Packaging method of OLED (organic light emitting diode) display panel

A display panel and packaging method technology, which is applied in the direction of organic light-emitting devices, semiconductor devices, electrical components, etc., can solve the problems of lower production efficiency of OLED display panels, lower paste efficiency of external barrier films, and lead wires in easily damaged binding areas. Achieve the effects of improving life and safety, improving paste efficiency, and improving paste efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

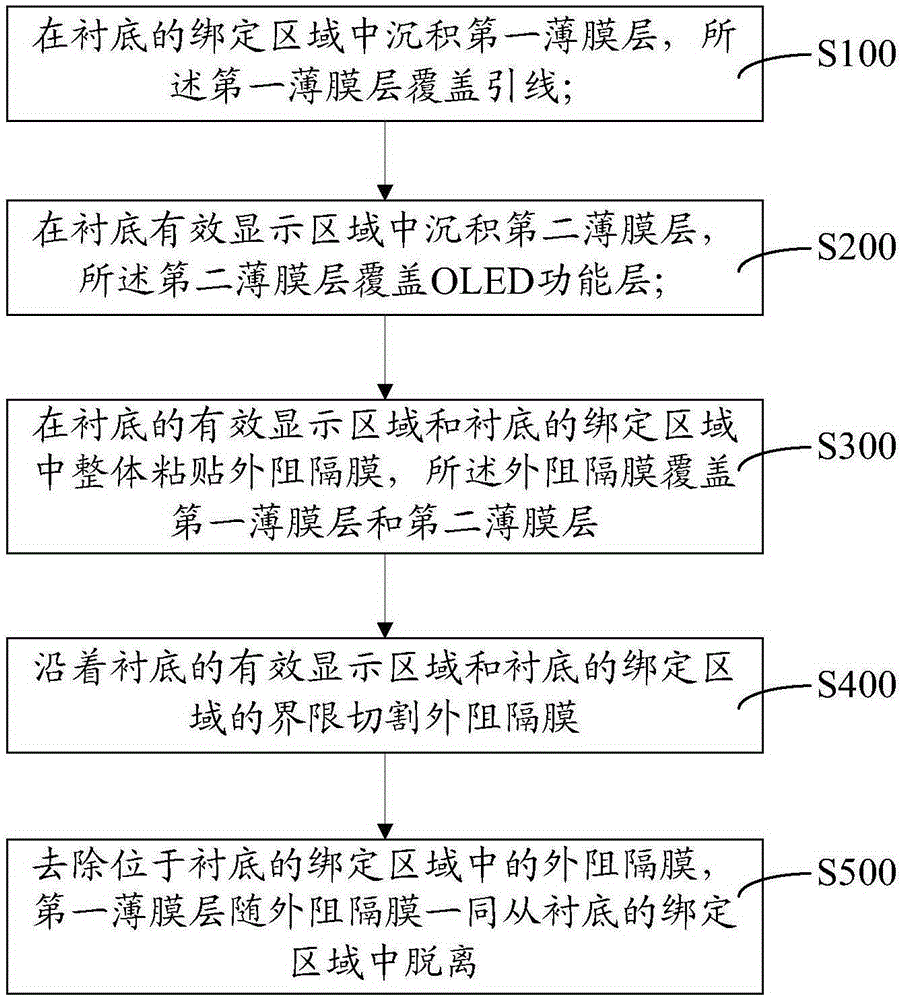

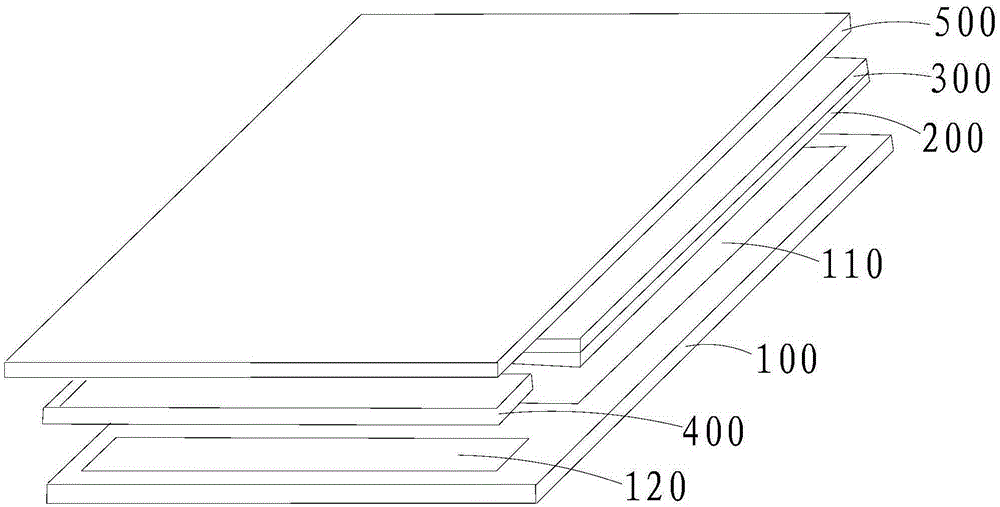

[0039] During the preparation of the OLED functional layer 200, a mask is usually used to cover the binding region 120 of the substrate 100, and then a thin film transistor, an anode electrode layer, an organic material layer, Cathode electrode layer and light coupling layer. Preferably, when depositing an organic material layer or an optical coupling layer in the effective display area 110, the first thin film layer 400 can be deposited in the binding area 120 at the same time, which can be specifically implemented in the following manner: depositing an organic material layer in the effective display area 110 material layer or optical coupling layer, the position corresponding to the binding region 120 of the substrate 100 in the mask is designed as a hollow structure, so that the organic material layer or optical coupling layer can be simultaneously deposited on the effective display of the substrate 100 In the area 110 and the binding area 120, the organic material layer or...

Embodiment 1

[0064] (1) When the hole injection layer is evaporated in the effective display area 110 of the substrate 100, the hole injection layer is evaporated in the binding area 120 of the substrate 100 at the same time, and the holes deposited in the binding area 120 The injection layer serves as the first film layer 400;

[0065] (2) Depositing the second thin film layer 300 on the surface of the OLED functional layer 200 located in the effective display area 110 by alternately depositing organic materials and inorganic materials;

[0066] (3) paste one deck outer barrier film 500 on the surface of the first film layer 400 and the second film layer 300 as a whole;

[0067] (4) cutting the outer barrier film 500 along the boundary between the binding area 120 and the effective display area 110 by laser cutting;

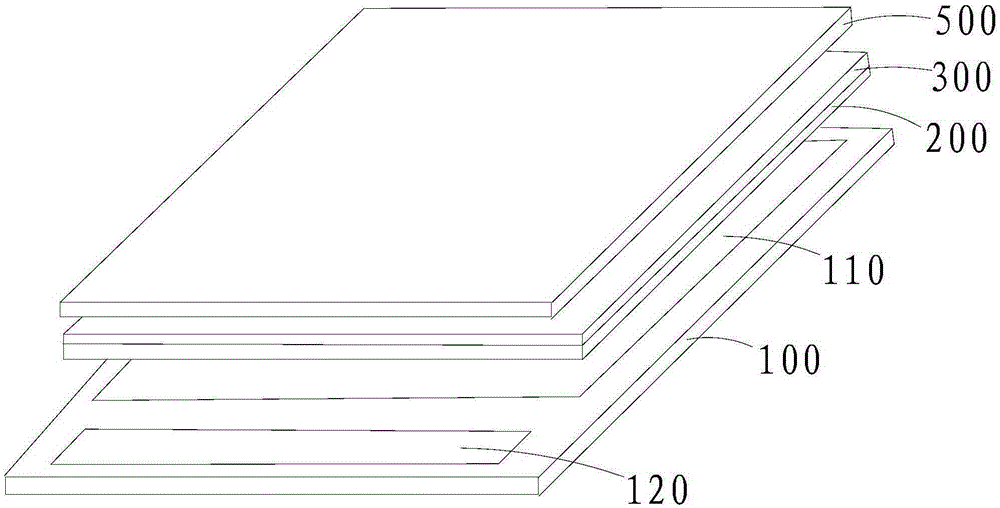

[0068] (5) Tear off the outer barrier film 500 located in the binding area 120, and the first film layer 400 is adhered under the sticking force of the outer barrier film 5...

Embodiment 2

[0071] (1) When the optical coupling layer is evaporated on the effective display area 110 of the substrate 100, the optical coupling layer is evaporated in the binding area 120 of the substrate 100 at the same time, and the optical coupling layer evaporated in the binding area 120 as the first film layer 400;

[0072] (2) Depositing the second thin film layer 300 on the surface of the OLED functional layer 200 located in the effective display area 110 by alternately depositing organic materials and inorganic materials;

[0073] (3) paste one deck outer barrier film 500 on the surface of the first film layer 400 and the second film layer 300 as a whole;

[0074] (4) The substrate 100 of the OLED display panel is integrally peeled off from the glass substrate by laser peeling, and then the OLED display panel obtained after peeling is cut into several small screen bodies according to the process requirements;

[0075] (5) Cutting the outer barrier film 500 along the boundary betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com