Experimental device for measuring periodical heat transfer coefficient

An experimental device and technology of heat transfer coefficient, applied in the direction of material thermal development, etc., can solve the problems of deformation of cooling steel plates, inability to continuously cool, etc., and achieve the effects of uniform heating, convenient replacement and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

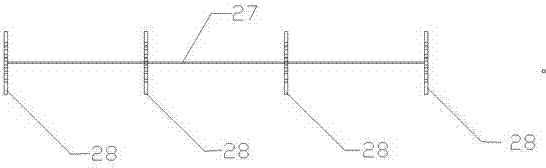

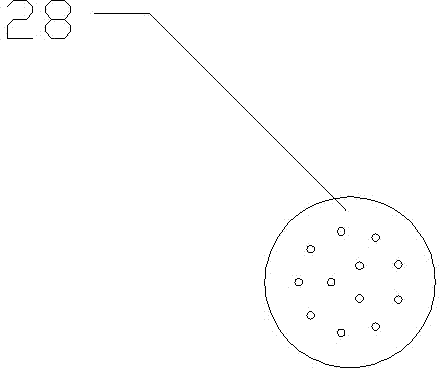

[0042] The invention provides an experimental device for measuring the periodic heat transfer coefficient, such as Figure 7 As shown, the device includes a steel cylinder rotation system, an air circuit, a water system, a heating system, a temperature acquisition system, a nozzle and its adjustment system, and the box of the experimental device.

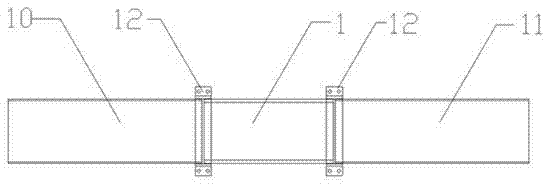

[0043] see Figure 7 , figure 1 , the steel cylinder rotating system includes a rotating steel cylinder 1, a left support cylinder 10, a right support cylinder 11, a transmission device and a speed regulating device, and the rotating steel cylinder 1 and the left support cylinder 10 and the right support cylinder 11 on the left and right sides pass through the card Tool 12 forms an internally penetrating cylindrical structure, and a heating device is installed throughout the cylindrical structure. The joints between the left support cylinder and the right support cylinder and the rotating steel cylinder are sealed with high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com