Steel plate splicing device

A technology for splicing devices and steel plates, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as unfavorable pre-alignment of steel plates 7 to be welded, low work efficiency, inconvenient removal, etc., so as to speed up heat dissipation and improve Efficiency, the effect of improving alignment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

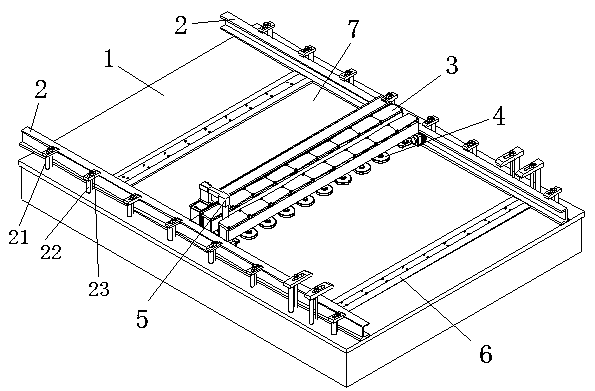

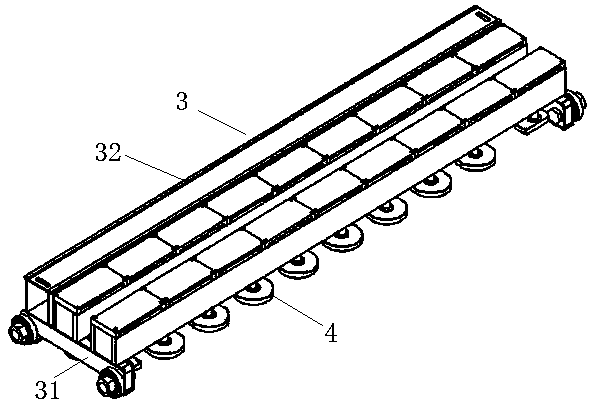

[0032] see figure 2 and image 3 , the steel plate splicing device shown includes a workbench 1, a guide rail 2, a beam 3, a pressing mechanism 4, a welding mechanism 5 and a copper pad 6; the number of the guide rails 2 is two, and they are arranged in parallel on the workbench 1 , the spacing between the guide rails 2 is adjusted according to the size of the steel plate 7 to be welded; the two ends of the beam 3 are provided with sliding seats 31 correspondingly matched with the guide rails 2, and the pressing mechanism 4 is fixed on the beam 1 for The steel plate 7 to be welded is positioned at the welding butt joint, and the upper surface of the beam 1 is provided with a guide rail 32, and the welding mechanism 4 is slidably arranged on the guide rail 32; corresponding to the weld position.

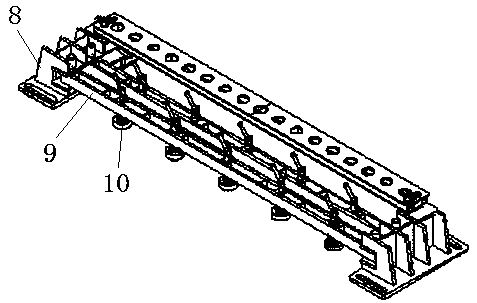

[0033] see Figure 4 A plurality of accommodating cavities are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com