Casting residual slag recovery and charging system

A charging system and powder slag technology are applied in the field of metallurgy to achieve the effects of eliminating costs, reducing dust, and reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

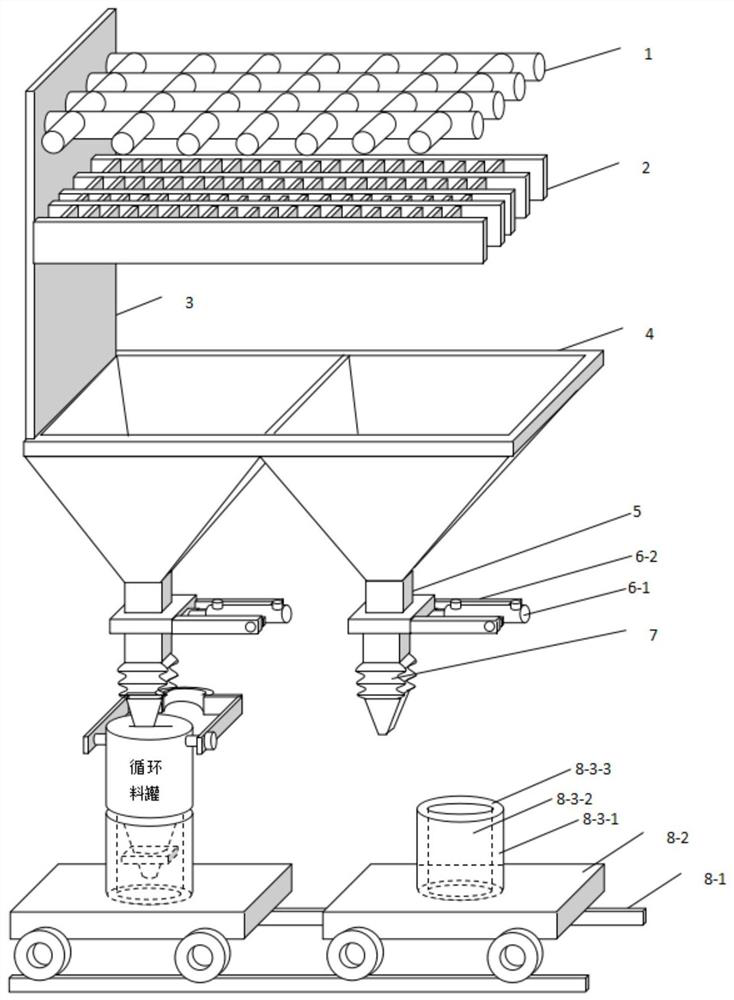

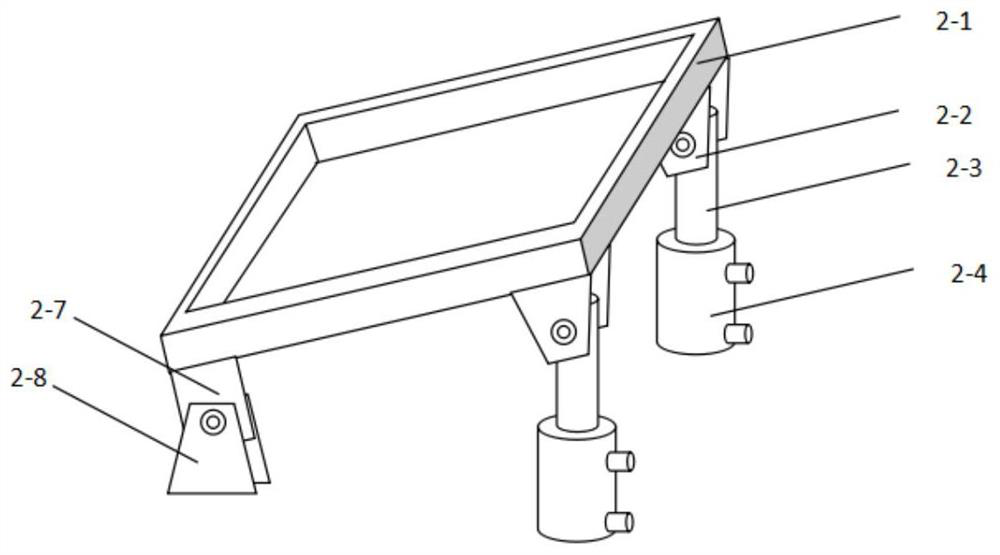

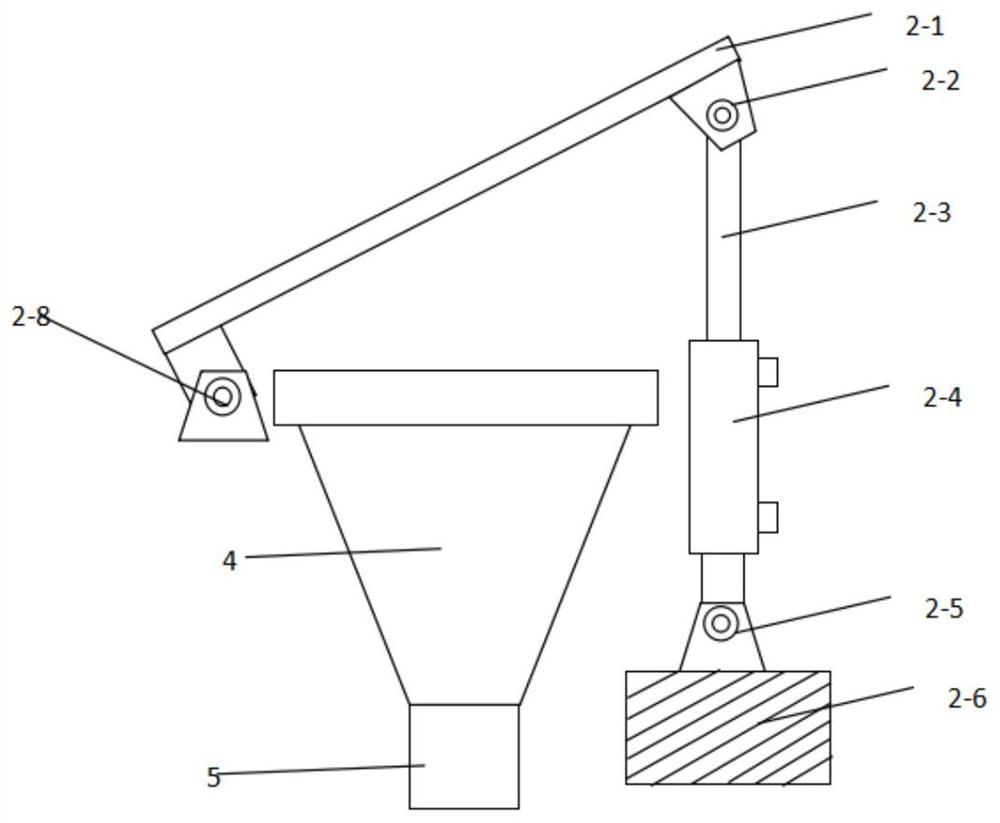

[0037] like figure 1 As shown, a system for recovering and charging the excess powder and slag of the present invention includes a frame and a primary fixed grid 1 for receiving and filtering the residual powder and slag, which is arranged inside the frame in turn, and is used to receive the primary fixed grid from the primary fixed grid. 1, the secondary active grid 2 for injecting and filtering the remaining powder slag, the powder collecting bin 4 for receiving the remaining powder slag from the secondary active grid 2, and the outlet port at the bottom of the access control powder collecting bin 4 The vertical pipe 5 and the valve 6 used for the on-off state of the vertical pipe 5, the movable feeder 7 installed at the output end of the vertical pipe 5 bottom and its own discharge port is retractable, and the movable feeder 7 arranged below the movable feeder 7 A charging assembly 8 for receiving materials from the movable feeder 7, and can be inserted into the charging ca...

Embodiment 2

[0052] This embodiment is based on Embodiment 1, and describes the structure of the movable feeder.

[0053] like figure 1 , Figure 4 and Figure 5 As shown, in the present invention, the movable feeder 7 includes a wire rope winch fixed on the outer wall of the vertical pipe 5, a telescopic pipe 7-2-1 installed at the output end of the vertical pipe 5 bottom, and a telescopic pipe 7-2-1 fixed on the telescopic pipe 7- 2-1 is away from the plug-in charging nozzle 7-2-5 at one end of the vertical pipe 5, and the lifting end of the wire rope 7-1-7 of the wire rope winch is connected with the bottom of the telescopic pipe 7-2-1.

[0054] The telescopic tube 7-2-1 includes but is not limited to a telescopic bellows type high-strength fiber material tube.

[0055] Further, the lifting end of the steel wire rope 7-1-7 is connected to the bottom of the telescopic tube 7-2-1 through a connection assembly, and the connection assembly includes a lifting frame 7-2- 3. The wire rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com