Tungsten and molybdenum copper alloy heat sink material and preparation method

A heat sink material, molybdenum-copper alloy technology, applied in the field of tungsten-copper and molybdenum-copper alloy heat sink materials and preparation, can solve the problems of inconsistent thermal expansion, chip damage and failure, unsatisfactory thermal conductivity, etc., to improve Z-direction heat conduction, The effect of ensuring airtightness and realizing miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

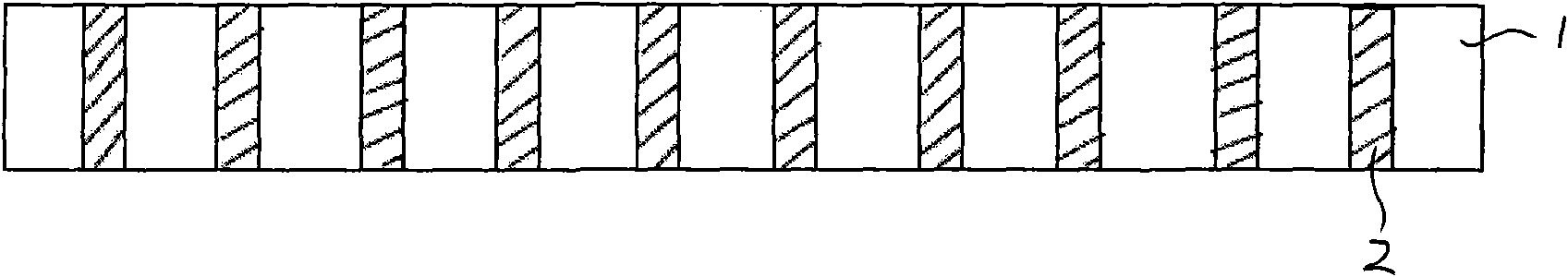

Embodiment 1

[0014] Embodiment 1: Referring to the accompanying drawings, a tungsten-copper plate 1 with a size of 45mm×45mm×1.1mm and a tungsten content of 85wt% is selected, and penetration holes are drilled according to the calculated ratio. Then choose an oxygen-free copper sheet of 45mm×45mm×1.3mm, and process the oxygen-free copper sheet by CNC to produce a nail-shaped integral copper core in the same position (same arrangement) and the same number as the tungsten-copper plate penetration holes, among which nail-shaped copper The core height is 1.2mm. Insert the perforated tungsten copper plate into the copper core nail plate, send it into a high-temperature furnace, and infiltrate it at a temperature of 1400 ° C, so that the copper core 2 and the penetration hole on the tungsten copper plate 1 are closely combined, and finally the two sides are coated with copper by grinding removed, processed to obtain the final product. The test coefficient of linear expansion (CTE) is 7ppm / ℃, th...

Embodiment 2

[0015] Embodiment 2: As in Embodiment 1, the copper cores are inserted one by one into the perforated tungsten-copper plate, rolled on both sides so that the expanded hole of the copper core is riveted with the tungsten-copper plate, and the two planes are ground and processed.

Embodiment 3

[0016] Example 3: As in Example 1, put the perforated tungsten copper plate into the molten copper solution or pour the molten copper solution to fill the holes, grind and process both sides after cooling.

[0017] Comparative example: example 1 tungsten-copper plate with tungsten content of 85wt%, thermal conductivity: about 180W / M·K, coefficient of linear expansion (CTE) 7ppm / °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com