Patents

Literature

167results about How to "Real-time monitoring of temperature changes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

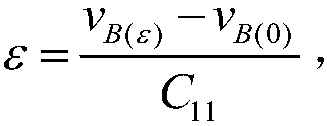

Method of temperature drift compensation for infrared thermometers

ActiveCN103424192AReal-time monitoring of temperature changesCorrect for non-uniformityPyrometry using electric radation detectorsMultiple responseEngineering

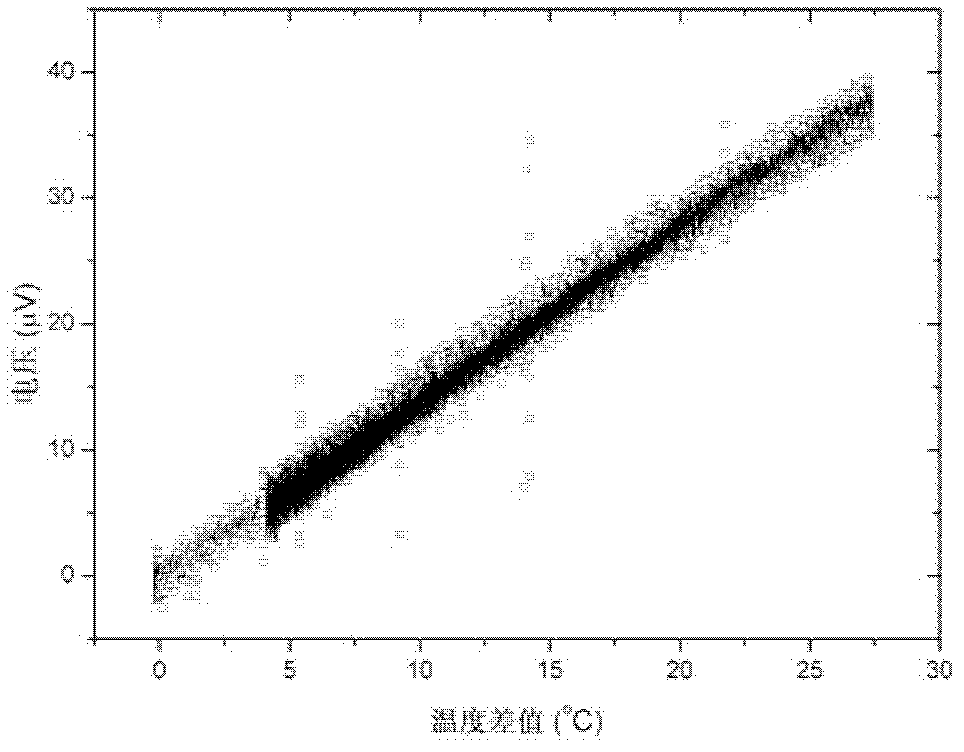

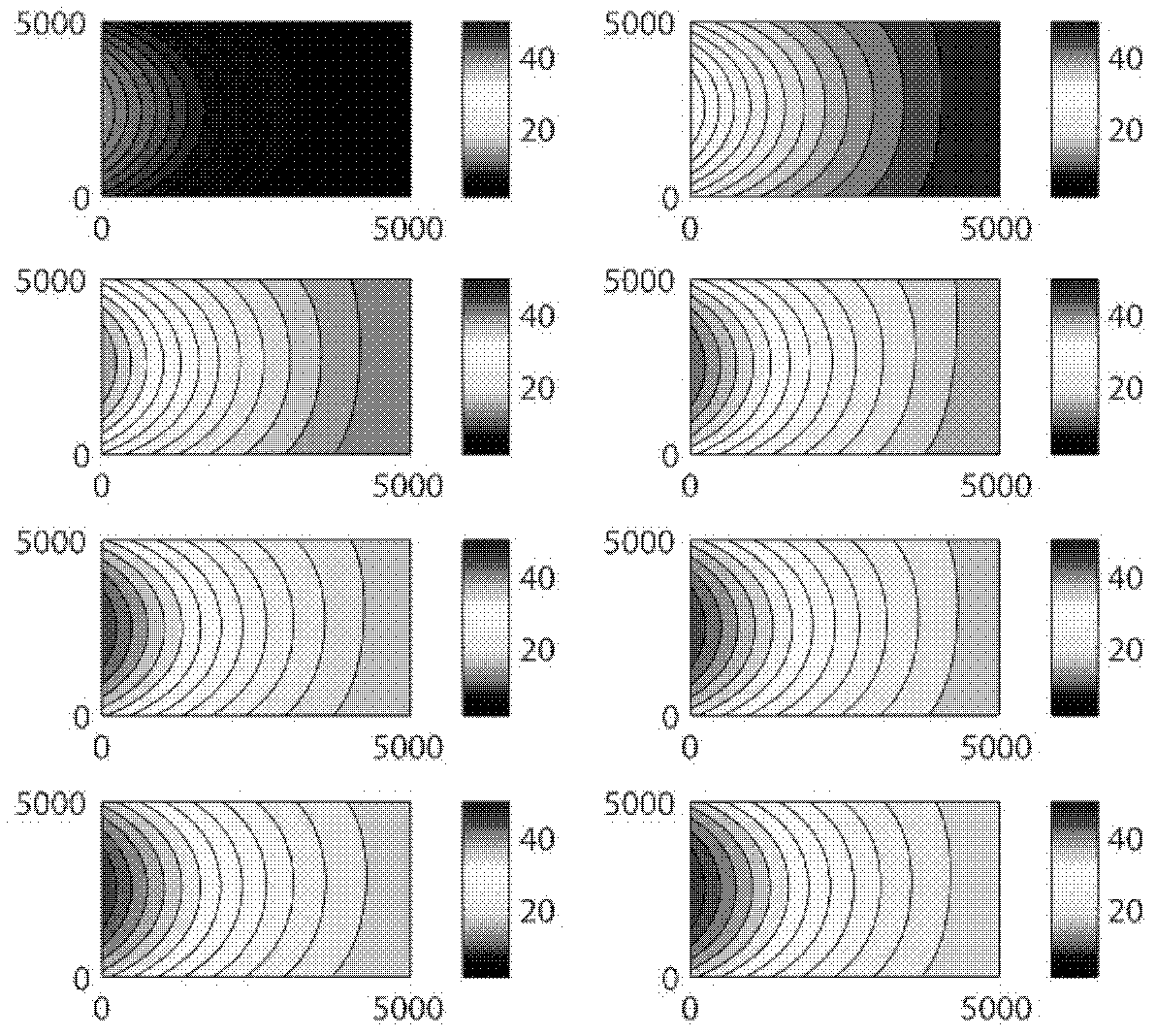

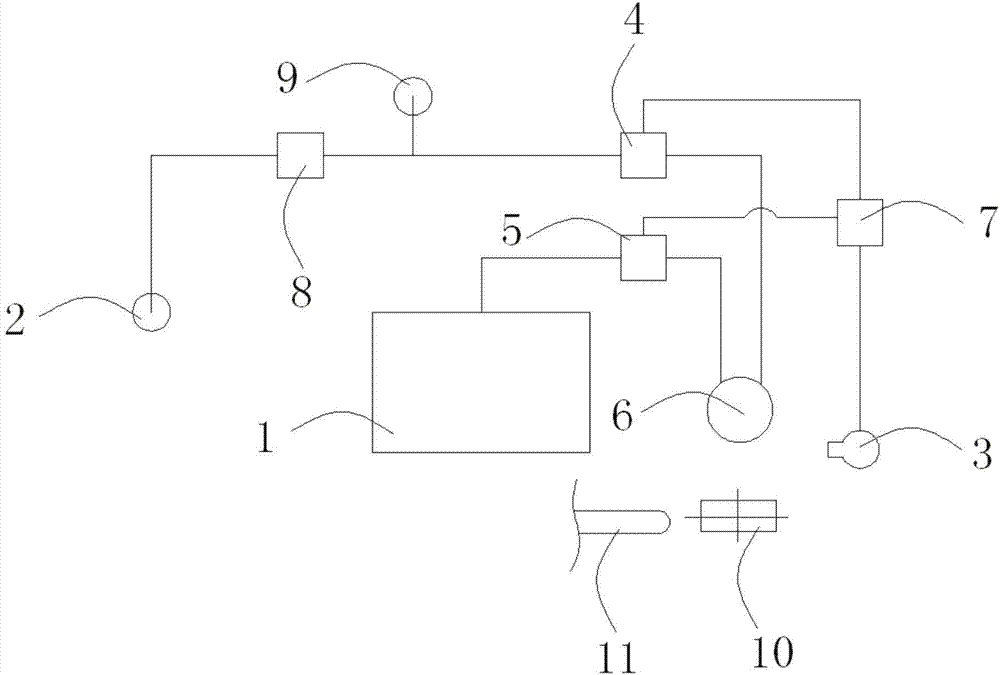

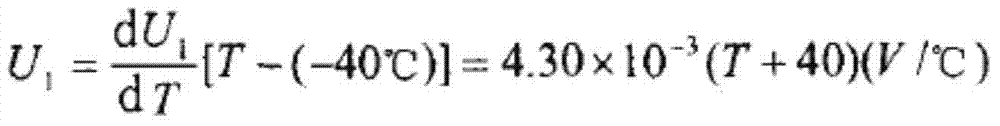

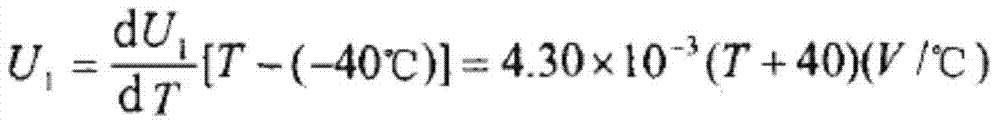

An embodiment of the invention discloses a method of temperature drift compensation for infrared thermometers. The method includes: setting temperature sensors on a core and a retainer plate respectively, responding to black-body radiation in a thermostat, and acquiring multiple response output groups by controlling the thermostat and the continuous change of black-body temperature; linearly fitting the response output of the infrared thermometer to black-body temperature, interior temperature of the thermostat and first temperature of the core by the obtained data groups; compensating temperature drift caused by the temperature of the core through fitting results, and acquiring a function of relation of the response output of the infrared thermometer to the black-body temperature, the interior temperature of the thermostat and the first temperature of the core; calibrating with the retainer plate, and acquiring current ambient temperature according to the fitted relation function; removing the retainer plate, measuring the temperature of a target object by the infrared thermometer, and calculating the temperature of the target object according to the current response output, the current ambient temperature and the fitted relation function. The method has the advantages that temperature change can be monitored in real time for the calibrating retainer plate and the core, the temperature drift caused by the change in the temperature of the core and the ambient temperature is compensated, nonuniformity of the infrared thermometer can be corrected effectively, and temperature measurement is more accurate.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

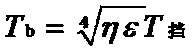

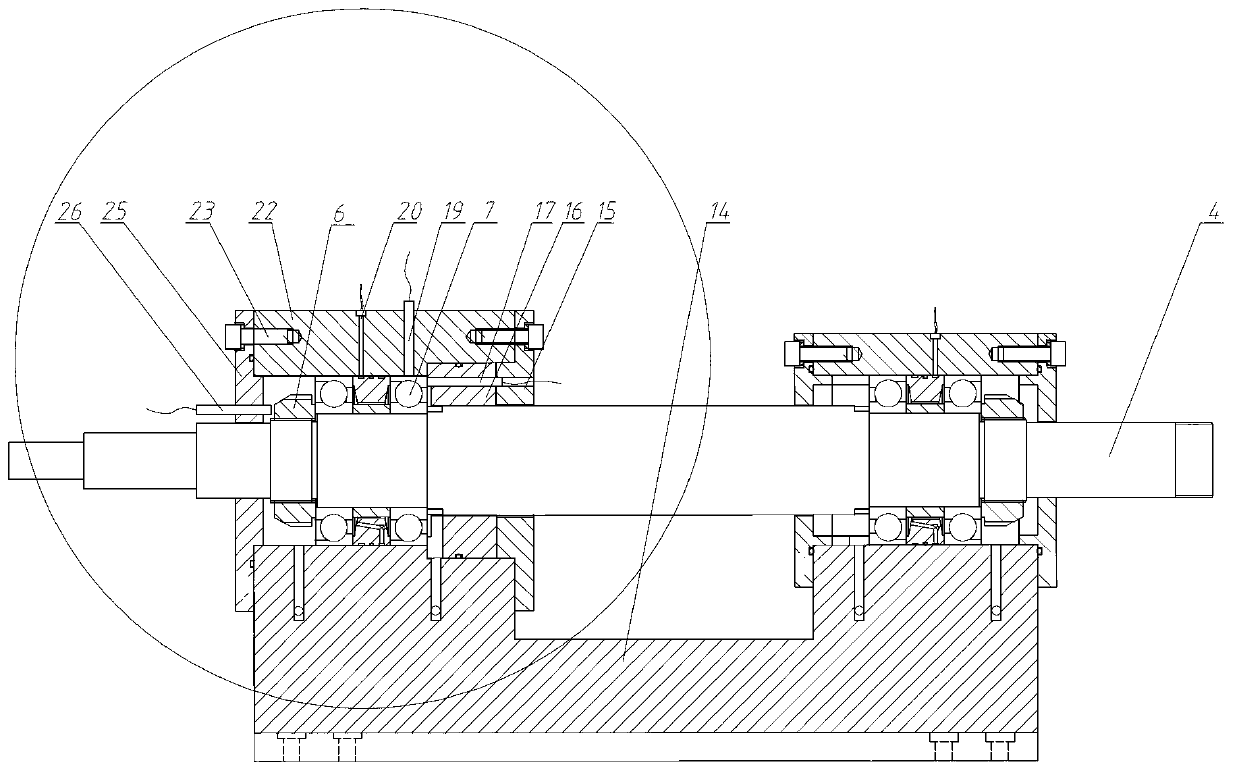

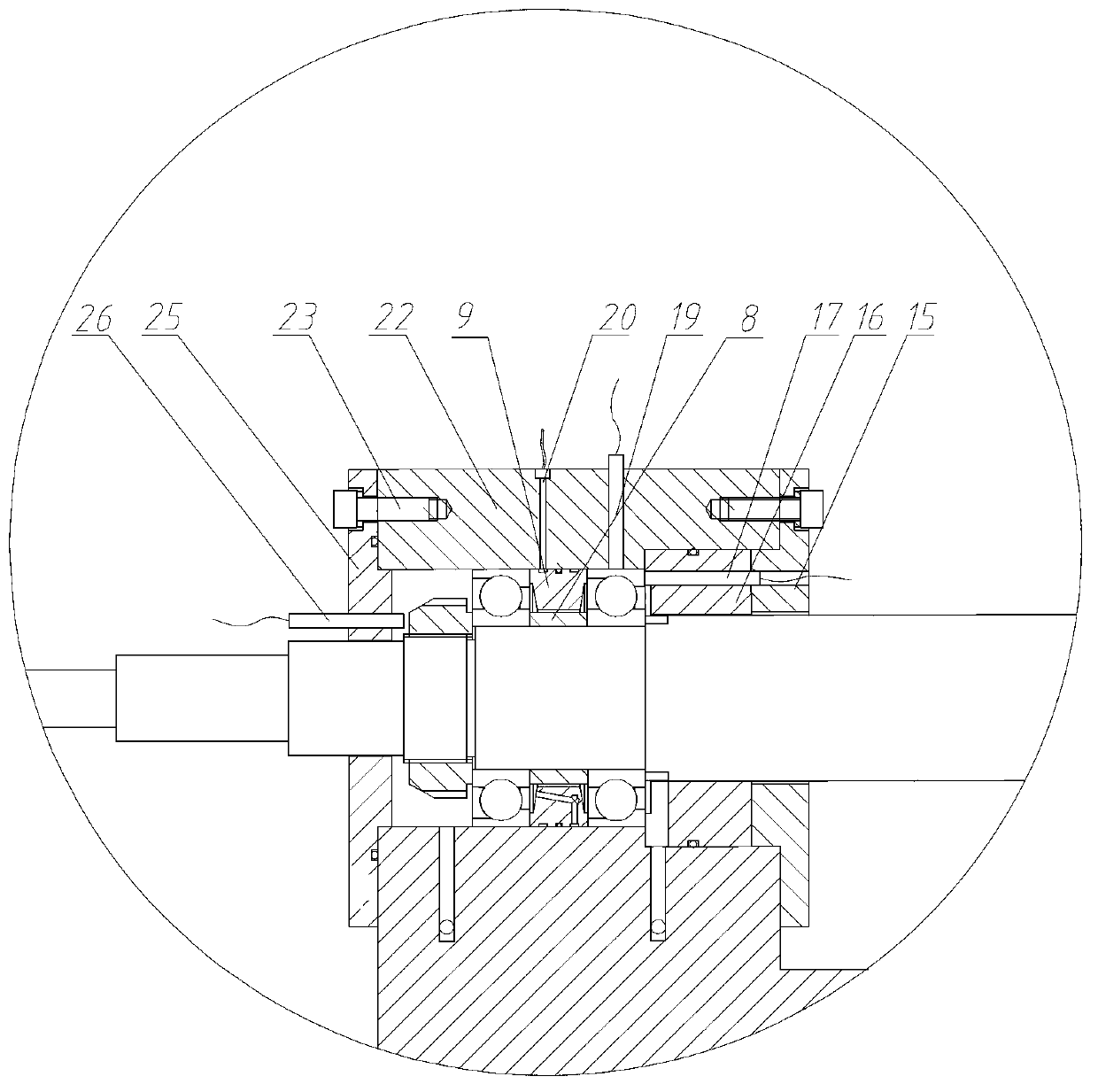

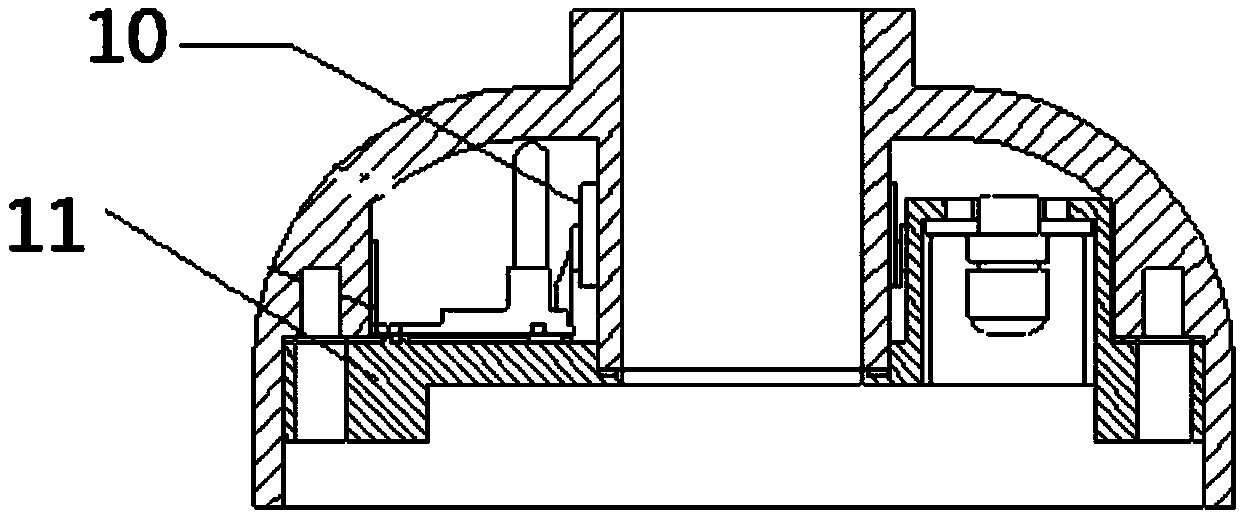

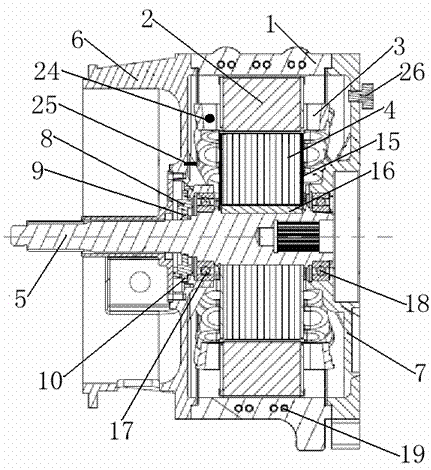

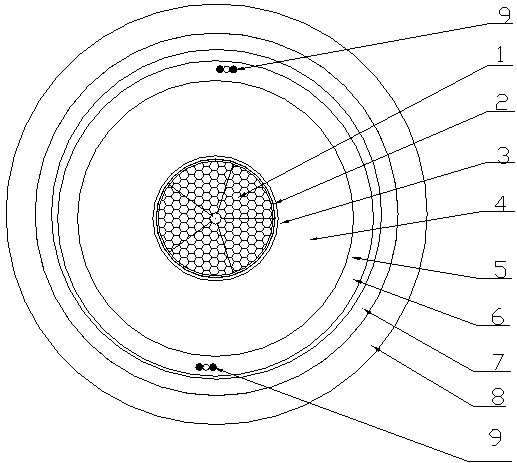

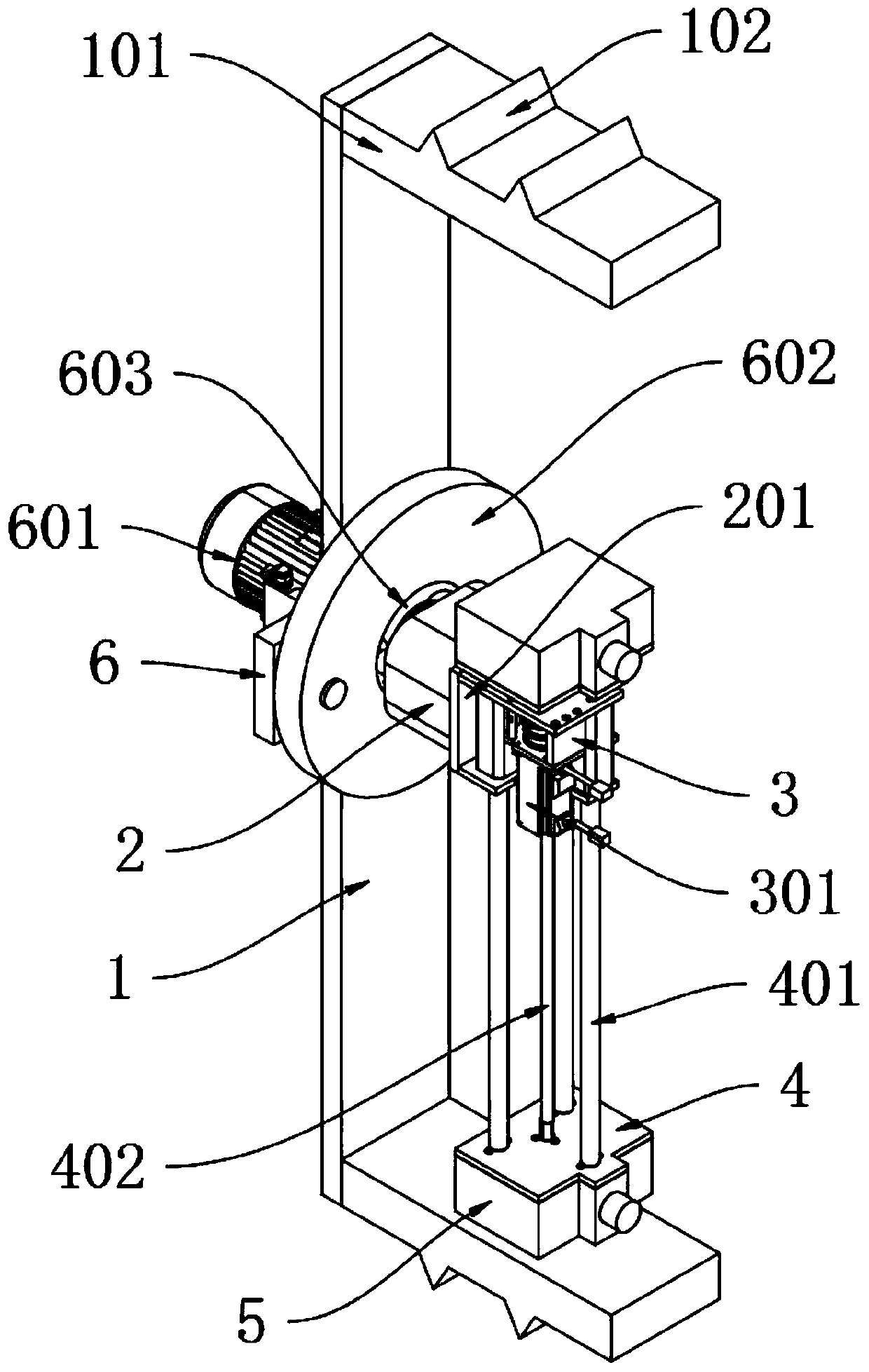

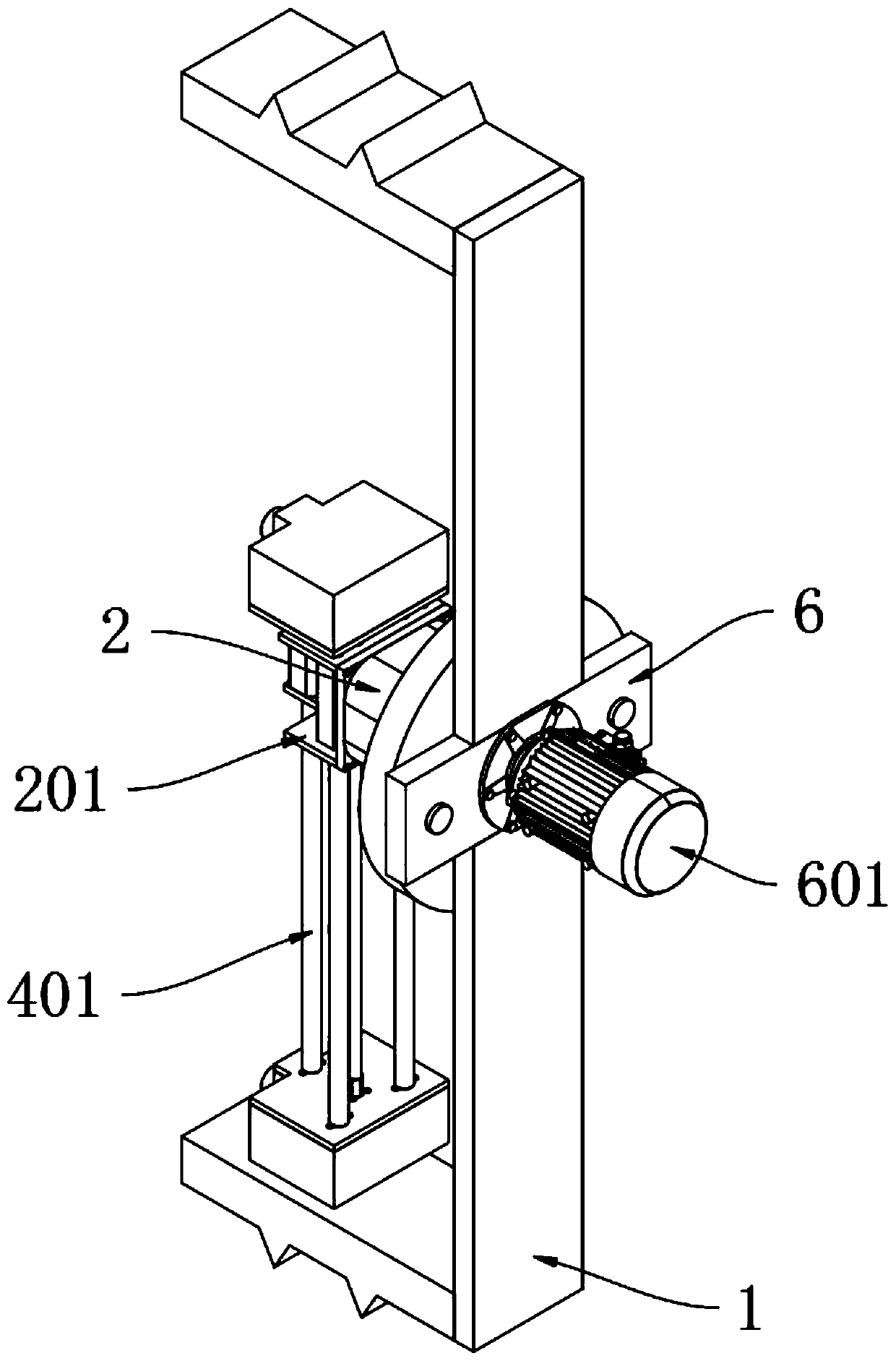

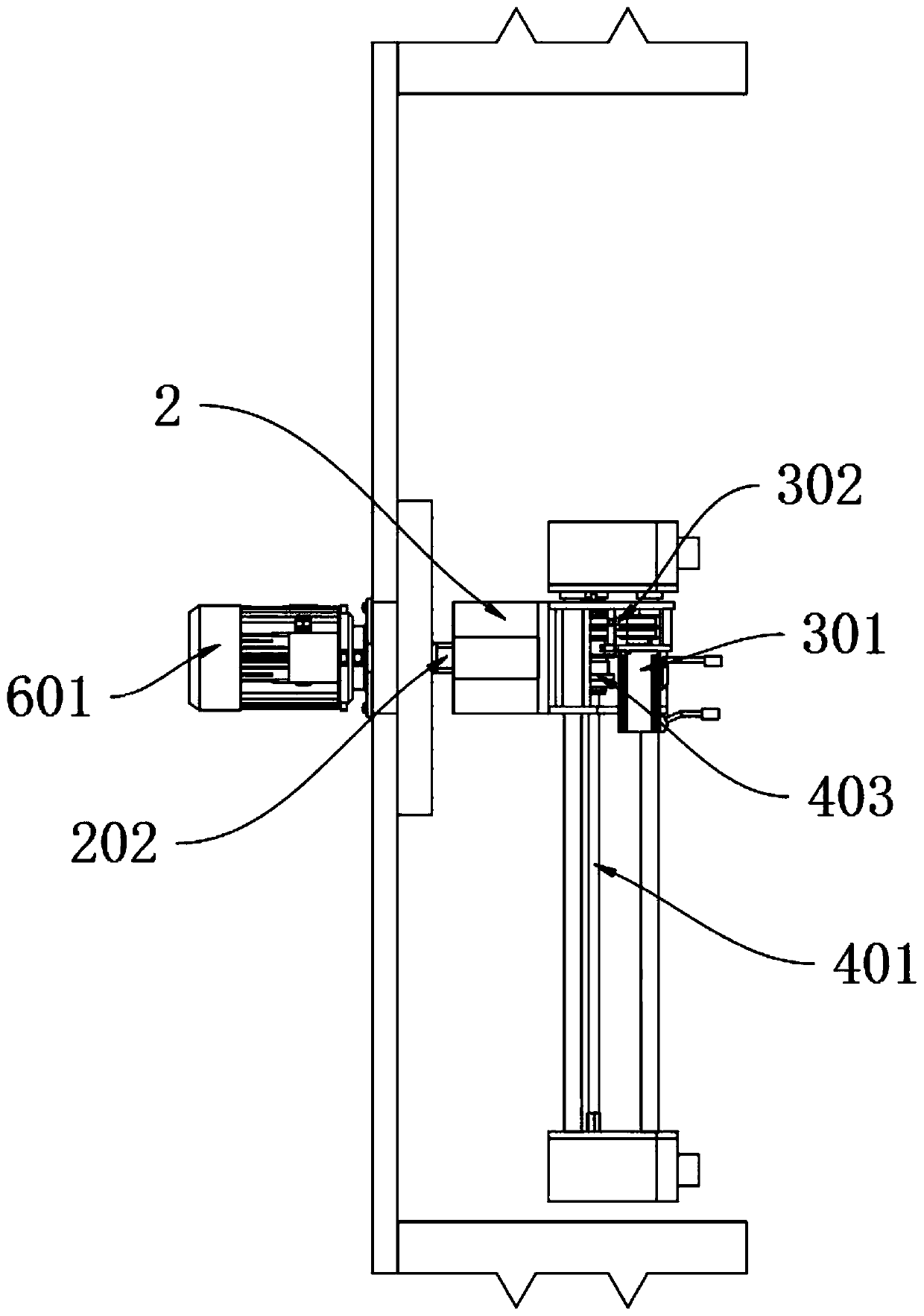

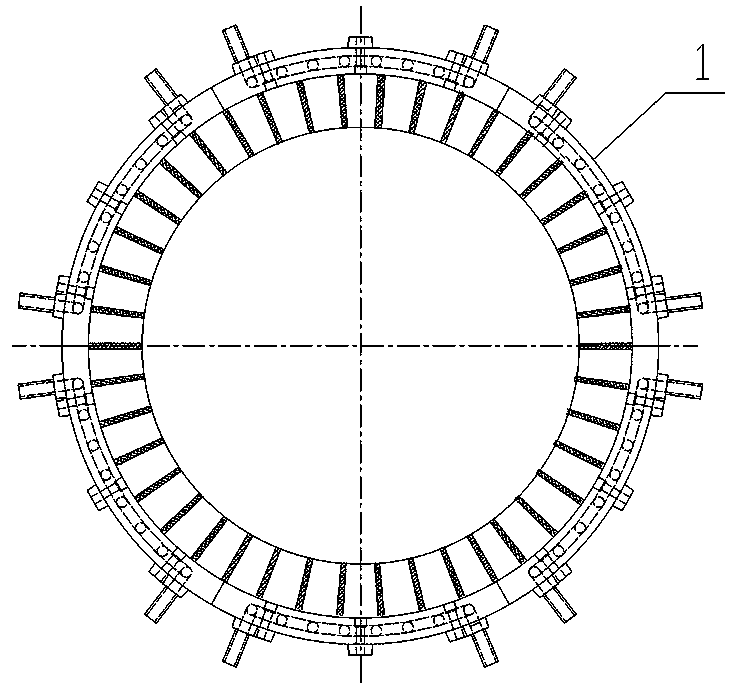

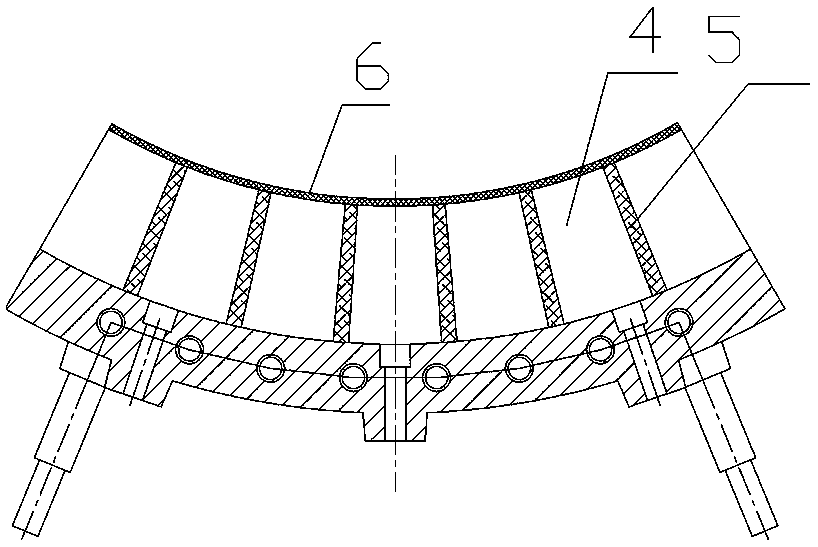

Strong-generality comprehensive experiment table for testing dynamic and static properties of spindle system

InactiveCN102866006ARealize the experimentVerify service performanceMachine bearings testingBall bearingPiezoelectric actuators

The invention discloses a strong-generality comprehensive experiment table for testing dynamic and static properties of a spindle system. The experiment table mainly comprises a driving electric spindle module, a mechanical spindle module and a hydraulic loading module, wherein the mechanical spindle module comprises a spindle, a bearing, a bearing pedestal, a pre-tightening force self-adaptive adjustment device, a temperature sensor, a displacement sensor, a pressure sensor and an air-oil lubrication device. The pre-tightening force self-adaptive adjustment is completed by six evenly distributed piezoelectric actuators, so as to realize the accurate control of the pre-tightening force of an angular contact ball bearing in the spindle system. According to the experiment table, different bearing configuration manners and different lubrication manners can be used, so that the properties of the experiment table are greatly expanded. Through controlling the rotation speed of an electric spindle, property test data such as temperature rise, rigidity and the like of the spindle under different configuration and pre-tightening conditions can be obtained by using the temperature sensor, the displacement sensor and the pressure sensor.

Owner:XI AN JIAOTONG UNIV

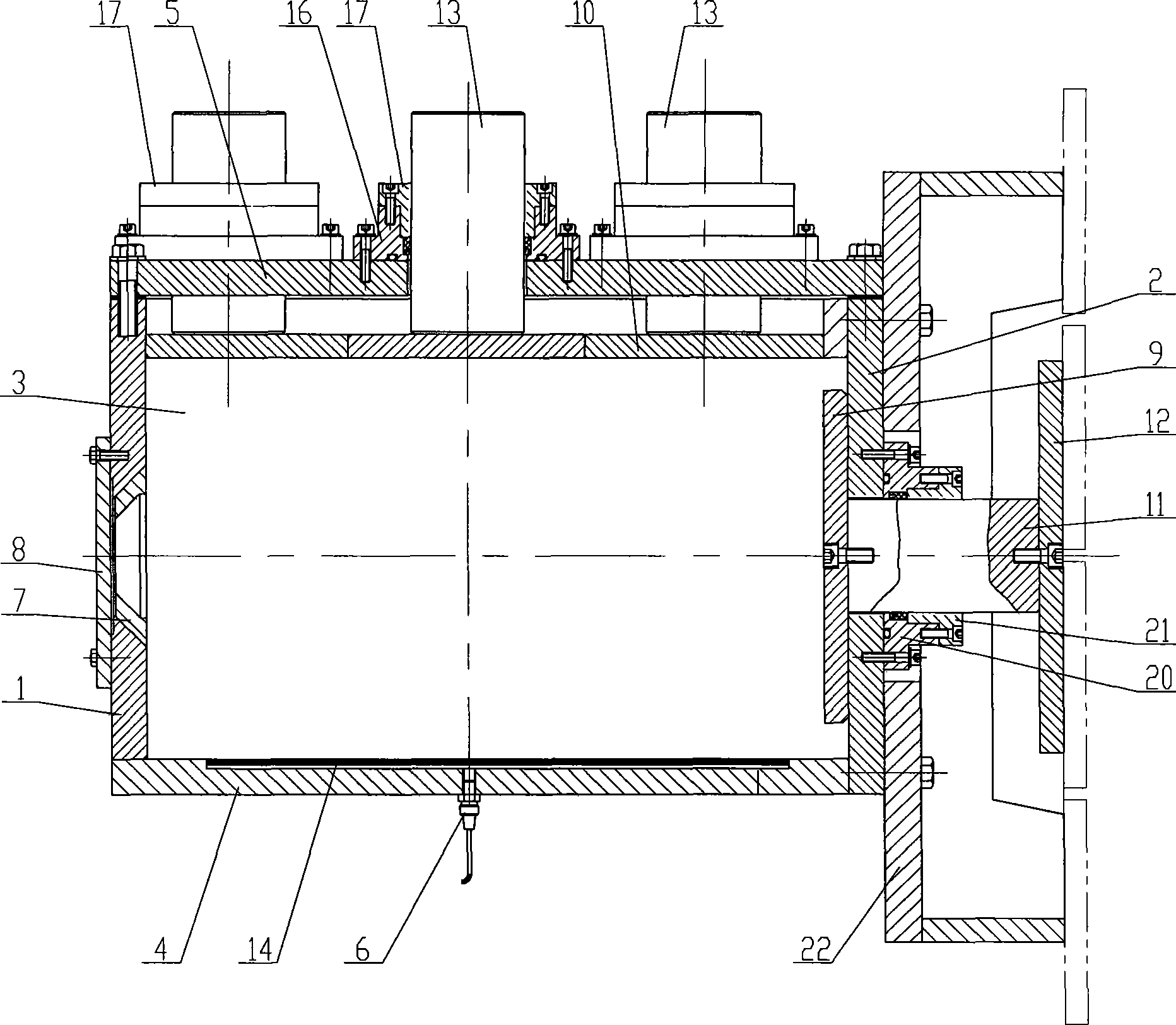

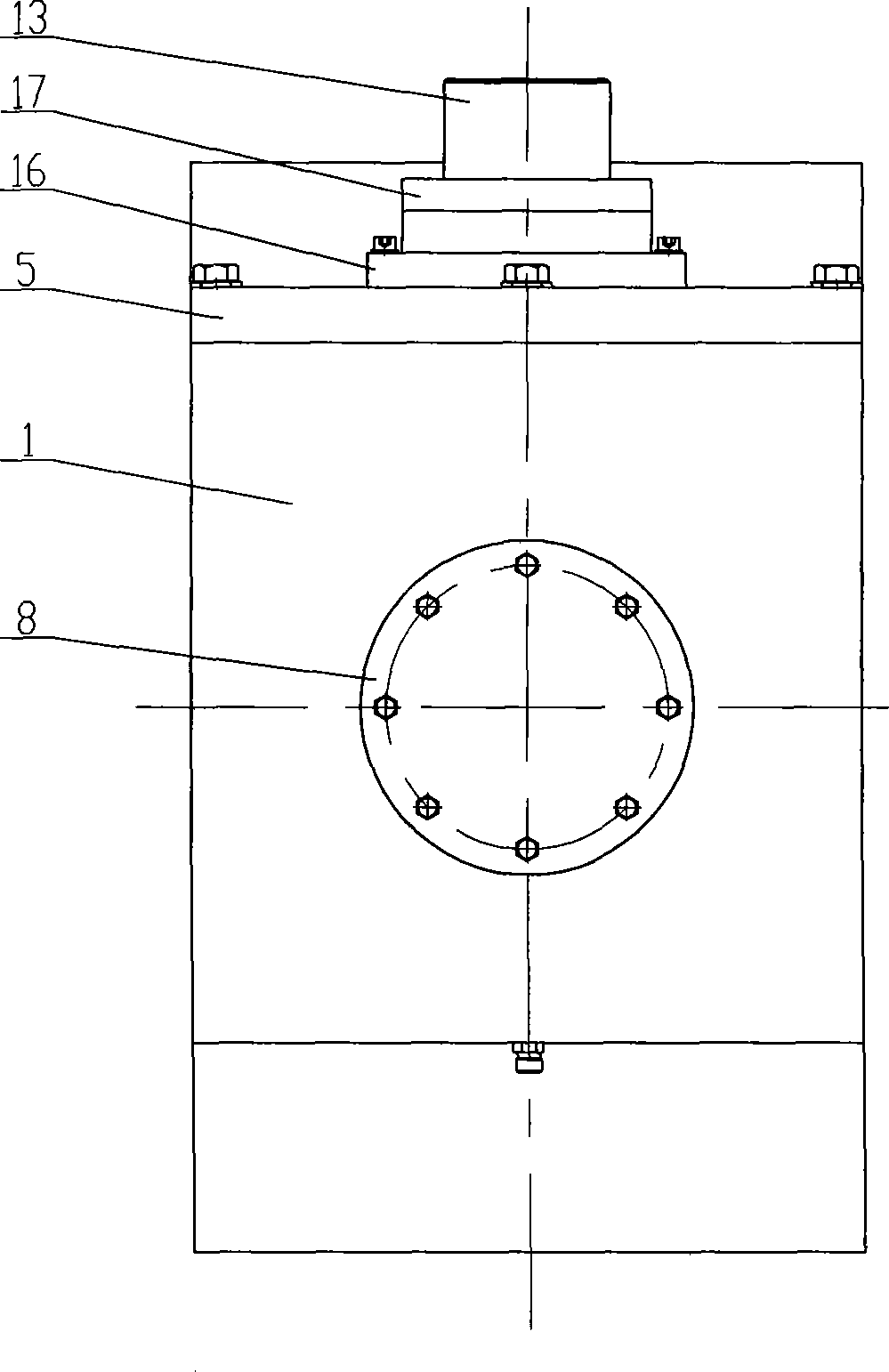

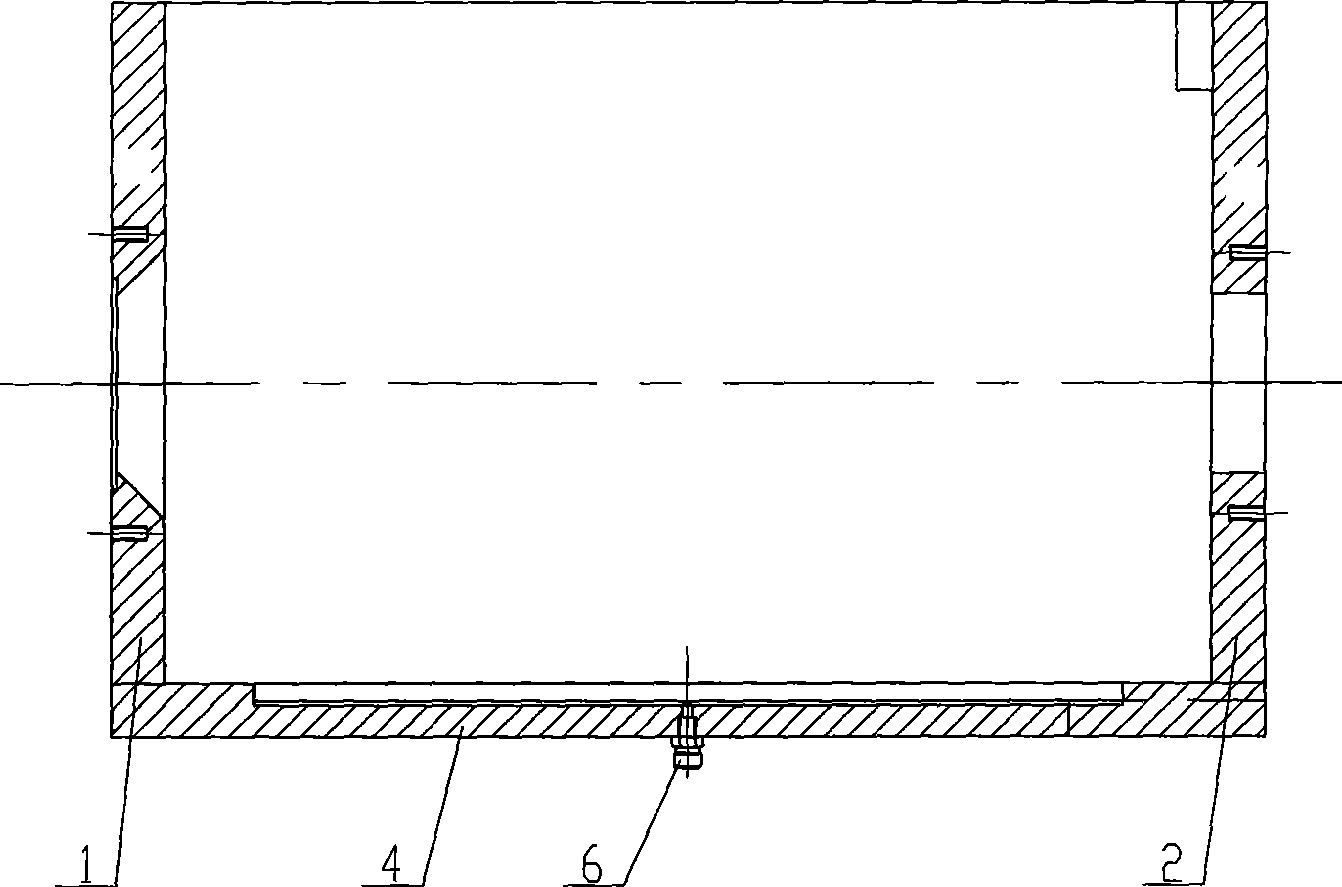

Coal and mash gas extrusion mold

InactiveCN101419146ASolve the difficult problem of accurate positioningAvoid the cumbersome process of coal loadingMaterial strength using tensile/compressive forcesStress concentrationEngineering

The invention relates to a coal and gas extruding mould. The center of a base plate is provided with a charging hole; a charging hole is provided with a gas inlet nozzle; the middle part of a front end plate is provided with a positioning hole; and the positioning hole is provided with an extruding port. The inside of a mould box is provided with a rear pressure plate and three upper pressure plates, wherein the rear pressure plate is fixed on the front end of a rear pressure head; the rear end of the rear pressure head runs through the rear end plate and is fixedly connected with a shim plate; three upper pressure plates are sequentially arranged from front to back and are fixed on the lower end of one upper pressure head respectively; the connecting lines between axes of three upper pressure heads are positioned in the same beeline; and the upper end of the upper pressure head runs through an upper sealing plate and protrudes upwards to the outside of the mould box. The coal and gas extruding mould adopts a mode of combining pressure in the horizontal direction and pressure in the vertical direction, can apply any ladder-type load on a protrudent coal body, has obvious gradient of force applied on a protrudent coal sample, can stimulate the phenomenon of concentrated stress in front of a protrudent working face and stimulate field horizontal ground stress; and a result obtained from a test is accurate and reliable.

Owner:CHONGQING UNIV

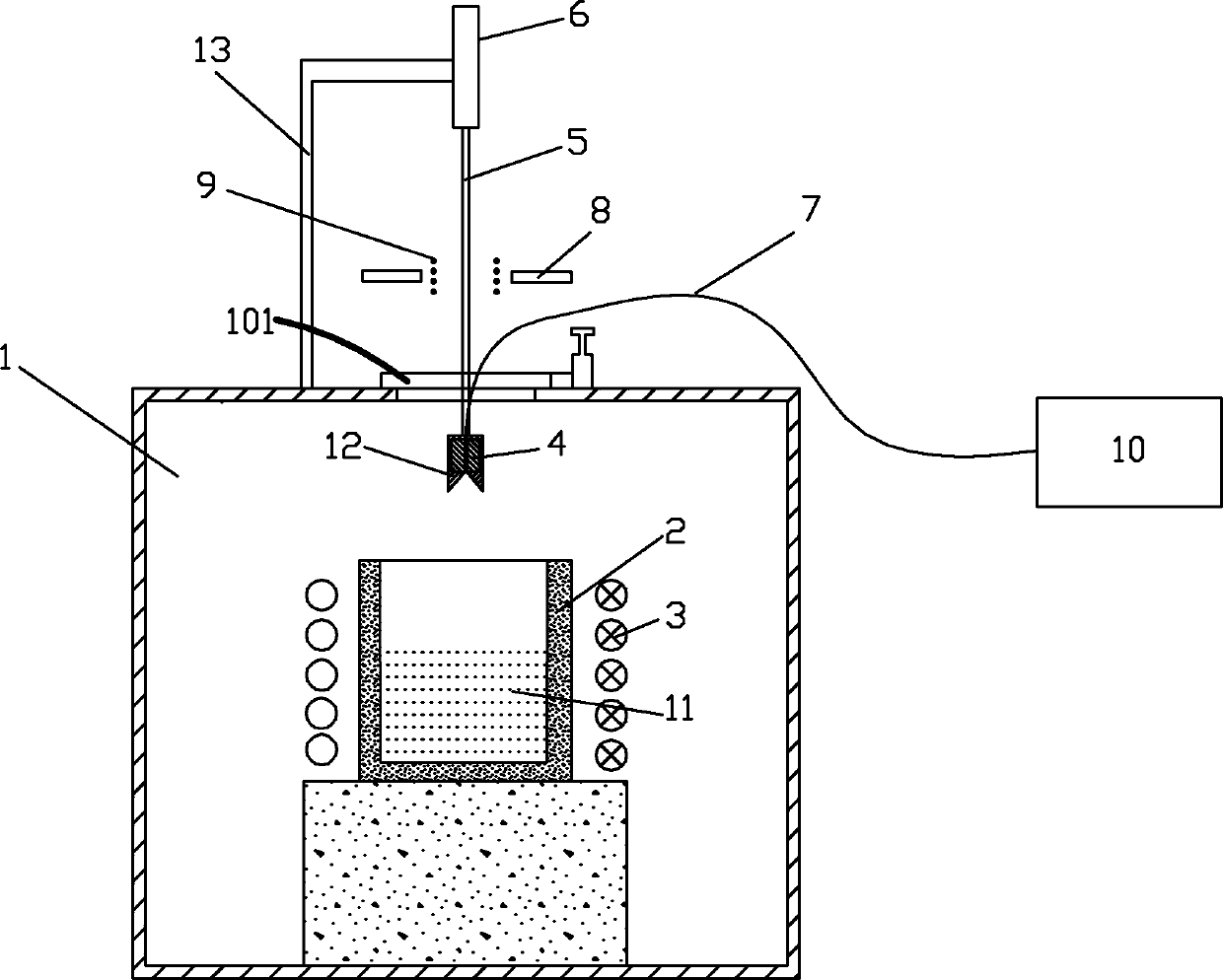

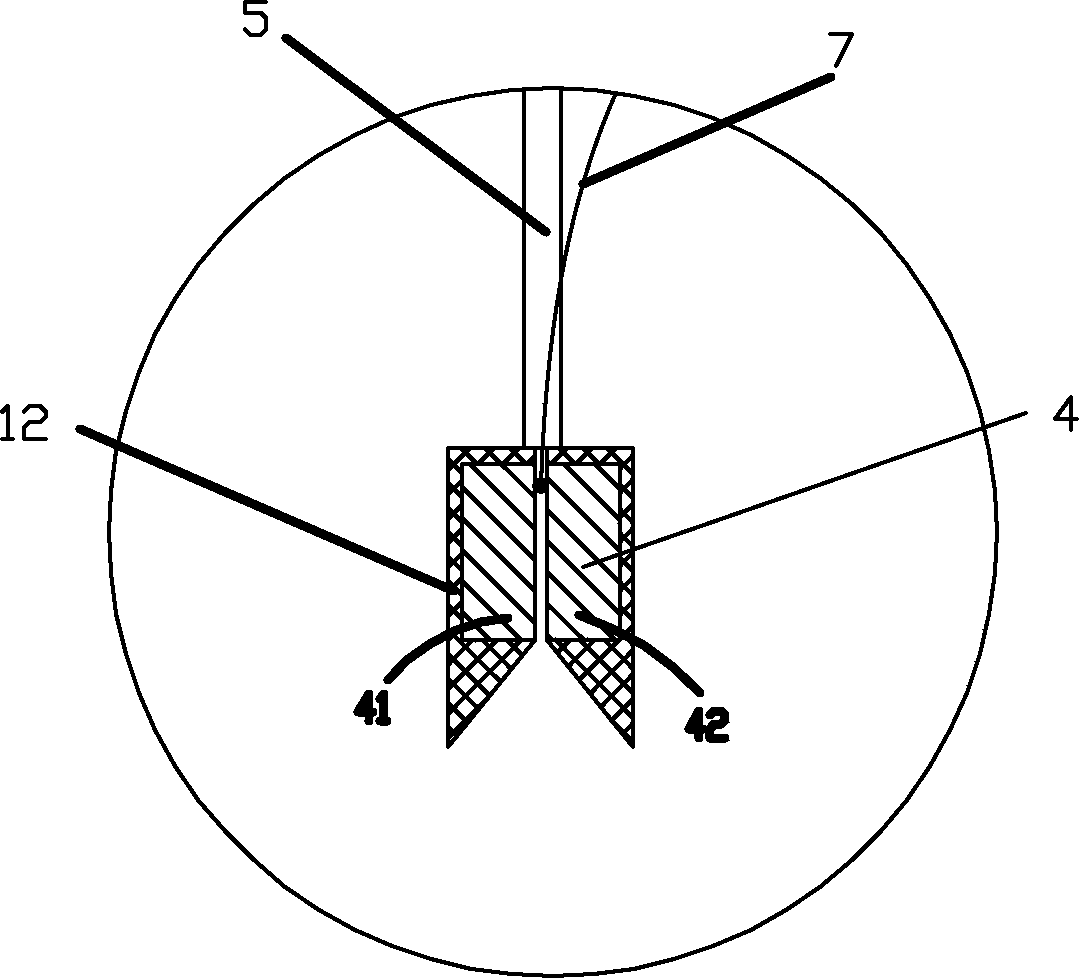

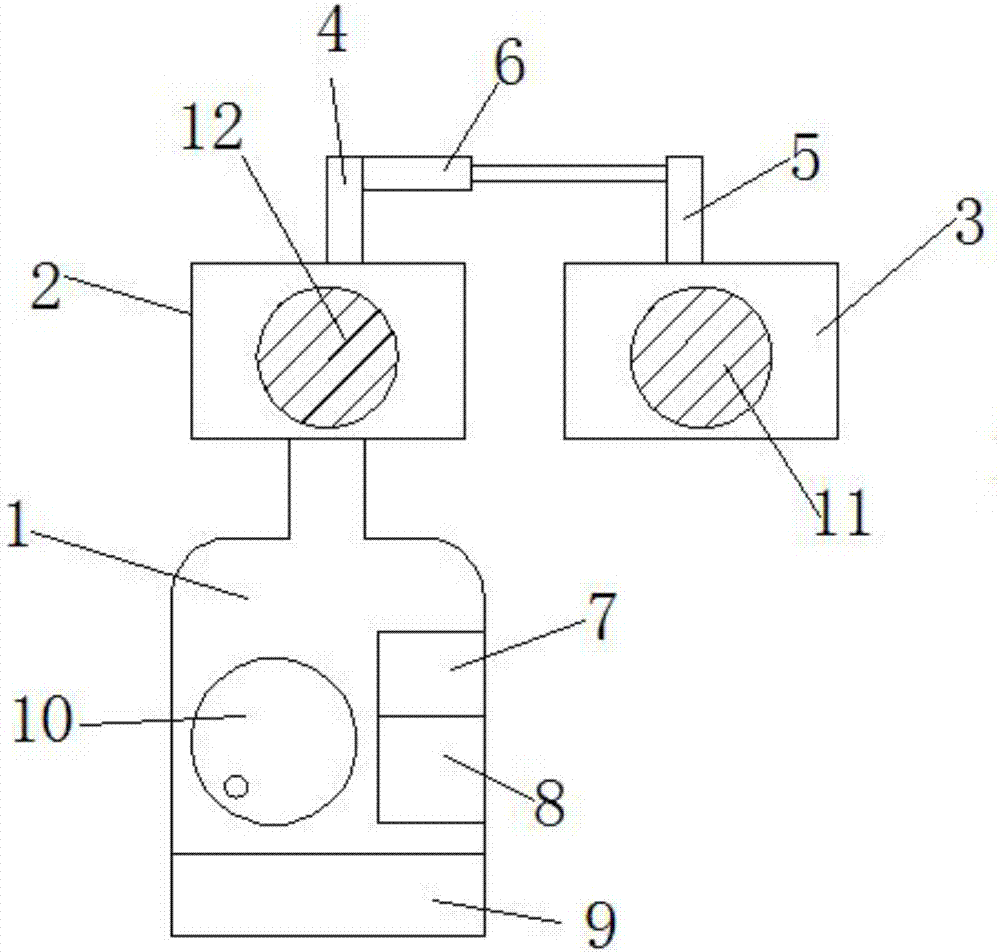

Method and device for simulating thin-strip continuous casting technical process

ActiveCN103962523AImprove complianceReal-time monitoring of temperature changesConfined spaceProduct gas

The invention discloses a method and a device for simulating a thin-strip continuous casting technical process. The method comprises the following steps: arranging a melting crucible in a confined space or a vacuum space, filled with a protective gas, and arranging cooling dies above the melting crucible; mounting the cooling dies on a driving rod; during a test, driving the cooling dies by the driving rod to be inserted in the molten steel in the melting crucible; after the cooling dies are inserted in the molten steel, quickly filling a gap between the two cooling dies with the molten steel; under the chilling function of the cooling dies, solidifying to form a solidified shell; mounting cooling nozzles in position rightly opposite to the surface of the solidified shell; utilizing a temperature thermocouple to record temperature change of the solidified shell in the cooling process; when reaching a set cooling temperature, closing the cooling nozzles; starting an induction coil arranged outside the melting crucible to quickly heat the solidified sample and then preserve heat, setting the sample temperature during the heat preservation according to the coiling temperature of the test design, and utilizing the induction coil to preserve heat and slow cooling to simulate the cooling slowing process of the thin-strip continuous casting product after online coiling.

Owner:BAOSHAN IRON & STEEL CO LTD

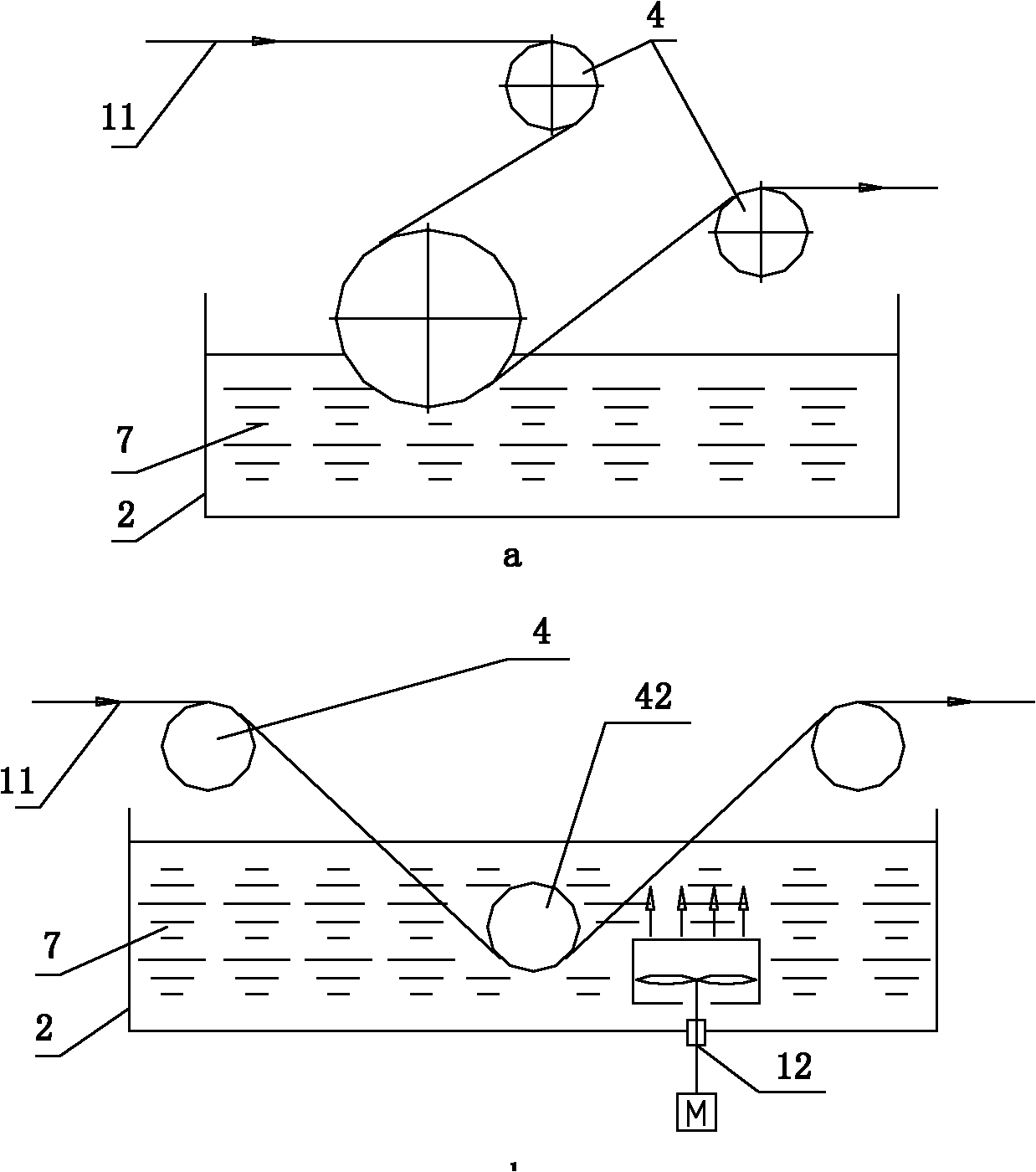

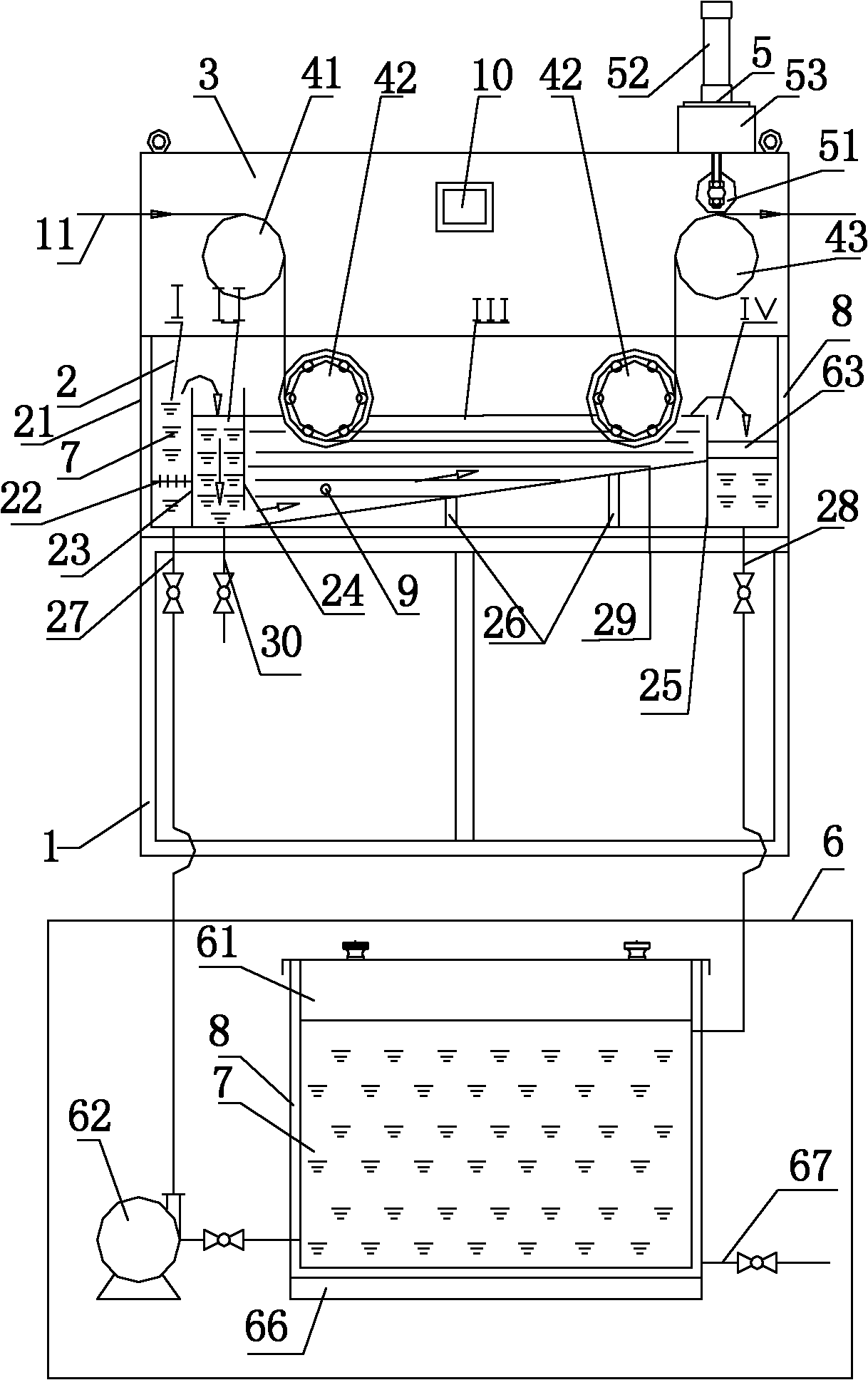

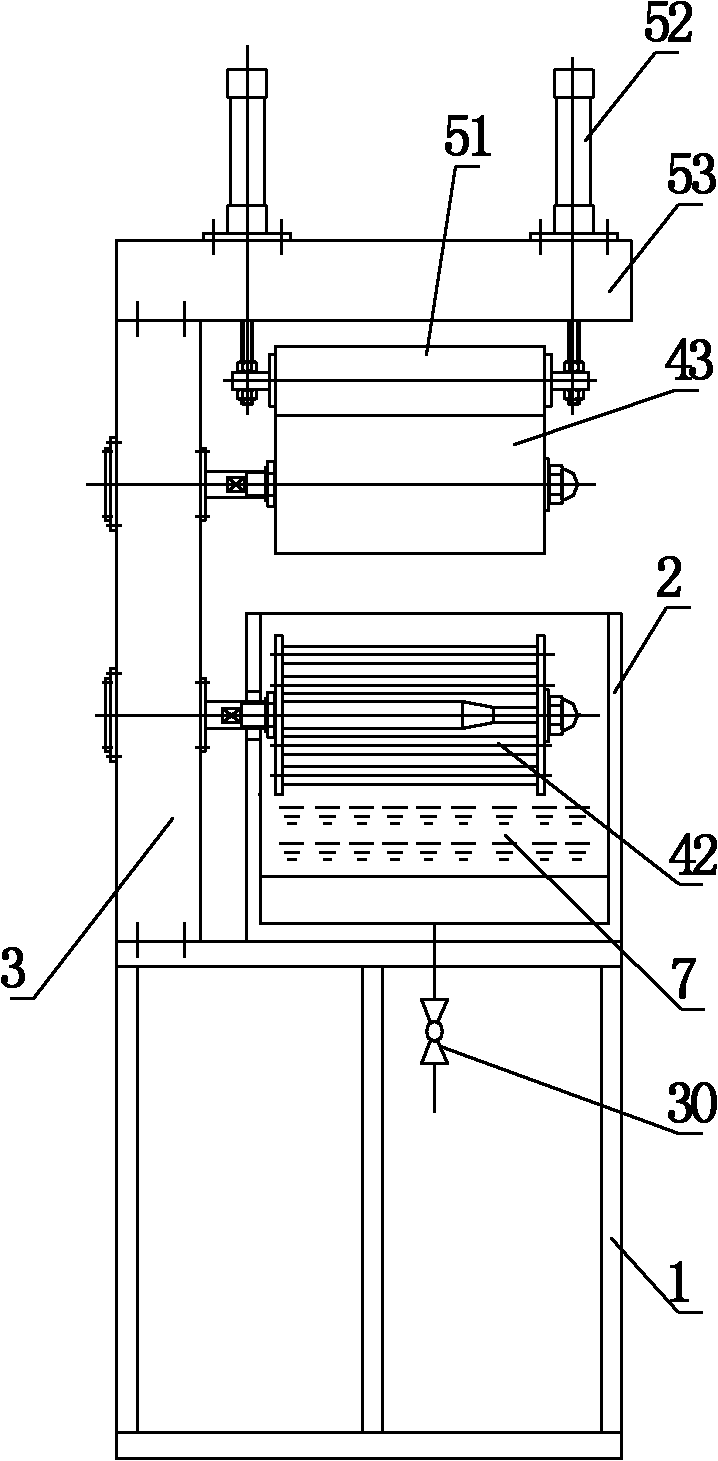

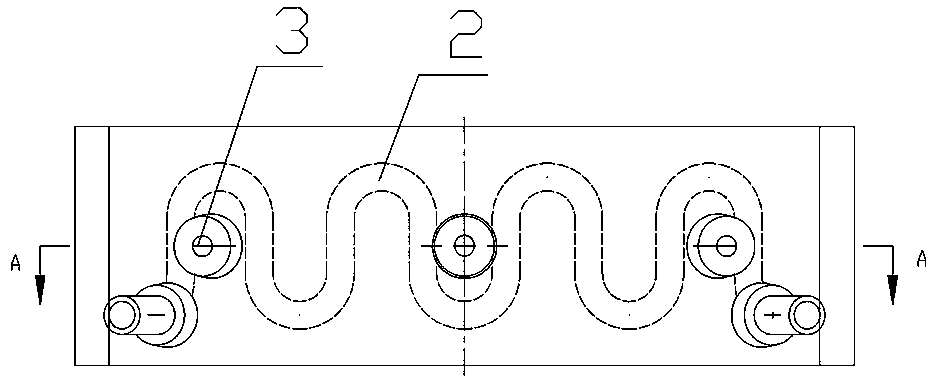

Sizing machine for producing continuous carbon fibers

InactiveCN102031654AAvoid Shaft Sealing ProblemsFlexible rotationTextile treatment rollersLiquid/gas/vapor yarns/filaments treatmentFiberCarbon fibers

The invention belongs to a sizing machine for producing continuous carbon fibers, comprising a box body, a sizing groove arranged in the box body and a driving device fixed on the box body, wherein the sizing groove comprises a groove body and a partition board, a liquid distribution plate and an overflow plate which are arranged in the groove body from left to right and are vertical to the bottom of the groove body; the driving device comprises an inlet driving roller arranged at the upper-left part of the sizing groove, two sizing driving rollers positioned in a sizing area and an outlet driving roller arranged at the upper-right part of the sizing groove; the two sizing driving rollers are horizontally arranged and positioned between the inlet driving roller and the outlet driving roller; and driving shafts of the two sizing driving rollers are higher than the liquid level of a sizing agent of the sizing area. The invention solves the problems of long stay time of the carbon fibers in the sizing agent, poor sizing effect, complex structure, high manufacturing cost and inconvenience for daily cleaning and maintenance caused by the traditional sizing machine. By using the invention, the processing and manufacturing cost of the equipment can be reduced, the time of the carbon fibers in the sizing agent can be prolonged and the favorable sizing effect can be obtained.

Owner:西安航科等离子体科技有限公司

Metal film micron-scale thermocouple device

InactiveCN102419217AAccurate temperature measurementImprove stabilityThermometers using electric/magnetic elementsUsing electrical meansMicron scaleWide band

The invention provides a metal film micron-scale thermocouple device. The thermocouple device comprises an insulating substrate, and a metal film thermocouple or a thermocouple array composed of a plurality of metal film thermocouples is attached to the insulating substrate, wherein the metal film thermocouple is two doubled-up films of a single metal, the width of one narrow band is less than 20microns, and the width of the other wide band is more than 100 microns. Compared with the prior art, the metal film micron-scale thermocouple device is easy to prepare, can realize measurement on thelocal temperature of micron scale, and can realize characterization for the temperature distribution on a plane, which is in contact with the thermocouple array, by being used in a combinational array manner.

Owner:PEKING UNIV

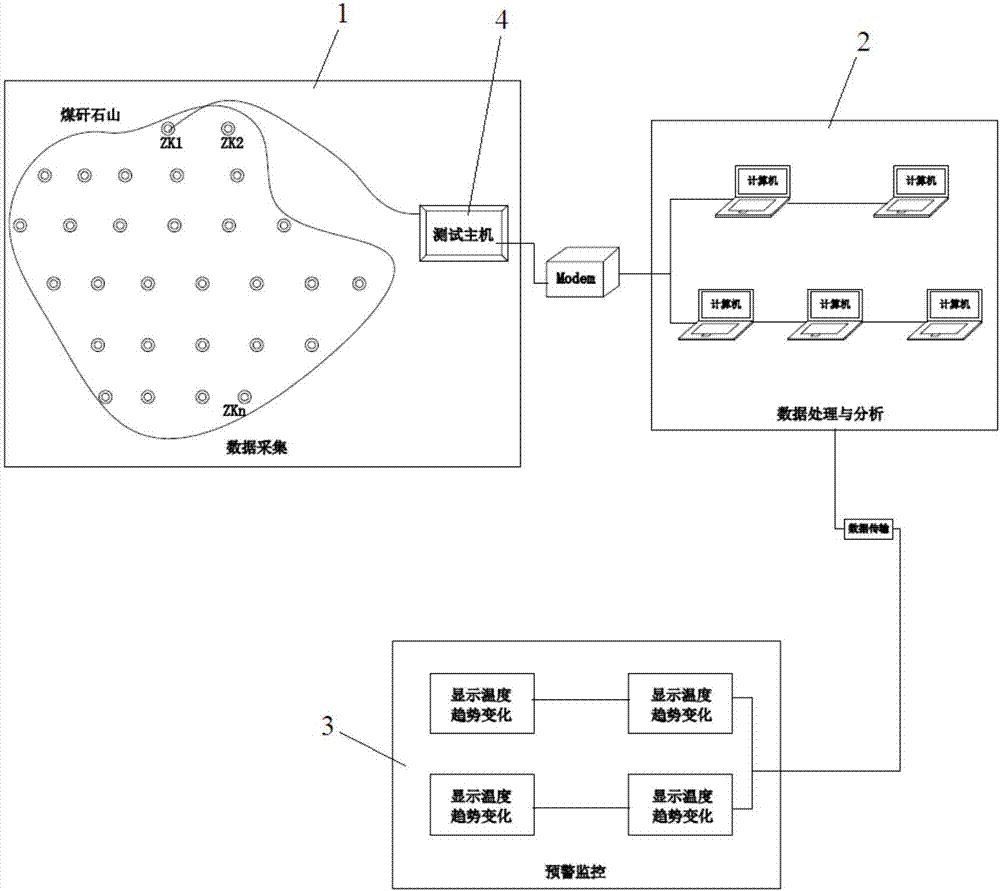

Monitoring system of omnibearing distributed coal-gangue-mountain spontaneous combustion prevention and method thereof

ActiveCN107101743AWith sensor transmission functionMake up for the missingThermometer detailsThermometers using physical/chemical changesSpontaneous combustionFiber

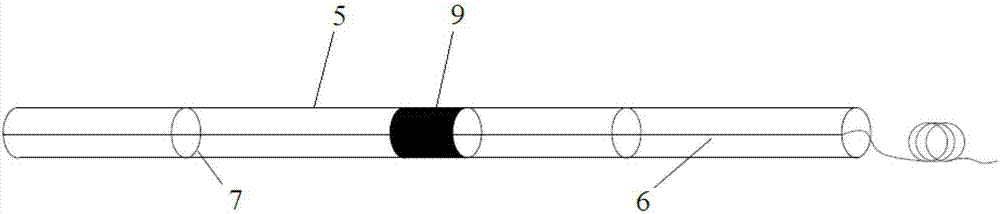

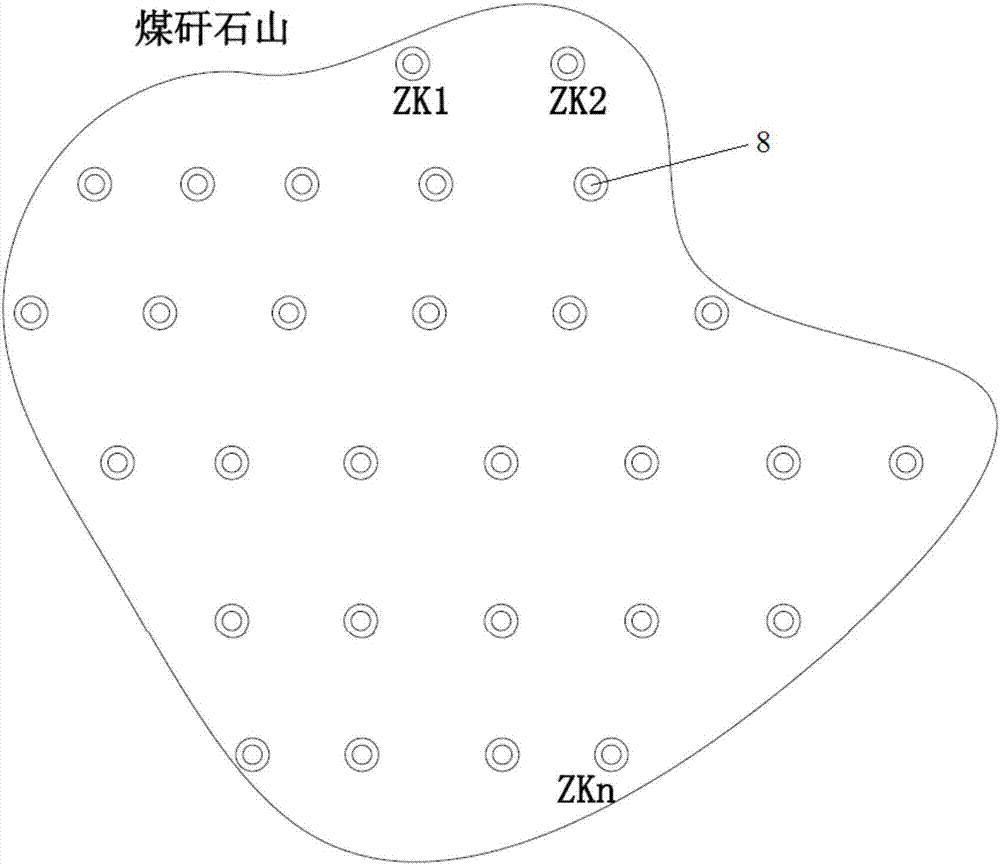

The invention discloses a monitoring system of an omnibearing distributed coal-gangue-mountain spontaneous combustion prevention and a method thereof. Through constructing an omnibearing distributed monitoring system, an internal temperature of a coal gangue mountain is monitored in real time, a corresponding technology parameter is acquired and coal-gangue spontaneous combustion is prevented. In the invention, through using a novel sensing test technology (a distributed fiber sensing test technology), a test device is improved and a set of complete coal-gangue-mountain spontaneous combustion prevention test method is acquired; and by using the acquired technology, good safety guarantee can be provided for aspects of coal-gangue spontaneous combustion prevention and fire extinguishing processing.

Owner:ANHUI UNIV OF SCI & TECH

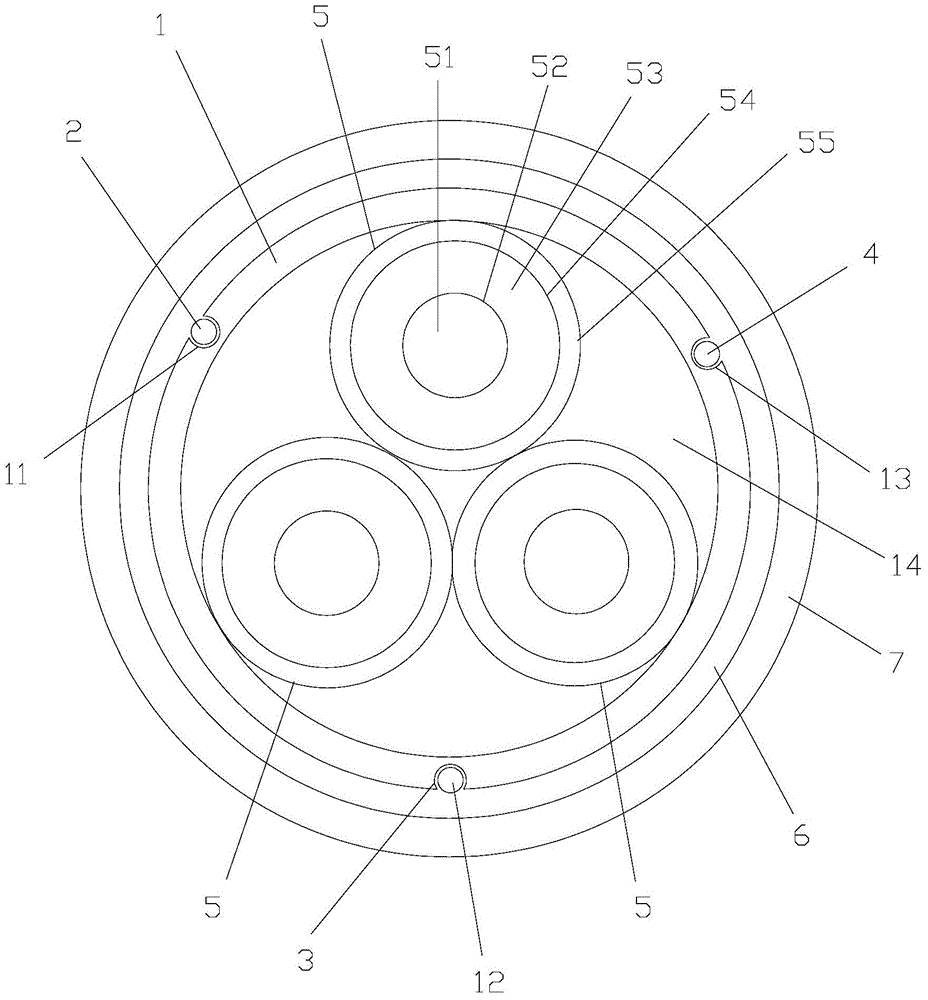

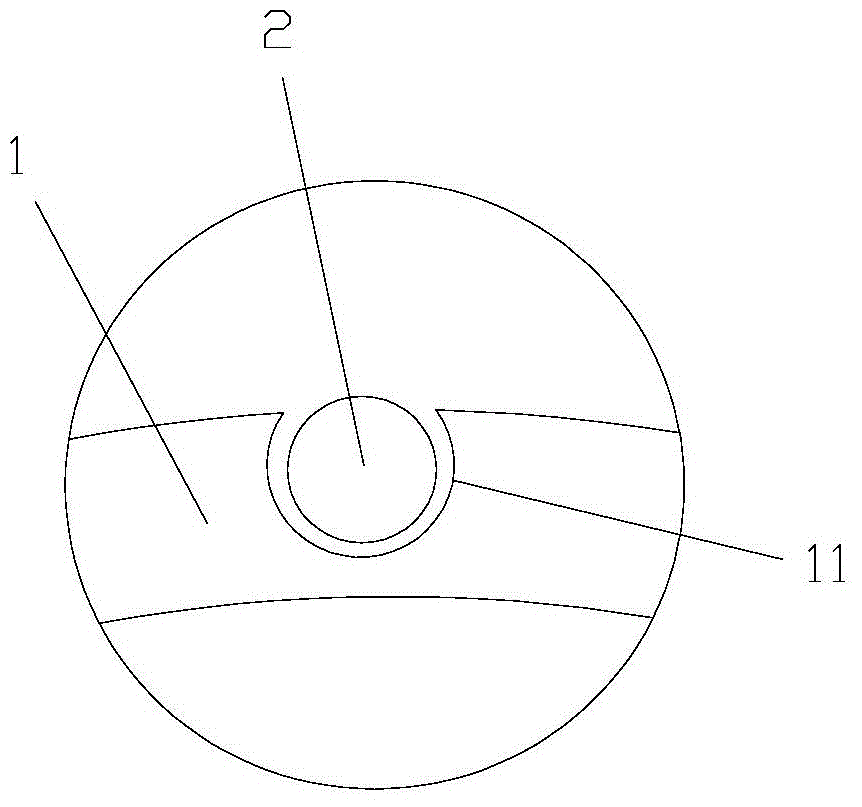

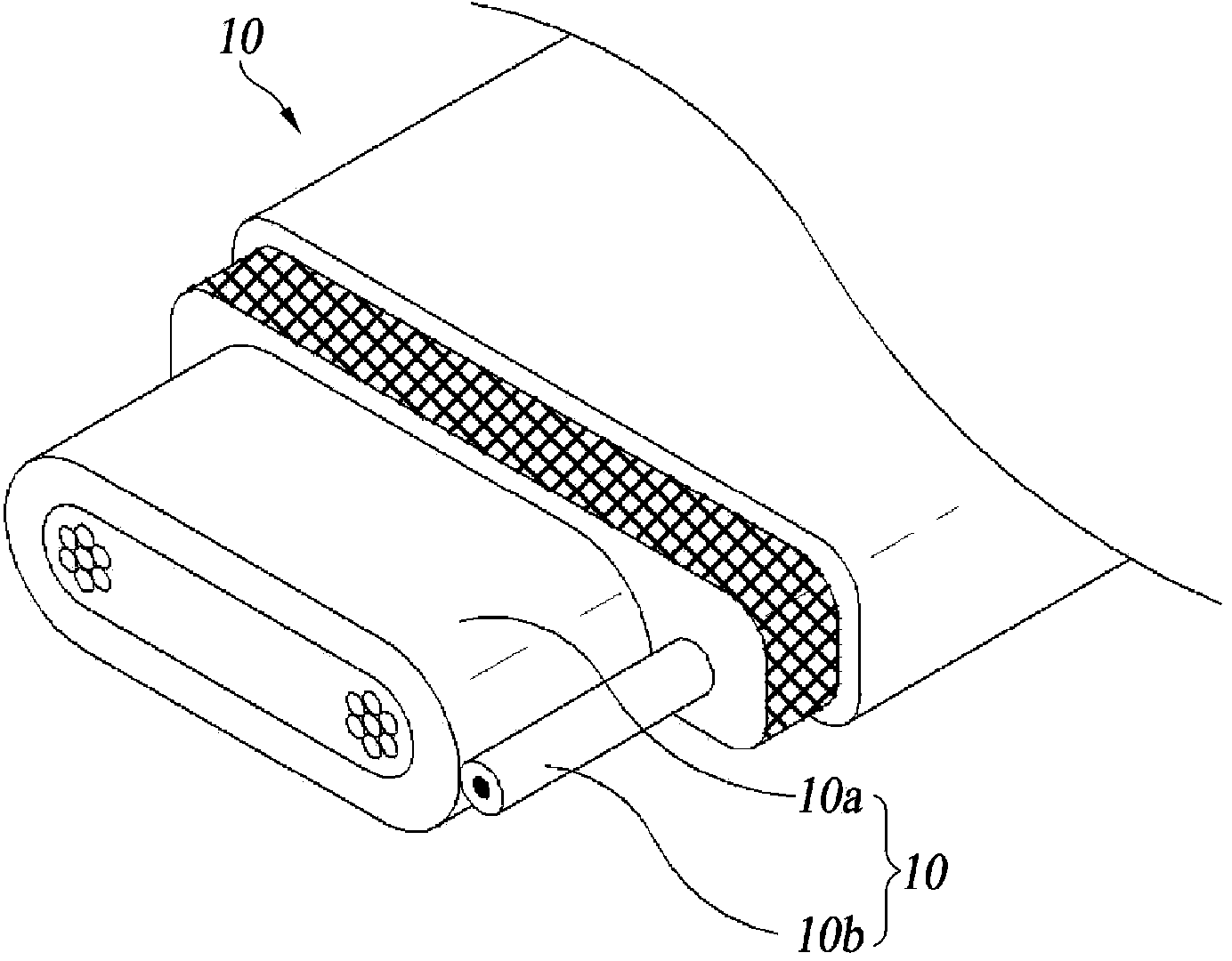

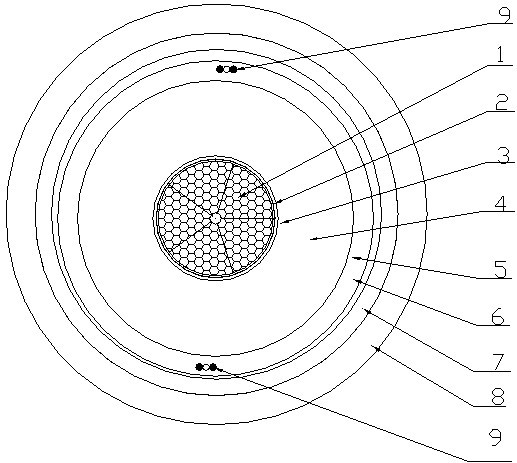

Multifunctional intelligent cable

InactiveCN104966573AReduce the chance of being stolenReal-time monitoring of temperature changesInsulated cablesPower cablesEngineeringTemperature monitoring

The invention discloses a multifunctional intelligent cable, comprising a circular first protective layer and a plurality of leads arranged in the cavity of the first protective layer. The first protective layer is provided with a first groove, a second groove and a third groove having openings back facing the leads, wherein the first groove is internally provided with a communication optical cable, the second groove is internally provided with a temperature measurement optical cable, and the third groove is internally provided with a vibration sensitive optical cable. The depth of the first groove is greater than the external diameter of the communication optical cable; the depth of the second groove is greater than the external diameter of the temperature measurement optical cable; and the depth of the third groove is greater than the external diameter of the vibration sensitive optical cable. The multifunctional intelligent cable integrates the functions of electric energy transmission, communication, temperature monitoring, fault locating, external force damage early warning, antitheft early warning, etc.

Owner:GUANGZHOU POWER SUPPLY CO LTD

Integrated intelligent fire hydrant

The invention discloses an integrated intelligent fire hydrant. The integrated intelligent fire hydrant comprises a fire hydrant cap, a fire hydrant body, a connecting rod, a valve body, a valve flap,a sensor, a control unit and a monitoring terminal. The upper end of the fire hydrant body is connected with the fire hydrant cap, the lower end of the fire hydrant body is connected with the upper end of the valve body, the valve flap is arranged inside the valve body, and the lower end of the valve body is connected with a fire-fighting water supply pipe; the connecting rod is arranged inside the fire hydrant body, one end of the connecting rod penetrates the fire hydrant cap, and the other end of the connecting rod is connected with the valve flap; the sensor is arranged on the valve flap,and the measuring end penetrates the valve flap and is used for monitoring the water pressure in the fire-fighting water supply pipe; and the control unit is arranged in the fire hydrant cap and usedfor receiving the data of the sensor and transmitting the data to the monitoring terminal. By the adoption of the integrated intelligent fire hydrant, the fire hydrant is monitored in real time, andthe integrated intelligent fire hydrant has the beneficial effects of being convenient to mount, easy to use, capable of being applied under the severe environment and long in service life and can bewidely applied to fire hydrant monitoring occasions.

Owner:MICRO SENSOR

Temperature and direction recognizable curvature sensing optical fiber and manufacturing and using method thereof

PendingCN111457861ARealize multi-channel simultaneous measurementRealize simultaneous measurementOptical fibre with multilayer core/claddingThermometers using physical/chemical changesResonance wavelengthAdhesive

The invention belongs to the field of optical fiber sensing, and mainly relates to a temperature and direction recognizable curvature sensing optical fiber. A double-clad D-shaped multimode optical fiber with a semi-circular quartz cladding and an annularly-clad low-refractive-index plastic cladding is prepared through precision side grinding of an optical fiber preform and secondary pressure coating; the coating layer and the plastic cladding are mechanically peeled off, an SPR sensing film is plated, the restored optical fiber is reshaped by using a low-refractive-index liquid or a low-refractive-index coating adhesive, and an SPR sensing module is manufactured on the restored optical fiber; the optical fiber is novel and stable in structure, and high in bending performance, liquid and solid environment temperature measurement can be carried out through the resonance wavelength; multi-point simultaneous measurement based on the wavelength division multiplexing technology can also becarried out; curvature measurement, bending direction judgment and multi-point simultaneous measurement based on the wavelength division multiplexing technology can be carried out through two parameters of resonance wavelength and resonance valley depth, and the optical fiber and the method have a good application prospect in the fields of biomedicine, electronic chip monitoring, three gorges reservoir area landslide, reservoir banks and other geological environment monitoring.

Owner:CHONGQING THREE GORGES UNIV

Flexible bendable electronic nephroscope for percutaneous nephroseopy surgery and application method of flexible bendable electronic nephroscope

InactiveCN104873167AExpand the field of viewAvoid damageLaproscopesEndoscopesLaser lithotripsyOperability

The invention relates to an electronic nephroscope, in particular to a flexible bendable electronic nephroscope for percutaneous nephroseopy surgery and an application method of the flexible bendable electronic nephroscope and belongs to a medical instrument. The flexible bendable electronic nephroscope comprises a nephroscope body, an upper bent steel rope and a lower bent steel rope. The application method includes the steps of entering a focus part, making preparations before laser lithotripsy, treating small calculi, treating large calculi and treating special positions. The flexible bendable electronic nephroscope for the percutaneous nephroseopy surgery and the application method of the flexible bendable electronic nephroscope have the advantages of compact structure, higher operability and precision in positioning.

Owner:THE FIRST AFFILIATED HOSPITAL OF GUANGZHOU MEDICAL UNIV (GUANGZHOU RESPIRATORY CENT) +1

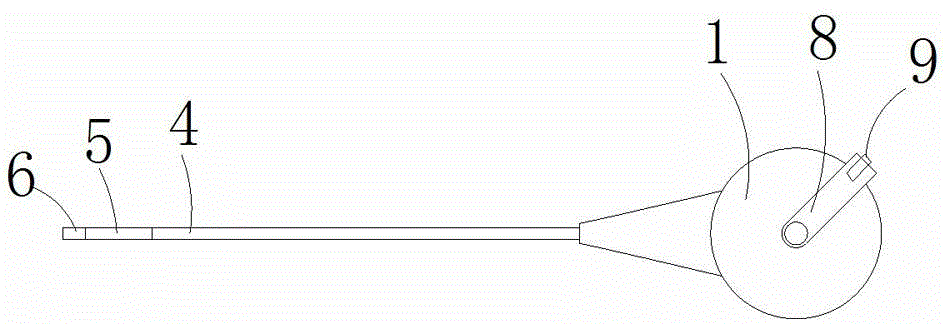

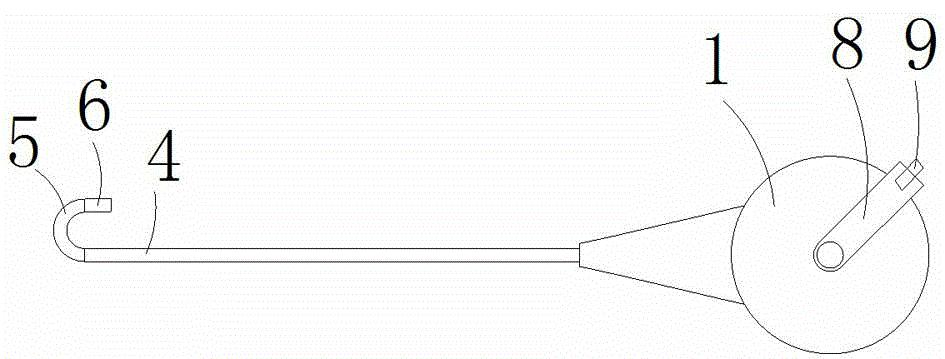

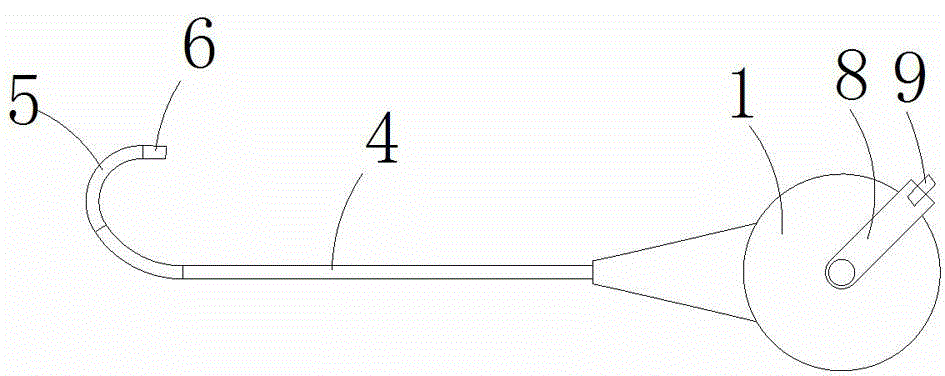

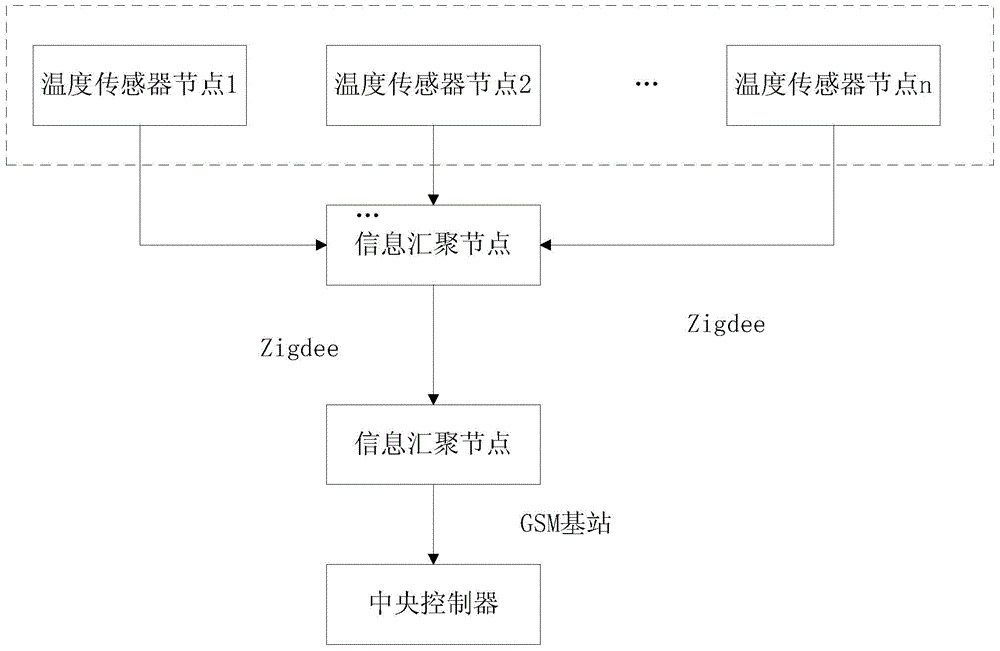

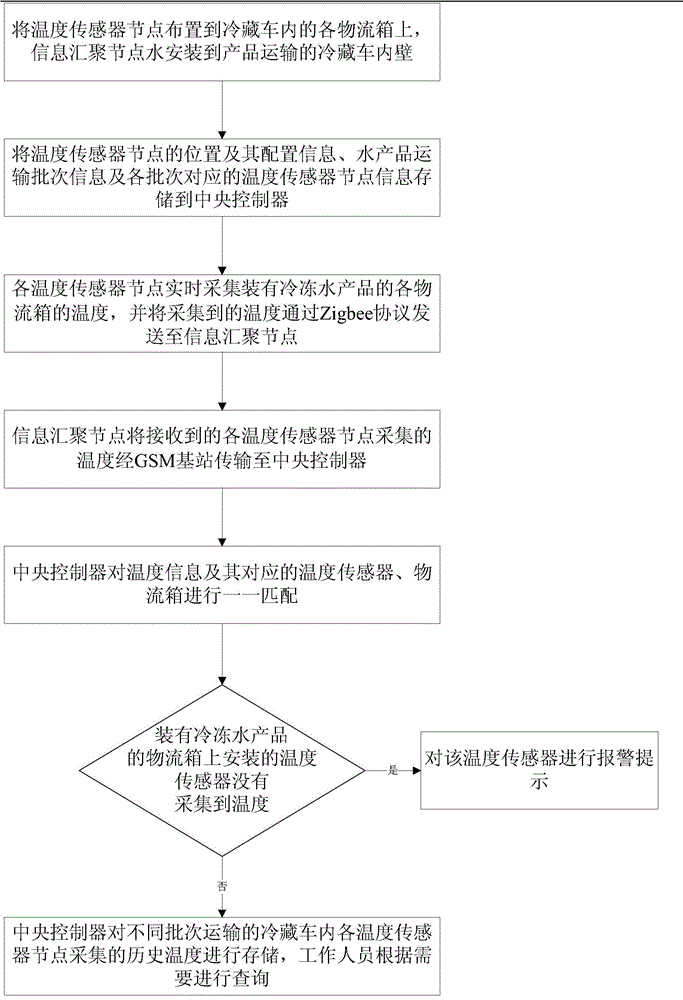

Aquatic product transportation monitoring system and method based on wireless sensor network

InactiveCN105628241AReal-time monitoring of temperature changesReal-time monitoring of working statusTransmission systemsThermometers using electric/magnetic elementsRefrigerator carWireless mesh network

The present invention provides an aquatic product transportation monitoring system and method based on a wireless sensor network. The system comprises the temperature sensor nodes installed on the logistics boxes in which the frozen aquatic products are put; an information aggregation node installed on the inner wall of a refrigerator car used for the aquatic product transportation; and a central controller installed in a scheduling center. The plurality of temperature sensor nodes are communicated via a Zigbee protocol, the temperature sensor nodes and the information aggregation node are communicated via the Zigbee protocol, and the central controller and the information aggregation node transmit the data via a GSM base station. The aquatic product transportation monitoring system based on the wireless sensor network of the present invention can monitor the temperature change of the logistics boxes real-timely during the transportation process of the frozen aquatic products and can monitor the working states of the temperature sensors real-timely, so that the aquatic product temperature change during the logistics transportation process can be acquired largely, and the refrigerated transportation of the frozen products can be finished better.

Owner:沈阳市东陵区真宬商务信息咨询事务所

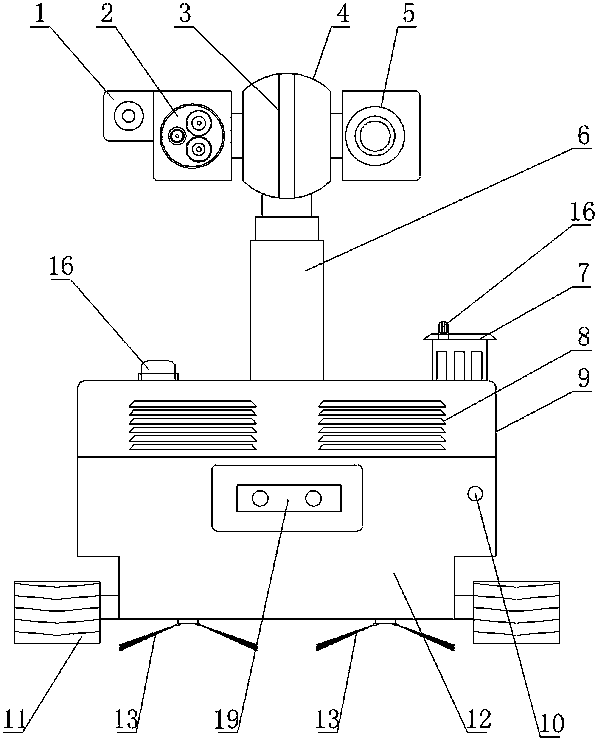

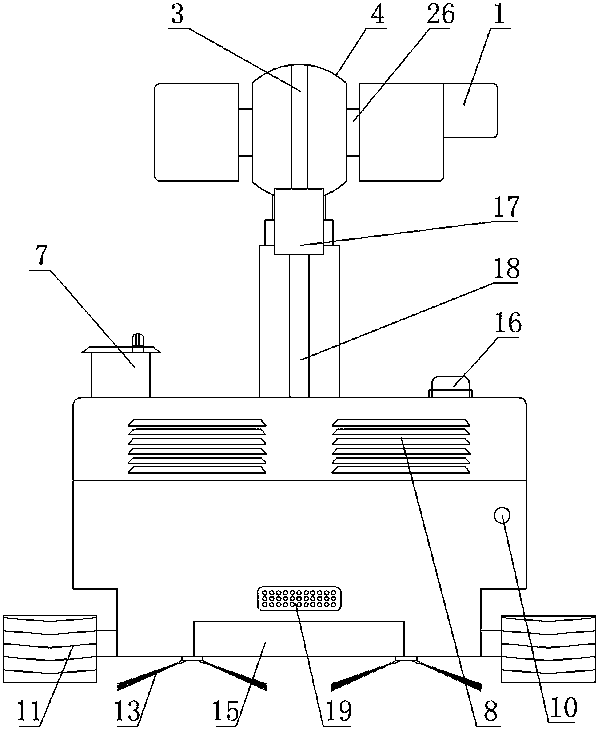

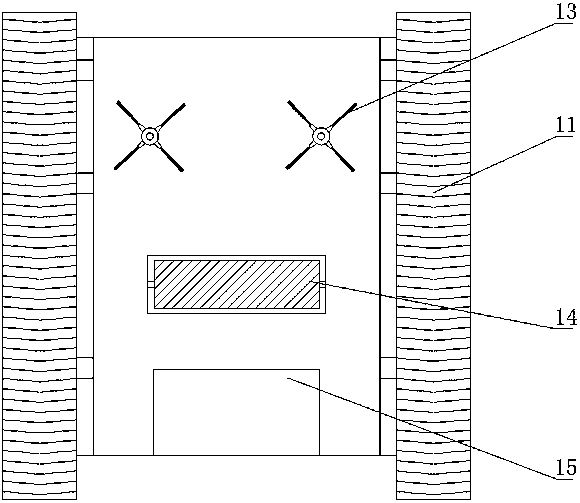

Intelligent inspection robot

PendingCN111061264AReduce noiseEnough tractionMeasurement devicesEndless track vehiclesThermographic cameraEngineering

The invention relates to an intelligent inspection robot which comprises a body. A charging connector is arranged on the front side of the body. Infrared distance measuring sensors are arranged on thefour faces of the body respectively. A host box is arranged on the upper side of the body. Heat dissipation holes are formed in the front side and the rear side of the mainframe box respectively. A first electric telescopic rod is arranged in the middle of the mainframe box. A spherical rotary joint is arranged on the upper side of the first electric telescopic rod. The right side of the spherical rotating wire joint is connected with an infrared thermal imager. The left side of the spherical rotary joint is connected with a camera. An illuminating lamp is arranged on the left side of the camera. A temperature and humidity sensor is arranged on the upper side of the right portion of a host. A sound sensor is arranged on the upper side of the temperature and humidity sensor. Crawler beltsare arranged on the two sides of the lower side of the body. Dusting brushes are arranged on the lower side of the body. A dust suction hole is formed in the rear side of the dusting brushes. A dust collection box is arranged on the rear side of the dust suction hole. The system has the advantages of being long in endurance time, high in intelligence, comprehensive in inspection, diversified in function and comprehensive in detection.

Owner:STATE GRID CORP OF CHINA +1

Cutting process and device for improving surface brightness of machined metal parts

InactiveCN103753349AImprove machined surface qualityReal-time monitoring of temperature changesMeasurement/indication equipmentsMaintainance and safety accessoriesSurface brightnessLiquid storage tank

The invention discloses a cutting process for improving surface brightness of machined metal parts. The cutting process comprises the following steps of arranging a machining machine tool and a high-pressure oil mist compression device; injecting cooling liquid into a cooling liquid storage tank of the compression device and filling compression air into an air compressor pump and delivering mixed high-pressure oil mist into a high-pressure oil mist pipeline of a machine tool spindle through the oil mist compression device after mixing the cooling liquid and the compression air; arranging an infrared sensor in a cutting area and monitoring the temperature change of the cutting area in real time; arranging a workpiece on a working platform of the machining machine tool to be fixed, confirming a machining stroke and parameters according to the three-dimensional size and setting a cutter stroke in the parallel or vertical X-axis / Y-axis direction; starting the machining machine tool and the high-pressure oil mist compression device to spray the towards the cutting area and utilizing triple enhanced heat exchange effects of jet flow impact, air-liquid convection and vaporization to reduce the temperature of the cutting area. The invention further discloses a device implementing the cutting process for improving the surface brightness of the machined metal parts.

Owner:DONGGUAN KONKA MOLD PLASTIC +1

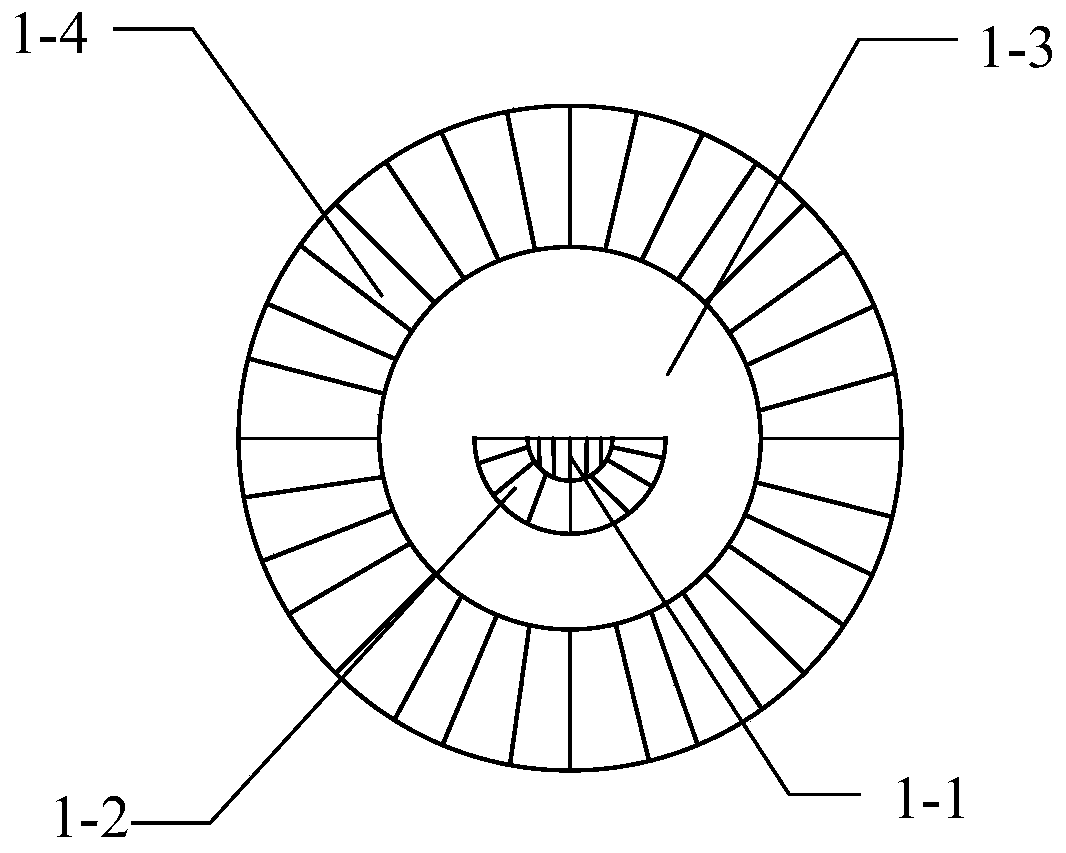

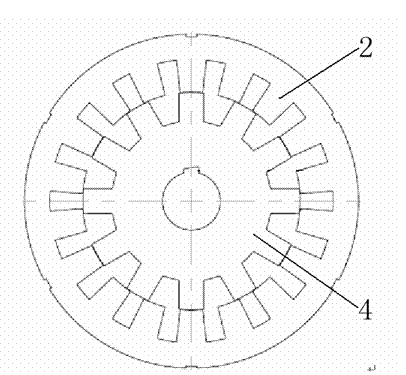

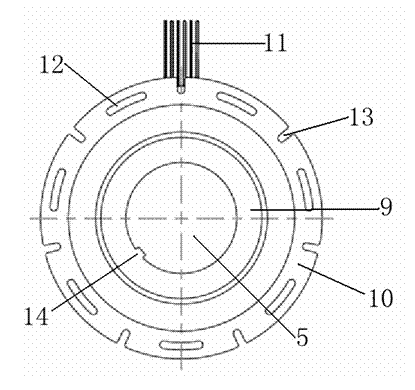

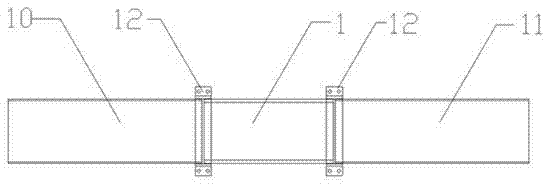

Switch reluctance motor

ActiveCN102891577AStable jobReduce radial magnetic attractionStructural associationSupports/enclosures/casingsLow noiseElectric machine

The invention discloses a switch reluctance motor comprising a motor base, wherein a stator is arranged on the motor base; a stator winding is wound on the stator; a rotor is arranged in the stator; a rotor shaft is fixed in the rotor; the motor base is provided with a front end cover and a rear end cover; the stator, the rotor and the rotor shaft are located in a sealed space defined by the front end cover and the rear end cover; a rotary transformer is arranged between the front end cover and the rotor; the transformer rotor of the rotary transformer is fixedly connected with the rotor shaft; the transformer stator of the rotary transformer is fixedly connected with t he front end cover; the stator winding is a three-phase concentrated winding; the stator and the rotor are in a doubly salient structure; eighteen magnetic poles are uniformly distributed on the stator; twelve magnetic poles are uniformly distributed on the rotor; and magnetic poles on the stator and the rotor are in a trapezoid gear structure. With the advantages of simple structure, reliable work, steady operation, small torque pulsation and low noise, the motor is conveniently applied on automobiles.

Owner:DONGFENG MOTOR CORP HUBEI

Experimental device for measuring periodical heat transfer coefficient

InactiveCN103792256AAvoid deformationEnables periodic cooling testsMaterial heat developmentTurbulent heat fluxEngineering

The invention discloses an experimental device for measuring a periodical heat transfer coefficient, which is used for measuring heat transfer coefficients of different heat transfer periods. The device comprises a steel cylinder rotating system, an air channel, a water channel system, a heating system, a temperature collecting system, nozzles and a regulating system thereof as well as a box body of the experimental device. The experimental device provided by the invention can regulate the revolving speed of a rotating steel cylinder so as to change the moving speed of a cooling surface, so that different heat transfer periods are realized, different nozzles are changed to realize different cooling manners, air pressure and water pressure are regulated, and the cooling intensity is changed; regulating devices of the nozzles can change a spraying angle and a spraying height of each nozzle, and the experimental device also can simulate the periodical cooling radiating process of an inner heat source.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

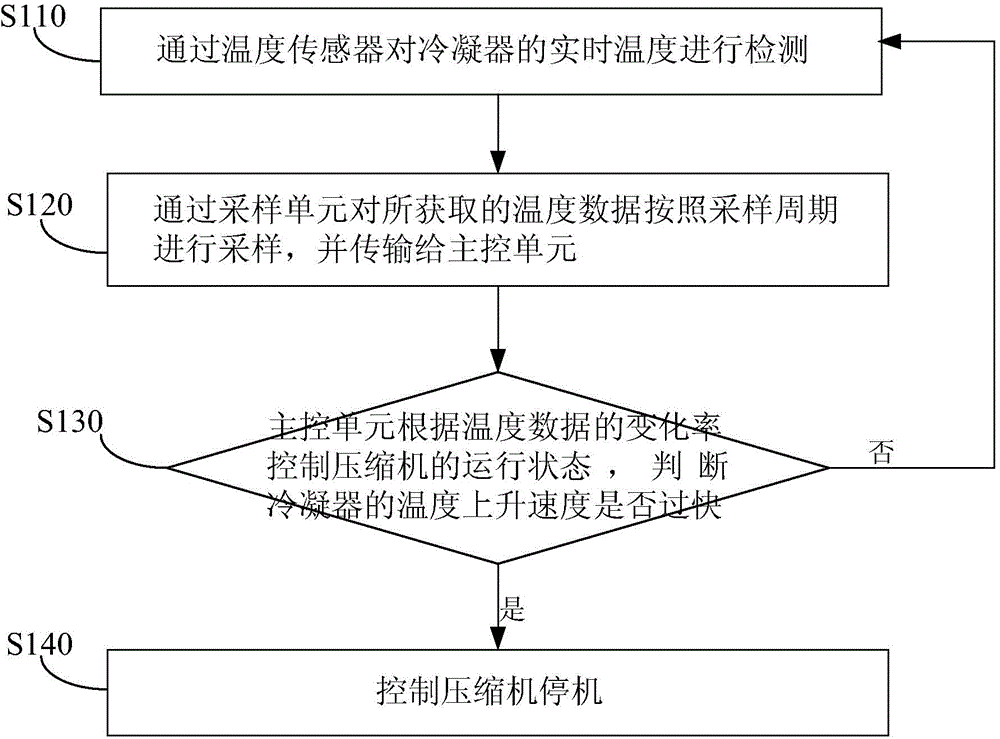

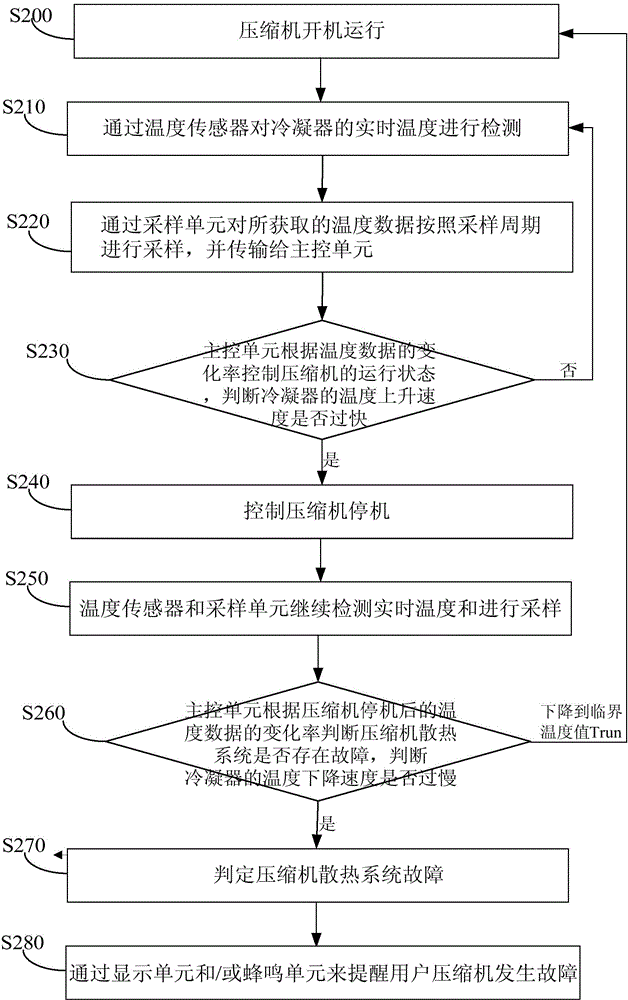

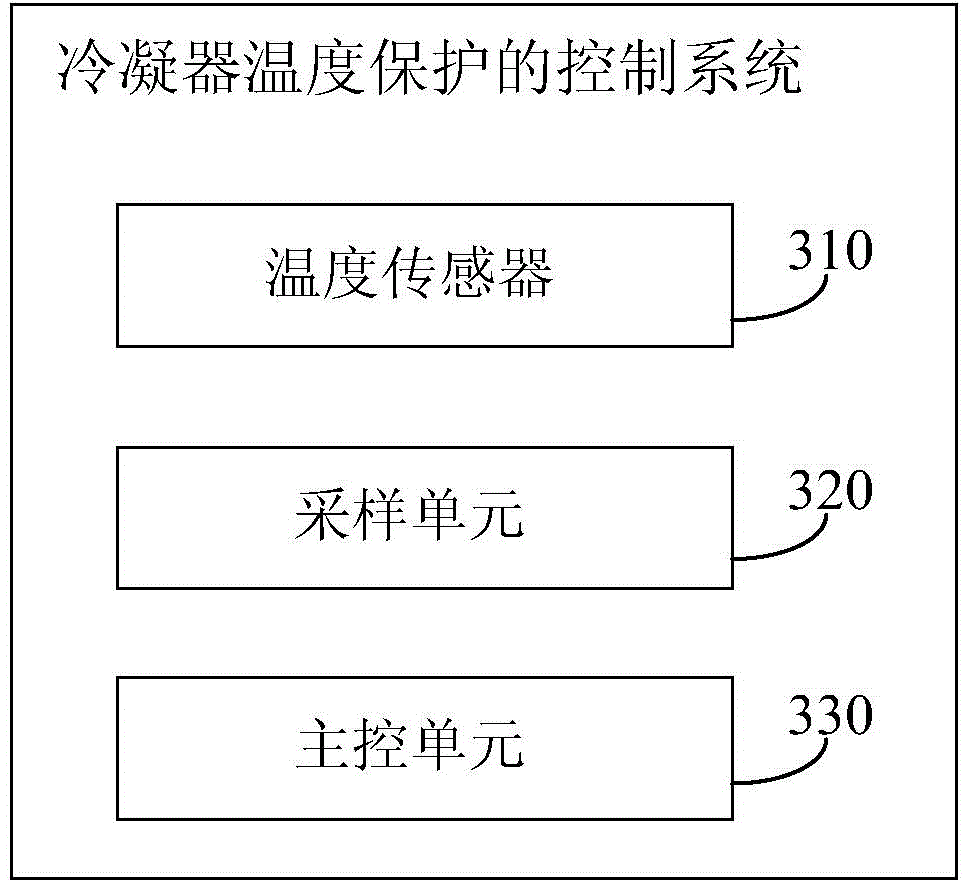

Control method and control system for condenser temperature protection

ActiveCN104613690AReal-time monitoring of temperature changesImprove reliabilityRefrigeration safety arrangementEngineeringControl system

The invention belongs to the field of refrigeration appliances, in particular to a control method and control system for condenser temperature protection. The control method for the condenser temperature protection comprises the following steps that real-time temperature of a condenser is detected by a temperature sensor, sampling is performed on obtained temperature data by a sampling unit according to a sampling period, the temperature data are transmitted to a main control unit, and the main control unit controls the operation state of a compressor according to the change rate of the temperature data; when the rising speed of the temperature of the condenser is judged to be too high, the compressor is controlled to be closed down; if the rising speed of the temperature of the condenser is not out of a normal range, the compressor is controlled to be operated normally. Accordingly, the temperature change of the condenser can be monitored in real time, the operation state of the compressor can be controlled through the change rate of the temperature data, the misinformation rate is reduced, and the stability and reliability of a refrigeration system are improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Liquid cooling server and fault diagnosis method and device and protection method and device thereof

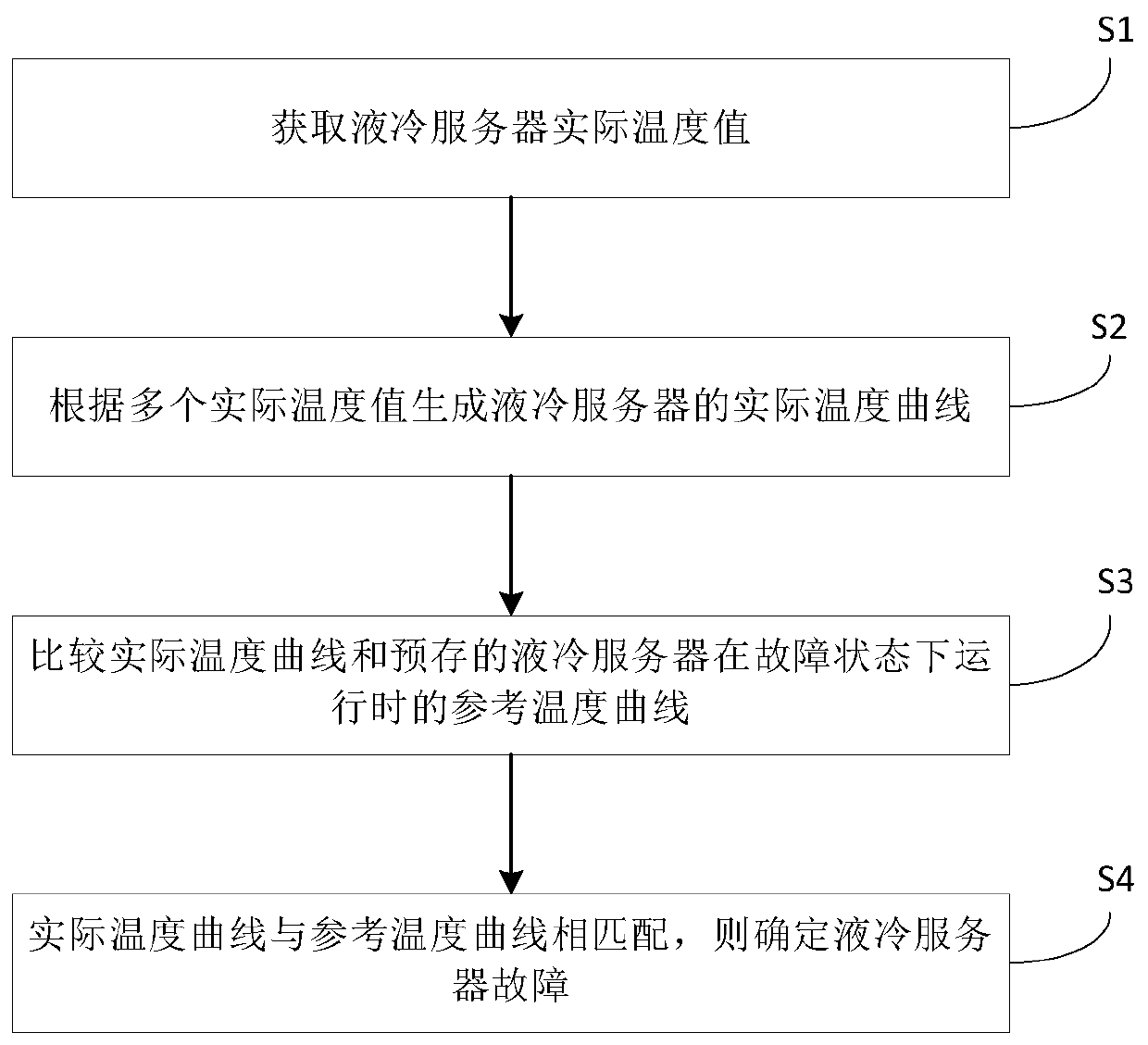

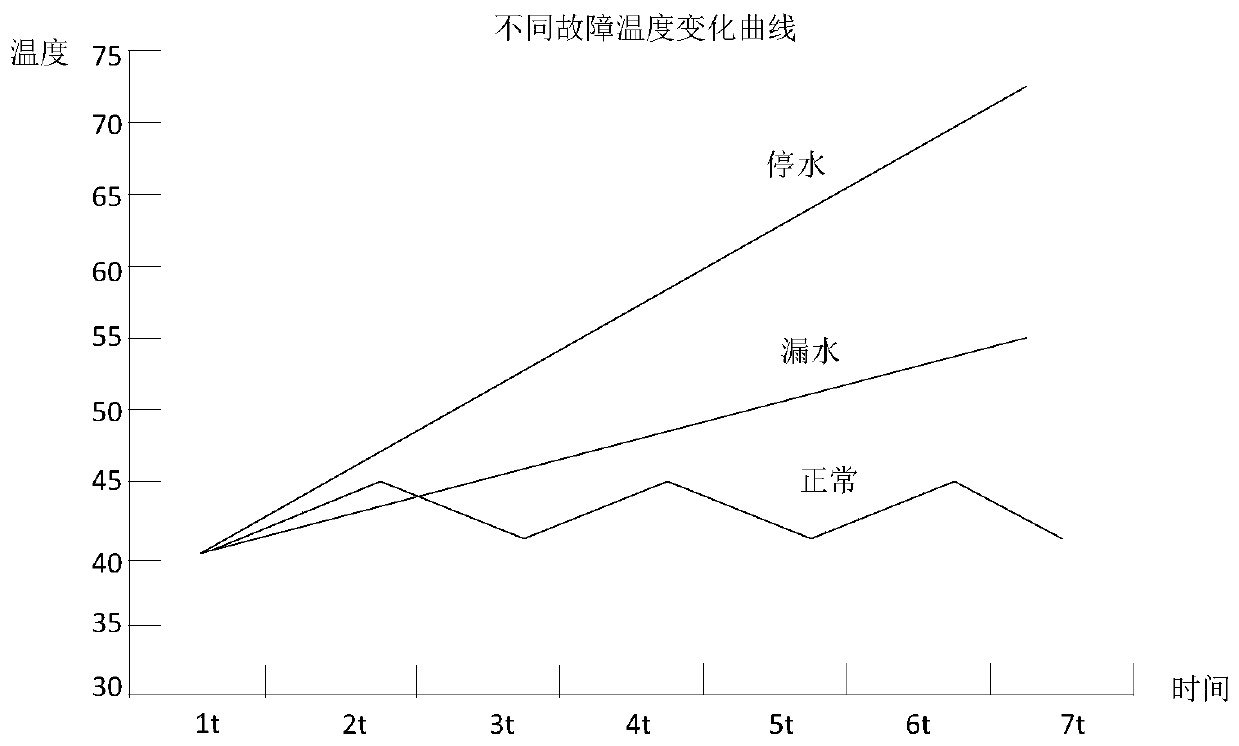

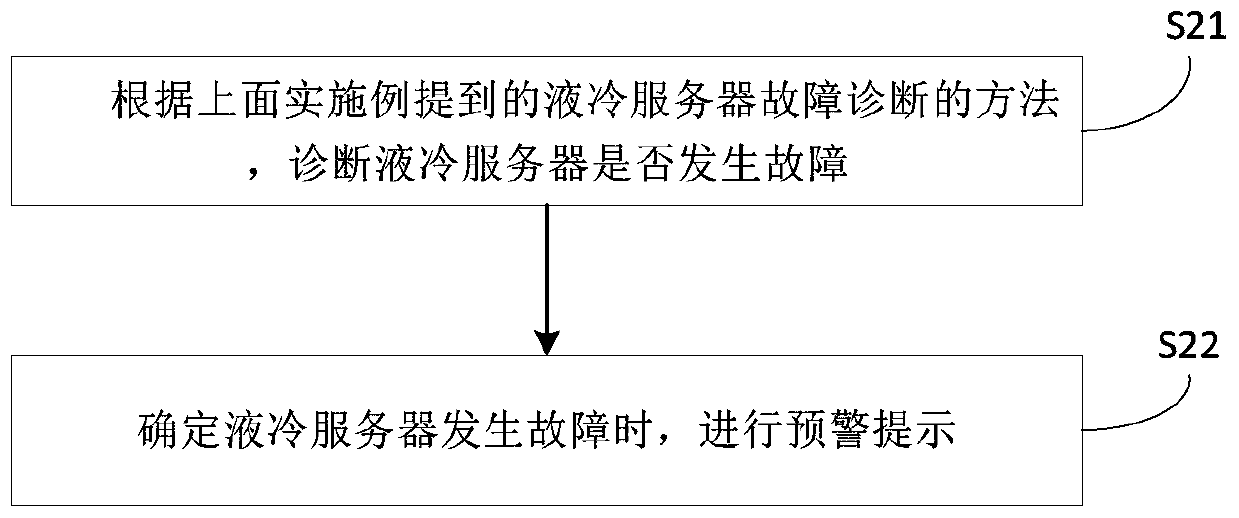

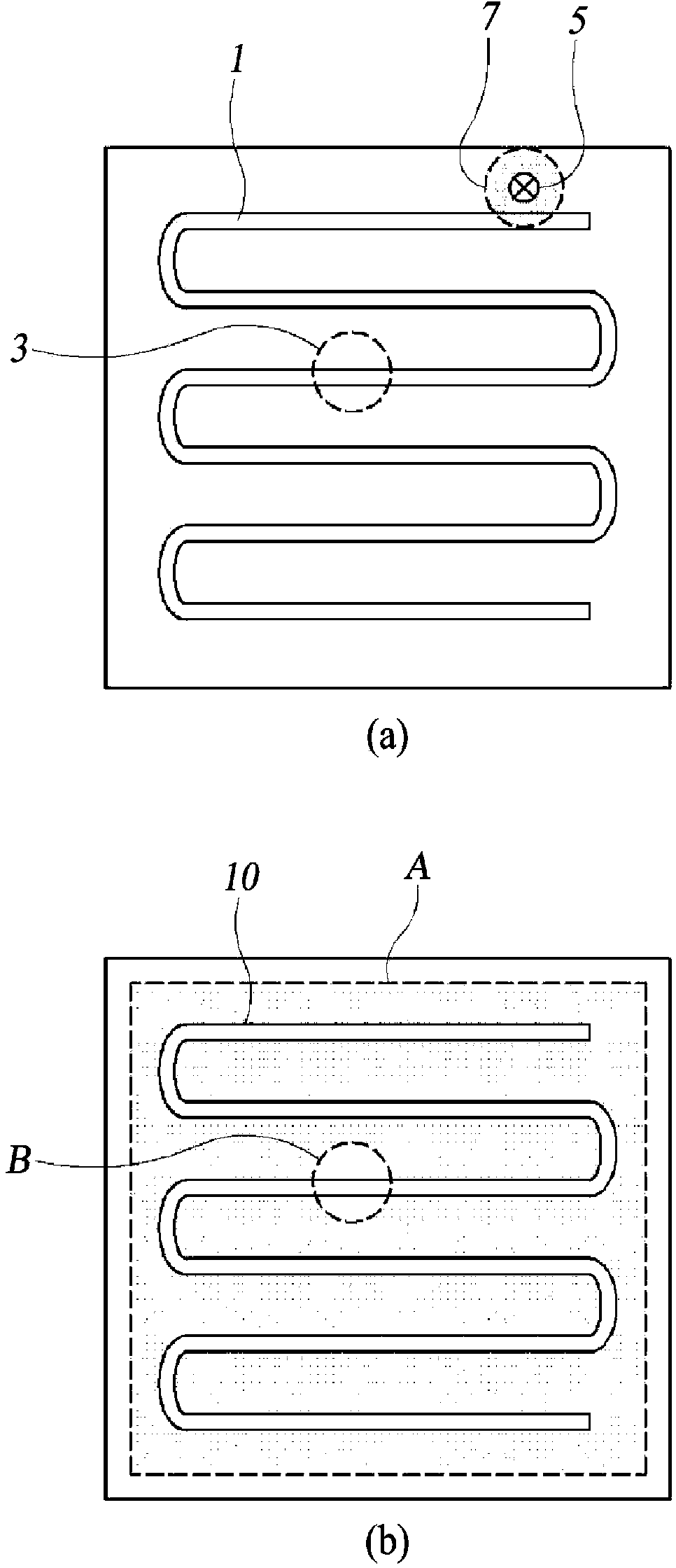

ActiveCN111176406AImprove reliabilityGuaranteed protectionDigital data processing detailsHardware monitoringReliability assuranceReal-time computing

The invention provides a liquid cooling server fault diagnosis method and device, a protection method and device after liquid cooling server fault diagnosis, a liquid cooling server, a computer readable storage medium and a computer program product. The liquid cooling server fault diagnosis method comprises the steps of obtaining an actual temperature value of the liquid cooling server; generatingan actual temperature curve of the liquid cooling server according to the plurality of actual temperature values; comparing the actual temperature curve with a pre-stored reference temperature curvewhen the liquid cooling server operates in a fault state; and if the actual temperature curve is matched with the reference temperature curve, determining that the liquid cooling server fails. According to the fault diagnosis method for the liquid cooling server, the reference temperature curve of the fault of the liquid cooling server is pre-stored, and the fault of the liquid cooling server is diagnosed when the actual temperature curve is matched with the reference temperature curve, so that the fault diagnosis reliability of the liquid cooling server is improved, and the protection effectof the liquid cooling server is ensured.

Owner:BEIJING BITMAIN TECH LTD

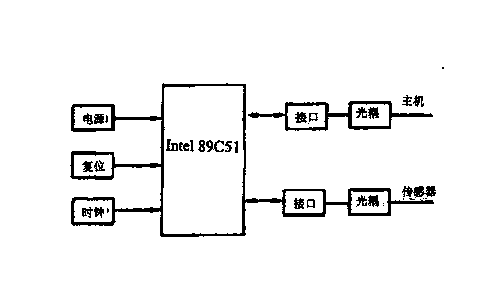

Intelligent heating cable having a smart function and method for manufacturing same

InactiveCN103814623AImprove energy efficiencyMonitor performance changesInsulated cablesHeating element shapesEngineeringHeating element

According to the present invention, a heating cable has a complex configuration in which an optical cable sensor is coupled to the heating cable to achieve the function of a sensor for sensing both a target object and the temperature of the heating cable with the result that the heating cable may serve as an active heat supply source capable of adjusting the output of the heating cable in accordance with temperature variations. To this end, an intelligent heating cable provided with a smart function according to the present invention is a heating cable for a heat tracing system. The cable comprising: a heating element, and an insulating outer layer formed on an outer surface of the heating element, characterized by having a structure in which an optical cable serving as a temperature sensor is coupled to the heating cable.

Owner:李完洙 +1

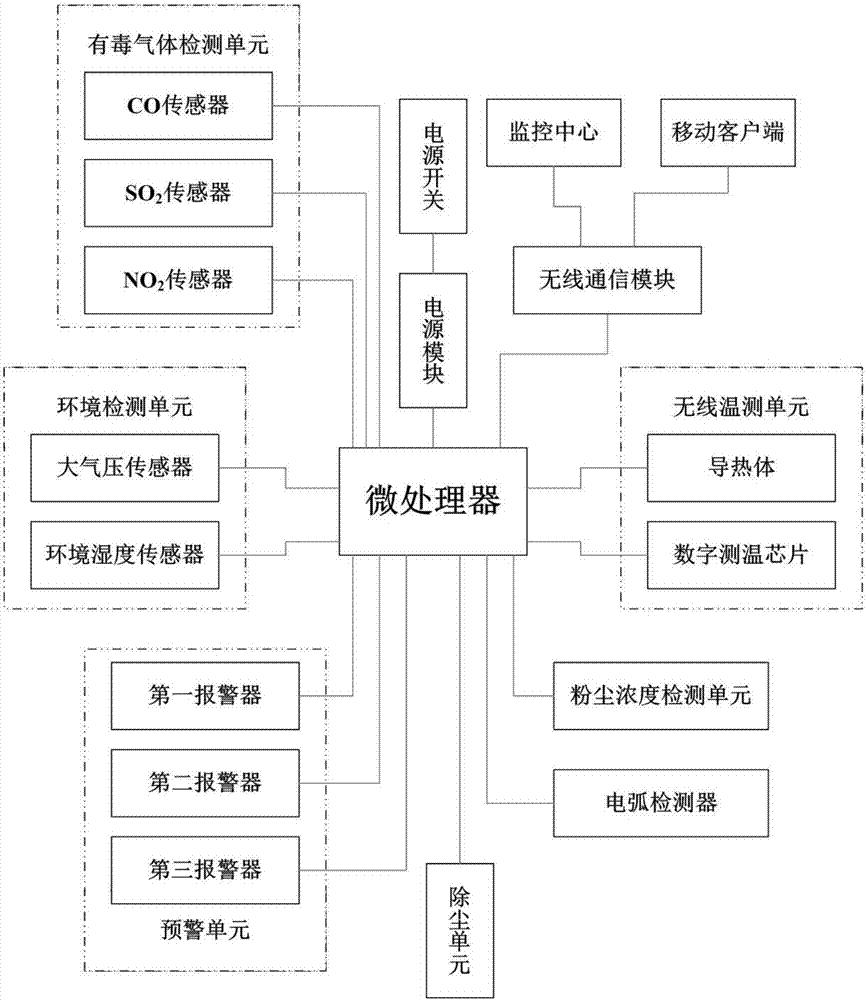

Automatic control system for power plant

InactiveCN106932022AReal-time monitoring of changes in environmental factorsReal-time monitoring of temperature changesMeasurement devicesPower flowAutomatic train control

Disclosed in the invention is an automatic control system for a power plant. The automatic control system comprises an environment detection unit, a poisonous gas detection unit, a wireless temperature measuring unit, a dust concentration detection unit, an early warning unit, a micro processor, and a wireless communication module. The environment detection unit is used for detecting a barometric pressure and environmental humidity of a line; the wireless temperature measuring unit is used for detecting a temperature of an electrically charged device; and the poisonous gas detection unit is used for detecting CO concentration, SO2 concentration, and NO2 concentration in a power plant. According to the automatic control system, comprehensive deduction is carried out by combining various factors including the residual current, environment temperature, environment humidity, barometric pressure, dust concentration, and poisonous gas instead of by using the residual current and import part temperatures as unique criteria of alarm outputting, so that the misjudgment rate of system alarming can be reduced and the electrical fire monitoring control system of the power plant can be improved.

Owner:WEIFANG UNIV OF SCI & TECH

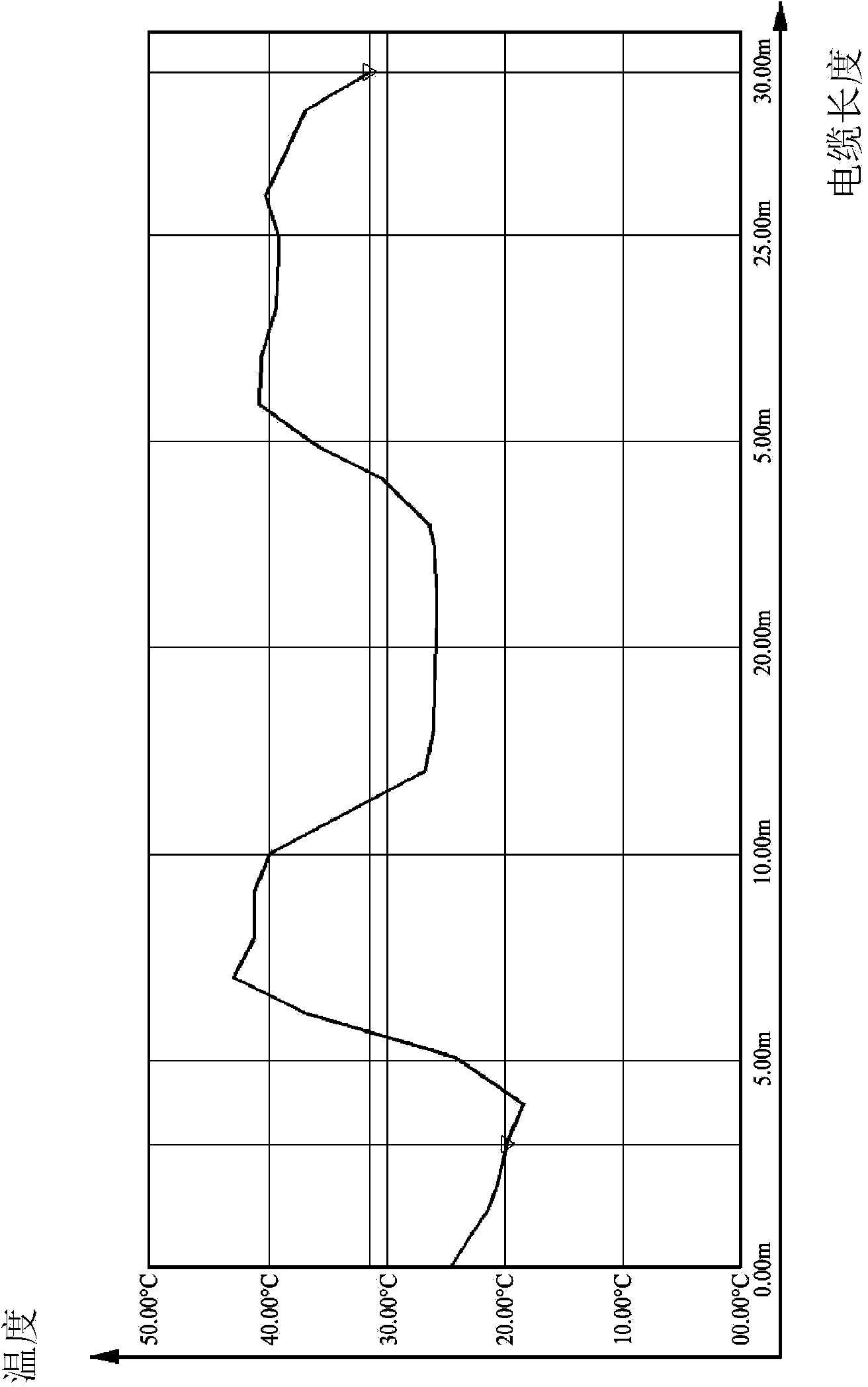

Power cable fire hazard on-line monitoring system

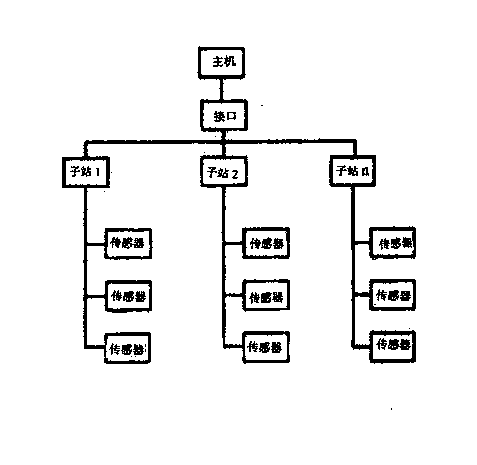

InactiveCN103616081AReal-time monitoring of temperature changesAvoid fireThermometer detailsDistributed structureElectric power system

The invention provides a power cable fire hazard on-line monitoring system, and belongs to the field of the electrical technology and equipment. The power cable fire hazard on-line monitoring system is designed to be of a dispersed-measuring and concentrated-monitoring layered distributed structure according to actual requirements of power cable operation, and comprises a host, a bus interface, sub stations and temperature sensors. The temperature sensors accurately measure the temperature of a cable connector and all points of a cable, all the sub stations collect data transmitted by the temperature sensors in real time, after simple processing, the number of the sensors and corresponding data are transmitted to the host through an interface circuit, and the host manages all the sub stations and manages and displays on-site data through a good interface under the Windows environment. The power cable fire hazard on-line monitoring system can give out an alarm timely when the temperature is out of limit or the temperature rising speed is beyond a set alarming value according to the real-time monitored temperature changing of the power cable, guarantees safe operation of an electric system, and is novel in design, reasonable in structure, reliable in operation, and convenient to maintain.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ANYANG POWER SUPPLY

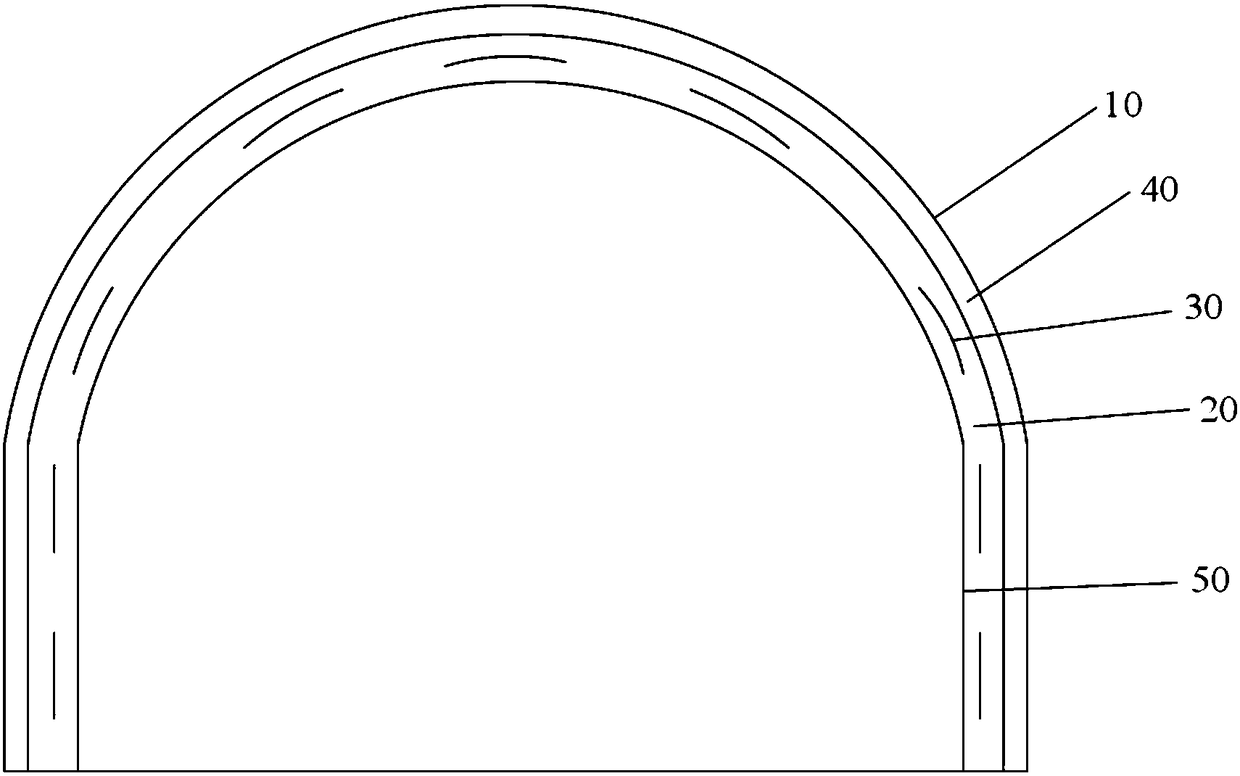

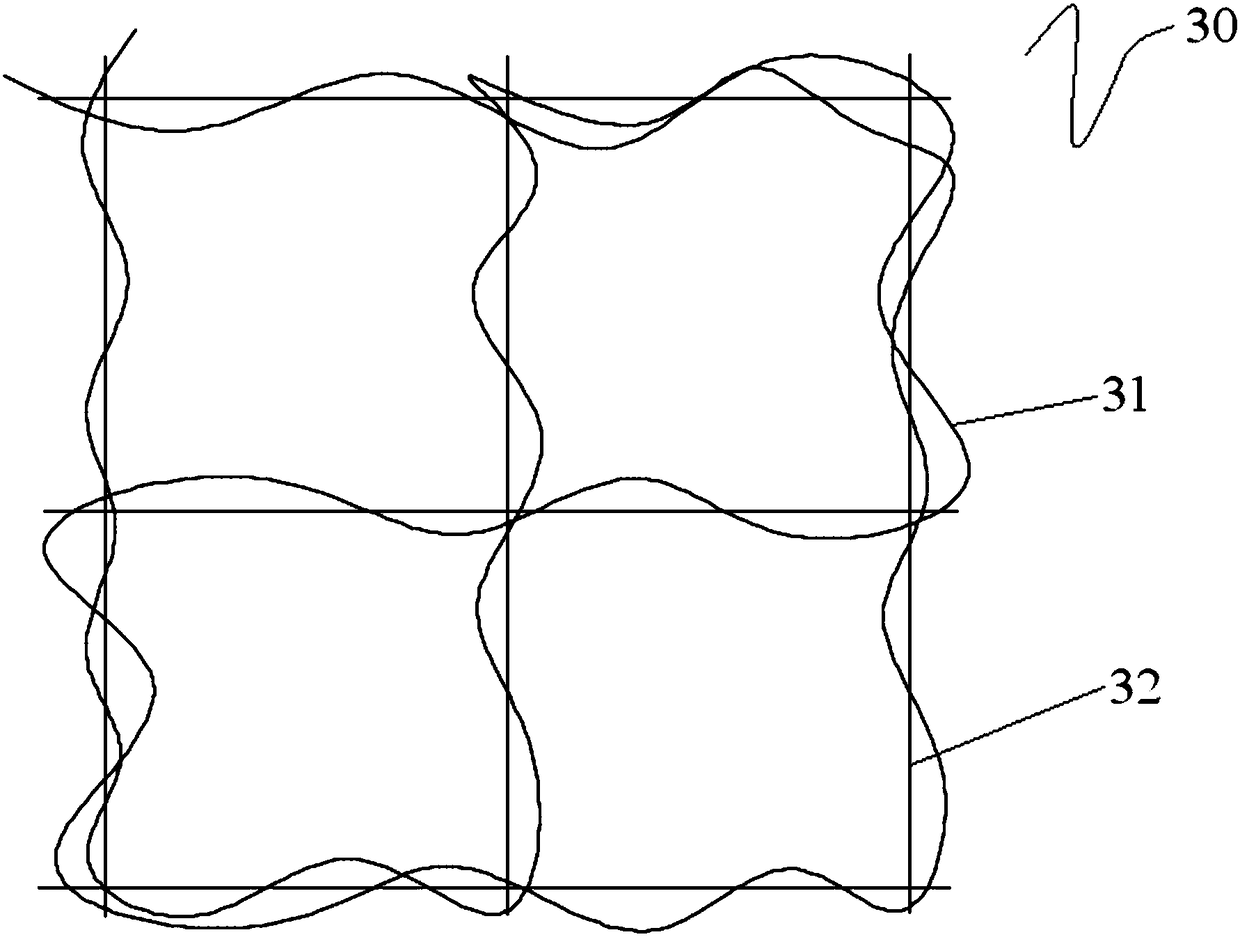

Tunnel monitoring system and tunnel monitoring method

InactiveCN108489456AWater pressure real-time monitoringSubsidence real-time monitoringThermometers using physical/chemical changesHeight/levelling measurementMonitoring systemEngineering

The invention provides a tunnel monitoring system and a tunnel monitoring method. The tunnel monitoring system comprises a tunnel, a concrete layer, a plurality of optical fiber monitoring pieces anda demodulator, wherein the concrete layer is laid on a wall surface of the tunnel; the optical fiber monitoring pieces are arranged in the concrete layer; the optical fiber monitoring pieces are connected with the demodulator. According to the tunnel monitoring system and method disclosed by the invention, the problem in the prior art that a safe state of the tunnel is inconveniently monitored issolved.

Owner:胡仲春 +1

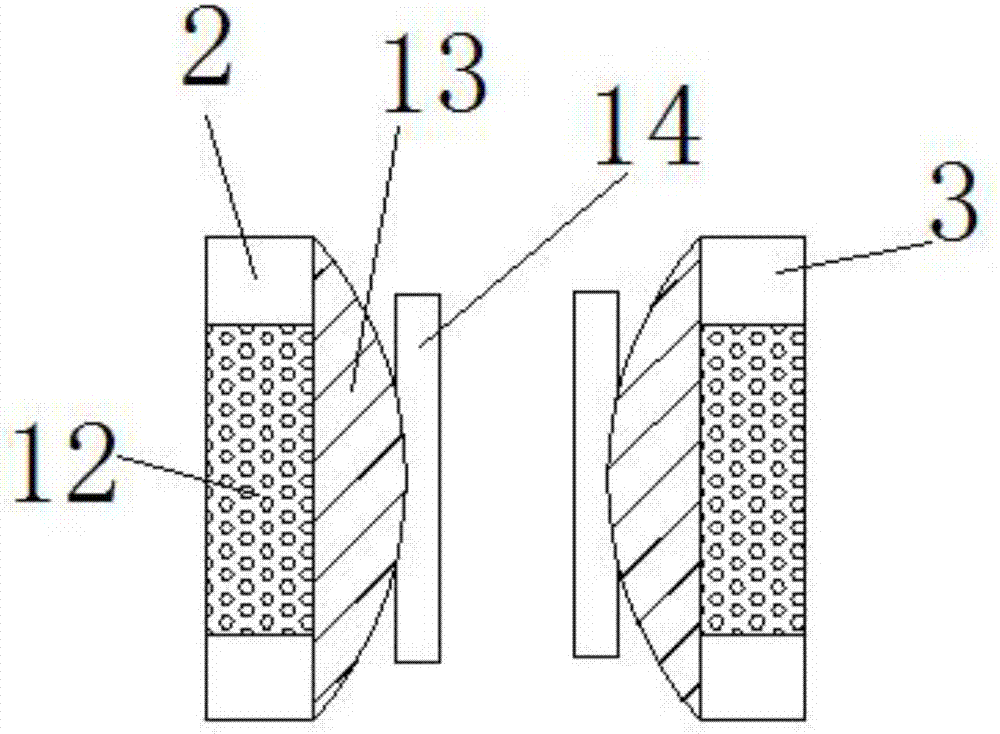

500KV extra-high voltage power cable with real-time temperature detection function

InactiveCN102097172AReal-time monitoring of temperature changesAccurately monitor temperature conditionsPower cables with screens/conductive layersThermometers using physical/chemical changesElectrical conductorWater block

The invention discloses a 500KV extra-high voltage power cable with a real-time temperature detection function, which comprises a conductor positioned in the center of the cable. A semiconductive tape, a conductor shielding layer, an insulating layer, an insulating shielding layer, a semiconductive water-blocking expansion buffer layer, a corrugated aluminum sheath and a nonmetallic sheath are sequentially arranged outside the conductor. A temperature detection optical fiber is arranged in the insulating shielding layer along the axial direction of the cable, and is connected with a switch cabinet temperature monitoring and early warning system. The 500KV extra-high voltage power cable with the real-time temperature detection function can monitor the temperature variations of long-distance cables in real time and accurately monitor the temperature conditions of high voltage switch contacts so as to realize point and line combination and comprehensive monitoring, and simultaneously can timely transmit fire alarming information to a fire alarming controller to realize gang control.

Owner:WUXI GREAT WALL ELECTRIC WIRE & CABLE

Convenience ear tag for sheep/goats

The invention discloses a convenience ear tag for sheep / goats, comprising an ear tag, connection block I and connection block II; the connection block I is connected to the upper portion of the ear tag, the connection block II is arranged on one side of the connection block I, a battery is arranged on one side of the inside of the ear tag, a GPS (global positioning system) unit is connected to thebottom of the battery, the bottom of the ear tag is provided with a temperature sensor, magnet II is arranged in the connection block I, and magnet I is arranged in the connection block II. The ear tag is effectively fixed to an ear of a sheep / goat through the magnets, a telescopic rod and a balloon; the GPS unit allows positional information of the sheep / goat to be accurately and effectively acquired so that loss of the sheep / goat is effectively avoided; the temperature sensor allows the changes in the temperature of the sheep / goat to be monitored effectively in real time.

Owner:扬中市红光金属制品有限公司

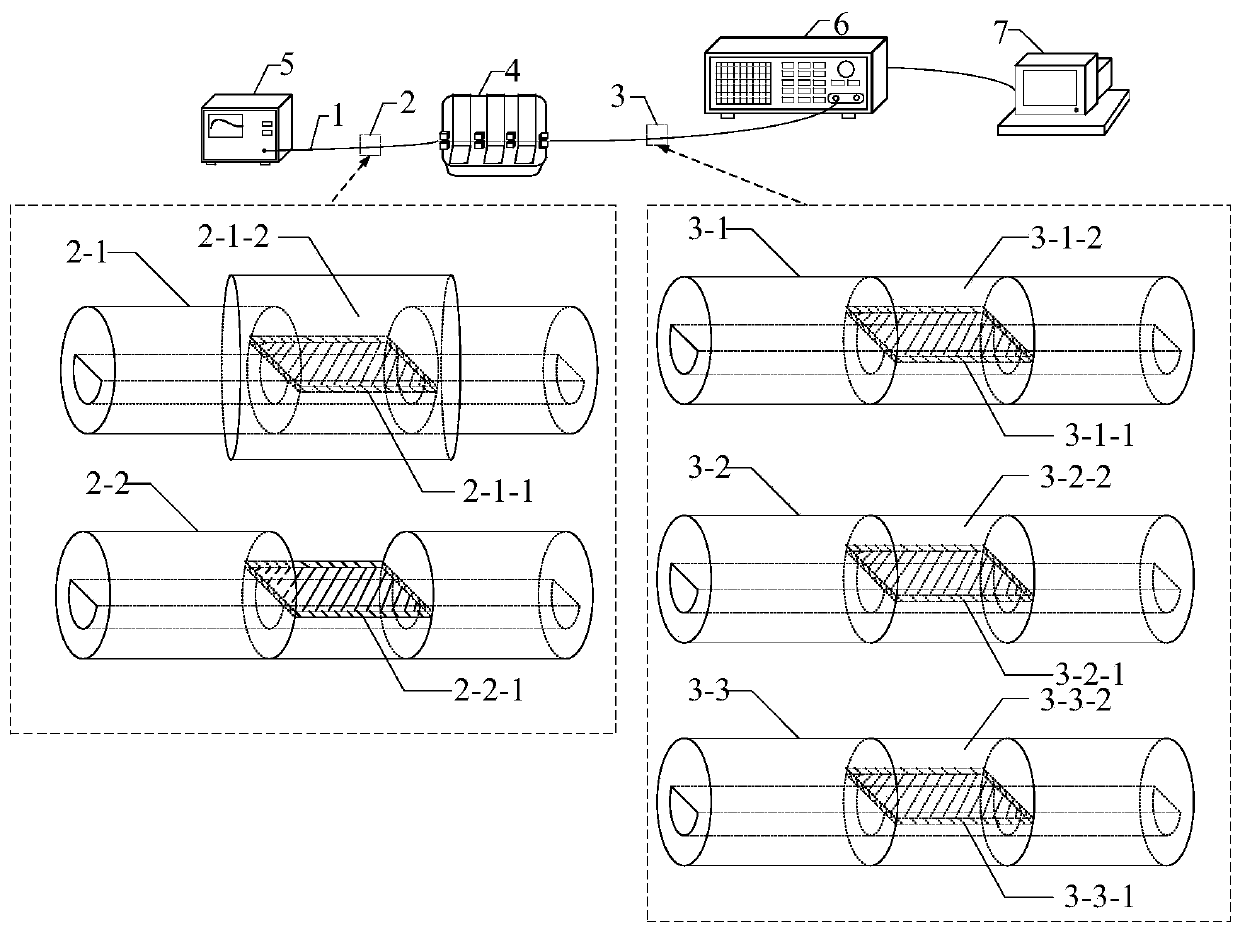

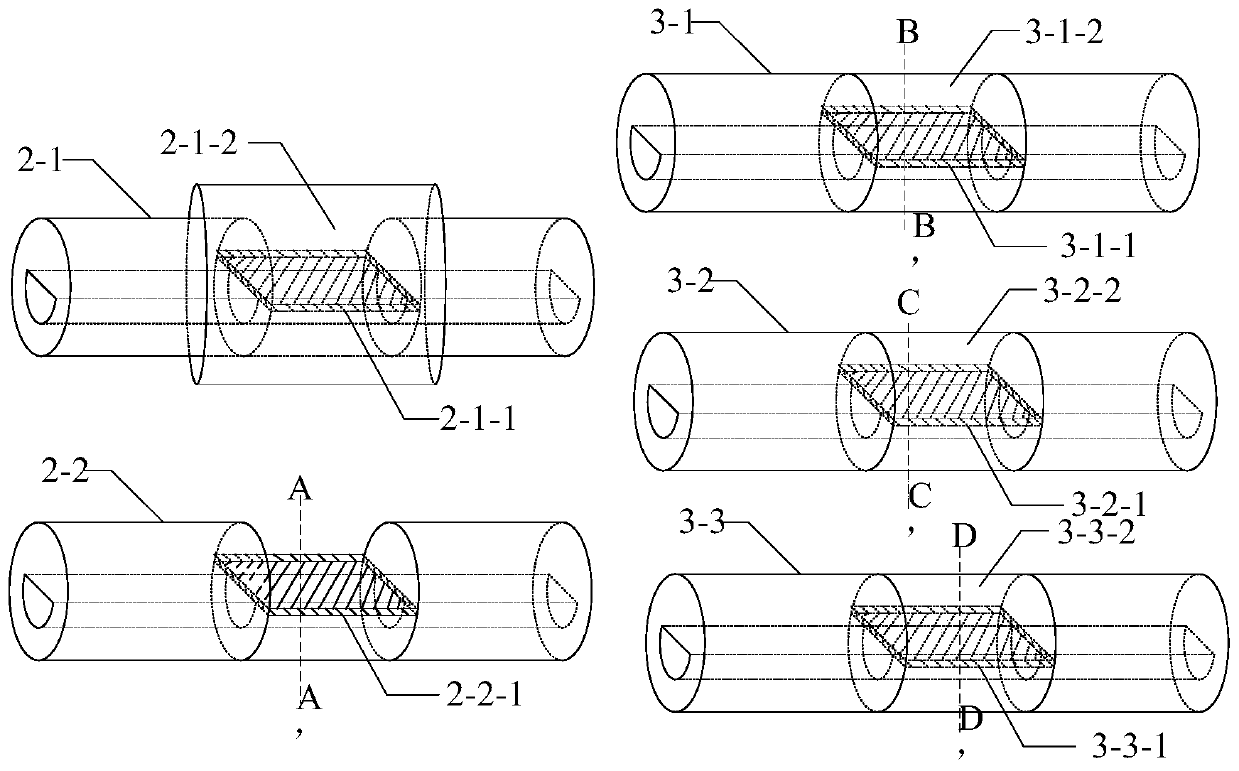

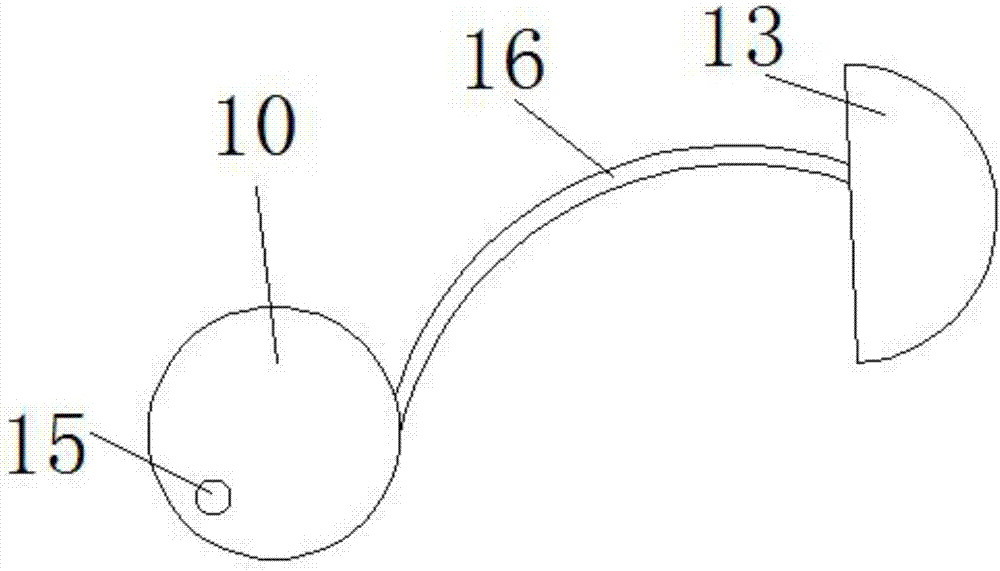

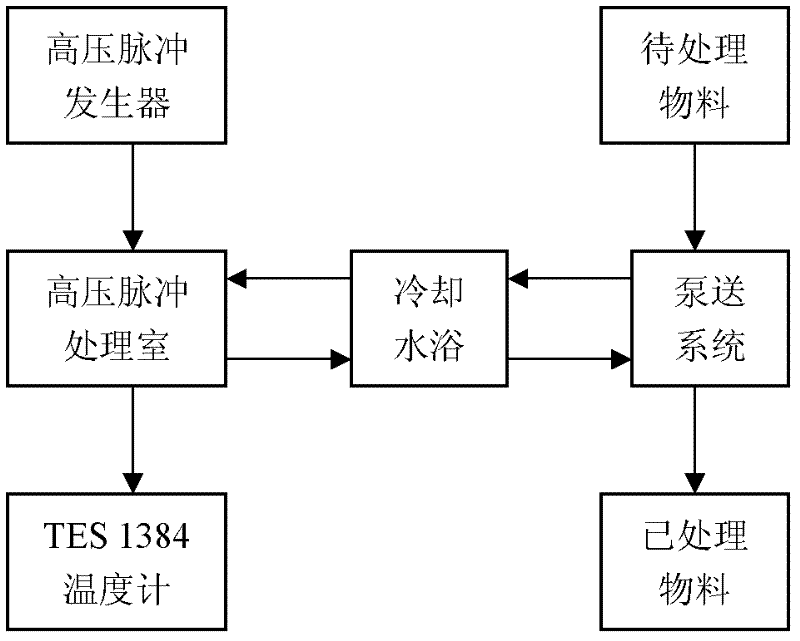

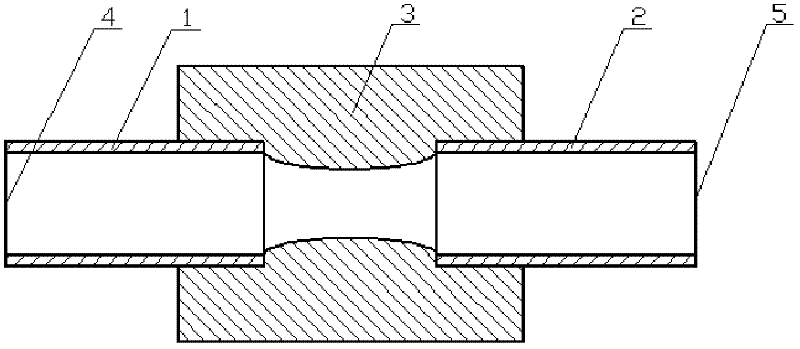

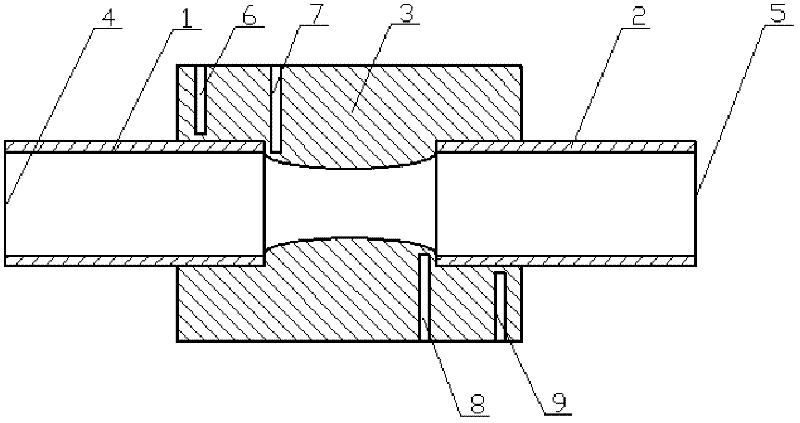

Coupling field-based structurally-optimized common-field treatment chamber for high-voltage pulsed electric field sterilizing system

InactiveCN102415599AImprove temperature distributionReal-time monitoring of temperature changesFood preservationElectrical field strengthData acquisition

The invention discloses a coupling field-based structurally-optimized common-field treatment chamber for a high-voltage pulsed electric field sterilizing system. The common-field treatment chamber consists of two metal hollow tubular electrodes and an insulator isolating tube. A coupling field-based structural optimization design is adopted, so that a peak electric field existing close to an electric field is eliminated, the problem of 'discharge' caused by an over-high local electric field is solved, the uniformity of electric field distribution in the treatment chamber is ensured simultaneously, high electric field strength is concentrated in a main region through which materials pass, the flowing characteristics of materials in the treatment chamber is improved, the temperature distribution situation in the treatment chamber is well improved, the temperature variation of the treatment chamber can be monitored in real time, the acquisition and analysis of temperature data in the sterilizing process are facilitated, and temperature abnormity occurring in the sterilizing process is alarmed. The common-field treatment chamber has the advantages of safety, high efficiency, economical efficiency and the like, and the application of a high-voltage pulsed electric field sterilizing technology from a laboratory to pilot scale and commercialization can be facilitated.

Owner:JIANGNAN UNIV +1

Hardware temperature detection device

InactiveCN111190795AReal-time monitoring of temperature changesAvoid monitoring blind spotsHardware monitoringDigital processing power distributionComputer hardwareFixed frame

The invention provides a hardware temperature detection device, relates to the technical field of computers, and aims at solving the problems that the existing computer hardware is generally installedin a mainframe box, the temperature detection device is mostly used for being close to the installation position of the heat dissipation fan, the temperature detection device can only detect the temperature of a fixed area, real-time detection cannot be carried out when the temperature of the edge position or other local positions of hardware is too high, the heat dissipation fan cannot dissipateheat of the hardware in the case in time and the hardware is prone to being damaged. The hardware temperature detection device comprises a fixed frame. A rotating mechanism is fixedly mounted in themiddle of the fixed frame. A reciprocating motor is fixedly mounted at the lower end of a driving mechanism so that a moving mechanism can move up and down on the mounting frame, the temperature sensors at the two ends of the moving mechanism can perform temperature measurement at different positions, the temperature change in the case can be monitored in real time and monitoring dead angles are avoided.

Owner:CHANGZHOU INST OF TECH

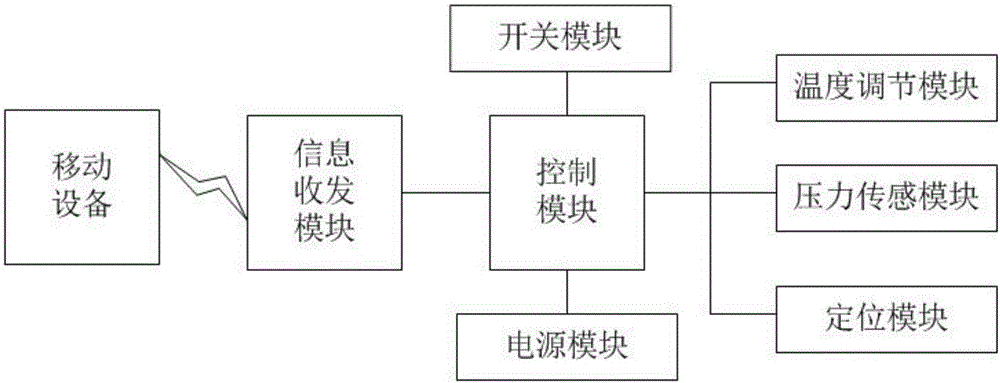

Intelligent shoe pads

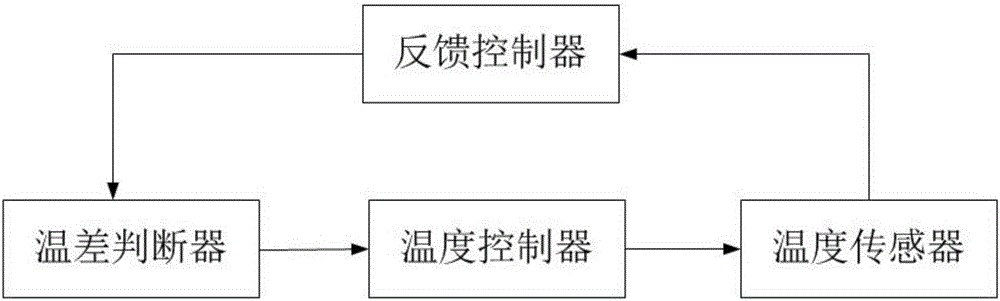

InactiveCN106617491AControl the heating processReal-time monitoring of temperature changesInsolesTemperature controlFeedback controller

The invention discloses intelligent shoe pads. Each intelligent shoe pad comprises a control module, a switch module, a power module, a temperature regulation module, a pressure sensing module and a locating module, wherein the temperature regulation module comprises a temperature controller, a temperature sensor, a temperature difference judger and a feedback controller; the temperature controller heats the shoe pad under the control of a central processor, the temperature sensor collects the temperature information of the intelligent shoe pad in real time, the feedback controller transmits the temperature information to the temperature difference judger, the temperature difference judger compares with the preset temperature and makes temperature difference comparison, when the temperature difference exceeds the preset range, the temperature controller makes adjustment so that the low-frequency mode is obtained, and thus the overhigh temperature is prevented. According to the intelligent shoe pads, by increasing the pressure of the feet or adopting a mobile device for triggering a heating switch, the heating process can be controlled, the temperature change can be monitored in real time, the overhigh temperature of the shoe pads can be prevented, energies can be saved, the functions are diversified, and the operation is convenient.

Owner:SHENZHEN SAIYI TECH DEV

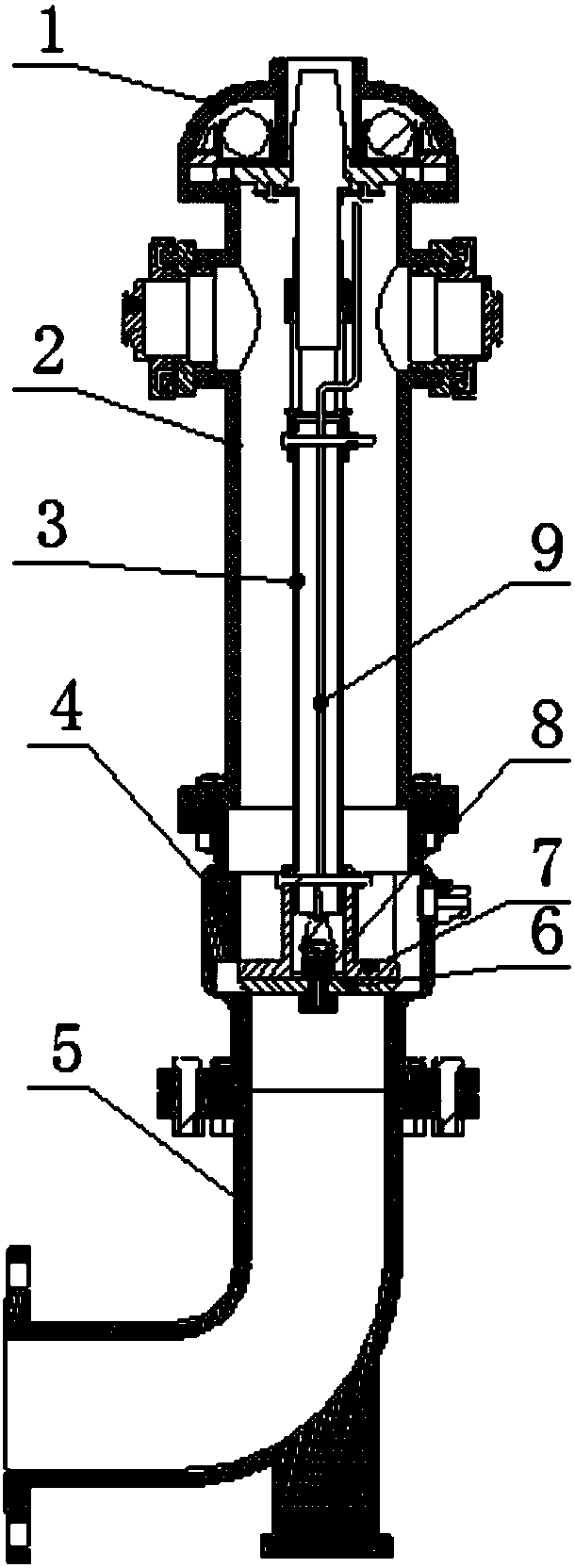

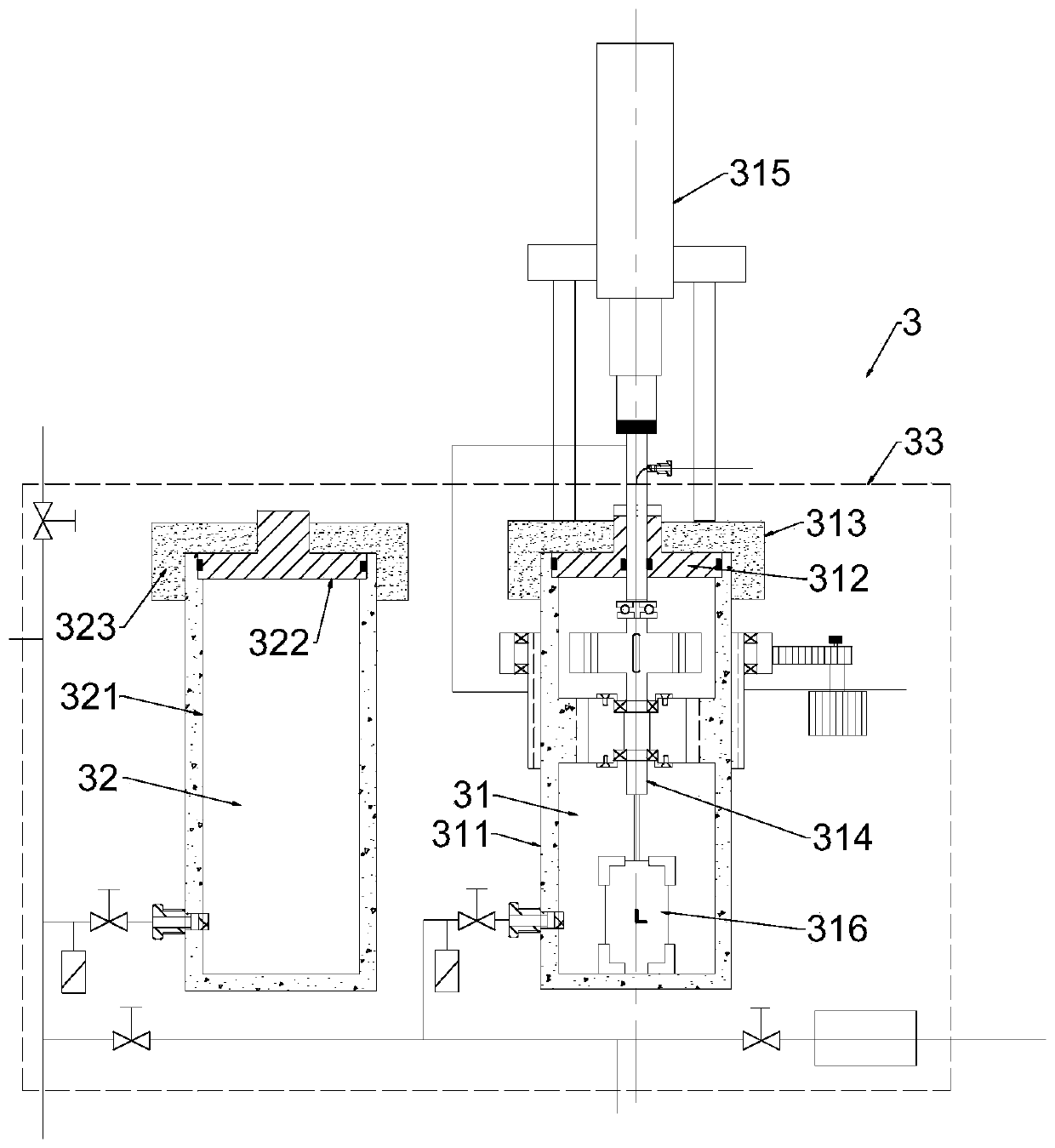

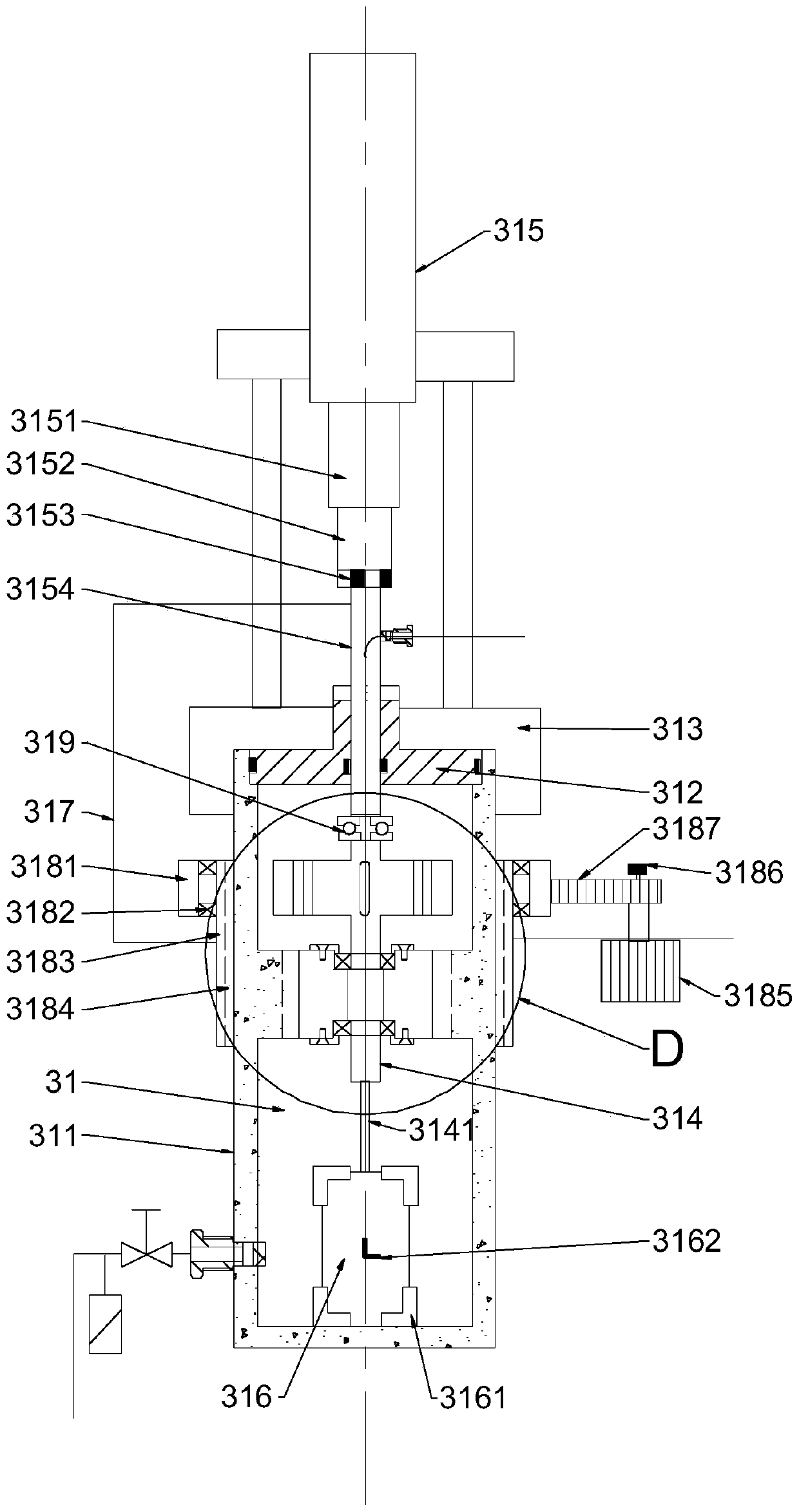

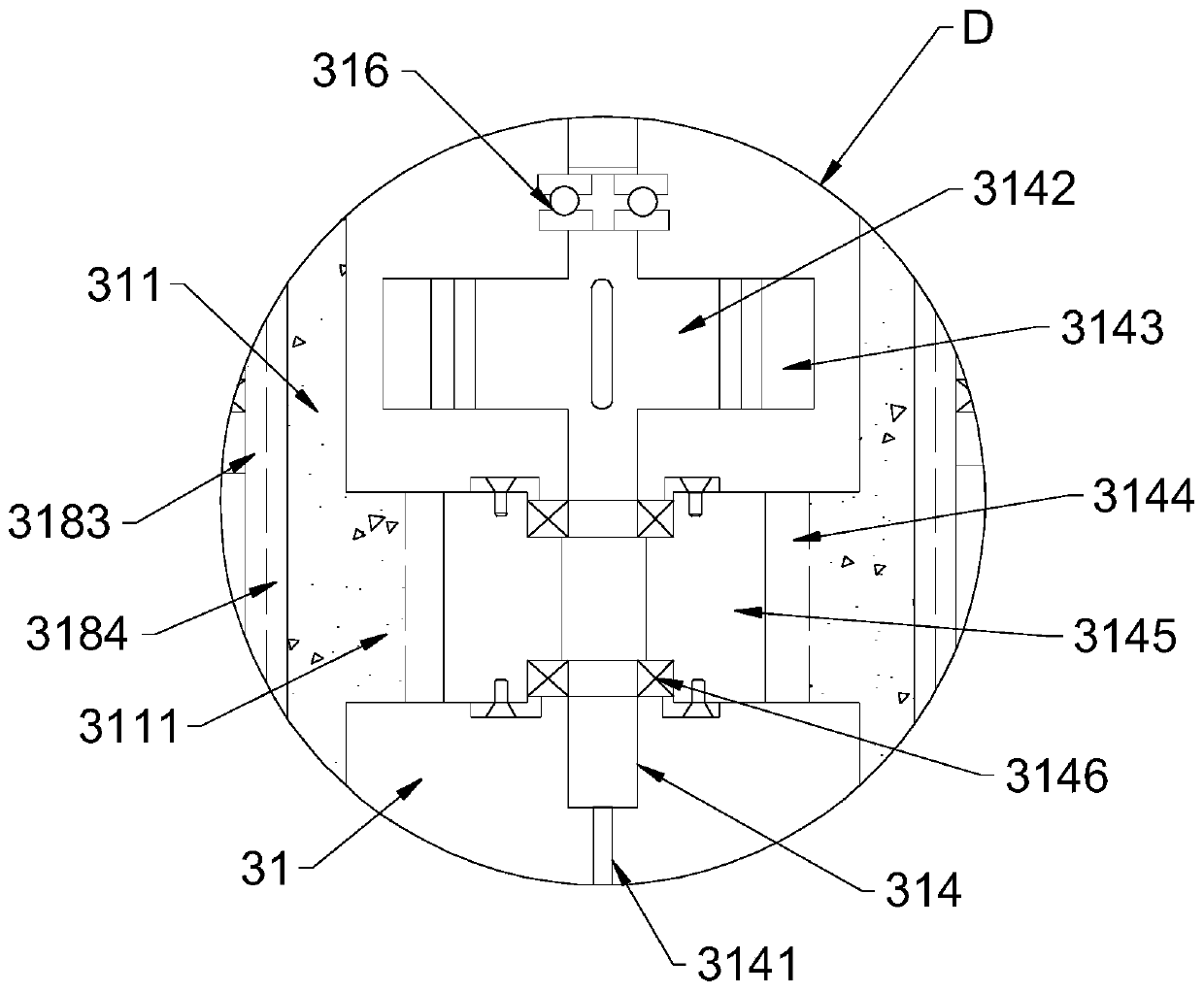

Multi-dimensional data measuring device for lump coal drilling process

ActiveCN111521537AReal-time monitoring of temperature changesGuaranteed air tightness requirementsPermeability/surface area analysisDrive motorTest chamber

The invention discloses a multi-dimensional data measuring device for a lump coal drilling process. The multi-dimensional data measuring device comprises an adsorption tank for adsorbing and desorbinglump coal, a reference tank which has the same size as the adsorption tank and is used for balancing pressure, and a high-low temperature test box for accommodating the adsorption tank and the reference tank, a temperature measuring drill rod is arranged in the adsorption tank, a non-contact magnetic coupling matching mode is adopted, the adsorption tank is driven by a driving motor to rotate, and the temperature measuring drill rod moves up and down through a propelling device; and the reference tank and the adsorption tank are respectively communicated with a gas source system for supplyinggas, a vacuum pumping system for pumping gas and a gas collecting device through a branch gas path and a main gas path. According to the method, various dimension data in the lump coal drilling process of the drill bit can be measured in different temperature environments,wherein the parameters comprise drill bit temperature change, while-drilling parameter change, lump coal gas content data, drill bit drilling process gas real-time analysis quantity and gas adsorption expansion deformation real-time monitoring data.

Owner:TAIYUAN UNIV OF TECH

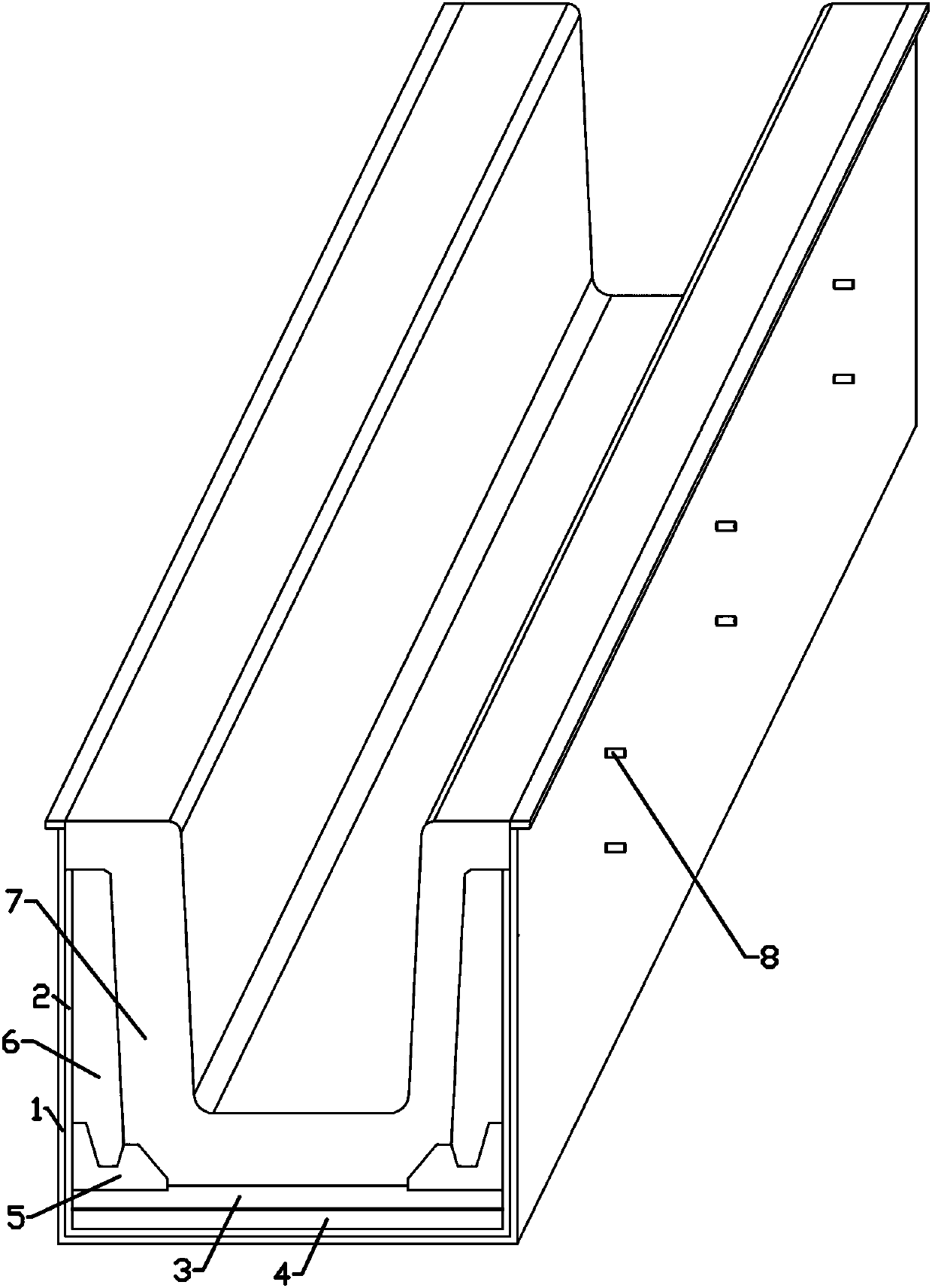

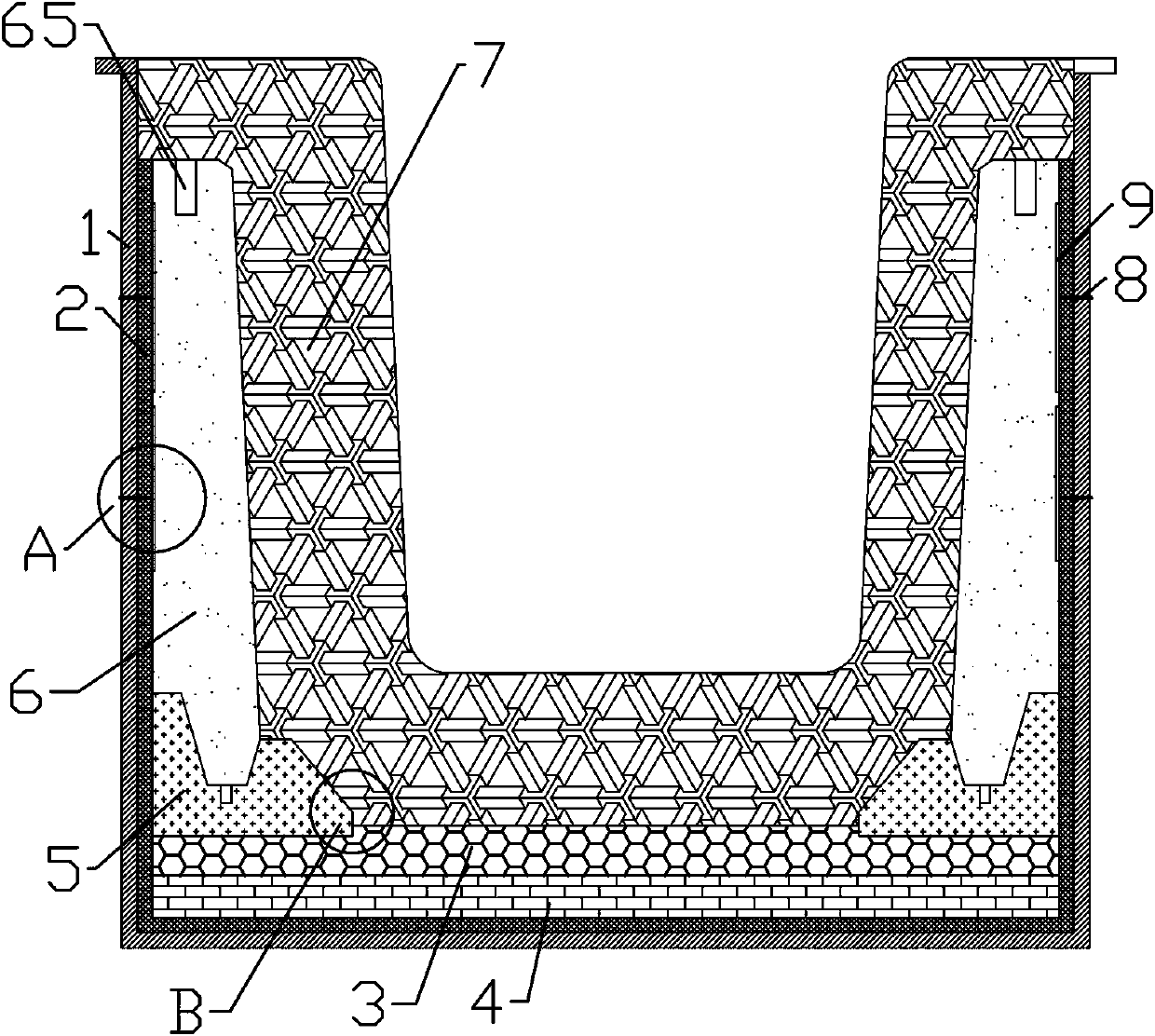

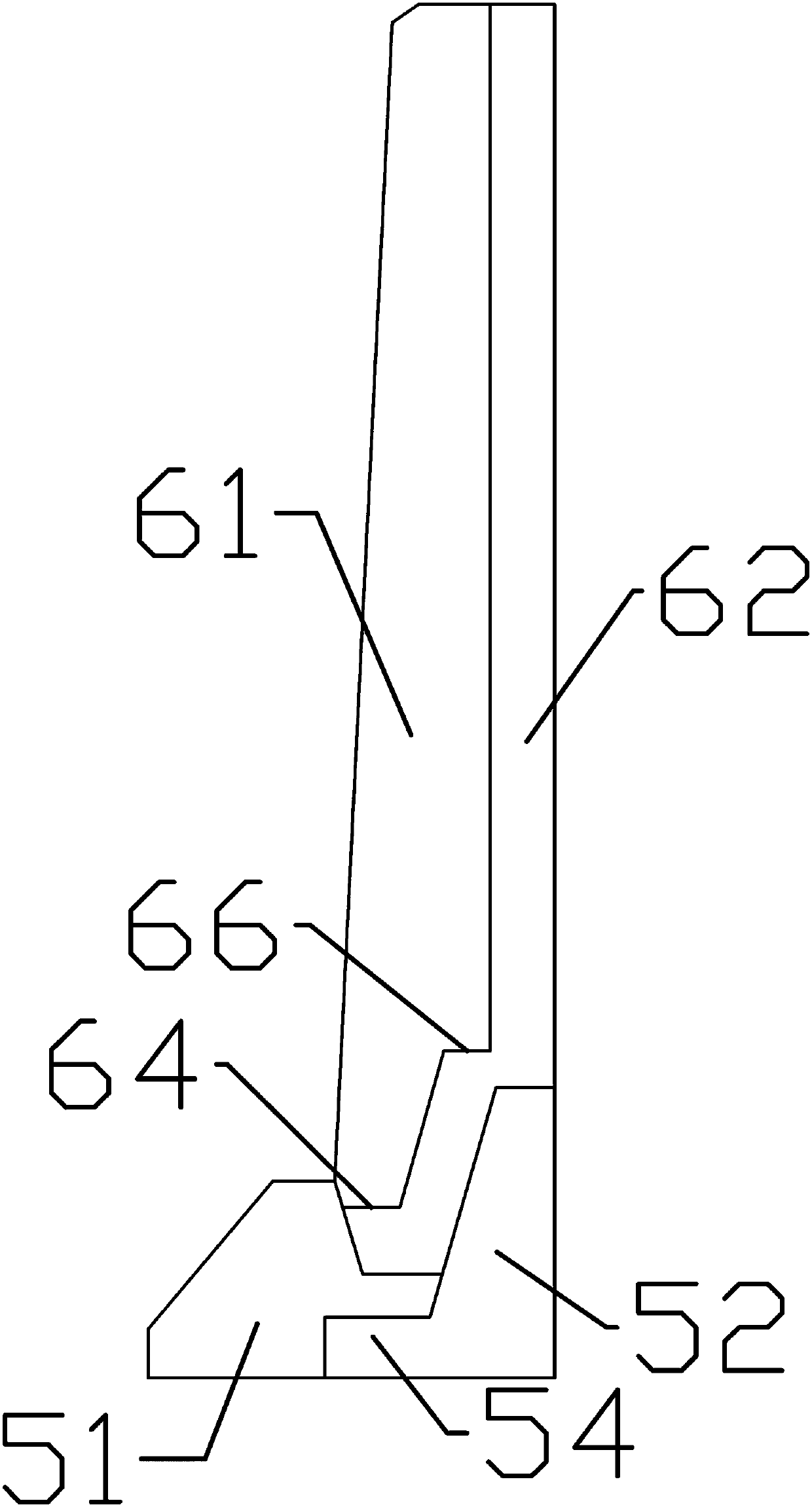

Prefabricated iron tap channel

PendingCN110093469AReal-time monitoring of temperature changesReduce outboundDischarge devicesSingle plateMaterials science

The invention relates to an iron smelting blast furnace, in particular to a prefabricated iron tap channel which comprises a steel shell with a U-shaped cross section, a permanent layer arranged in the steel shell, and a working layer arranged on the permanent layer. The permanent layer comprises a prefabricated base arranged on the inner edge of the steel shell; the prefabricated base comprises multiple prefabricated base blocks assembled together along a straight line; each two adjacent prefabricated base blocks are occluded; a prefabricated plate is inserted into the upper end of the prefabricated base through an installation groove and comprises multiple refabricated single plates assembled together along a straight line; each two adjacent prefabricated single plates are occluded; a temperature measurement plate installation groove is formed in the outer side surface of each prefabricated single plate; a temperature measurement plate is arranged in each temperature measurement plate installation groove; a temperature sensor is arranged on each temperature measurement plate; and cables of the temperature sensors penetrate through the steel shell so as to be connected to a controller. The prefabricated iron tap channel is convenient to install and maintain, long in service life, high in safety coefficient, and simple in structure.

Owner:ZHENGZHOU SAIWO TECH CO LTD

Manufacturing method of ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting

ActiveCN108866427AMeet technical requirementsShorten the setting timeFoundry mouldsFoundry coresNuclear powerDuctile iron

The invention discloses a manufacturing method of an ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting. The spheroidal graphite iron casting is more than 50 tons in weight, is 400mm or more in wall thickness, and is prepared from the following components: 3.6 to 3.7 percent of C, 0.9 to 1.0 percent of Si<original>, 1.9 to 2.0 percent of Si<final>, less than or equal to 0.1 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 0.03 to 0.08 percent of Mg, 0.01 to 0.02 percent of RE, 0.6 to 0.8 percent of Ni and0.003 to 0.005 percent of Sb. During manufacturing, the technical measures of ''high-temperature pure base iron melt, water-cooled metal mold, cold iron, spheroidizing agent 5800, compound strengthening inoculation, alloying and low-temperature box beating'' are adopted, so that the prepared ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting can meet the quality standard of a spheroidal graphite iron casting of which the license number is QT400-18, and can meet the technical requirements of ultra-large-section spheroidal graphite iron castings applied to wind power, nuclear power and the like.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com