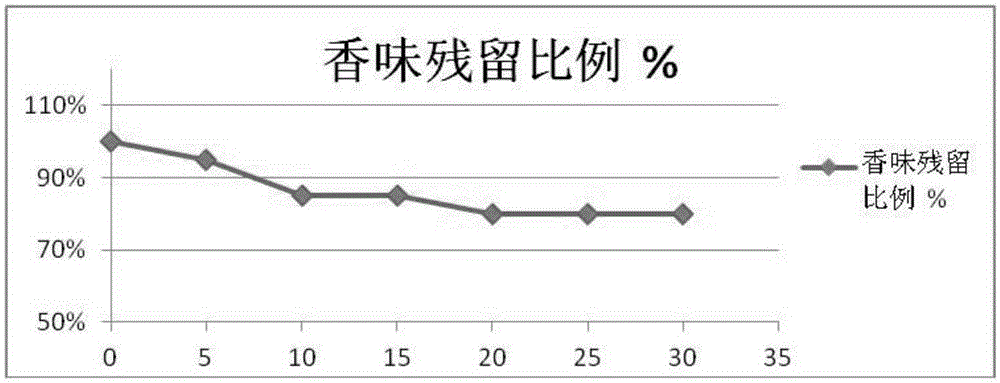

Multifunctional aroma environment-friendly PVC leather production method

A production method and multi-functional technology, applied in the direction of layered products, applications, road vehicles, etc., can solve the problems of single function, non-compliance with environmental protection requirements, and inability to release aroma, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

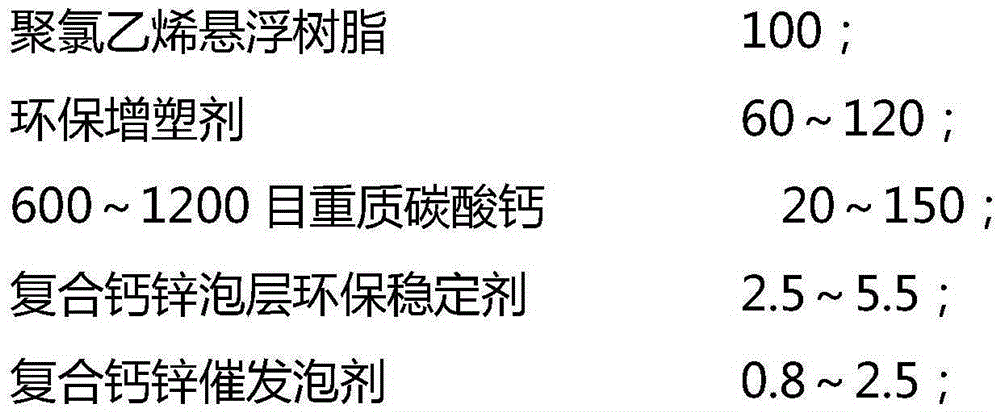

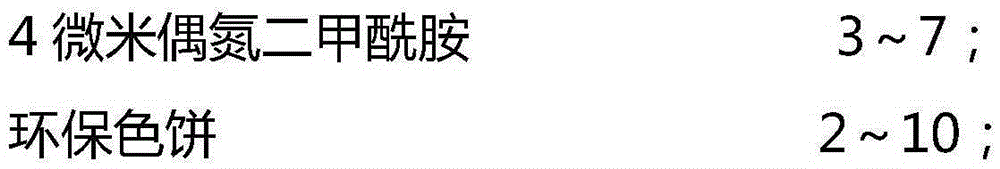

[0018] Embodiment: the production method of multifunctional aromatic and environment-friendly PVC leather, comprising: S1, calendering process: (1) mix the bubble layer formula evenly through a high-speed mixer, transfer to an internal mixer for mixing for 3 to 6 minutes (minutes), and wait for the rubber After the plasticization is completed, the open mill is mixed for 5 to 10 minutes (minutes), filtered through a filter, and the material is transferred to a four-roll calender to compress the film into a film between 0.10 and 0.40 mm (millimeters). Combine with the leather base cloth for use; (2) Mix the surface layer formula evenly through a high-speed mixer, transfer to an internal mixer for 3 to 6 minutes (minutes), and wait for the rubber to be plasticized, and then mix it by an open rolling mill Knead for 4-6 minutes (minutes), filter through a filter, transfer the material to a four-roller calender, press a film and pull a film into a film between 0.10-0.20mm (millimeter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com