Water supply throttling system based on temperature control and control method

A temperature control and controller technology, used in hydropower generation, safety devices, machines/engines, etc., it can solve the problems of wasting cooling water, increasing valve opening, and maintaining the same, so as to ensure safe operation and safety. and reliability, assuring security and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

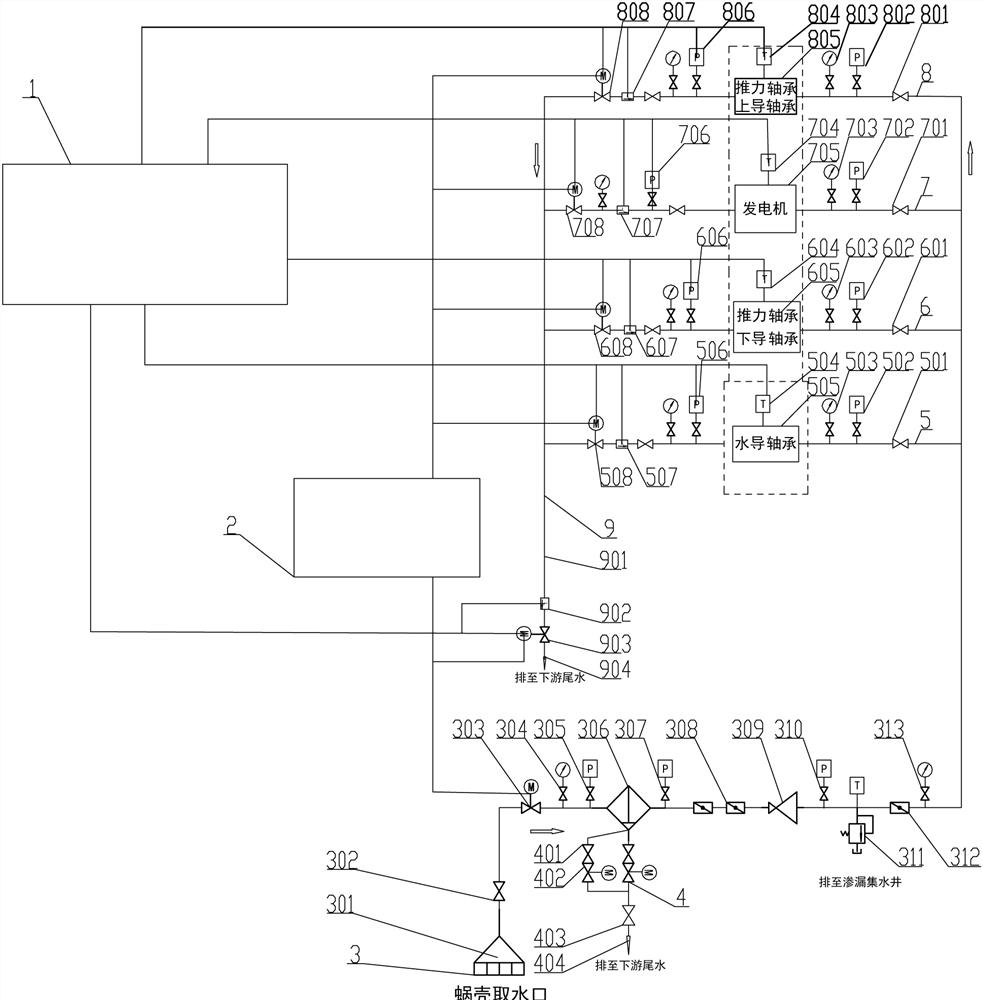

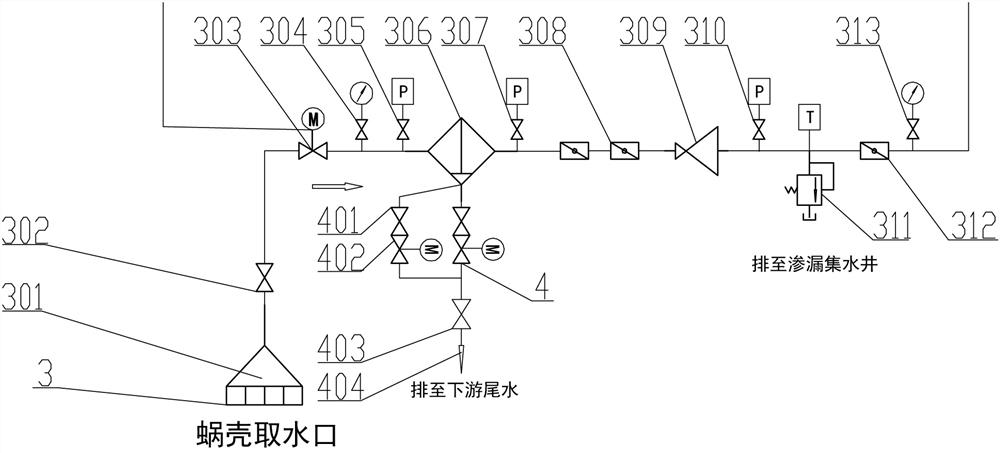

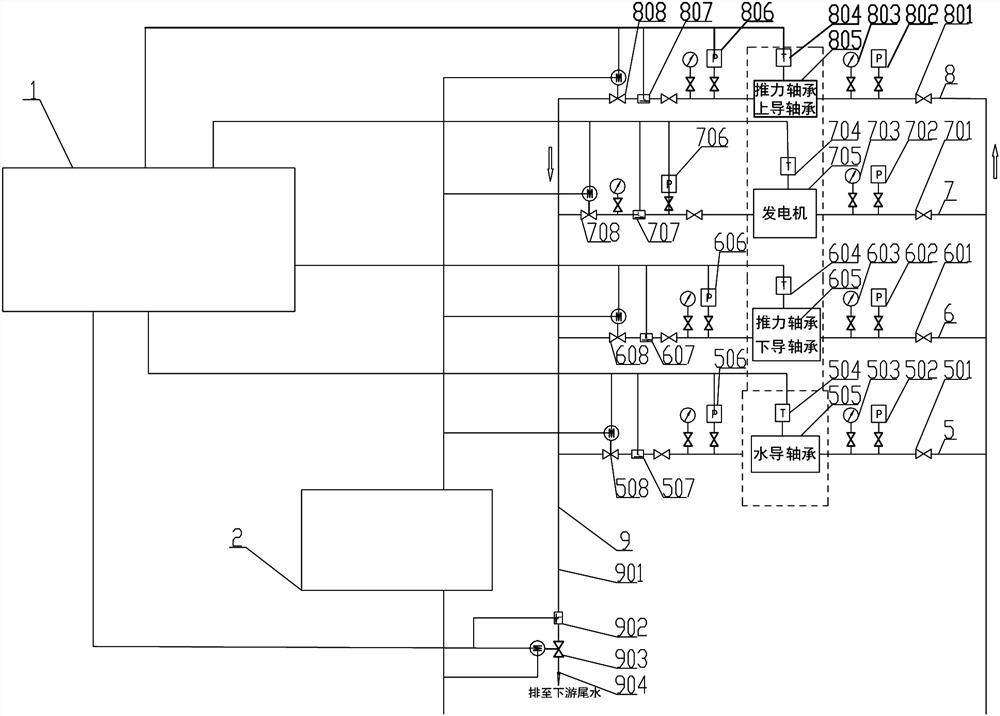

[0043] see Figure 1-3 , a water supply throttling system based on temperature control, which includes a water intake system 3 for introducing cooling water; an overflow system 4 for overflow is connected to the water intake system 3; The water guide bearing cooling system 5 for cooling the guide bearing, the thrust bearing lower guide bearing cooling system 6 for cooling the thrust bearing lower guide bearing, the generator air cooling system 7 for cooling the generator, and the thrust bearing cooling system 7 for cooling the thrust bearing. The upper guide bearing cooling system 8 of the thrust bearing cooling the upper guide bearing of the bearing; the cooling system 5 of the water guide bearing, the cooling system 6 of the lower guide bearing of the thrust bearing, the air cooling system 7 of the generator and the cooling system 8 of the upper guide bearing of the thrust bearing are all related to the signal acquisition. The signal collector 1 is used to collect the temper...

Embodiment 2

[0053] The control method of the water supply throttling system based on temperature control includes the following steps:

[0054] Step 1: During the operation of the system, the cooling water inside the volute is filtered and decompressed through the water intake system 3 and then introduced into the corresponding water guide bearing cooling system 5, thrust bearing lower guide bearing cooling system 6, and generator air cooling system 7 And thrust bearing upper guide bearing cooling system 8;

[0055] Step 2: During the operation of the water guide bearing cooling system 5, the temperature of the water guide bearing cooler 505 is collected in real time through the first temperature sensor 504, and the temperature signal is transmitted to the signal collector 1; The pipeline pressure is collected, and the pressure signal is transmitted to the signal collector 1; the pipeline flow is collected in real time through the first flow meter 507, and the flow signal is transmitted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com