Jig and carrier plate used for attaching circuit board strength reinforcing pieces

A technology for reinforcing patches and circuit boards, used in printed circuits, printed circuit manufacturing, electrical components, etc. Bit time, improved pasting accuracy, and the effect of improving pasting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

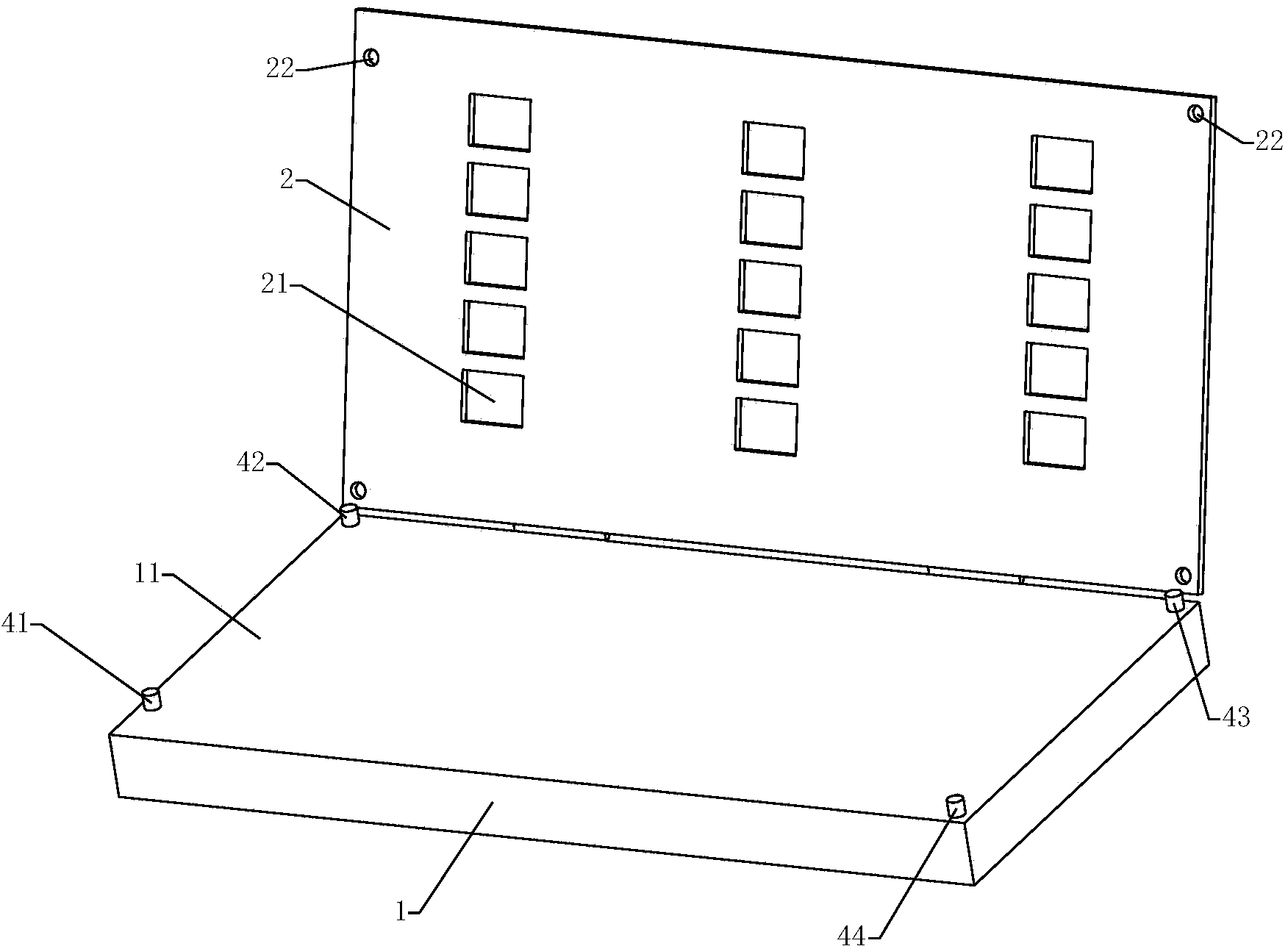

[0044] Such as Figure 1-2As shown, the jig for attaching the circuit board reinforcement patch includes a base plate 1 and a cover plate 2 . The bottom plate 1 has an upper surface 11 for supporting a circuit board. The cover plate 2 is rotatably connected to the bottom plate 1 through a hinge (not shown in the figure). The cover plate 2 is provided with a plurality of first through holes 21 . The shape and size of each first through hole 21 is determined according to each area to be reinforced on the circuit board, so that each first through hole 21 and its corresponding area to be reinforced maintain the same shape and size. In this embodiment, the shapes and sizes of the regions to be reinforced on the circuit board to be reinforced are the same, so the shapes and sizes of the first through holes 21 on the cover plate 2 are the same.

[0045] The jig for attaching the circuit board reinforcement patch also includes a positioning device. The positioning device includes ...

Embodiment 2

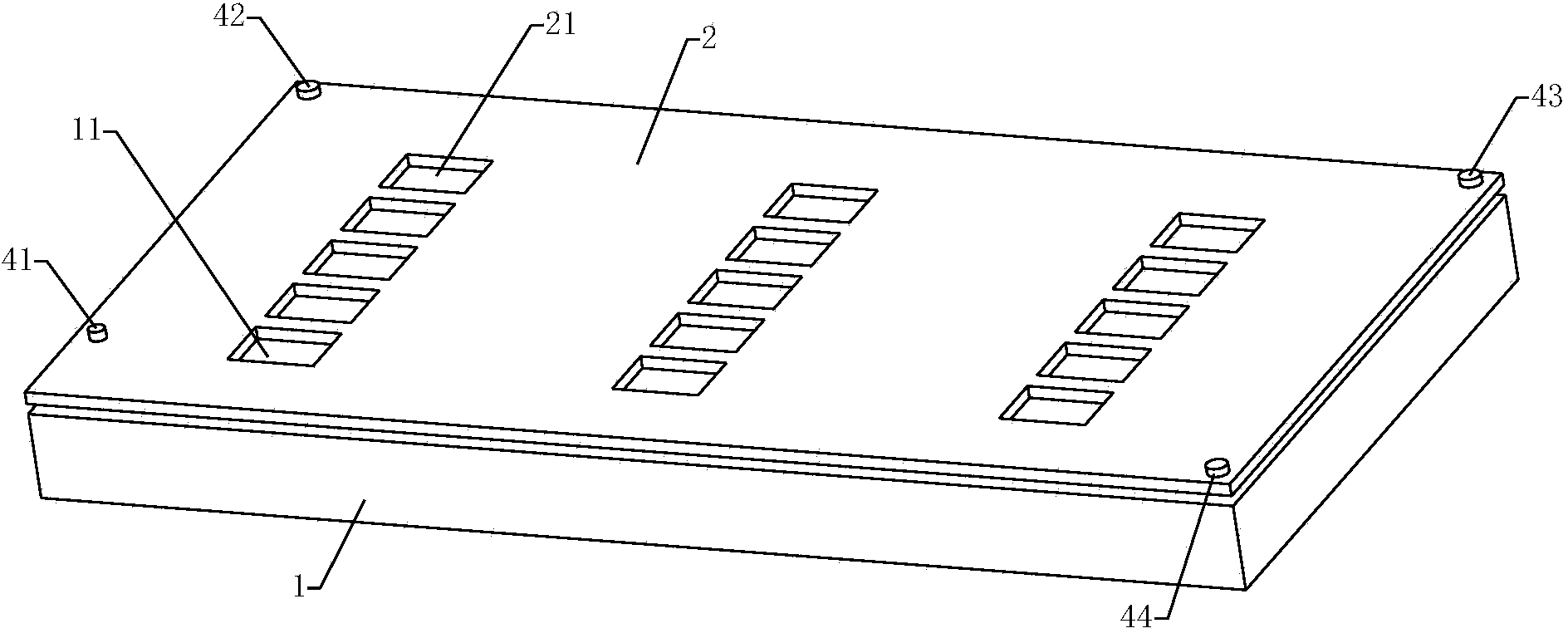

[0056] Such as Figure 8 As shown, the jig for attaching circuit board reinforcement patches includes a base plate 1 and a cover plate 2 . The bottom plate 1 has an upper surface 11 for supporting a circuit board. The cover plate 2 is rotatably connected to the bottom plate 1 through a hinge. The cover plate 2 is provided with a plurality of first through holes 21 . The shape and size of each first through hole 21 is determined according to each area to be reinforced on the circuit board, so that each first through hole 21 and its corresponding area to be reinforced maintain the same shape and size. In this embodiment, the shapes and sizes of the regions to be reinforced on the circuit board to be reinforced are the same, so the shapes and sizes of the first through holes 21 on the cover plate 2 are the same.

[0057] The jig for attaching the circuit board reinforcement patch also includes a positioning device. The positioning device includes four cylindrical positioning ...

Embodiment 3

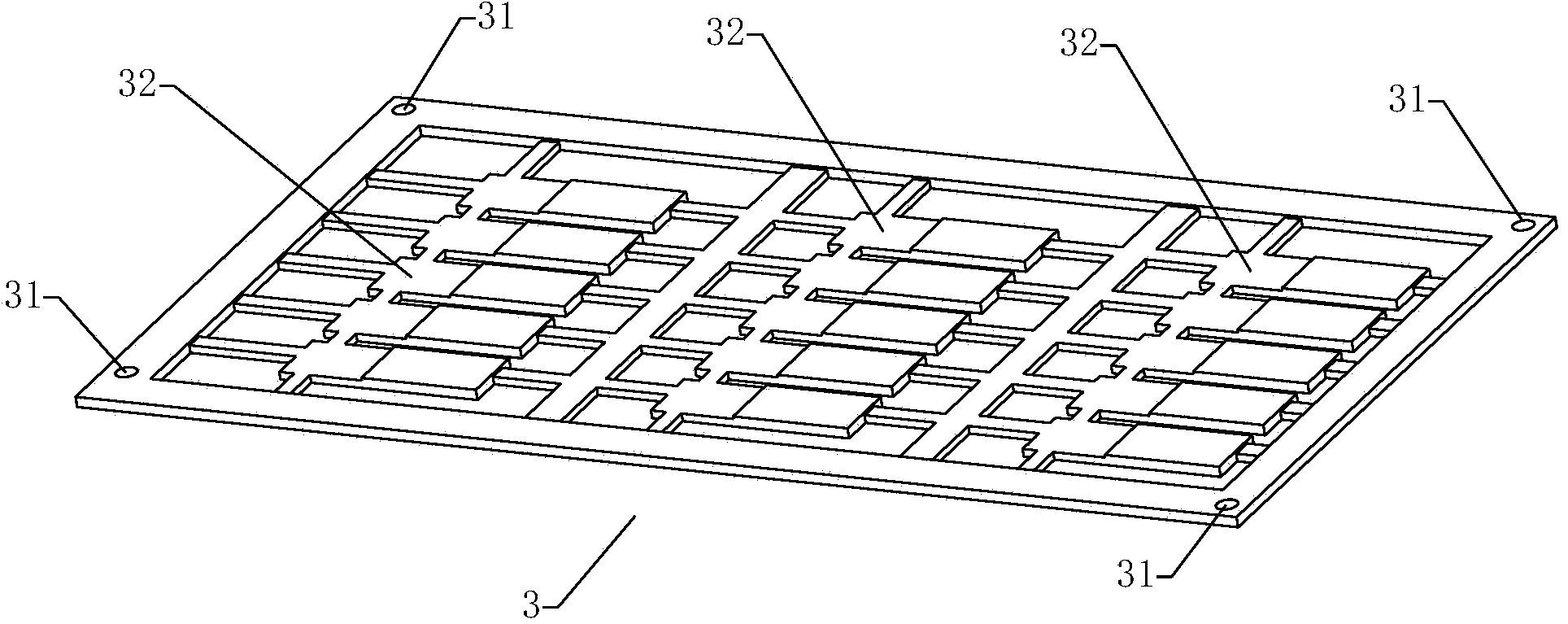

[0073] Such as Figure 9-11 Shown is a reinforcement patch. The reinforcement sheet includes a carrier plate 6 and a plurality of reinforcement sheets 5 . The reinforcement sheet 5 is bonded to the carrier plate 6 by a low-viscosity adhesive.

[0074] The carrier board 6 includes a positioning board 61 and three bonding boards 62 . The positioning plate 61 is provided with a plurality of second through holes 611 , and the shape of the second through holes 611 is the same as that of the reinforcing sheet 5 . The bonding plate 62 is bonded on the positioning plate 61 and covers the second through hole 611 . The reinforcing sheet 5 is inserted into the second through hole 611 and bonded to the bonding plate 62 by a low-viscosity adhesive. The surface of the reinforcement sheet 5 in contact with the adhesive plate 62 is the first surface, and the surface of the reinforcement sheet 5 opposite to the first surface is the second surface, and the second surface is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com