Patents

Literature

46results about How to "Improve pasting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

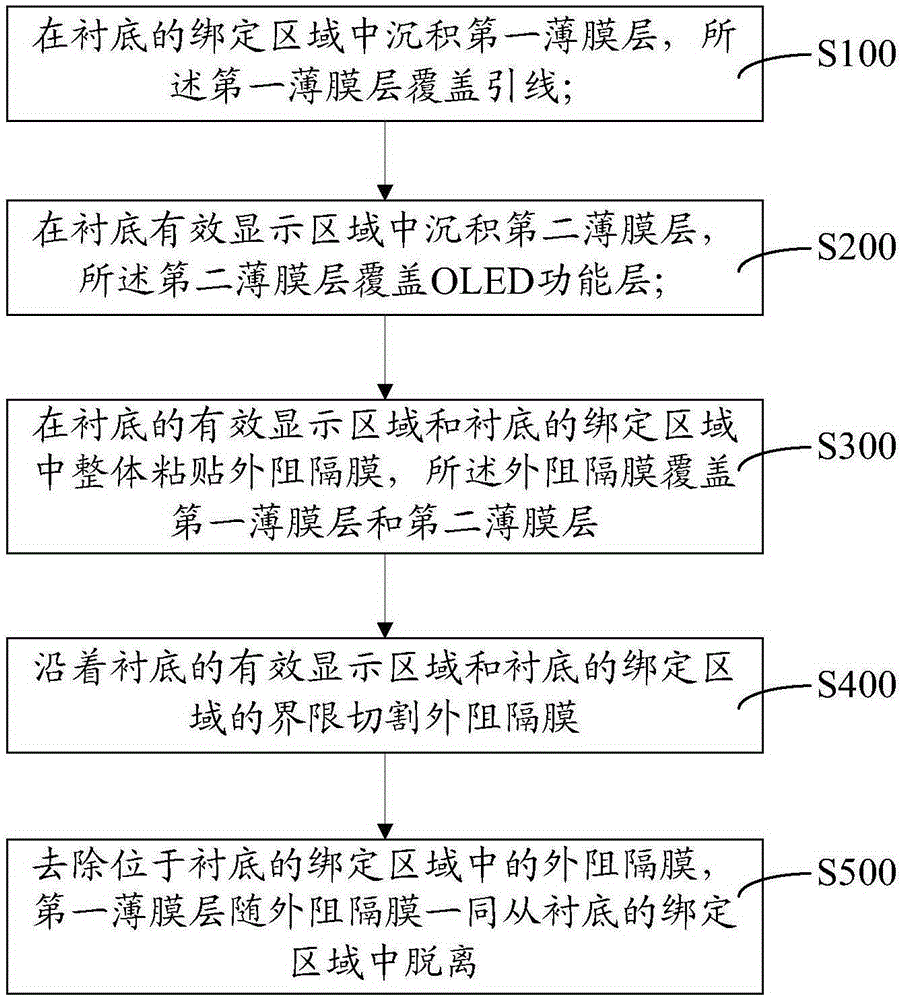

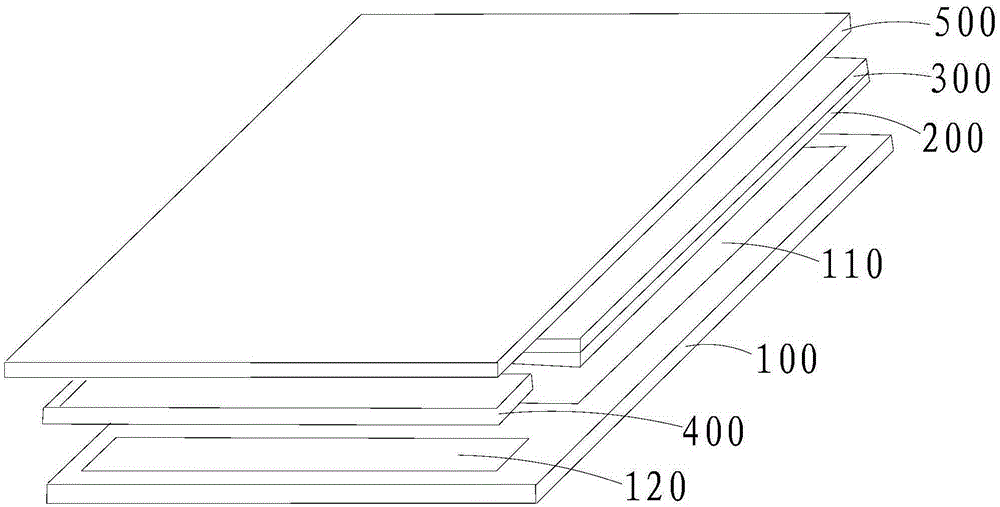

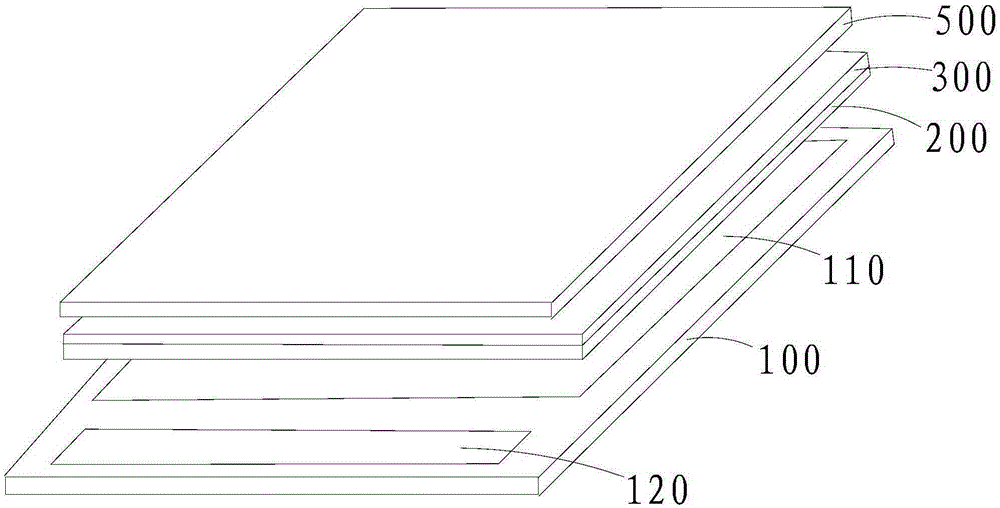

Packaging method of OLED (organic light emitting diode) display panel

ActiveCN105322104AImprove production efficiencyExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeSeparation process

The invention discloses a packaging method of an OLED (organic light emitting diode) display panel. The method comprises the following steps: depositing a first film layer in a binding area of a substrate, wherein the first film layer covers a lead; depositing a second film layer in an effective display area of the substrate, wherein the second film layer covers an OLED functional layer; integrally adhering an outer obstruction film in the effective display area of the substrate and the binding area of the substrate, wherein the outer obstruction film covers the first film layer and the second film layer; cutting the outer obstruction film along a boundary of the effective display area and the binding area of the substrate; and removing the outer obstruction film in the binding area of the substrate, wherein the first film layer is separated from the effectively display area along with the obstruction film. The outer obstruction film is adhered in an integral pasting manner, so that the adhesion efficiency and adhesion precision of the outer obstruction film are effectively improved, damage on the lead in the binding area during the separation process of the outer obstruction film is avoided, the service life of the OLED display panel is prolonged, and the application safety is improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

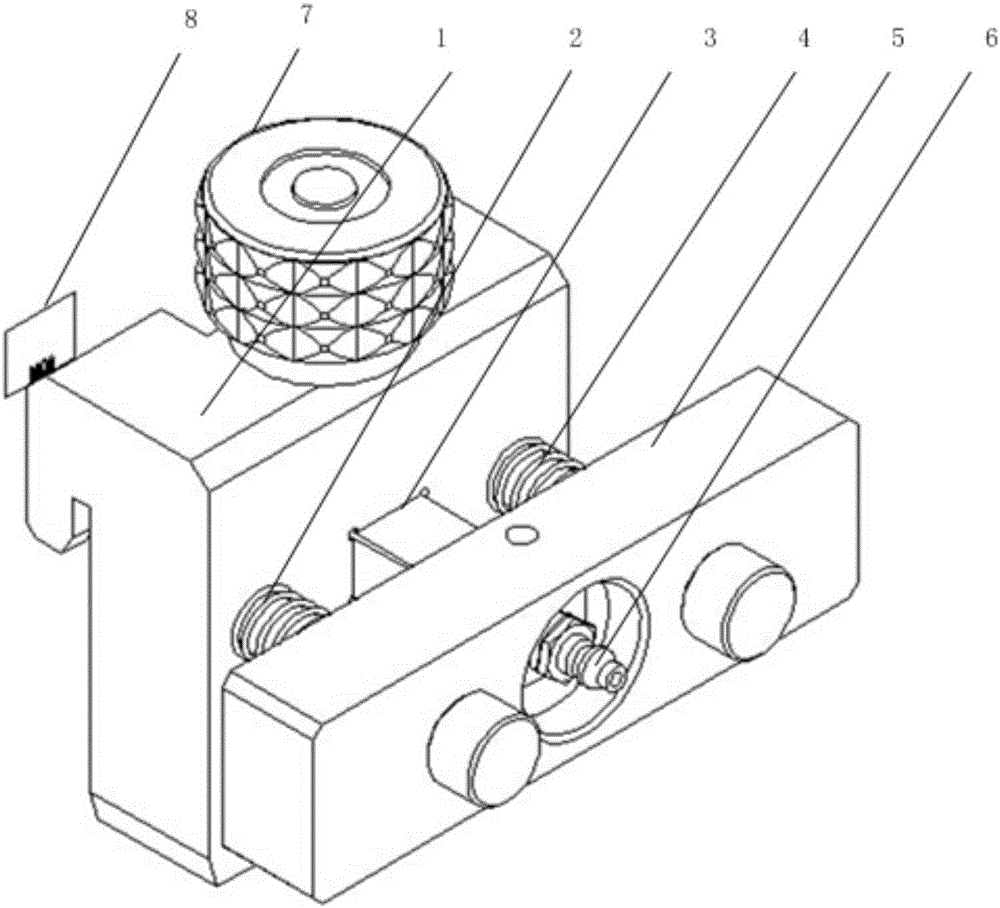

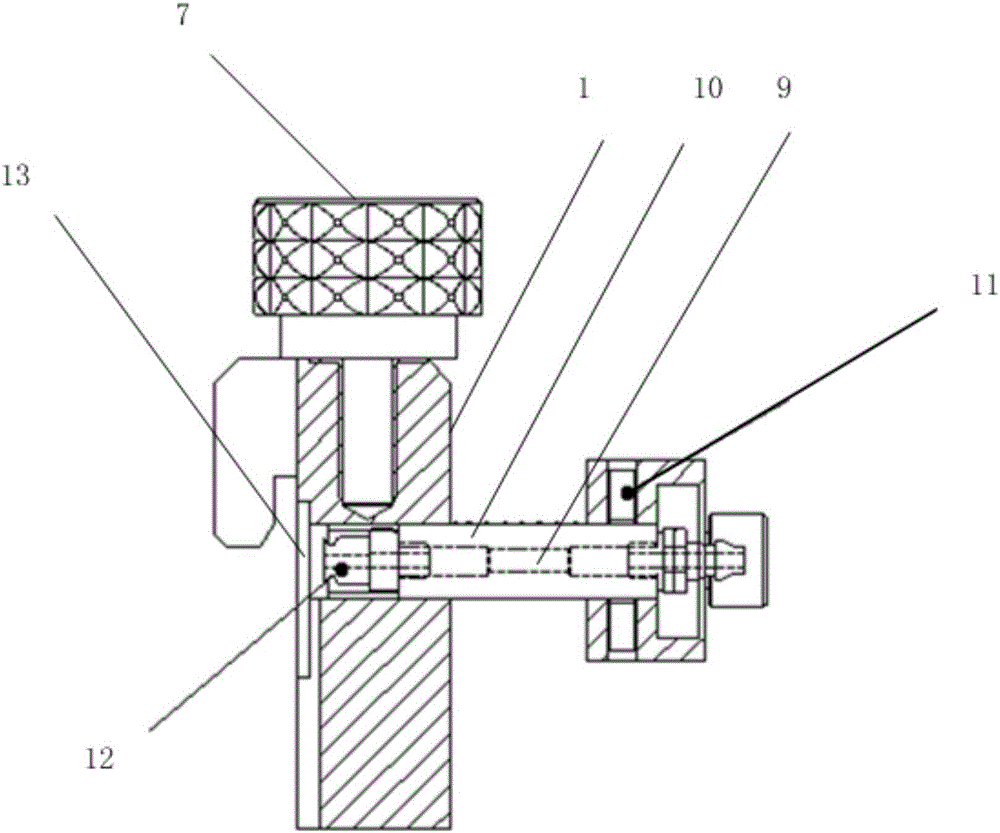

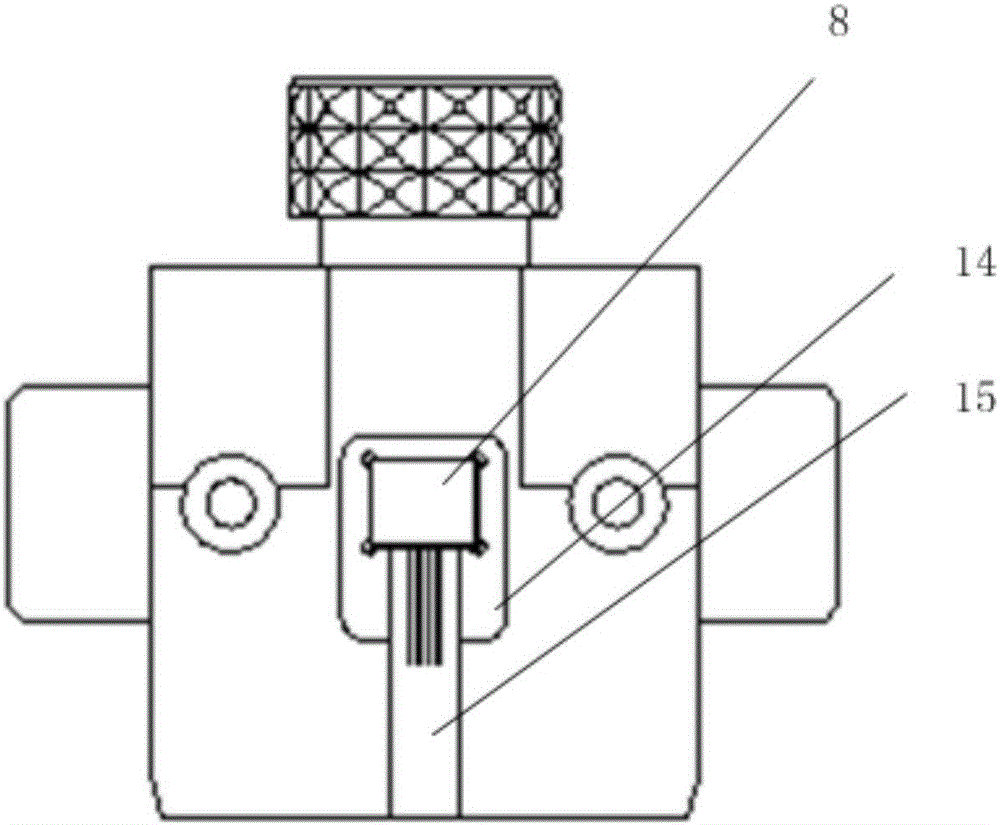

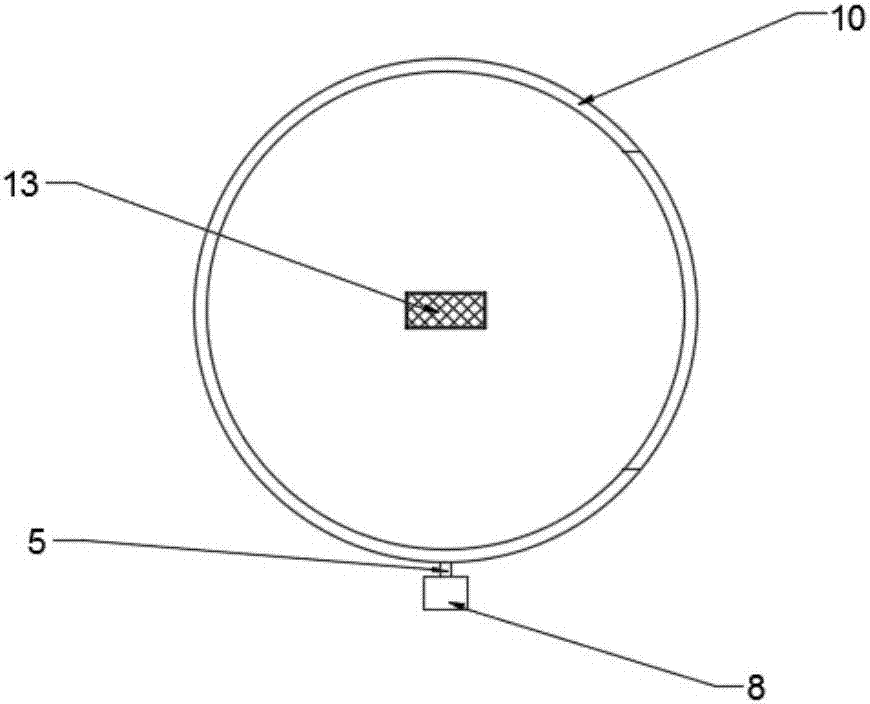

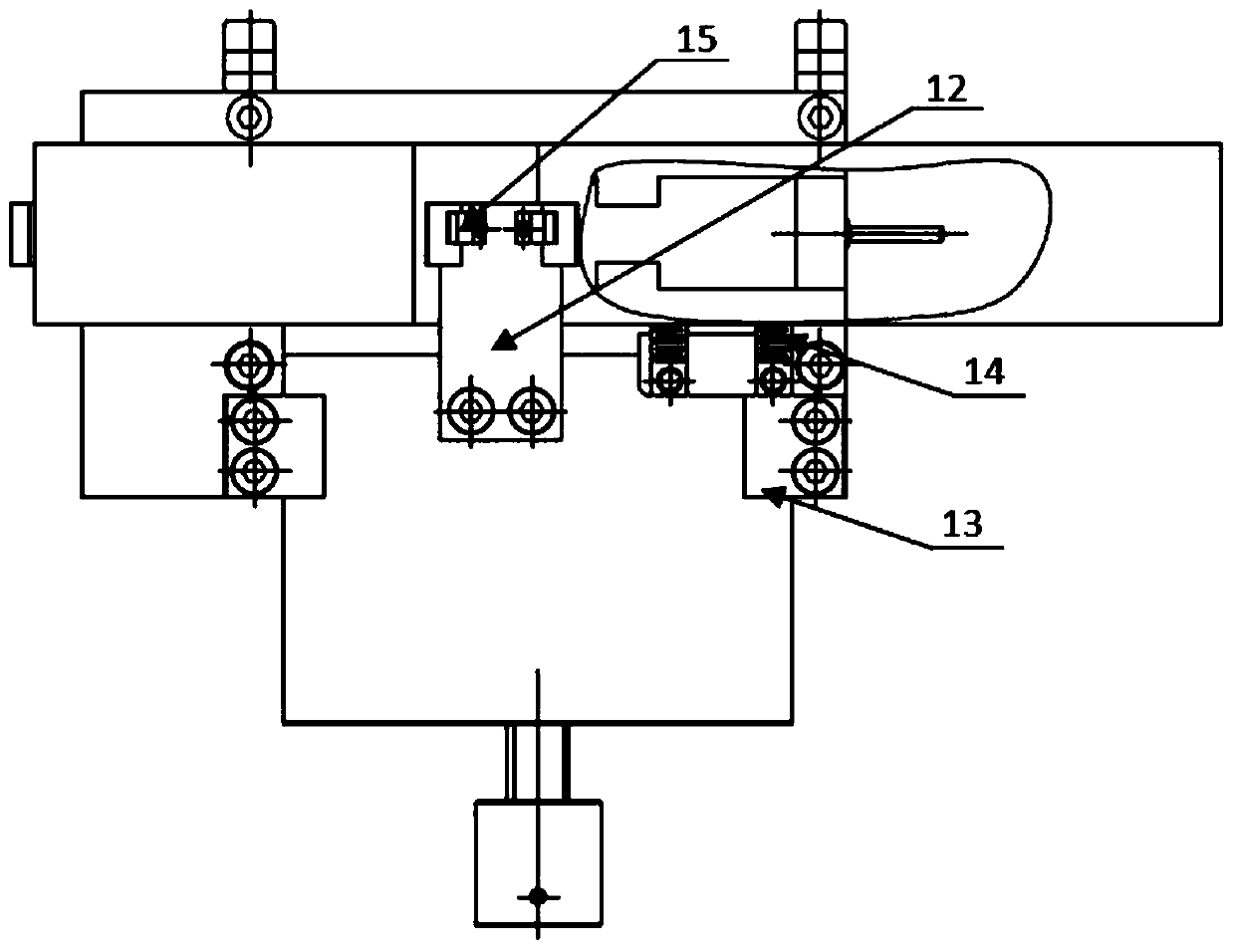

Strain gage pasting device

ActiveCN105065397APlace stableImprove pasting efficiencyFastening meansPulp and paper industryStrain gauge

The invention discloses a strain gage pasting device which is used for pasting a strain gage to a to-be-pasted area. The strain gage pasting device comprises a positioning plate, a compression mechanism and a sucking disc assembly, wherein a strain gage positioning groove and a strain gage line guiding groove are formed in the front end of the positioning plate, and a through hole is formed in the positioning plate and communicated with the strain gage positioning groove; the compression mechanism comprises a pressing plate, a pressing block and a guide column, the guide column is connected to the back end of the positioning plate, the pressing plate is connected to the guide column in a sliding manner, the pressing block is connected to the through hole in a sliding manner, and the back end of the pressing block is connected with the pressing plate; the back end of the pressing block does not exceed the strain gage positioning groove, and a containing hole is formed inside the pressing block; and the sucking disc assembly comprises a vacuum sucking disc, a connecting pipe and a connecting joint, the vacuum sucking disc is fixed to the front end of the containing hole, the connecting joint is fixed to the back end of the containing hole, and a connecting pipe is used for connecting the vacuum sucking disc with the connecting joint and located in the containing hole. By means of the pasting device, the strain gage can be sucked to be accurately pasted into the to-be-pasted area.

Owner:NINEBOT (CHANGZHOU) TECHCO LTD

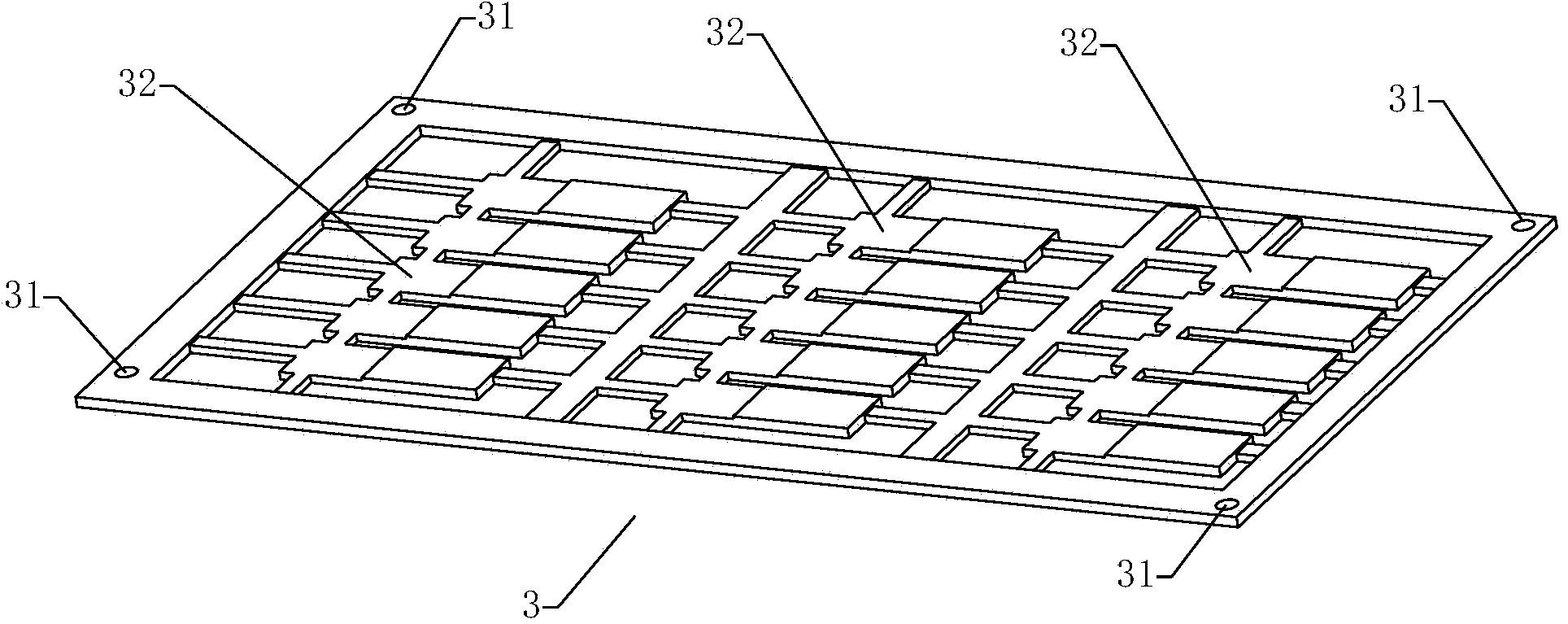

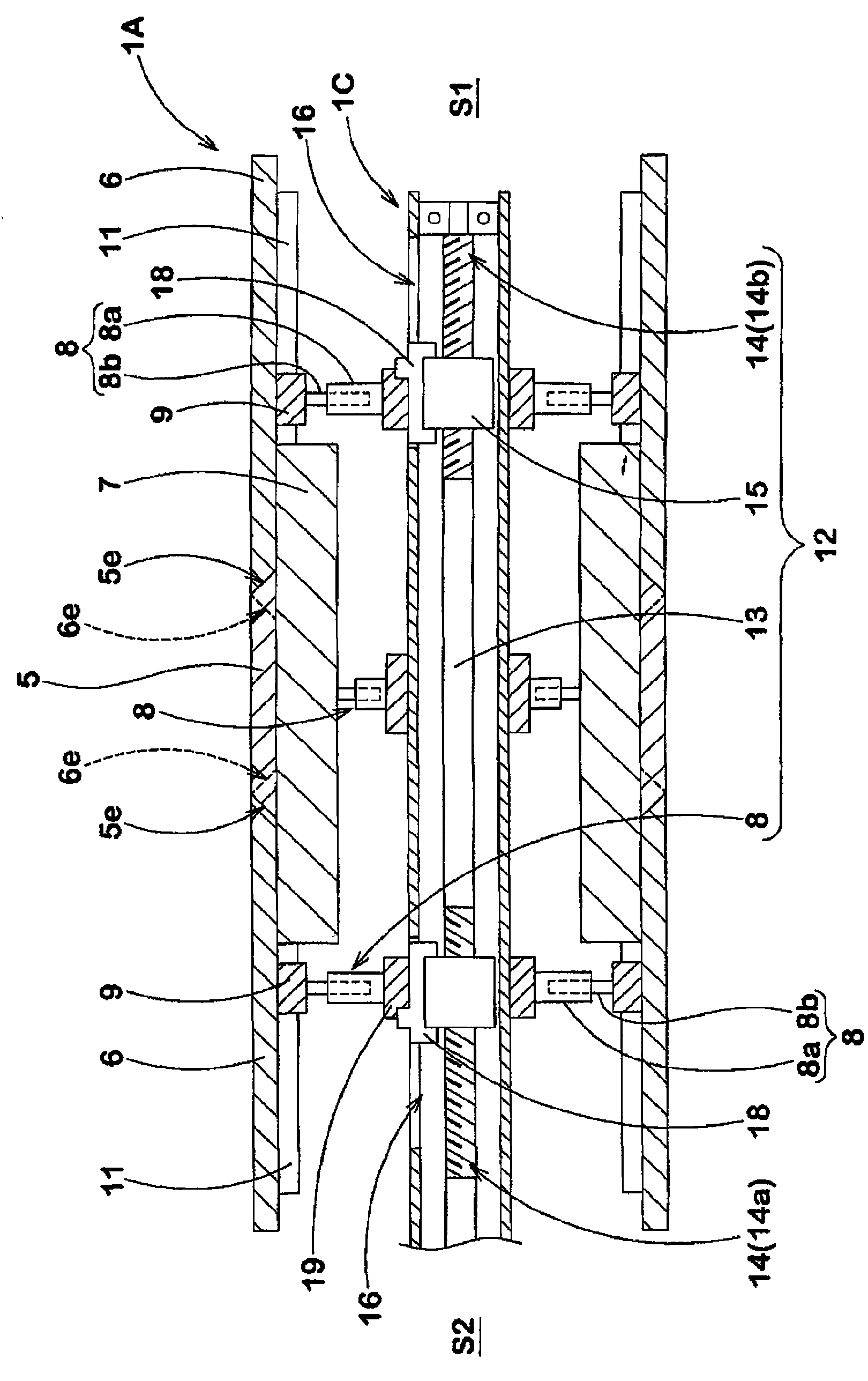

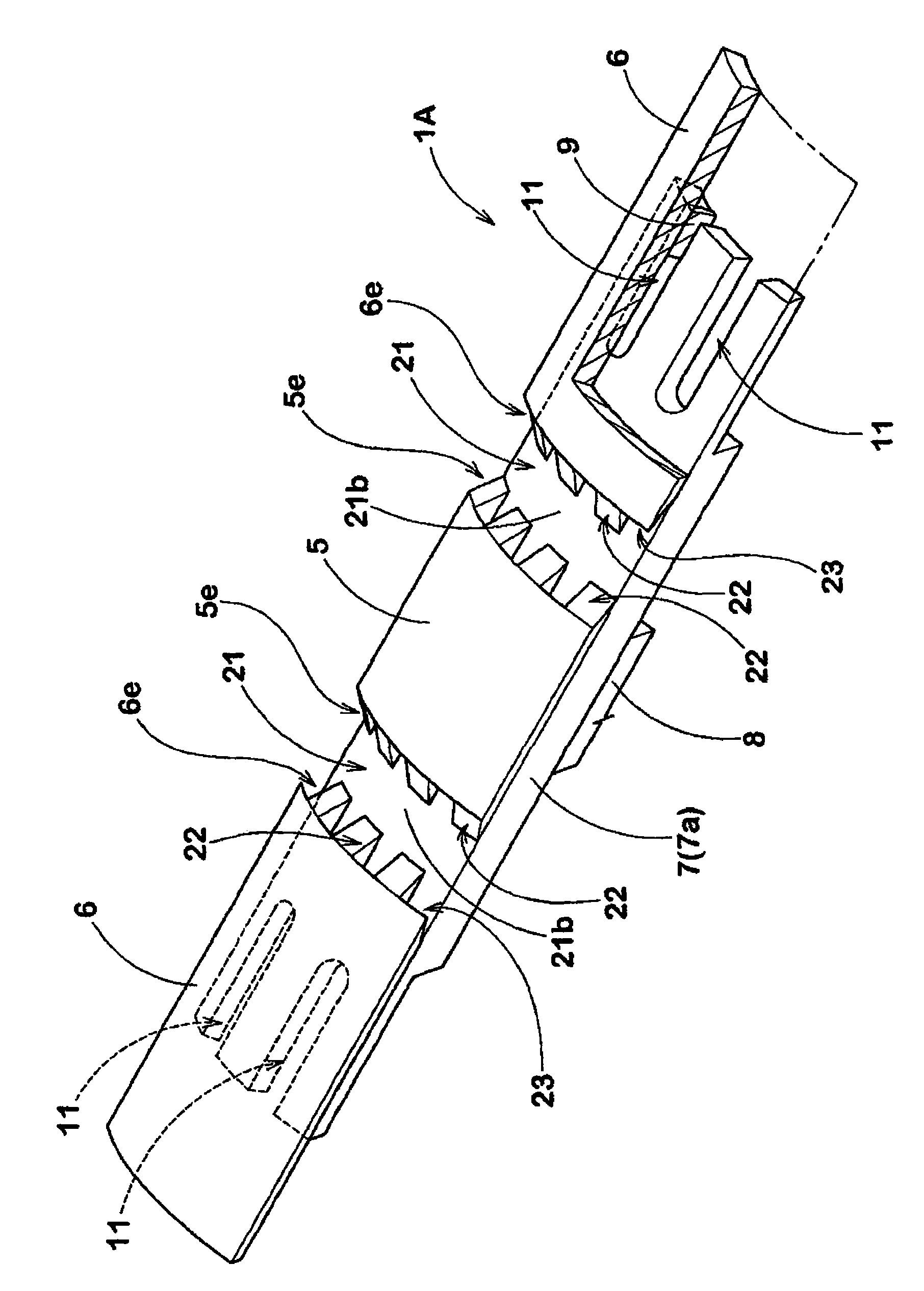

Jig and carrier plate used for attaching circuit board strength reinforcing pieces

ActiveCN103957666AImprove qualityReduce alignment timePrinted circuit manufactureEngineeringMechanical engineering

Owner:SHANGHAI MEADVILLE ELECTRONICS

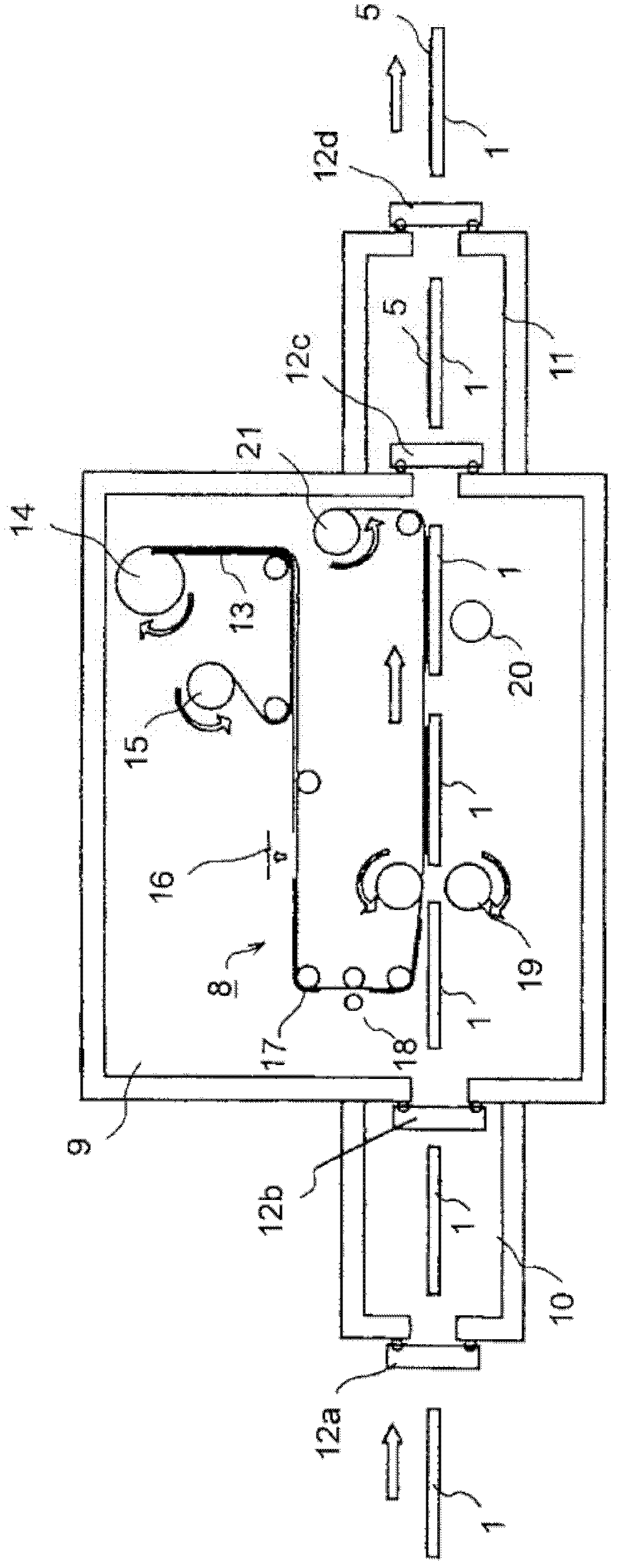

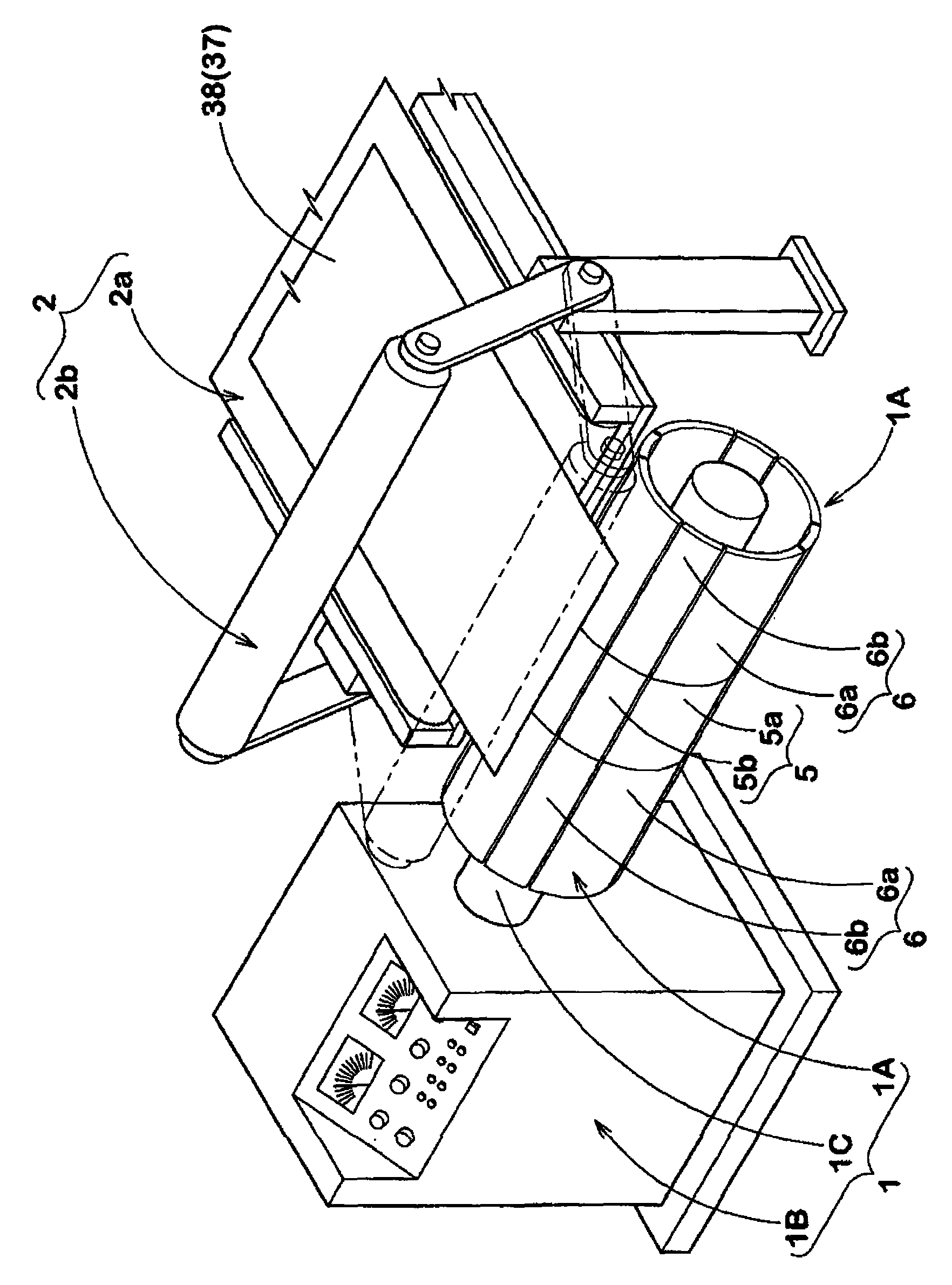

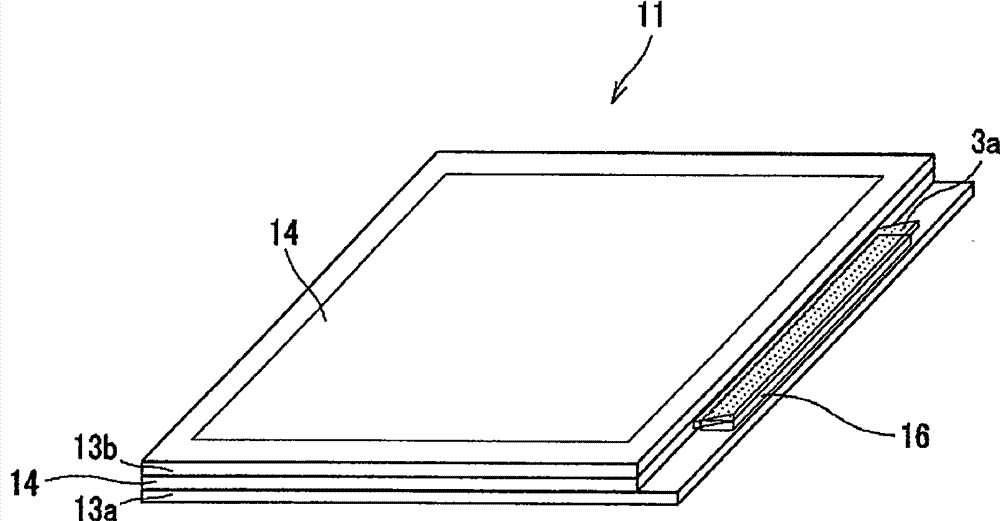

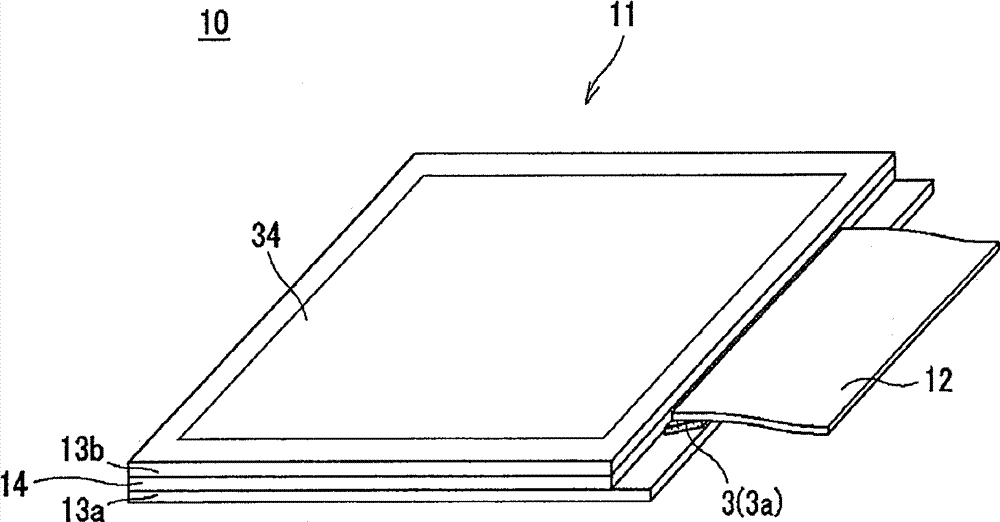

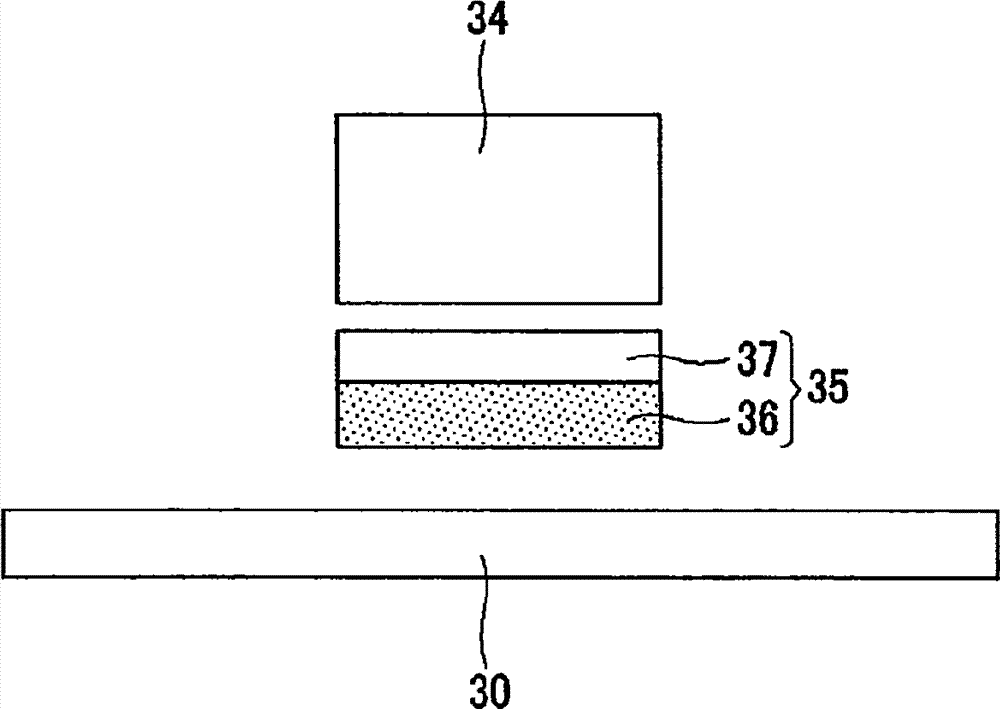

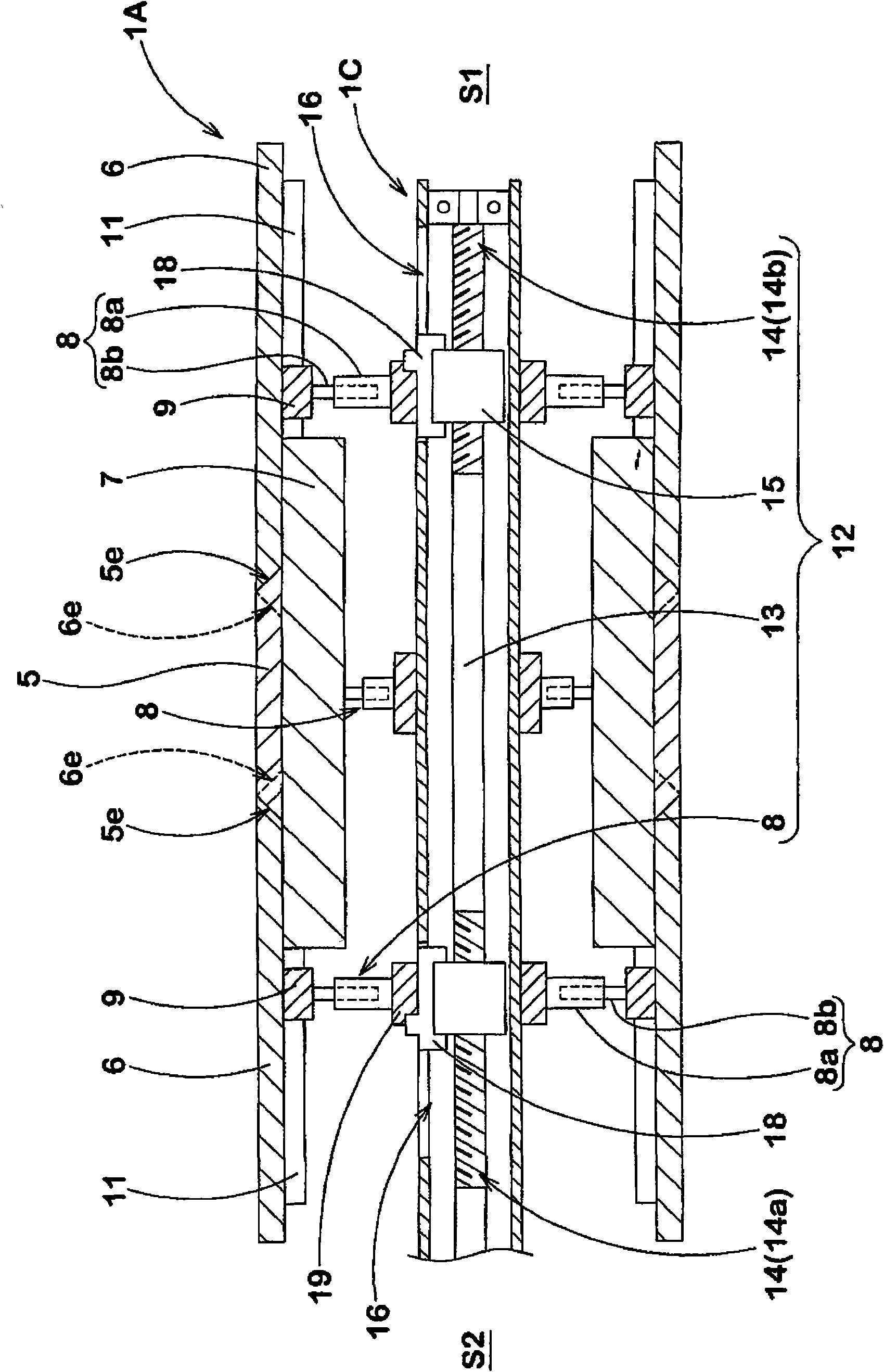

Substrate surface sealing device and organic el panel fabrication method

ActiveCN102326449AImprove pasting accuracyImprove qualityLamination ancillary operationsLayered product treatmentEngineeringSubstrate surface

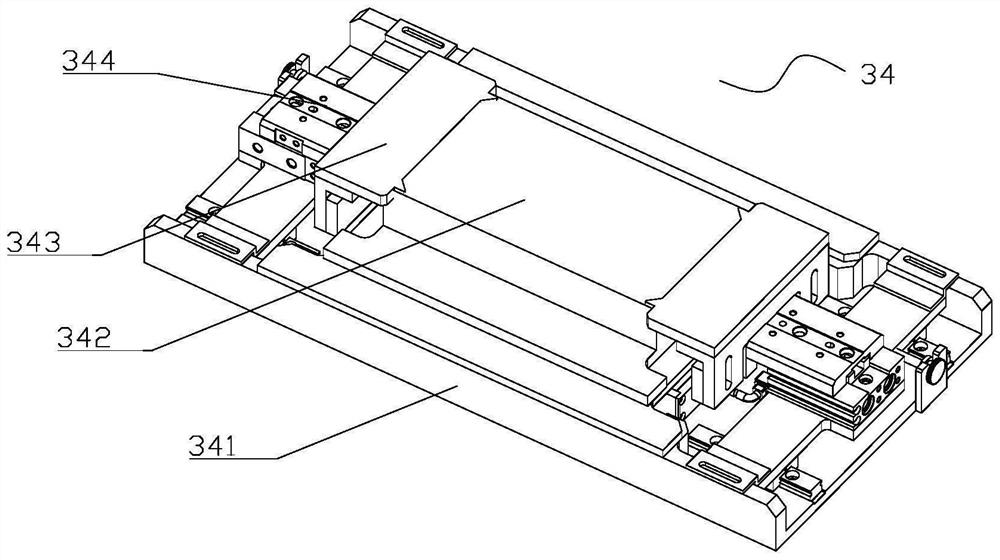

Operating labor is diminished to improve takt time, and lamination that prevents deterioration of the performance of the finished product can be realized. The cover films (13a) are peeled by a cover film uptake mechanism (15) (figure 4) from films (13) from film rolls (24a-24d) (figure 6) of a film out-feed mechanism (14), and then fed to an inter-substrate processing mechanism (16). In the inter-substrate processing mechanism (16), sheet sealing materials (5) (figure 3) are formed, in which specified lengths of the sealing material films (5') of the films (13) (figure 4) are peeled off at specified intervals, as shown in figure 9, by means of half-cut members (34) and a peel-off tape (36) (figure 7). The films (13), treated in this way, are fed into a lamination mechanism (19), where the sheet sealing materials (5) are heated and press-applied to a substrate (1) from the preceding chamber (10), and then cooled by a substrate cooling mechanism (30), and then the base films (13b) (figure 4) of the films (13) are peeled off by a base film uptake mechanism (21).

Owner:SHARP KK

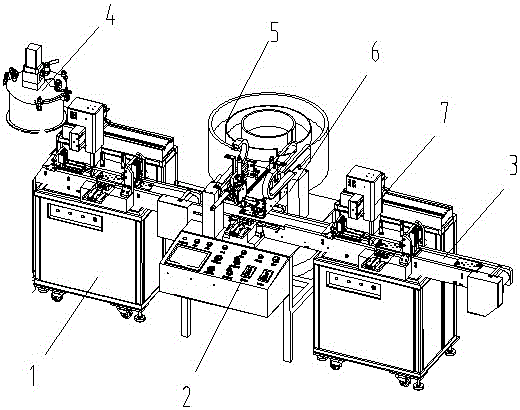

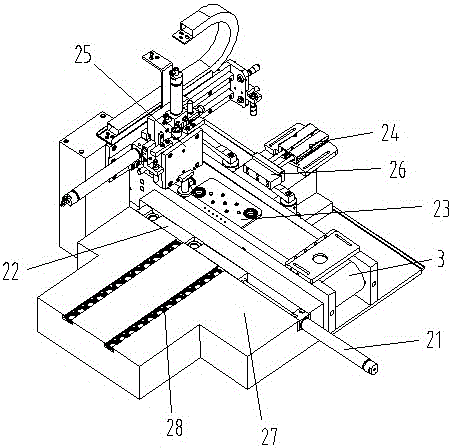

Label sticking device and label sticking method

InactiveCN104276316AReduce labor intensityImprove accuracy and efficiencyLabelling machinesData miningMass Consistency

The invention discloses a label sticking device and a label sticking method. The label sticking device comprises a working platform, a rack and a product positioning component are arranged on the working platform, and a sending / receiving component, a label stripping and adsorption component, a label positioning component and a label sticking component are arranged on the rack. By virtue of a series of action of the sending / receiving component, the label stripping and adsorption component, the label positioning component and the label sticking component, a label can be precisely stuck onto a product. Therefore, by virtue of the label sticking device and the label sticking method, the product label can be stuck mechanically, the labor intensity is lowered, the label sticking efficiency and the label sticking precision are improved, and the consistency of product label sticking quality is further enhanced.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

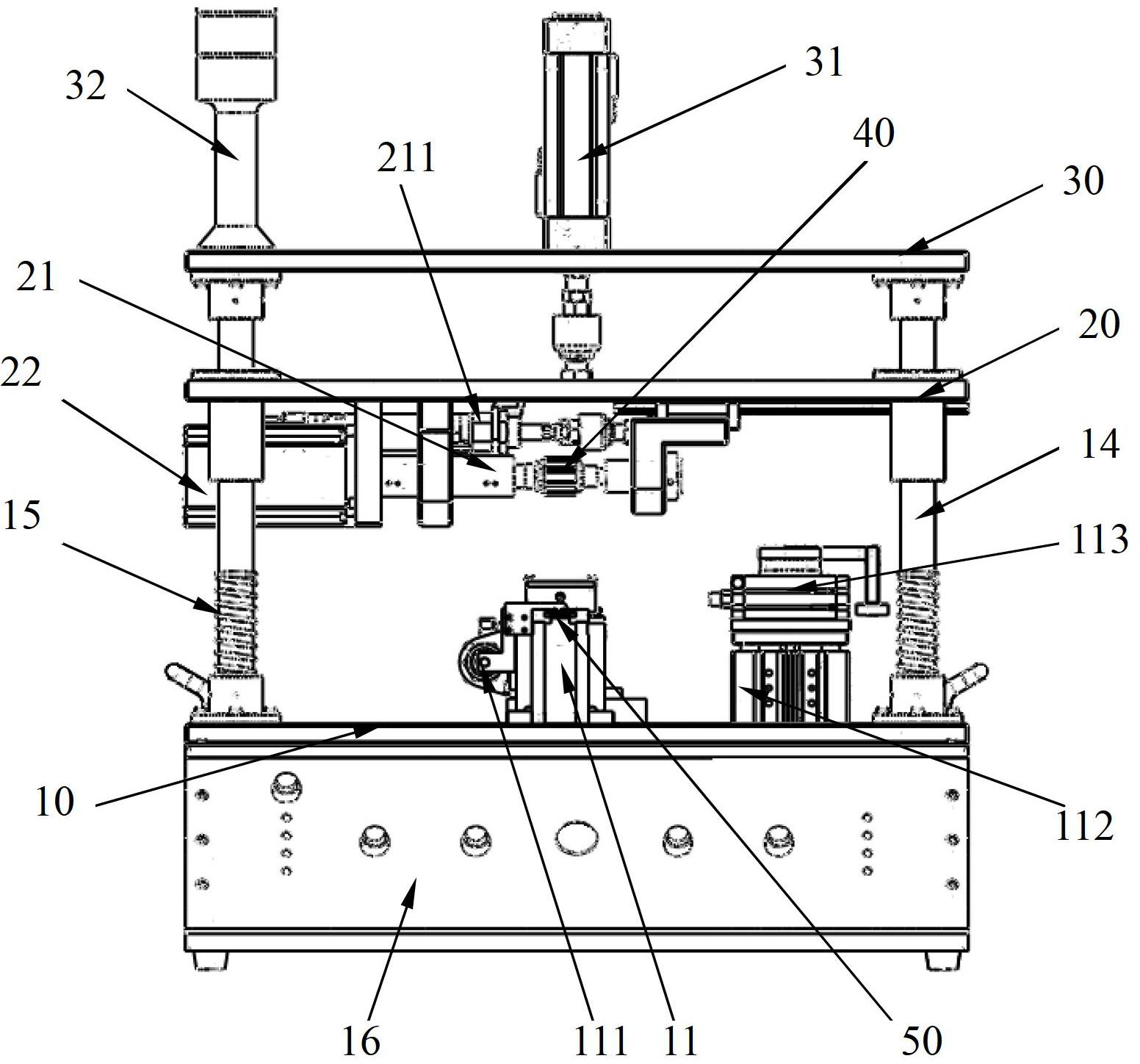

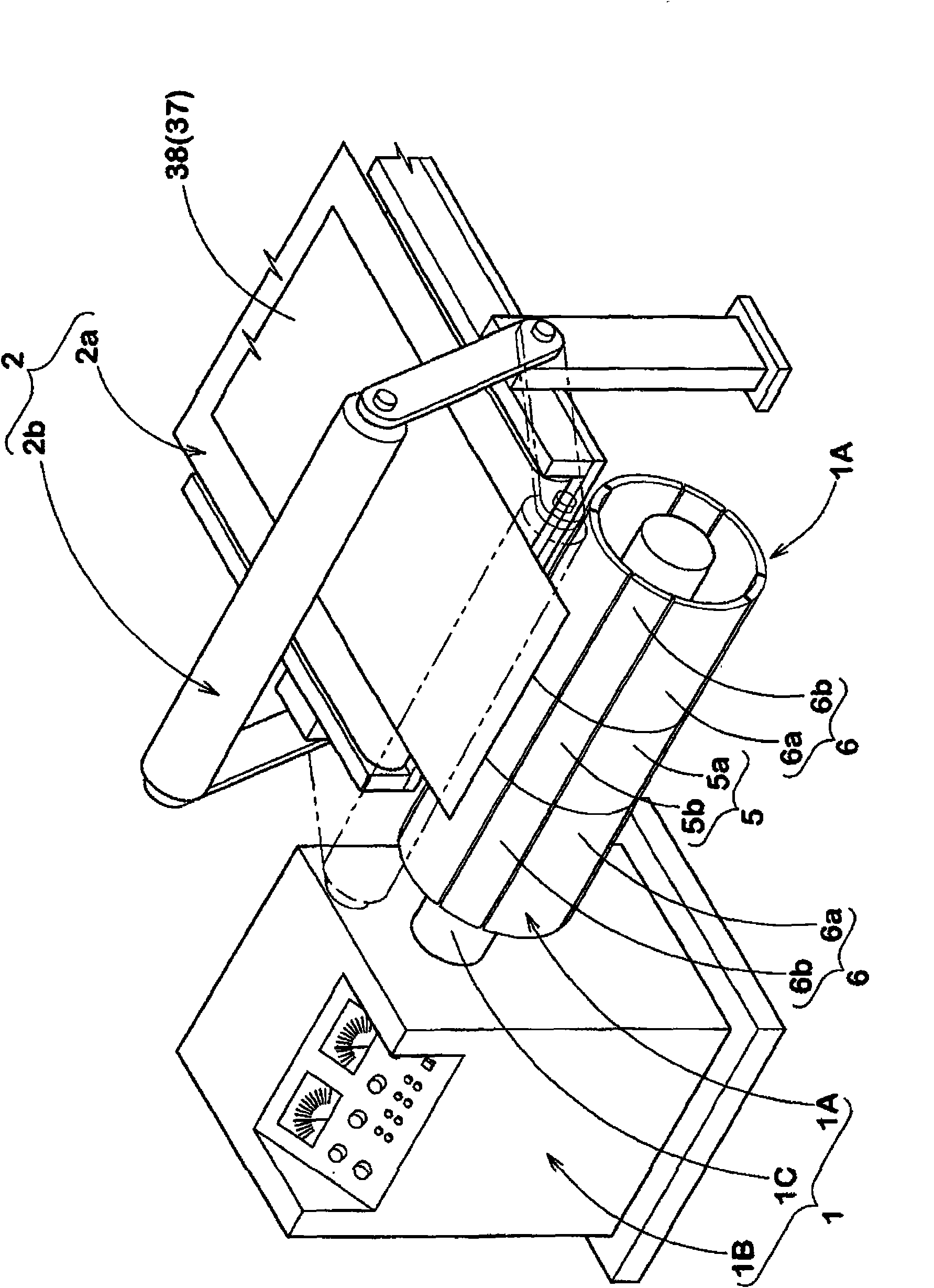

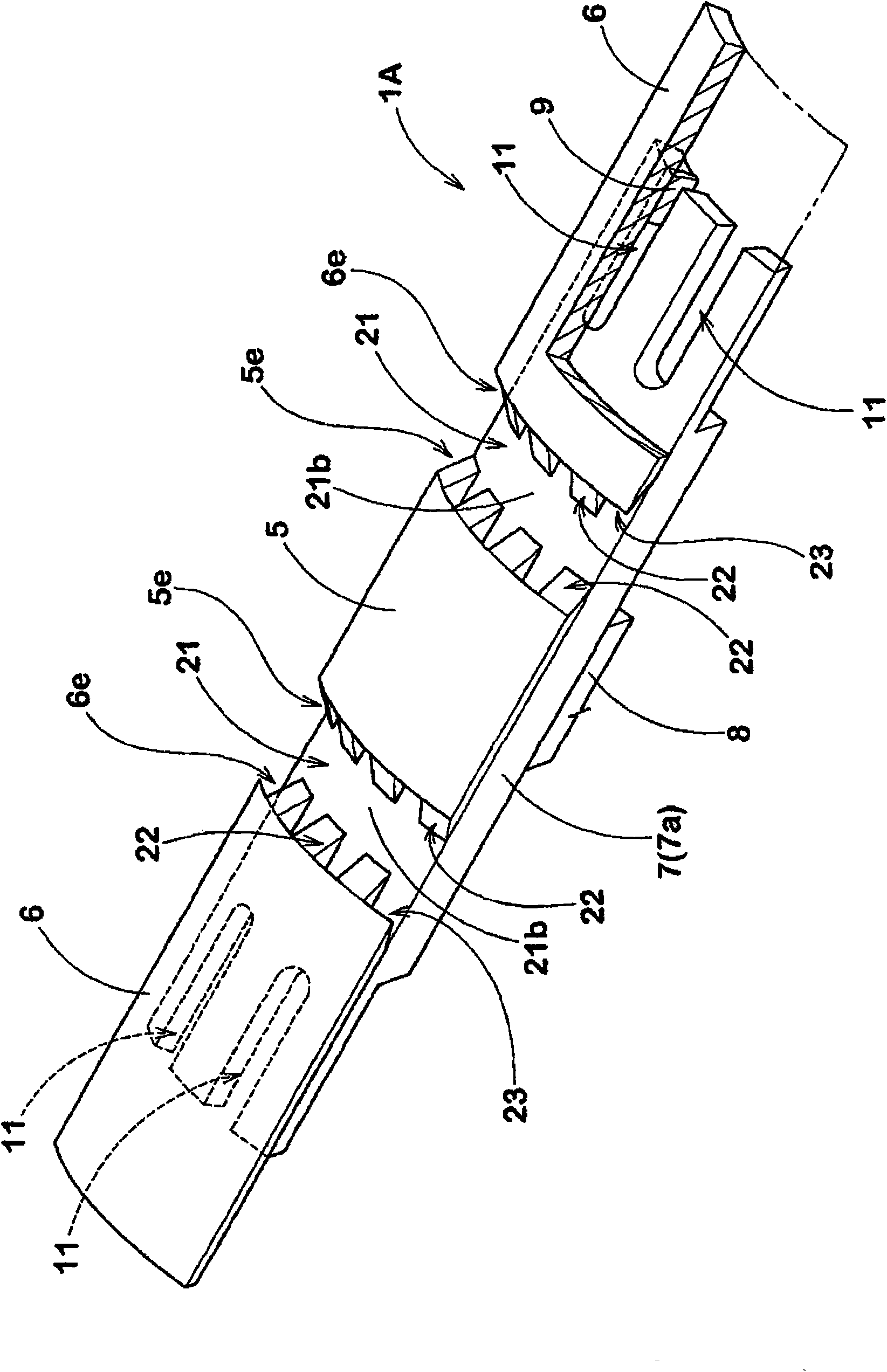

Method for making run-flat tire and assembly drum device for same

ActiveCN101659127AImprove pasting accuracyUniform elasticityTyresPneumatic tyre reinforcementsBand shapeEngineering

The invention can improve the homogeneity of a run-flat tire. A method for making the run-flat tire of which a tire side part is provided with a tire side reinforcing glue with the cross section approximately in the crescent shape is provided. The method includes: winding flaky inner lining glue on the external circumstance of a cylindrical drum main body; winding and sticking band-shaped tire side reinforcing glue in the region of the external circumstance of the cylindrical inner lining glue equivalent to a pair of tire sides to form a first cylindrical object; arranging a pair of circumferential channels on the external circumstance of the drum main body and the inner side of the tire side reinforcing glue, expanding the drum main body, thereby the portion of the first cylindrical object, reinforced with the tire side reinforcing glue goes down into the circumferential channels; and winding the flaky carcass cord fabric by means of the external circumstance of the sinking and flat first cylindrical object to form a basal body of the tire.

Owner:SUMITOMO RUBBER IND LTD

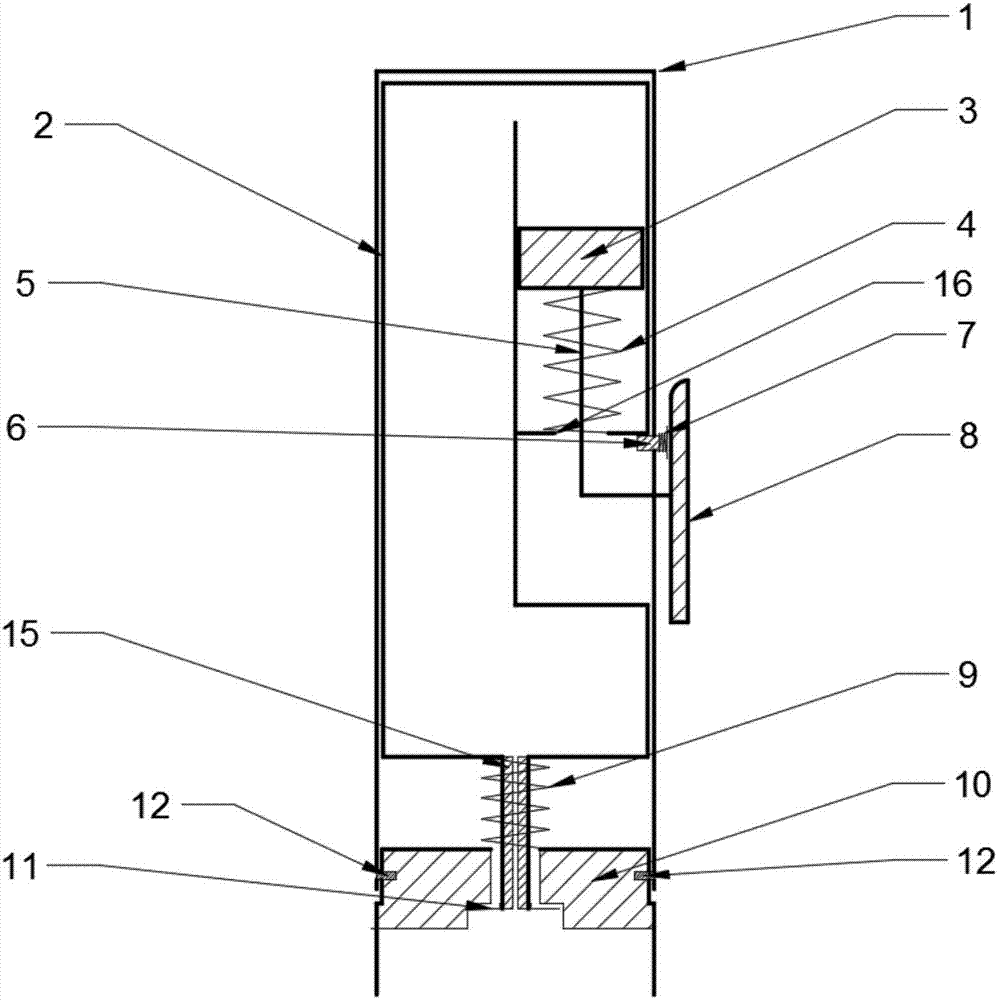

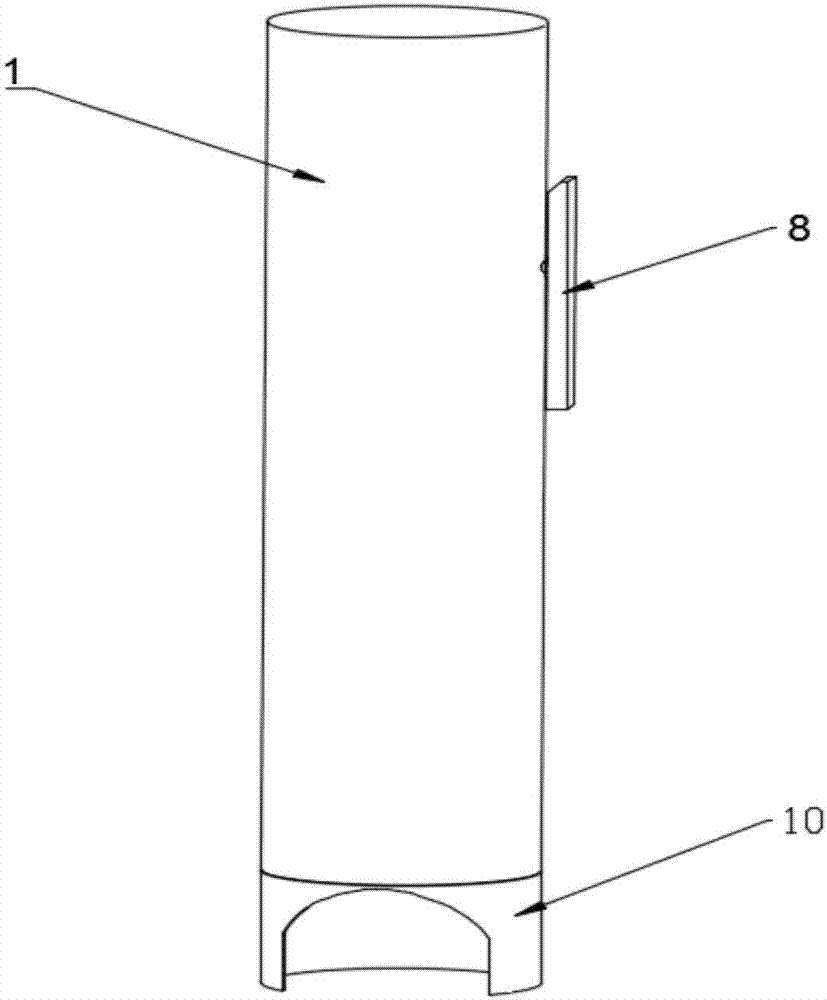

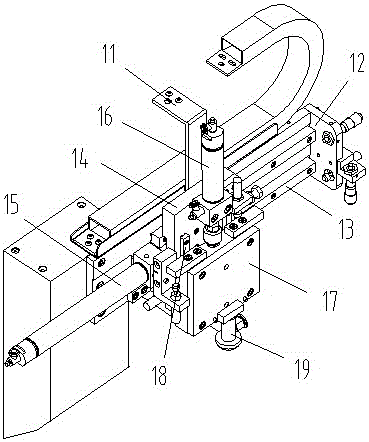

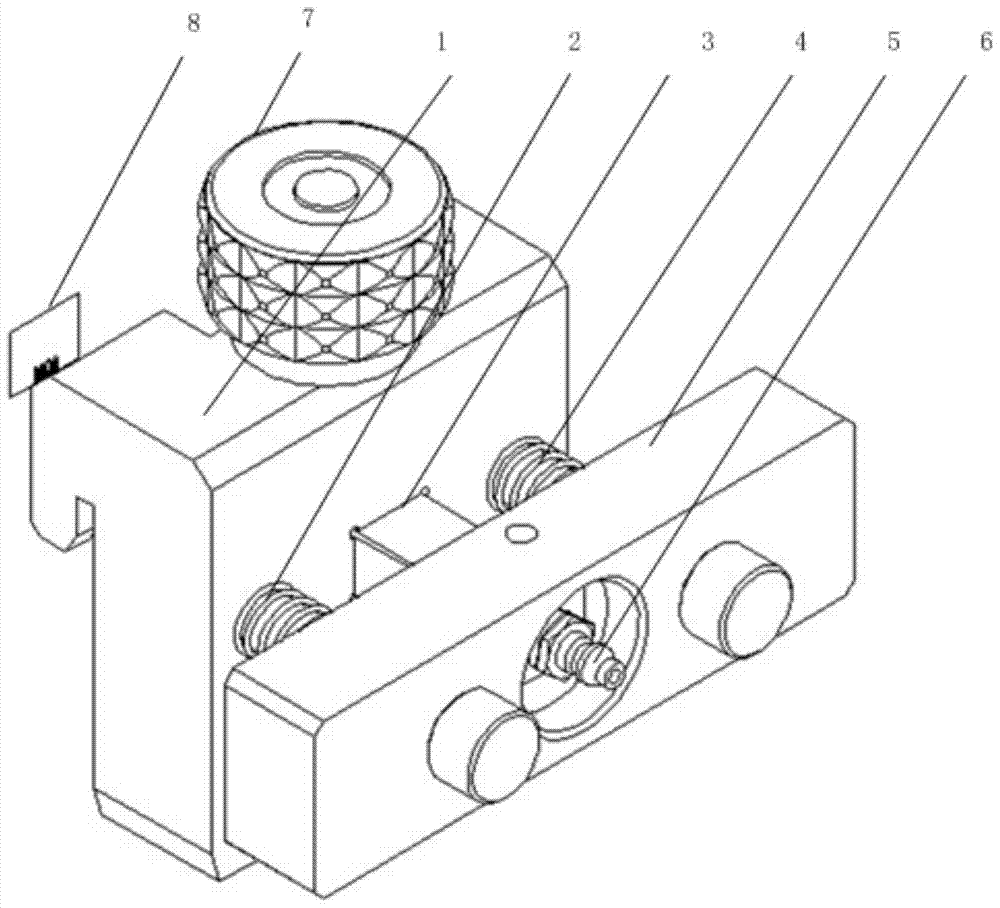

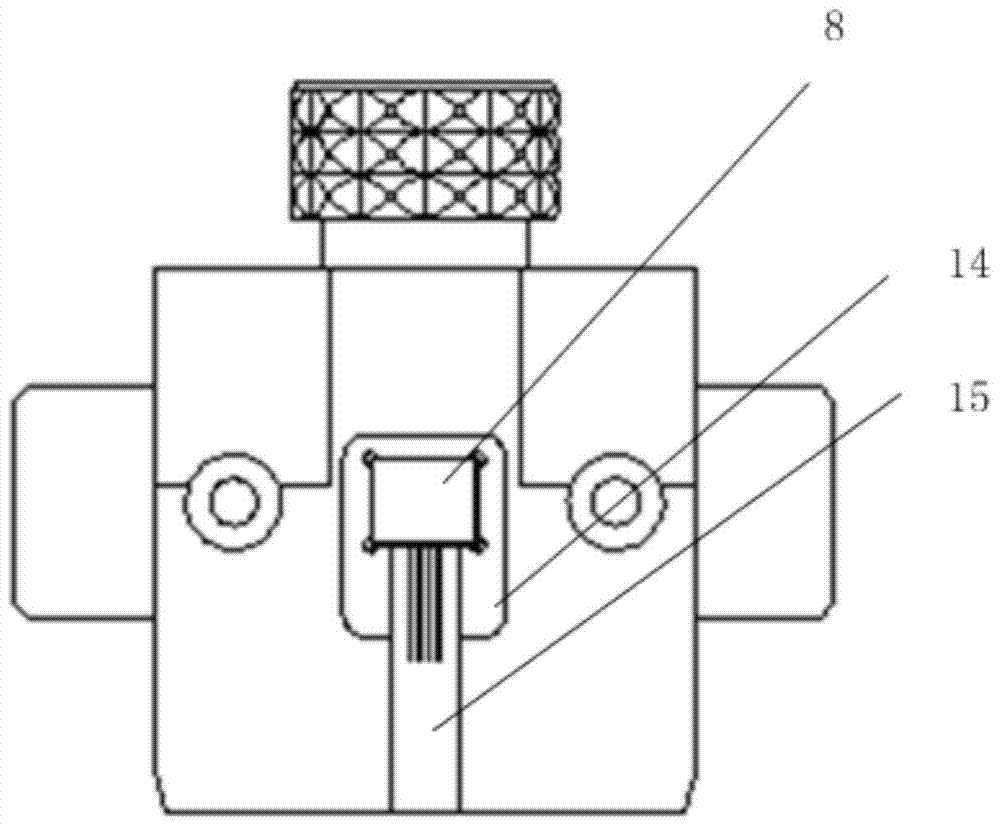

Resistance strain gauge pasting device and operation method thereof

ActiveCN106949828ASimple structureEasy to operateElectrical/magnetic solid deformation measurementStrain gaugeEmbedded system

The invention discloses a resistance strain gauge pasting device and an operation method thereof. The device comprises a housing, a replaceable positioning pedestal, a strain gauge adsorption device and an operation device. The replaceable positioning pedestal is inserted into a lower end opening of the housing, and is connected with the housing through a countersink blot. The operation device comprises a connection rod and a slide button which are fixedly connected. The slide button is arranged outside the housing. A spacing pin is arranged between the slide button and the housing. The strain gauge adsorption device comprises a cylinder, a piston and a strain gauge pedestal which are arranged in the housing. The resistance strain gauge pasting device is convenient to operate and is suitable for various types of resistance strain gauges.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

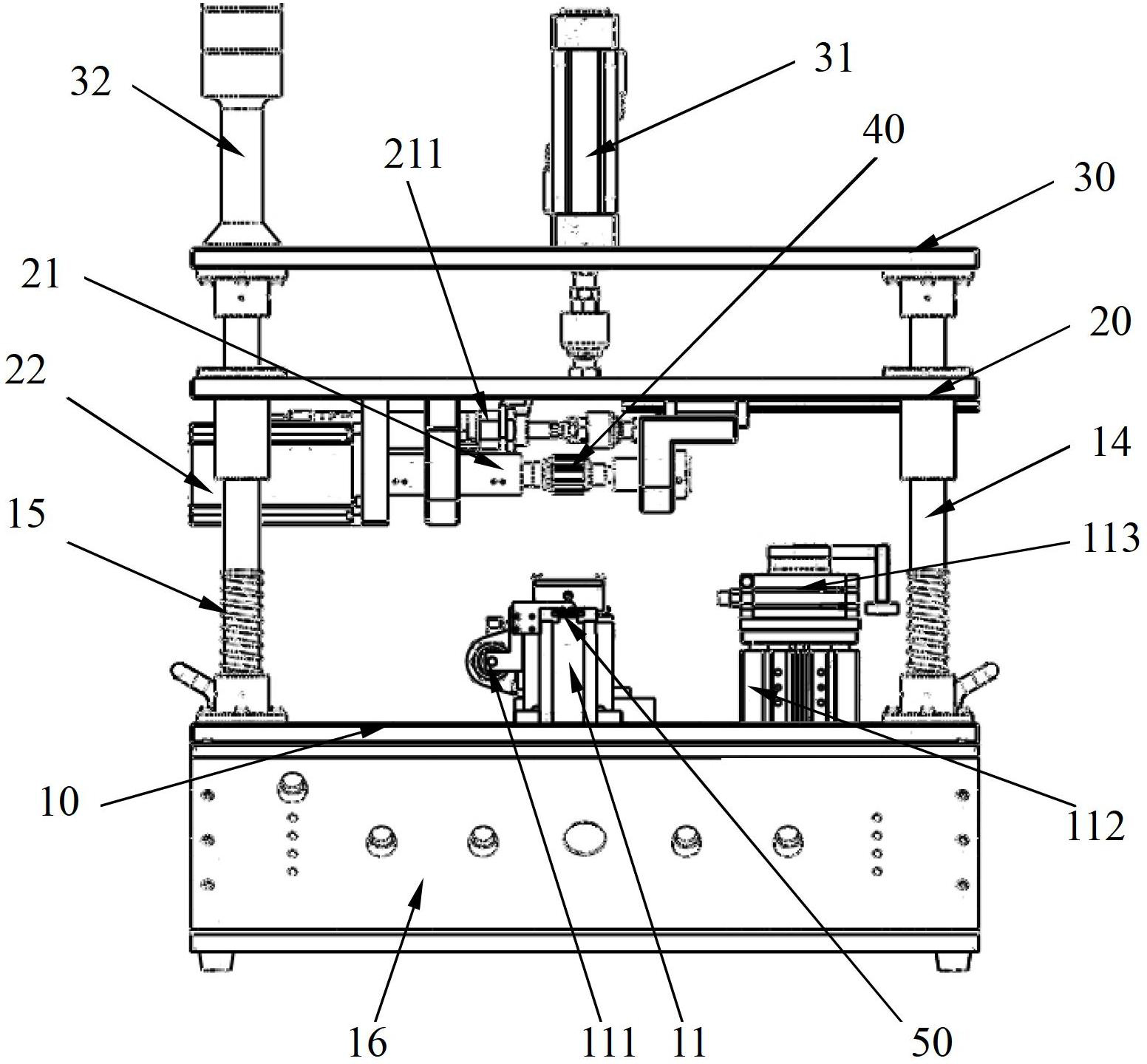

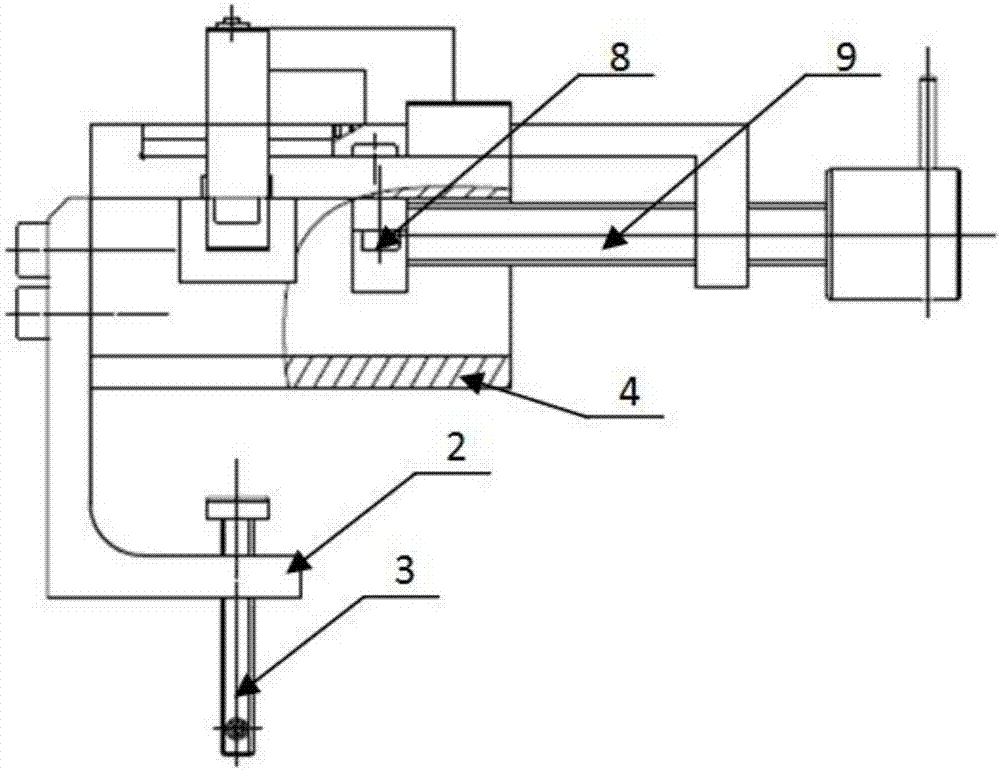

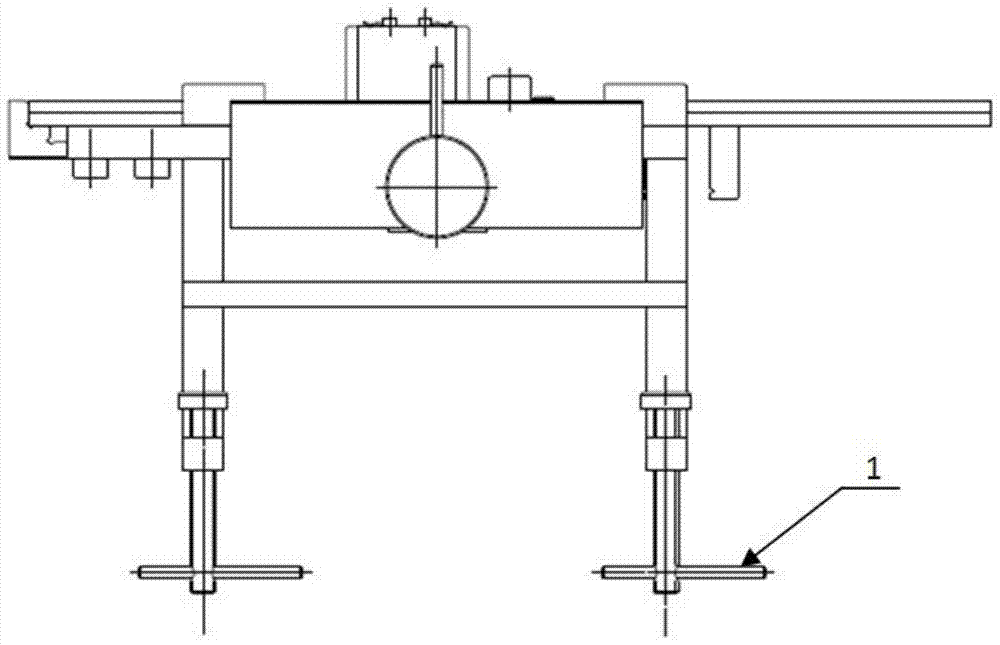

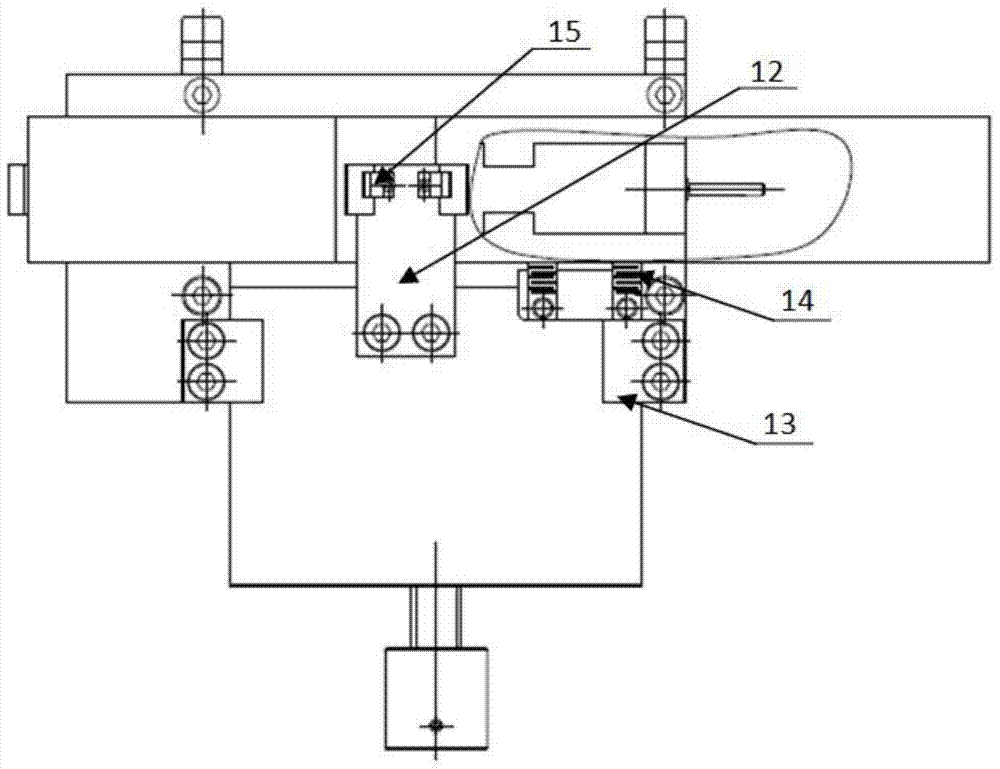

Device and process for sticking front magnetizing magnetic steel on motor rotor

ActiveCN102651593AImprove pasting accuracyPrecise positioningManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention discloses a device for sticking front magnetizing magnetic steel on a motor rotor. The device comprises a magnetic steel sticking platform, a rotor fixing assembly, a pushing assembly and a control unit, wherein a sliding rod and a magnetic steel feeding assembly which is fixedly provided with magnetic steel are arranged on the magnetic steel sticking platform, the rotor fixing assembly is sheathed on the sliding rod and comprises a rotor clamping mechanism which is used for clamping the motor rotor, and under the control of the control unit, the pushing assembly drives the rotor fixing assembly to move along the sliding rod so as to enable the motor rotor to move along with the rotor fixing assembly and to be contacted with the magnetic steel on the magnetic steel feeding assembly. The invention also provides a sticking process corresponding to the device. According to the device and the process, a fixed shaft is pushed along the sliding rod to the fixed magnetic steel to be sticked, so that the defect that the position is bad due to magnetic force adsorption in a sticking procedure, and the sticking accuracy of the magnetic steel is improved.

Owner:SUZHOU INOVANCE TECH CO LTD +1

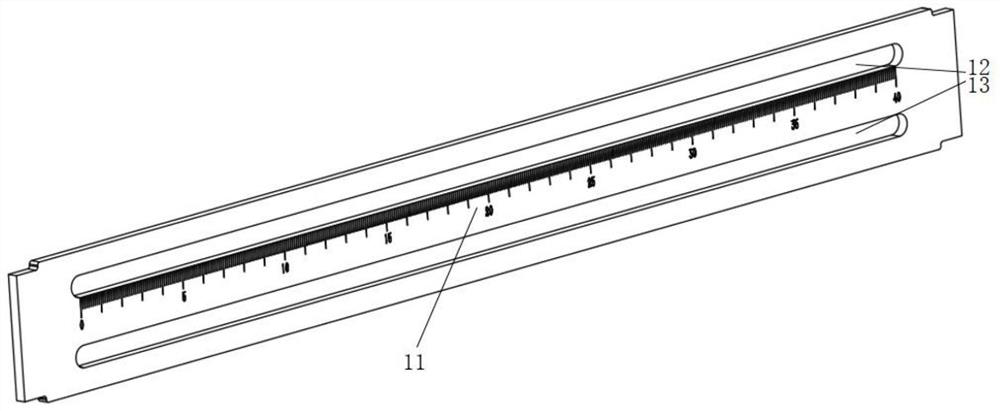

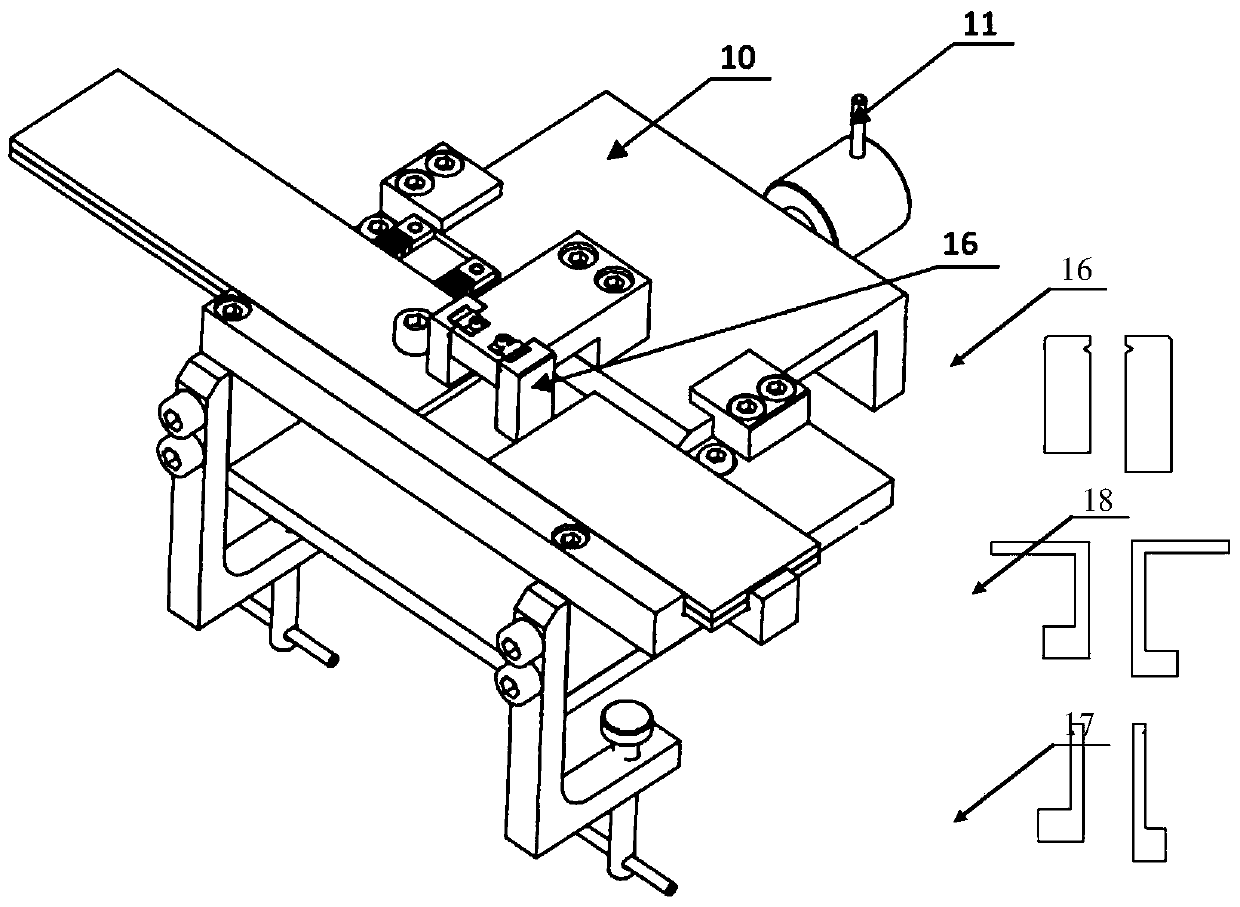

Universal tool for pasting reinforcing sheets and using method and application thereof

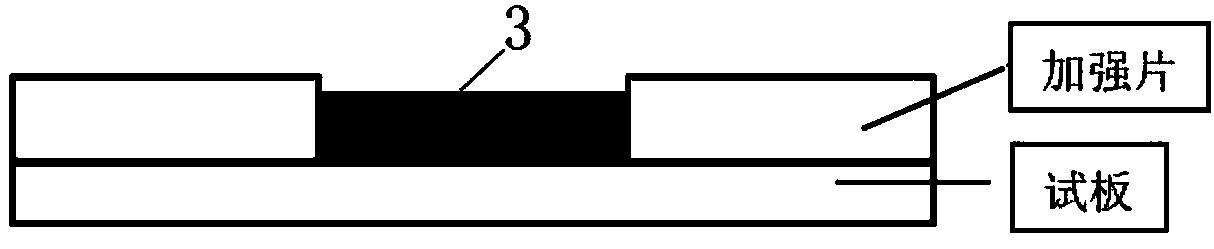

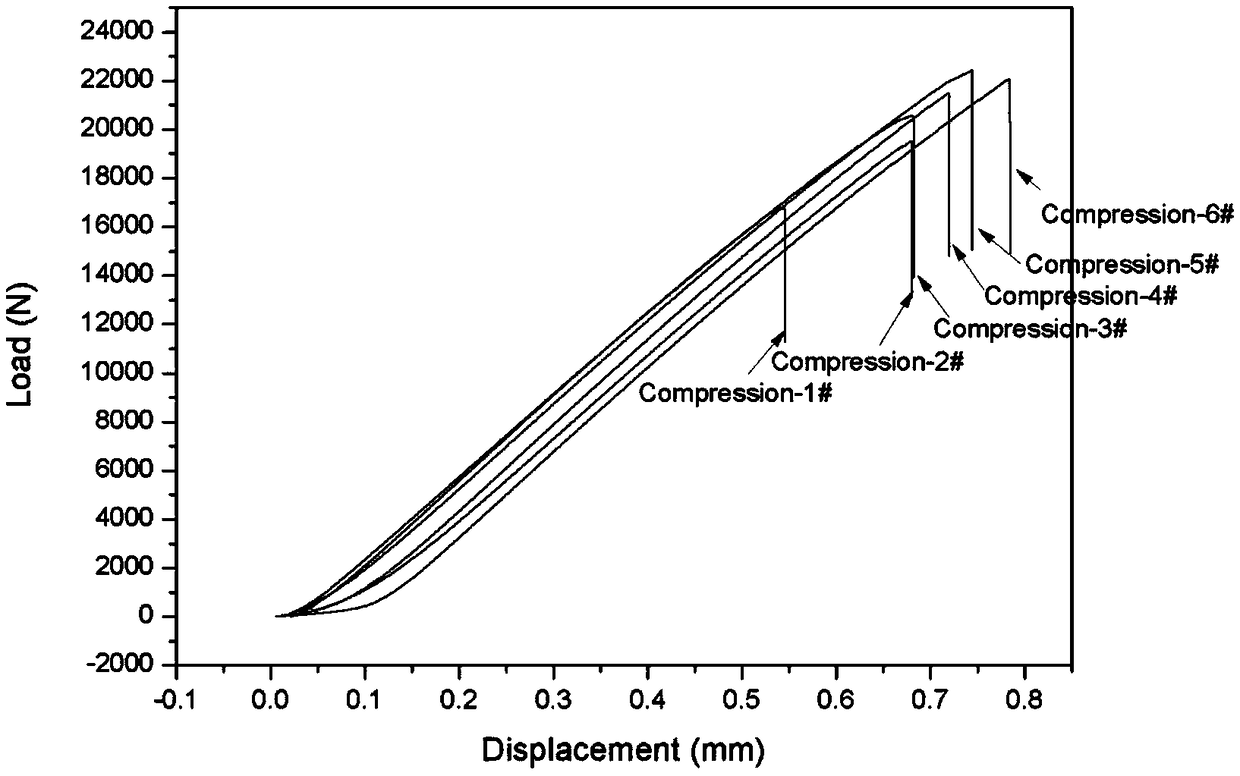

PendingCN109085037ASimplify the pasting processPaste implementationPreparing sample for investigationSoftware engineeringGauge length

The invention belongs to the field of universal tools, and particularly relates to a universal tool for pasting reinforcing sheets and a using method and application thereof. The universal tool comprises an L-shaped right-angle main positioning arm, a first sliding arm perpendicular to one side of the right-angle main positioning arm, a second sliding arm perpendicular to the other side of the right-angle main positioning arm, a positioning slide knob for connecting the first sliding arm and the second sliding arm, and a limiting block for positioning the reinforcing sheets and ensuring the gauge length of a tested test piece, wherein the limiting block is arranged in a rectangle formed by the right-angle main positioning arm, the first sliding arm and the second sliding arm. The universaltool can be used for pasting reinforcing sheets on composite test pieces which have different types and specifications and can assist in rapid preparation of the test pieces with the reinforcing sheets, so that the reinforcing sheet pasting procedure is simplified, the reinforcing sheet pasting tool cost is lowered, and pasting efficiency and the test piece machining dimension precision are improved.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

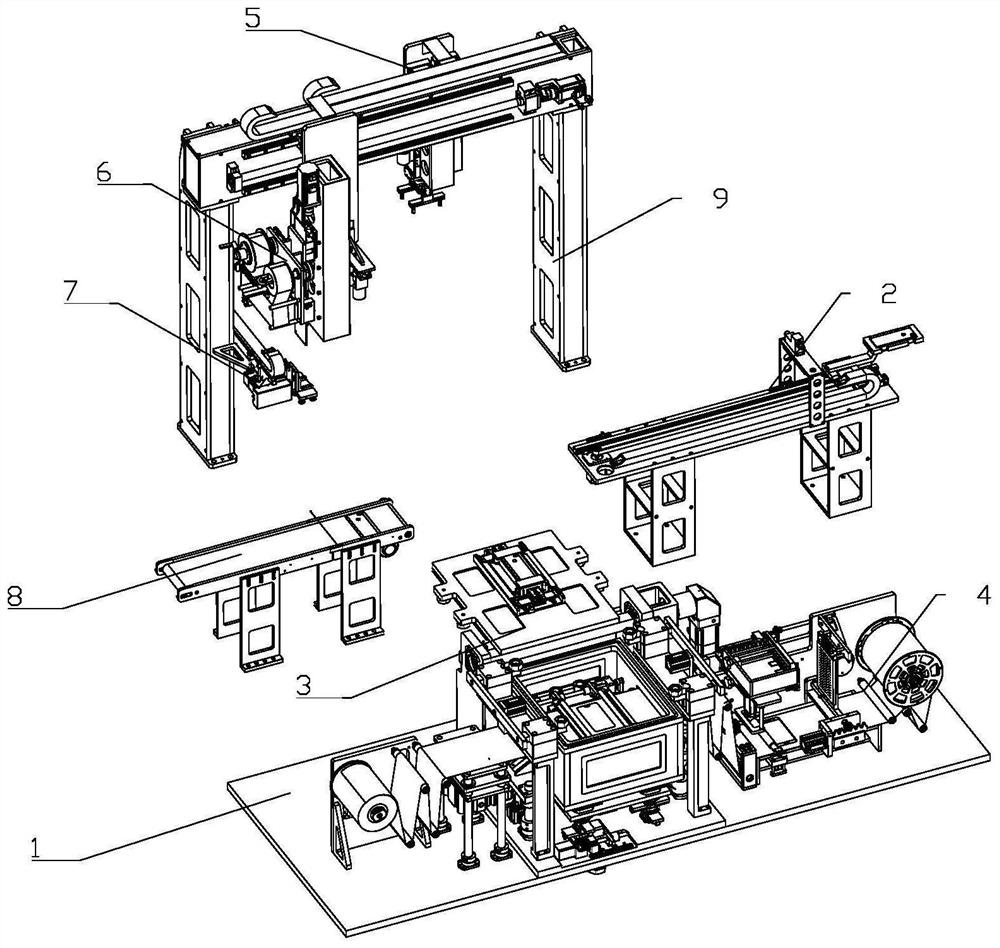

Automatic foam sticking machine and processing technology adopting same

InactiveCN105172304ASimple structureEasy to useLaminationLamination apparatusEngineeringMechanical engineering

The invention relates to an automatic foam sticking machine which comprises a rack, a control device, a first loading rack and a second loading rack, wherein a first material feeding mechanism is arranged on the first loading rack and comprises a first baseplate, a first material laying plate, a first driving mechanism and a second driving mechanism, a first sunken part is arranged on the first material laying plate, and at least one second material feeding mechanism layer is arranged on the second loading rack; a material taking mechanism capable of moving horizontally is arranged on the rack, a needle plate capable of moving vertically and a material bearing plate are arranged on the material taking mechanism, a plurality of needles are arranged on the needle plate, a second sunken part is arranged on the material bearing plate, and the first sunken part and the second sunken part correspond in the vertical direction; an electrical heating mechanism is arranged on the rack; based on input parameters or instructions, the control device controls the sticking machine to work. The invention further relates to a processing technology adopting the automatic foam sticking machine. The automatic foam sticking machine and the processing technology adopting the same have the benefits that loading is convenient and safe, and the sticking accuracy is high.

Owner:JIANGSU BVM INTELLIGENT TECH

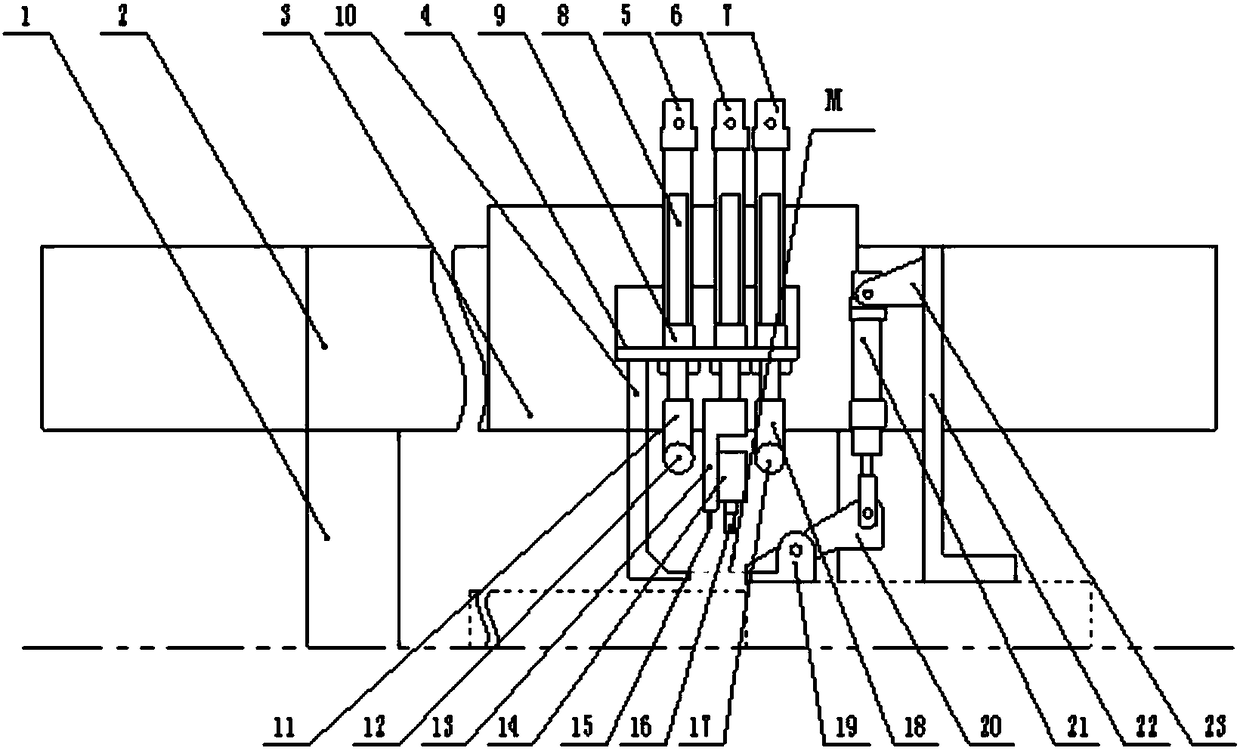

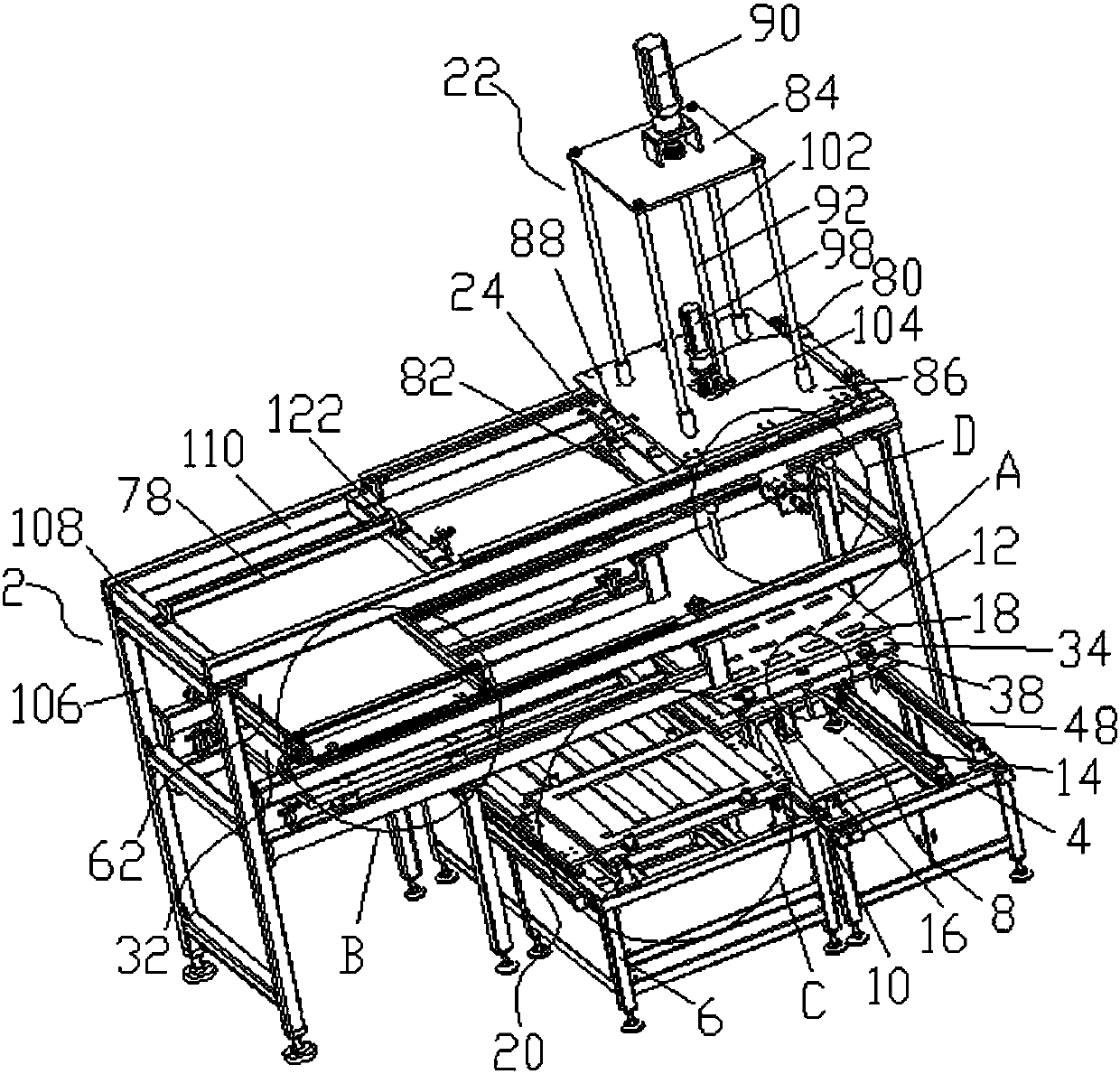

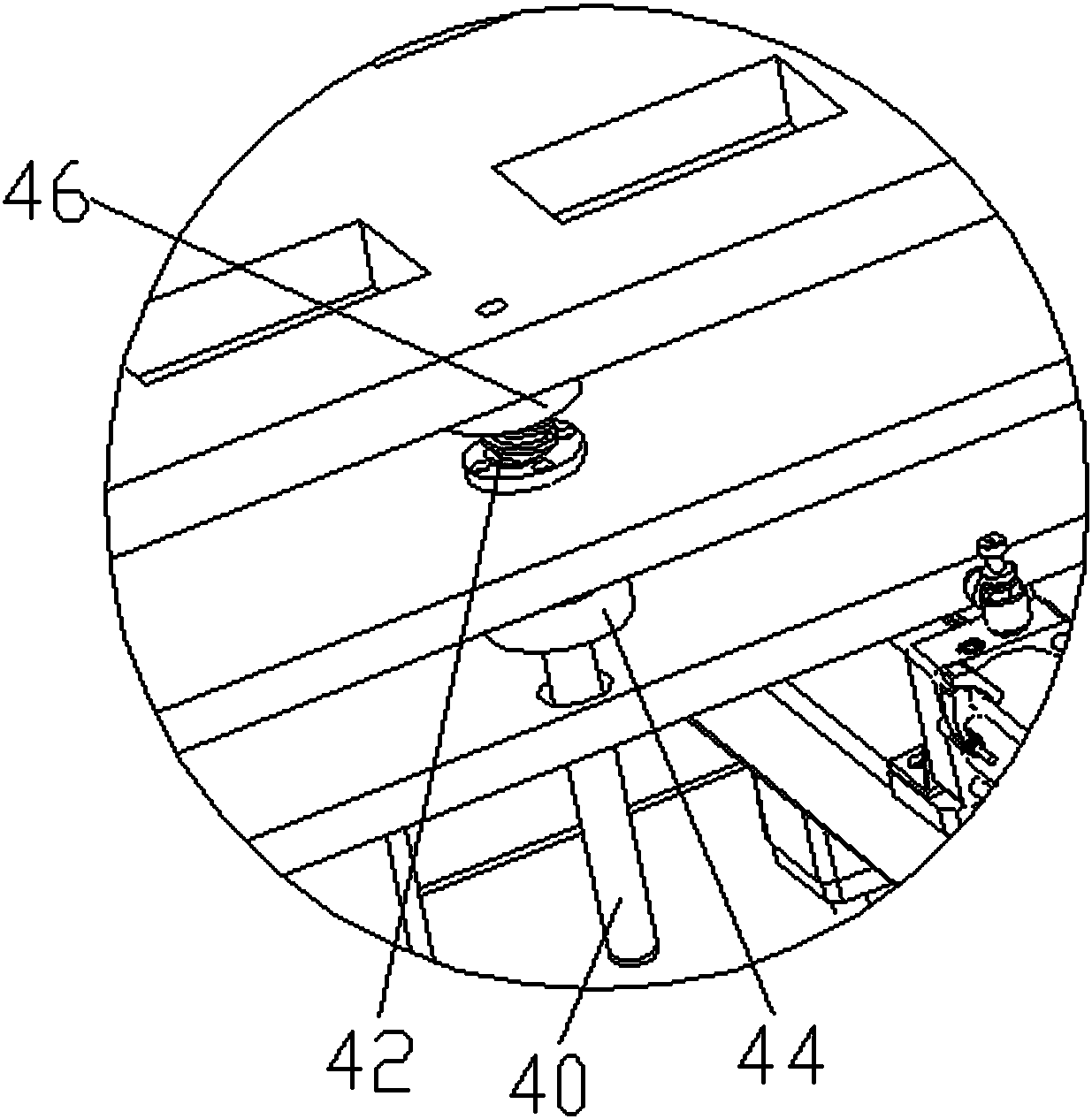

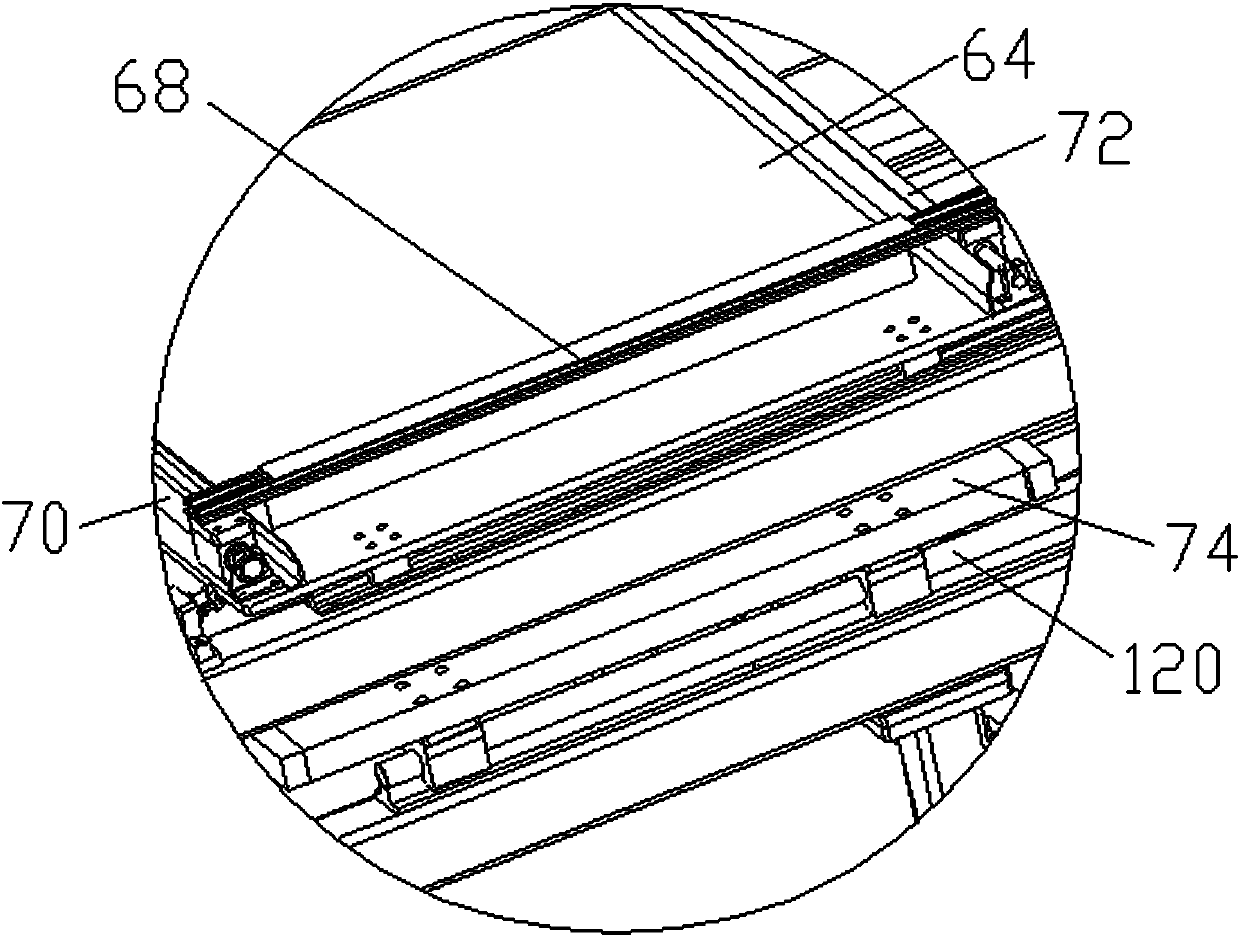

Prefabricated fragment strip adhesive tape adhering device

ActiveCN108106504AReduce deformationRealize automatic pasteAmmunitionEngineeringMechanical engineering

The invention discloses a prefabricated fragment strip adhesive tape adhering device. The prefabricated fragment strip adhesive tape adhering device comprises a rack, a downward pressing adhesive tapeholding device, a downward pressing cutter device, a downward pressing adhesive pressing device and an adhesive tape end portion clamping device, and the downward pressing adhesive tape holding device, the downward pressing cutter device, the downward pressing adhesive pressing device and the adhesive tape end portion clamping device are located on the A side of the rack and are sequentially arranged in the advancing direction of adhesive tape; the downward pressing adhesive tape holding device, the downward pressing cutter device and the downward pressing adhesive pressing device are all located over the advancing path of the adhesive tape; and the adhesive tape end portion clamping device is provided with a clamping port located in the advancing path of the adhesive tape. The prefabricated fragment strip adhesive tape adhering device is simple in structure, convenient to use and capable of achieving the effects that automatic adhering of the prefabricated fragment strip adhesive tape is achieved, the production efficiency is improved, meanwhile, the adhering precision and the adhering effect can be improved, and it is guaranteed that deformation of the adhesive tape is minimum,

Owner:中国兵器装备集团自动化研究所有限公司

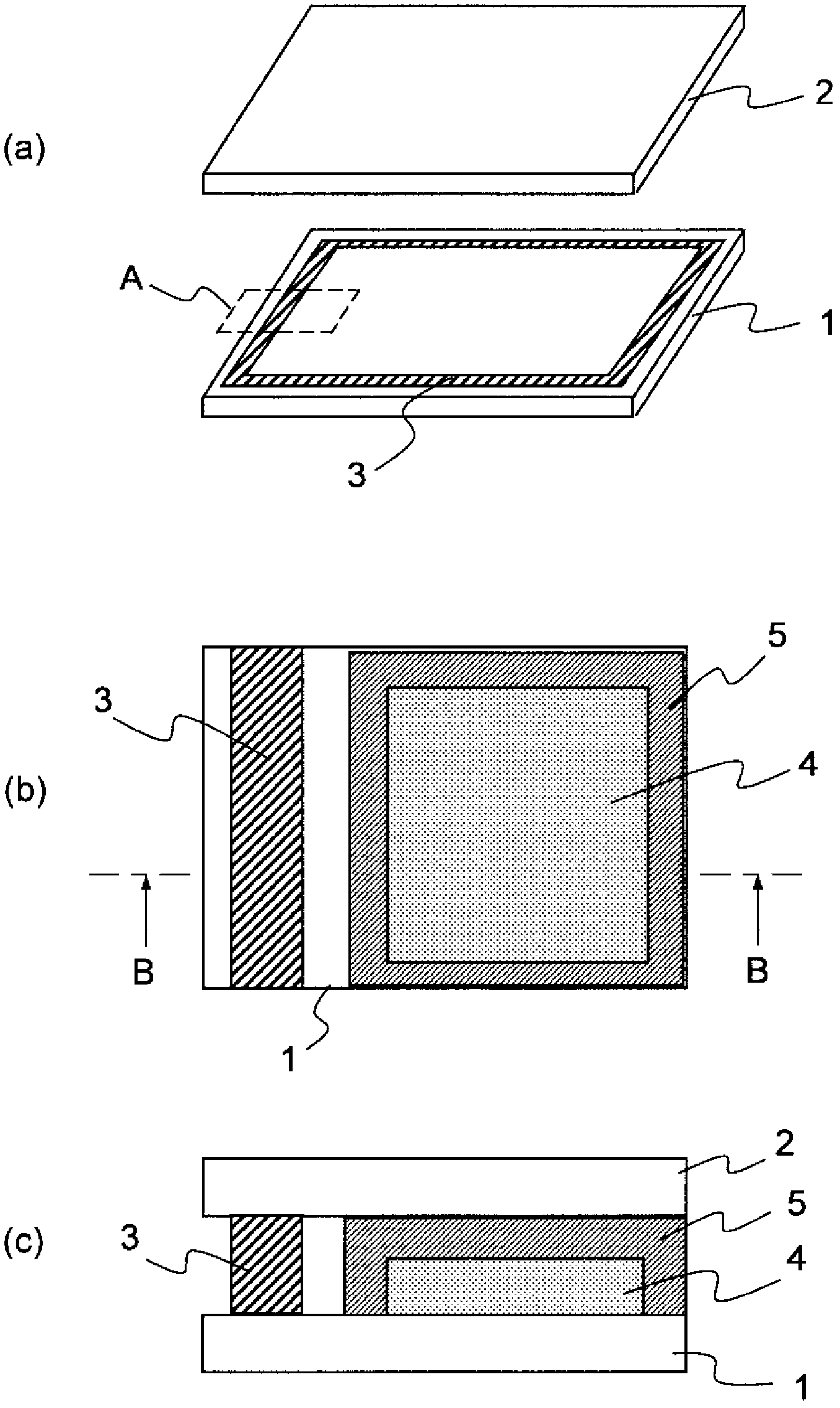

Anisotropic conductive film, production method for anisotropic conductive film, connection method between electronic components, and connection structure

InactiveCN102906941AImprove pasting accuracyLine/current collector detailsNon-insulated conductorsAnisotropic conductive filmOptoelectronics

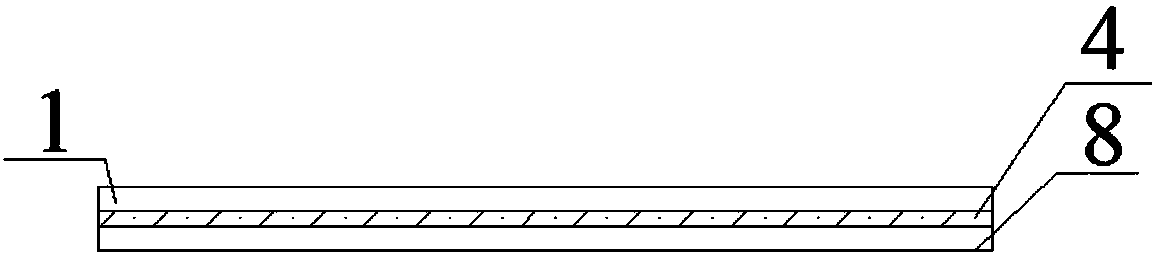

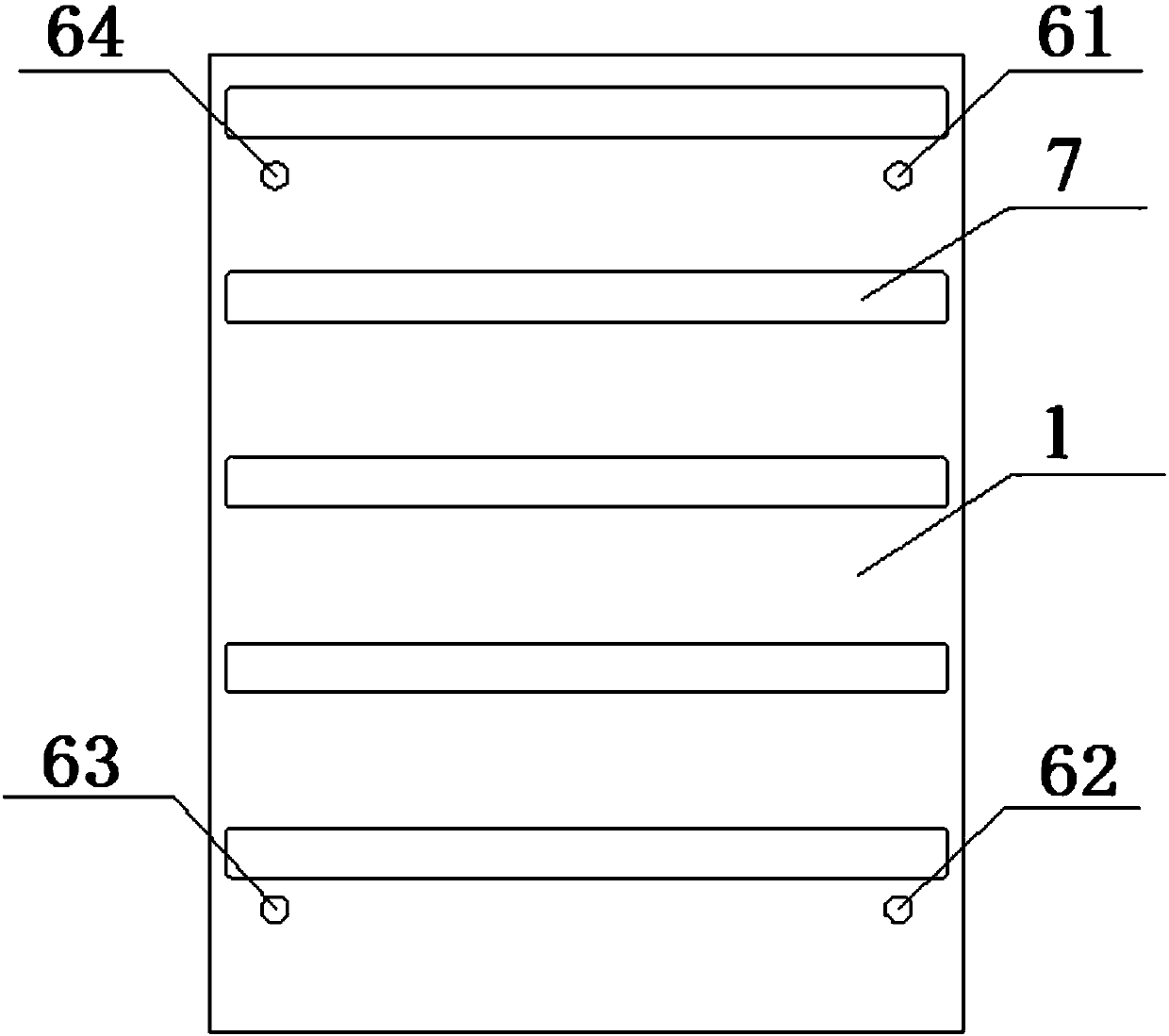

The present invention provides an anisotropic conductive film with which production efficiency can be improved. The present invention is configured in such a manner that: a conductive particle-containing layer (3), which is obtained by dispersing at least conductive particles in a binder, is formed on a substrate (2); slit lines (4), which have an angle b with respect to the longitudinal direction (L) of the substrate (2) and divide the conductive particle-containing layer (3), are formed on at least the conductive particle-containing layer (3); and the angle b satisfies 180 degrees > b > 0 degrees (excluding 90 degrees).

Owner:DEXERIALS CORP

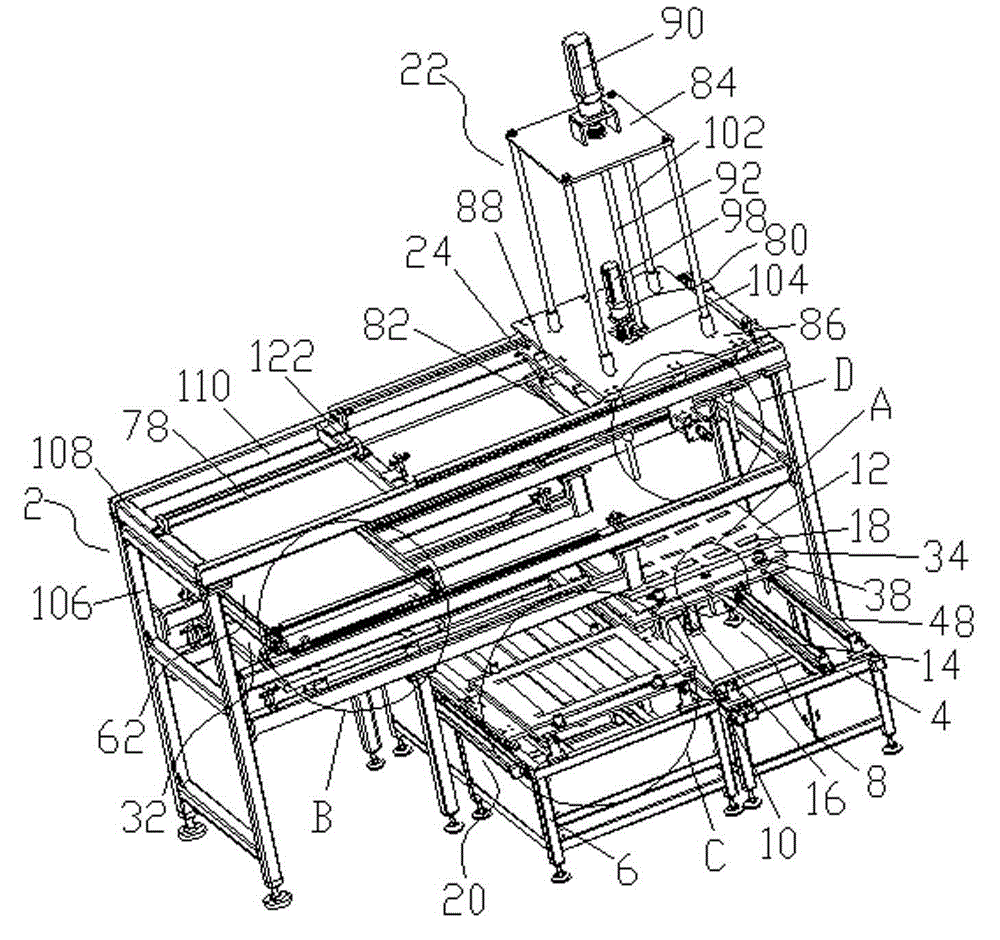

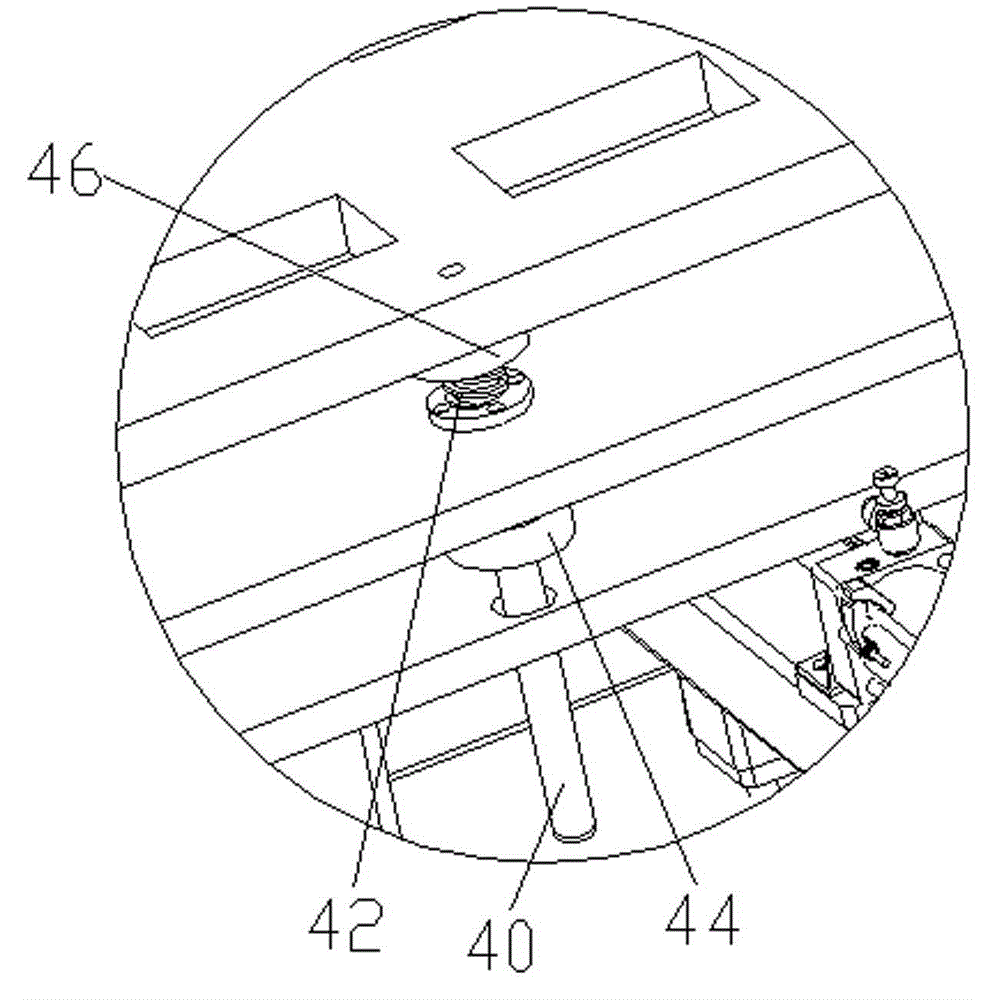

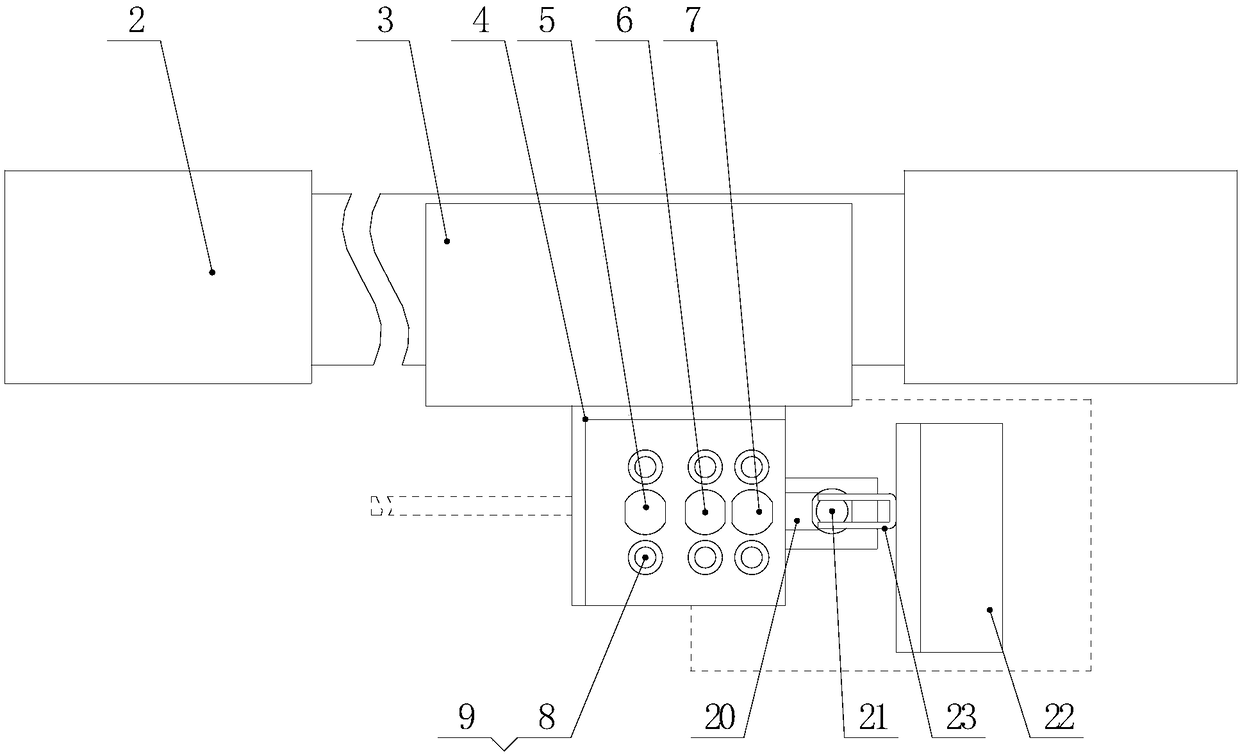

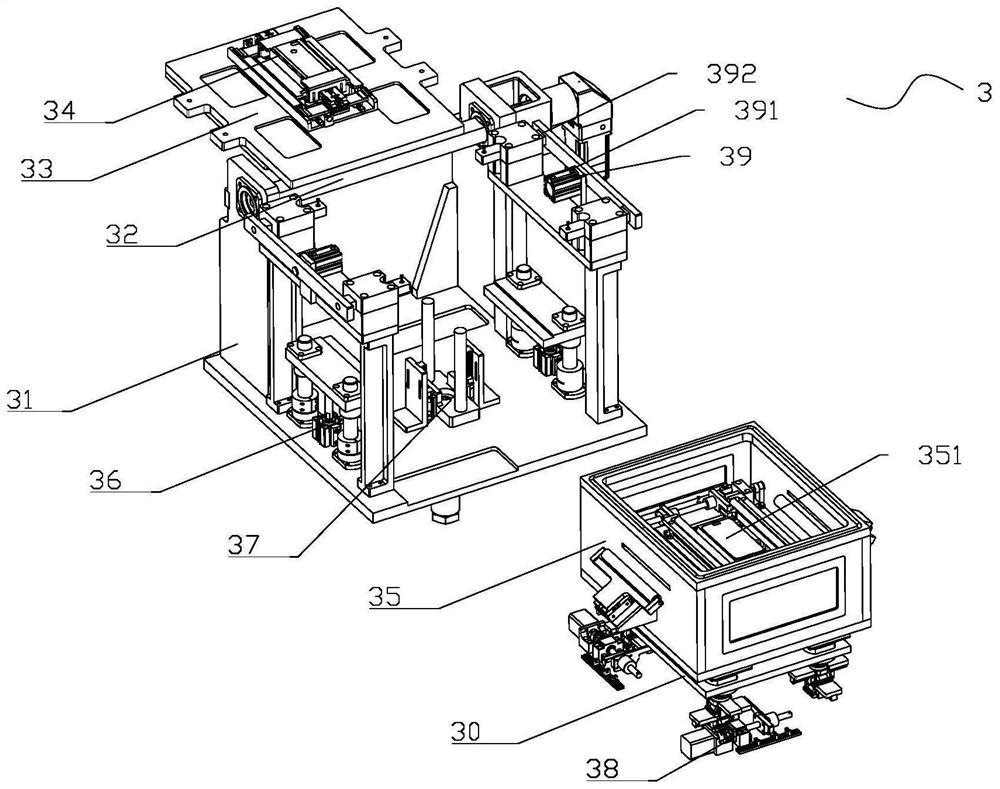

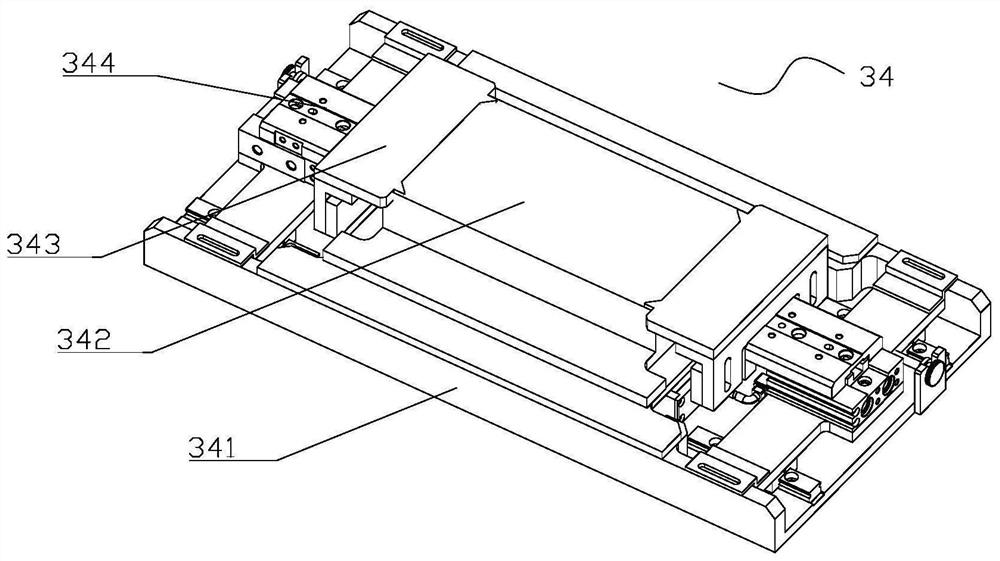

Automatic plate and sleeve glue dispensing assembly machine

ActiveCN106807593AEasy to pasteIncrease productivityLiquid surface applicatorsMaterial gluingDistribution controlAssembly machine

The invention relates to an automatic plate and sleeve glue dispensing assembly machine which comprises a power distribution control cabinet. A conveying device and a pressure device are arranged on the power distribution control cabinet. Glue dispensing devices matched with a product plate are arranged on the left portion and the right portion of the conveying device. A match sleeve assembly mechanism matched with the product plate is arranged in the middle of the conveying device. The assembly mechanism comprises an assembly frame and a vibrating feed plate located on the assembly frame, and the vibrating feed plate is matched with discharging grooves in the assembly frame. An assembly device is arranged in the position, located on the assembly frame, of the conveying device. The assembly device comprises an assembly movable device and a matched fetching plate. The matched fetching plate is matched with matching grooves in the discharging grooves. The assembly frame is provided with an operation screen connected with the power distribution control cabinet. The automatic plate and sleeve glue dispensing assembly machine is provided with the conveying device, the assembly mechanism is arranged in the middle of the conveying device, the glue dispensing devices are arranged on the two sides of the assembly mechanism, the assembly mechanism takes matched sleeves out of the discharging grooves through the matched fetching plate and pastes the matched sleeves to plate holes accurately so that pasting can be completed, and the production efficiency is greatly improved.

Owner:浙江珠龙包装科技股份有限公司

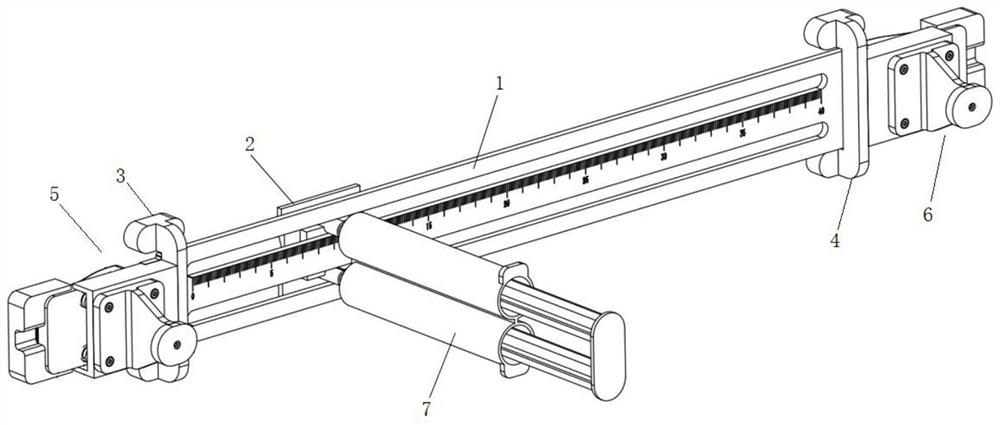

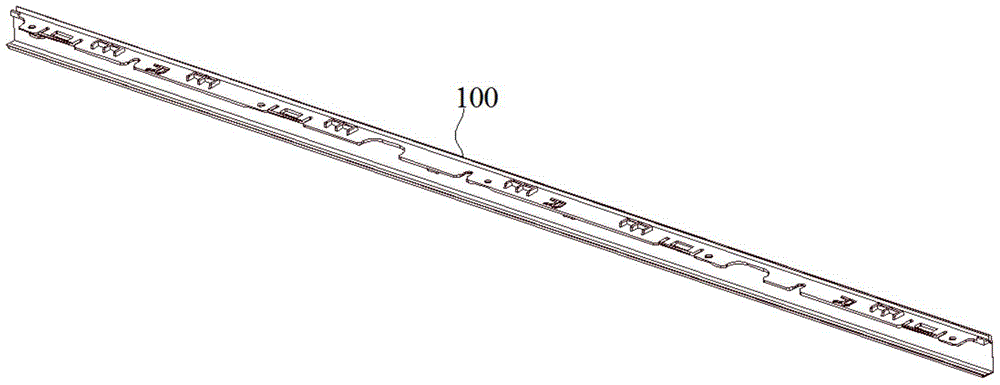

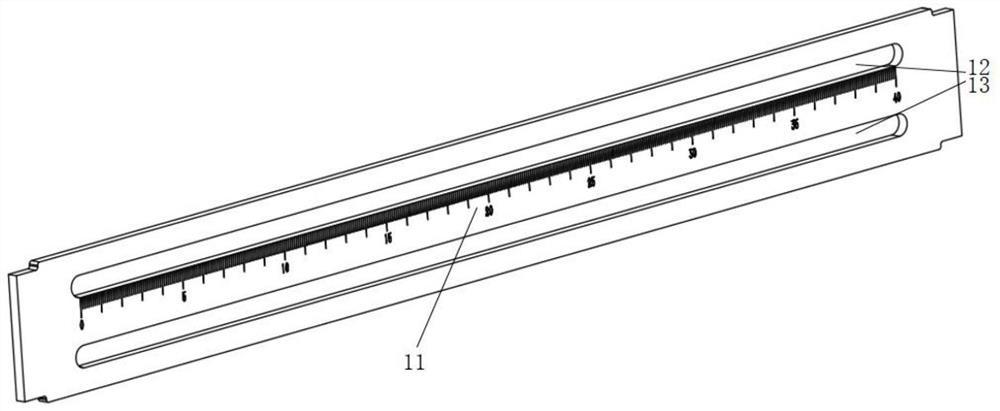

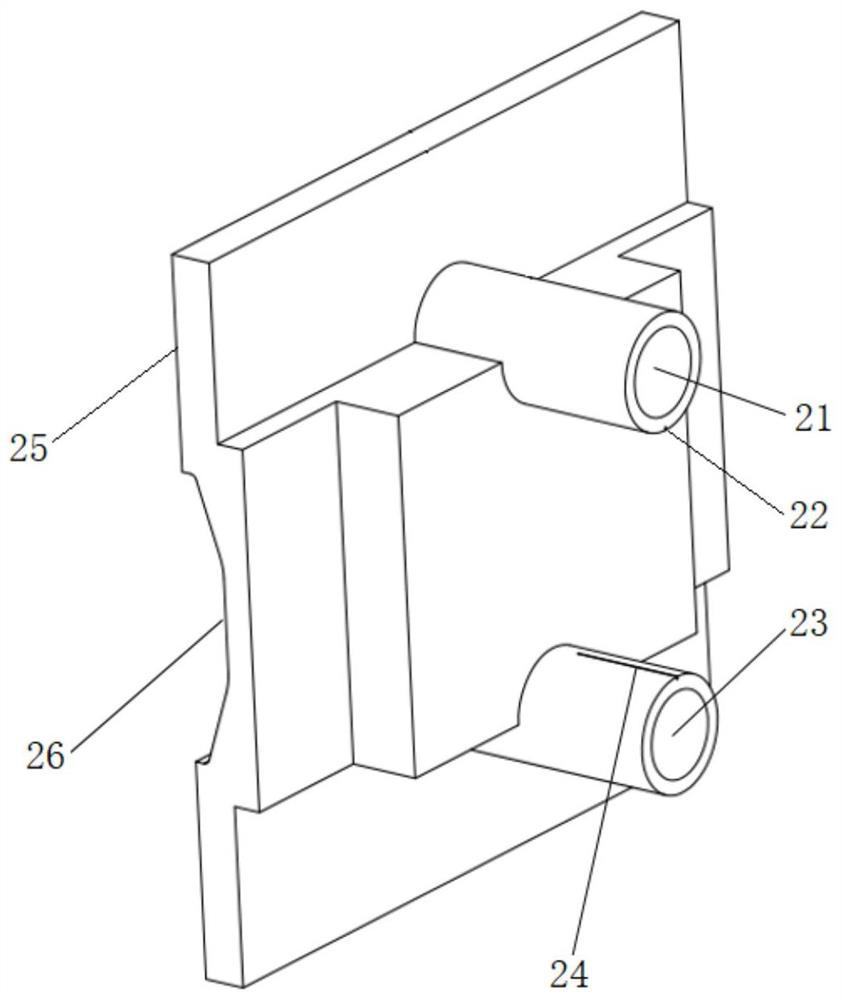

Rapid positioning and pasting device and method for fiber grating sensor

ActiveCN112439643AImplement fixed functionRapid positioningLiquid surface applicatorsMaterial gluingViscoseEngineering

The invention discloses a rapid positioning and pasting device and method for a fiber grating sensor, and relates to the technical field of fiber sensor installation. The device comprises a guide scale, a movable gluing head, a first fixing buckle, a second fixing buckle, a first supporting component and a second supporting component, wherein the guide scale comprises scale marks and is used for positioning the pasting position of the fiber grating sensor; the movable gluing head is movably connected with the guide scale and used for moving along the scale marks to enable the pasting positionof the fiber grating sensor to be coated with a gluing material; the first fixing buckle and the second fixing buckle are buckled on the surfaces of the two sides of the guide scale in a sleeving moderespectively and used for fixing the guide scale to the surface of a measured structure; and the first supporting component and the second supporting component are connected to the two ends of the guide scale respectively and used for fixedly supporting the two ends of the fiber grating sensor, so that the fiber grating sensor is straightened in the scale mark direction of the guide scale and tightly attached to the surface of the measured structure. The rapid positioning and pasting device and method have the advantages of being high in pasting speed, high in precision, good in quality, reliable in work and convenient to operate.

Owner:QINGDAO DMAR OCEAN ENG

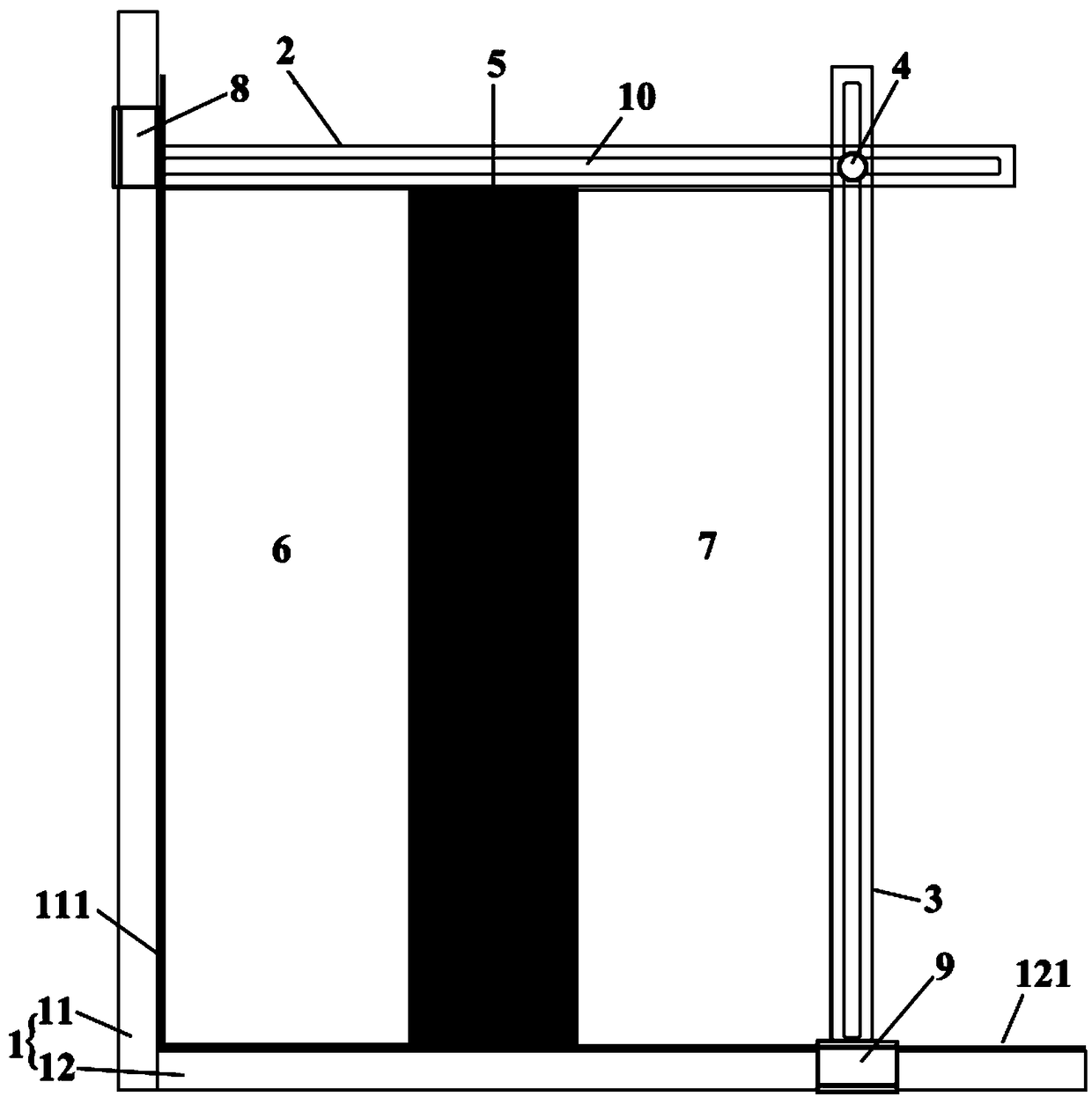

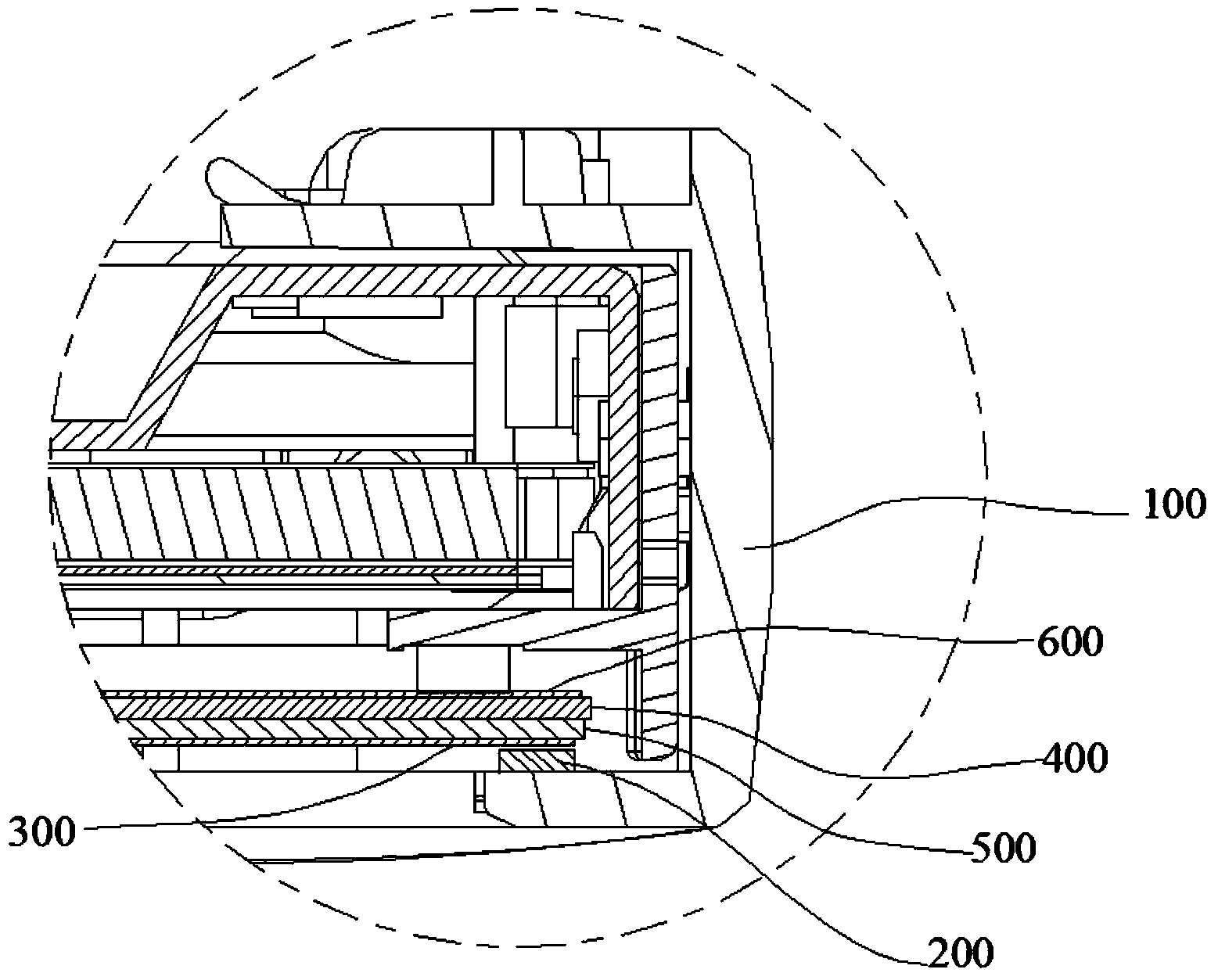

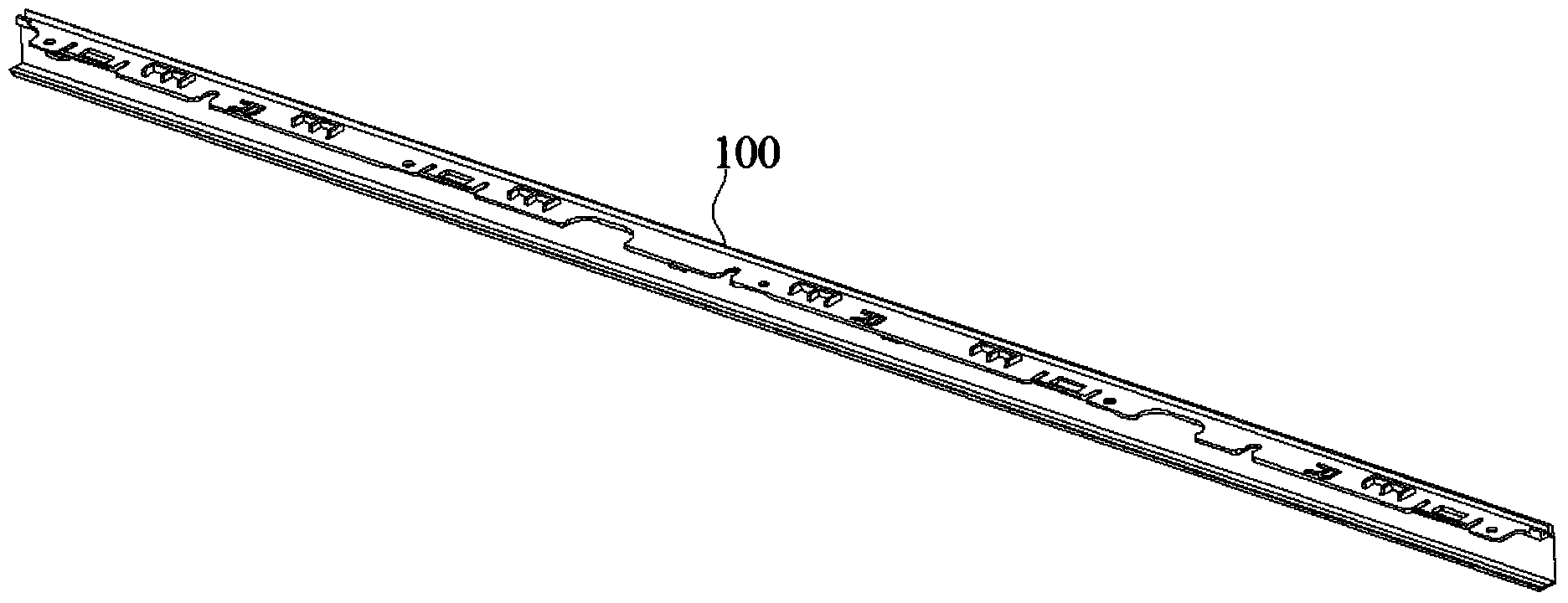

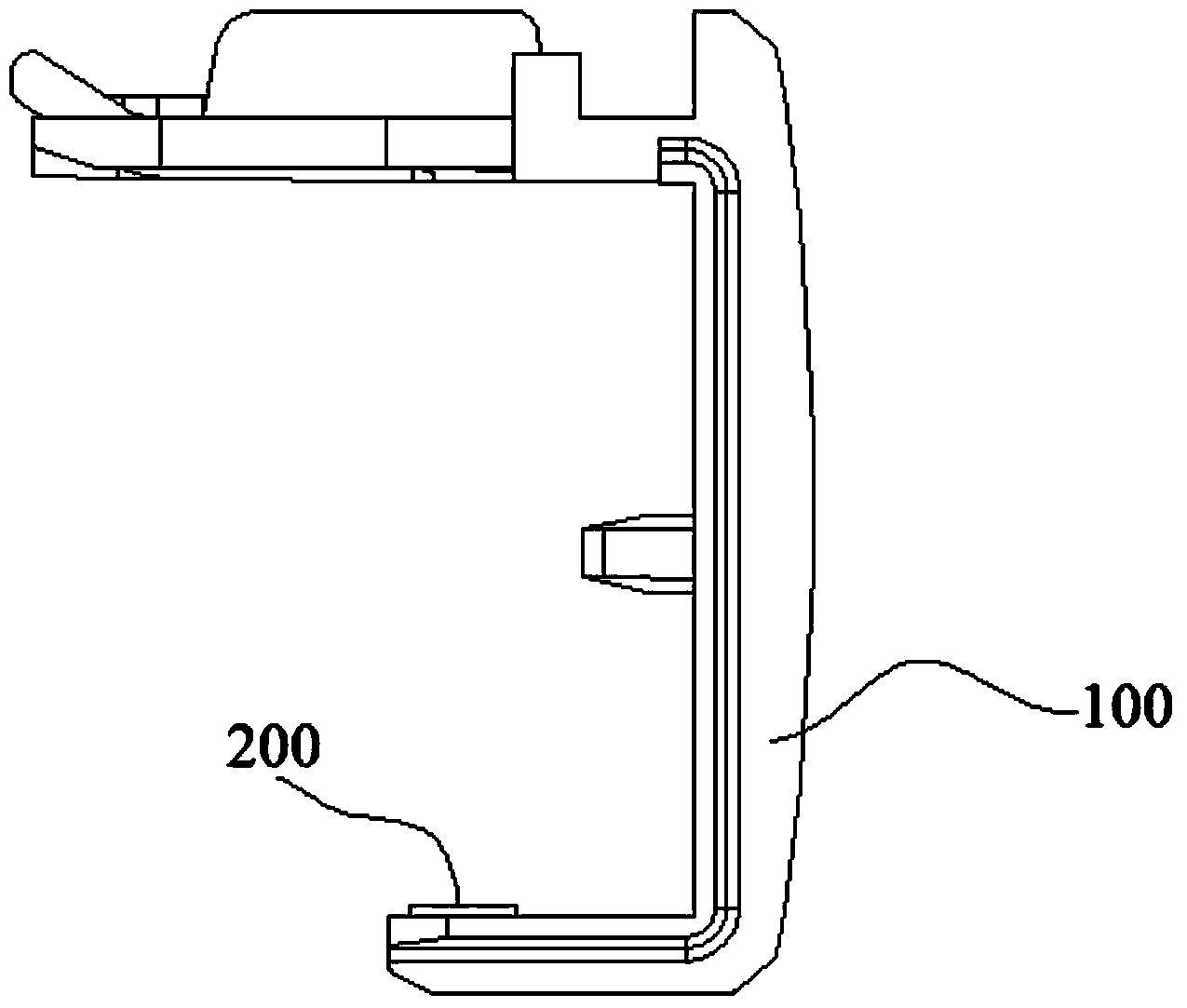

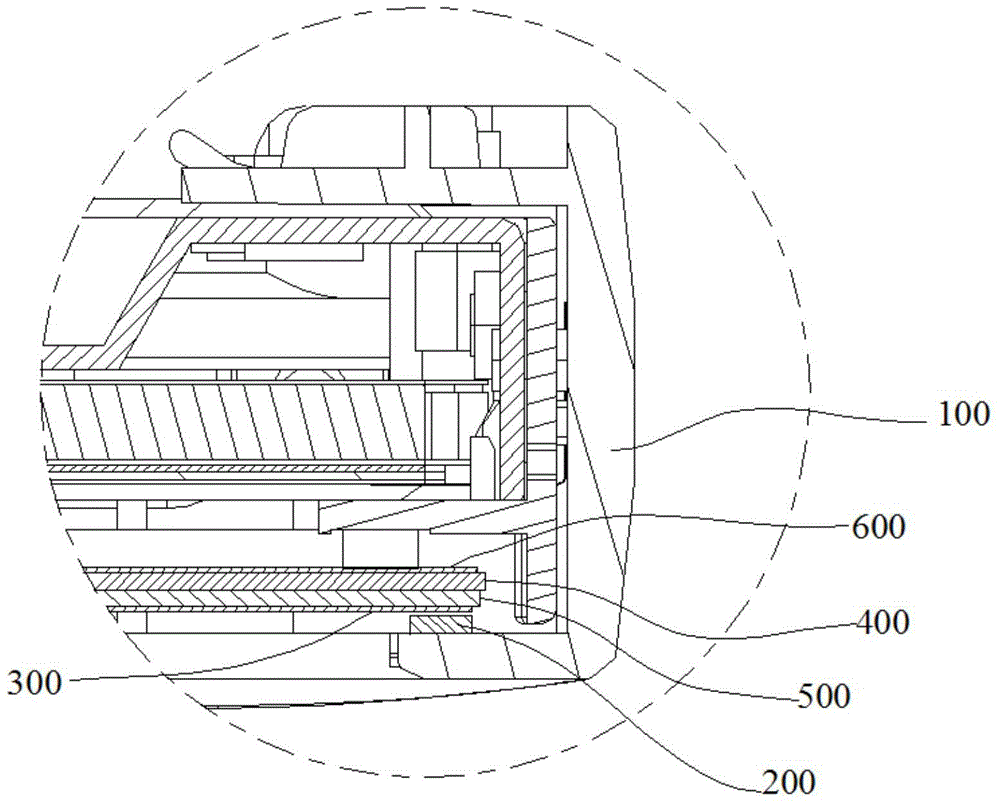

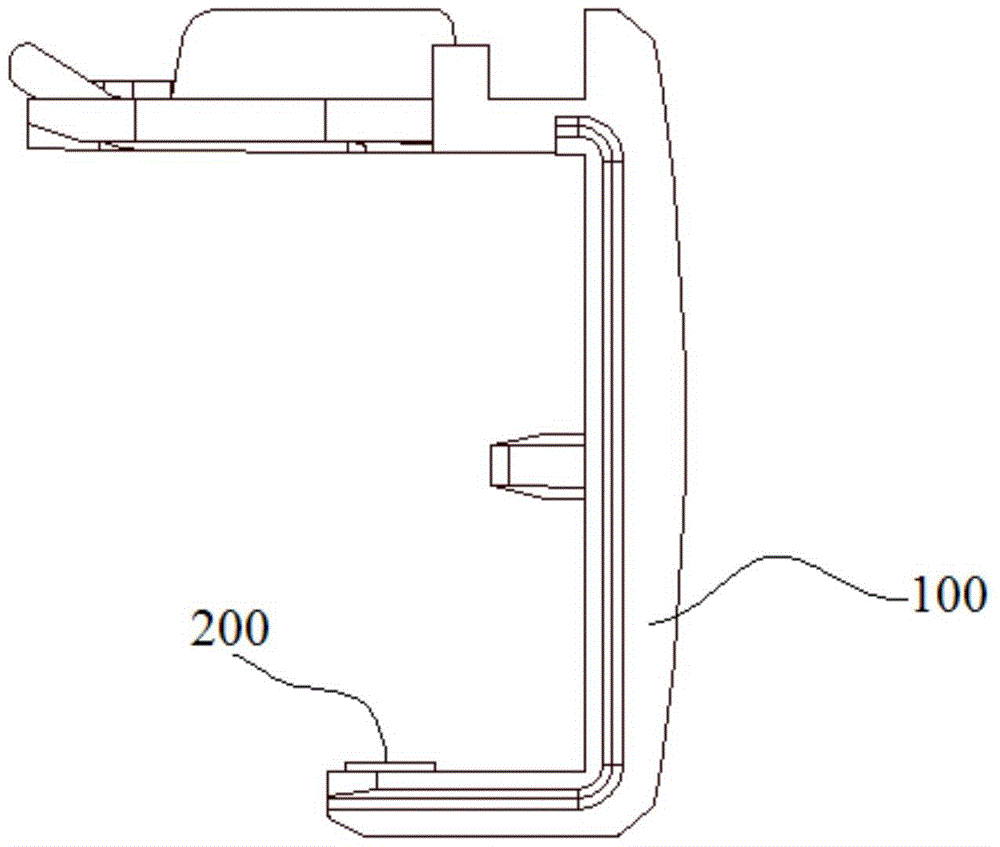

Material pasting device for display device

ActiveCN103885220AImprove pasting efficiencyEasy to pasteNon-linear opticsLiquid-crystal displayEngineering

The embodiment of the invention provides a material pasting device for a display device, and relates to the technical field of liquid crystal display. The device reduces difficulty of material pasting and improves the pasting precision of the materials. The material pasting device for the display device comprises a base, a sliding support and a sealing brush. A mounting groove for containing a part of to-be-pasted materials of the display device is formed in the base, the sliding support is erected on the base and is in sliding connection with the base, the sliding direction of the sliding support is consistent with the pasting direction of the to-be-pasted materials, the sealing brush comprises a brush handle connected with the sliding support and a brush head arranged at one end of the brush handle, a press-fit face is arranged on the side, facing the to-be-pasted materials of the part, of the brush head, and a limiting groove for limiting the materials is formed in the brush head. The material pasting device for the display device is used for pasting materials for the display device.

Owner:HISENSE VISUAL TECH CO LTD

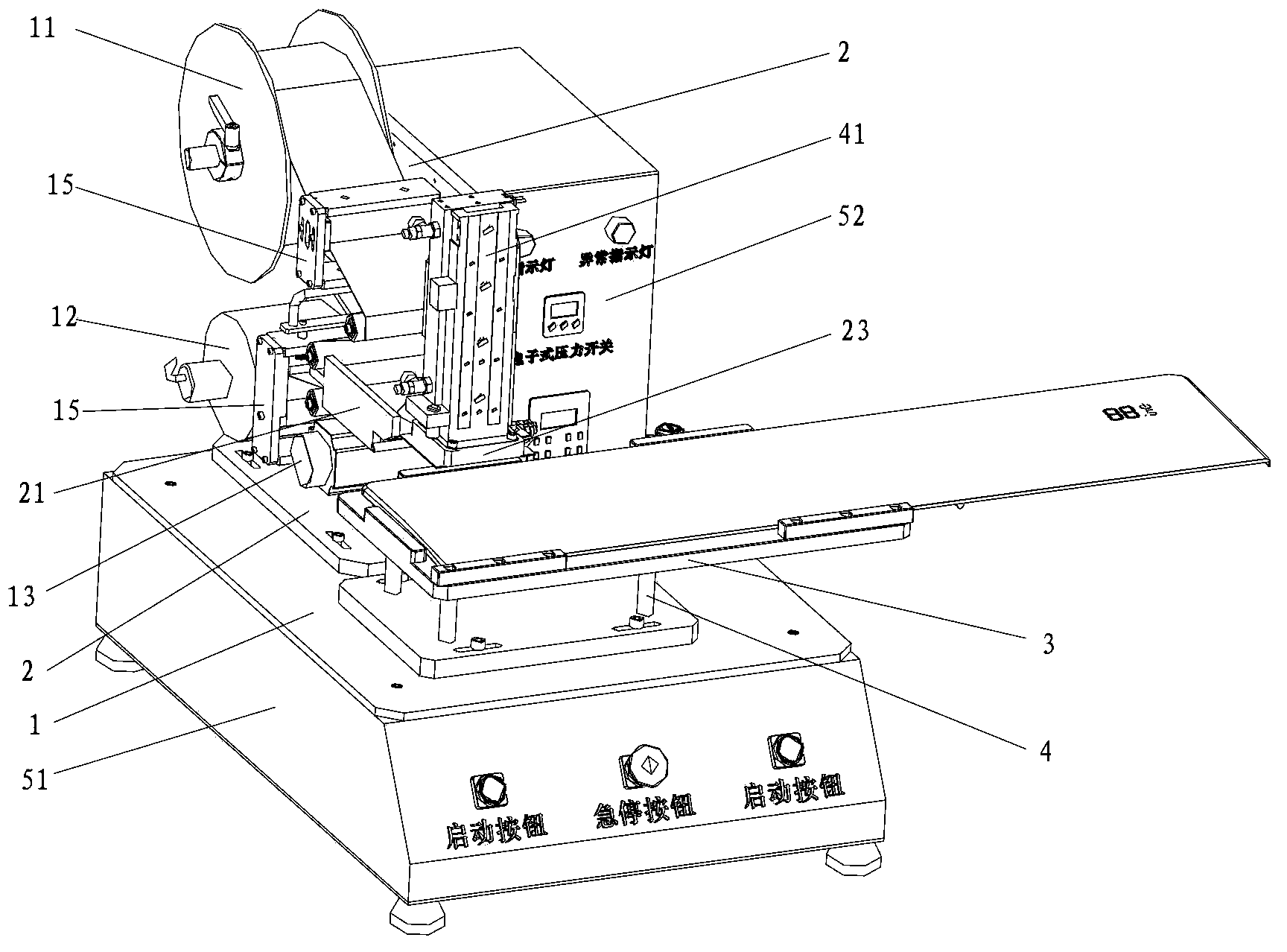

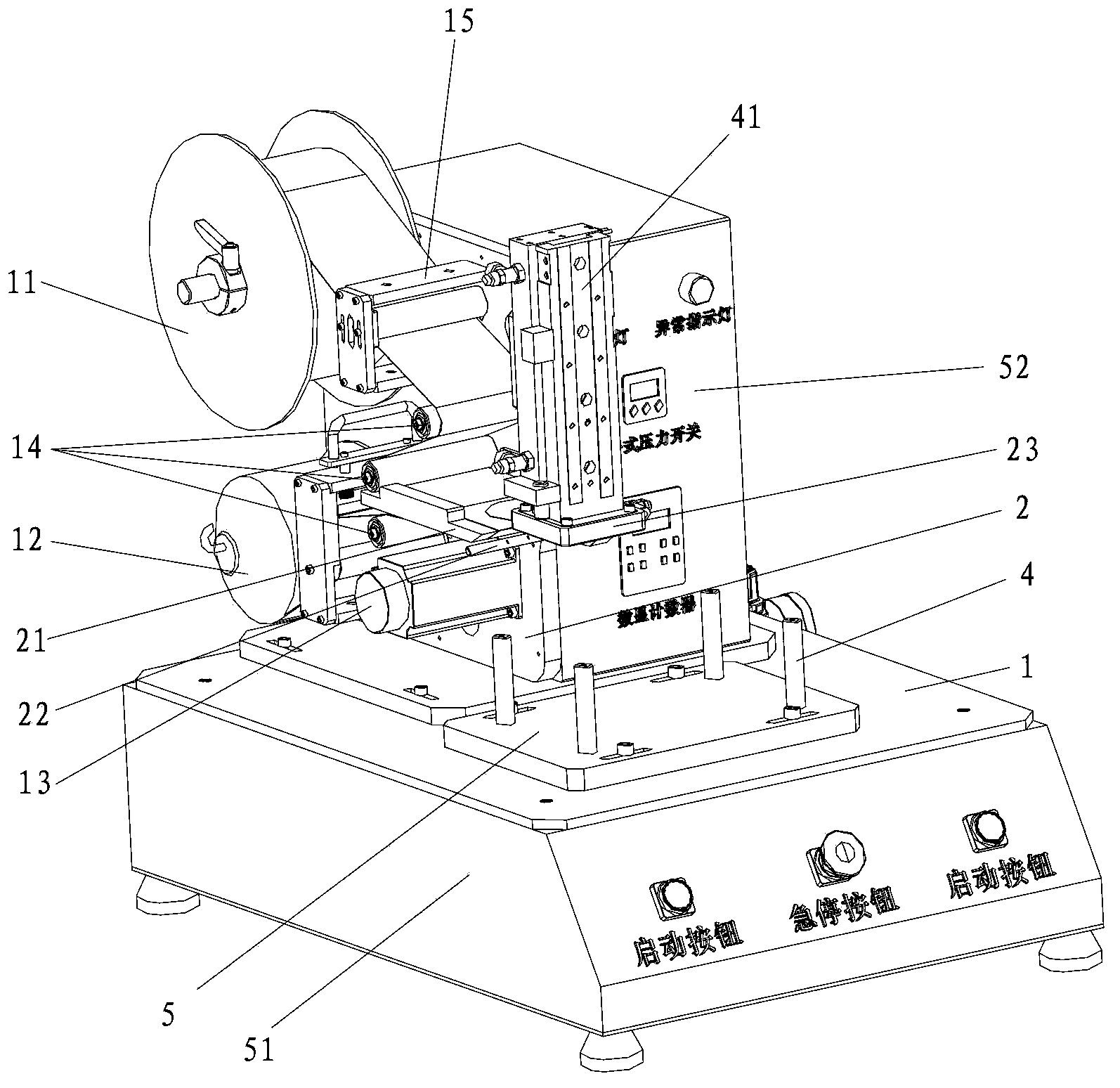

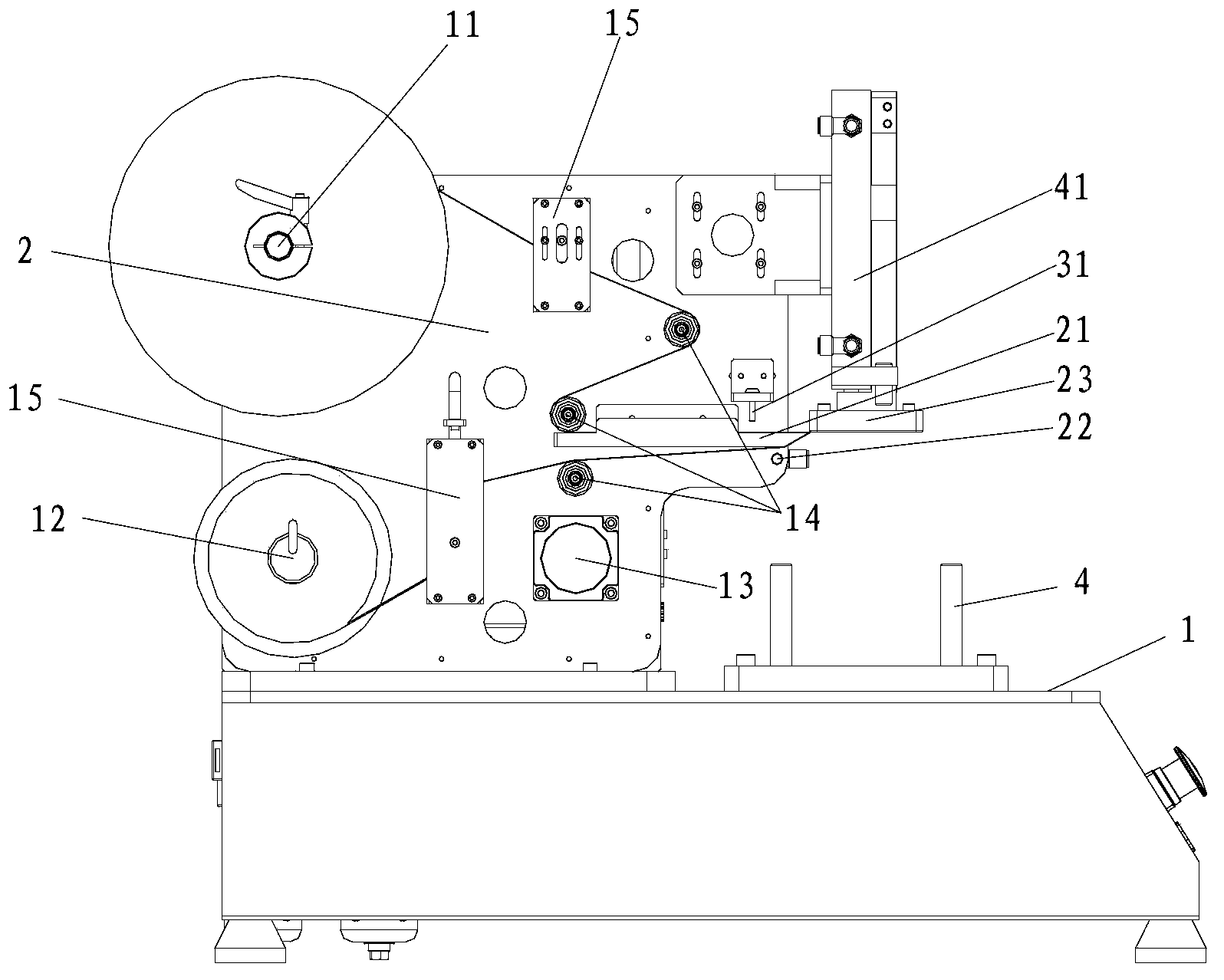

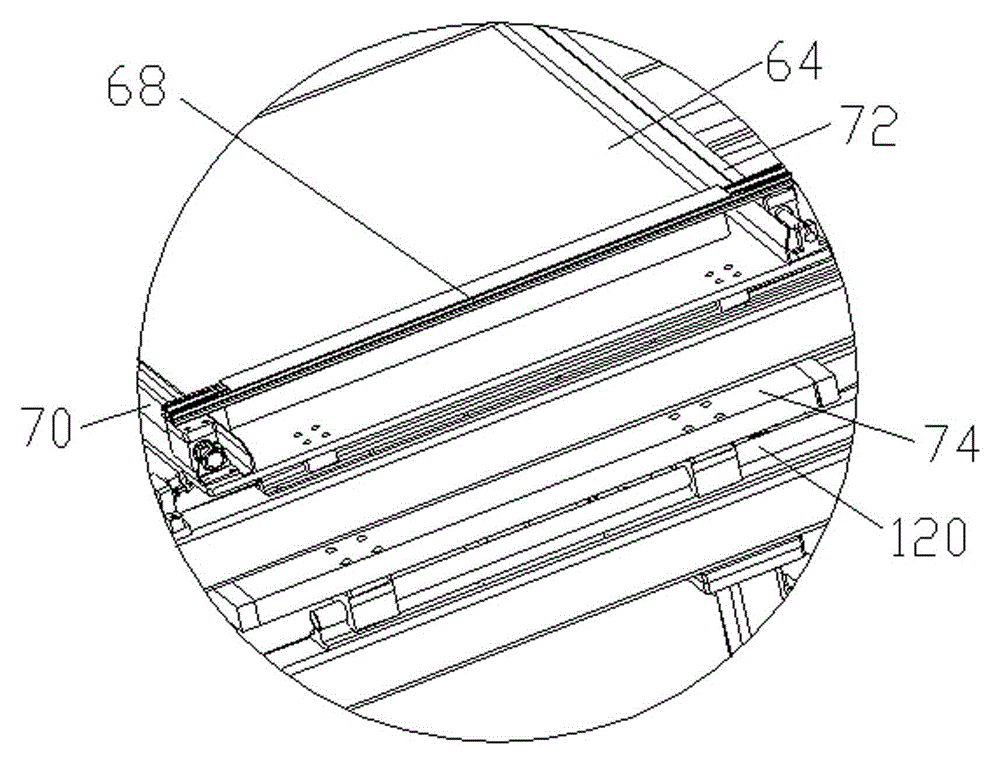

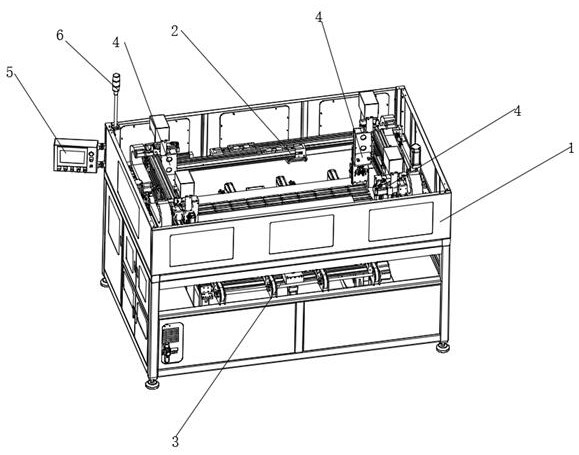

Adhesive tape pasting machine

PendingCN111646282AImprove pasting efficiencyImprove pasting accuracyFinal product manufactureSemiconductor/solid-state device manufacturingSilicone tapeTransfer mechanism

The invention discloses an adhesive tape pasting machine which comprises a rack. The rack is provided with a transfer module, an automatic return module and an adhesive tape pasting module; the transfer module comprises at least two transverse transfer mechanisms and two longitudinal transfer mechanisms; the two ends of the two transverse transfer mechanisms are respectively connected with the twolongitudinal transfer mechanisms; the adhesive tape pasting module comprises at least two first adhesive tape pasting mechanisms and two second adhesive tape pasting mechanisms, the two first adhesive tape pasting mechanisms and the two second adhesive tape pasting mechanisms are respectively located on the two longitudinal transfer mechanisms, and the two first adhesive tape pasting mechanisms and the second adhesive tape pasting mechanisms respectively move on the two longitudinal transfer mechanisms and the two transverse transfer mechanisms. When the first adhesive tape pasting mechanismsand the second adhesive tape pasting mechanisms move on the transverse transfer mechanisms, the first adhesive tape pasting mechanisms and the second adhesive tape pasting mechanisms are distributedin a staggered manner. According to the adhesive tape pasting machine, the pasting efficiency is high, and the pasting precision is high.

Owner:苏州德睿联自动化科技有限公司

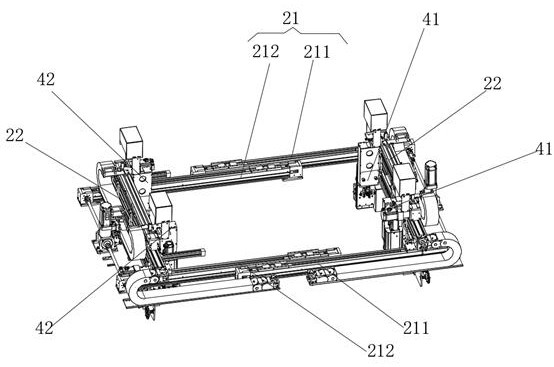

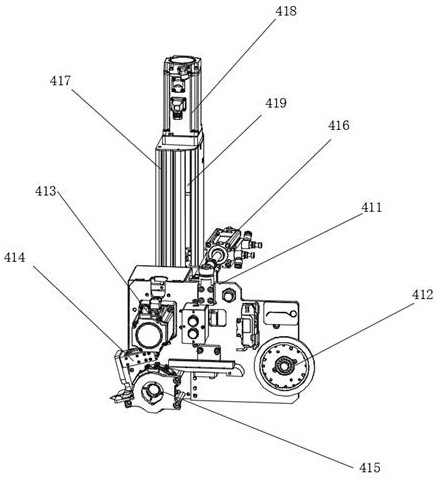

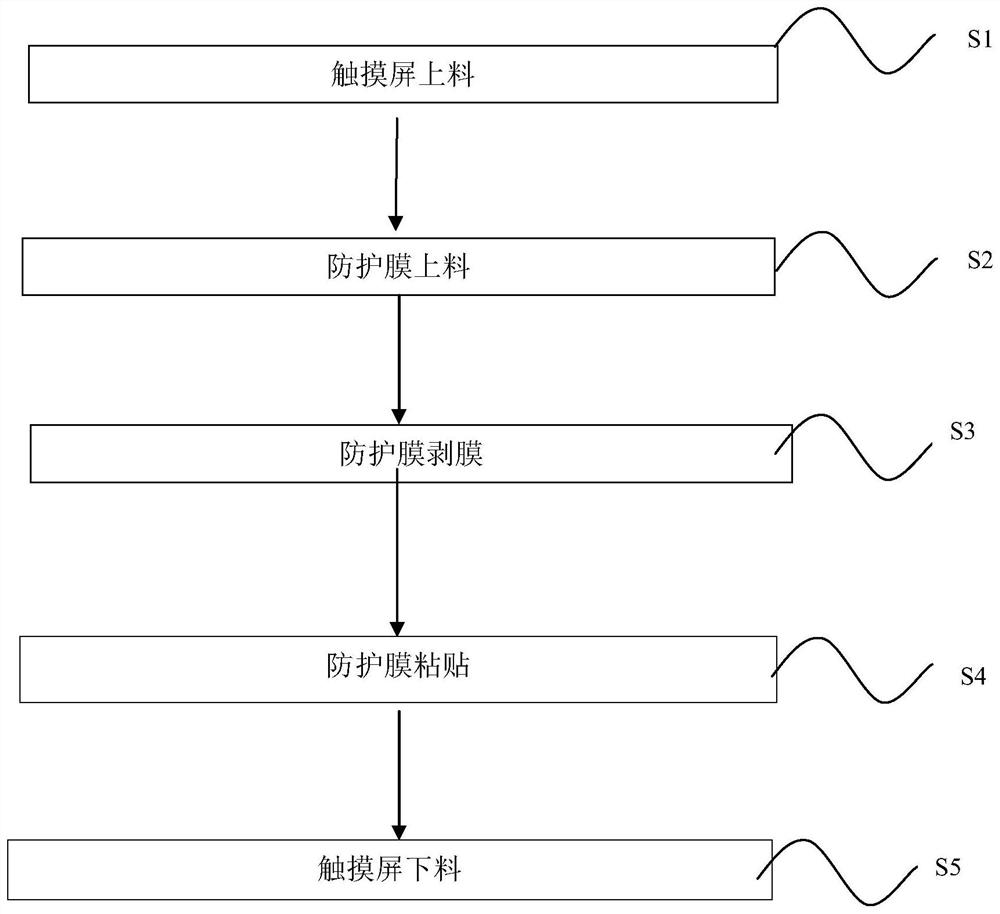

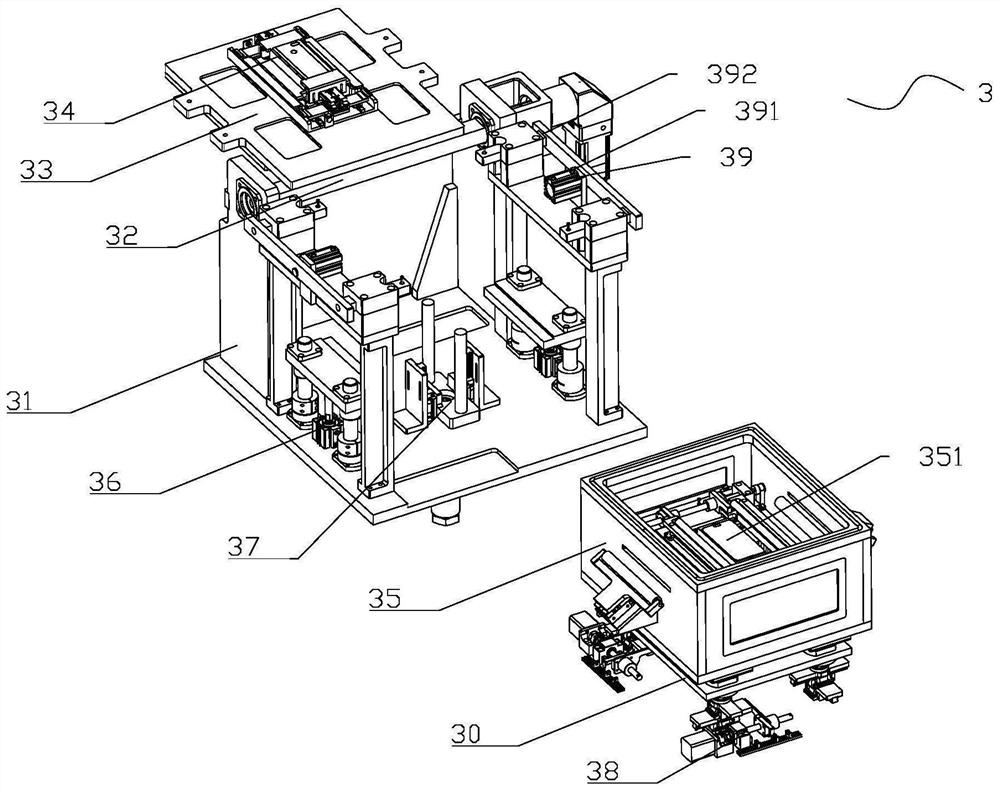

Touch screen protective film pasting equipment and film pasting process

The invention discloses touch screen protective film pasting equipment. The touch screen protective film pasting equipment comprises a rack, and further comprises a touch screen feeding device, a vacuum film pasting device, a protective film feeding device, a touch screen feeding carrying device, a film stripping device, a discharging carrying device and a discharging device which are installed onthe rack; the touch screen feeding device and the discharging device are located on the same straight line, and the protective film feeding device is located between the touch screen feeding device and the discharging device during feeding; the vacuum film pasting device is located in the middle of the protective film feeding device, and the film stripping device is located above the vacuum filmpasting device; and the discharging carrying device is connected with the discharging end of the protective film feeding device and the discharging device. The touch screen protective film pasting equipment has the advantages of being efficient in workpiece circulation, high in production efficiency and high in automation degree.

Owner:NINGBO YINZHOU TEERFEI ELECTRONICS CO LTD

Cover layer seal film for strain gauge, and production method and using method thereof

InactiveCN107933003ASolve the problem of poor positioning consistencyRealize self-sealingLamination ancillary operationsMeasurement devicesEngineeringStrain gauge

The invention discloses a cover layer seal film for a strain gauge, and a production method and a using method thereof. The cover layer seal film comprises a strain gauge cover layer, the seal layer surface of the strain gauge cover layer is provided with an adhesive layer, and the adhesive layer is adhered with cover layer release paper, wherein the strain gauge cover layer is provided with a plurality of marking points, and positions, corresponding to strain gauge bonding pads, of the strain gauge cover layer, are hollow-out; and the cover layer seal film is used for sealing the whole straingauge. The cover layer seal film can realize the automatic sealing of the whole gauge strain, especially special-shaped pattern sealing which cannot be realized through a conventional technology, allows the alignment precision to be 3 times higher than that the manual alignment precision, improves the sealing efficiency by 5 times or more, and completely solves the problems of low efficiency, unstable quality and poor product consistence of existing artificial production.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

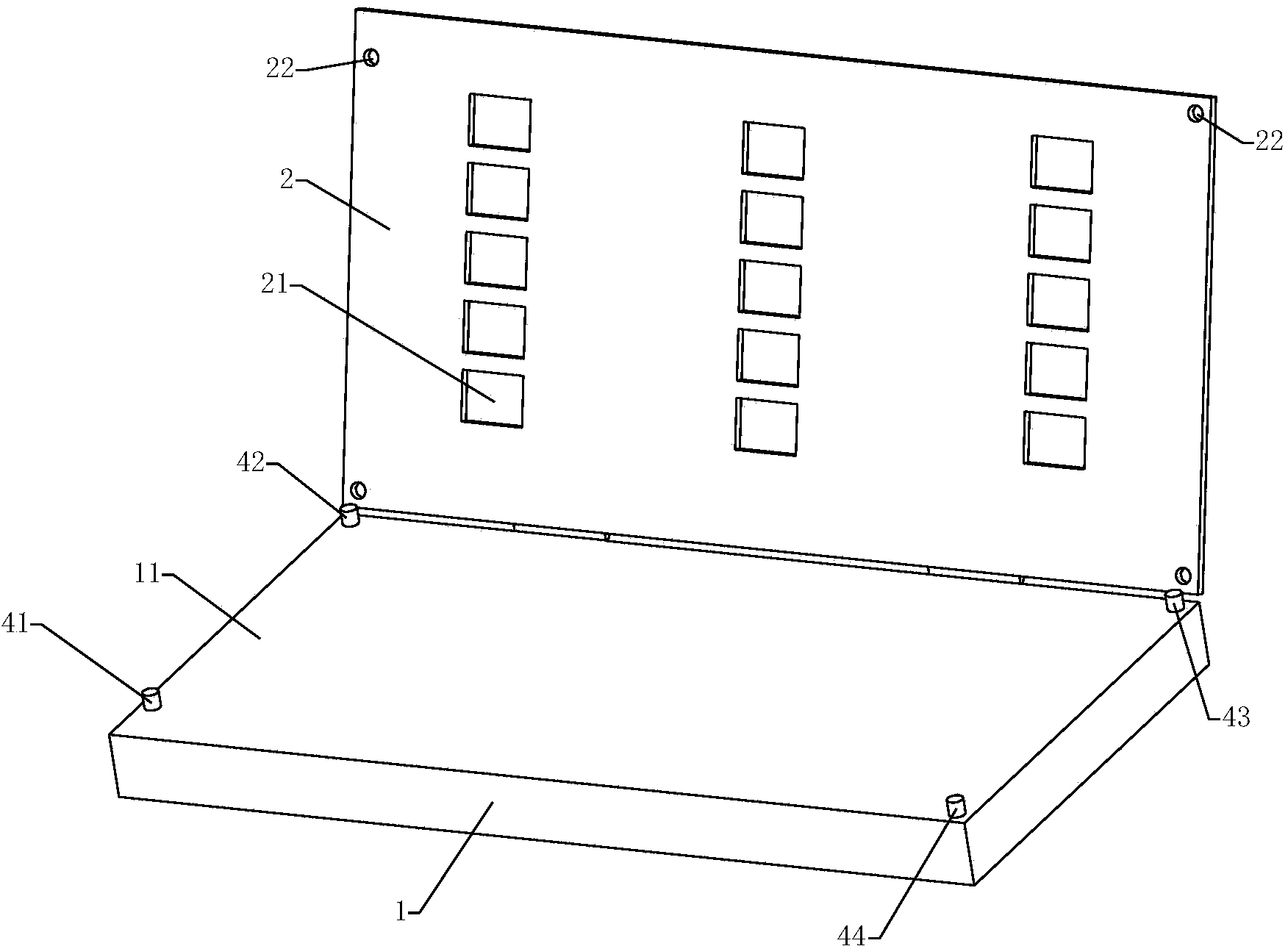

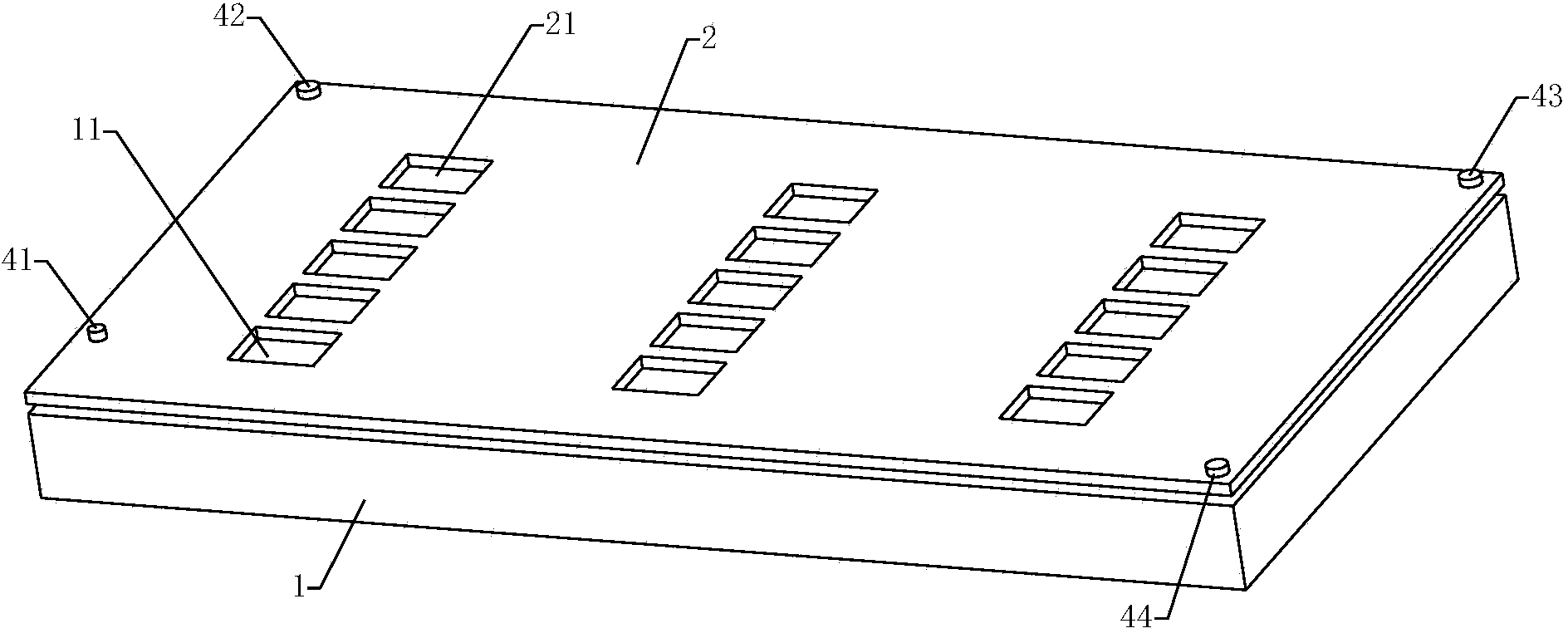

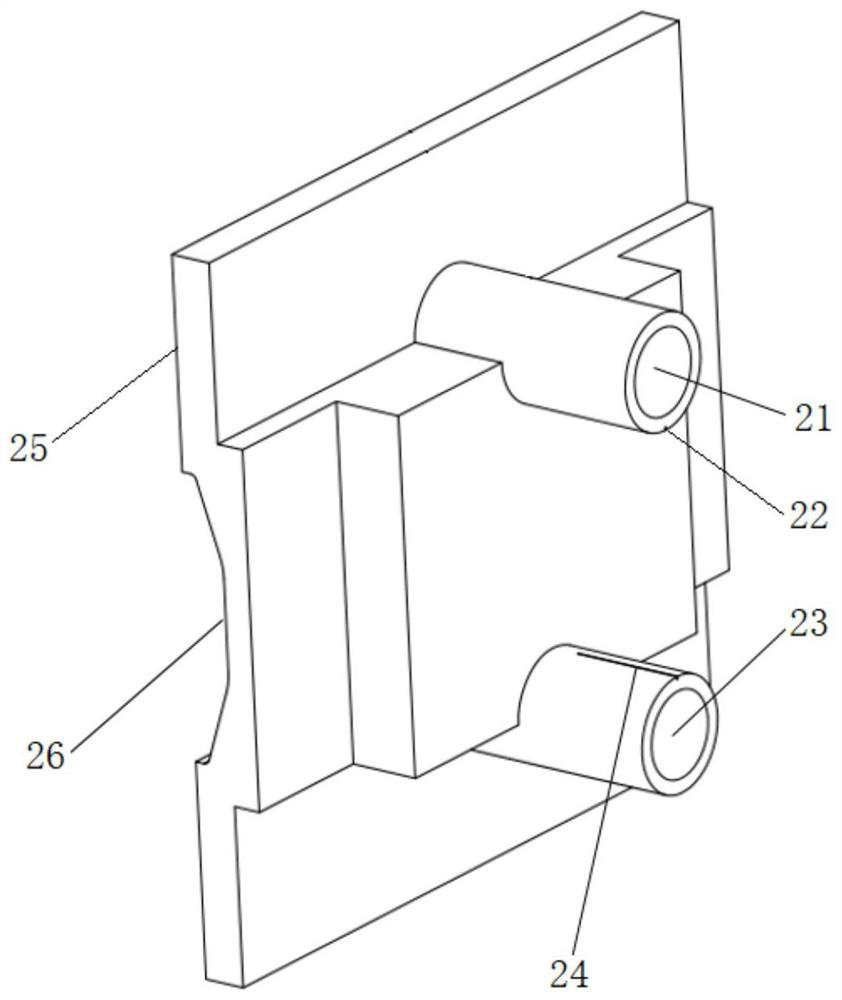

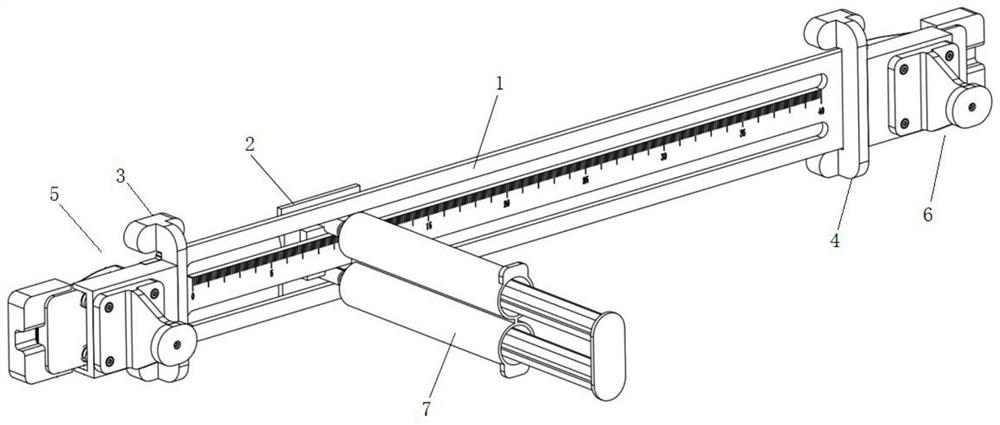

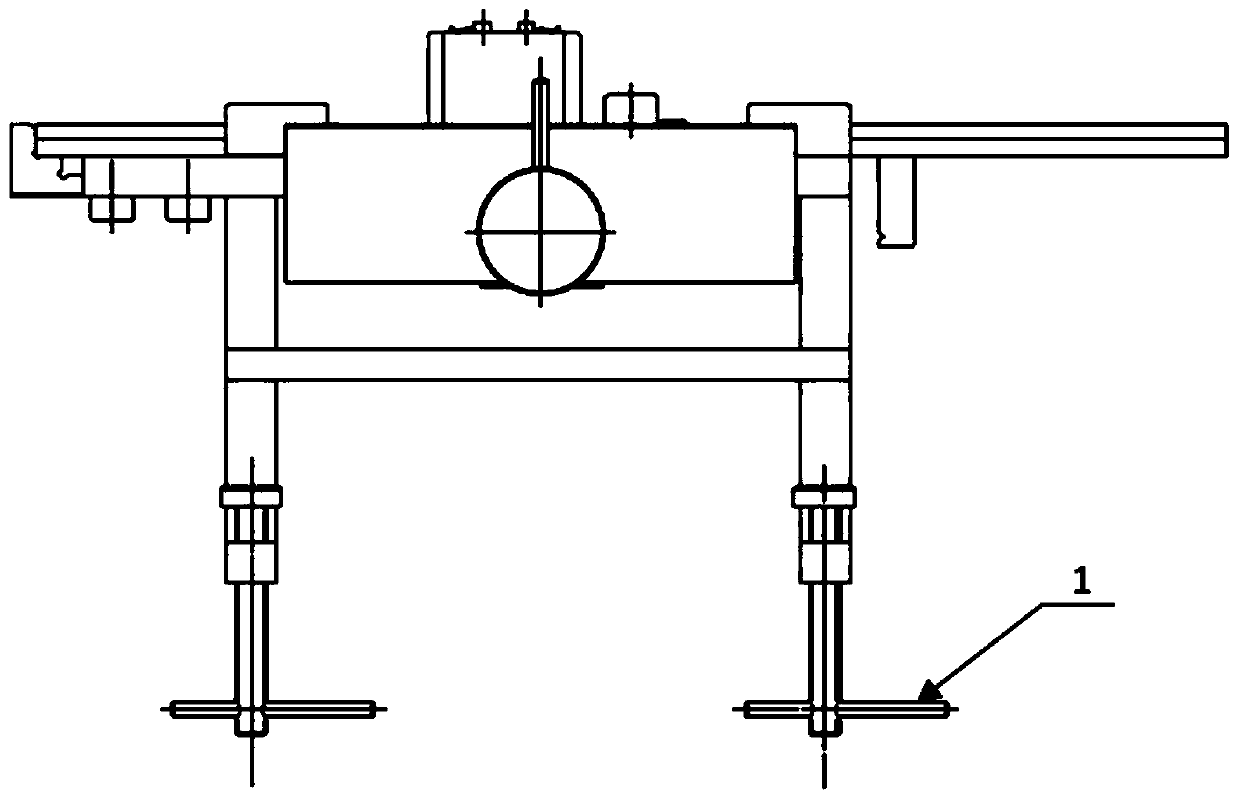

Assistant clamp for measurement of racking strain of composite material

ActiveCN106872261AReduce operating linksImprove pasting accuracy and efficiencyStrength propertiesBiomedical engineeringStrain measurement

The invention discloses an assistant clamp for measurement of the racking strain of a composite material. The clamp can effectively reduce operation procedures for preparation of extrusion samples, lower the labor intensity of supporting staff and improve pasting efficiency and quality of extensometer installation blocks. Main technical points of the assistant clamp lie in that the assistant clamp can rapidly and accurately position and paste extensometer installation blocks, adjust the curing pressure of an adhesive and paste extensometer installation blocks on two surfaces of a sample and is applicable to single-bolt double-shear samples, single-bolt single-shear samples and double-bolt single-shear samples.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

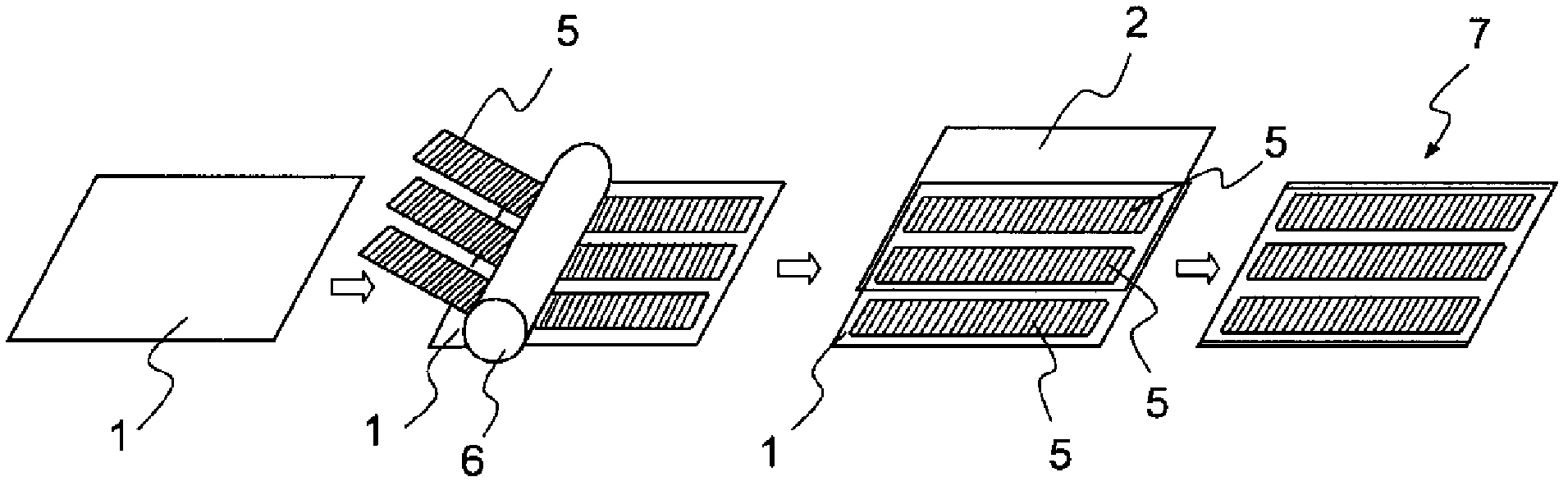

Process for producing pneumatic tire

InactiveUS20050247394A1Improve pasting accuracyPoor workabilitySpecial tyresTyresEngineeringBand shape

In a method of producing a pneumatic tire comprising a belt comprised of at least two belt layers each constituted with steel cords and a coating rubber covering the cord between a tread and a radial carcass by spirally winding a band-shaped uncured rubber composition extruded through an extruder on a rotating support to form a rubber member having a given sectional shape, a rubber composition formed by compounding a rubber component with a compound having a melting point of 120-220° C. and / or a resin having a softening point prior to curing of 90-150° C., in which a total compounding amount of the compound and the resin is 0.5-25 parts by mass based on 100 parts by mass of the rubber component, is applied in the coating rubber. In this method, the extrusion workability at the uncured state is good, and a tire having a high durability can be produced.

Owner:BRIDGESTONE CORP

Protective film moving and pasting mechanism and protective film moving and pasting method

InactiveCN112477096AThe feeding method is stable and reliableImprove efficiencyPolymer scienceTouchscreen

The invention relates to the field of film pasting of touch screen films. The protective film moving and pasting mechanism comprises a discharging assembly and a pre-pasting assembly, the pre-pastingassembly is located below the discharging assembly, the discharging assembly is used for storing a protective film, the pre-pasting assembly is used for pre-pasting the protective film to a bottom film to achieve feeding, and the discharging assembly comprises a material frame, a lateral moving air cylinder, an adjusting plate, a pressing plate, a pressing air cylinder, a longitudinal moving air cylinder, a fixing suction plate and a moving plate. The protective film moving and pasting mechanism and the protective film moving and pasting method have the advantages of being efficient in protective film movement and smooth in movement.

Owner:NINGBO YINZHOU TEERFEI ELECTRONICS CO LTD

Method for making run-flat tire and assembly drum device for same

ActiveCN101659127BImprove pasting accuracyUniform elasticityTyresPneumatic tyre reinforcementsBand shapeEngineering

The invention can improve the homogeneity of a run-flat tire. A method for making the run-flat tire of which a tire side part is provided with a tire side reinforcing glue with the cross section approximately in the crescent shape is provided. The method includes: winding flaky inner lining glue on the external circumstance of a cylindrical drum main body; winding and sticking band-shaped tire side reinforcing glue in the region of the external circumstance of the cylindrical inner lining glue equivalent to a pair of tire sides to form a first cylindrical object; arranging a pair of circumferential channels on the external circumstance of the drum main body and the inner side of the tire side reinforcing glue, expanding the drum main body, thereby the portion of the first cylindrical object, reinforced with the tire side reinforcing glue goes down into the circumferential channels; and winding the flaky carcass cord fabric by means of the external circumstance of the sinking and flat first cylindrical object to form a basal body of the tire.

Owner:SUMITOMO RUBBER IND LTD

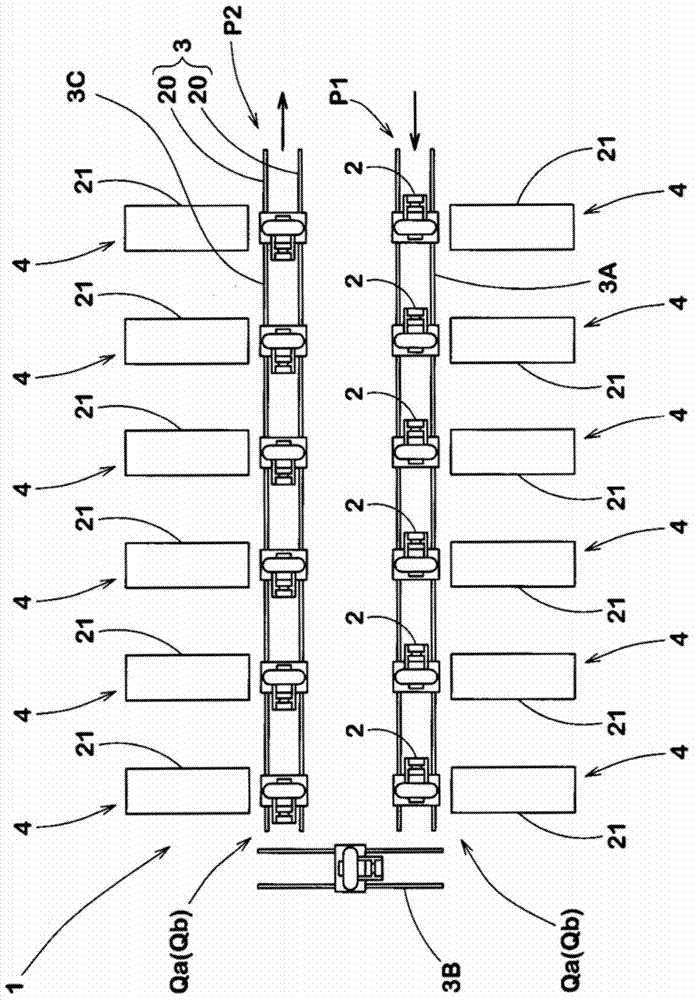

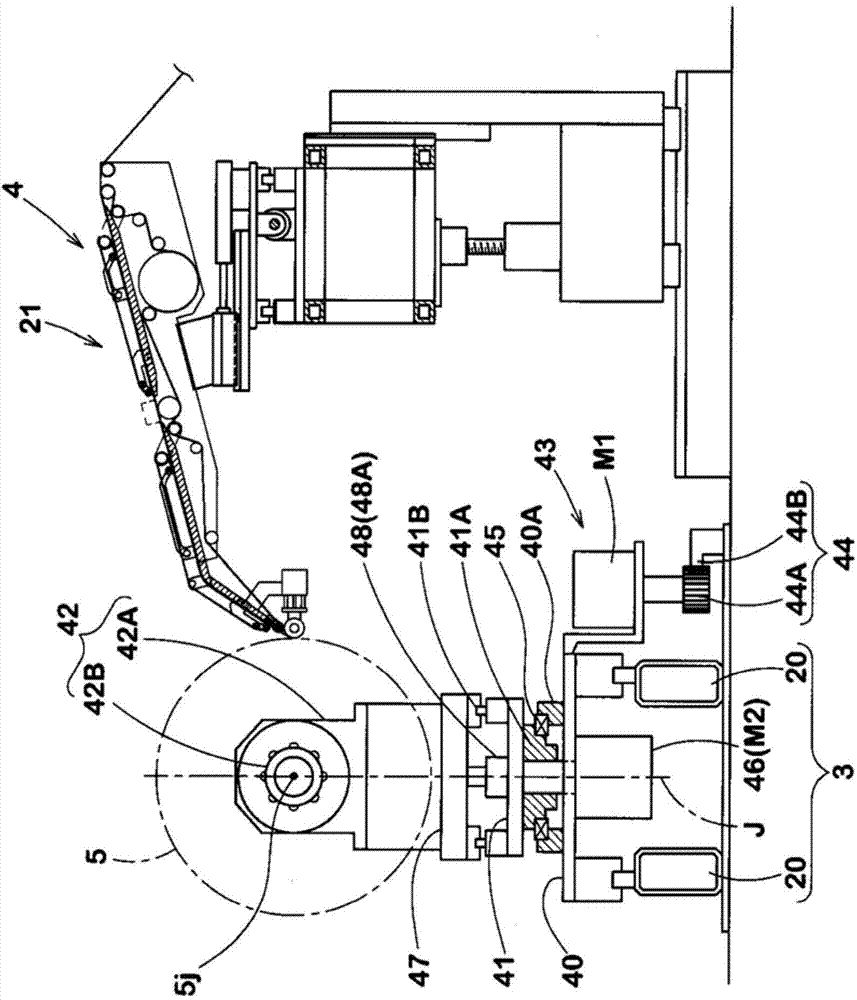

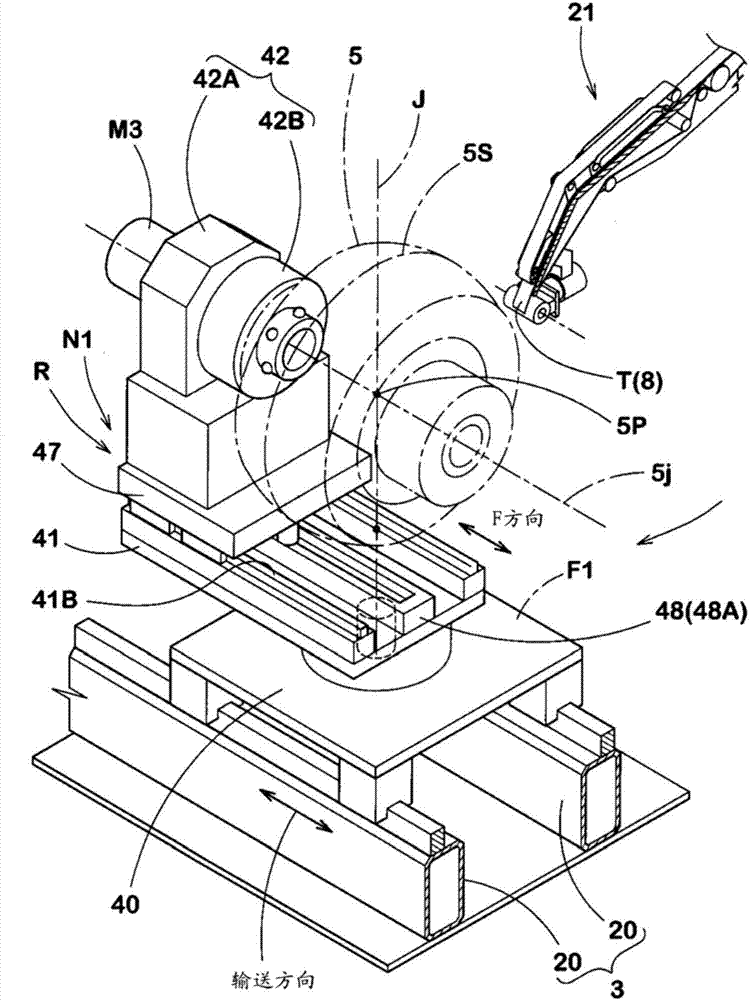

Model core conveying trolley

The invention provides a model core conveying trolley. Handing over of model cores between two model core conveying trolleys on a track is allowed. The model core conveying trolley comprises a conveying bench capable of moving along the track, a rotary bench supported on the conveying bench and revolving about a vertical revolving axis, a horizontal moving bench which is supported on the rotary bench, and can be horizontally moved to a second position from a first position along a horizontal F directional line passing through a revolving axis, and a model core supporting bench which is supported on the horizontal moving bench and can be connected with a supporting shaft connection portion at one side of a rigid model core in a dismounting free means. When the F directional line is in parallel to the conveying direction under a revolving referential state, and on the second position, the equatorial plane of the rigid model core is on a position outside than the conveying bench and the horizontal moving bench relative the conveying direction.

Owner:SUMITOMO RUBBER IND LTD

A material pasting device for a display device

ActiveCN103885220BImprove pasting efficiencyEasy to pasteNon-linear opticsLiquid-crystal displayDisplay device

The embodiment of the invention provides a material pasting device for a display device, and relates to the technical field of liquid crystal display. The device reduces difficulty of material pasting and improves the pasting precision of the materials. The material pasting device for the display device comprises a base, a sliding support and a sealing brush. A mounting groove for containing a part of to-be-pasted materials of the display device is formed in the base, the sliding support is erected on the base and is in sliding connection with the base, the sliding direction of the sliding support is consistent with the pasting direction of the to-be-pasted materials, the sealing brush comprises a brush handle connected with the sliding support and a brush head arranged at one end of the brush handle, a press-fit face is arranged on the side, facing the to-be-pasted materials of the part, of the brush head, and a limiting groove for limiting the materials is formed in the brush head. The material pasting device for the display device is used for pasting materials for the display device.

Owner:HISENSE VISUAL TECH CO LTD

Device and method for fast positioning and pasting of fiber grating sensor

ActiveCN112439643BImplement fixed functionRapid positioningLiquid surface applicatorsMaterial gluingGratingViscose

Owner:QINGDAO DMAR OCEAN ENG

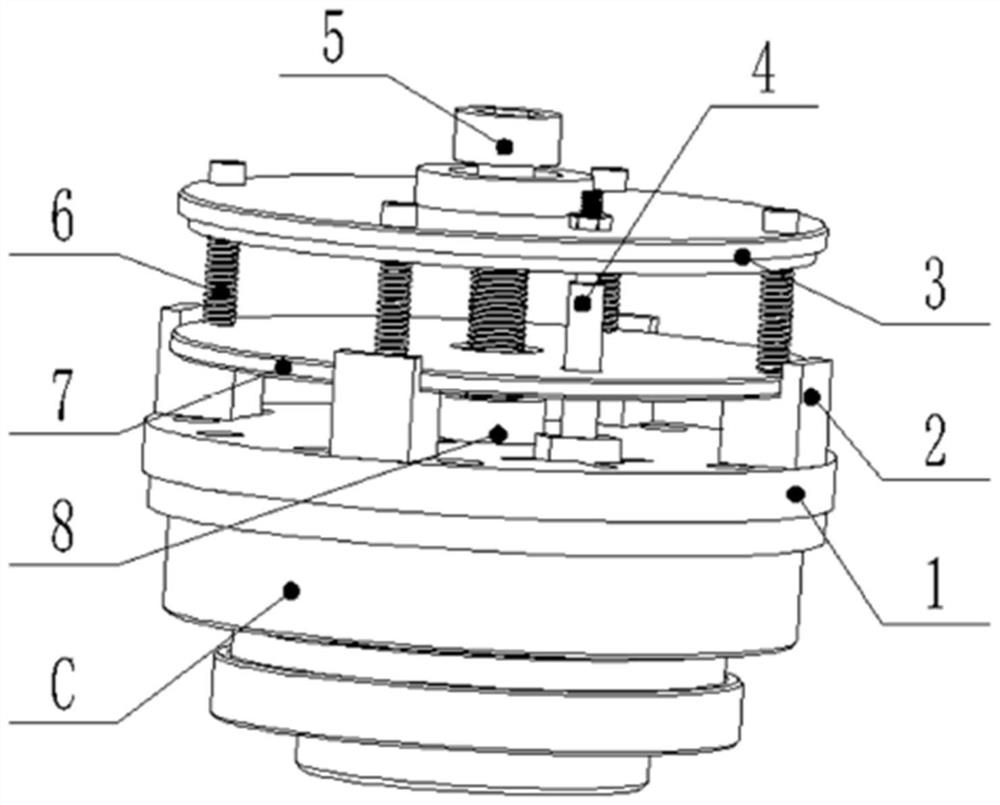

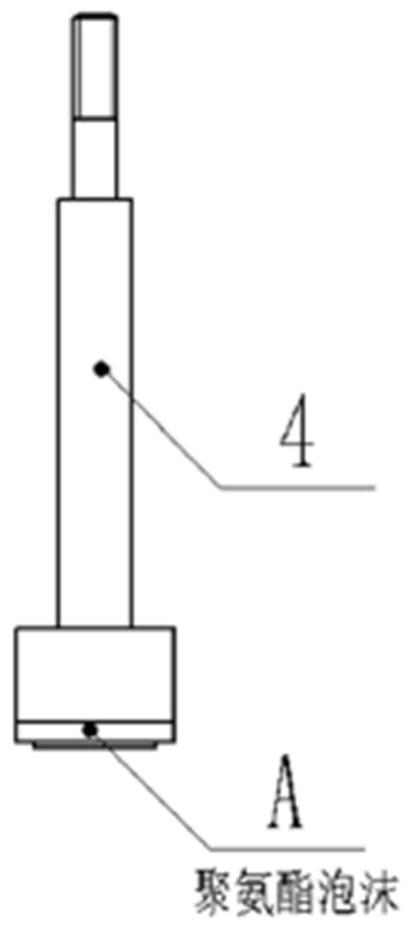

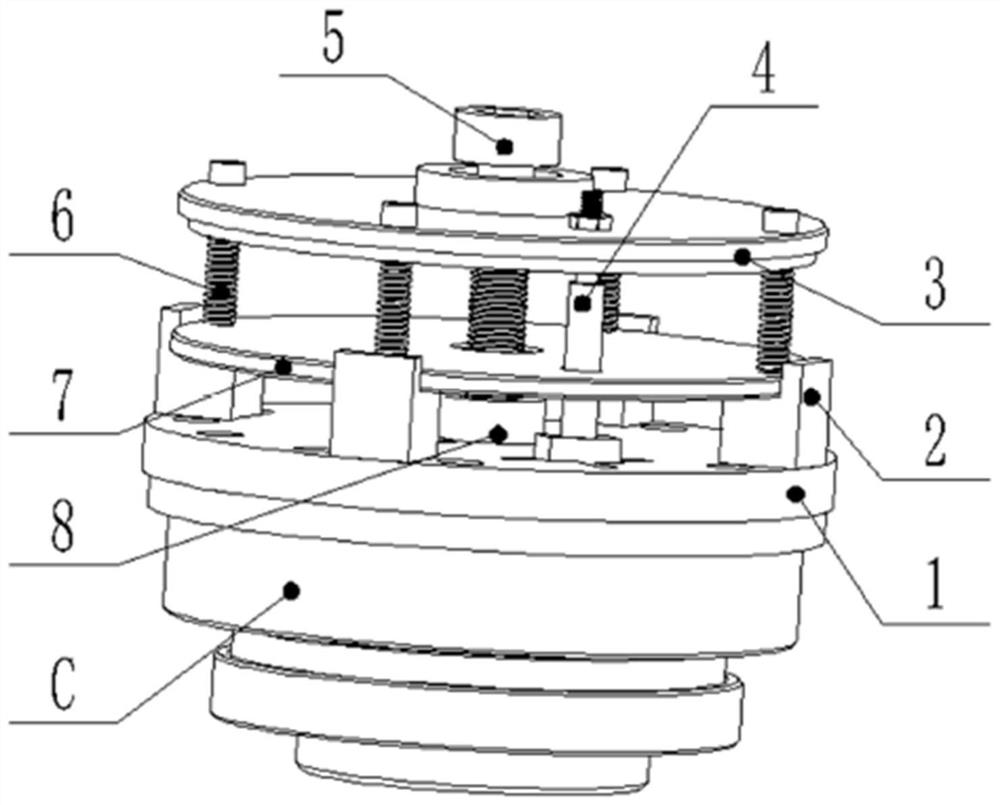

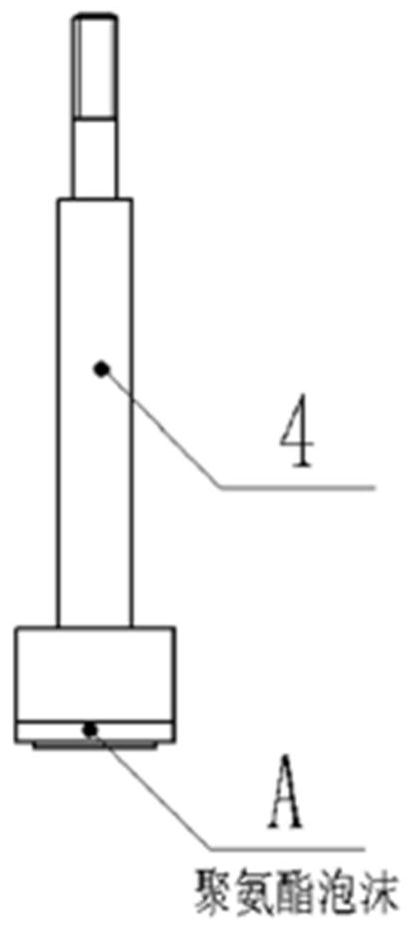

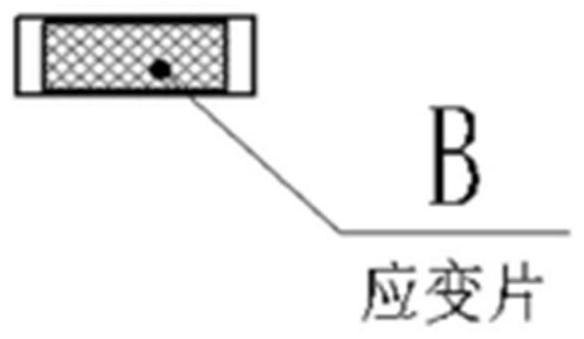

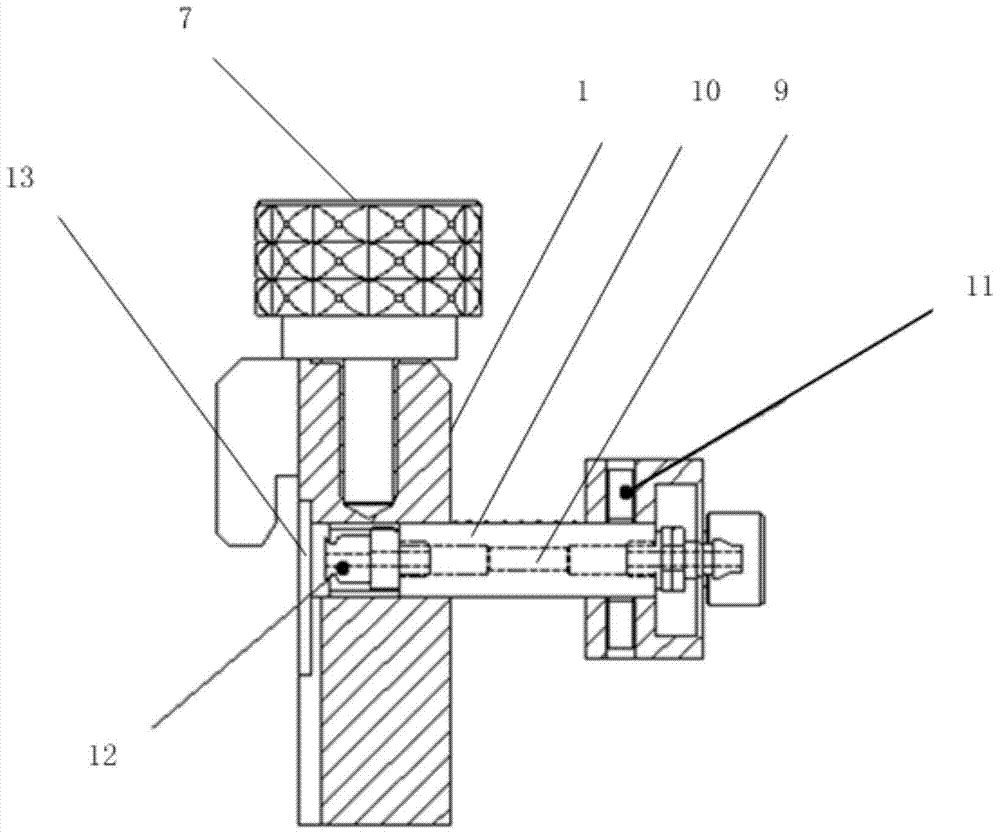

Strain gauge sticking device and method for harmonic reducer fault diagnosis

ActiveCN113389785BPrecise and error-free pastingPrecise positioningMaterial gluingGearingReduction driveClassical mechanics

The invention provides a strain gauge pasting device and method for fault diagnosis of a harmonic reducer. The device includes a base flange assembly, a force control assembly, an expansion rod with a seat cushion and a compression screw; the base flange assembly includes Install the flange cover, the boss with threaded holes and the support seat with holes. The boss with threaded holes and the support seat with holes are installed on the flange cover through screws, and the flange cover is buckled on the harmonic reducer through the inner hole. ;The force control assembly includes a gland, a pressure seat and a spring assembly, and the distance between the gland and the pressure seat can be controlled by a telescopic spring; the telescopic rod with a seat cushion passes through the pressure seat and the gland, and is embedded in the mounting flange Cover, with seat cushion The bottom of the telescopic rod is used to fix the resistance strain gauge; the compression screw passes through the gland and is fixed on the boss with threaded holes. When the device is in use, the strain gage is fixed on the seat cushion at the bottom of the telescopic rod, and after dripping glue, the compression screw is used to adjust the spring force, thereby controlling the movement of the telescopic rod to complete the compression and pasting of the strain gage.

Owner:浙江环动机器人关节科技股份有限公司

Foam automatic sticking machine and its processing technology

InactiveCN105172304BSimple structureEasy to useLaminationLamination apparatusEngineeringMechanical engineering

The invention relates to an automatic foam sticking machine which comprises a rack, a control device, a first loading rack and a second loading rack, wherein a first material feeding mechanism is arranged on the first loading rack and comprises a first baseplate, a first material laying plate, a first driving mechanism and a second driving mechanism, a first sunken part is arranged on the first material laying plate, and at least one second material feeding mechanism layer is arranged on the second loading rack; a material taking mechanism capable of moving horizontally is arranged on the rack, a needle plate capable of moving vertically and a material bearing plate are arranged on the material taking mechanism, a plurality of needles are arranged on the needle plate, a second sunken part is arranged on the material bearing plate, and the first sunken part and the second sunken part correspond in the vertical direction; an electrical heating mechanism is arranged on the rack; based on input parameters or instructions, the control device controls the sticking machine to work. The invention further relates to a processing technology adopting the automatic foam sticking machine. The automatic foam sticking machine and the processing technology adopting the same have the benefits that loading is convenient and safe, and the sticking accuracy is high.

Owner:JIANGSU BVM INTELLIGENT TECH

Strain gauge pasting device and method for harmonic reducer fault diagnosis

ActiveCN113389785APrecise and error-free pastingPrecise positioningMaterial gluingGearingStrain gaugeClassical mechanics

The invention provides a strain gauge pasting device and method for harmonic reducer fault diagnosis. The strain gauge pasting device comprises a base flange assembly, a force control assembly, a telescopic rod with a seat cushion and a compression screw. The base flange assembly comprises a mounting flange cover, a boss with a threaded hole and a supporting seat with a hole, the boss with the threaded hole and the supporting seat with the hole are mounted on the flange cover through screws, and the mounting flange cover is buckled on a harmonic speed reducer in a matched mode through an inner hole; the force control assembly comprises a pressing cover, a pressure-bearing seat and a spring assembly, and the distance between the pressing cover and the pressure-bearing seat can be controlled through a telescopic spring; the telescopic rod with the seat cushion penetrates through the pressure-bearing seat and the pressing cover and is embedded into the mounting flange cover, and the bottom of the telescopic rod with the seat cushion is used for fixing the resistance strain gauge; and the compression screw penetrates through the pressing cover and is fixed to the boss with the threaded hole. When the strain gauge pasting device is used, the strain gauge is fixed to the seat cushion at the bottom of the telescopic rod, after glue is dripped, the elastic force of the spring is adjusted by the compression screw, so that the telescopic rod is controlled to move, and the compression and pasting of the strain gauge are completed.

Owner:浙江环动机器人关节科技有限公司 +1

An Auxiliary Fixture for Extrusion Strain Measurement of Composite Materials

ActiveCN106872261BAdjustable curing pressureReduce the number of operationsStrength propertiesUltimate tensile strengthBiomedical engineering

The invention discloses an assistant clamp for measurement of the racking strain of a composite material. The clamp can effectively reduce operation procedures for preparation of extrusion samples, lower the labor intensity of supporting staff and improve pasting efficiency and quality of extensometer installation blocks. Main technical points of the assistant clamp lie in that the assistant clamp can rapidly and accurately position and paste extensometer installation blocks, adjust the curing pressure of an adhesive and paste extensometer installation blocks on two surfaces of a sample and is applicable to single-bolt double-shear samples, single-bolt single-shear samples and double-bolt single-shear samples.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Strain gauge sticking device

ActiveCN105065397BPlace stableImprove pasting efficiencyFastening meansPulp and paper industryStrain gauge

The invention discloses a strain gage pasting device which is used for pasting a strain gage to a to-be-pasted area. The strain gage pasting device comprises a positioning plate, a compression mechanism and a sucking disc assembly, wherein a strain gage positioning groove and a strain gage line guiding groove are formed in the front end of the positioning plate, and a through hole is formed in the positioning plate and communicated with the strain gage positioning groove; the compression mechanism comprises a pressing plate, a pressing block and a guide column, the guide column is connected to the back end of the positioning plate, the pressing plate is connected to the guide column in a sliding manner, the pressing block is connected to the through hole in a sliding manner, and the back end of the pressing block is connected with the pressing plate; the back end of the pressing block does not exceed the strain gage positioning groove, and a containing hole is formed inside the pressing block; and the sucking disc assembly comprises a vacuum sucking disc, a connecting pipe and a connecting joint, the vacuum sucking disc is fixed to the front end of the containing hole, the connecting joint is fixed to the back end of the containing hole, and a connecting pipe is used for connecting the vacuum sucking disc with the connecting joint and located in the containing hole. By means of the pasting device, the strain gage can be sucked to be accurately pasted into the to-be-pasted area.

Owner:NINEBOT (CHANGZHOU) TECHCO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com