Coal and mash gas extrusion mold

A gas outburst and mold technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of insufficient force gradient, inaccurate results, and small outburst coal sample size, etc., to improve the authenticity and force gradient. Visible, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

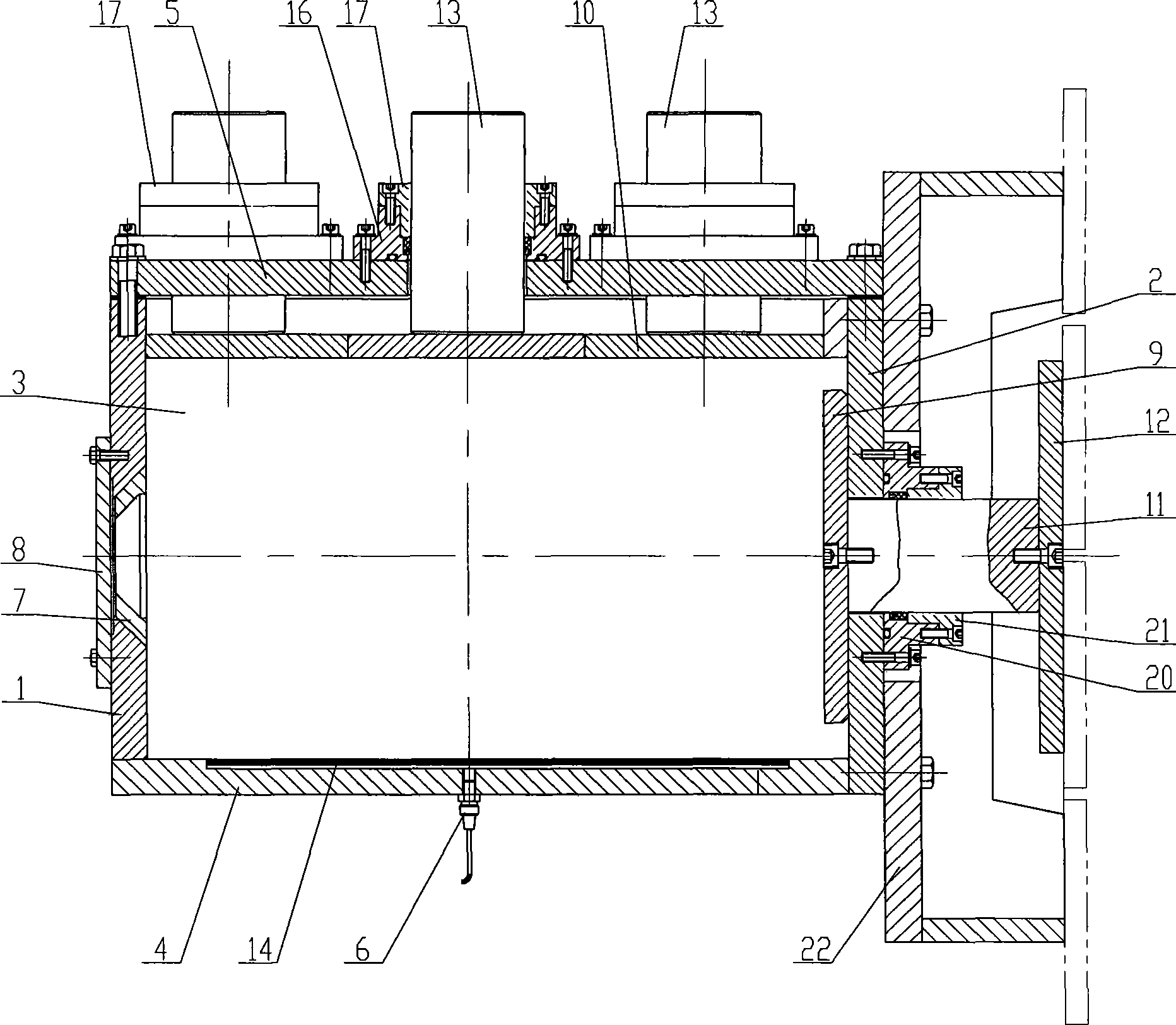

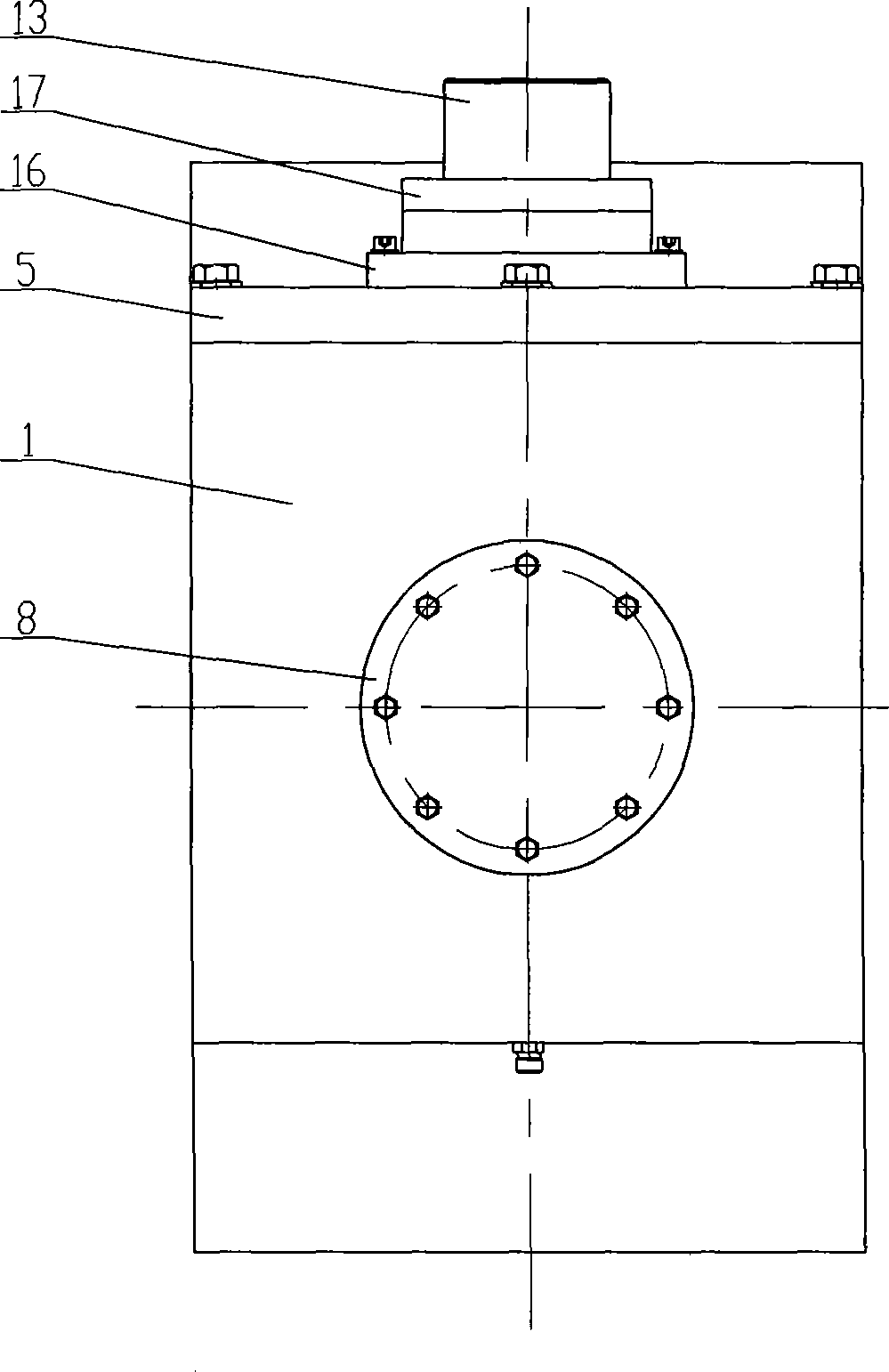

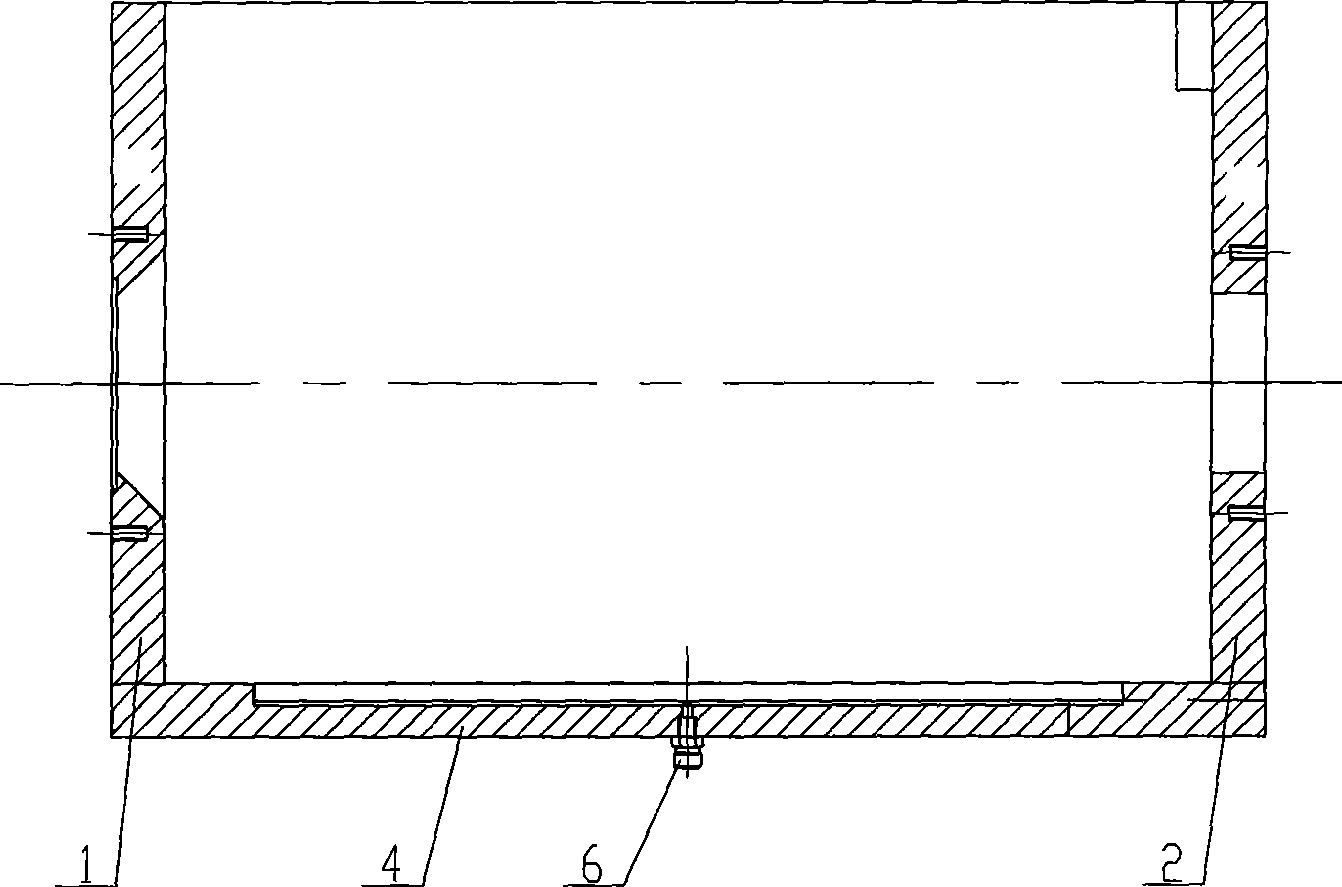

[0039] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0040] like figure 1 , figure 2 , image 3 and Figure 4 As shown in the figure, a coal and gas outburst mould has a mould box, which is a cuboid box-like structure with an open upper end, and is surrounded by a front end plate 1, a rear end plate 2, left and right end plates 3 and a bottom plate 4, Each plate is a steel structure, and two adjacent plates are fixed by welding. A rectangular sink is provided on the upper surface of the bottom plate 4, and a filter mesh 14 suitable for the shape and size is embedded in the sink slot, and the filter mesh 14 is made of metal foam. The bottom surface of the sink is provided with reticulated grooves 15, and the bottom surface of the intersection of the two grooves 15 located in the middle is provided with an air hole, in which the air intake nozzle 6 is installed, and the air intake nozzle 6 can pass through....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com