Assistant clamp for measurement of racking strain of composite material

A strain measurement and auxiliary fixture technology, applied in measurement devices, analytical materials, instruments, etc., can solve the problems of non-parallel bayonet, reduced strain measurement accuracy, low efficiency, etc., to reduce operation links, improve pasting accuracy and efficiency, Ensure the effect of paste quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

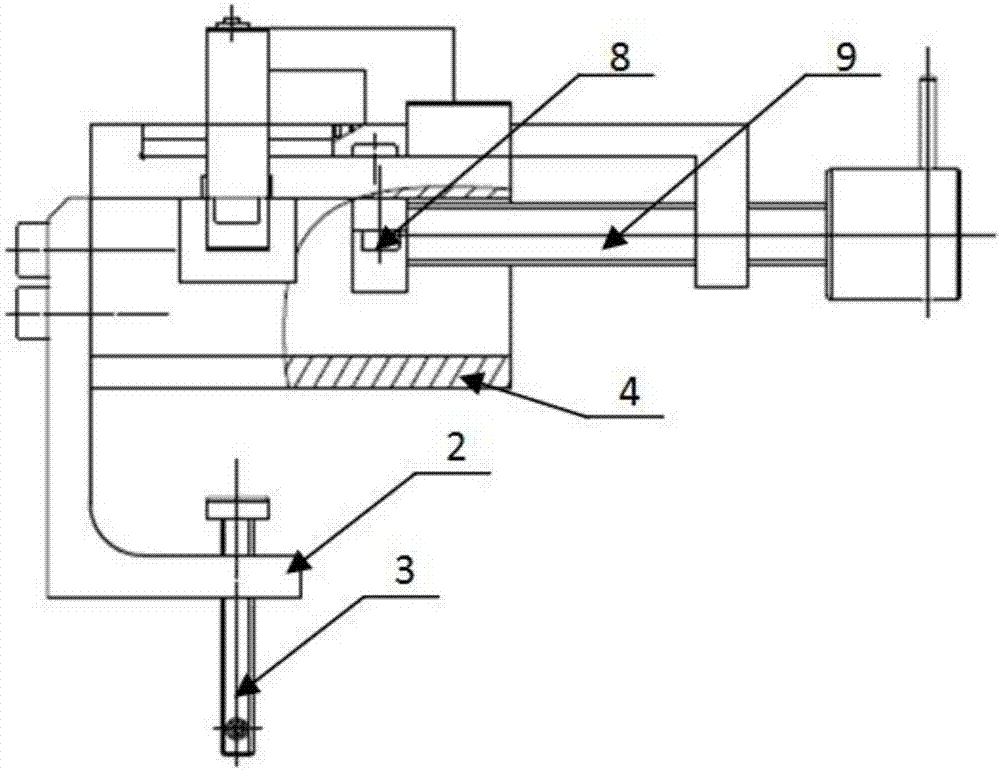

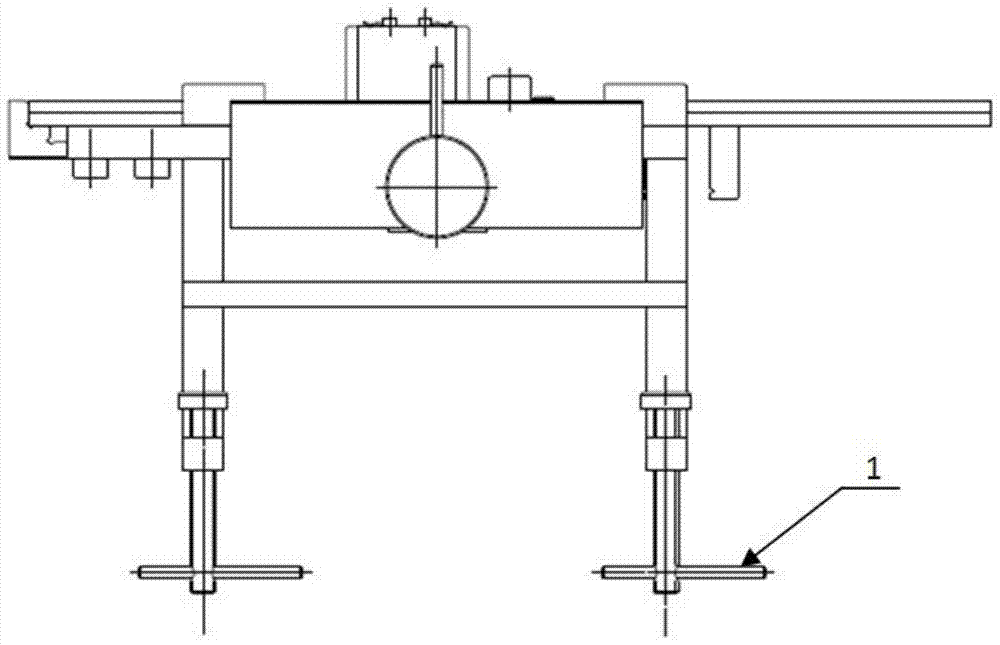

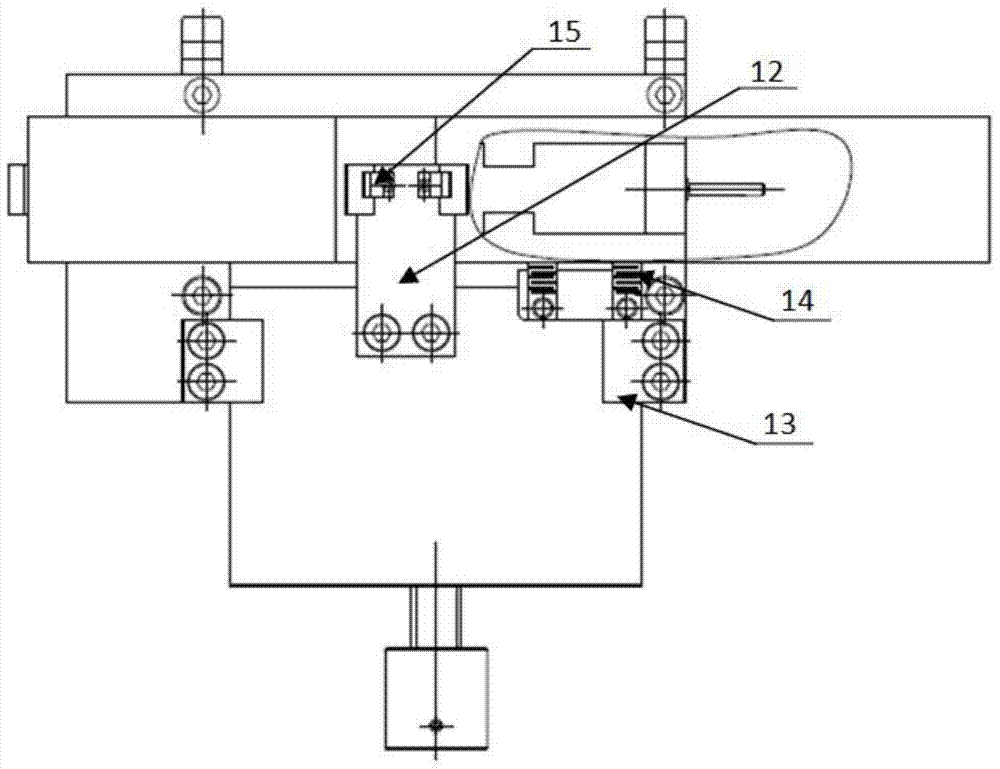

[0024] Such as Figure 1 to Figure 5 As shown, an auxiliary fixture for extrusion strain measurement of composite materials, the fixture is composed of a base, a stage, a clamping device and an extensometer mounting block:

[0025] The base includes a rocking bar 1, an L-shaped card 2, a fastening screw 3, a bottom plate 4 and a side plate 5, and the fastening screw 3 is provided with a round hole, and the rocking bar 1 cooperates with the fastening screw 3 through the round hole, and the L The shape card 2 is provided with a threaded hole, and the fastening screw 3 cooperates with the L-shaped card 2 through the threaded hole; the L-shaped card 2 is in contact with the side of the side plate 5 and fixed by bolts, and the upper surface of the bottom plate 4 is in contact with the lower surface of the side plate 5 and fixed by bolts; the stage includes an axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com