Prefabricated iron tap channel

A technology of iron trough and groove, which is applied in the field of iron smelting blast furnace, can solve the problems that the service life of the iron trough cannot be effectively improved, the temperature change of the iron trough cannot be fully monitored, and it is inconvenient to dissipate heat, so as to reduce the risk of iron leakage, Easy surface smoothness and improved safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

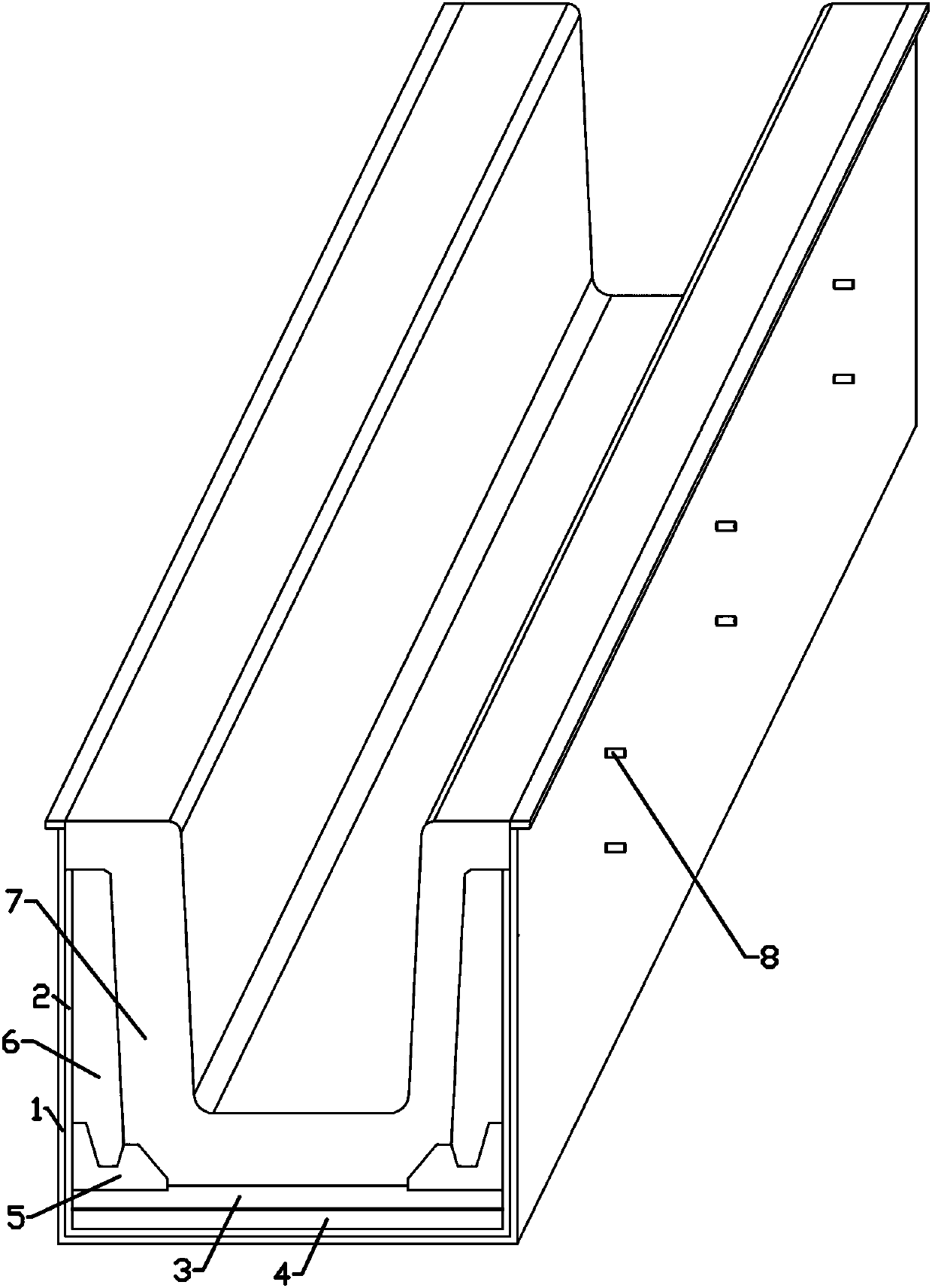

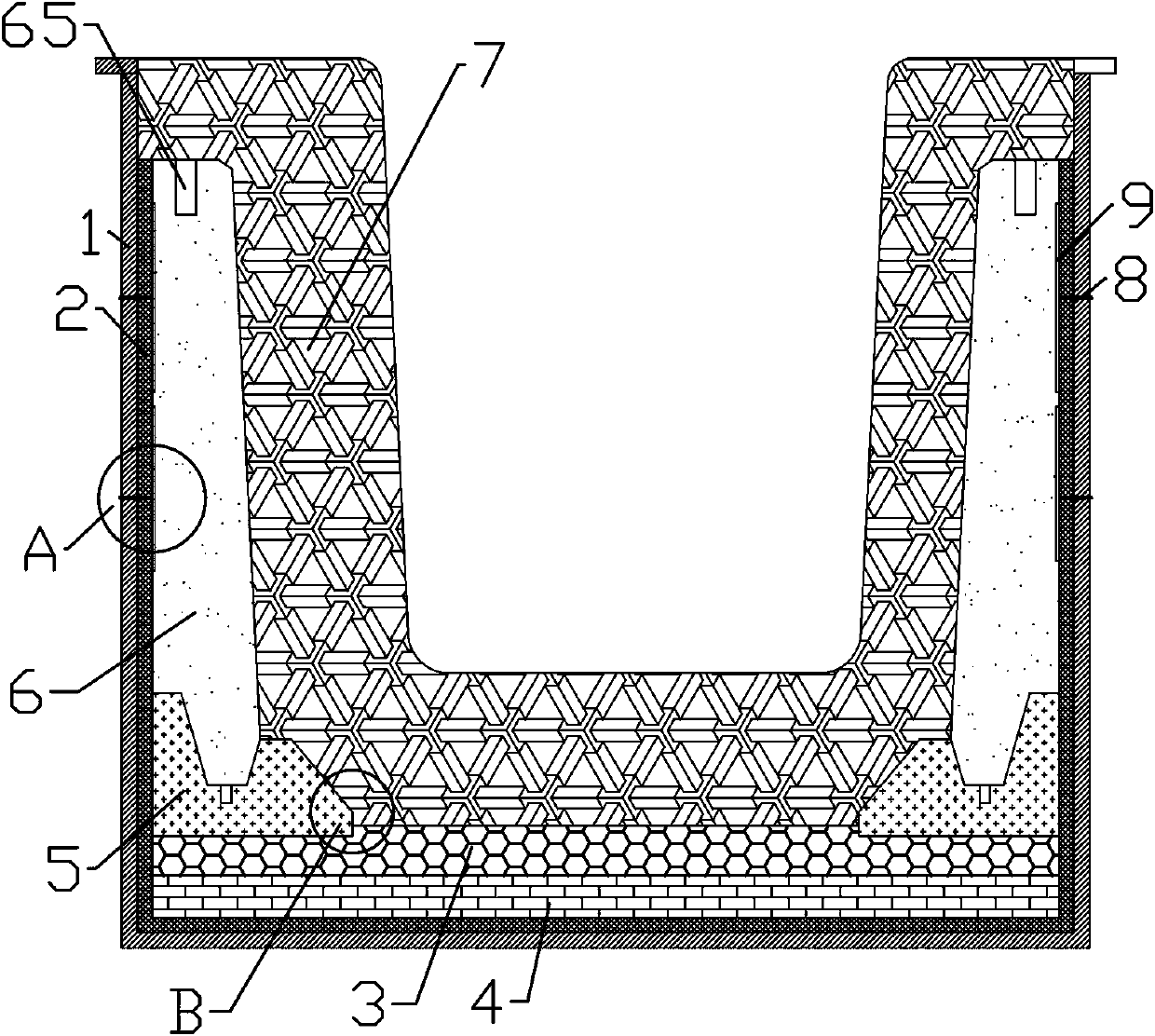

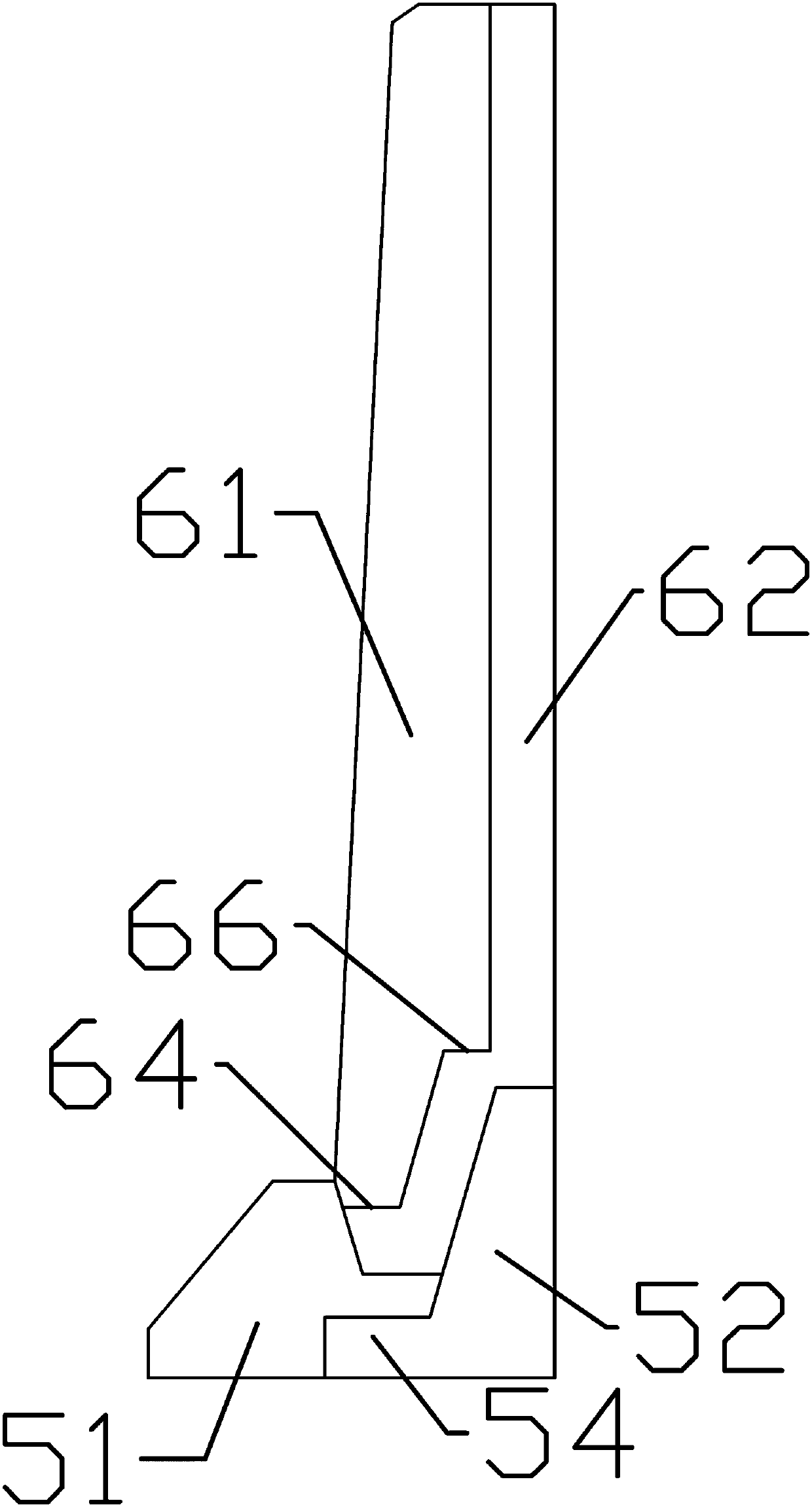

[0029] Such as Figure 1-8 As shown, a prefabricated iron trench includes a steel shell 1 with a U-shaped cross section, a permanent layer installed in the steel shell 1, and a working layer 7 installed on the permanent layer. The steel shell 1 is made of a steel shell with a thickness of 25-35mm. It is made of heat-resistant steel plate, which is divided into 3-4 sections and welded before tailor welding. It is easy to manufacture and has high structural strength. The steel shell is fixed on the track by bolts. The outer walls of both sides of the steel shell 1 are exposed to the air, which can be naturally air-cooled. To avoid heat accumulation and improve the service life, the inner wall of the steel shell 1 is attached with a thermal insulation layer 2 made of asbestos. The thermal insulation layer can also be made of degradable fiber with a thickness of 50-80mm, which has a good thermal insulation effect. It can reduce heat conduction to the steel shell, reduce energy con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com