Energy-saving ammonia water distillation technology

An ammonia water and steam technology, applied in heating water/sewage treatment, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of high heat supply, high energy consumption, and water vapor phase transition heat that is not reasonably recycled. and other problems, to achieve the effect of achieving heat balance and reducing the amount of cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

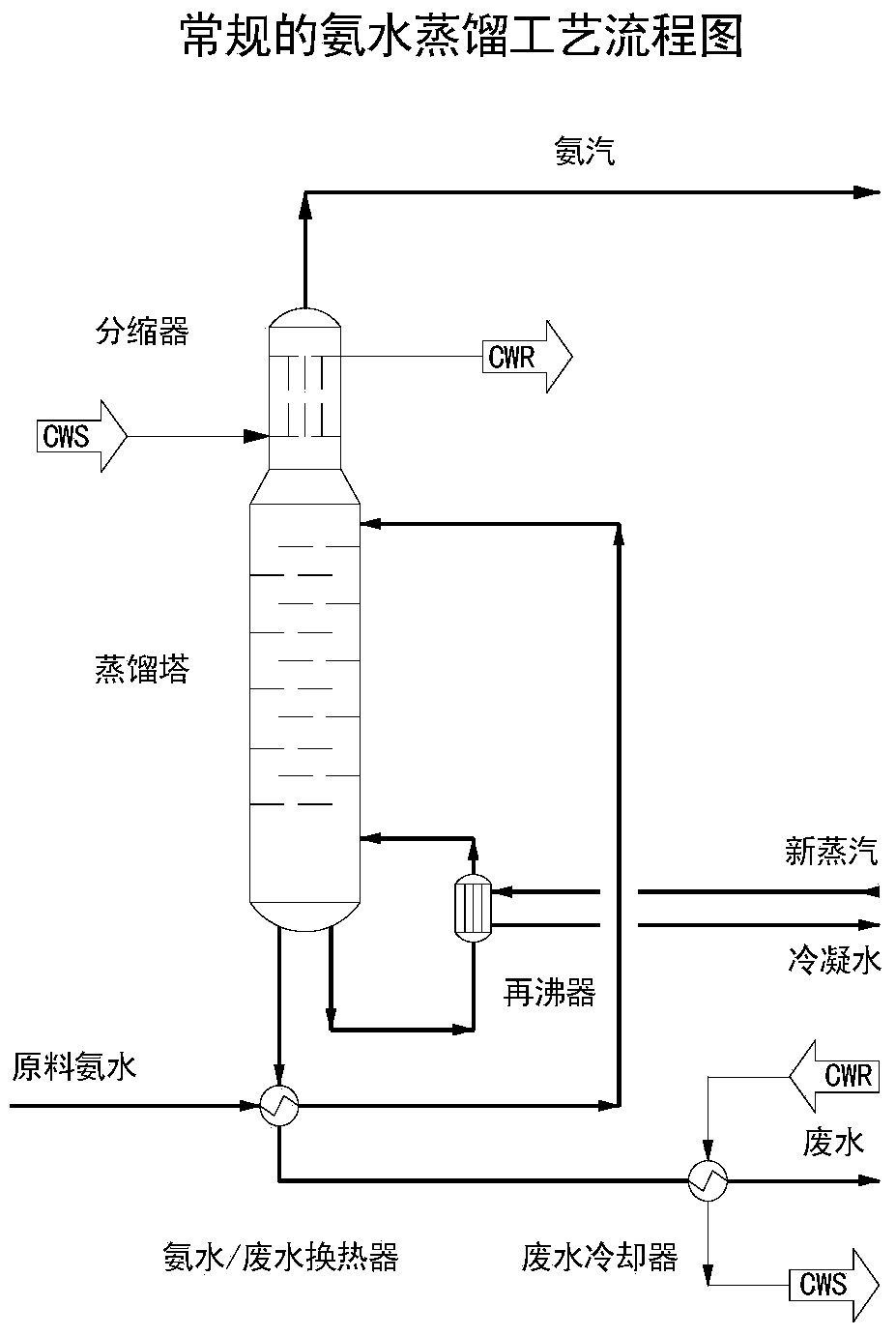

[0058] The raw ammonia water at about 75°C after fully standing and filtered by ceramic tubes is heated to about 96°C with the waste water from the bottom of the distillation tower in the ammonia water / waste water heat exchanger, and then enters the upper part of the distillation tower.

[0059] The ammonia vapor (containing hydrogen sulfide, etc.) at about 102°C in the upper part of the distillation tower is condensed and cooled to about 100°C by the circulating waste water in the shrinker, and then sent to the outside of the boundary area for further processing.

[0060] The ammonia distilled waste water at the bottom of the distillation tower at about 105°C is in the ammonia water / waste water heat exchanger, exchanges heat with raw ammonia water and cools down to 86°C, and then enters the evaporator. The 20kPa(a) and 60°C vacuum evaporation steam that escapes from the top of the evaporator enters the MVR steam compressor, and the compressed evaporation steam enters the lower...

Embodiment 1

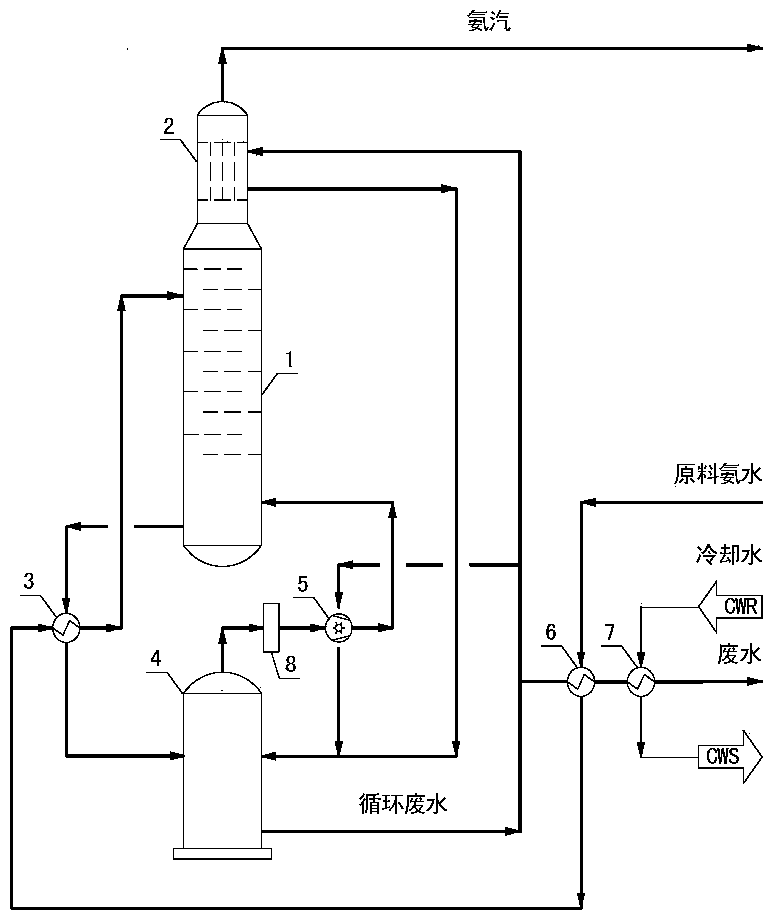

[0075] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0076] When pressing the ammonia distillation process of accompanying drawing of the present invention, raw material ammonia is earlier exchanged heat with waste water in raw material ammonia water / waste water heat exchanger 6, then in raw material ammonia water / waste water heater 3 and waste water heat exchange or in shrinker 2 After exchanging heat with ammonia vapor, it enters the upper part of distillation tower 1.

[0077] Ammonia vapor (contains H 2 S and HCN and CO 2 and other impurities) escape from the top of the distillation tower, and after being condensed and cooled by circulating waste water or raw ammonia water in the shrinker 2, it is sent to the outside of the boundary area.

[0078]The high-temperature wastewater at the bottom of the distillation tower 1 enters the evaporator 4 for flash evaporation after being cooled by the...

Embodiment 2

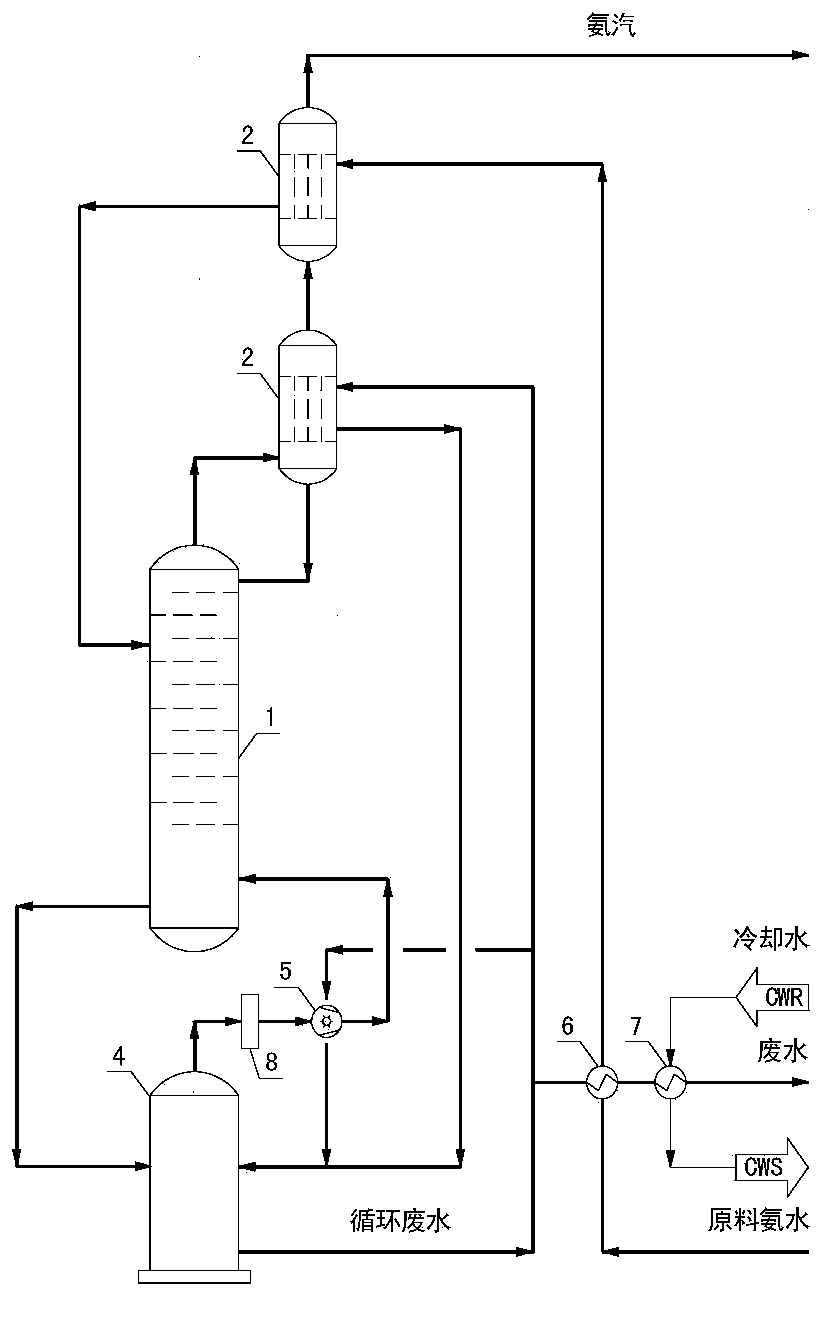

[0087] Embodiment 2 (attached figure 2 ):

[0088] The process is similar to Example 1.

[0089] The raw ammonia water from outside the boundary area exchanges heat with the effluent waste water from the evaporator to 70-75°C, and then exchanges heat with the ammonia vapor of the distillation tower in the shrinker to 125-130°C and enters the upper part of the distillation tower. The ammonia vapor at 140°C to 145°C escaping from the top of the distillation tower is condensed and cooled to 90°C to 94°C by the evaporator circulating wastewater and the raw ammonia water in the shrinker, and then the ammonia vapor with a concentration of 13.5% to 14% is sent out of the boundary area. The circulating wastewater from the evaporator is heated by ammonia vapor from 80°C to 85°C to 115°C to 120°C in the shrinker, and then returns to the evaporator to evaporate part of the steam. The wastewater cooled to 88-93°C by raw ammonia water enters the evaporator for flash evaporation. The ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com