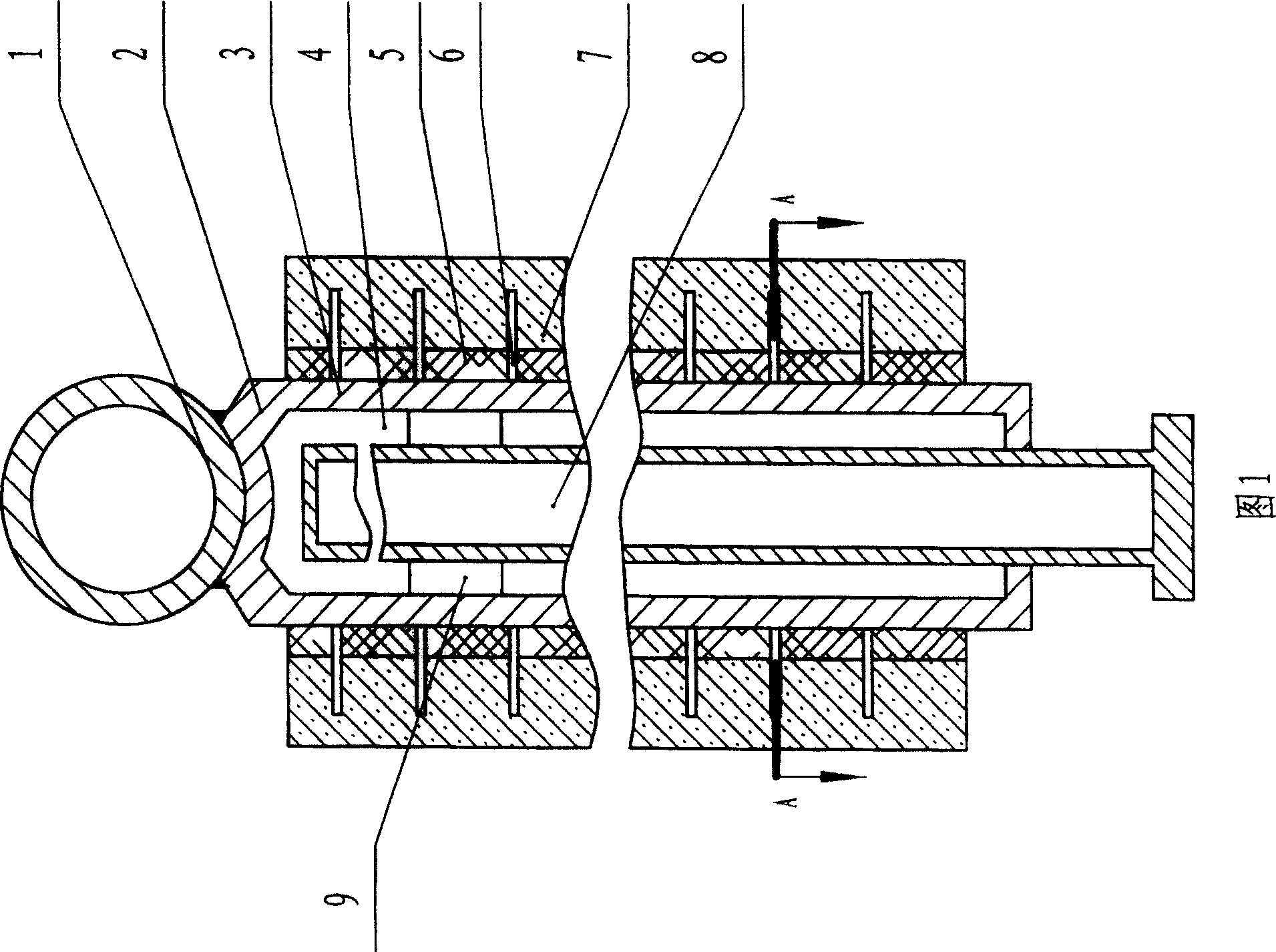

Servo annular nozzle device

PendingCN108161745AEnables real-time tracking of coolingReduce cooling water consumptionGrinding/polishing safety devicesCooling effectControl theory

The invention belongs to the technical field of mechanical machining, and particularly relates to a servo annular nozzle device. The servo annular nozzle device is composed of a fixed inner ring, a rotary outer ring, a nozzle, a lower supporting plate, a servo motor and a transmission device. The rotary outer ring is arranged on the fixed inner ring in a sleeved manner and is supported and positioned through the lower supporting plate installed at the bottom of the fixed inner ring. The rotary outer ring is provided with an annular cavity and forms a sealed flow channel with the fixed inner ring. The bottom of the annular cavity is provided with a water outlet, and the nozzle is installed on the water outlet. The fixed inner ring is provided with a water inlet corresponding to the annularcavity. The rotary outer ring is connected with the servo motor through the transmission device and can rotate around the center axis of the servo motor under the action of the servo motor; and the servo motor is installed on the fixed inner ring. The servo annular nozzle device is simple in structure, real-time tracking cooling of machined points can be achieved, and the cooling effect is fully guaranteed.

Owner:BEIJING JINGDIAO GRP CO LTD

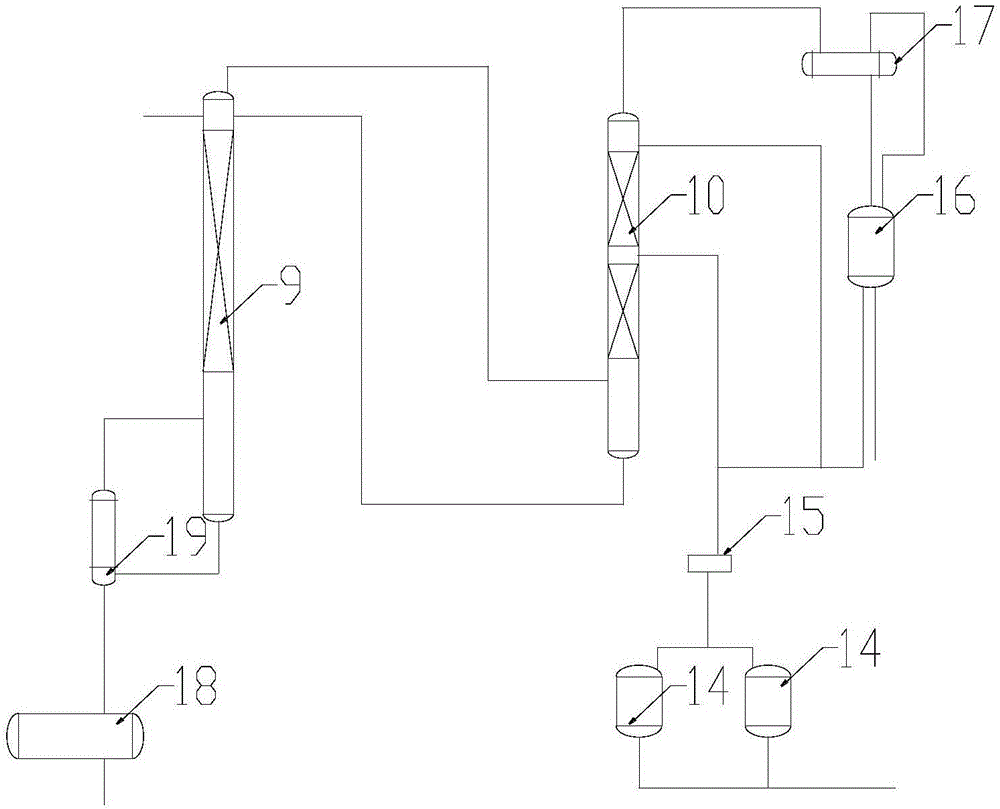

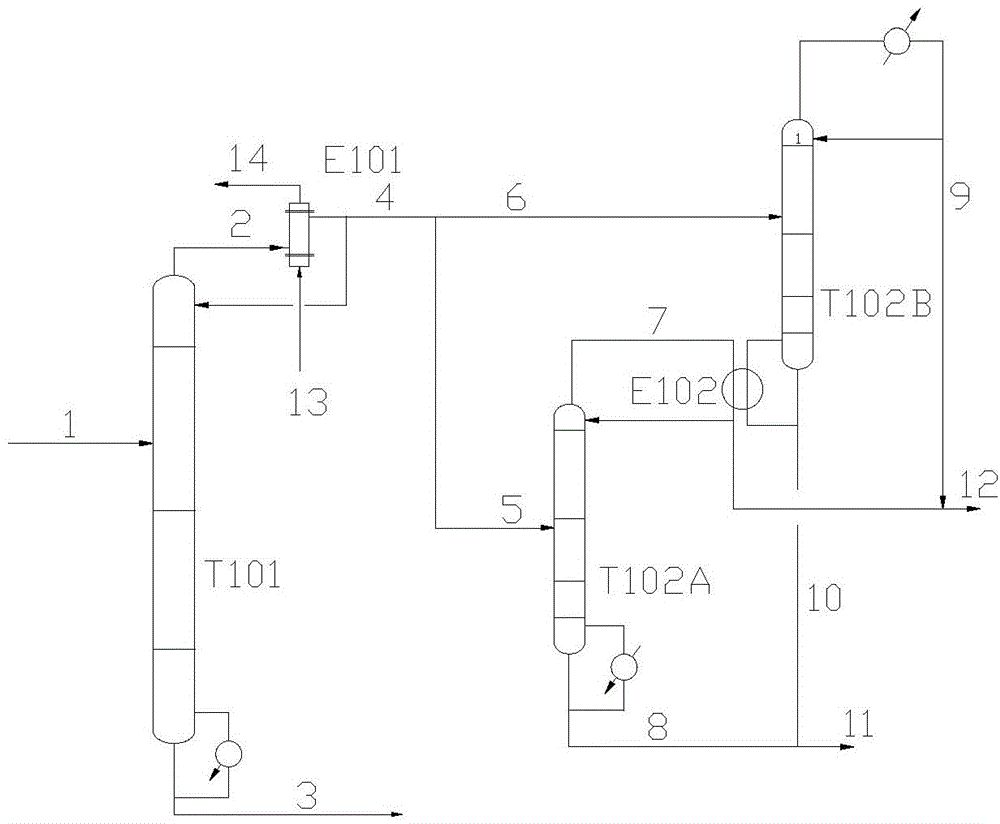

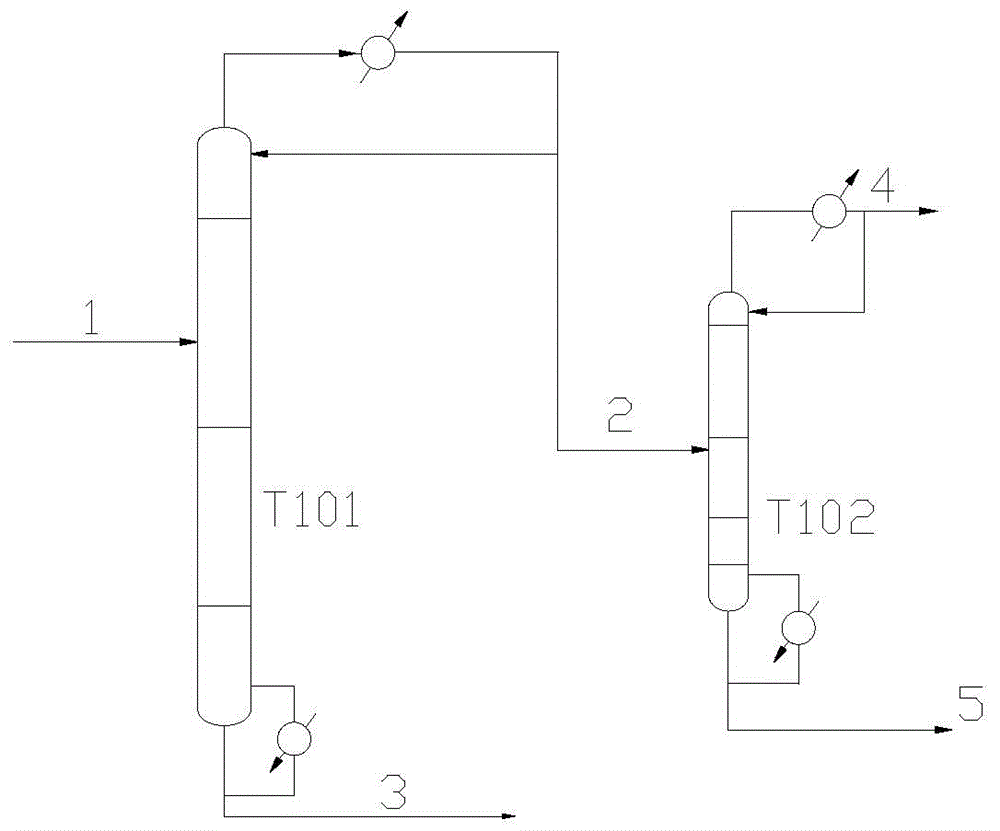

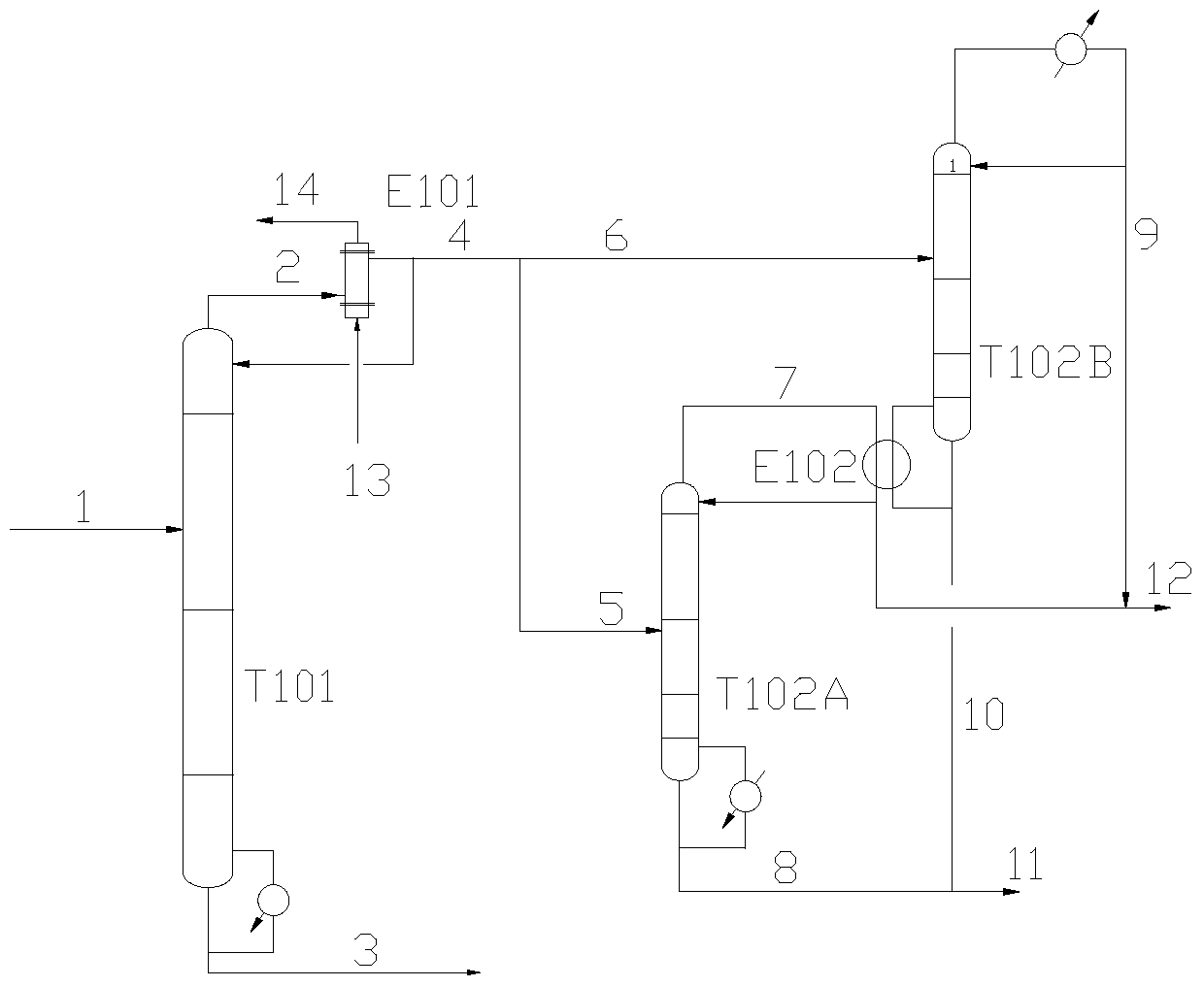

Ethylbenzene/styrene energy-saving separation method

ActiveCN105669352AEfficient use ofReduce separation energy consumptionDistillation purification/separationHigh energyGas phase

The present invention relates to an ethylbenzene / styrene energy-saving separation method, and mainly solves the high energy consumption problem of ethylbenzene / styrene separation system industrial devices in the prior art. The ethylbenzene / styrene energy-saving separation method can well solve the problem, the ethylbenzene / styrene energy-saving separation method comprises the following steps: a) a dehydrogenation liquid containing mainly ethylbenzene and styrene enters an ethylbenzene / styrene separation tower T101 to obtain an overhead gas material stream I containing benzene, toluene and ethylbenzene and a tower bottom liquid material stream II containing styrene; b) the material stream I enters an ethylbenzene / water azeotrope evaporator, an external ethylbenzene / water mixture is heated to obtain a heat-exchanged ethylbenzene / water azeotrope material stream III, and the material stream I is condensed and partly collected to enter an ethylbenzene separation tower; c) the ethylbenzene separation tower is divided into two towers (T102A and B) for operation, pressure of the T102A is higher, pressure of the T102B is lower, and a T102A overhead gas phase is used for heating a T102B bottom liquid, and the ethylbenzene / styrene energy-saving separation method can be used for industrial production of ethylbenzene / styrene separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

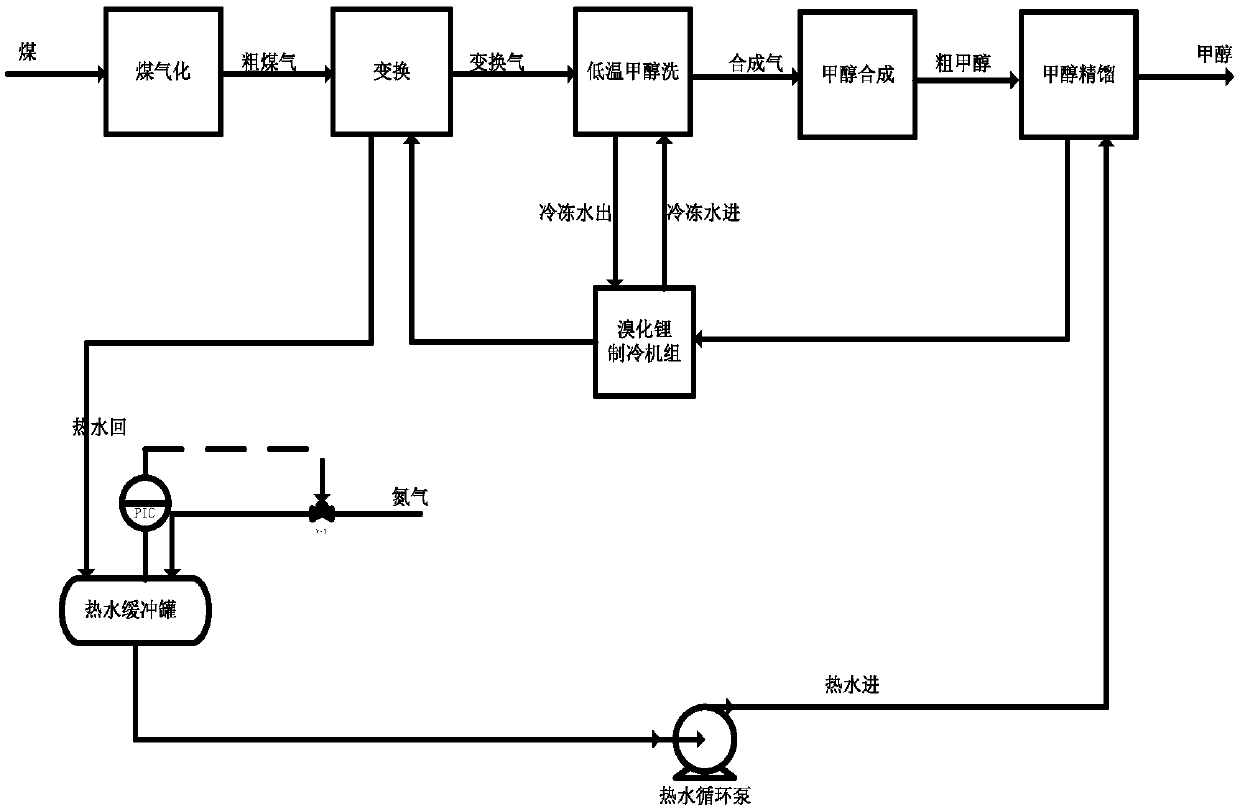

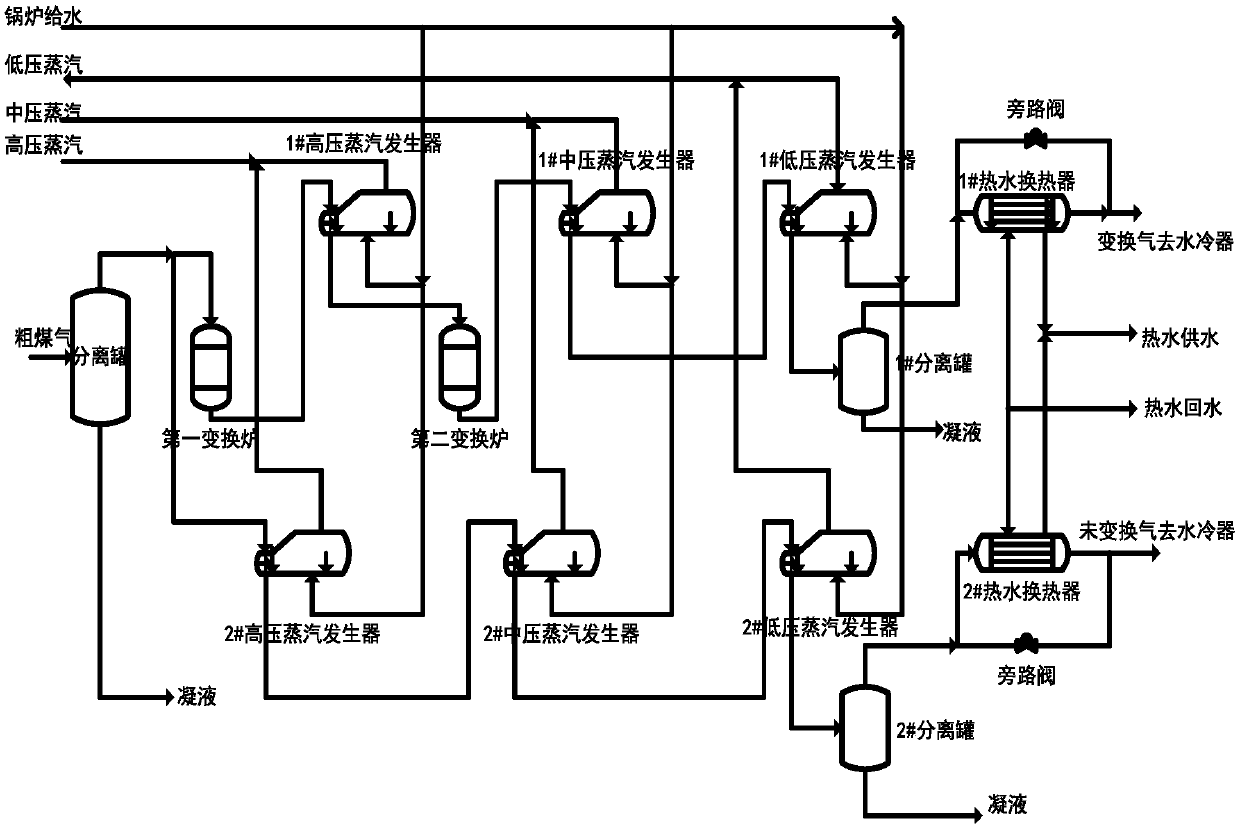

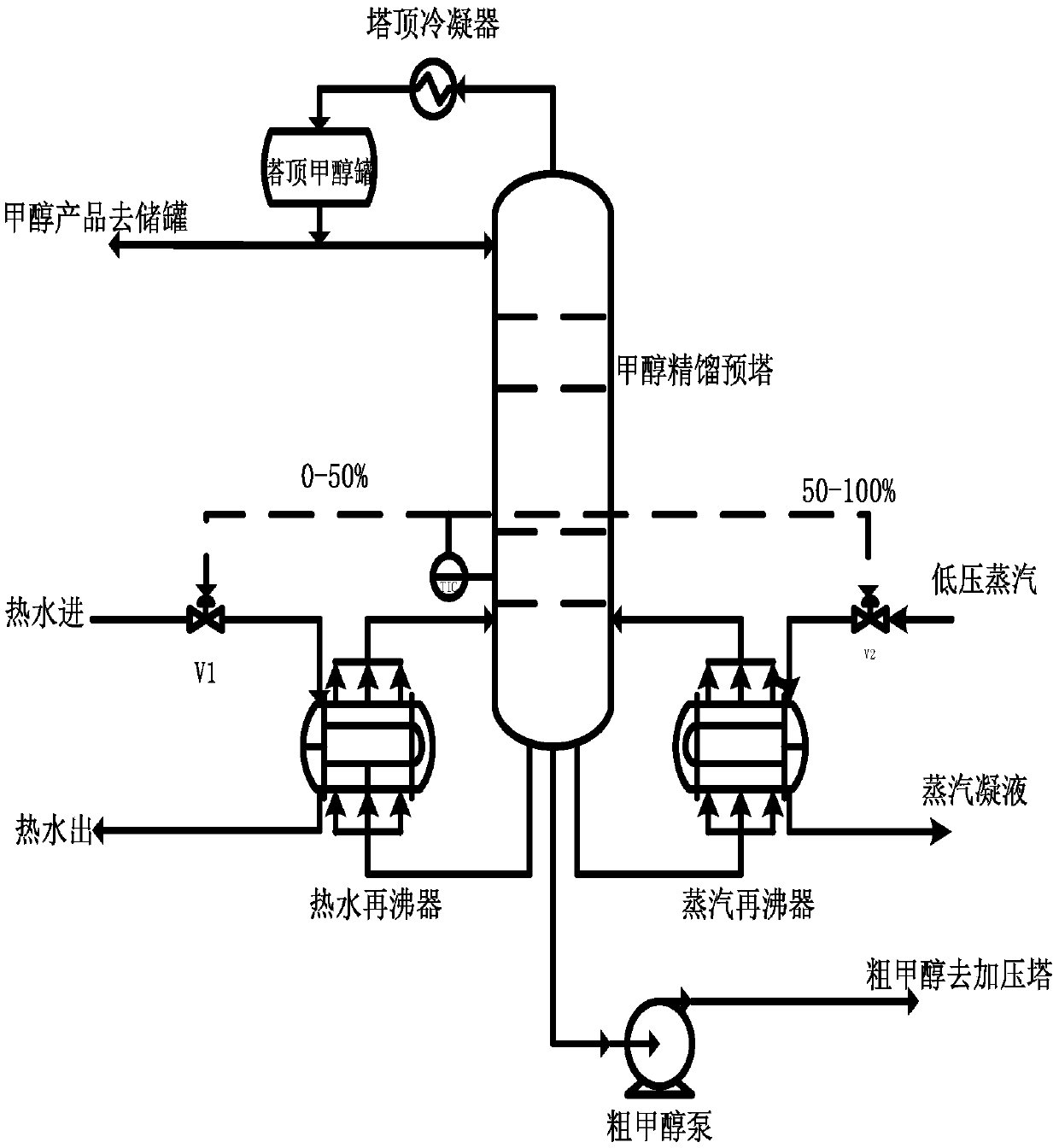

Energy-saving process of coal methanol

ActiveCN110642675AOptimize cooling configurationReduce cooling water consumptionOrganic compound preparationChemical industryLithium bromideWater circulation

The invention discloses an energy-saving process of coal methanol. The process scheme comprises technical processes such as coal gasification, conversion, low-temperature methanol washing, methanol synthesis and methanol rectification. A hot water circulation system is connected with a methanol rectification unit, a lithium bromide refrigerating unit and a conversion unit to form a great circle ofa hot water system, and chilled water is connected with the lithium bromide refrigerating unit and a low-temperature methanol washing unit to form a minor cycle of a chilled water system. A connection way is that high-temperature hot water enters an inlet of a hot water circulation pump from the bottom of a hot water buffering tank, enters a methanol rectification pre-tower hot water reboiler after being pressurized, enters the lithium bromide refrigerating unit after flowing out of the reboiler, enters a conversion unit hot water heater after flowing out of the lithium bromide refrigeratingunit and returns to the hot water buffering tank after being heated by the hot water heater to form a closed cycle; and chilled water generated by the lithium bromide refrigerating unit enters the low-temperature methanol washing unit, is heated after exchanging heat with a process material and flows back to the lithium bromide refrigerating unit so as to be cooled to form a closed cycle.

Owner:WANHUA CHEM GRP +1

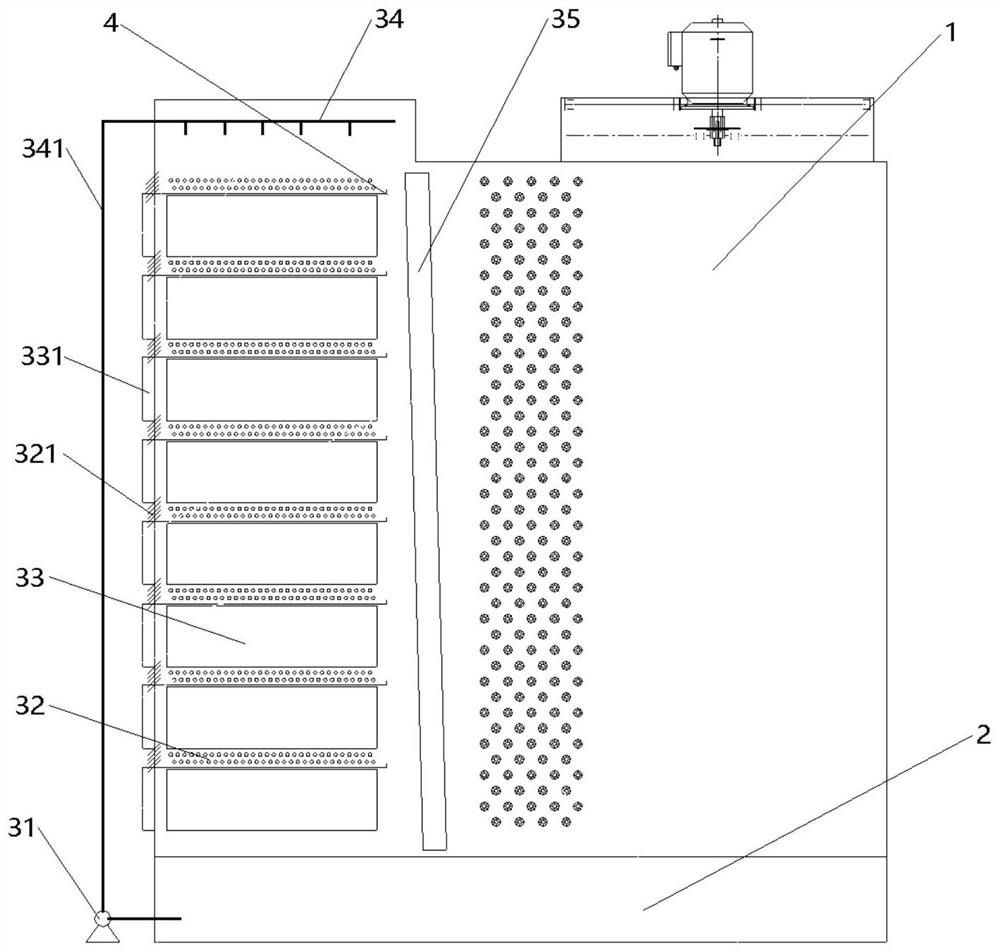

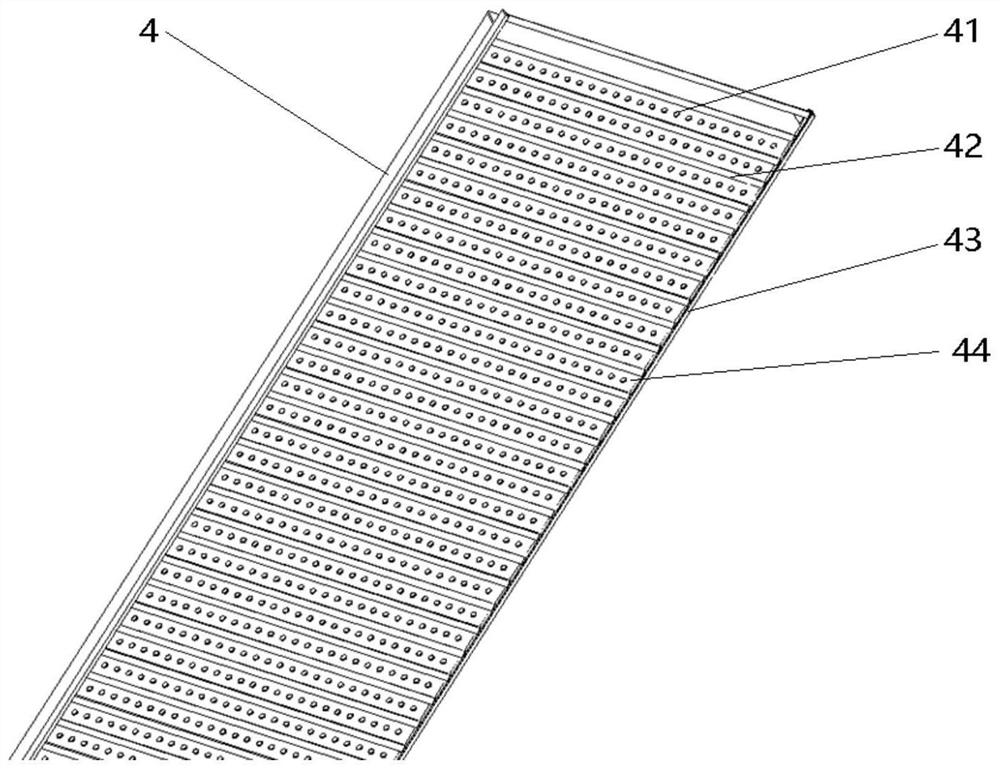

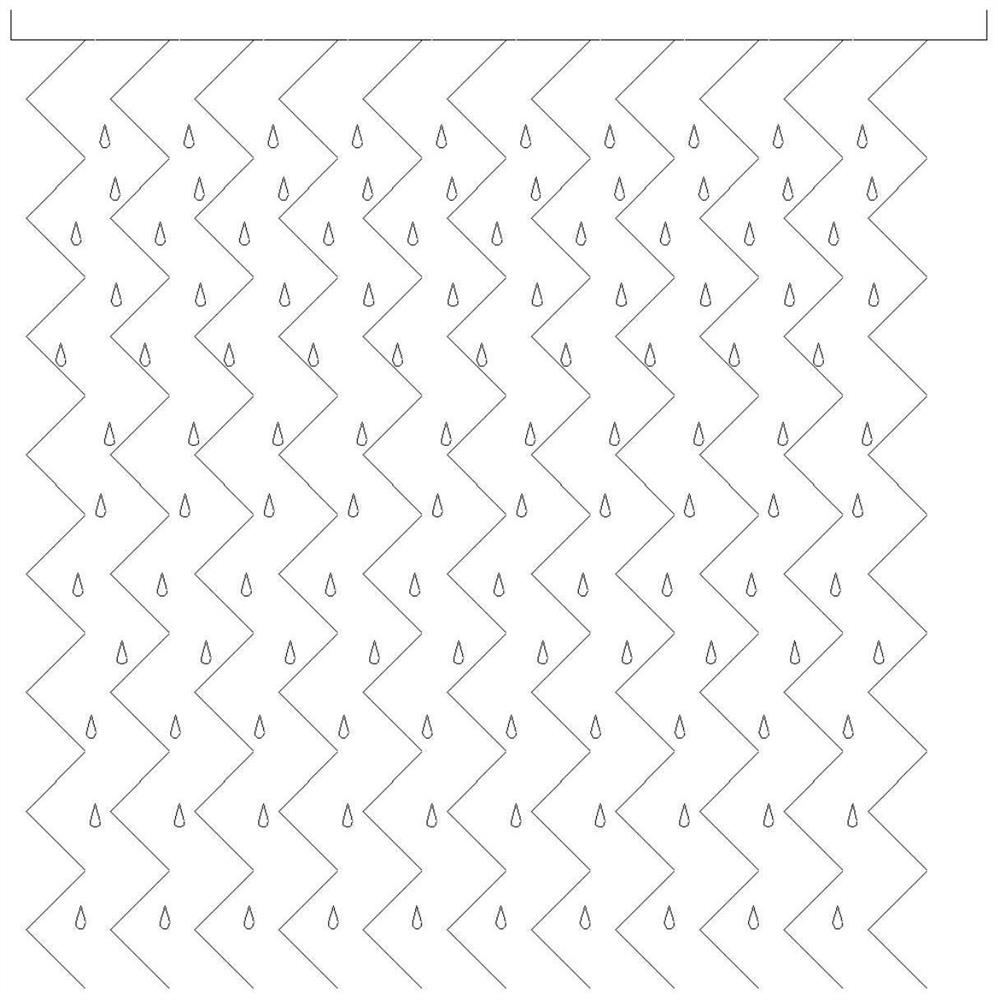

Novel dry-wet combined water-saving cooling tower and using method thereof

PendingCN114812219AAchieve removalPrevent adhesionHeat exchange apparatusTrickle coolersThermodynamicsCooling tower

The invention discloses a novel dry-wet combined water-saving cooling tower and a using method thereof.The novel dry-wet combined water-saving cooling tower comprises a wet cooling section cooling module and a dry cooling section cooling module which are transversely arranged, the air outlet end of the wet cooling section cooling module corresponds to the air inlet end of the dry cooling section cooling module, and the air inlet end of the dry cooling section cooling module corresponds to the air outlet end of the wet cooling section cooling module. A water collecting tank is arranged at the bottoms of the wet cooling section cooling module and the dry cooling section cooling module; switching of multiple modes is achieved by adjusting air inlet and water spraying modes; the wet cooling section cooling module and the dry cooling section cooling module are transversely arranged, air is evaporated through the wet cooling section cooling module to become saturated wet and hot air, and finally the saturated wet and hot air is converted into unsaturated dry and hot air through convection of the dry cooling section cooling module, so that rain and fog at an outlet of the cooling tower are removed.

Owner:WUXI WANHENG HEAT TRANSFER TECH CO LTD

A powder spraying top gun for rh vacuum refining

The invention discloses a powder spraying top lance for RH vacuum refining. The powder spraying top lance comprises a laval tube, a core tube, a top lance center tube, a top lance power conveying tube, a top lance inner tube, a top lance outer tube and a top lance waterproof tube, wherein an annular shrinkage tube section and an annular expansion tube section are formed between the laval tube and the core tube. The annular shrinkage tube section and the annular expansion tube section are capable of accelerating airflow to supersonic speed, thereby improving the working lance height, reducing splash steel liquid adhered to the lance and prolonging the service life of a nozzle of the top lance; meanwhile, a throat between the laval tube and the core tube is an annular throat, so that the oxygen blowing flow can be increased, and the heating efficiency of oxygen-blowing decarbonization and oxygen-blowing aluminum addition can be improved; oxygen, gas and desulphurization powder are conveyed to an RH vacuum chamber through different channels; the desulphurization powder can reach the surface of the steel liquid under the surrounding of ambient protective gas; the powder taken away in a vacuum pumping manner is reduced, and the yield of the desulphurization powder is improved; moreover, compared with the existing top lance, the powder spraying top lance for RH vacuum refining is free of precision casting, so that the manufacturing difficulty is obviously reduced.

Owner:CISDI SHANGHAI ENG CO LTD +1

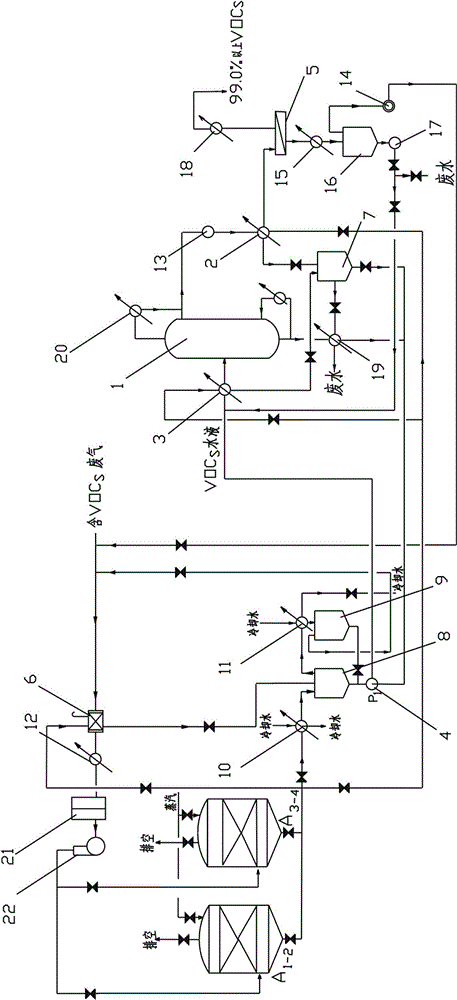

Device and method for treating VOCs

PendingCN113117520ASimple and efficient recyclingEfficient and easy to useGas treatmentDispersed particle separationAmmoniaCracking reaction

The invention relates to a device and a method for treating VOCs (volatile organic compounds), and the method comprises the following steps: pressurizing VOCs gas, feeding the VOCs gas into a catalytic cracking riser reactor, and feeding the gas obtained by reaction into a separation and purification system of a catalytic cracking device along with catalytic cracking reaction oil gas. According to the present invention, an existing catalytic cracking unit riser reactor in a refinery plant and a product separation and purification system thereof are adopted, the reaction recovery method is adopted, the VOCs gas is simply and efficiently recovered and utilized, a VOCs gas treatment device does not need to be additionally arranged, and the disadvantages of high investment, heat waste, serious secondary pollution and the like of a traditional combustion method are avoided; and according to the method, sulfur, nitrogen and other impurities in the VOCs gas can be effectively removed, and meanwhile, the pre-lifting steam consumption of a riser reactor of a catalytic cracking device can be reduced, so that the cooling water consumption of a fractionating tower in the oil gas fractionation process and the amount of sulfur-containing ammonia sewage discharged by the device are reduced, and the energy consumption and the operation cost of the device are reduced.

Owner:SINOPEC ENG +1

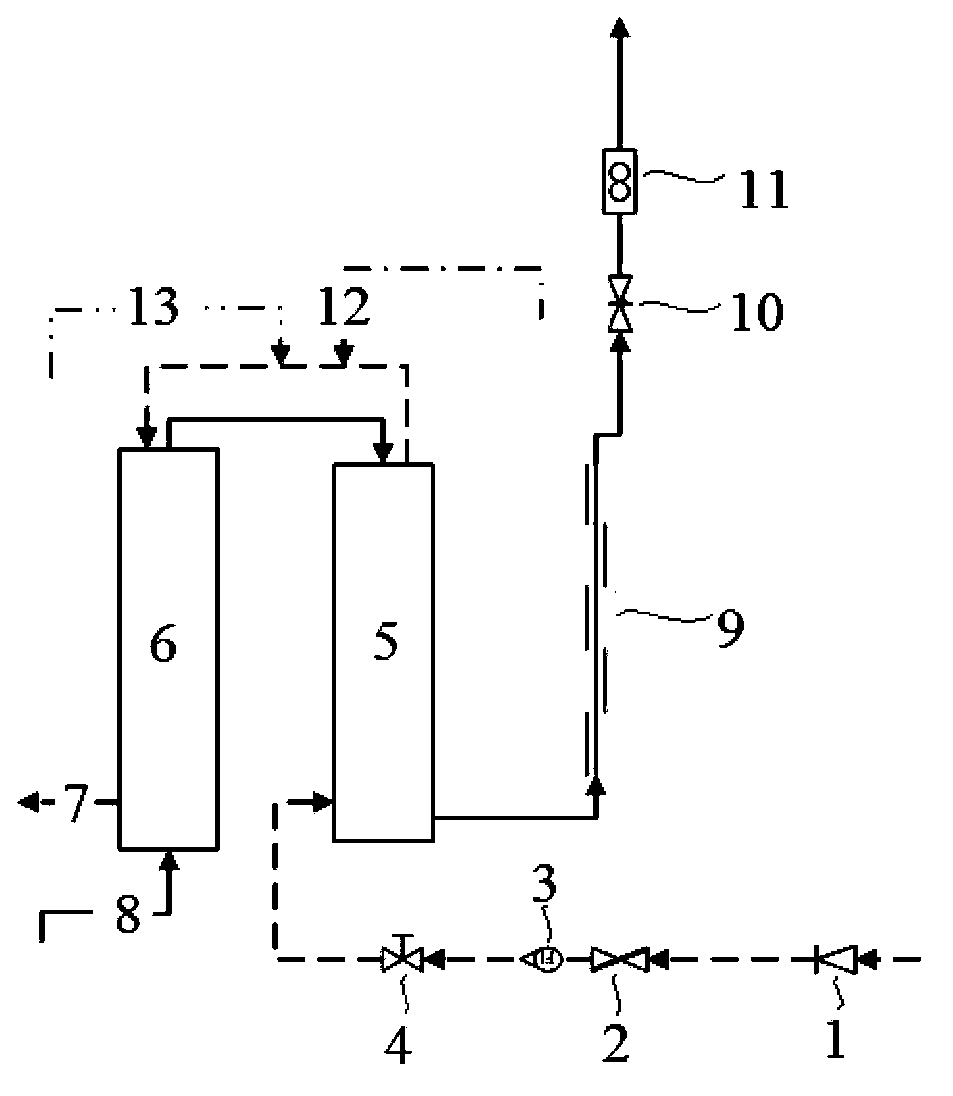

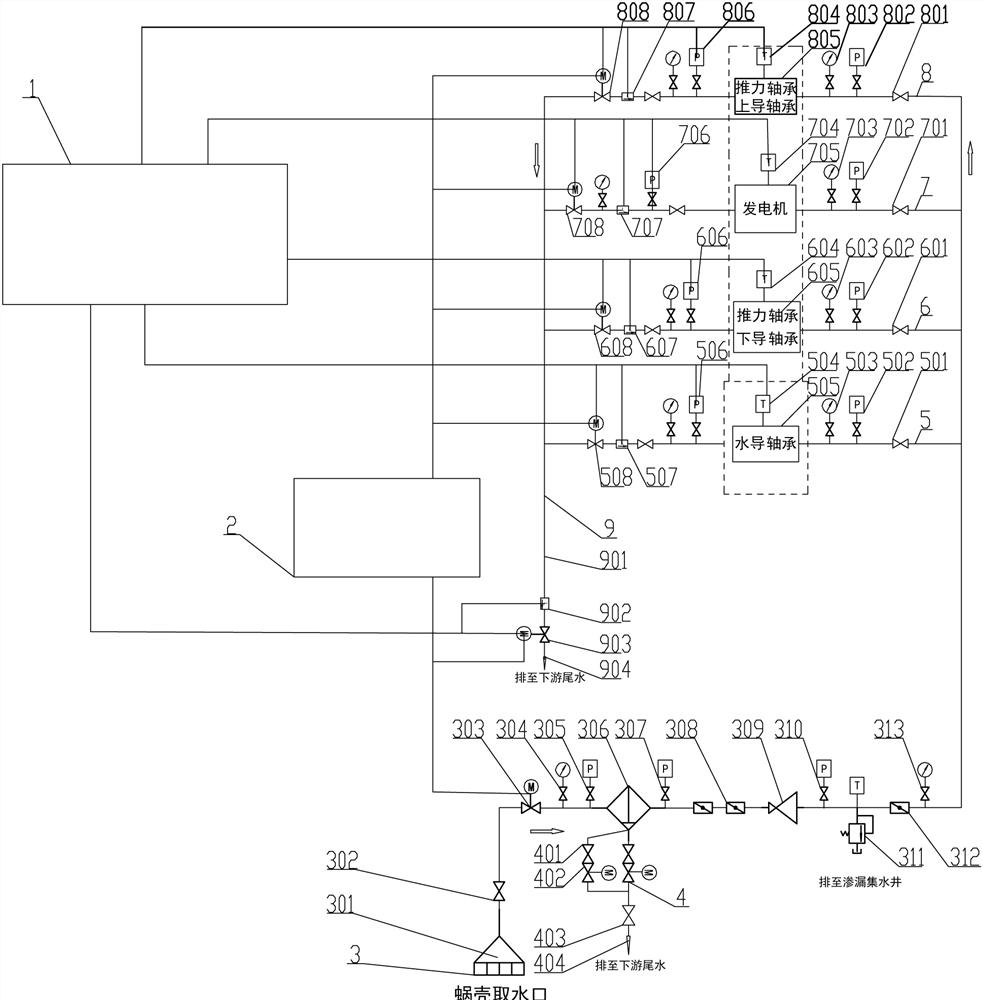

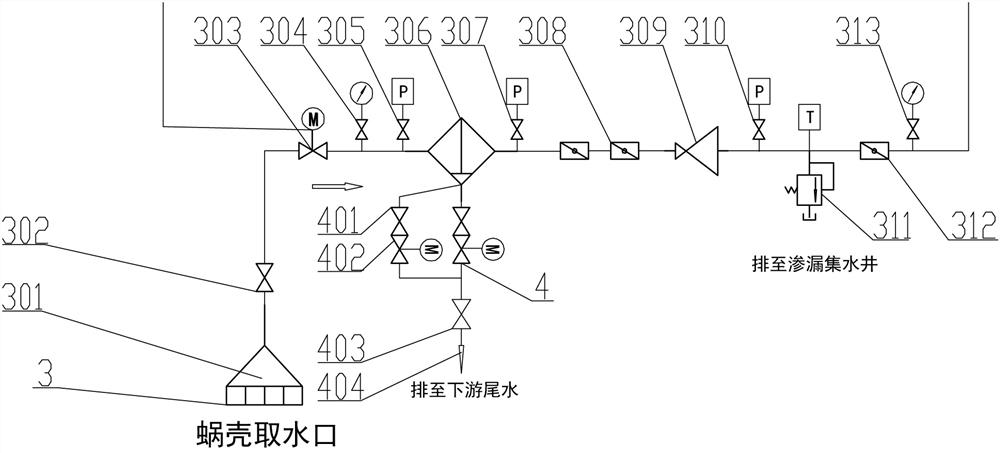

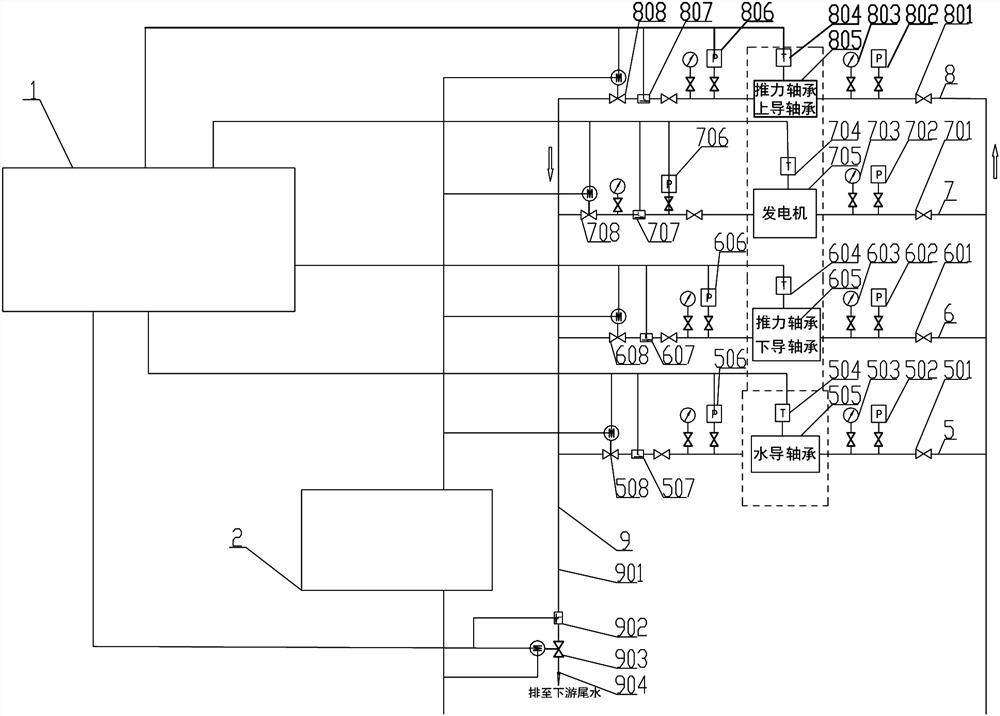

Water supply throttling system based on temperature control and control method

ActiveCN114542356AReal-time monitoring of temperature changesGuaranteed temperatureHydro energy generationMachines/enginesTemperature controlThrust bearing

The invention provides a water supply throttling system based on temperature control and a control method. An overflow system used for overflowing is connected to a water taking system; the output end of the water taking system is connected with a water guide bearing cooling system used for cooling a water guide bearing and a thrust bearing lower guide bearing cooling system used for cooling a thrust bearing lower guide bearing in parallel. The generator air cooling system is used for cooling the generator; the thrust bearing upper guide bearing cooling system is used for cooling the thrust bearing upper guide bearing; the water guide bearing cooling system, the thrust bearing lower guide bearing cooling system, the generator air cooling system and the thrust bearing upper guide bearing cooling system are all connected with the signal collector; and the signal collector is connected with the valve opening controller. According to the system, the temperature change of the cooler can be monitored in real time, a corresponding coping method is made, the temperature of the cooler can be accurately guaranteed, and stable operation of a unit is achieved.

Owner:CHINA YANGTZE POWER

Energy-saving separation method of ethylbenzene and styrene

ActiveCN105669352BLarge temperature difference between hot and cold sectionsSimple designDistillation purification/separationDehydrogenationHigh pressure

The invention relates to an energy-saving separation method of ethylstyrene and styrene, which mainly solves the problem of high energy consumption of industrial devices of a styrene separation system in the prior art. The present invention comprises the following steps by adopting: a) the dehydrogenation liquid mainly containing ethylbenzene and styrene enters the ethylbenzene / styrene separation tower T101, obtains the tower top gas stream I containing benzene, toluene, ethylbenzene and containing styrene The bottom liquid stream II; b) stream I enters the ethylbenzene / water azeotropic evaporator, heats the external ethylbenzene / water mixture, and obtains the ethylbenzene / water azeotrope stream III after heat exchange, and part of the stream I condenses The extraction enters the ethylbenzene separation tower; c) The ethylbenzene separation tower is divided into two towers (T102A, B) for operation, the pressure of T102A tower is higher, the pressure of T102B tower is lower, and the gas phase at the top of tower A is used to heat the liquid at the bottom of tower B The scheme solves this technical problem well and can be used in the industrial production of ethylbenzene / styrene separation.

Owner:CHINA PETROLEUM & CHEM CORP +1

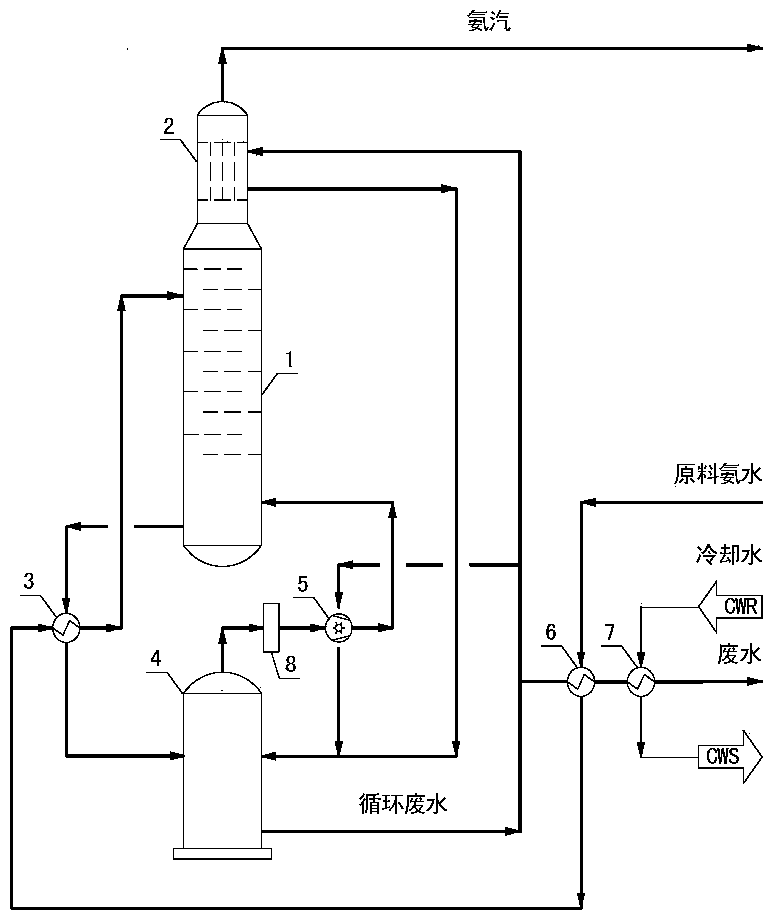

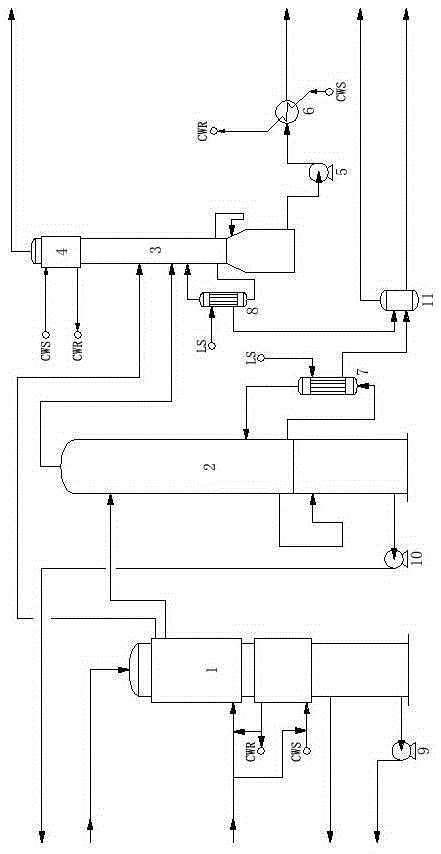

Mother liquor deamination process and equipment for soda production through thermal method

ActiveCN105174346AReduce dosageReduce evaporation equivalentWater contaminantsDispersed particle separationThermal methodsWater consumption

The invention discloses a mother liquor deamination process and equipment for soda production through a thermal method. The equipment comprises a furnace gas condenser, a mother liquor deamination tower and a tail gas rectifying tower. According to the mother liquor deamination process and equipment for the soda production through the thermal method, preheating is conducted on deamination mother liquor by means of high-temperature furnace gas of a calcining section, the self cooling purpose of the furnace gas is achieved simultaneously, energy is utilized reasonably, cooling water consumption of the furnace gas is greatly reduced, deamination tail gas exhausted through the mother liquor deamination tower enters the tail gas rectifying tower to conduct NH3 and CO2 concentration, when one ton of sodium carbonate deamination liquor equivalent is produced, 400 kg of water can be reduced, equivalent evaporation of the evaporation process is reduced, and the ammonia content of a thin solution at the tower bottom is lower than 5 ppm. According to the mother liquor deamination process and equipment for the soda production through the thermal method, by means of energy consumption structure analysis and optimal design of processes, energy consumption in the technical process is optimized, and the comprehensive energy consumption is reduced by 20 percent.

Owner:CHINA CHENGDA ENG

Combined technique of separating and recycling VOCS (volatile organic compounds) from industrial waste gas by adsorption-desorption-rectification-pervaporation

ActiveCN102764559BReduce dosageReduce cooling water consumptionOrganic compound preparationDispersed particle separationFiberSaturated water vapor

The invention relates to a combined technique of separating and recycling VOCS (volatile organic compounds) from industrial waste gas by adsorption-desorption-rectification-pervaporation, which comprises the following steps: drying, cooling and filtering the industrial waste gas containing the VOCS, then conveying into a plurality of adsorption-desorption groups to carry out adsorption-desorption operation, uniformly spraying through upper parts of adsorption-desorption devices by saturated vapor with the pressure at 0.15-0.5MPa, heating GAC (granular active carbon) or ACF (active carbon fiber) to desorb the adsorbed VOCS; after finishing the desorption, entering the next adsorption, using the VOCS-containing saturated vapor desorbed by the vapor in a pervaporation membrane for separation and heat supply. The combined technique provided by the invention forms an impact and enclosed circulation to sufficiently recycle the VOCS from the waste gas. The VOCS-containing saturated vapor desorbed by the saturated vapor contains large amount of latent heat and sensible heat, and the sensible heat of residual liquid on the bottom of a rectification tower is utilized sufficiently.

Owner:武汉旭日华环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com