Method and device for simulating thin-strip continuous casting technical process

A continuous casting process and thin strip technology, which is applied in the field of simulating the thin strip continuous casting process, can solve the problems of inability to verify the production feasibility of the product, and cannot be taken out quickly, and achieve good compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

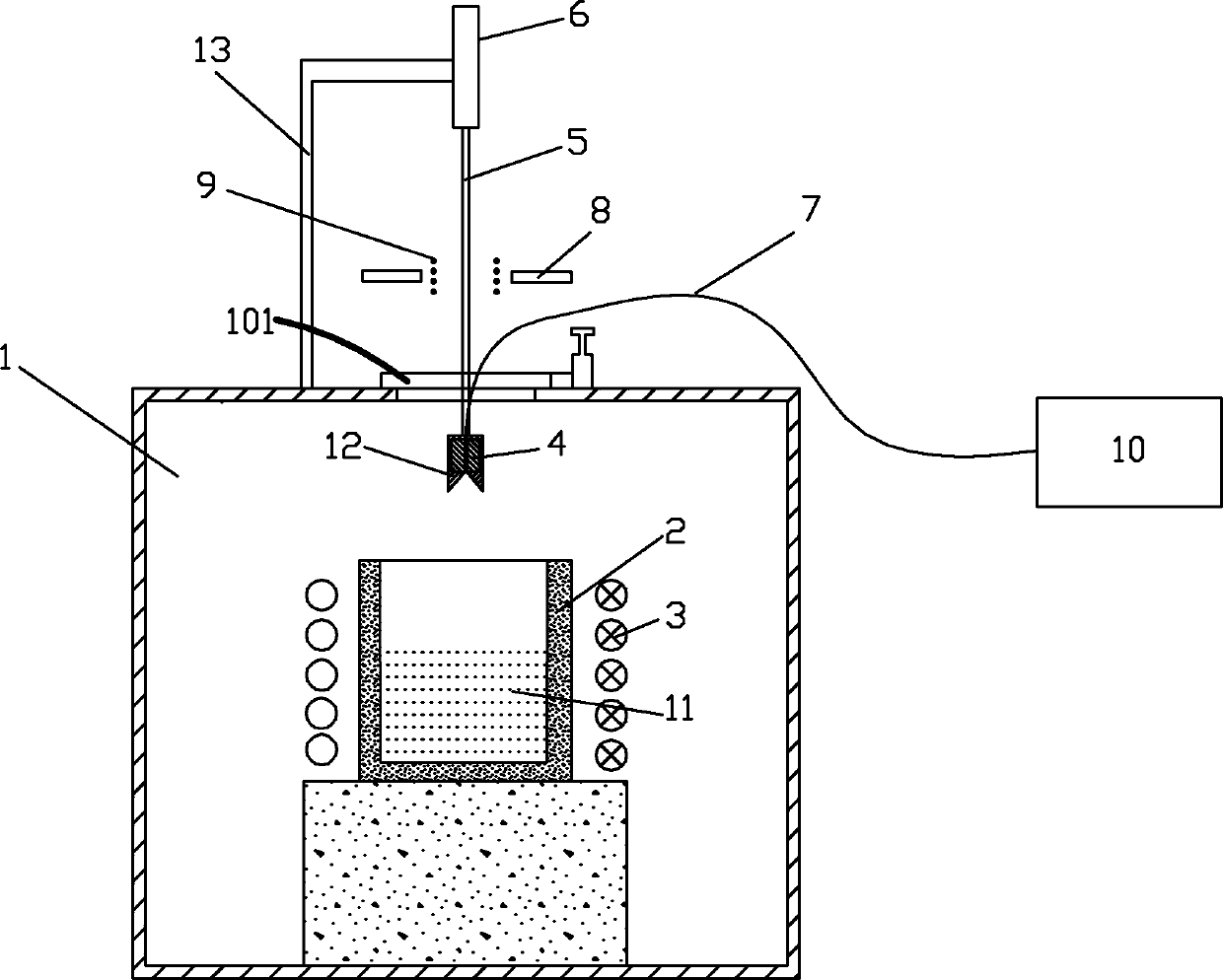

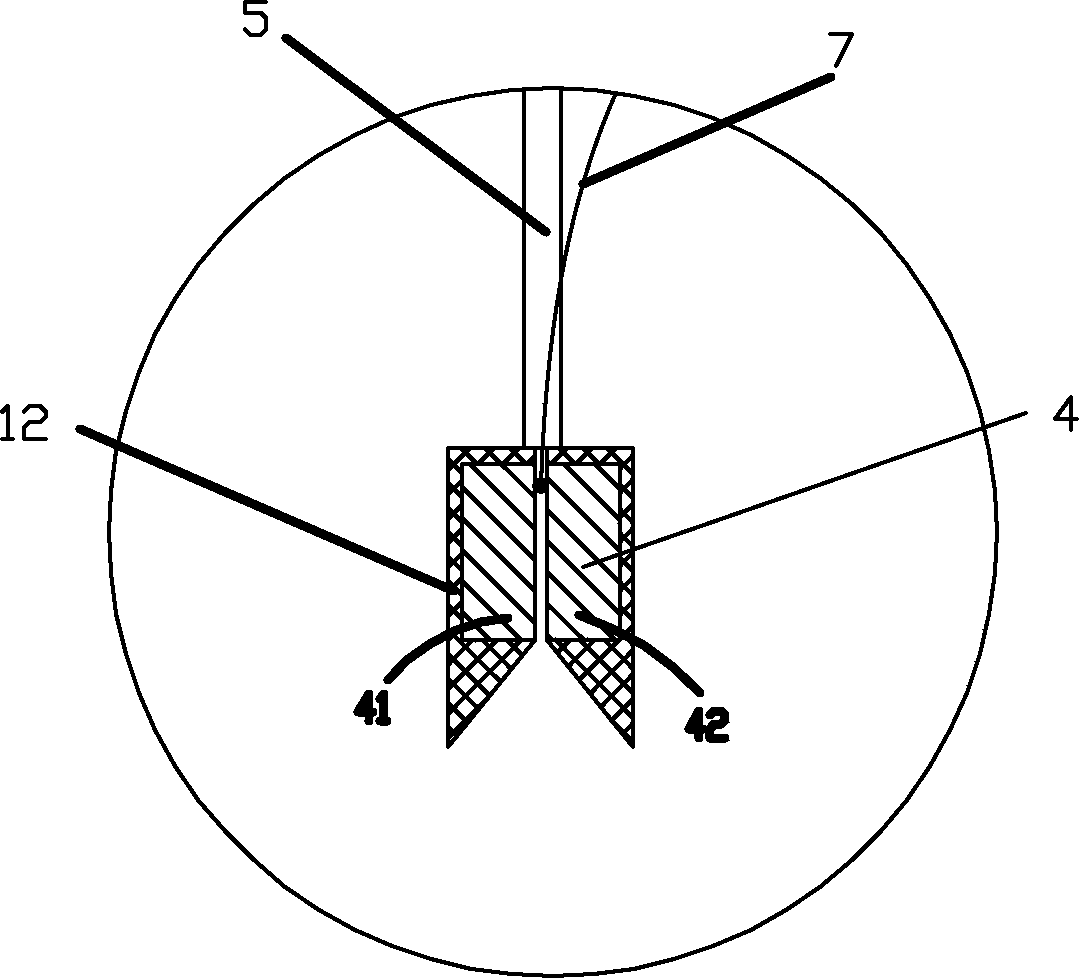

[0040] The cooling mold of the present invention is composed of two cooling molds (copper blocks) with a certain gap in the middle, and the gap distance is 2.5 mm, which is used to simulate the roll gap of the thin strip continuous casting crystallization roll. A temperature-measuring thermocouple is installed in the gap between the two cooling molds, and the graduation number of the thermocouple is S-type. When the molten steel solidifies in the gap of the cooling mold, the thermocouple can be directly covered and embedded in the solidified sample, and the thermocouple is connected with the data acquisition system. , the temperature change of the solidified sample can be monitored during the experiment. The two cooling molds (copper blocks) can be separated quickly. Except for the inner surface in contact with the molten steel, the other sides and bottom surfaces of the cooling mold are covered with heat-insulating refractory materials. The refractory material is alumina to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com