Patents

Literature

38results about How to "Guaranteed air tightness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for actively sealing sapphire sheet and metal

ActiveCN103949742AGuaranteed wall thicknessReduce the chance of burstingSoldering apparatusThermal dilatationTitanium zirconium

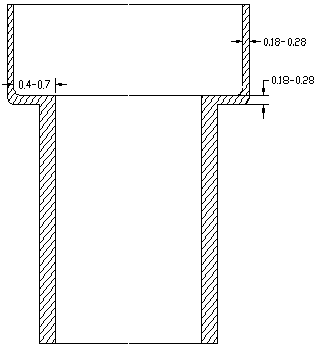

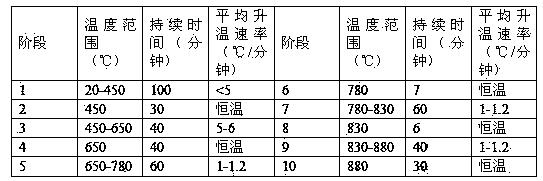

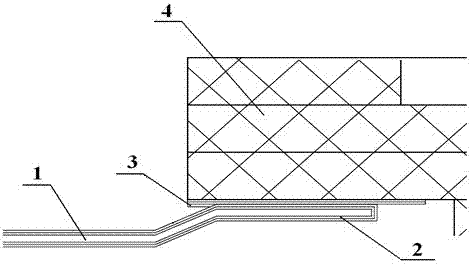

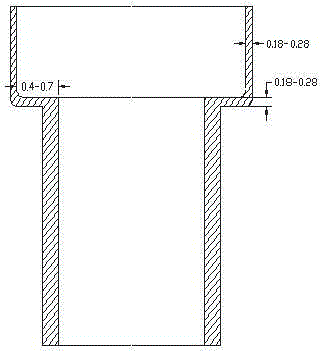

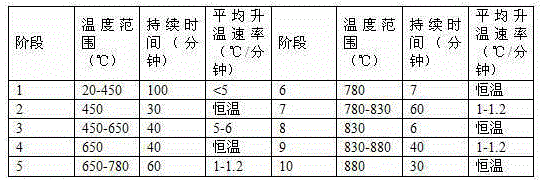

The invention provides a method for actively sealing a sapphire sheet and metal. The method is low in welding temperature, high in efficiency, good in reliability and low in cost. According to the method, high-temperature metallization is not required, expensive vacuum coating equipment and precious metal targets are also not required, the defects of long intermediate treatment process and time consumption are overcome, the total welding time is shortened, and the production efficiency is improved; the defect that flatness with high precise size and demanding requirement is required to be machined when welding sheets are adopted is avoided, and active titanium, zirconium, copper and nickel welding flux is directly adopted; the thickness of the wall of the sealing part of a metal piece is small, so that the thermal stress effect caused by the reaction of extrusion to the metal piece by the thermal expansion of the sapphire sheet during welding is reduced, and the probability of explosion of the sapphire sheet is reduced; meanwhile, welding can be accomplished at one step when the vacuum atmosphere temperature is lower than 1000 DEG C, the requirement on welding equipment is low, the product welding reliability and the yield are high, the air impermeability is good when baking is performed at the high temperature of 560 DEG C for 36 hours, and the requirement on the air impermeability of ultrahigh frequency electron tubes can be guaranteed.

Owner:XI AN JIAOTONG UNIV +1

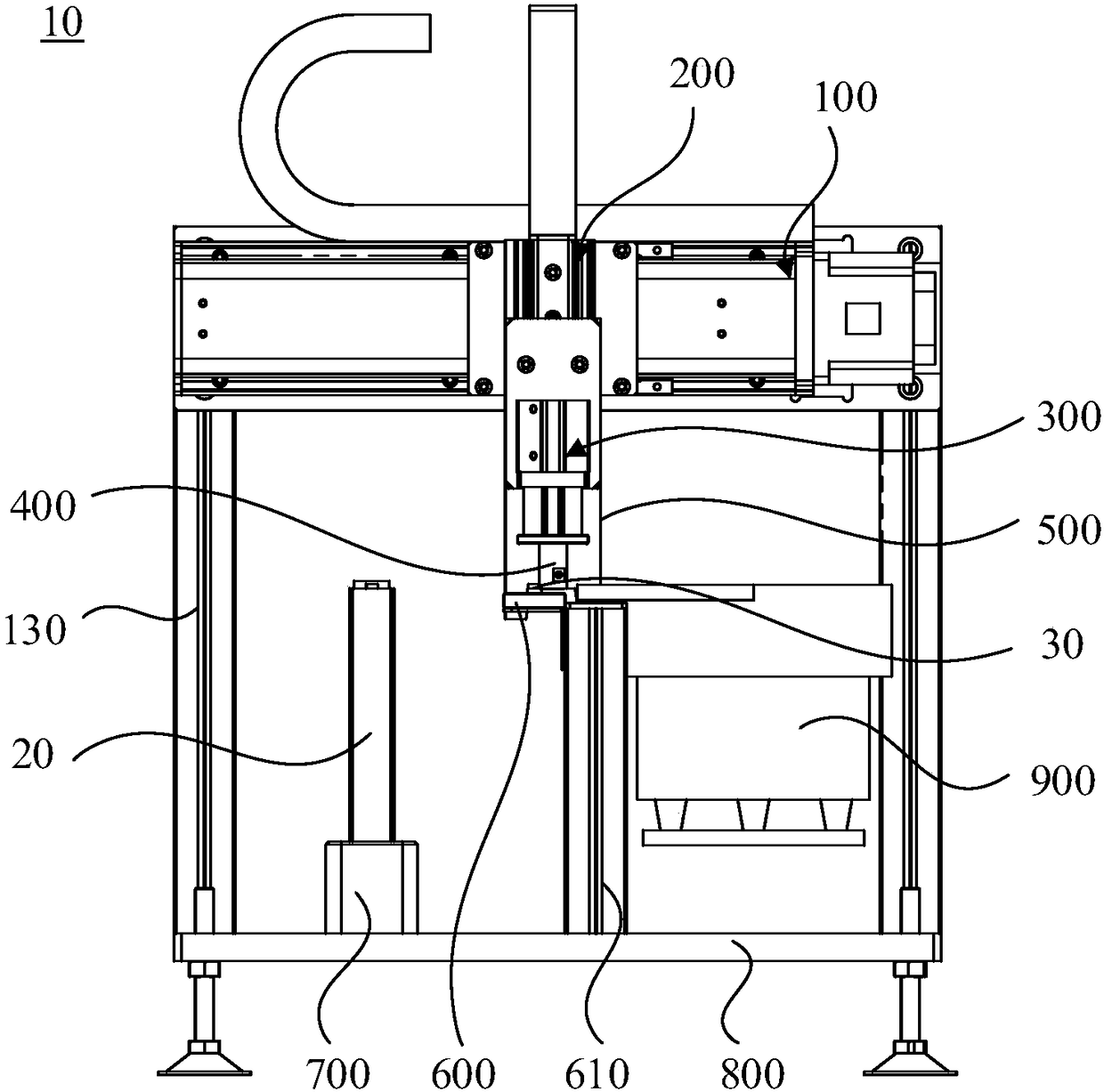

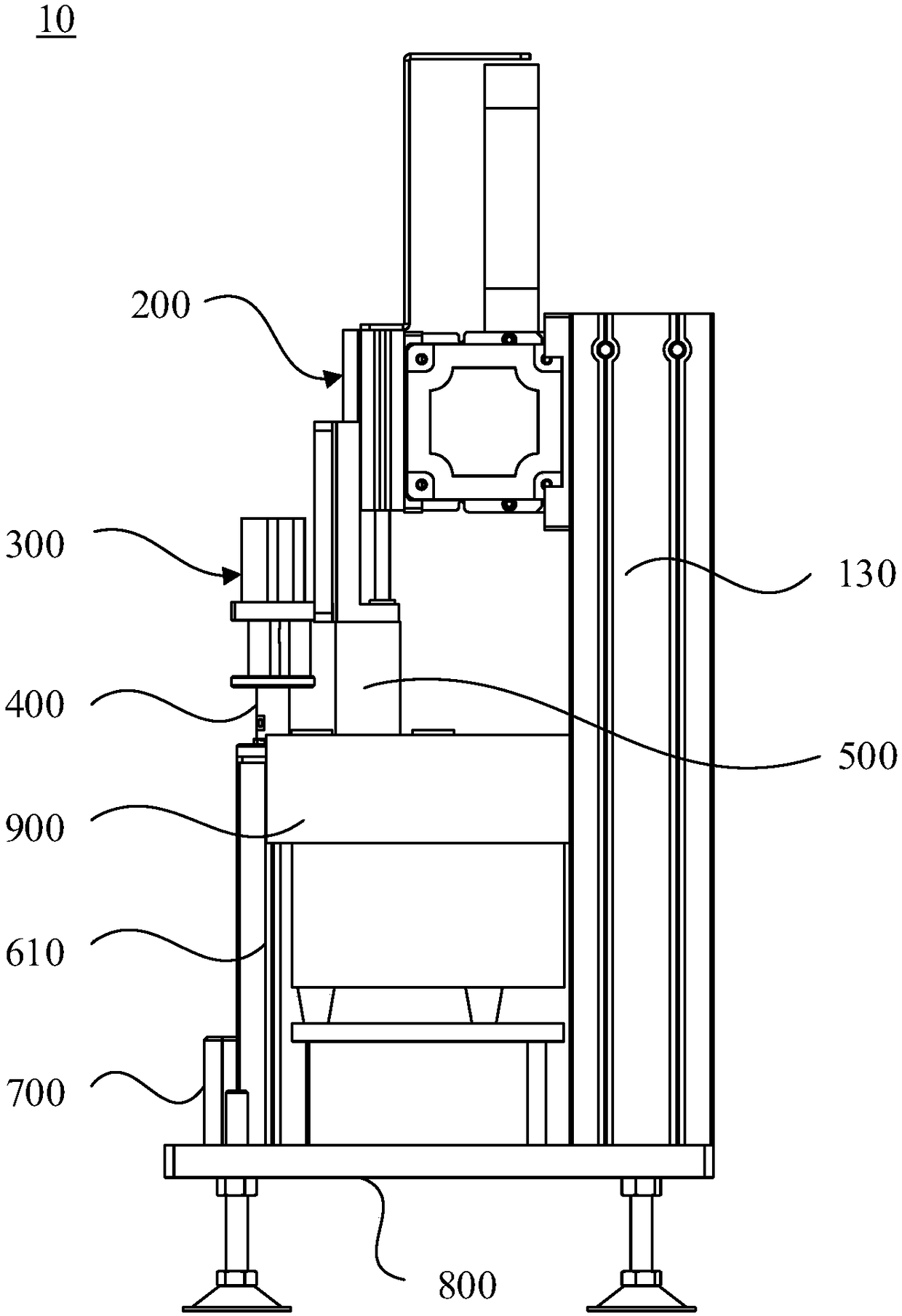

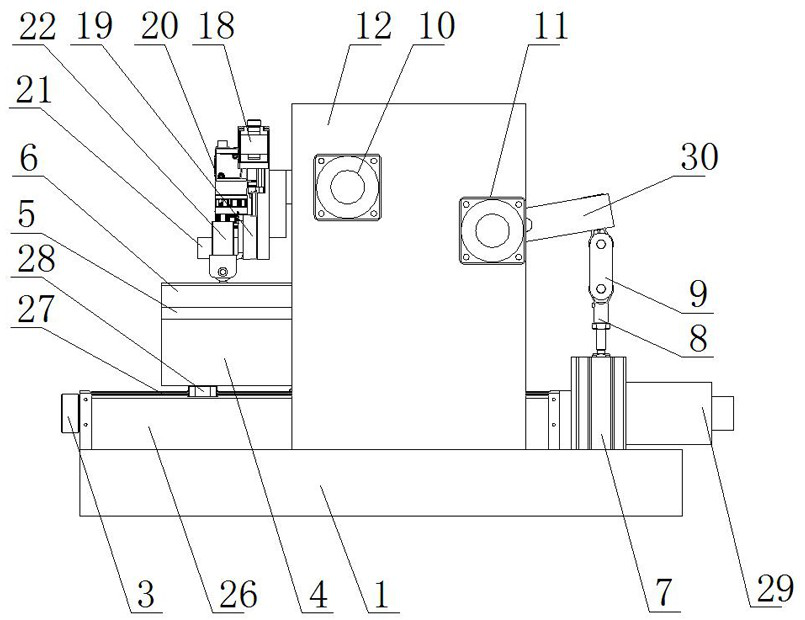

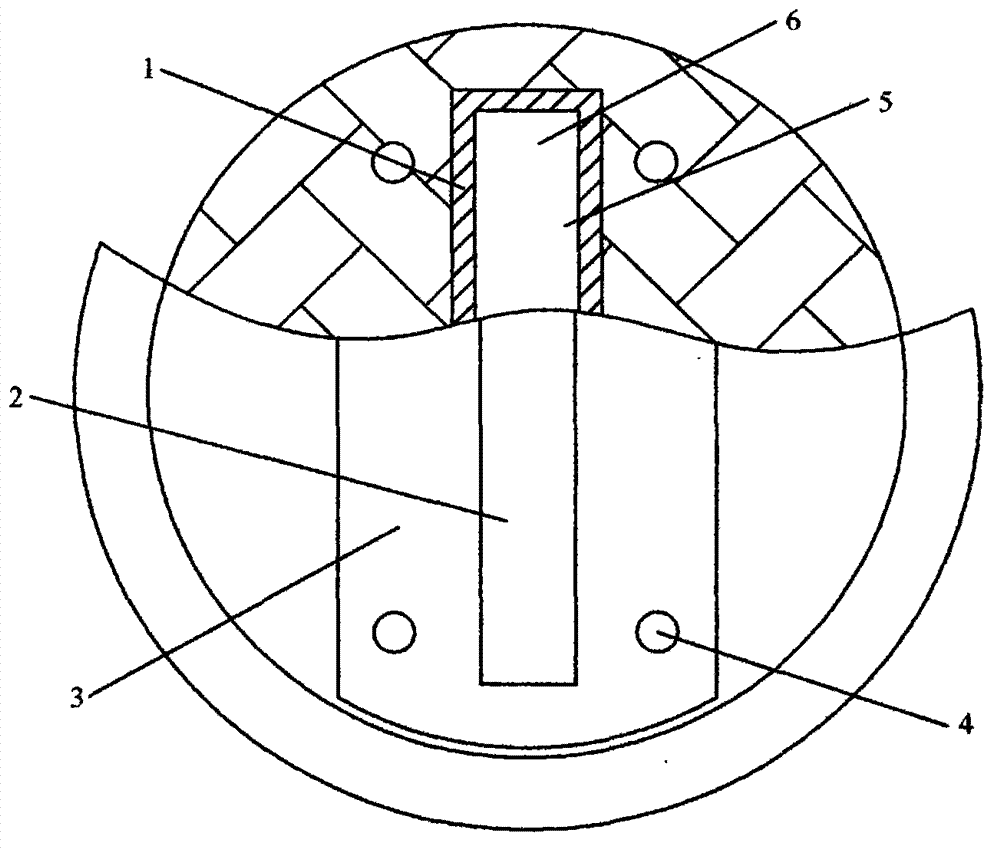

Nailing apparatus

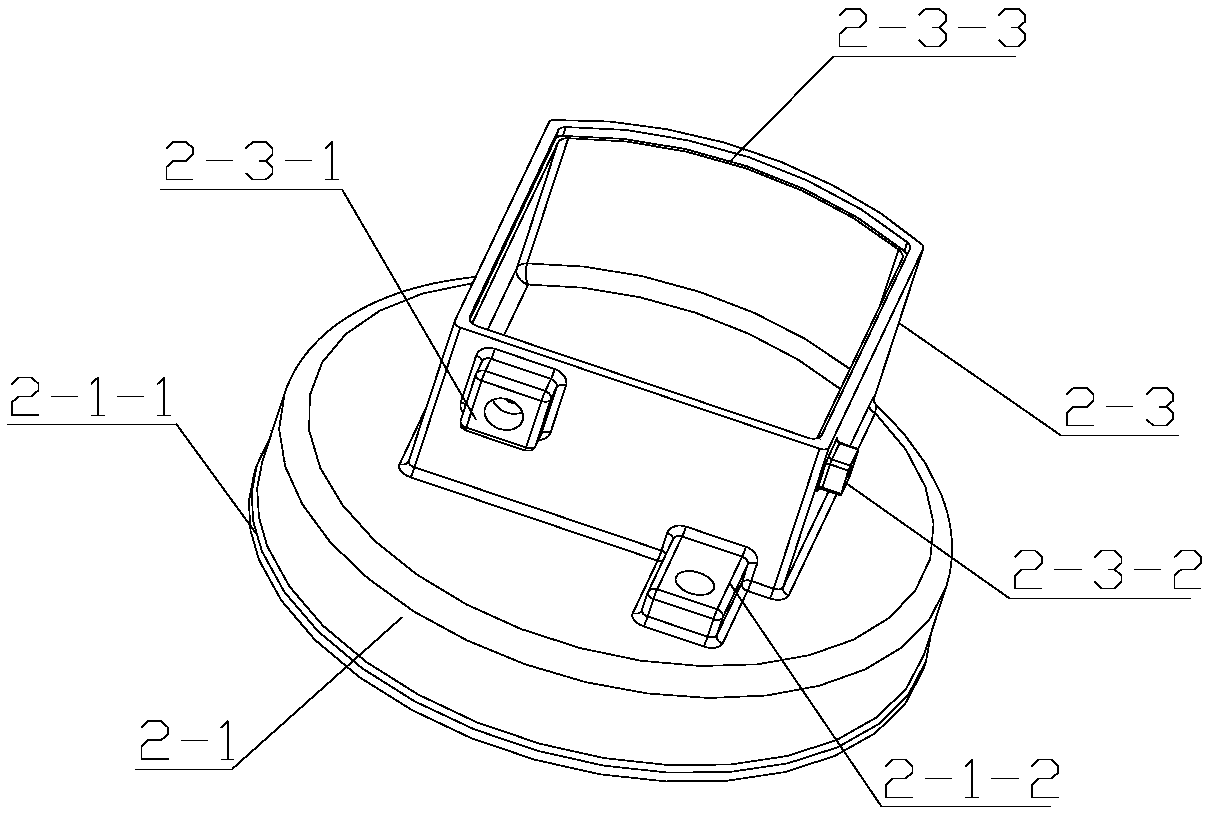

PendingCN108400279ASimple structureGuaranteed air tightness requirementsFinal product manufactureLi-accumulatorsEngineeringMoving parts

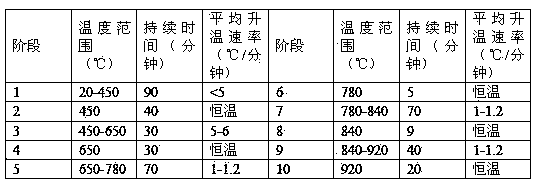

The invention relates to a nailing apparatus used for a sealing operation of a plastic nail of a lithium battery. The nailing apparatus comprises a moving assembly, a lifting assembly, a nailing assembly and a sealing assembly; the moving assembly comprises a first traction part and a sliding-moving part; the lifting assembly comprises a second traction part and a connecting piece; the nailing assembly comprises a third traction part and a material taking part used for drawing the plastic nail; the sealing assembly is fixedly connected to the third traction part; a sliding channel connected with an electrolyte injection opening of the lithium battery is formed in the sealing assembly to perform vacuumizing and protection gas inflating of the lithium battery, wherein the extension directionof the sliding channel is the same as the second direction; and the material taking part is connected with the sealing assembly in a sealing manner, and the third traction part can drive the materialtaking part to move in the sliding channel in the second direction. According to the nailing apparatus, high sealing of the electrolyte injection opening of the lithium battery is formed through thesealing assembly, and the plastic nail is pressed into the electrolyte injection opening when the electrolyte injection opening is sealed by the sealing assembly, so that the structure of processing equipment is simplified.

Owner:SHENZHEN BROTHERS AUTOMATION TECH CO LTD

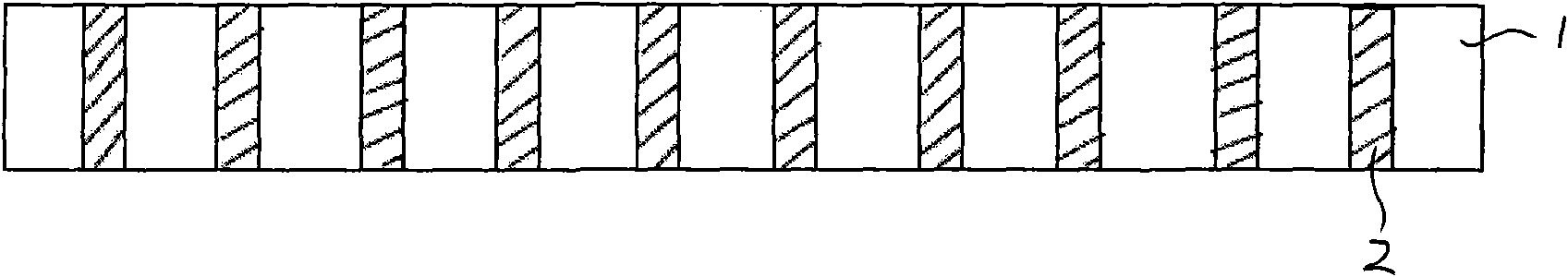

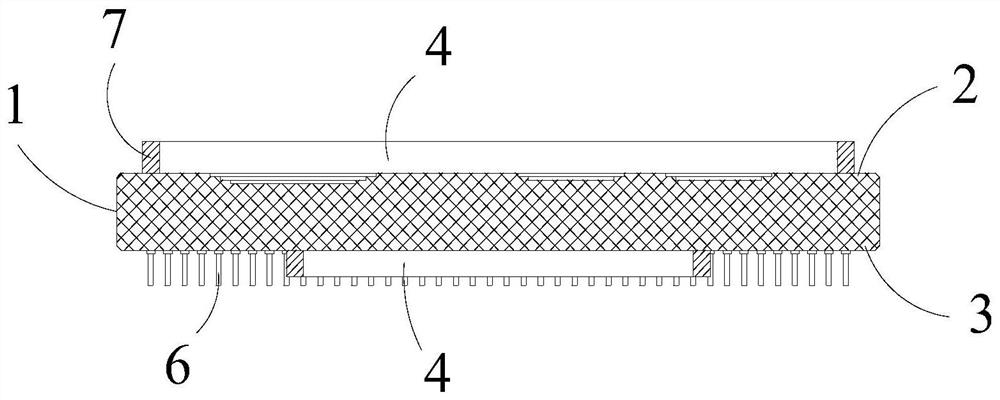

Tungsten and molybdenum copper alloy heat sink material and preparation method

The invention relates to improvement on a tungsten and molybdenum copper alloy heat sink material, which is characterized in that: a plurality of Z-direction through holes are formed on a tungsten copper alloy plate, and copper cores which are level with two surfaces of the plate are riveted into the through holes, so that the coefficient of linear expansion of the heat sink material is between 6 an 8 ppm / DEG C, and compared with the heat sink material on which the copper cores are not riveted, the heat conductivity of the heat sink material is at least increased by over 10 percent. Compared with the heat sink material on which the copper cores are not riveted, the Z-direction heat conductivity is improved greatly, and the heat of an encapsulation internal surface of a substrate can be conducted to an encapsulation external surface quickly, so that the heat is dispersed quickly; compared with the heat sink material on which the copper cores are not riveted, the heat conductivity of the heat sink material is at least increased by over 10 percent, so the heat sink material is favorable for realizing the miniaturization and high power of miniaturization devices; and a riveting form for forming core columns can ensure gas tightness, and the leakage rate of sample tests is less than or equal to 5*10<9>Pa / m<3> / s. The tungsten and molybdenum copper alloy heat sink material has a simple preparation method, and can realize industrial production.

Owner:JIANGSU DINGQI SCI & TECH

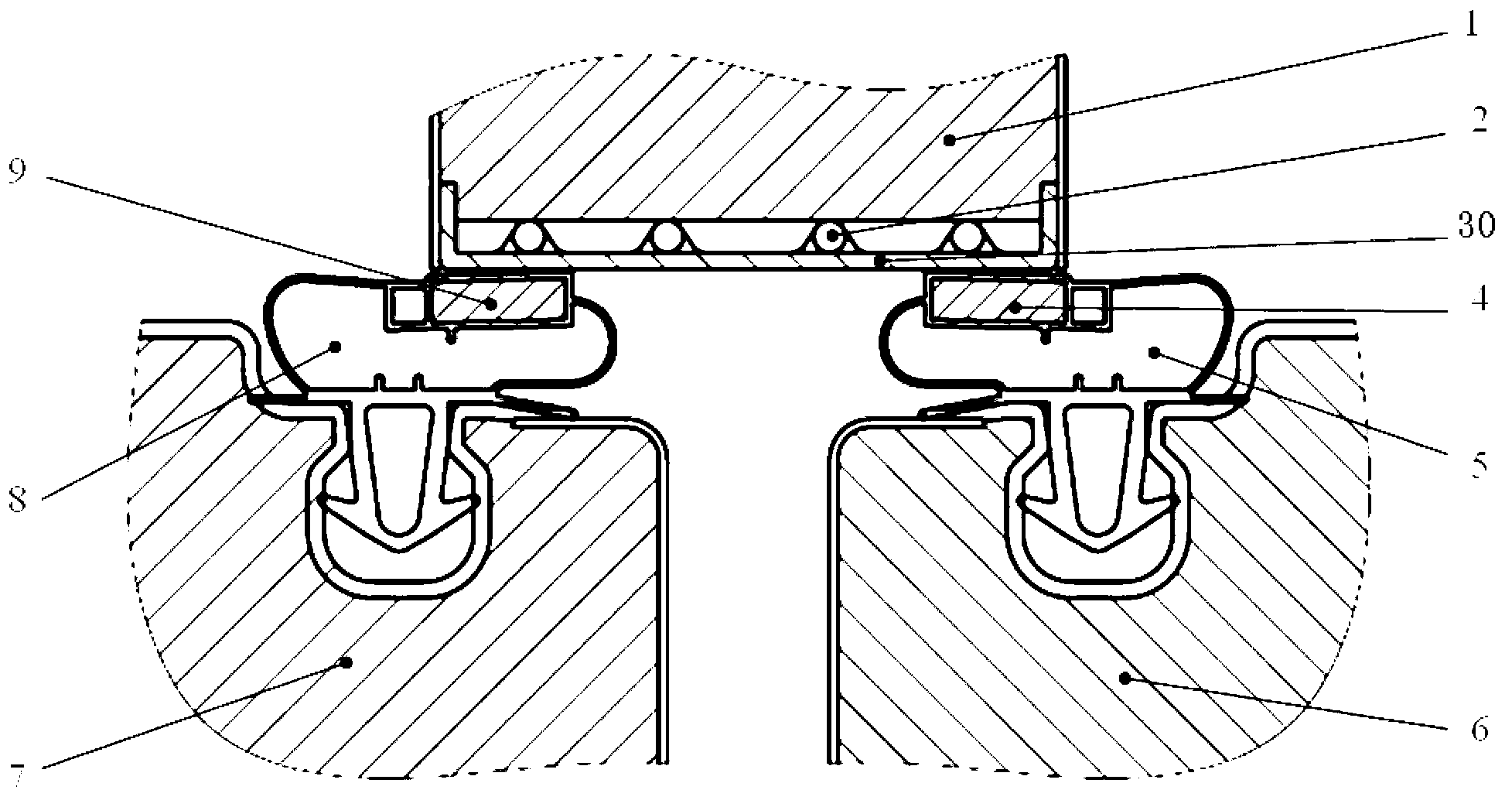

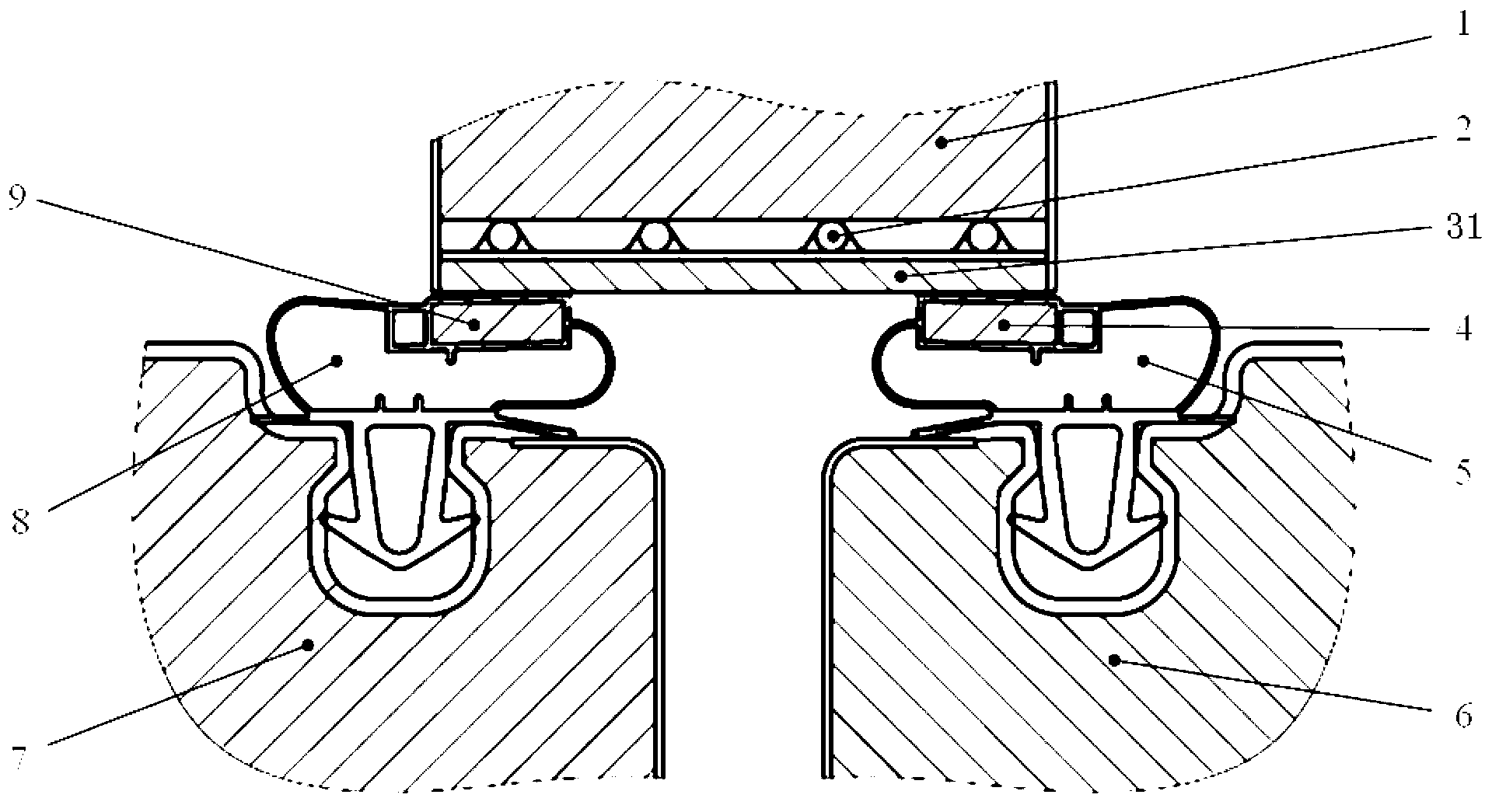

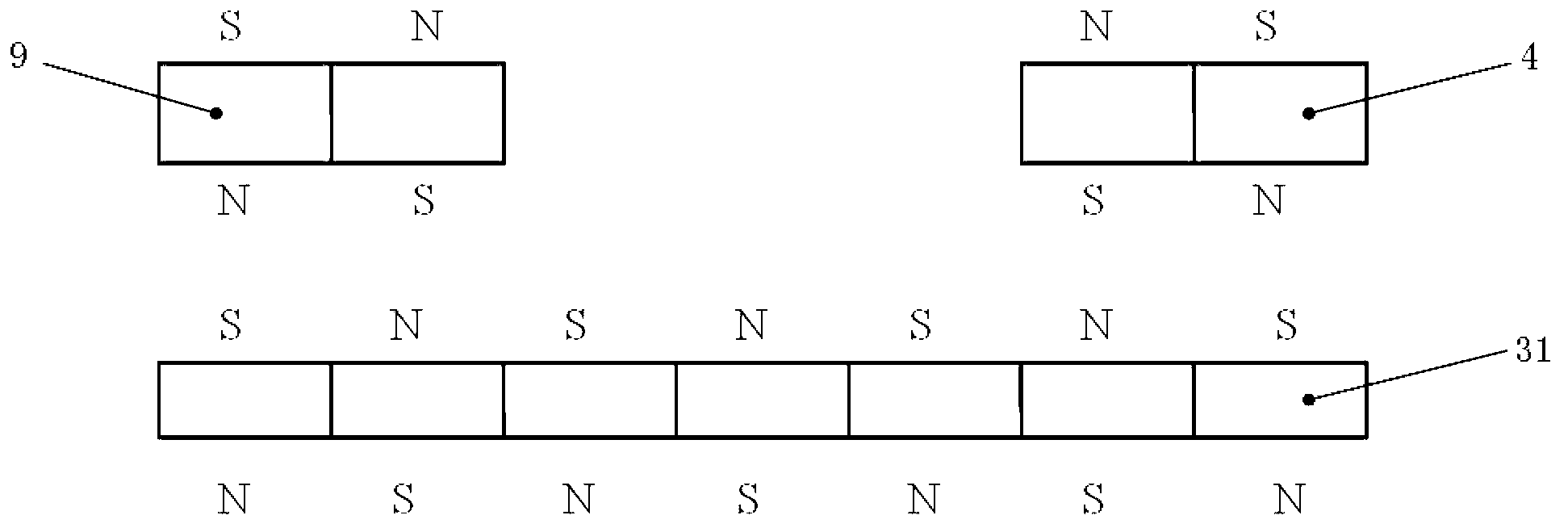

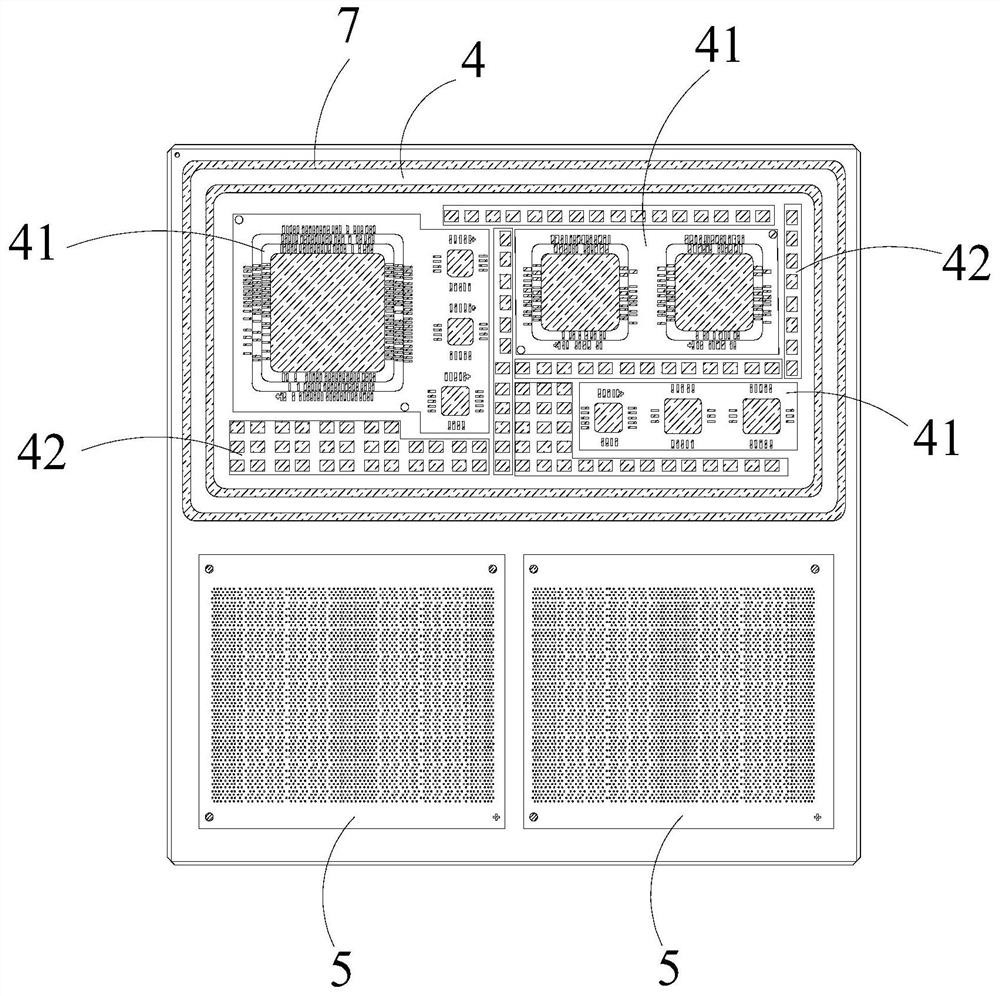

Refrigeration longitudinal beam of side-by-side combination refrigerator and side-by-side combination refrigerator

ActiveCN103185445AGuaranteed air tightness requirementsLow powerDomestic cooling apparatusLighting and heating apparatusIceboxCool storage

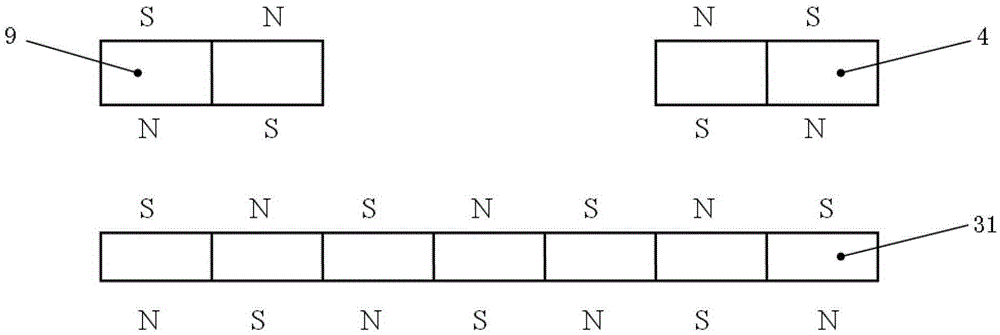

The invention belongs to the technical field of electrical equipment and particularly relates to a refrigeration longitudinal beam of a side-by-side combination refrigerator and the side-by-side combination refrigerator with the same. The refrigeration longitudinal beam comprises a longitudinal beam body sucked with left and right door seal magnetic strips; the longitudinal beam body is a plastic beam body; and the surface of the longitudinal beam body is covered with a magnetic plastic layer. The magnetic plastic layer is provided with a plurality of pairs of magnetic poles, so that the refrigeration longitudinal beam can be automatically sucked with door seals on both sides when doors are closed, and have good airtightness. Due to poor thermal conductivity and weak cold accumulation capacity of plastic, when the plastic is used as the surface material of the longitudinal beam, cold energy adsorbed from the refrigerator is less than that adsorbed when a steel plate is used as the surface material, the surface temperature is also relatively high and the refrigeration longitudinal beam has the advantages of good heat preservation effect, light weight, corrosion resistance and difficulty in generating condensation on the surface.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

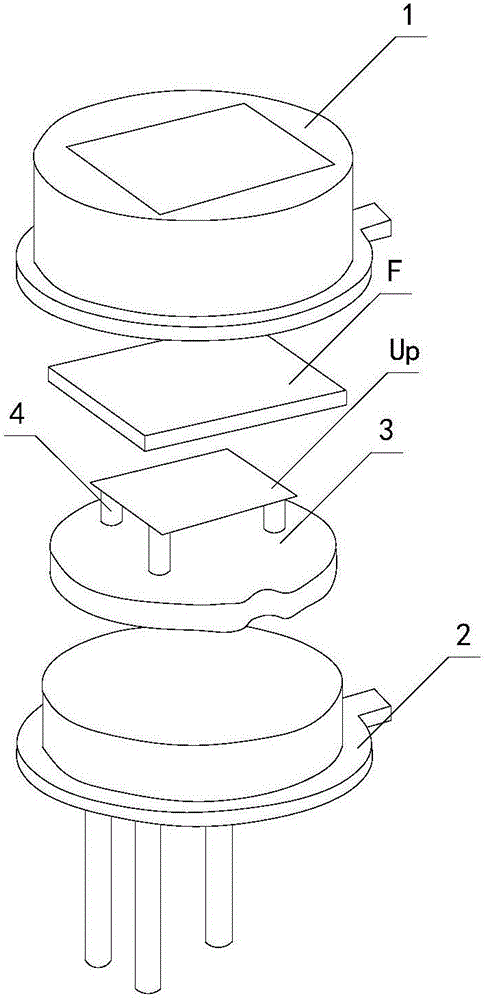

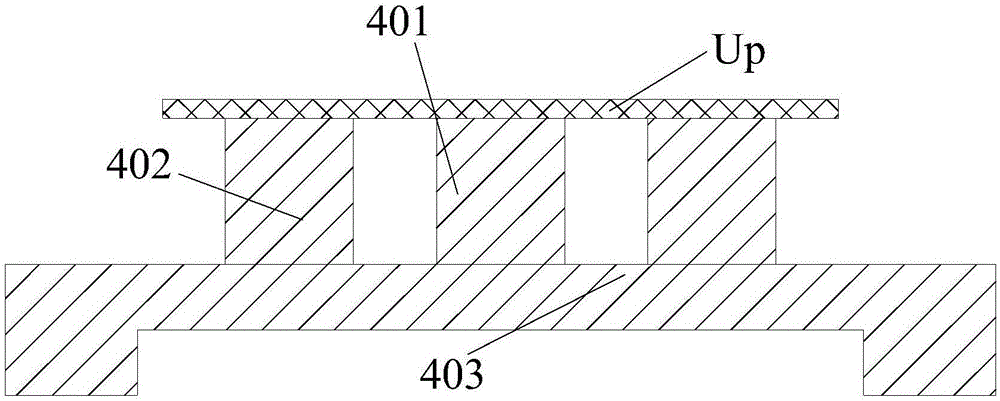

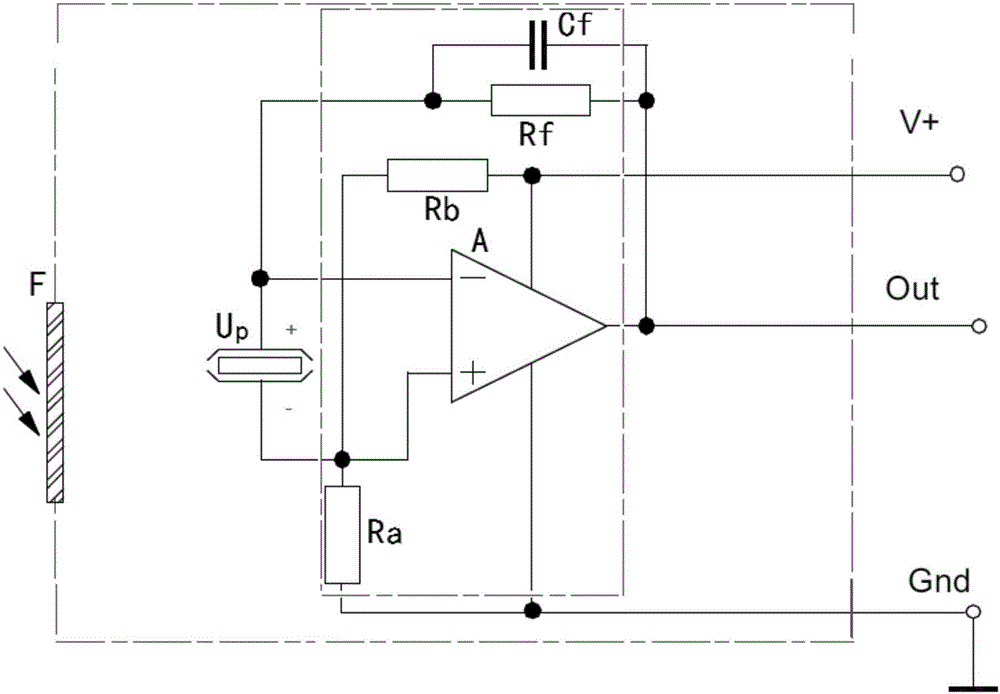

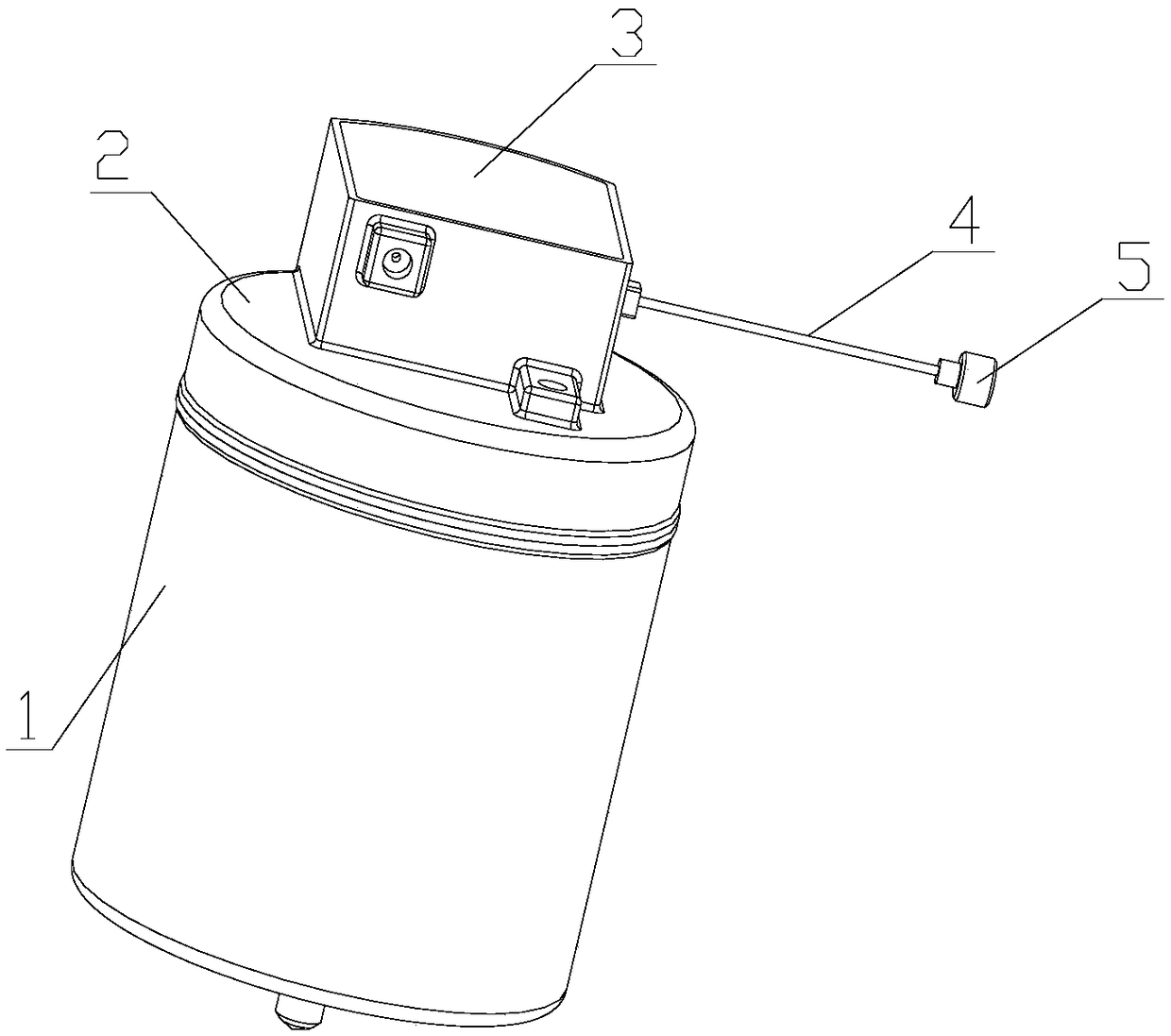

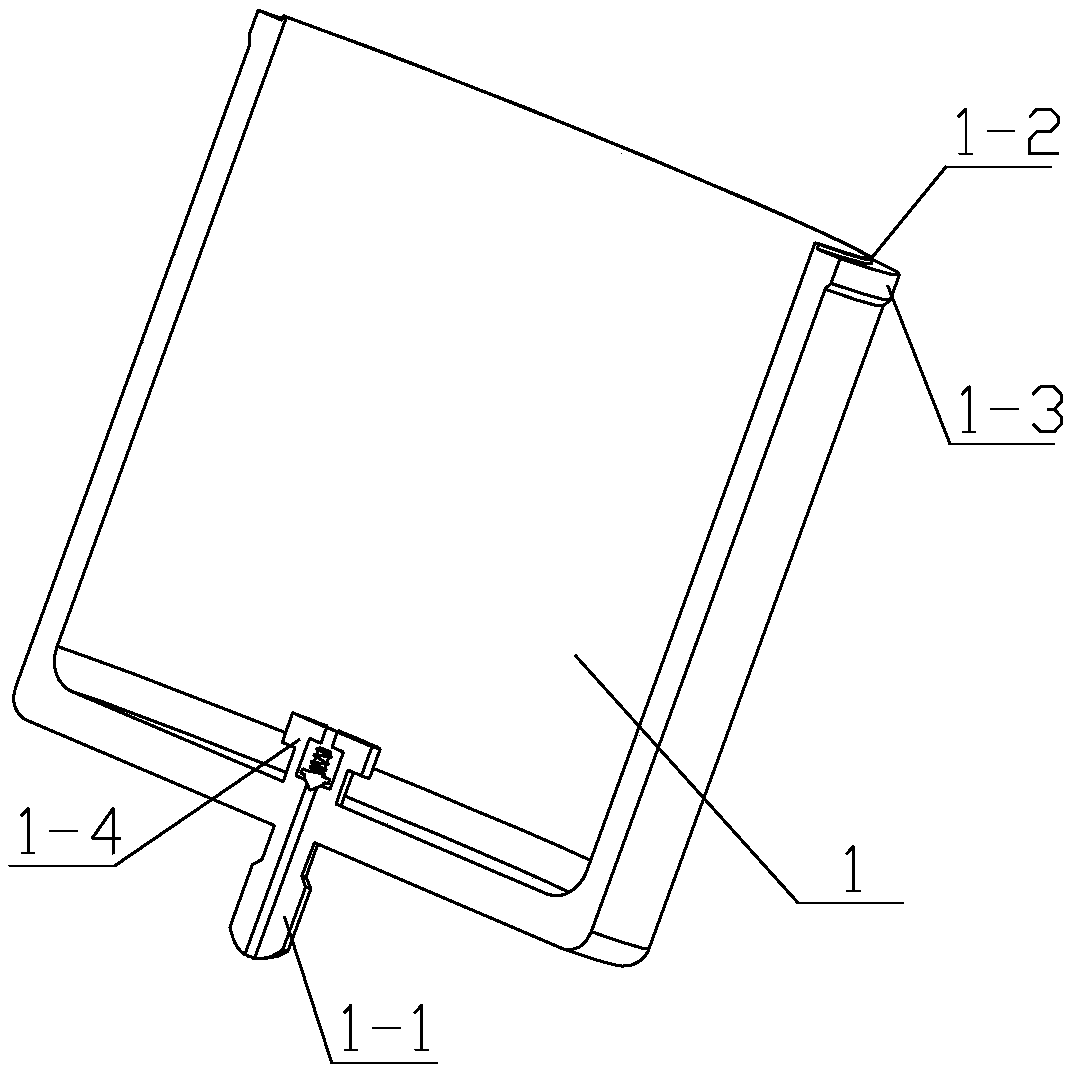

Pyroelectric detector based on current type relaxor ferroelectric single crystal and preparing method thereof

InactiveCN106768389AQuick responseStrong ability to resist external noise interferencePyrometry using electric radation detectorsPyroelectric detectorsSingle crystal

The invention relates to a pyroelectric detector based on current type relaxor ferroelectric single crystal. The pyroelectric detector comprises a hollow packaging tube shell, an optical filter, a sensitive element chip Up and a line substrate. The packaging tube shell comprises a tube cap and a base, the optical filter is embedded in a window formed in the upper surface of the tube cap, the lower end of the tube cap is fixedly connected with the base and forms a hollow seal structure with the base, the line substrate is arranged on the base and located in the seal structure, a suspension supporting frame is arranged on the line substrate, and the sensitive element chip Up is arranged on the upper surface of the suspension supporting frame and located under the optical filter; a feedback amplifying circuit is arranged on the line substrate, and the sensitive element chip Up is connected between the two input ends of the feedback amplifying circuit through the suspension supporting frame. The current type circuit is adopted, pyroelectric detector is high in capacity for resisting outside noise interference and capable of fast responding outside infrared radiation, and the time of startup preheating and signal stabilizing is shortened.

Owner:北立传感器技术(武汉)有限公司

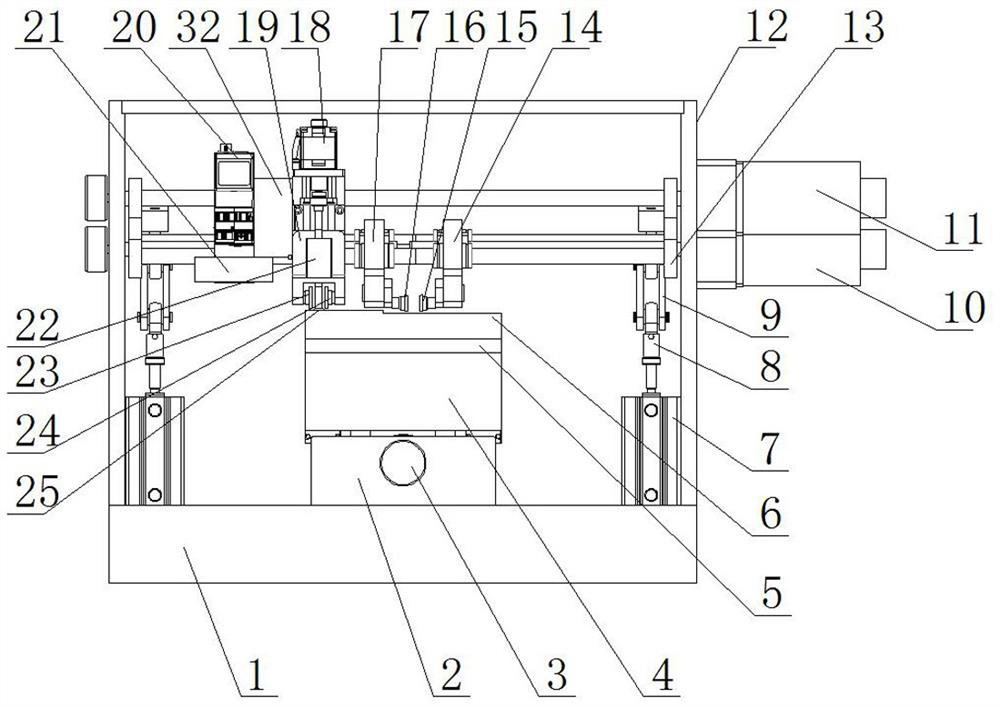

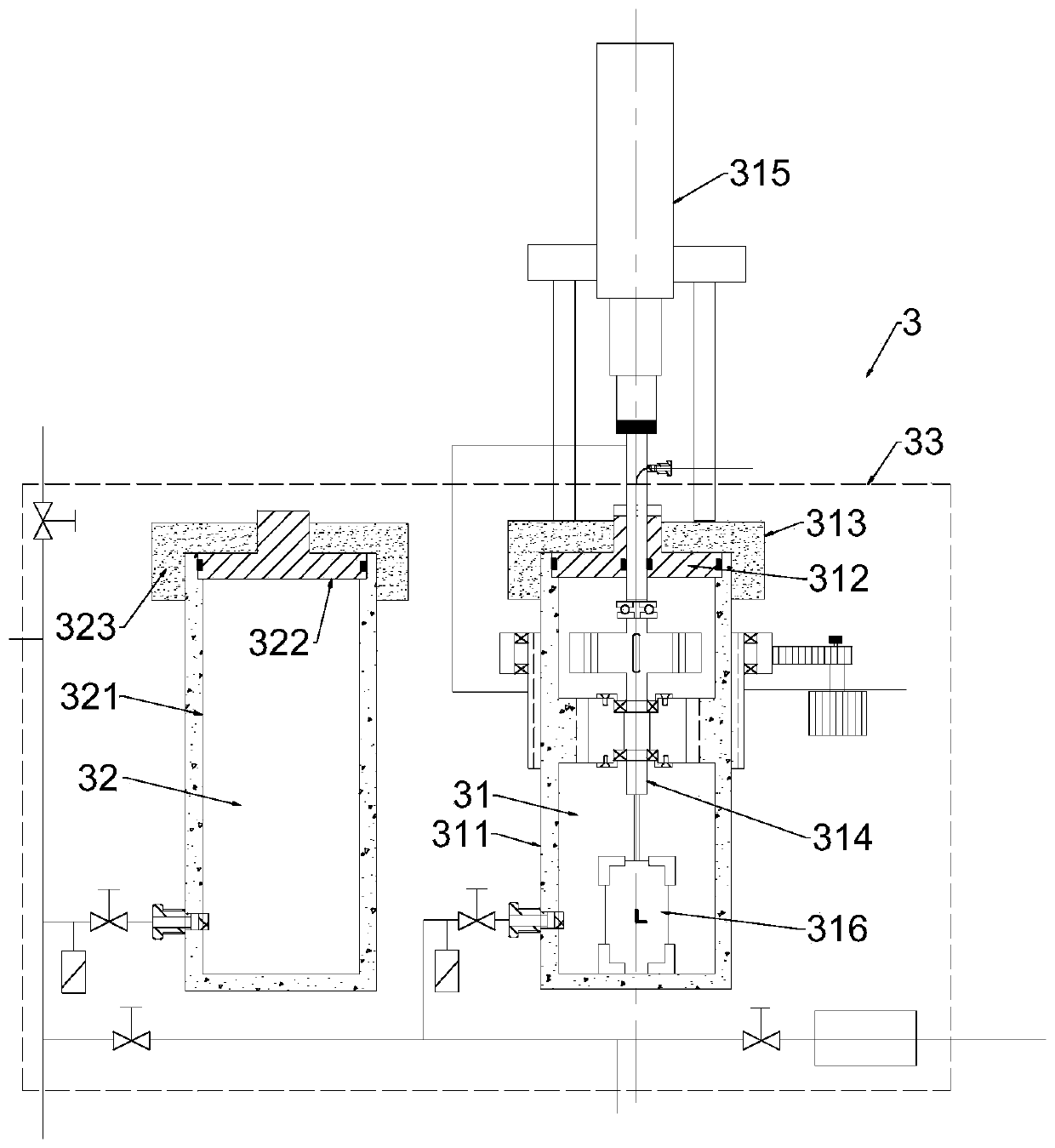

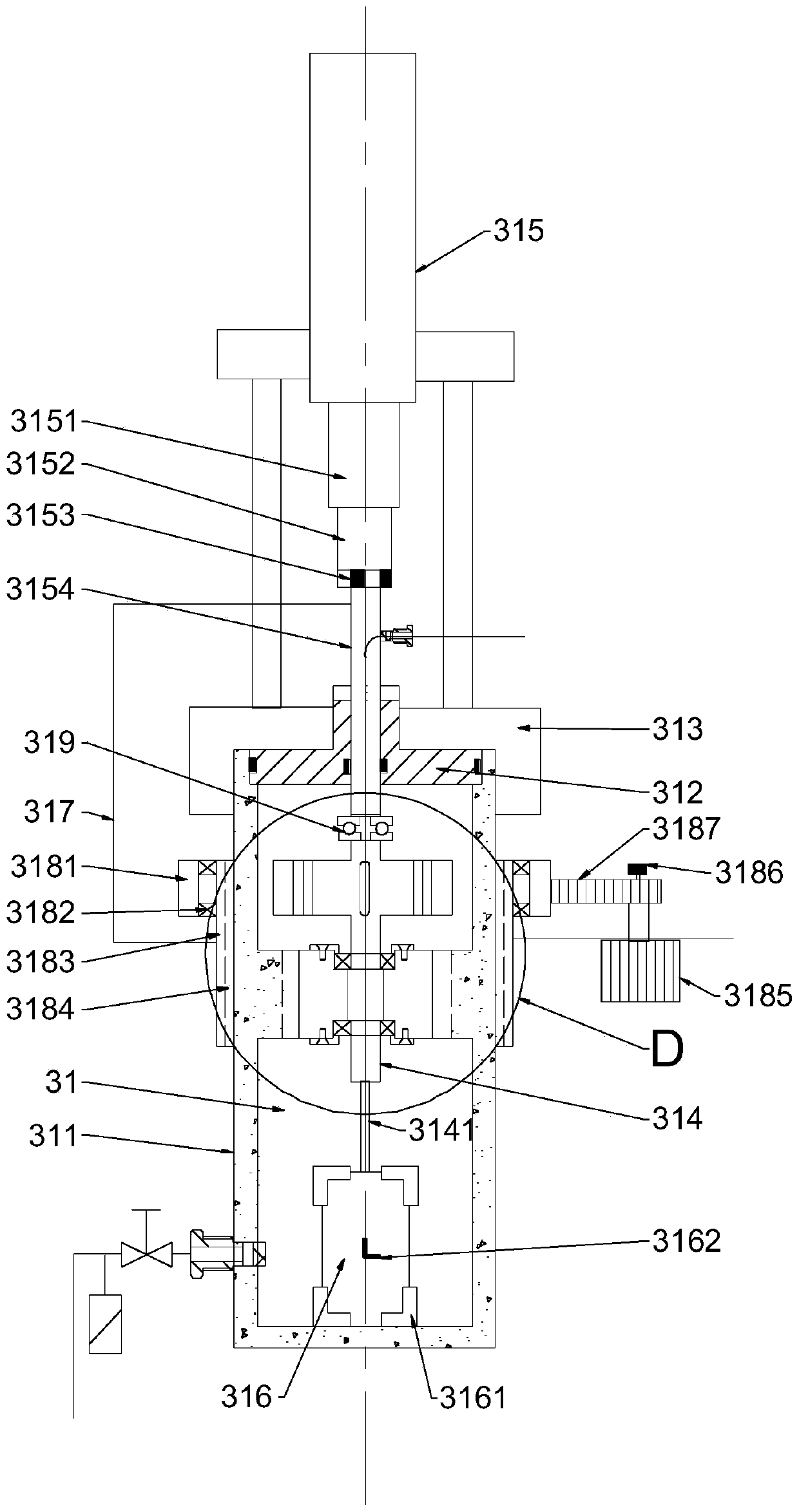

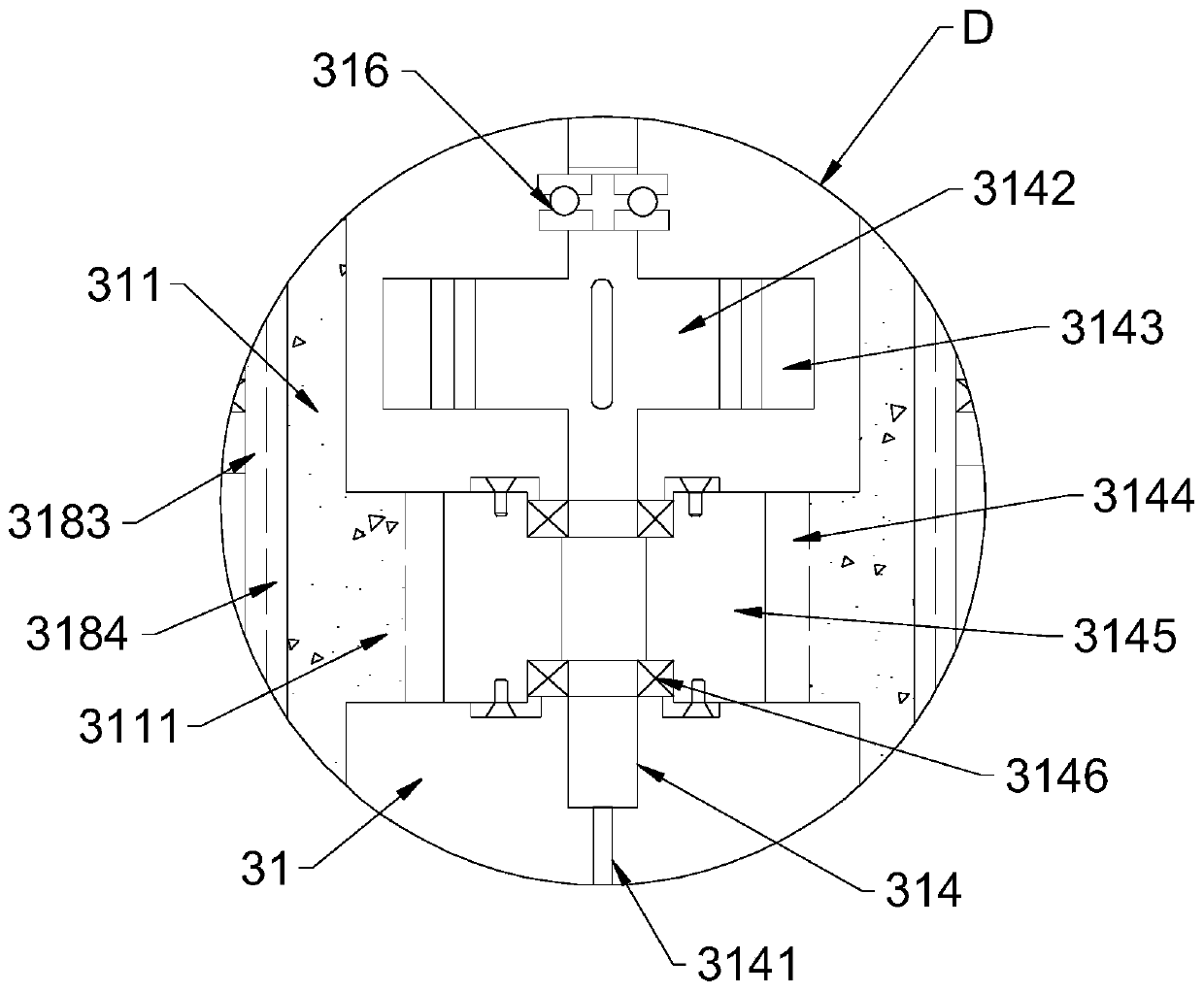

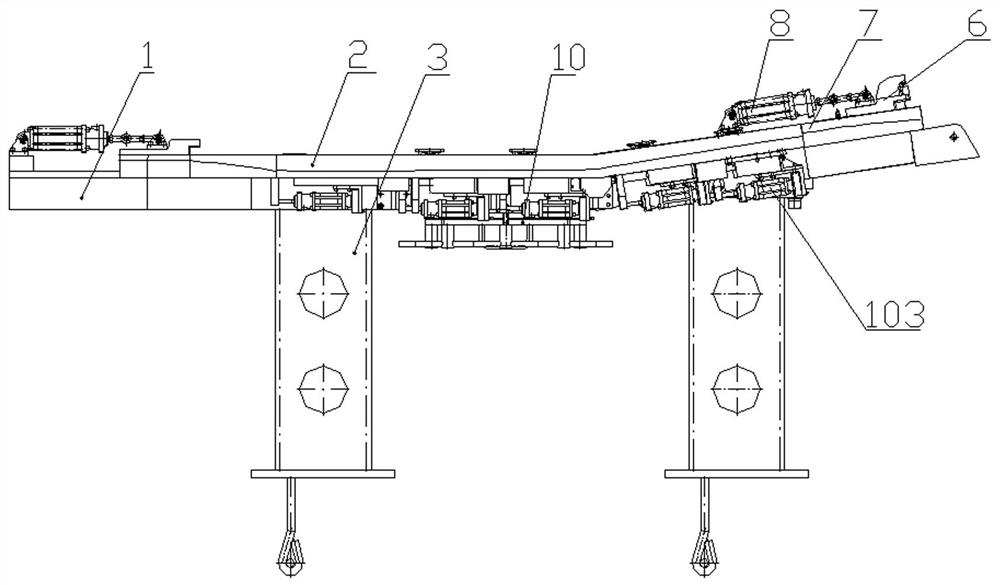

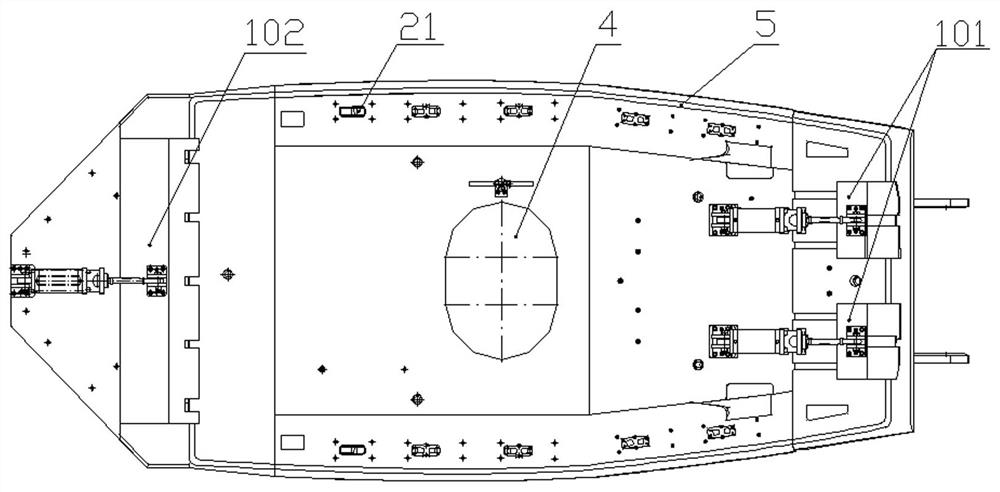

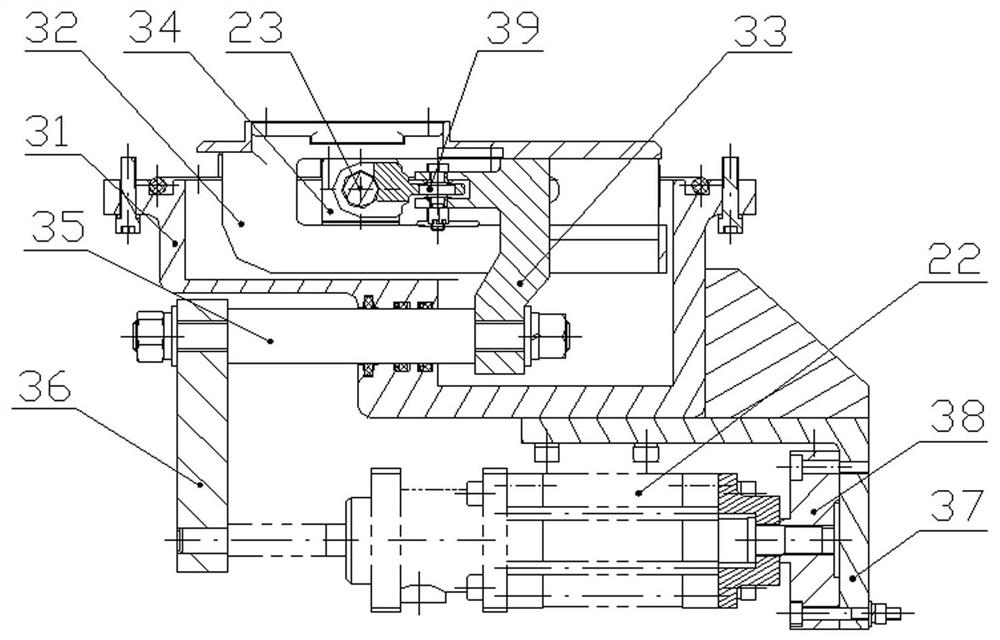

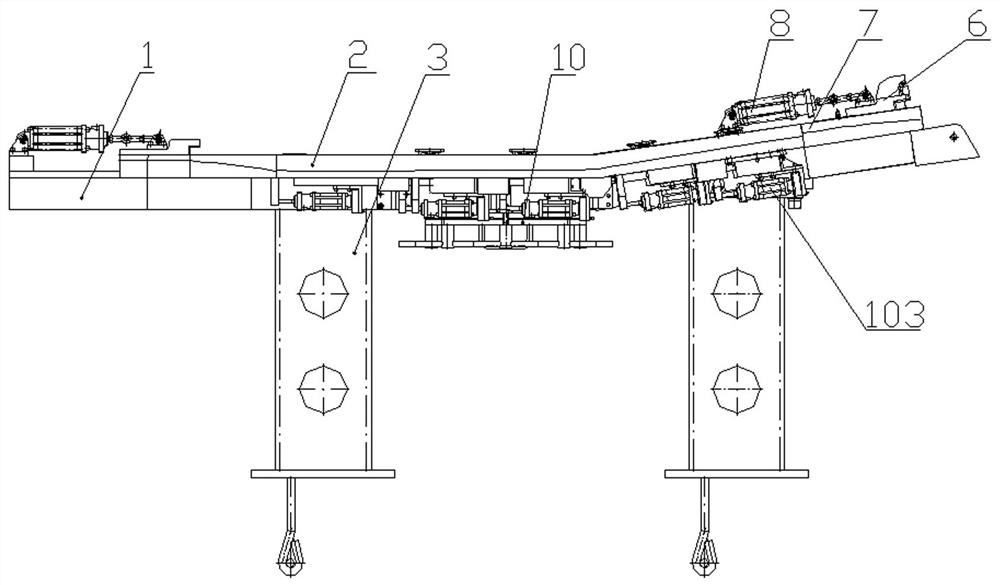

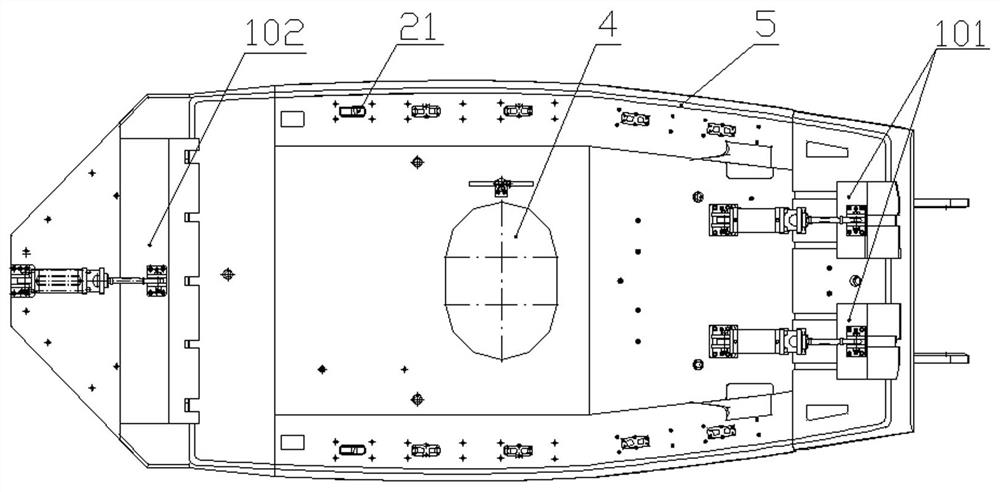

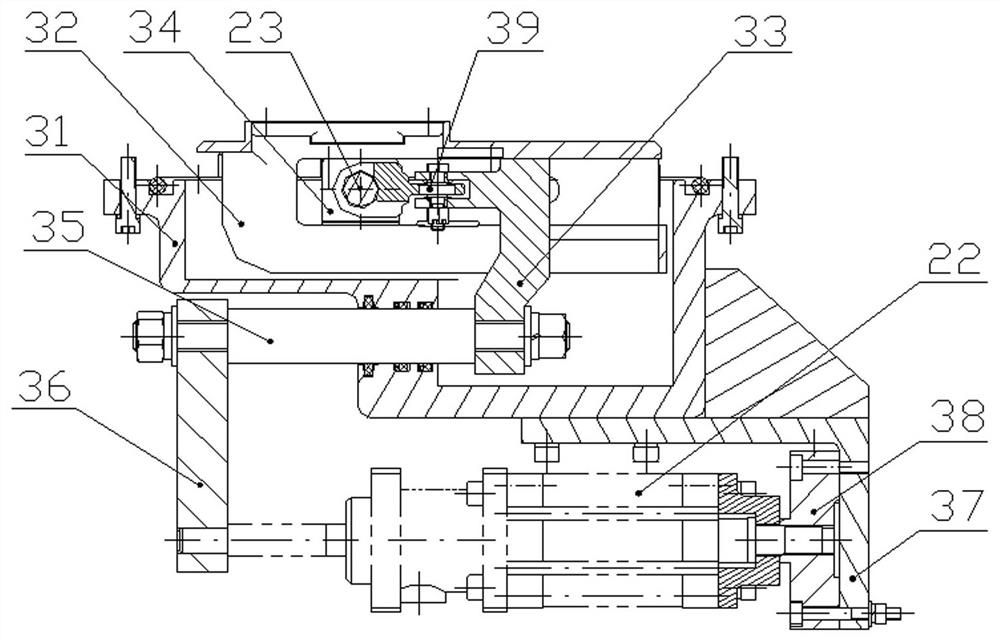

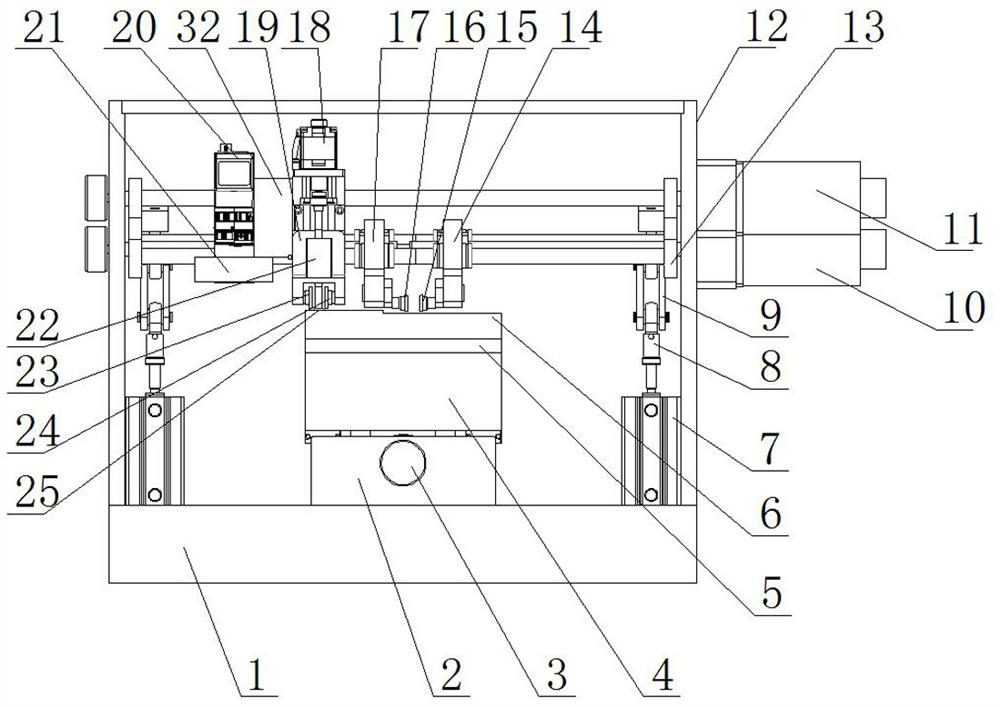

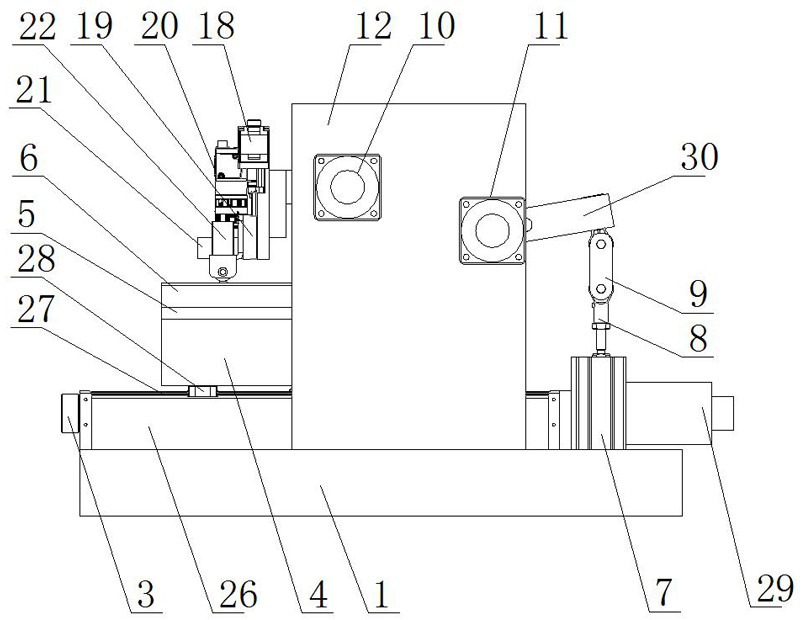

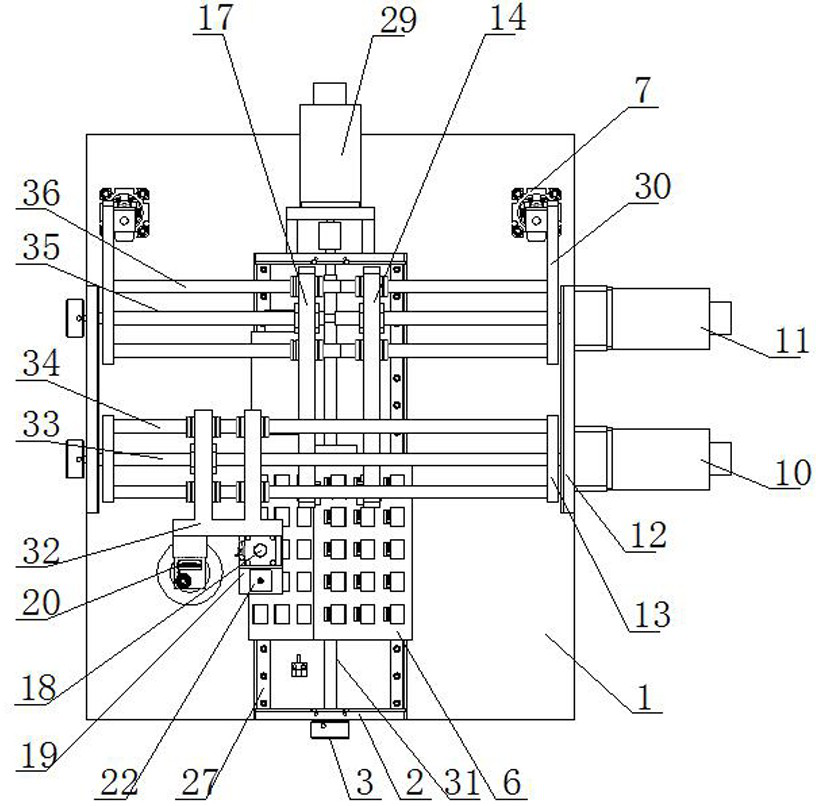

Automatic parallel seal welding device based on image recognition and seal welding method

ActiveCN111730185AAchieve absorptionAchieve releaseCurved planar seam weldingMetal working apparatusControl systemVisual inspection

The invention relates to an automatic parallel seal welding device based on image recognition and a seal welding method, and belongs to the technical field of fine electronic product welding. The automatic parallel seal welding device comprises a baseplate as well as a product tooling positioning mechanism, a spot welding positioning mechanism, a seam welding positioning mechanism, a visual inspection system and a control system, wherein the product tooling positioning mechanism comprises a longitudinal reciprocating moving mechanism and a rotating mechanism; the longitudinal reciprocating moving mechanism is mounted on the baseplate; the rotating mechanism is mounted on the longitudinal reciprocating moving mechanism; a product tooling is mounted on the rotating mechanism; two parallelly-arranged rack vertical plates are mounted on the baseplate; the spot welding positioning mechanism and the seam welding positioning mechanism are both mounted on the rack vertical plates; spot weldingelectrode wheels are mounted on the spot welding positioning mechanism; seam welding electrode wheels are mounted on the seam welding positioning mechanism; and the visual inspection system is mounted on the spot welding positioning mechanism. The automatic parallel seal welding device is utilized for solving the technical problem that during the seal welding process in the prior art, the degreeof automation is low, the production efficiency is low, the product air-tightness is poor, and the appearance quality is poor.

Owner:烟台华创智能装备有限公司

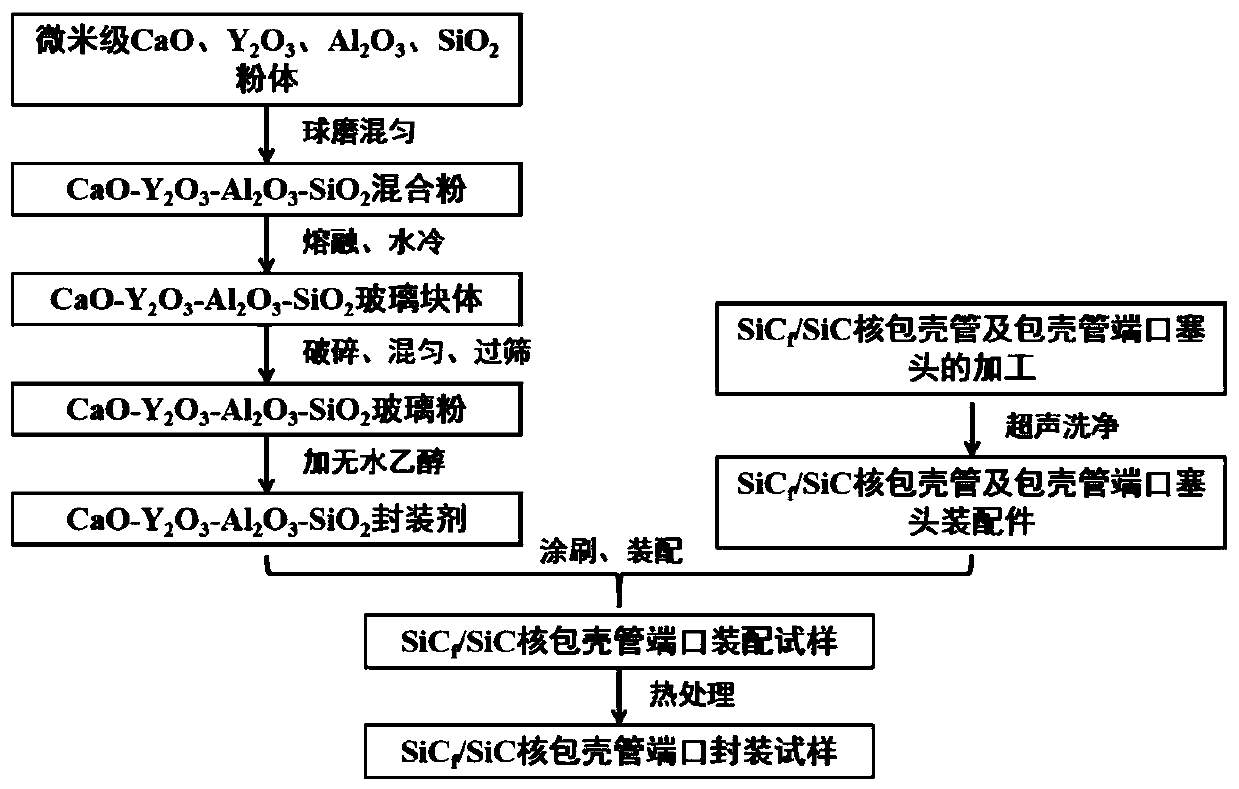

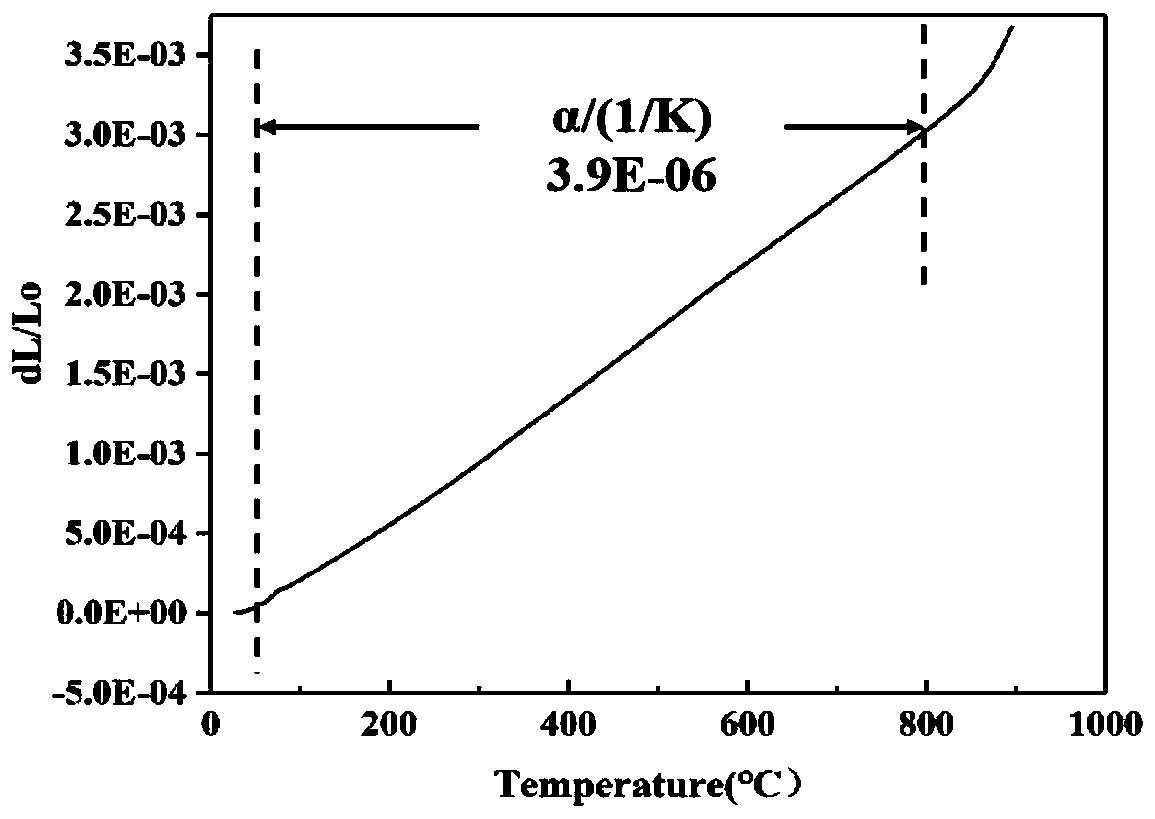

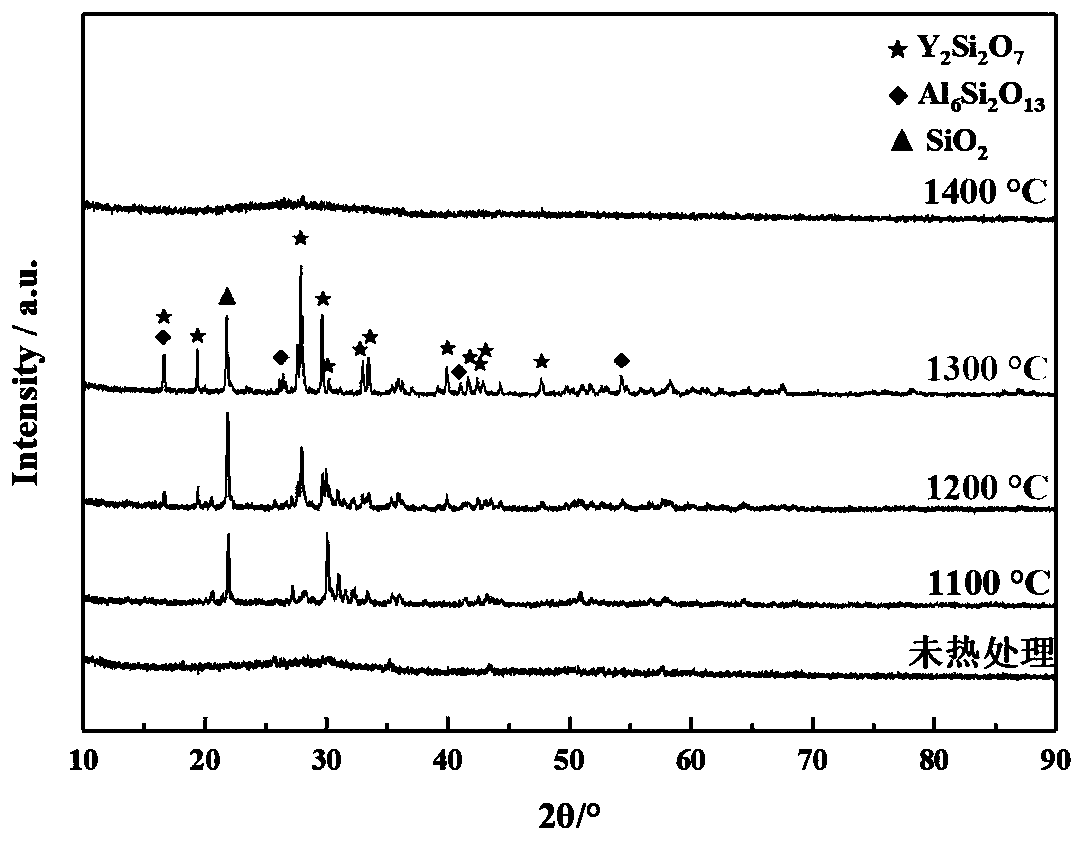

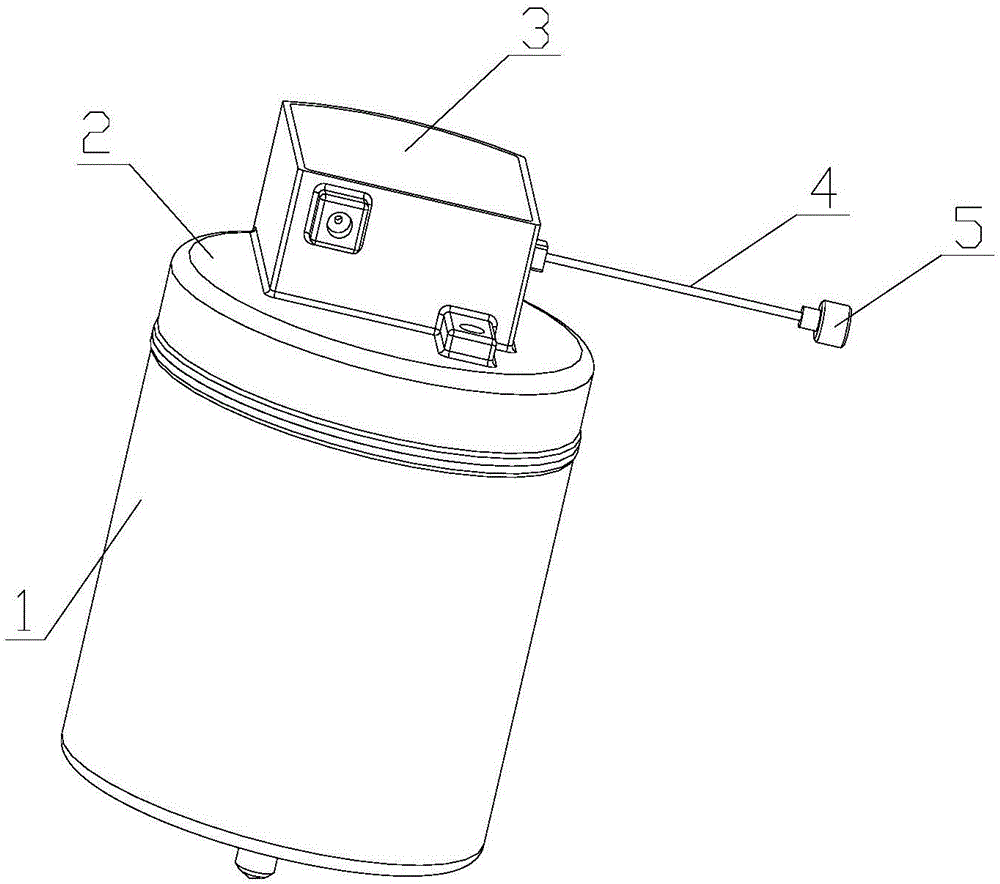

Method for encapsulating CaO-Y2O3-Al2O3-SiO2 glass at port of SiCf/SiC core cladding tube

ActiveCN110903102AImprove securityReduce reactivityFuel elementsNuclear energy generationThermal dilatationNuclear radiation

The invention relates to a method for encapsulating CaO-Y2O3-Al2O3-SiO2 glass at a port of a SiCf / SiC core cladding tube. Part of raw materials which are low in reaction activity and low in nuclear irradiation decay rate and have no side effects on the nuclear reaction process are selected, and a glass brazing filler metal is prepared through a melting-water cooling method; by means of the SiCf / SiC matched thermal expansion coefficient, good wettability and low high-temperature viscosity, packaging / connection of the SiCf / SiC composite core cladding tube is achieved under the conditions that the temperature is lower than the applicable temperature (<=1450 DEG C) of domestic third-generation SiC fibers and no pressure exists. The SiCf / SiC core cladding tube is promoted to be applied to a nuclear reactor, nuclear radiation leakage accidents are prevented in advance, and the operation safety of the nuclear reactor is improved. The method has the beneficial effects that the raw materials selected by an encapsulating agent are low-activity elements, the nuclear radiation decay of the encapsulating agent is small, the encapsulating agent has no side effect on a nuclear reaction process, and the mechanical and airtight requirements of port encapsulation of the core cladding tube are met, so that nuclear radiation leakage in the cladding tube can be effectively prevented in a harsh service environment, and nuclear radiation leakage accidents are prevented in advance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Laser welding method for stainless steel thick-wall pressure container

ActiveCN106392325ASolve welding strength problemsAvoid defectsDomestic vesselsMetal working apparatusThick wallHigh intensity

The invention provides a laser welding method for a stainless steel thick-wall pressure container. The pressure container comprises a high-pressure tank, a low-pressure buffering pressure container and a pipeline. Solution strengthening or ageing strengthening stainless steel materials are adopted in the high-pressure tank. A circular seam at the connecting position between the high-pressure tank and the low-pressure buffering pressure container is continuously welded through a laser. According to continuous welding parameters of the circular seam, when the tank wall thickness ranges from 5 mm to 10 mm, the laser power ranges from 4.2 KW to 7.5 KW, the welding speed ranges from 0.8 m / min to 1.5 m / min, the defocusing amount ranges from -2 mm to 3 mm, and the protection gas flow ranges from 15 L / min to 25 L / min. According to the laser welding method, the problem about welding strength of the high-strength stainless steel materials in a solution or ageing strengthening state is solved, the welding strength is high and stable, and equal-strength connection of base metal is achieved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

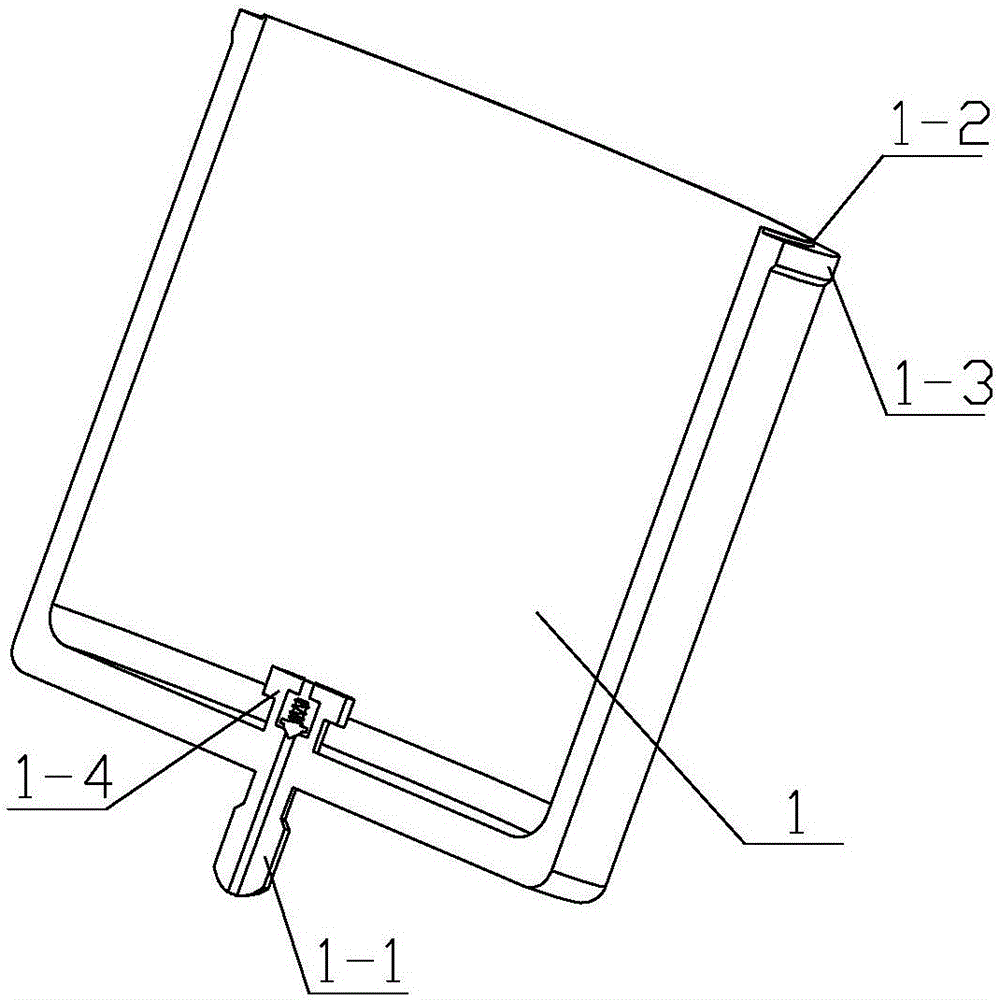

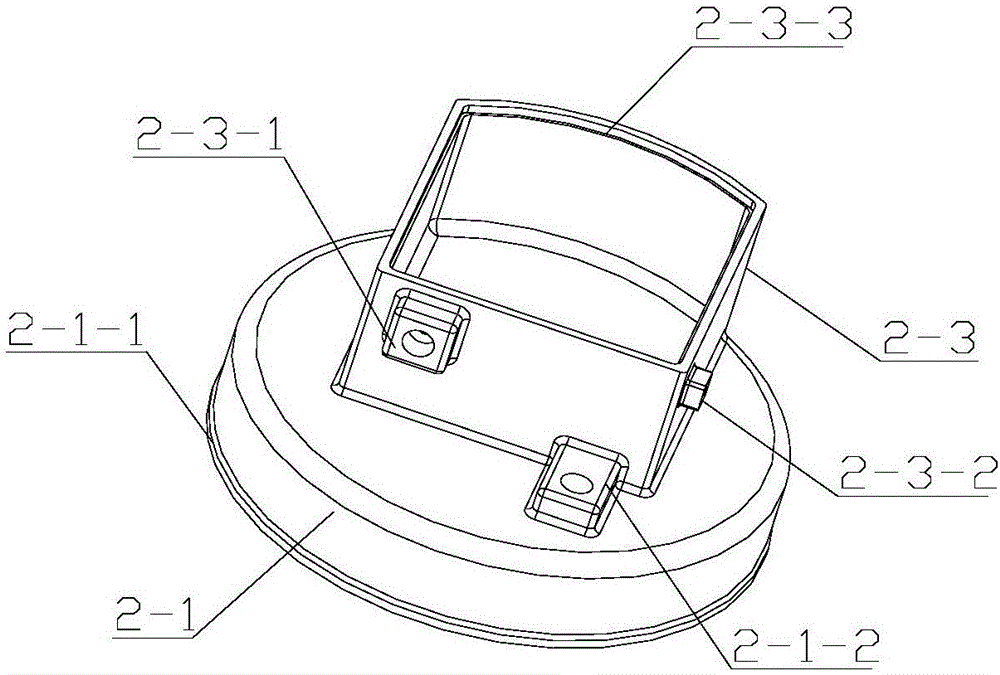

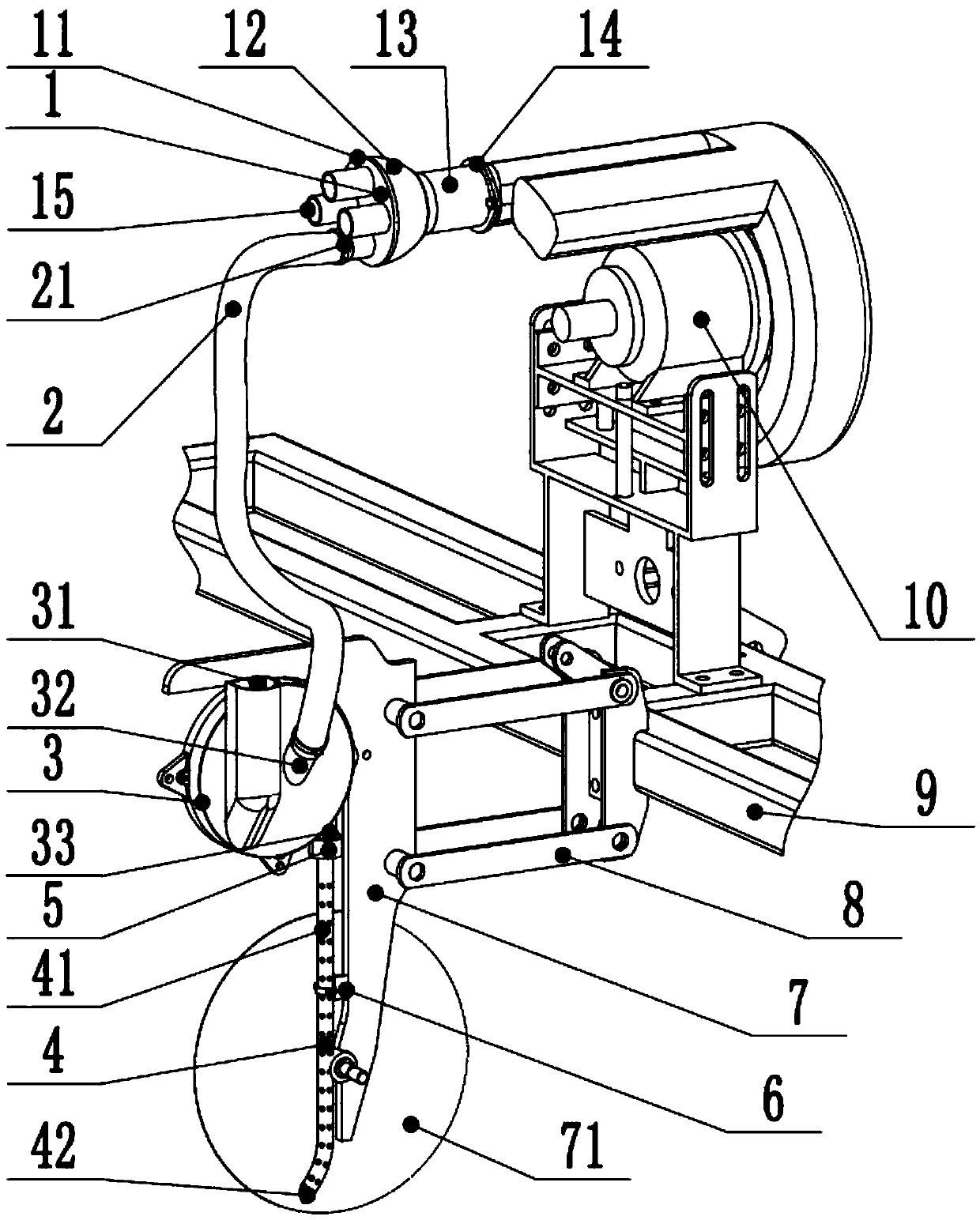

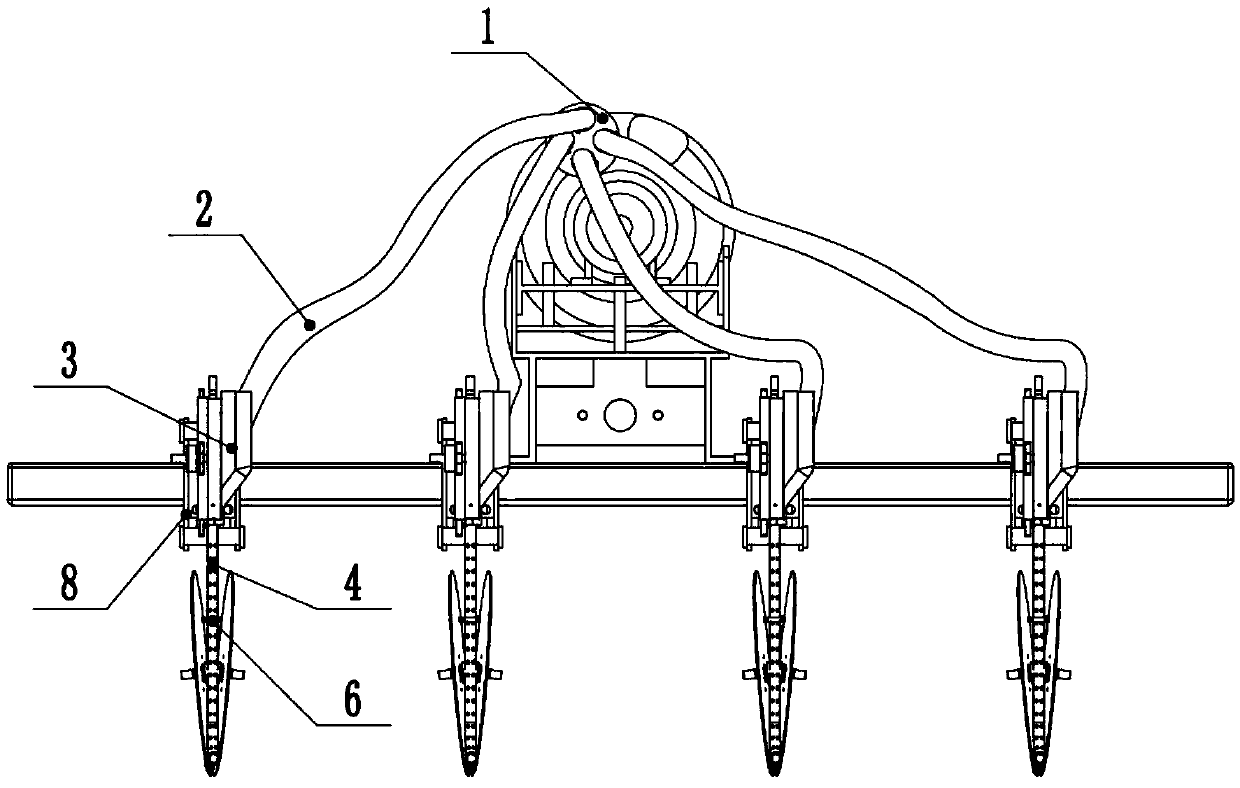

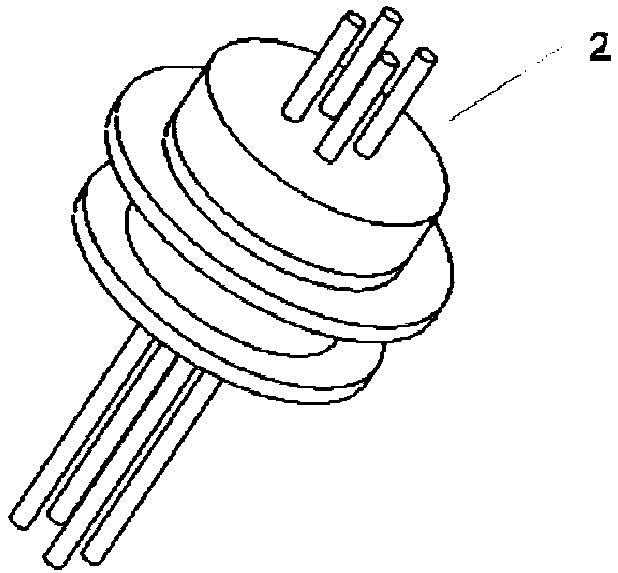

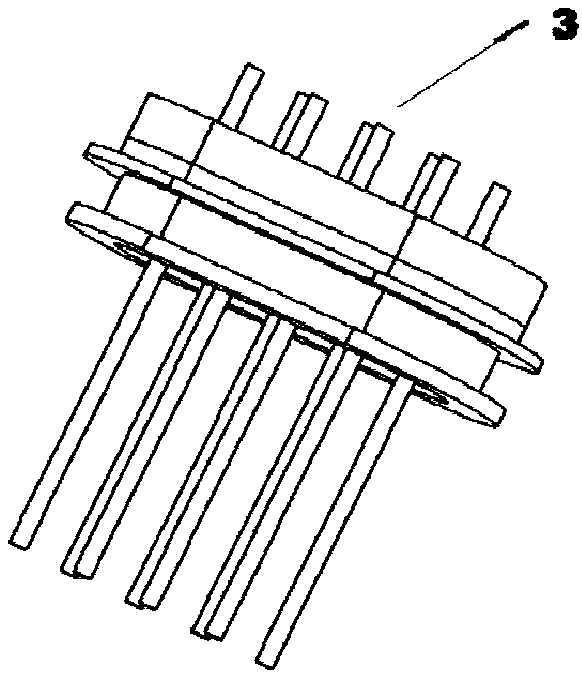

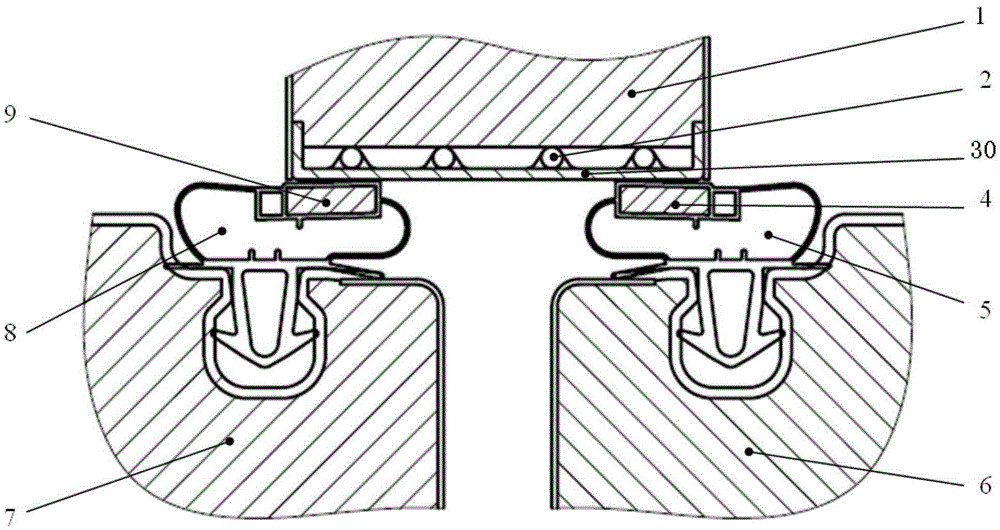

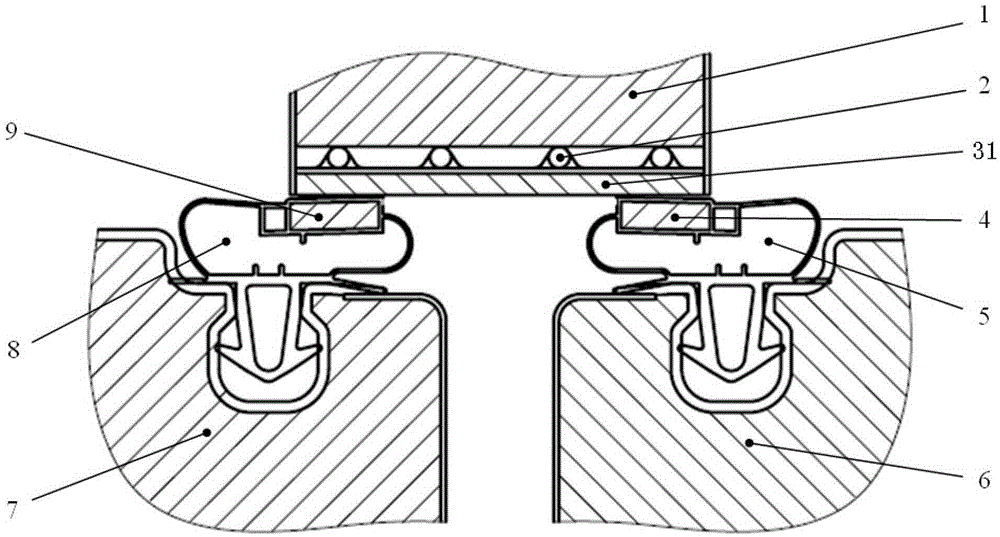

Pneumatic planter uniform low-loss gas path system, and gas distribution method

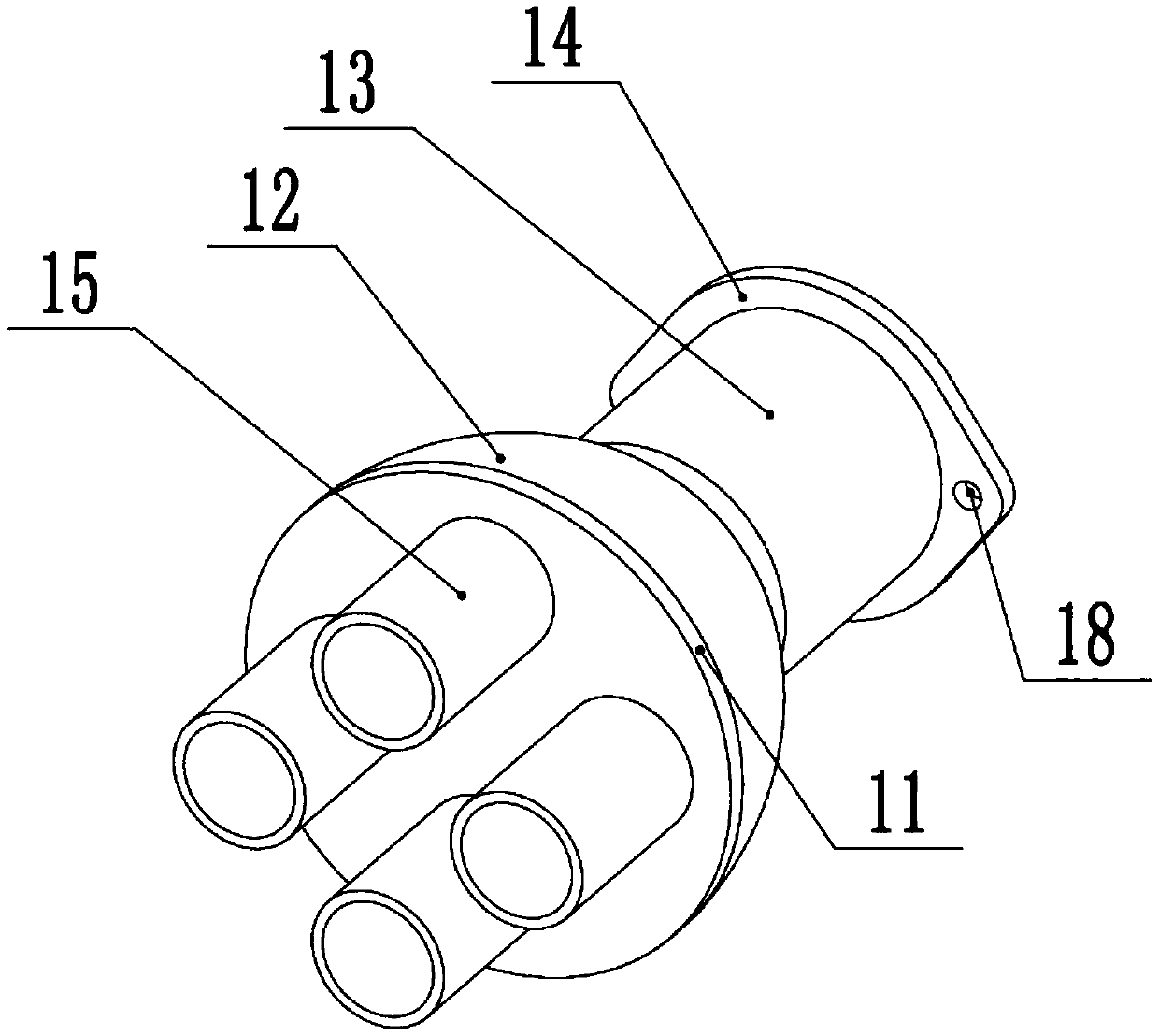

ActiveCN105359685AReduce lossesReduced Power RequirementsSeed depositing seeder partsRegular seed deposition machinesDistribution methodProcess engineering

The invention belongs to the field of agricultural machine, and relates to a pneumatic planter uniform low-loss gas path system, and a gas distribution method. According to the pneumatic planter uniform low-loss gas path system, gas flow is delivered into a gas inlet pipe (13) of a gas flow distributor (1), and, through a diameter variable joint (12), is divided into a plurality of gas flows with the same gas flow size via a plurality of gas outlet pipes (15) uniformly distributed on a distributor circular plate (11), and then is delivered into a seed outlet pipe (4) via a pneumatic seed discharging unit (3); gas flow is released gradually via gas outlets (41) uniformly arranged on the pipe body of the seed outlet pipe (4) when every certain seed height is reduced, gas flow pressure in the seed outlet pipe (4) is reduced gradually, falling speed of seeds along with gas flow is reduced obviously, and at last the seeds are discharged via a seed outlet pipe seed outlet (42). The pneumatic planter uniform low-loss gas path system is capable of maintaining supply gas pressure of a plurality of lines of seeding unit seed sowing devices to be the same effectively, reducing draught fan power requirements via reducing loss generated in gas distribution process, and reducing pneumatic seed sowing device seed discharging speed obviously via increasing pressure relief of seed discharging process.

Owner:CHINA AGRI UNIV

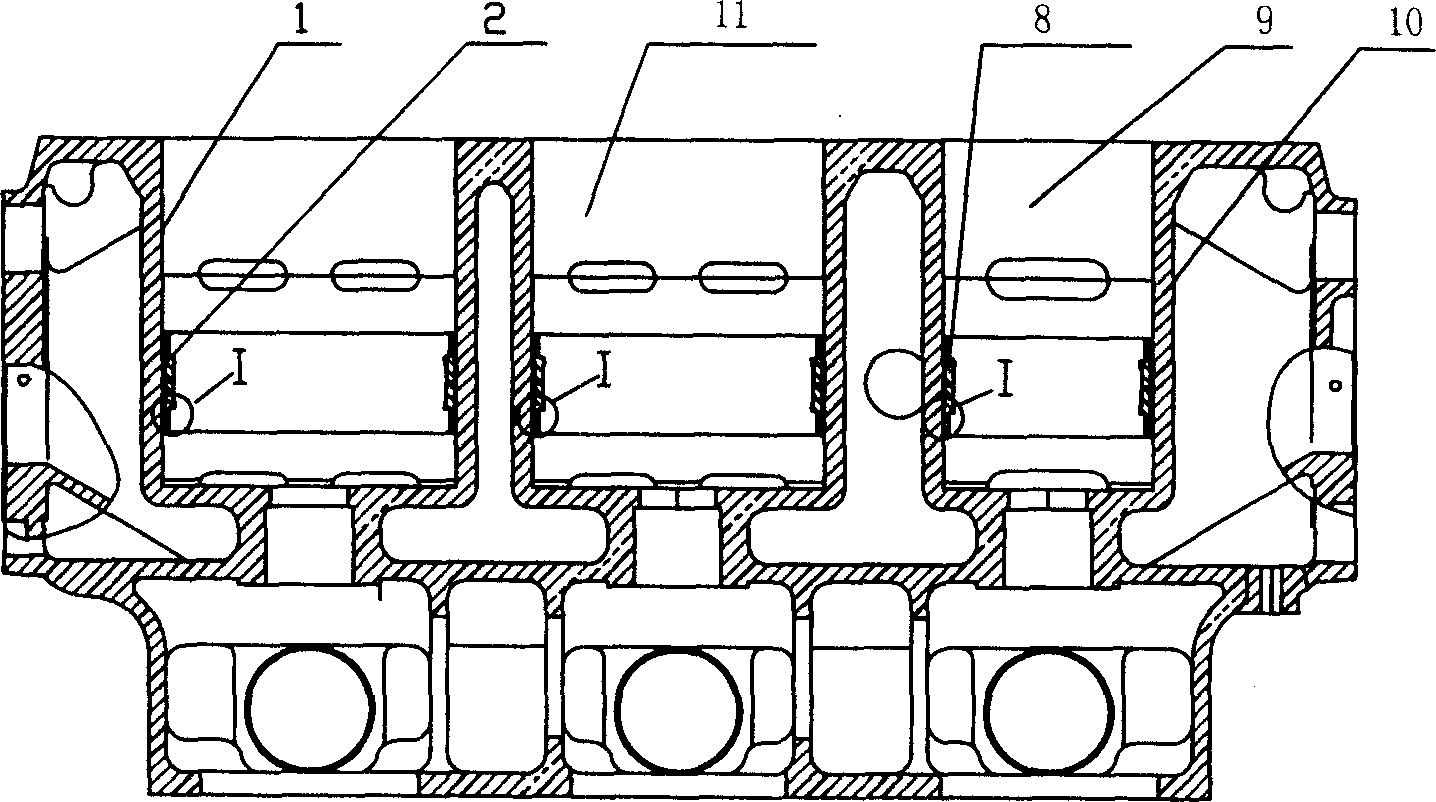

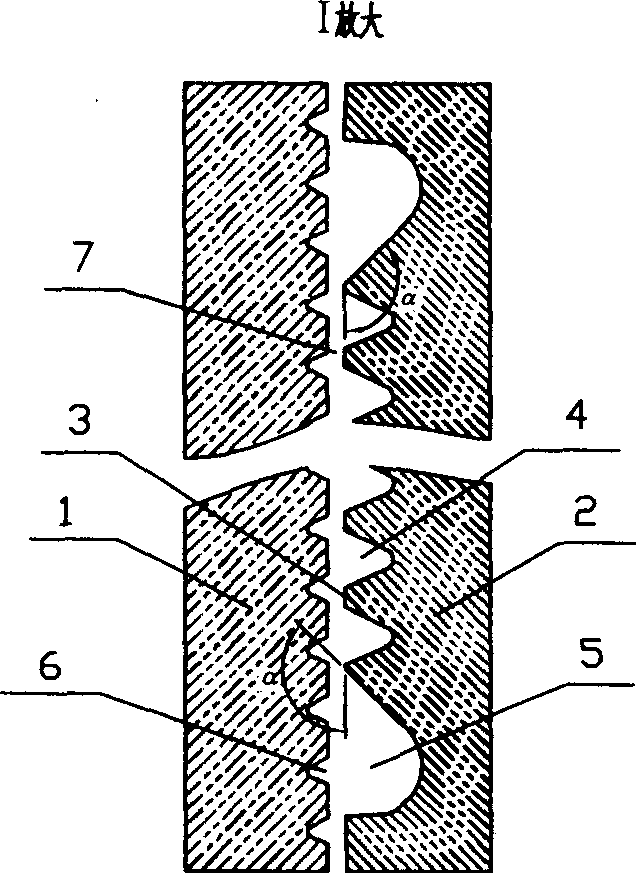

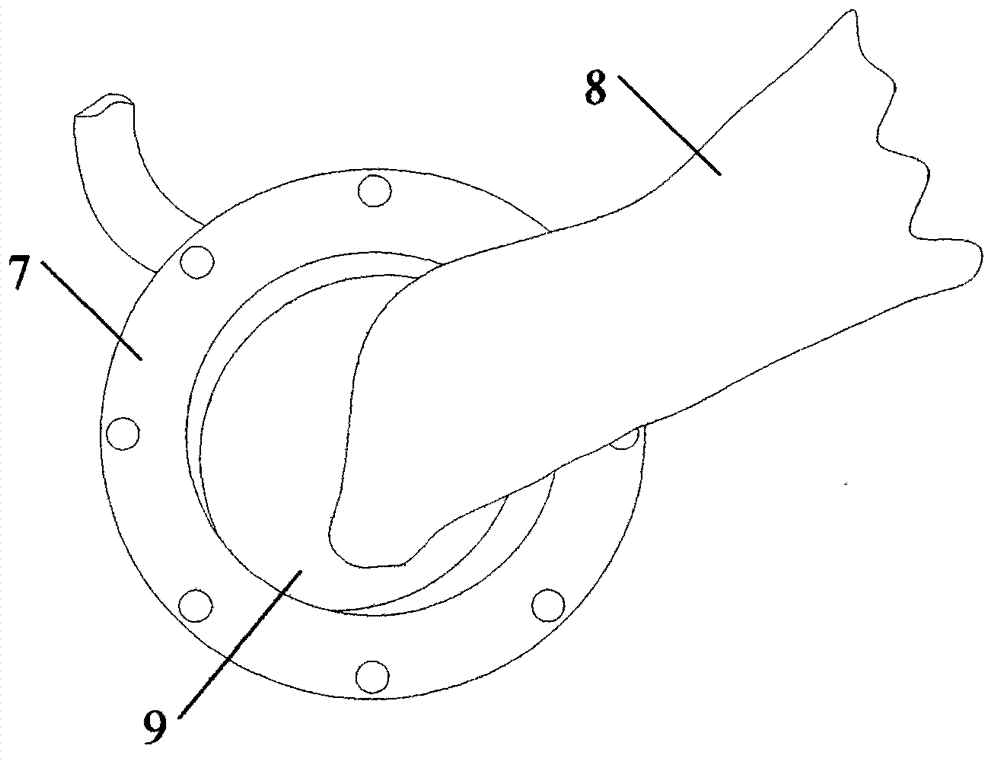

Labyrinth sealing structure of industrial labyrinth compressor

InactiveCN1854515AExtended service lifeReduce the number of spare partsPositive displacement pump componentsMulti-stage pumpsSolid particleHigh pressure

The invention comprises an air cylinder, are disposed in which an air cylinder cavity and a piston jacket. On both sides of the air cylinder cavity there are air cylinder walls, on which is disposed a labyrinth groove volume room and on the piston jacket are disposed throttle port and a volume room. The piston jacket and the air cylinder walls are separated to form small gaps.

Owner:WUXI COMPRESSOR CO LTD +1

Cable bundle flange filling and sealing method

The invention discloses a cable bundle flange filling and sealing method which mainly includes the steps: a, sealing a flange needing filling by the aid of a silicon rubber sealing ring; and b, filling fluid silicon rubber into the flange in a layered manner through a hole on the sealed flange until a filling rubber surface is parallel and level to the inner surface of the flange. The cable bundle flange filling and sealing method can overcome the defects of uneven rubber surface, easy leakage, poor sealing performance, low reliability and the like in the prior art, and accordingly has the advantages of even rubber surface, difficulty in leakage, fine sealing performance and high reliability.

Owner:BEIJING XINLI MACHINERY

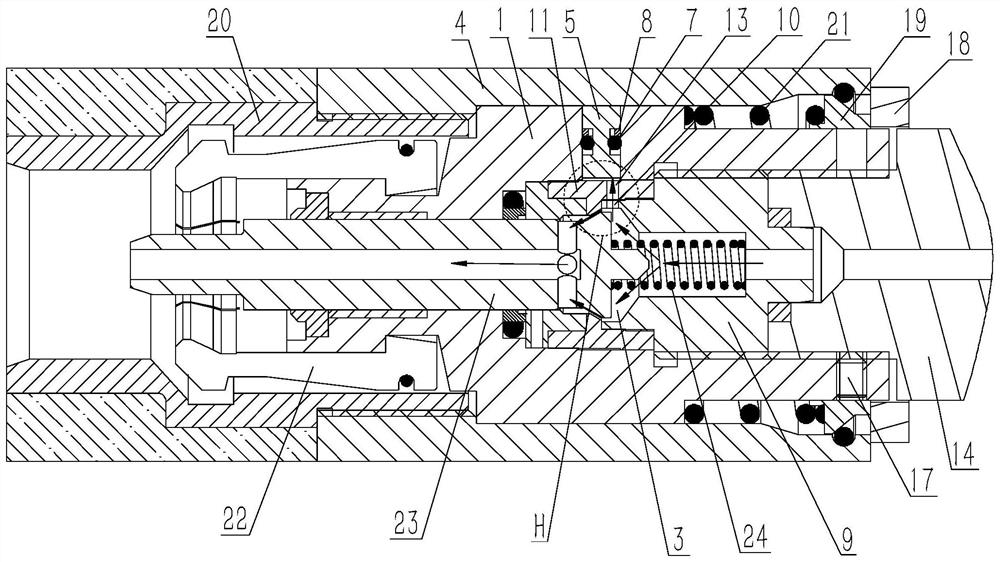

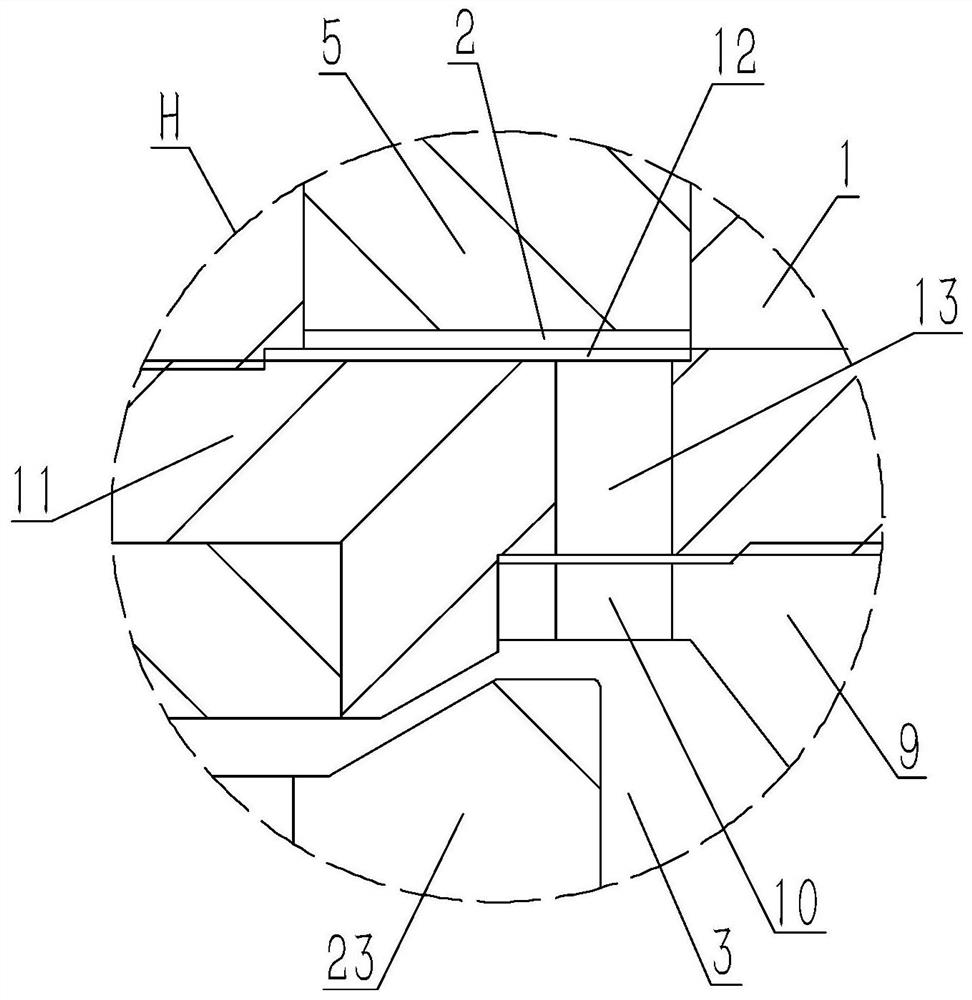

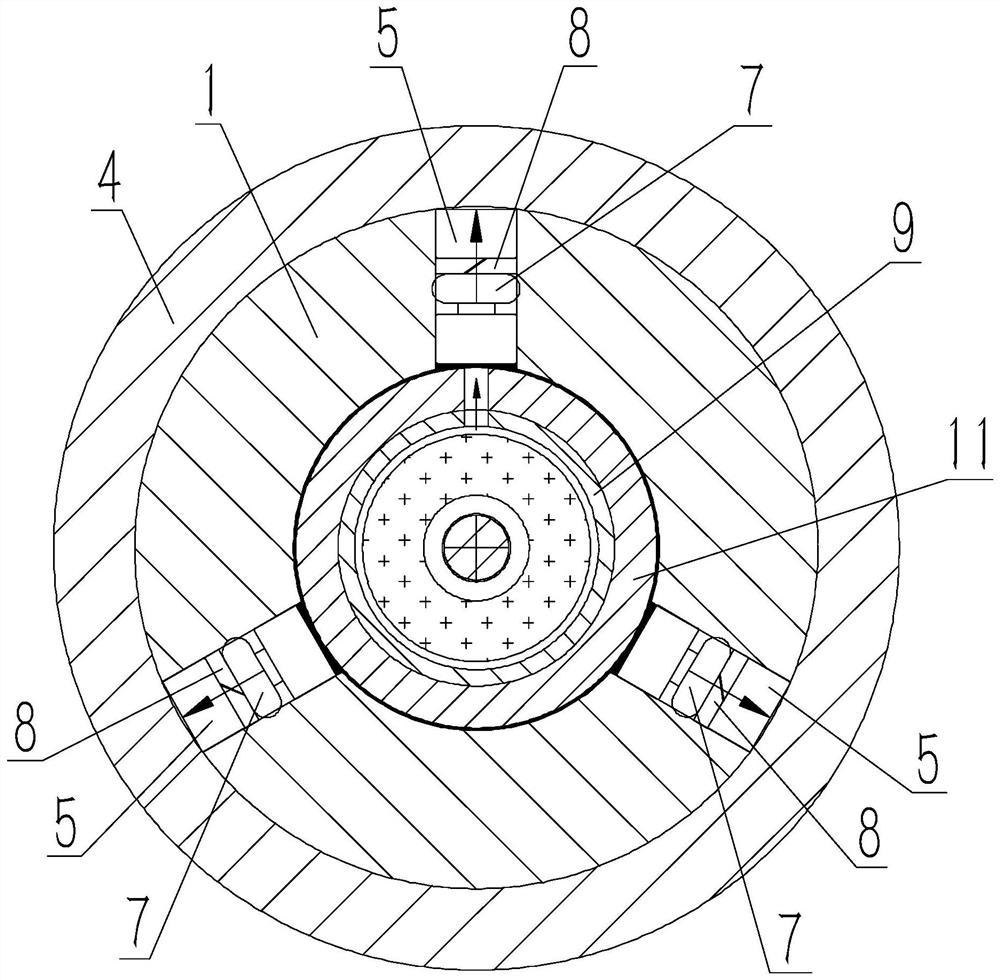

Safety self-locking structure of high-pressure hydrogen refueling gun

PendingCN112483743AGuaranteed air tightness requirementsReduce accidentsCheck valvesGas handling/storage effectsStructural engineeringWasher

The invention discloses a safety self-locking structure of a high-pressure hydrogen refueling gun. One radial installing hole is at least formed in a gun core shell of the high-pressure hydrogen refueling gun in the periphery direction. All the radial installing holes communicate with a gas refueling channel in the hydrogen refueling gun through a gas input channel. A self-locking sealing assemblyis arranged in each radial installing hole. Each self-locking sealing assembly can move along the corresponding radial installing hole to make contact with the inner wall of a gun head shell and canmake contact with the corresponding radial installing hole for sealing. Each self-locking sealing assembly comprises a sealing pin arranged in the corresponding radial installing hole, and a circle ofannular positioning groove is formed in the outer wall of each sealing pin. An O-shaped sealing ring and an open washer are sequentially nested in each annular positioning groove in the axial direction of the corresponding sealing pin, and each O-shaped sealing ring is located on the side close to the axis of the gun core shell. The structure has the advantage of improving use safety of the hydrogen refueling gun in the working state.

Owner:SHANGHAI HUAJING HYDROGEN ENERGY TECH CO LTD +1

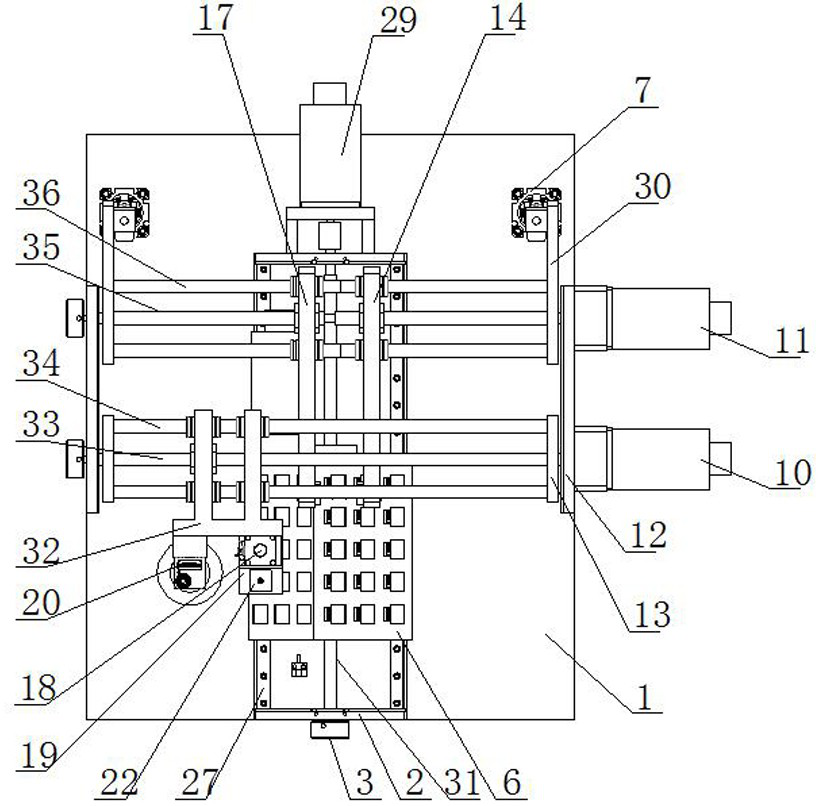

Multi-dimensional data measuring device for lump coal drilling process

ActiveCN111521537AReal-time monitoring of temperature changesGuaranteed air tightness requirementsPermeability/surface area analysisDrive motorTest chamber

The invention discloses a multi-dimensional data measuring device for a lump coal drilling process. The multi-dimensional data measuring device comprises an adsorption tank for adsorbing and desorbinglump coal, a reference tank which has the same size as the adsorption tank and is used for balancing pressure, and a high-low temperature test box for accommodating the adsorption tank and the reference tank, a temperature measuring drill rod is arranged in the adsorption tank, a non-contact magnetic coupling matching mode is adopted, the adsorption tank is driven by a driving motor to rotate, and the temperature measuring drill rod moves up and down through a propelling device; and the reference tank and the adsorption tank are respectively communicated with a gas source system for supplyinggas, a vacuum pumping system for pumping gas and a gas collecting device through a branch gas path and a main gas path. According to the method, various dimension data in the lump coal drilling process of the drill bit can be measured in different temperature environments,wherein the parameters comprise drill bit temperature change, while-drilling parameter change, lump coal gas content data, drill bit drilling process gas real-time analysis quantity and gas adsorption expansion deformation real-time monitoring data.

Owner:TAIYUAN UNIV OF TECH

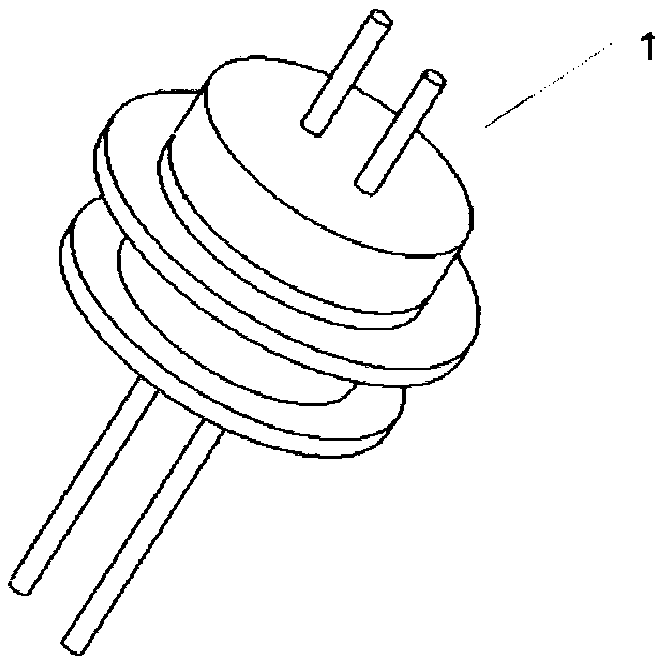

Feedthrough filter, manufacturing method thereof, and implantable electrical stimulator

ActiveCN108899710ALess componentsSimple structureCoupling for high frequencyHeart stimulatorsEngineeringElectrical stimulator

The invention discloses a feedthrough filter, a manufacturing method thereof, and an implantable electrical stimulator. The feedthrough filter includes a feedthrough connector and a filter attached tothe feedthrough connector, wherein the feedthrough connector includes a ferrule, a feedthrough member, and at least one signal line; the ferrule is provided with an upper edge, a lower edge and an inner hole; the upper edge and the lower edge form an annular mounting groove for assembling with the outer side surface of the ferrule; the inner hole seals the feedthrough member; the inner hole and the feedthrough member have the identical shape and are matched and connected to each other; the feedthrough member is composed of a single or combined implantable ceramic or glass material, and formsa sealing body with the ferrule and the at least one signal line; and the at least one signal line passes through a first through hole in the feedthrough member for connecting an internal interface terminal and an external terminal of an electrical stimulator. By attaching the filter to the feedthrough connector, the feedthrough filter can satisfy the demand of a feedthrough connector and also hasfiltering performance.

Owner:BEIJING PINS MEDICAL +1

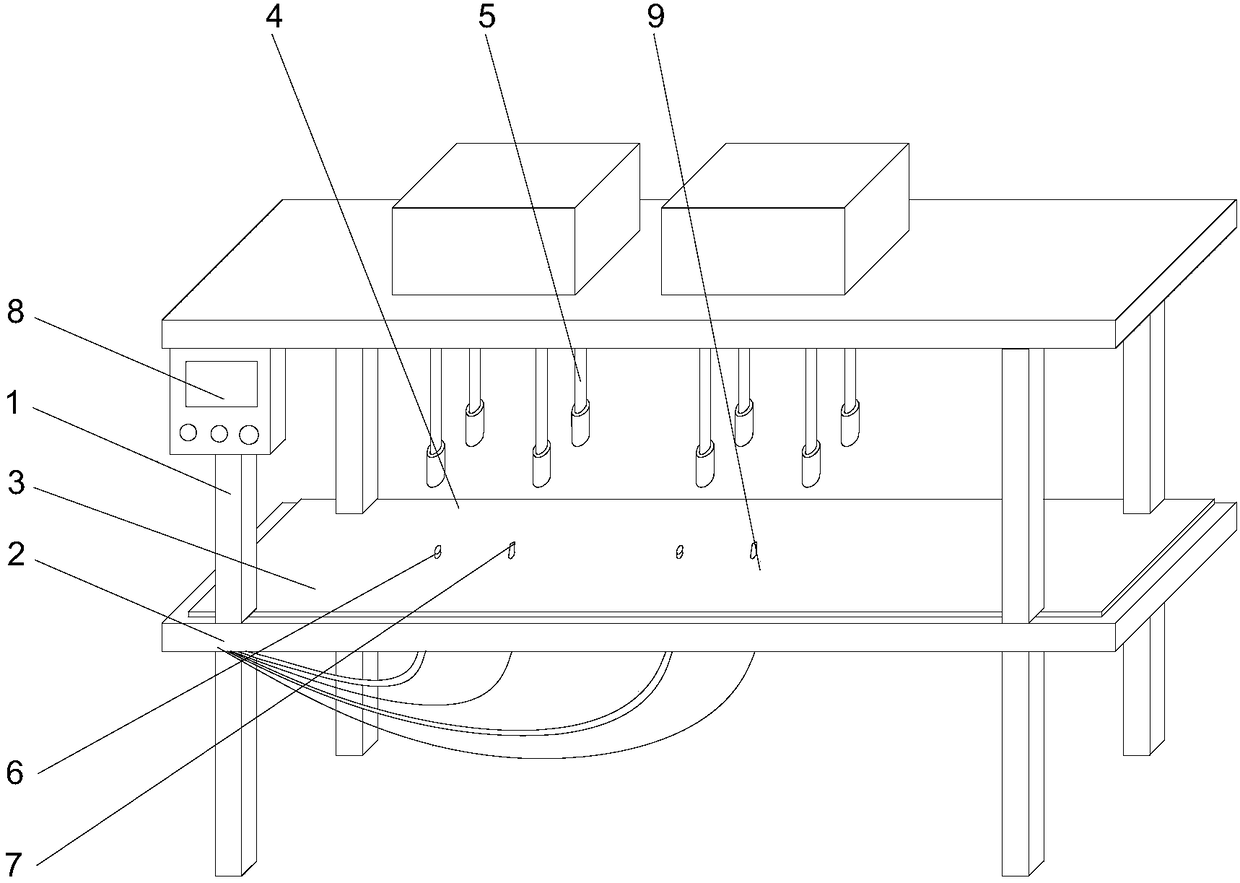

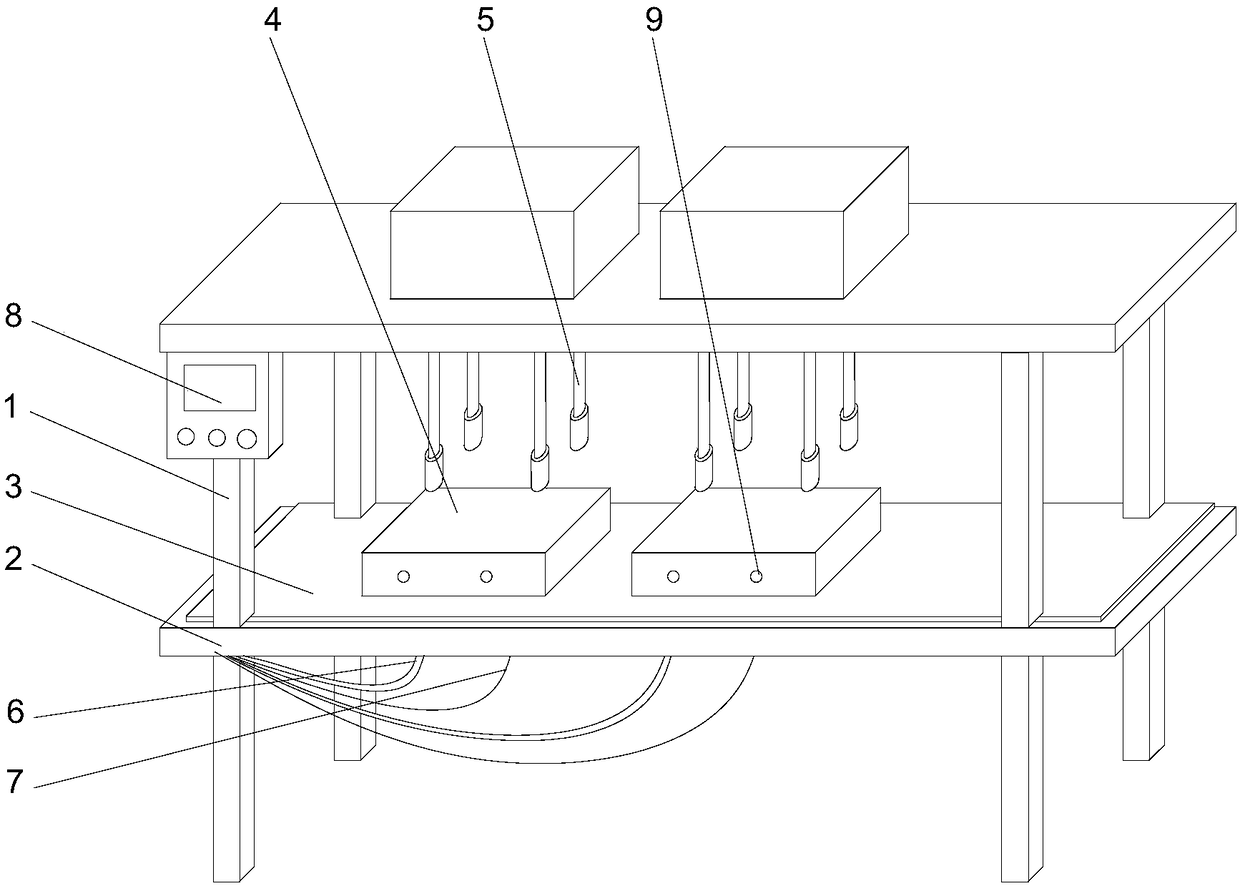

Welding airtightness detecting device and detecting method of battery box

InactiveCN108254137ASolve airtight test problemsGuaranteed air tightness requirementsMeasurement of fluid loss/gain ratePunchingEngineering

The invention discloses a welding airtightness detecting device of a battery box. The detecting device comprises a detection bench arranged on a rack; a plurality of detection stations are arranged onthe detection bench; and an elastic base plate is arranged on the surface of the detection bench. A battery box is arranged on the elastic base plate of the corresponding the detection station. A punching cylinder is arranged above each detection station; when the punching cylinder is pressed down, the battery box is buckled on the elastic base plate in an airtightness manner; a pressurization air pipe connected to the inner cavity of the battery box and a pressure sensor are arranged on the elastic base plate of each detection station; the pressurization air pipe is used for leading compressed gas in the battery box; and the pressure sensor is used for detecting the air pressure of the inner cavity of the battery box and a display terminal is connected to the output terminal of the pressure sensor. According to the invention, a test problem of airtightness of the battery box is solved. The welding airtightness detecting device having advantages of simple operation, quick detection and accurate determination is suitable for batched detection.

Owner:福建渃博特自动化设备有限公司

Canopy air tightness test fixture

ActiveCN113977499AGuaranteed air tightness requirementsGuaranteed tightnessWork holdersFluid-tightness measurementRubber ringStructural engineering

The invention relates to a canopy airtightness test fixture, which is characterized in that: an airtight platform is positioned and connected on the upper surface of a base of a frame structure, and upright posts are respectively arranged in front and back of the lower surface of the base; a sealing rubber ring is arranged on the periphery of the airtight platform, and the lower edge of a canopy to be detected and the sealing rubber ring of the airtight platform are pressed, sealed and matched by an external pressure applying device; the external pressure applying device is composed of a front pressing device, a rear pressing device and a side tensioning device; an inspection hole is formed in the middle of the base and communicates with an inner cavity of a canopy to be detected, the bottom of the inspection hole is connected with a shielding cover plate, and the cover plate is in sealed connection with the base through bolts arranged on the circumference; the base is provided with a sealing joint for inflating and a sealing joint for vacuumizing, which communicate with the inner cavity of the canopy to be detected. The canopy air tightness test fixture is uniformly distributed, so that the pressing force is uniform in the automatic locking process, and the sealing performance is improved.

Owner:辽宁华天航空科技股份有限公司

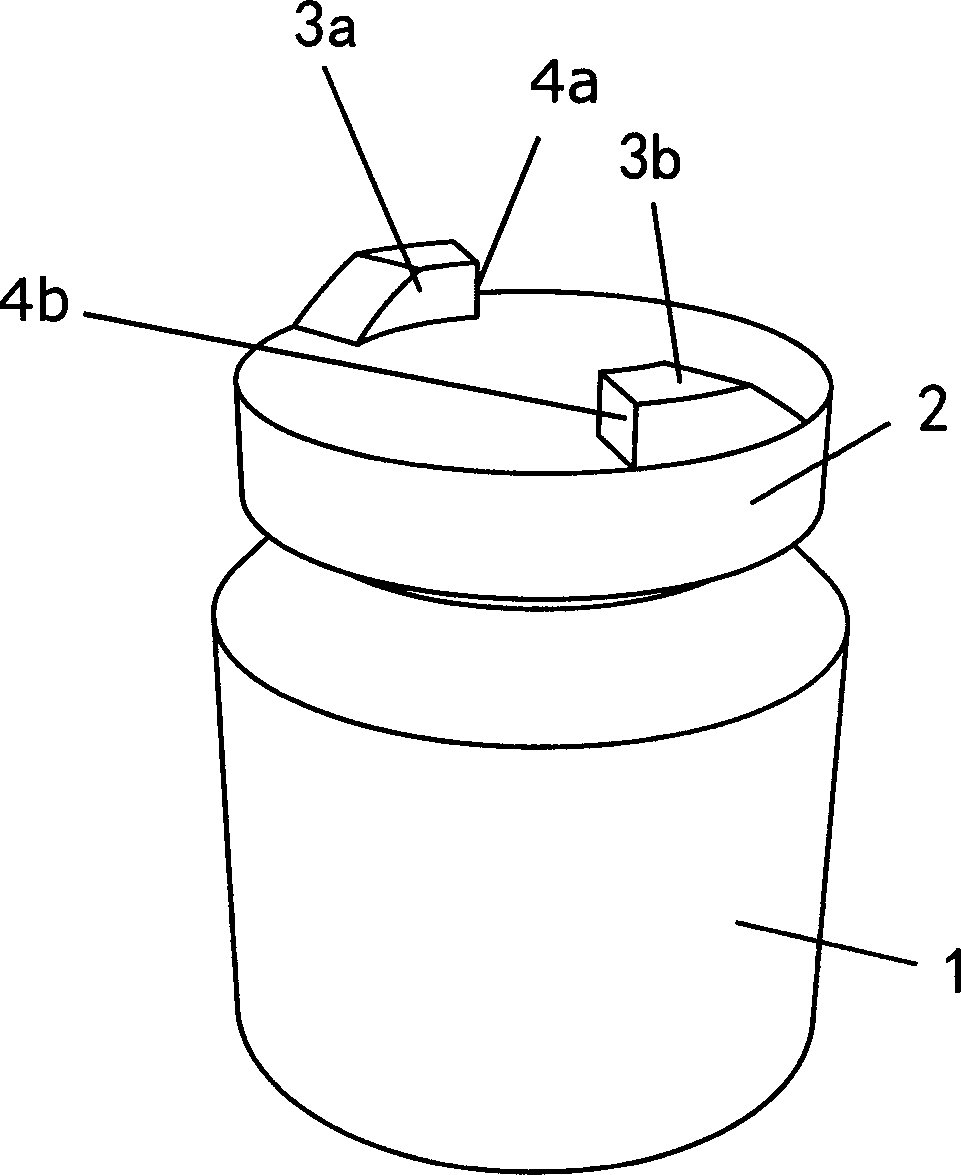

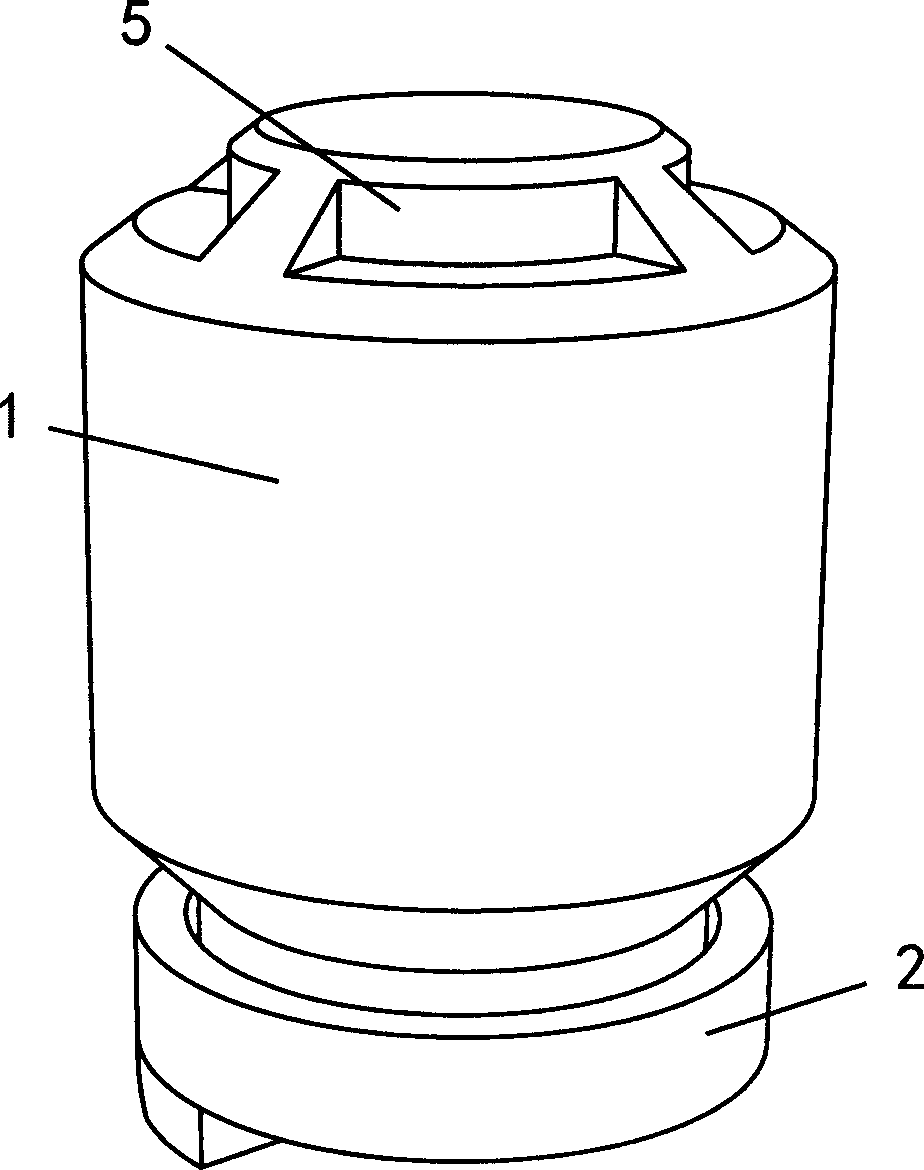

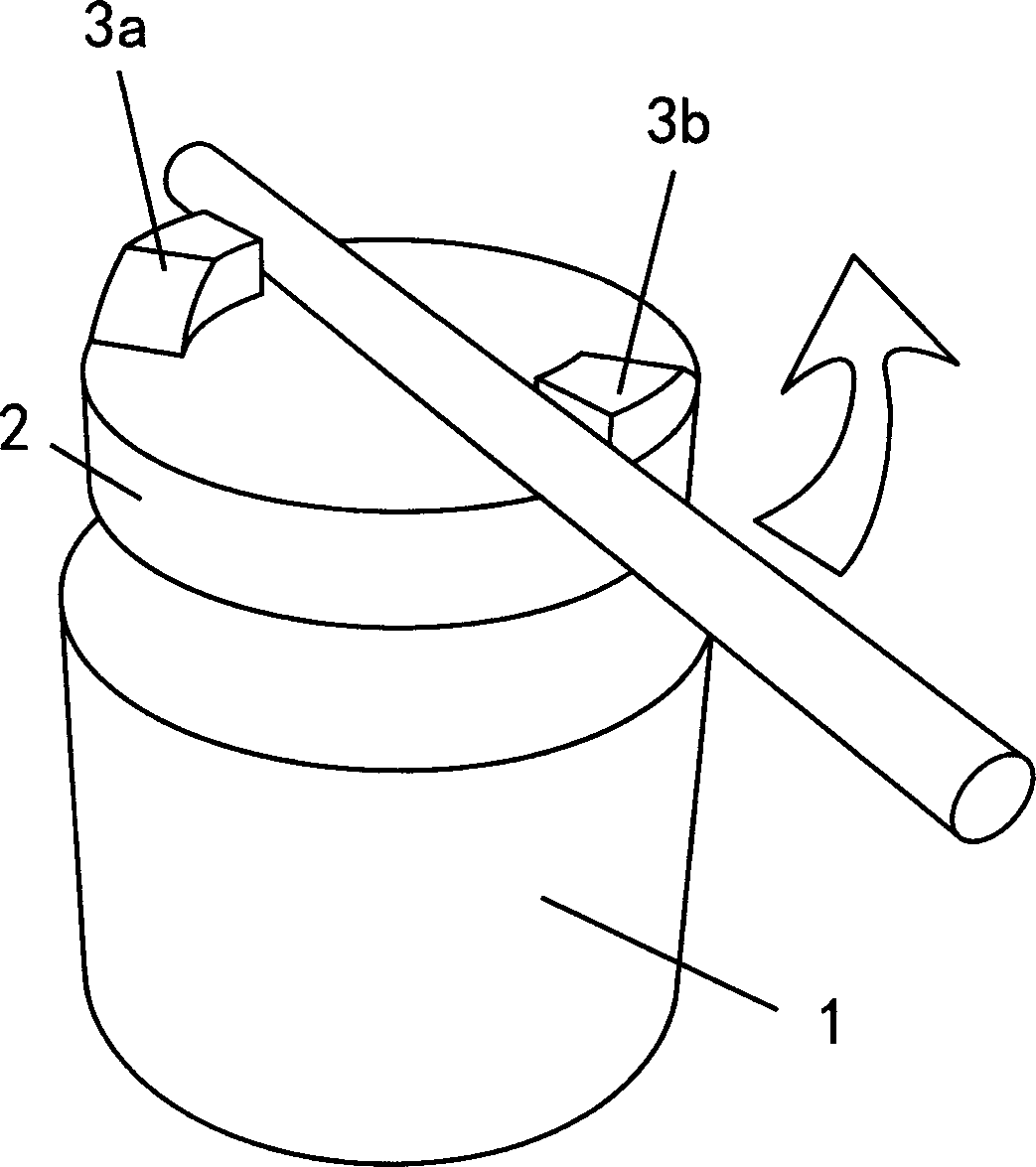

Easy-open can

InactiveCN104176362AGuaranteed air tightness requirementsDoes not affect stackingCapsBottlesEngineeringBottle cap

The invention discloses an easy-open can which comprises a bottle and a bottle cap. Two protrusions are circumferentially symmetrically arranged on the bottle cap, and a stress edge is arranged on a side of each protrusion. Grooves which are structurally matched with the protrusions are formed in the bottom of the bottle. The easy-open can has the advantages that the protrusions are additionally arranged on the bottle cap and are used as fulcrums, the corresponding grooves are additionally formed in the bottom of the bottle, accordingly, influence on stacking cans can be prevented, and the easy-open can also can be used as a can opener; the easy-open can is simple in structure and convenient to use, the arm of force is enlarged by the aid of a lever principle, the contact area of the hand of a user and the can is expanded, accordingly, the easy-open can is easy to open, and requirements on the air tightness of a container can be assuredly met.

Owner:王天亿

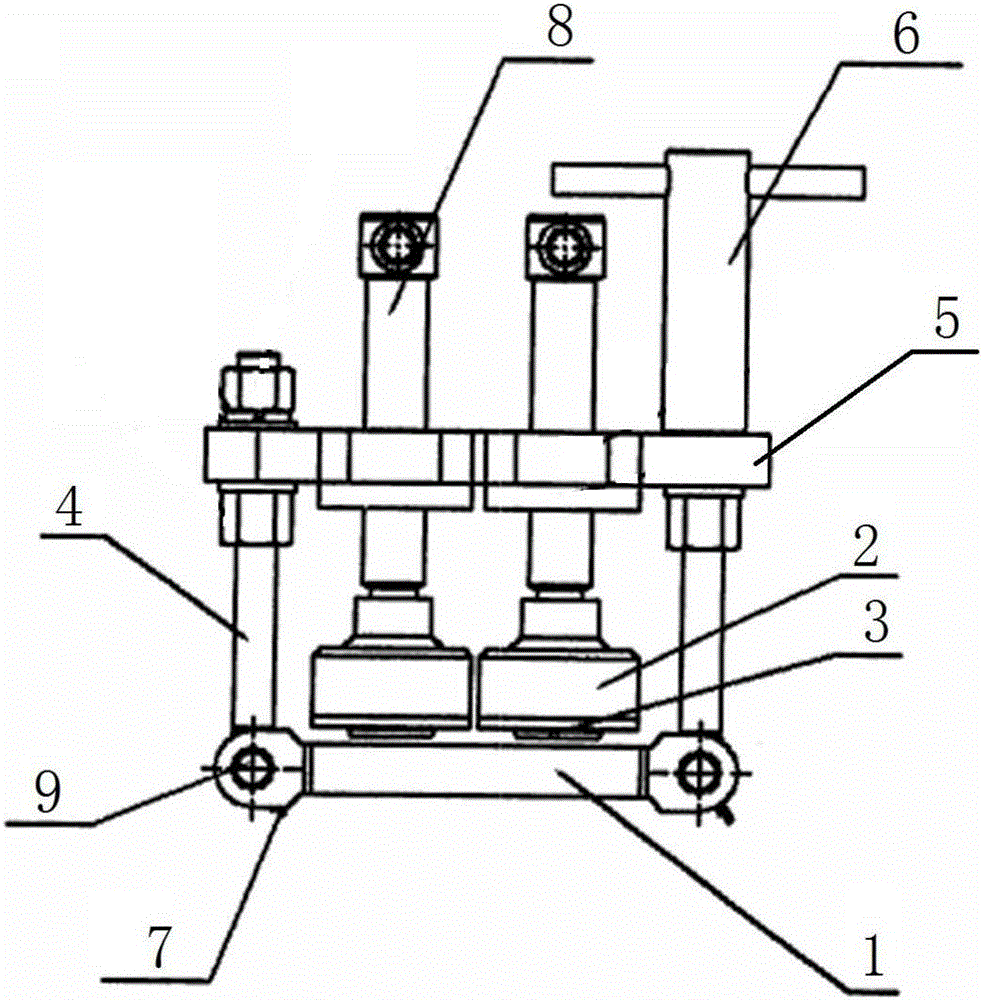

Multi-connection-flange tester and using method thereof

InactiveCN106066230AGuaranteed air tightness requirementsEasy to operateFluid-tightness measurement using fluid/vacuumEngineeringAir tightness

The invention relates to a multi-connection-flange tester and a using method thereof. The structure of the multi-connection-flange tester is characterized in that a crossbeam is disposed over a base plate and is connected with the base plate via bolts; compactors are arranged between the base plate and the crossbeam; screws are disposed on the upper end face of the compactors and pass through the crossbeam; and a handle is disposed on the upper end face of the crossbeam and corresponds to the position of a bolt at a side. A flange required to be subjected to an air impermeability test is arranged between the base plate and the crossbeam and the compactors and rubber gaskets installed on the bottom of multi-connection-flange and the base plate guarantee the air impermeability of the multi-connection-flange. The multi-connection-flange tester adapts to multiple flanges and increases operating efficiency while saving raw material.

Owner:SHENYANG AIRCRAFT CORP

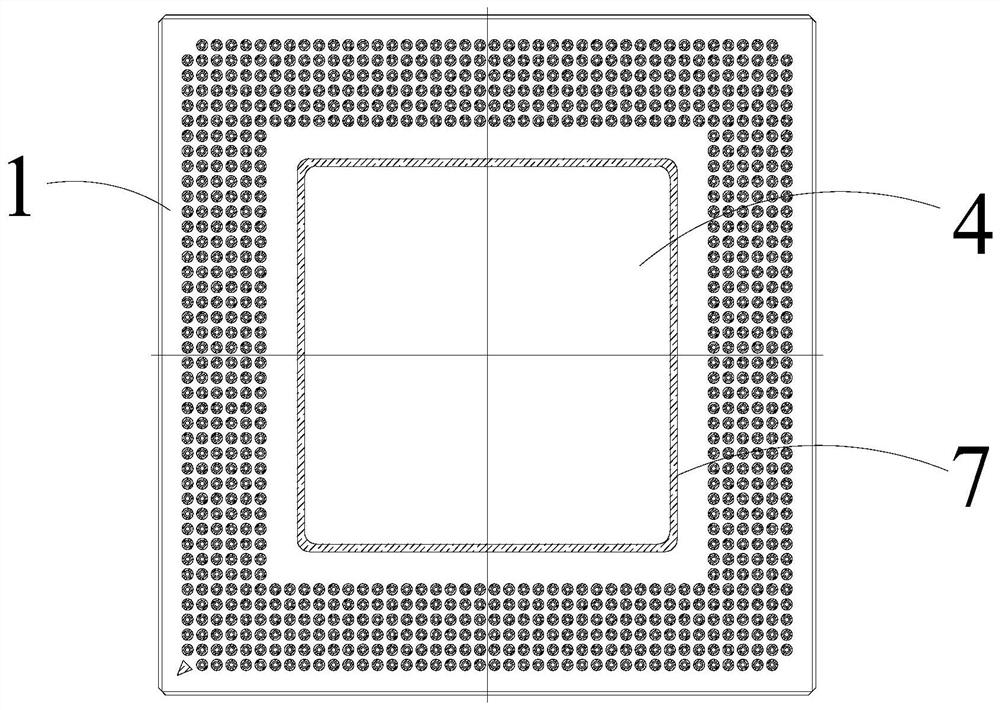

Ceramic shell, ceramic packaging structure and micro-system

PendingCN113517234AGuaranteed air tightness requirementsMeet thermal requirementsSemiconductor/solid-state device detailsSolid-state devicesKovarFlip chip

The invention provides a ceramic shell, a ceramic packaging structure and a micro-system. The ceramic shell comprises a ceramic shell body, the ceramic shell body is provided with a first surface and a second surface which are oppositely arranged, the first surface is provided with an airtight packaging area and a non-airtight packaging area, the non-airtight packaging area is provided with a circular flip bonding pad, and the second surface is provided with an airtight packaging area and a lead. The airtight packaging area is formed by a kovar metal welding ring in an enclosing manner, a chip mounting area and / or a component mounting area are / is arranged in the airtight packaging area, and the chip mounting area is of a multi-layer cavity structure used for mounting bonding chips. According to the ceramic shell, various devices and chips can be installed on the first surface and the second surface, the air tightness requirement of a common bonding chip can be guaranteed through the airtight packaging area, a flip chip can be installed in the non-airtight packaging area, the heat dissipation requirement of a high-power flip chip can be met, and miniaturization and high integration level can be achieved.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Side-by-side refrigerator refrigerating vertical beam and side-by-side refrigerator

ActiveCN103185445BGuaranteed air tightness requirementsLow powerDomestic cooling apparatusLighting and heating apparatusMagnetic polesEngineering

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

High bending fatigue strength ceramic package outer lead and preparation method

InactiveCN107481989AImprove conductivityImprove stabilitySemiconductor/solid-state device detailsSolid-state devicesEtchingThermal expansion

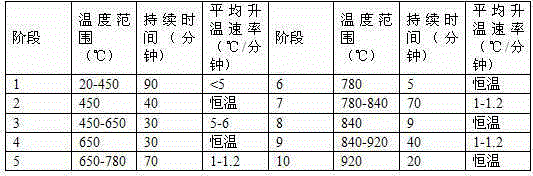

The invention provides a high bending fatigue strength ceramic package outer lead and a preparation method. The method comprises the steps of (a) selecting a metal with good electrical conductivity and a thermal expansion coefficient matched with a ceramic, (b) processing the metal into a shape which meets requirements by using a mode of etching, cutting or stamping, (c) using N2, H2 or mixed atmosphere protection, and removing material surface detects by using program temperature controlled heat treatment, (d) using sputtering or plating process to deposit a protective and functional metal or alloy at a surface, (e) using vacuum, N2 or H2 protection, and completing welding in a program temperature control furnace, (f) processing the above material in alkaline and acidic solutions with different pH values to remove an oxide layer or pollutants at a lead surface, and (g) carrying out functional and protective coating deposition. The high bending fatigue strength ceramic package outer lead and the preparation method have the advantages that the processed ceramic package has higher lead bending fatigue strength and good conductivity, solderability and corrosion resistance performance, and the improvement of the stability and long-term reliability of a system is facilitated.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

A kind of sapphire chip and metal active sealing method

ActiveCN103949742BGuaranteed wall thicknessReduce the chance of burstingSoldering apparatusThermal dilatationTitanium zirconium

The invention provides an active sealing method between sapphire sheet and metal with low welding temperature, high efficiency, good reliability and low cost. It eliminates the defects of long, complex and time-consuming intermediate processing, shortens the total welding time, and improves production efficiency; avoids the defects that the solder sheet must be processed into precise dimensions and requires extremely high flatness, and directly uses active titanium zirconium copper Nickel solder; the wall thickness of the sealing part of the metal part is made relatively thin to reduce the thermal stress caused by the reaction of the thermal expansion of the sapphire sheet to the extrusion of the metal part during welding, and reduce the probability of the sapphire sheet bursting; at the same time, the temperature of the welding in the vacuum atmosphere is less than 1000 It can be completed at one time at ℃, and the requirements for welding equipment are extremely low. The welding reliability and yield rate of the product are high. The airtightness is good when baked at 560℃ for 36 hours, which can ensure the airtightness requirements of ultra-high frequency electric vacuum devices.

Owner:XI AN JIAOTONG UNIV +1

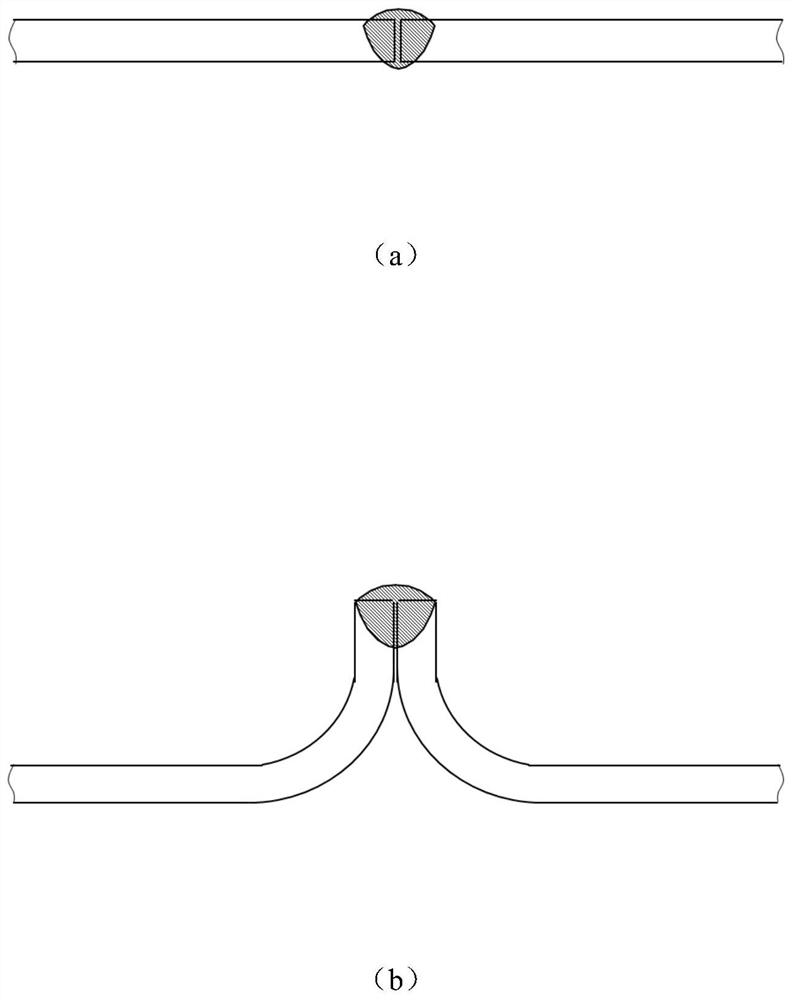

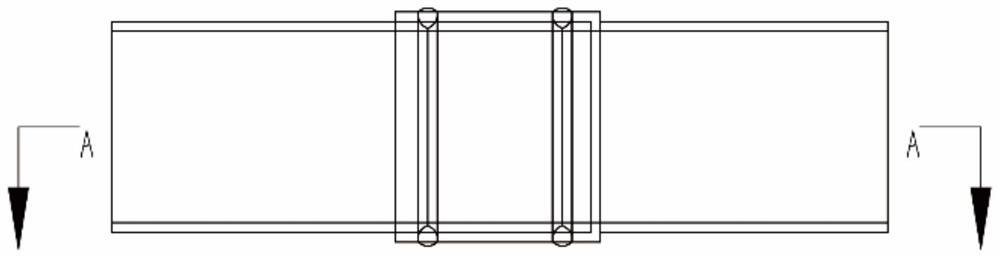

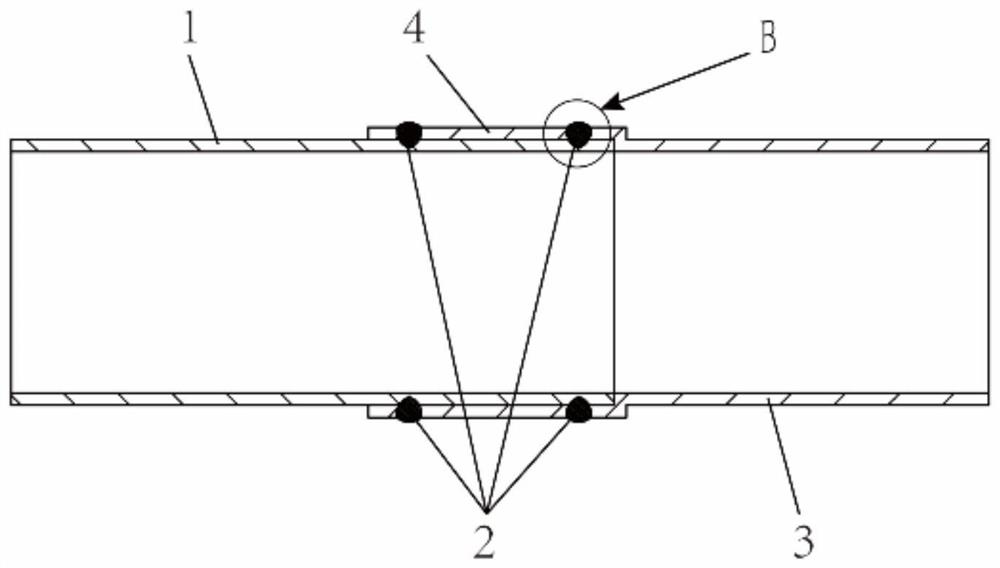

Welding method suitable for easy-to-oxidize alloy thin-walled tube

PendingCN113263244AAssembly accuracy is lowSimplify the assembly processArc welding apparatusMetal working apparatusAlloyMaterials science

The invention belongs to the technical field of easy-to-oxidize alloy material welding, and discloses a welding method suitable for an easy-to-oxidize alloy thin-walled tube. The welding method comprises the steps that when two tube sections with the same tube diameter are connected, a parallel flaring process is conducted on the connecting end of one tube section; when two tube sections with similar tube diameters are connected, the connecting end of the tube section with the larger tube diameter is subjected to a taper necking process, and the connecting end of the tube section with the smaller tube diameter is subjected to a taper flaring process; and the two tube sections are assembled and connected after being cleaned, and two circular seam autogenous welding is carried out between the connecting ends of the two tube sections by adopting argon arc welding, so that reliable connection is realized. According to the welding method, the assembly precision requirement and the welding difficulty can be lowered, the method is suitable for being used in field maintenance operation, and efficient connection of the easy-to-oxidize alloy thin-walled tube is achieved.

Owner:TIANJIN UNIV

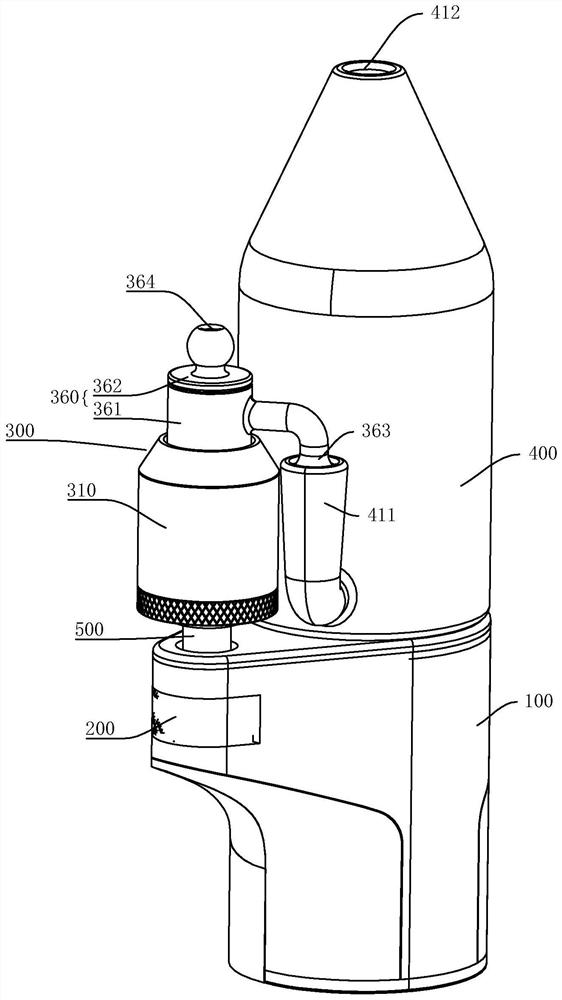

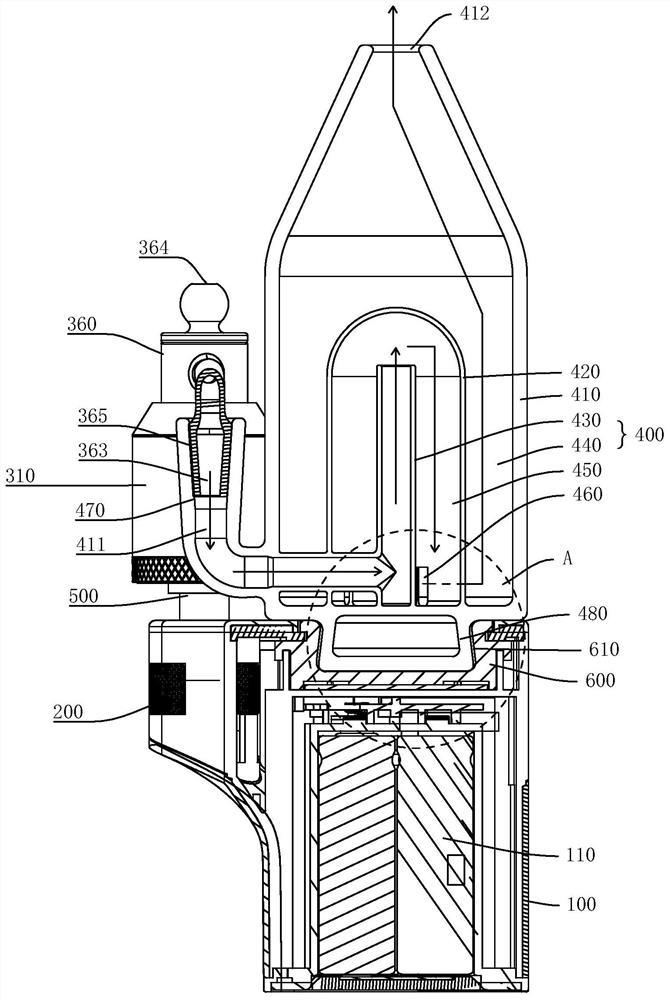

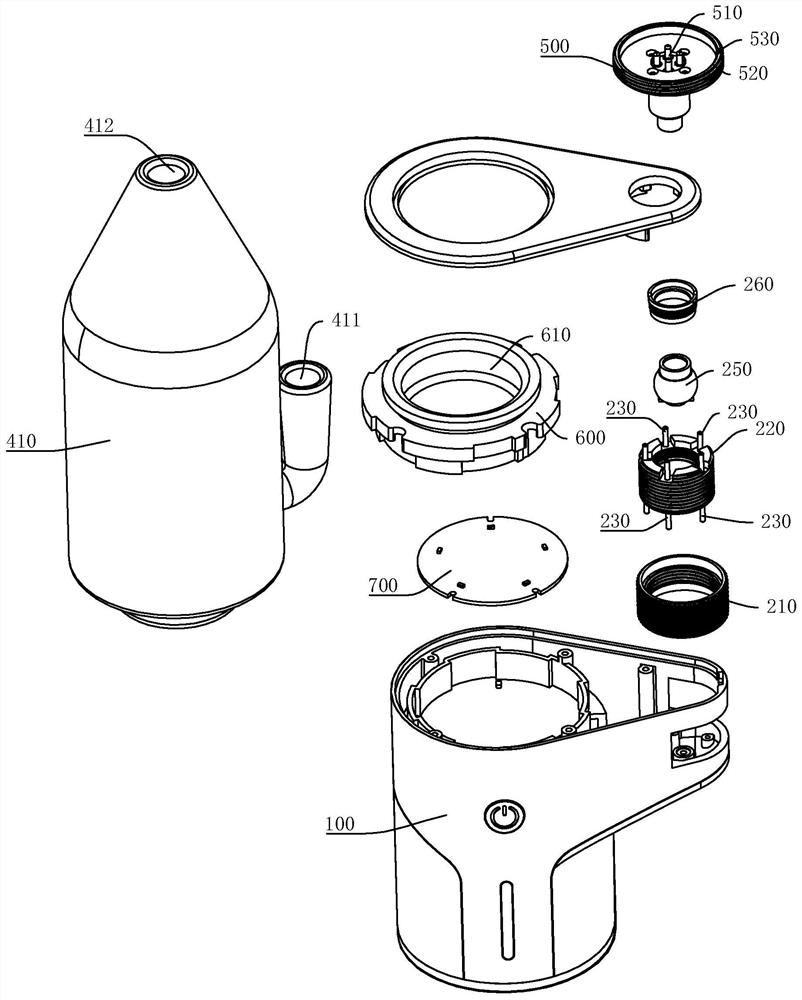

Electronic cigarette capable of adjusting butt joint position

The invention discloses an electronic cigarette capable of adjusting a butt joint position. The electronic cigarette comprises an electronic cigarette base, a position adjusting mechanism, a cigarettepaste heating assembly and a water filtering assembly. The position adjusting mechanism is arranged on the electronic cigarette holder, the tobacco paste heating assembly is provided with an air outlet end and an air inlet end, the water filtering assembly is provided with an air inlet end and a smoke suction end, and the position adjusting mechanism is connected with the tobacco paste heating assembly and / or the water filtering assembly so as to adjust the relative position of the tobacco paste heating assembly and the water filtering assembly, so that the air outlet end of the tobacco pasteheating assembly can be in butt joint with the air inlet end of the water filtering assembly; the position of at least one of the tobacco paste heating assembly and the water filtering assembly can be adjusted through the position adjusting mechanism, so that the air outlet end of the tobacco paste heating assembly can directly face the air inlet end of the water filtering assembly, the air tightness requirement in the using process can be guaranteed, and the product using quality is improved.

Owner:中山市聚泰莱电子科技有限公司

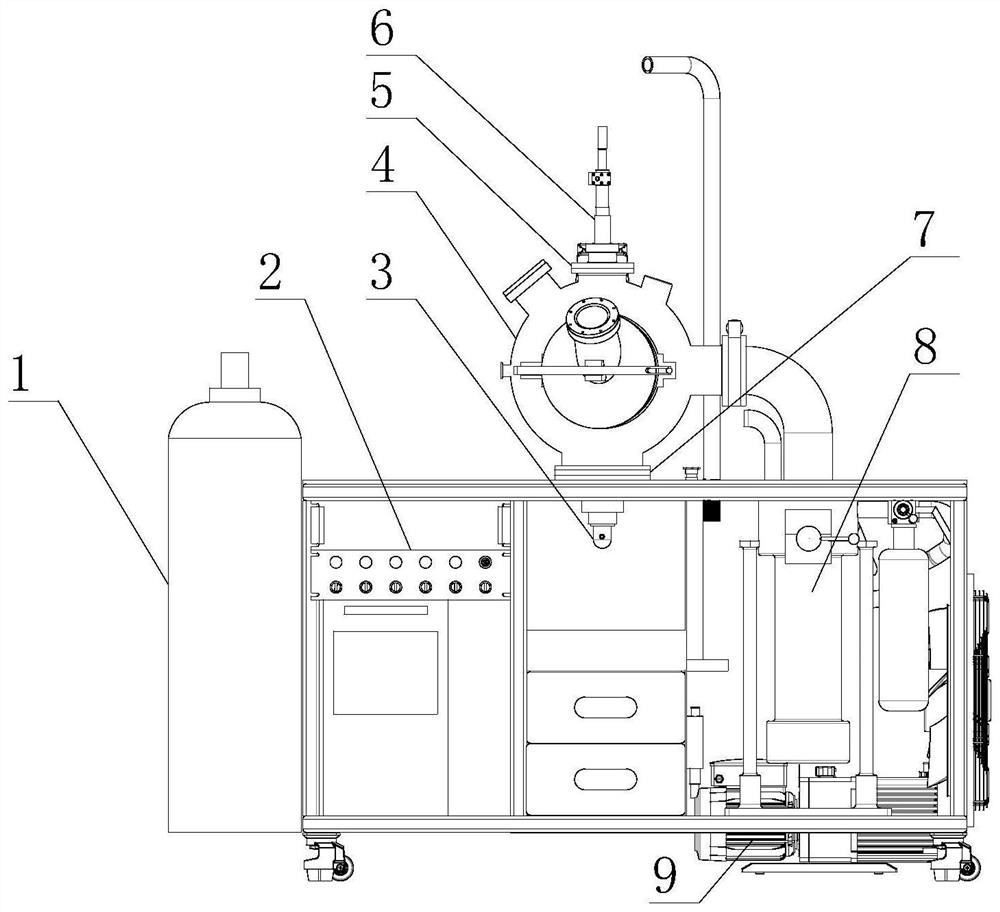

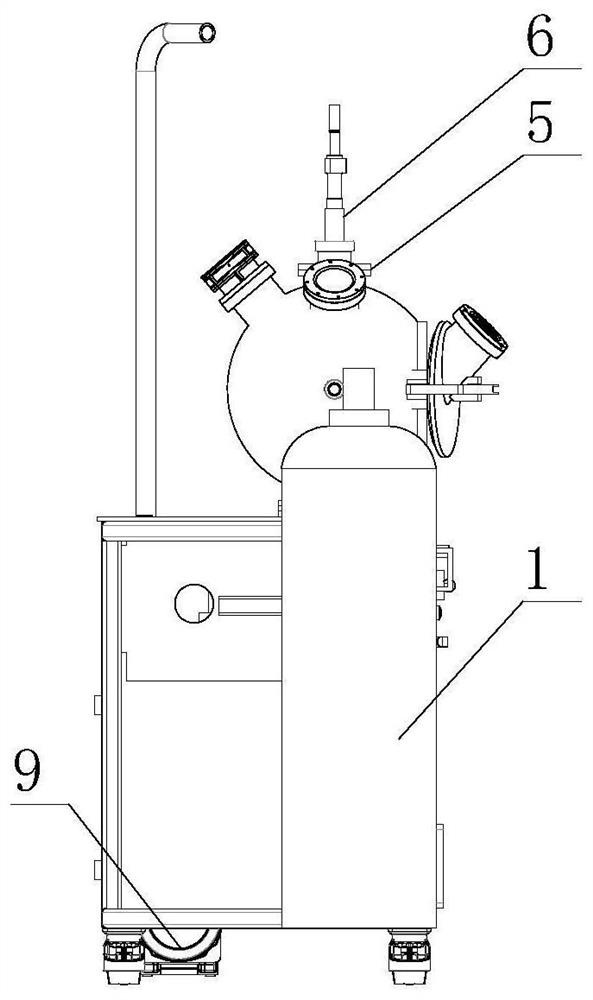

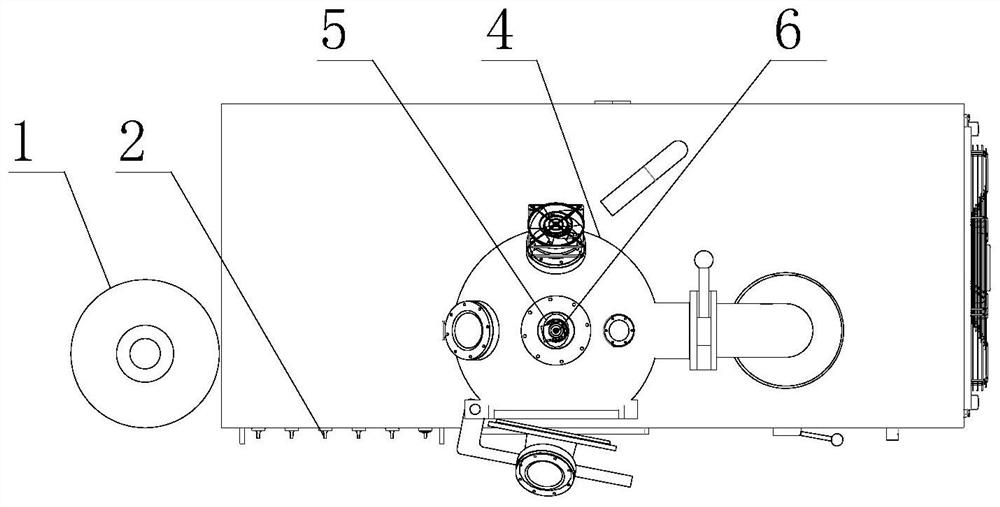

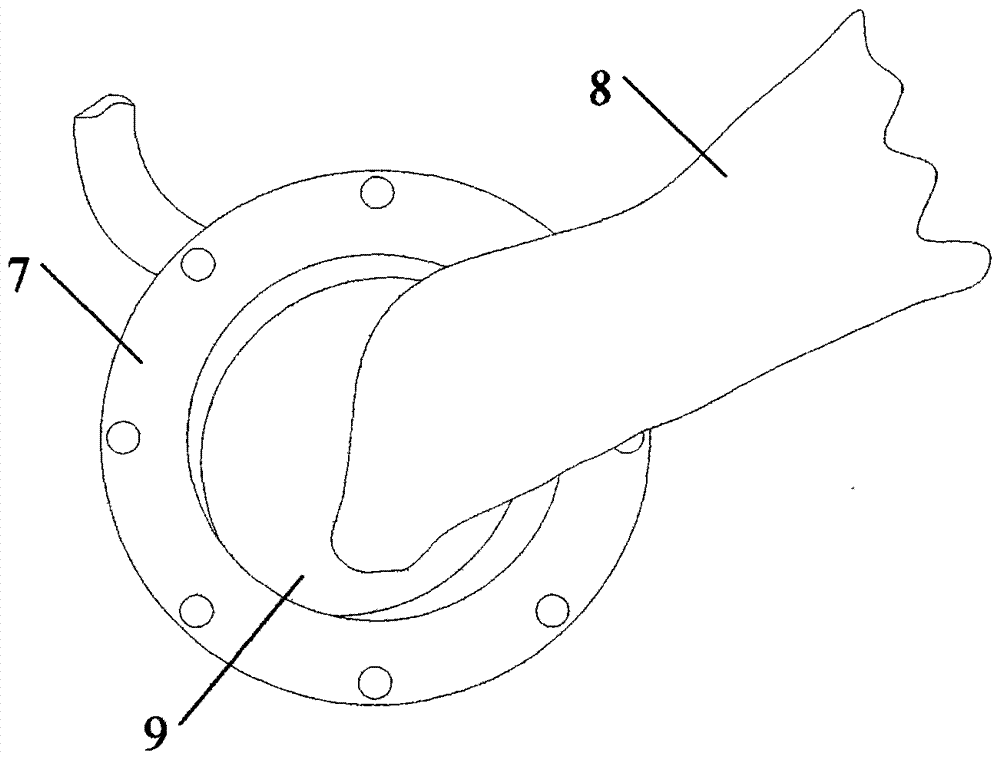

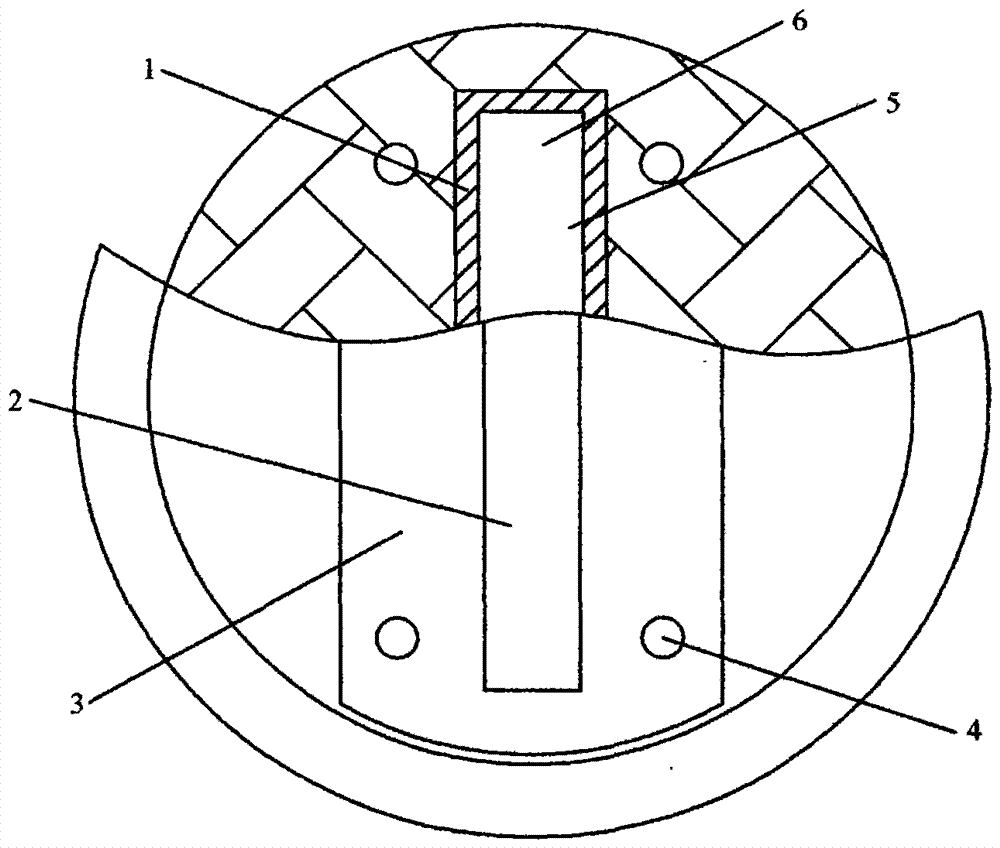

Vacuum efficient electric arc melting furnace system

PendingCN113324408AReduce gapIncrease surface areaEngine sealsCharge treatment typeElectric arc furnaceAir tightness

The invention belongs to the technical field of electric arc melting furnace equipment, and aims to provide a vacuum efficient electric arc melting furnace system aiming at the technical problem of poor air tightness in the prior art. The vacuum efficient electric arc melting furnace system comprises an argon tank, an electric arc furnace, a diffusion pump and a vacuum pump, wherein the argon tank is connected with the electric arc furnace through a gas pipeline, and the electric arc furnace is filled with argon through the argon tank; the top end of the electric arc furnace is connected with a rocker through a rocker base, the bottom end of the electric arc furnace is connected with a copper cap through a crucible, the side of the electric arc furnace is connected with a diffusion pump through a pipeline, the electric arc furnace is connected with a vacuum pump through a gas pipeline, and the vacuum pump is started to control the electric arc furnace to vacuumize. Airtightness of the system is improved. According to the design of the comprehensive system provided by the invention, the high-vacuum air exhaust time of the smelting furnace is improved from 30 minutes every time to 1 minute every time. The time of scientific researchers is greatly saved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

A kind of cable harness flange filling and sealing method

ActiveCN103206577BGuaranteed air tightness requirementsImprove reliabilityPipesFlangeSilicone rubber

The invention discloses a cable bundle flange filling and sealing method, which mainly includes: a. using a silicon rubber sealing ring to seal the flange that needs to be poured; b. Holes are opened, and the fluid silicone rubber is poured into the flange in layers until the pouring surface of the silicone rubber is flush with the inner surface of the flange. The cable harness flange filling and sealing method of the present invention can overcome the defects of uneven rubber surface, easy leakage, poor sealing performance and low reliability in the prior art, so as to achieve smooth rubber surface, not easy to leak, good sealing performance and The advantage of high reliability.

Owner:BEIJING XINLI MACHINERY

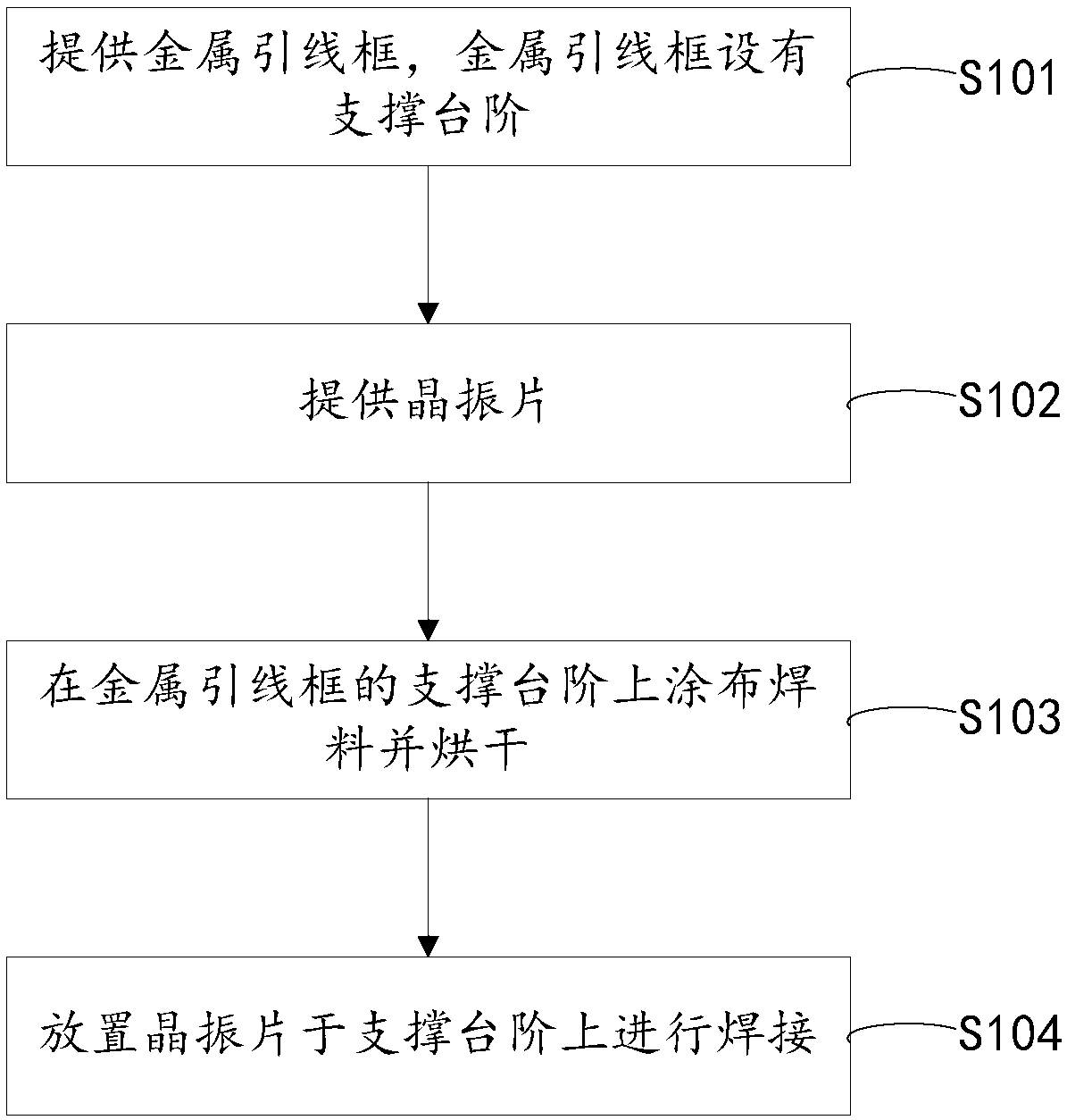

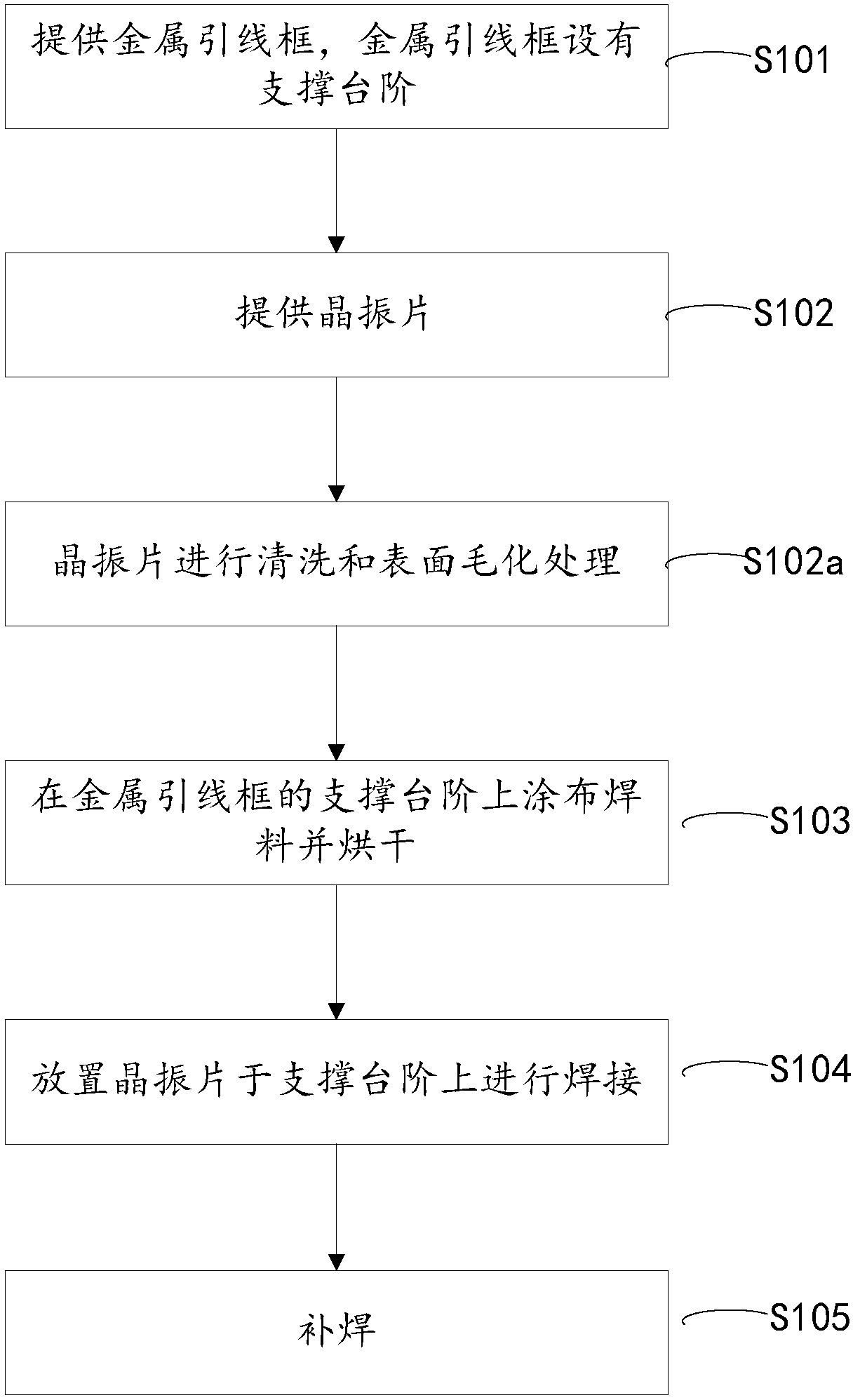

Crystal oscillator welding method

InactiveCN109727879ALow soldering temperatureLow costSemiconductor/solid-state device manufacturingEngineeringLead frame

A crystal oscillator welding method of the invention includes the following steps: providing a metal lead frame having a support step; providing a crystal oscillator; coating the support step of the metal lead frame with solder and drying the solder; and placing the crystal oscillator plate on the support step for welding. The welding method has the advantages of low welding temperature, high efficiency, good reliability and low cost.

Owner:SAE TECH DELEVOPMENT DONGGUAN

A laser welding method for stainless steel thick-walled pressure vessel

ActiveCN106392325BSolve welding strength problemsAvoid defectsDomestic vesselsMetal working apparatusThick wallHigh intensity

The invention provides a laser welding method for a stainless steel thick-walled pressure vessel. The pressure vessel includes a high-pressure tank body, a low-pressure buffer pressure vessel and pipelines. The high-pressure tank body is made of solid-solution-strengthened or aging-strengthened stainless steel; The circular seam at the joint between the high-pressure tank and the low-pressure buffer pressure vessel is continuously welded by laser. The continuous welding parameters of the circular seam include: when the wall thickness of the tank is 5mm-10mm, the laser power is 4.2-7.5KW, the welding Speed 0.8~1.5m / min, defocus amount -2mm~3mm, protective gas flow 15~25L / min. The invention solves the welding strength problem of high-strength stainless steel materials in solid solution or age-strengthening state, has high and stable welding strength, and realizes equal-strength connection of base materials.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Canopy air tightness test fixture

ActiveCN113977499BGuaranteed air tightness requirementsGuaranteed tightnessWork holdersFluid-tightness measurement using fluid/vacuumRubber ringStructural engineering

The invention relates to a test fixture for the airtightness of a canopy. An airtight platform is positioned and connected to the upper surface of the base of the frame structure, and upright columns are respectively arranged at the front and back of the lower surface of the base; The pressing device presses and seals the lower edge of the canopy to be tested with the sealing rubber ring of the airtight platform; the external pressing device consists of a front pressing device, a rear pressing device and a side tensioning device; The inspection hole communicates with the inner cavity of the canopy to be tested, and the bottom of the inspection hole is connected to the shielded cover plate, which is sealed and connected to the base through the bolts arranged around the circumference; Use sealing joints and vacuum sealing joints. The canopy airtightness test fixtures are evenly distributed to ensure that the pressing force is uniform during the automatic locking process, thereby improving the sealing performance.

Owner:辽宁华天航空科技股份有限公司

An automatic parallel sealing welding device and sealing welding method based on image recognition

ActiveCN111730185BAchieve absorptionAchieve releaseCurved planar seam weldingMetal working apparatusControl systemVisual inspection

The invention relates to an automatic parallel seal welding device based on image recognition and a seal welding method, and belongs to the technical field of fine electronic product welding. The automatic parallel seal welding device comprises a baseplate as well as a product tooling positioning mechanism, a spot welding positioning mechanism, a seam welding positioning mechanism, a visual inspection system and a control system, wherein the product tooling positioning mechanism comprises a longitudinal reciprocating moving mechanism and a rotating mechanism; the longitudinal reciprocating moving mechanism is mounted on the baseplate; the rotating mechanism is mounted on the longitudinal reciprocating moving mechanism; a product tooling is mounted on the rotating mechanism; two parallelly-arranged rack vertical plates are mounted on the baseplate; the spot welding positioning mechanism and the seam welding positioning mechanism are both mounted on the rack vertical plates; spot weldingelectrode wheels are mounted on the spot welding positioning mechanism; seam welding electrode wheels are mounted on the seam welding positioning mechanism; and the visual inspection system is mounted on the spot welding positioning mechanism. The automatic parallel seal welding device is utilized for solving the technical problem that during the seal welding process in the prior art, the degreeof automation is low, the production efficiency is low, the product air-tightness is poor, and the appearance quality is poor.

Owner:烟台华创智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com