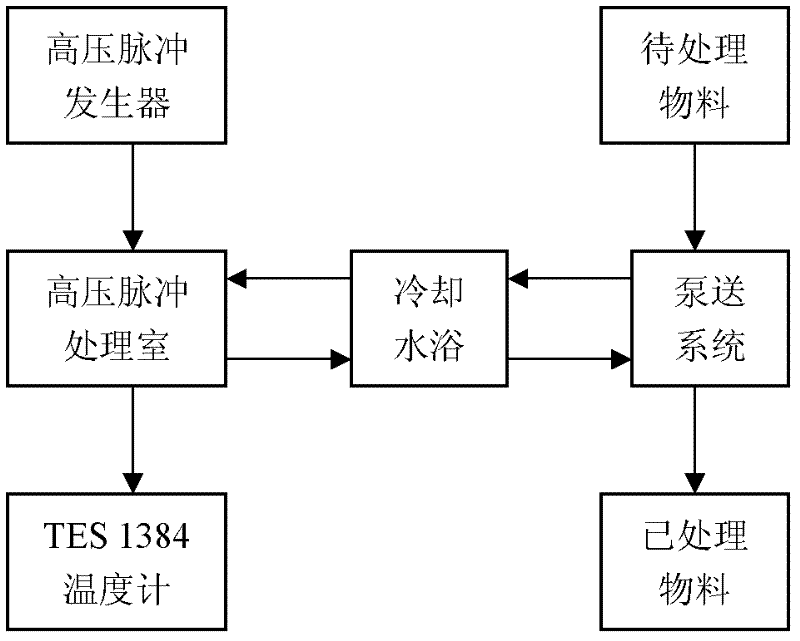

Coupling field-based structurally-optimized common-field treatment chamber for high-voltage pulsed electric field sterilizing system

A high-voltage pulsed electric field and processing chamber technology, which is applied in the field of common field processing chambers, can solve problems such as temperature sensor failure, uneven flow rate, and large changes in the temperature rise of the processing room, achieve uniform electric field intensity distribution, eliminate peak electric fields, and improve flow The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

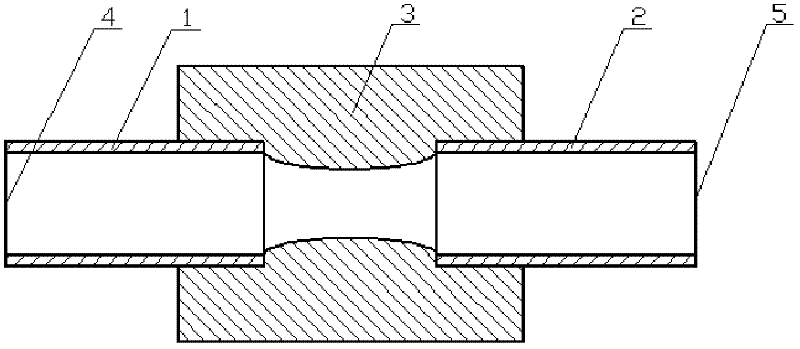

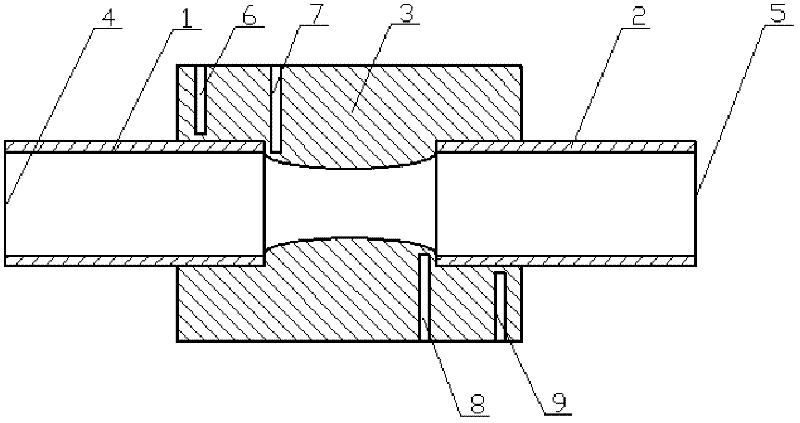

[0018] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Such as figure 2 As shown, the co-field treatment chamber of the high-voltage pulsed electric field sterilization system based on coupling field structure optimization provided by the present invention is composed of a metal hollow tubular ground electrode 1, a metal hollow tubular high-voltage electrode 2, an insulator isolation tube 3, a feed port 4, and The discharge port is composed of 5, the insulator isolation tube is located between the metal hollow tubular ground electrode and the metal hollow tubular high voltage electrode to form a processing chamber cavity, the metal hollow tubular ground electrode is connected to the feed port, and the metal hollow tubular high voltage electrode is connected to the discharge port ; The geometric shape of the protrusion inside the insulator isolation tube 3 is oval (the protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com